Page 1

123B/124B/125B

January 2016

© 2016 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Industrial ScopeMeter®

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is three years and

begins on the date of shipment. Parts, product repairs, and services are warranted for 90 days. This warranty extends only to the original buyer or end-user

customer of a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in Fluke's opinion, has been misused,

altered, neglected, contaminated, or damaged by accident or abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke does not warrant

that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or

different warranty on behalf of Fluke. Warranty support is available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country

is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair, or replacement of a defective product which is

returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return authorization information, then send the product to that service

center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following warranty

repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that failure was caused by neglect, misuse,

contamination, alteration, accident, or abnormal condition of operation or handling, including overvoltage failures caused by use outside the product’s specified

rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE

OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

Table of Contents

Title Page

Introduction .................................................................................................................... 1

How to Contact Fluke ..................................................................................................... 1

Safety Information .......................................................................................................... 1

Test Tool Kit Contents .................................................................................................... 5

Get Started ..................................................................................................................... 7

Battery Pack .............................................................................................................. 7

Mains Power Source ................................................................................................. 8

SD Memory Cards ..................................................................................................... 8

Test Tool Setup .............................................................................................................. 9

Reset the Test Tool ................................................................................................... 9

Screen Brightness ..................................................................................................... 10

Menu Selection .......................................................................................................... 10

Measurement Connections ........................................................................................ 11

Input A .................................................................................................................. 11

Input B .................................................................................................................. 11

COM ..................................................................................................................... 11

i

Page 4

123B/124B/125B

Users Manual

Measurement Probe Setup ....................................................................................... 11

Tilt Stand ................................................................................................................... 12

Hanger ...................................................................................................................... 12

Language Selection .................................................................................................. 12

Scope and Meter Mode ................................................................................................. 13

How to Read the Screen ........................................................................................... 14

Connect-and-View™ ................................................................................................. 15

Measurements .......................................................................................................... 15

Inputs ........................................................................................................................ 19

Voltage Measurements ........................................................................................ 19

Ohm, Continuity, Diode, Capacitance Measurements .......................................... 19

Current Measurements ........................................................................................ 19

Temperature Measurements ................................................................................ 19

Power Measurements .......................................................................................... 19

IntellaSet™ / AutoReading ........................................................................................ 19

Measurement Type ................................................................................................... 20

Screen Freeze .......................................................................................................... 21

How to Hold a Stable Reading .................................................................................. 21

Relative Measurements ............................................................................................ 22

Auto Range/Manual Range ....................................................................................... 23

Screen Graphic Adjustment ...................................................................................... 23

Amplitude ............................................................................................................. 23

Time Base ............................................................................................................ 23

Waveform Position ............................................................................................... 23

Noise Reduction ................................................................................................... 24

Glitch Display ....................................................................................................... 24

Waveform Smoothing ........................................................................................... 25

Reading Smoothing .............................................................................................. 26

How to Display the Envelope of a Waveform ....................................................... 26

Waveform Acquisition ............................................................................................... 27

ii

Page 5

Contents (continued)

Single Acquisition ................................................................................................. 27

Slow Signals ......................................................................................................... 28

AC Coupling.......................................................................................................... 29

Waveform Trigger ...................................................................................................... 29

Set Trigger Level and Slope ................................................................................. 29

Select Trigger Parameters .................................................................................... 30

Cursor Measurements ............................................................................................... 32

Horizontal Cursors ................................................................................................ 32

Vertical Cursors .................................................................................................... 33

Rise Time Measurements .......................................................................................... 34

High Frequency Measurements with 10:1 Probe ....................................................... 35

Probe Attenuation ................................................................................................. 35

Probe Adjustment ................................................................................................. 35

Power and Harmonics Mode .......................................................................................... 35

Volts/Amps/Watt Measurements ............................................................................... 36

Harmonics Measurements ......................................................................................... 38

Zooming Harmonics .................................................................................................. 42

Fieldbus Mode ................................................................................................................ 42

How to Read the Screen ........................................................................................... 44

How to View the Bus Waveform Screen .................................................................... 47

Test Limits ................................................................................................................. 48

Recorder Mode .............................................................................................................. 49

Start and Stop Meter Recording ................................................................................ 50

Cursor Measurements ............................................................................................... 52

Zoom In/Out on Logged Meter Data .......................................................................... 53

Events ....................................................................................................................... 53

Scope Record Mode .................................................................................................. 53

Save and Recall Data Sets ............................................................................................ 55

Test Sequence .......................................................................................................... 56

Setting Recall ............................................................................................................ 57

iii

Page 6

123B/124B/125B

Users Manual

Data Set Management .............................................................................................. 57

Waveform Comparison ............................................................................................. 58

Communication .............................................................................................................. 59

Optical Interface ........................................................................................................ 59

Wireless Interface ..................................................................................................... 59

Maintenance .................................................................................................................. 61

How to Clean ............................................................................................................ 61

Storage ..................................................................................................................... 61

Battery Replacement ................................................................................................ 61

10:1 Scope Probes ................................................................................................... 62

Calibration Information .............................................................................................. 63

Replaceable Parts and Accessories .............................................................................. 64

Tips ................................................................................................................................ 67

Battery Life ................................................................................................................ 67

Power Off Timer ........................................................................................................ 67

Autoset Options ........................................................................................................ 68

Grounding Guidelines ............................................................................................... 68

Specifications ................................................................................................................ 69

Dual Input Oscilloscope ............................................................................................ 69

Dual Input Meter ....................................................................................................... 71

Cursor Readout (124B, 125B)................................................................................... 78

Recorder ................................................................................................................... 79

Power Quality (125B) ................................................................................................ 80

Field Bus Measurements (125B) ............................................................................... 81

Miscellaneous ........................................................................................................... 82

Environmental ........................................................................................................... 83

iv

Page 7

List of Tables

Table Title Page

1. Symbols ................................................................................................................................. 4

2. Packing List ........................................................................................................................... 5

3. Parts of the Screen ................................................................................................................ 14

4. Volt/Amp Readings ................................................................................................................ 37

5. Watt Readings ....................................................................................................................... 37

6. Harmonics Voltage Measurements ....................................................................................... 39

7. Harmonics Current Measurements ........................................................................................ 40

8. Harmonics Power Measurements ......................................................................................... 41

9. Bus Measurement Inputs....................................................................................................... 43

10. Field Bus Test Screen ........................................................................................................... 44

11. Test Signal Properties ........................................................................................................... 45

12. Bus Test Screen Indicators ................................................................................................... 46

13. Replaceable Parts and Accessories ...................................................................................... 65

14. Optional Accessories ............................................................................................................. 66

v

Page 8

123B/124B/125B

Users Manual

vi

Page 9

List of Figures

Figure Title Page

1. Test Tool Kit .......................................................................................................................... 6

2. Battery Charging ................................................................................................................... 7

3. Power Up/Reset Screen ........................................................................................................ 9

4. Input Connections for Measurement ..................................................................................... 11

5. Tilt Stand and Hanger ........................................................................................................... 12

6. Auto Set Function .................................................................................................................. 15

7. Measurement Setup .............................................................................................................. 16

8. Correct Grounding Setup ....................................................................................................... 17

9. Temperature and Current Measurement Setup ..................................................................... 18

10. AutoReading Function ........................................................................................................... 20

11. Waveform Smoothing ............................................................................................................ 25

12. Bus Health Indicator Boundaries ........................................................................................... 47

13. WiFi USB Adapter ................................................................................................................. 59

14. 10:1 Scope Probes ................................................................................................................ 63

15. Max. Input Voltage vs. Frequency for BB120 and STL120-IV ............................................... 85

16. Safe Handling: Max. Voltage Between Test Tool Reference and Earth Ground ................... 85

vii

Page 10

123B/124B/125B

Users Manual

viii

Page 11

Introduction

The 123B/124B/125B ScopeMeter® (the Test Tool or

Product) is an integrated Test Tool, with oscilloscope,

multimeter, and 'paperless' recorder in one easy-to-use

instrument.

How to Contact Fluke

To contact Fluke, call one of the following telephone

numbers:

• Technical Support USA: 1-800-44-FLUKE

(1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE

(1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com.

To register your Product, visit http://register.fluke.com.

To view, print, or download the latest manual supplement,

visit http://us.fluke.com/usen/support/manuals.

Safety Information

A Warning identifies hazardous conditions and

procedures that are dangerous to the user.

A Caution identifies conditions and procedures that can

cause damage to the Product or the equipment under

test.

XW Warning

To prevent possible electrical shock, fire, or

personal injury:

• Read all safety information before you

use the Product.

• Use the Product only as specified, or the

protection supplied by the Product can

be compromised.

• Carefully read all instructions.

1

Page 12

123B/124B/125B

Users Manual

• Do not apply more than one phase of a

multiphase system simultaneously to

any COM

Common (COM) connections should be

equipotential, as marked.

• Remove the batteries if the Product is

not used for an extended period of time,

or if stored in temperatures above 50 °C.

If the batteries are not removed, battery

leakage can damage the Product.

• The battery door must be closed and

locked before you operate the Product.

• Comply with local and national safety

codes. Use personal protective

equipment (approved rubber gloves, face

protection, and flame-resistant clothes)

to prevent shock and arc blast injury

where hazardous live conductors are

exposed.

• Do not apply more than the rated

voltage, between the terminals or

between each terminal and earth ground.

˜ (common) connection. All

• Limit operation to the specified

measurement category, voltage, or

amperage ratings.

• Use Product-approved measurement

category (CAT), voltage, and amperage

rated accessories (probes, test leads,

and adapters) for all measurements.

• Measure a known voltage first to make

sure that the Product operates correctly.

• Use the correct terminals, function, and

range for measurements.

• De-energize the circuit or wear personal

protective equipment in compliance with

local requirements before you apply or

remove the flexible current probe from

hazardous live conductors.

• Do not touch voltages > 30 V ac rms,

42 V ac peak, or 60 V dc.

• Do not use the Product around explosive

gas, vapor, or in damp or wet

environments.

2

Page 13

Industrial ScopeMeter®

Safety Information

• Do not use the Product if it operates

incorrectly.

• Examine the case before you use the

Product. Look for cracks or missing

plastic. Carefully look at the insulation

around the terminals.

• Do not use test leads if they are

damaged. Examine the test leads for

damaged insulation, exposed metal, or if

the wear indicator shows. Check test

lead continuity.

• Use only cables with correct voltage

ratings.

• Connect the common test lead before

the live test lead and remove the live test

lead before the common test lead.

• Keep fingers behind the finger guards on

the probes.

• Remove all probes, test leads, and

accessories before the battery door is

opened.

• Remove all probes, test leads, and

accessories that are not necessary for

the measurement.

• Do not exceed the Measurement

Category (CAT) rating of the lowest rated

individual component of a Product,

probe, or accessory.

• Do not use a current measurement as an

indication that a circuit is safe to touch.

A voltage measurement is necessary to

know if a circuit is hazardous.

• Disable the Product if it is damaged.

• Do not use the Product if it is damaged.

• Do not use the Product above its rated

frequency.

• Do not use the Current Probe if it has

damaged insulation, exposed metal, or if

the wear indicator is visible.

• Do not wear loose-fitting clothing or

jewelry and keep long hair tied back

when near rotating machinery. Use

approved eye protection and approved

personal-protective equipment where

necessary.

3

Page 14

123B/124B/125B

Users Manual

See Table 1 for a list of symbols used on the Product and

in this manual.

Table 1. Symbols

Symbol Description Symbol Description

W

T

˜

/

~

4

WARNING. RISK OF DANGER.

Consult user documentation.

Double Insulated

Earth

Equipotential

Conforms to relevant Australian Safety and EMC standards.

Measurement Category III is applicable to test and measuring circuits connected to the distribution part of the

building’s low-voltage MAINS installation.

Measurement Category IV is applicable to test and measuring circuits connected at the source of the building’s

low-voltage MAINS installation.

This product contains a Lithium-ion battery. Do not mix with solid waste stream. Spent batteries should be

disposed of by a qualified recycler or hazardous materials handler per local regulations. Contact your

authorized Fluke Service Center for recycling information.

This product complies with the WEEE Directive marking requirements. The affixed label indicates that you must

not discard this electrical/electronic product in domestic household waste. Product Category: With reference to

the equipment types in the WEEE Directive Annex I, this product is classed as category 9 "Monitoring and

Control Instrumentation" product. Do not dispose of this product as unsorted municipal waste.

X

P

Ã

)

y

WARNING. HAZARDOUS VOLTAGE. Risk of electric shock.

Conforms to European Union directives.

Conforms to relevant South Korean EMC Standards.

Certified by CSA Group to North American safety standards.

Battery Safety Approval

Page 15

Industrial ScopeMeter®

Test Tool Kit Contents

Test Tool Kit Contents

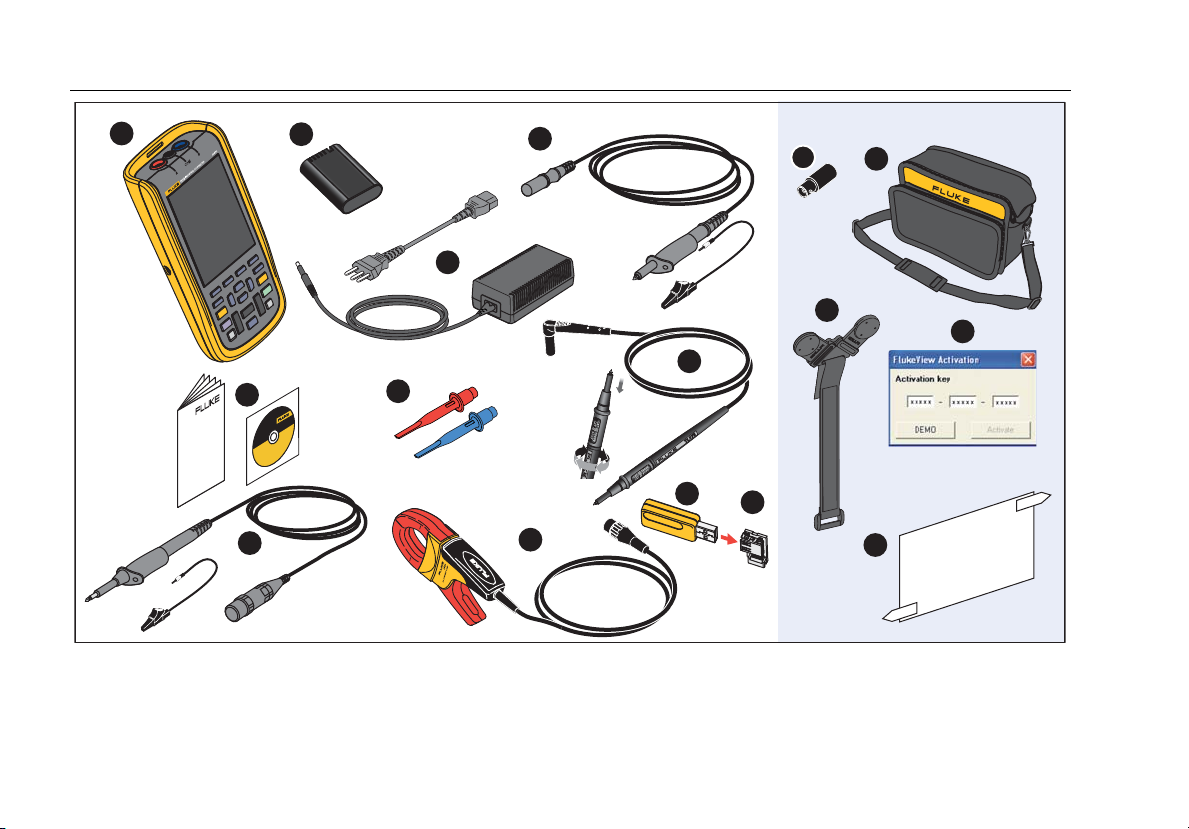

Table 2 is a list of the items included in your Test Tool kit.

Also see Figure 1.

Table 2. Packing List

Item Description 12x-B 12x-B/S

Fluke Test Tool 123B, 124B or 125B 123B/S, 124B/S or 125B/S

Rechargeable Li-ion Battery Pack • •

Switch Mode Power Supply, Adapter/Battery Charger • •

D Shielded Test Leads with Black Ground Leads • •

E Test Lead Black (for Grounding) • •

F Hook Clips (red, blue) • •

G Banana-to-BNC Adapters (black) • (x1) • (x2)

H Safety Information + CD-ROM with Users Manuals • •

I 10:1 Voltage Probe 124B, 125B 124B/S, 125B/S

J i400s AC Current Clamp 125B 125B

K USB Angled Adapter • •

L WiFi USB Adapter depends on version

M Soft Carrying Case •

N Magnetic Hanger •

O FlukeView

ScopeMeter Software for Windows

•

P Screen Protector •

5

Page 16

123B/124B/125B

Users Manual

1

2

3

(2x)

8

9

6

10

(2x)

4

5

12

7

14

11

S-Version

13

12345 - 12345 - 12345

16

15

hxv01.eps

Figure 1. Test Tool Kit

6

Page 17

Industrial ScopeMeter®

Get Started

Get Started

Before you use your Test Tool for the first time, read this

section.

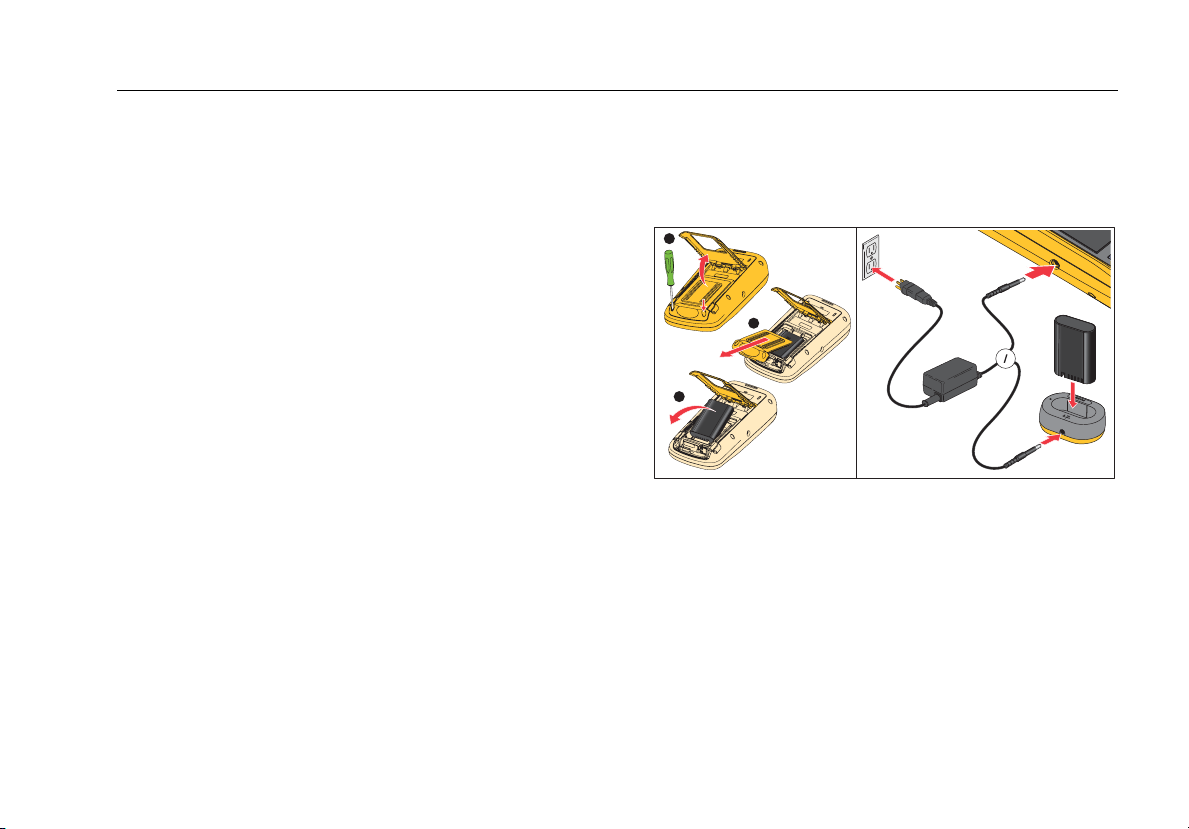

Battery Pack

Li-ion batteries may be discharged at delivery. Completely

discharged batteries can cause the Test Tool not to start

up when it is turned on. To reach full charge, charge for 4

hours with the Test Tool turned off.

When fully charged, the batteries provide up to 7 hours

(single channel, time base slower than 1 µs/div) of use

when the backlight is dimmed.

The battery status shows as an icon in the top right

corner of the screen:

b - full charge

- about 5 minutes of operation remains

To charge the batteries and power the instrument, connect

the power adapter as shown in Figure 2. To charge the

batteries more quickly, turn off the Test Tool.

W Caution

To prevent overheating of the batteries

during charging, do not exceed the allowable

ambient temperature in the specifications.

Note

The power adapter does not damage the Test

Tool even when connected over consecutive

days. The power adapter automatically switches

to a trickle charge.

1

2

3

Figure 2. Battery Charging

E

G

R

A

H

C

hxv51.eps

7

Page 18

123B/124B/125B

Users Manual

Alternatively, you may choose to exchange the battery

(Fluke accessory BP290) with a fully charged one and

use the external battery charger EBC290 (optional Fluke

accessory).

To accommodate connection to various line power

sockets, the BC430/820 universal Battery Charger /

Power Adapter is equipped with a male plug that must be

connected to a line cord appropriate for local use.

Because the adapter is isolated, the line cord does not

need to be equipped with a terminal for connection to

protective ground. Or use a line cord with a protective

grounding terminal.

Mains Power Source

To use the mains power source:

1. Attach the power cord to the mains power.

2. Attach the DC power connector in the left side of the

Test Tool.

3. Push to turn on the Test Tool.

The Test Tool turns on within 10 seconds in its last setup

configuration.

SD Memory Cards

The Test Tool has a SD Memory Card for storage of

recorder measurement data or data sets (see page 55).

The file format is FAT32. This data is retained also when

the Test Tool is disconnected from its power sources. The

memory card is located in the battery compartment.

To lock or unlock the card, press it down. The correct

position of the card is shown in the compartment. This

compartment also contains a connector for adding WiFi

connectivity with a USB flash drive. See Wireless

Connectivity for more information.

W Caution

To prevent damage to the SD memory card,

do not touch the contacts.

8

Page 19

Industrial ScopeMeter®

Test Tool Setup

Test Tool Setup

This section explains the basics for how to use your Test

Tool.

Reset the Test Tool

To restore the Test Tool to the factory default settings:

1. Push and hold + .

2. Release .

3. Release .

Figure 3 shows the Test Tool screen the first time you

power on or after a successful reset.

hxv10.eps

Figure 3. Power Up/Reset Screen

9

Page 20

123B/124B/125B

Users Manual

Screen Brightness

By default the display is at the brightest setting. To extend

the battery life, you can decrease the brightness setting.

To change the brightness of the display:

1. With the Test Tool turned on, push for >3 seconds

and release.

2. Push

YZ to increase or decrease the backlight.

Menu Selection

The buttons on the keypad provide the navigation through

the functions you see on the display. For example, this is

the basic sequence for how to adjust a parameter:

YZ

YZ

YZ

YZWX

Tips:

• Push a second time to close the MENU and

resume normal measurement. This toggle enables

you to check the menu without changing the settings.

• When you do not change an item with the cursor

keys, push to step through a menu without

changing the setup of the Test Tool.

• Gray text in a menu or button bar indicates that the

function is disabled or the status is not valid.

open the MENU

move cursor to highlight USER OPTIONS

select the USER OPTIONS menu

move cursor to highlight Date Format

select DATE FORMAT menu

move cursor to highlight a date format

confirm the selection

select the date

confirm the selection

10

Page 21

Industrial ScopeMeter®

Test Tool Setup

Measurement Connections

The Test Tool has two 4 mm safety-shielded banana jack

inputs (red input A and blue input B) and a black safety

4 mm banana jack input (COM). See Figure 4.

hxv05.eps

Figure 4. Input Connections for Measurement

Input A

Use the input A (red) for all single input measurements.

Input B

For measurements on two different signals, use B input

(blue) together with input A (red).

COM

Use the COM input (black) as the single ground for low

frequency, continuity, Ohm (Ω), diode, and capacitance

measurements.

XW Warning

To prevent electrical shock or fire, use only

one COM ˜ (common) connection, or ensure

that all connections to COM ˜ are at the

same potential.

Measurement Probe Setup

The Test Tool supports measurement probes, for

example:

• 10:1 voltage probe

• 1 mV/°C temperature probe

• 10 mV/A current clamp

To set up a specific probe type:

1. Push to open the Scope and Meter menu.

2. Push 3 to open the INPUT A menu.

3. Use Y/Z to highlight SELECT.

4. Push to open the PROBE select menu.

5. Use

6. Push to accept the probe type and close the

Y/Z to highlight the probe type.

menu.

11

Page 22

123B/124B/125B

Users Manual

Tilt Stand

The Test Tool is equipped with a tilt stand, allowing

viewing from an angle. You can also use the tilt stand to

hang the Test Tool at a convenient viewing position. See

Figure 5.

Hanger

The optional hanger accessory is magnetic and used to

hang the Test Tool on metal surfaces such as a cabinet

door. See Figure 5.

Language Selection

To change the language:

1. Push to open the Menu.

2. Use YZ to highlight USER OPTIONS.

3. Push to open the USER OPTIONS menu.

4. Use

5. Push to open the USER > LANGUAGE menu.

6. Use YZ to highlight the language preference.

7. Push to accept the change and exit the menu.

YZ to highlight Language.

7.

1

2

3

Figure 5. Tilt Stand and Hanger

hxv50.eps

12

Page 23

Industrial ScopeMeter®

Scope and Meter Mode

Scope and Meter Mode

The Scope and Meter mode is the default operation

mode. When in another mode, such as Recorder, Power

Harmonics, or BusHealth, push to return to Scope

and Meter operation. In Scope and Meter mode, the

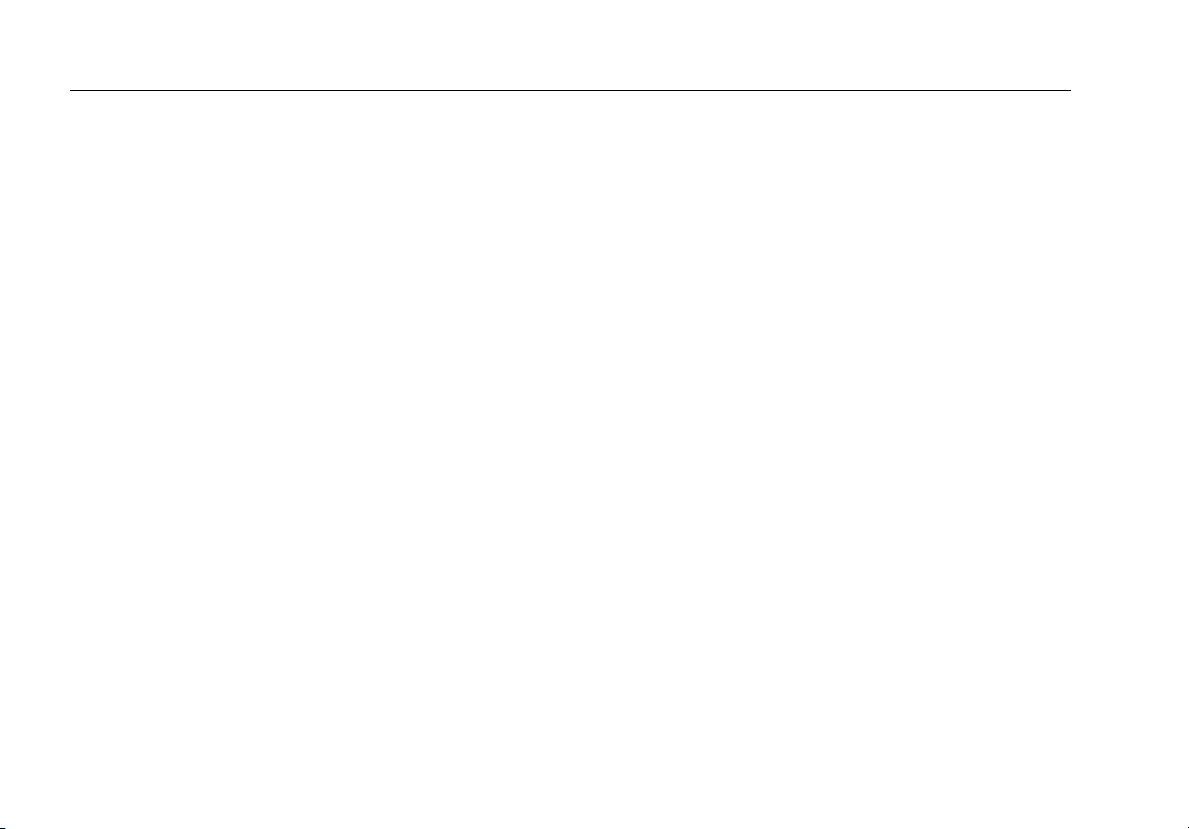

button bar looks like this:

sm_bar_eng.eps

To go to the Move and Zoom button bar, push until

you have left any open button bar or menu.

mz_bar_eng.eps

The yellow text on the button bar indicates the status.

Push the button to change the status.

XW Warning

To prevent possible electrical shock, fire, or

personal injury:

• Do not touch exposed metal on banana

plugs. They can have voltages that could

cause death.

• Disconnect power and discharge all

high-voltage capacitors before you

measure resistance, continuity,

capacitance, or a diode junction.

• Do not put metal objects into

connectors.

• Do not use exposed metal BNC or

banana plug connectors.

• Do not use the HOLD function to

measure unknown potentials. When

HOLD is turned on, the display does not

change when a different potential is

measured.

13

Page 24

123B/124B/125B

Users Manual

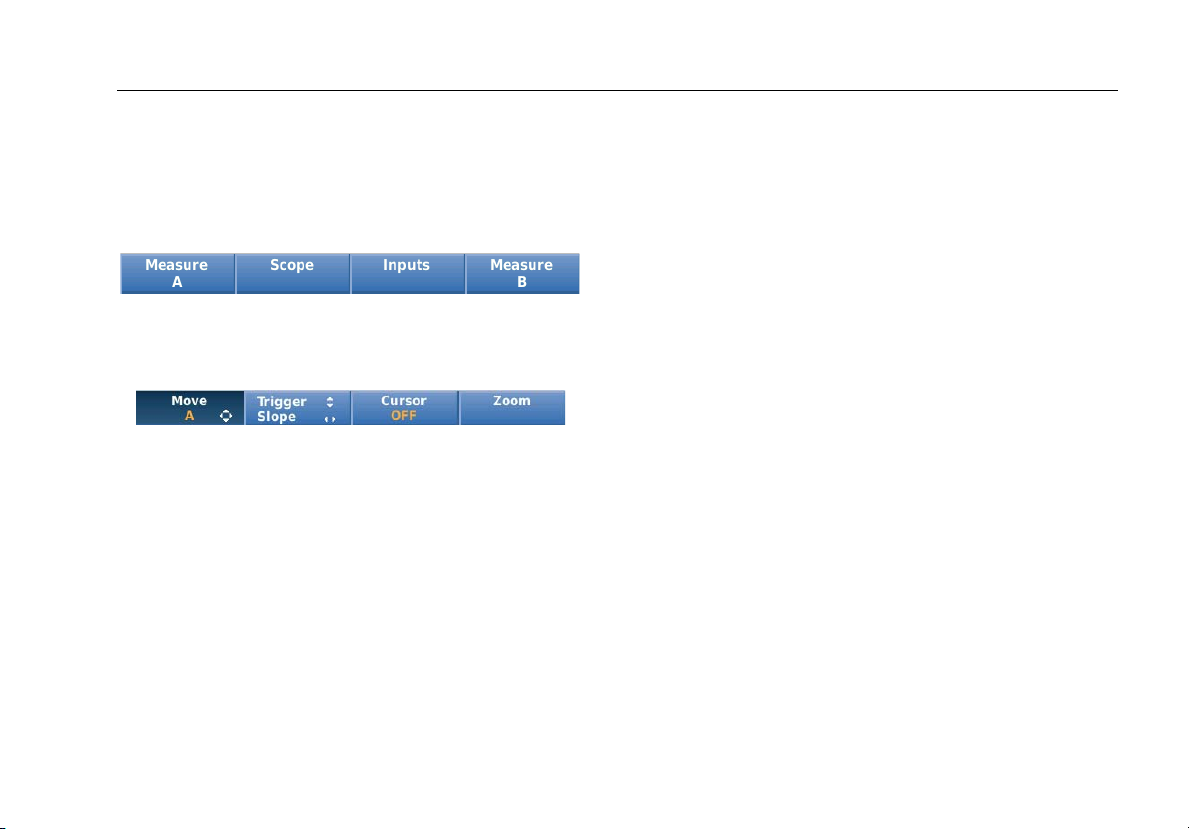

How to Read the Screen

The screen is divided into these areas: Information,

Reading, Waveform, Status, and Menu. See Table 3.

Table 3. Parts of the Screen

1

Item Area Description

2

Reading

D Status

3

4

5

hxv13.eps

E Button Bar

Information

Waveform

Date, time, and indicators like Auto range,

Hold/Run, AutoHold, and battery status.

Numeric readings. If only input A is on, you will see

the input A readings only.

Waveforms. If only input A is on, you will see the

input A waveform only.

Displays status of attenuations, timebase,

couplings, trigger source, and trigger slope.

Displays the choices available with

1234.

14

Page 25

Industrial ScopeMeter®

Scope and Meter Mode

When you change a setup, a part of the screen shows the

choices. Use WXYZ to access the menu choices.

Connect-and-View™

The Connect-and-View™ function (Auto Set) enables

hands-off operation to display complex unknown signals.

This function optimizes the position, range, time base,

and triggering to ensure a stable display on most

waveforms. The setup will track the changes if the signal

changes. This feature is enabled by default.

To enable the Connect-and-View™ function when in

Manual mode:

1. Connect the red test lead from red input A to the

unknown signal to be measured.

2. Push to toggle between the Auto (automatic) and

Manual modes.

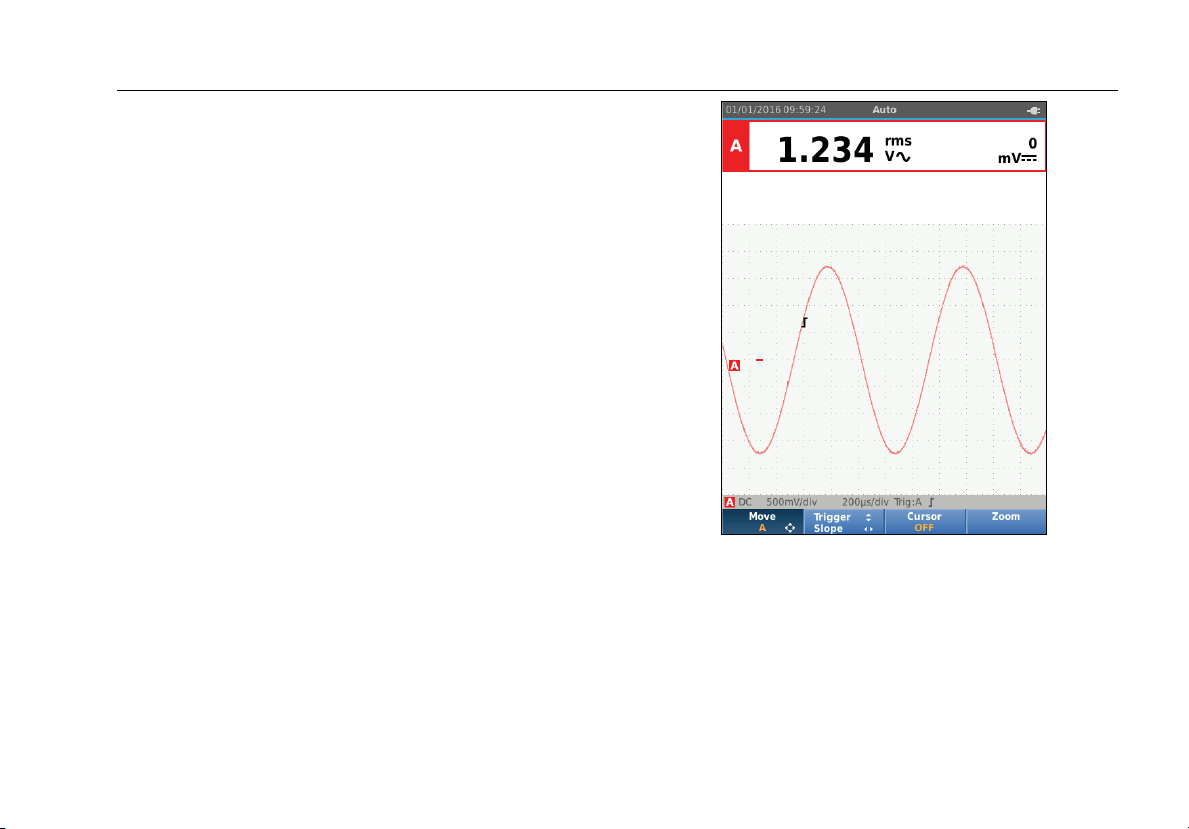

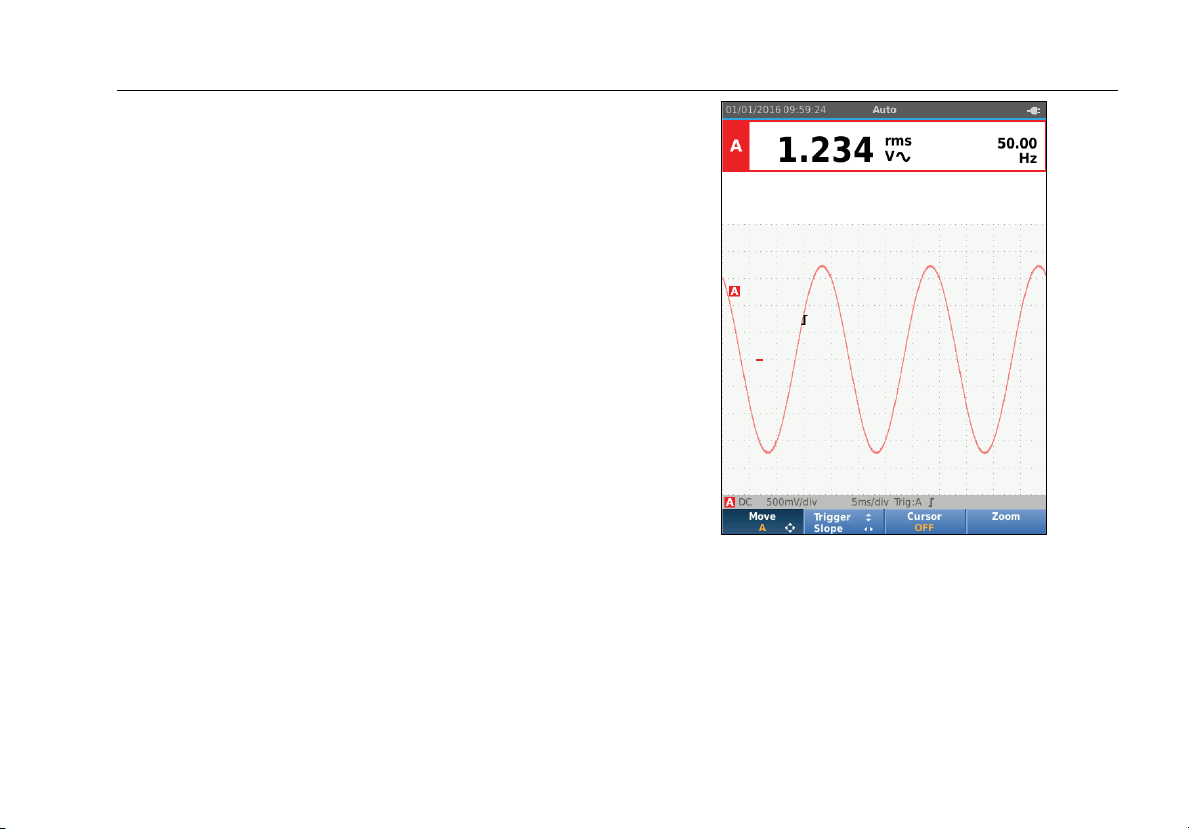

In Figure 6 the screen displays “1.234” in large numbers

and “50.00” in smaller numbers. A scope trace gives a

graphical representation of the waveform.

The trace identifier is visible at the left side of the

waveform area. The zero icon (-) identifies the ground

level of the waveform.

Figure 6. Auto Set Function

Measurements

The reading area shows the numeric readings of the

chosen measurements on the waveform that is applied to

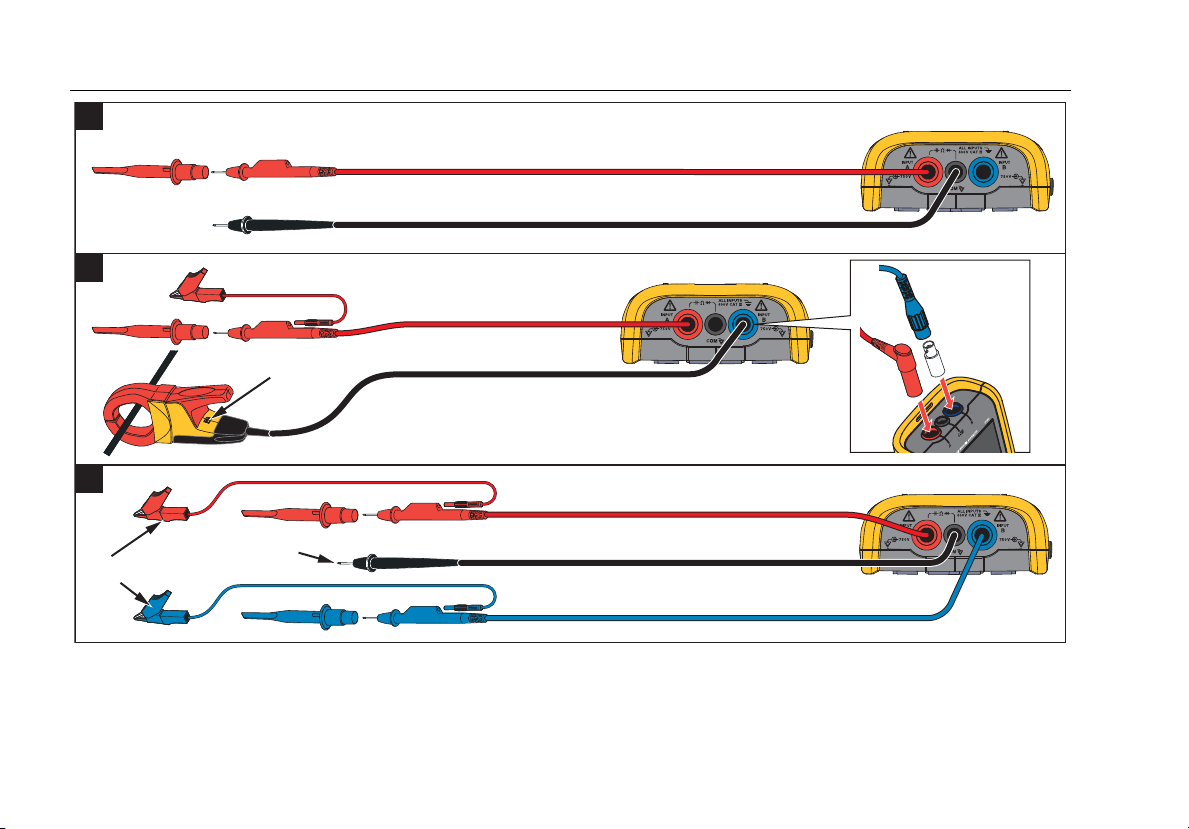

the input jack. Figure 7, Figure 8, and Figure 9 illustrate

the setups for measurements.

hxv55.eps

15

Page 26

123B/124B/125B

Users Manual

1

2

3

2

see Figure 8

item 4

10 mV/A - 1 mV/A

see Figure 8

item 5

AB

Figure 7. Measurement Setup

AB

BB120

AB

hxv03.eps

16

Page 27

Industrial ScopeMeter®

Scope and Meter Mode

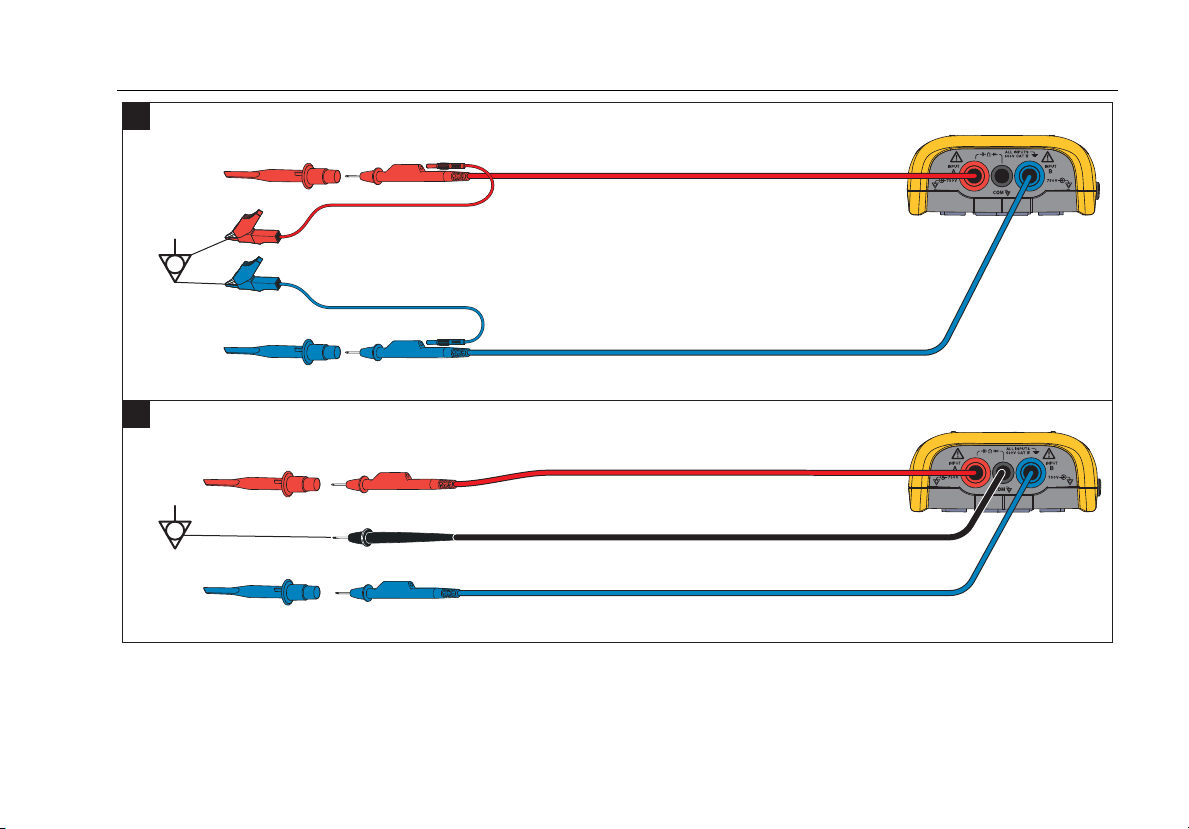

4

5

Figure 8. Correct Grounding Setup

AB

AB

hxv04.eps

17

Page 28

123B/124B/125B

Users Manual

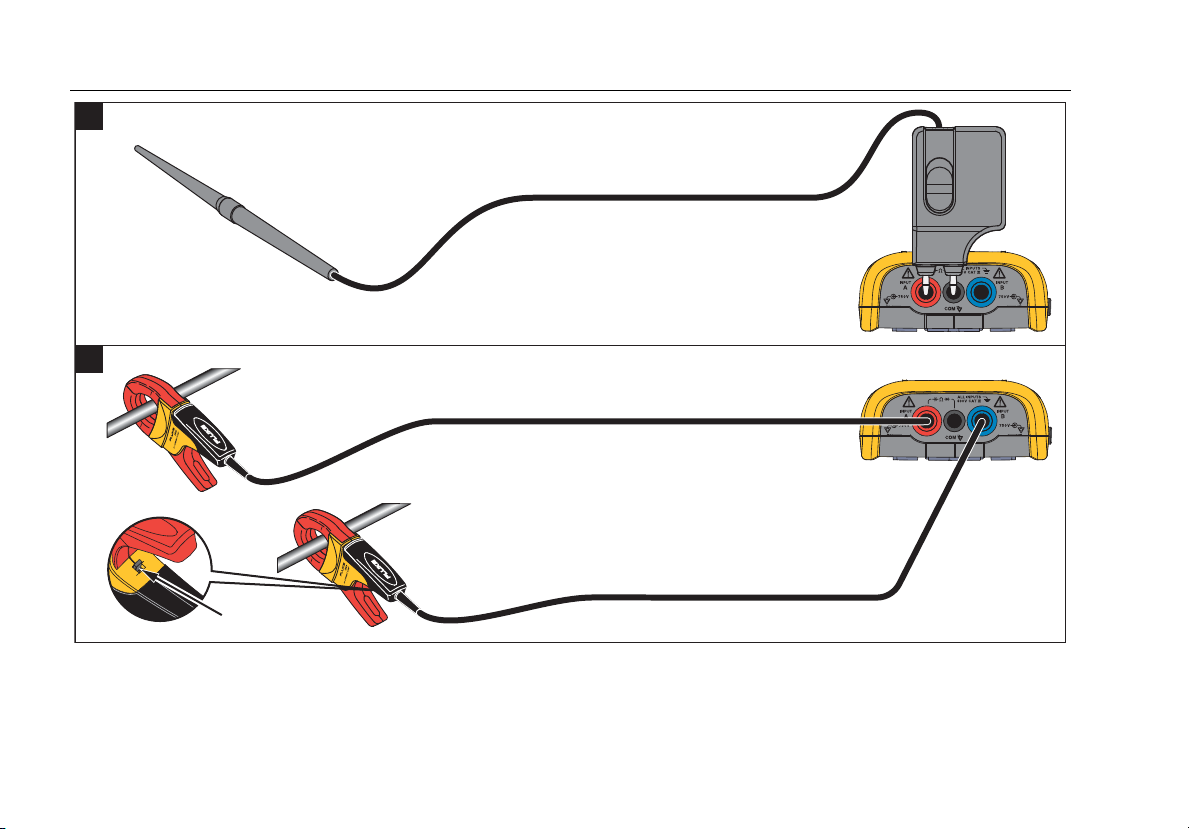

6

7

18

10 mV/A - 1 mV/A

Figure 9. Temperature and Current Measurement Setup

AB

hxv57.eps

Page 29

Industrial ScopeMeter®

Scope and Meter Mode

Inputs

Voltage Measurements

For proper grounding, connect the short ground leads to

the same ground potential, see Figure 8 setup 4. You can

also use test leads for grounding, see Figure 8 setup 5.

See also Grounding Guidelines on page 68.

Ohm, Continuity, Diode, Capacitance Measurements

Use the red shielded test lead from input A and the black

unshielded ground lead from COM (common) for Ohms

(Ω), continuity, diode, and capacitance measurements.

See Figure 7 setup 1.

Current Measurements

Select the probe setting that matches the used current

clamp and its setting, for example, 1 mV/A. See Figure 9

and Measurement Probe Setup.

Temperature Measurements

Use a 1 mV/°C or 1 mV/°F temperature transmitter (not

available in all countries) to get the correct temperature

reading. See Figure 9.

Power Measurements

Select correct probe settings for voltage measurement on

input A and current measurement on input B. See

Figure 7 setup 2.

IntellaSet™ / AutoReading

The AutoReading function uses Fluke IntellaSet™

technology to enable hands-off operation to display meter

readings that correspond with the shape of the waveform.

This function automatically selects the meter readings

that are most often used with the measurement of the

waveform shape. As an example, when the waveform is a

line voltage signal, the V ac + dc and Hz readings show

automatically.

To enable the AutoReading function on input A:

1. Push to open the Scope and Meter button bar.

2. Push 1 to open the MEASURE menu. See

Figure 10.

3. Push 1 to select the AutoReading to ON.

4. Push 4 to select Done and close the menu.

To disable this function, repeat the steps and select the

AutoReading to OFF.

19

Page 30

123B/124B/125B

Users Manual

Measurement Type

To manually set up or change the measurement type:

1. Push to open the Scope and Meter button bar.

2. Push 1 to open the MEASURE menu for Input A.

Push 4 to open the MEASURE menu for Input B.

3. Push Z/Y to highlight the measurement type, for

example, Hz.

When more setup selections are available for a

measurement type, you see a . Push to open

the submenu and make a selection.

20

hxv11.eps

Figure 10. AutoReading Function

hxv12.eps

4. Push to accept the measurement type and

close the menu.

5. Confirm that the selected measurement type is the

main reading. The former main reading moves to the

smaller secondary reading position.

Page 31

Industrial ScopeMeter®

Scope and Meter Mode

Screen Freeze

You can freeze the screen (all readings and waveforms)

at any time:

1. Push to freeze the screen. The information area

at the top of the screen shows .

2. Push again to resume measurements.

How to Hold a Stable Reading

The AutoHold® mode captures a stable main (large)

reading on the display. When the Test Tool detects a new

stable reading, it beeps and shows the new reading.

To use the AutoHold function:

1. Push to open the Scope and Meter button bar.

2. Push 1 to open the MEASURE A button bar.

3. Push 3 to enable AutoHOLD. The Information

area of the screen updates and the button label

shows AutoHOLD ON.

4. Push 4 to close the MEASURE A menu and

button bar.

5. Wait to hear the audible beep that means you have a

stable reading.

6. Repeat Step 1 to Step 4 to disable the AutoHold

function.

hxv13-1.eps

21

Page 32

123B/124B/125B

Users Manual

Relative Measurements

Zero Reference shows the present measurement result

with respect to the defined value. Use this feature to

monitor the measured value in relation to a known good

value.

To setup:

1. Push to open the Scope and Meter button bar.

2. Push 1 to open the MEASURE A button bar.

3. Push 2 to enable the relative measurement

(Zero On).

4. Push 4 to close the MEASURE A menu and

button bar.

The relative measurement is now the main reading,

and the former main measurement is now the smaller

secondary reading position.

5. Repeat Step 1 to Step 4 to disable the relative

measurement.

hxv14.eps

22

Page 33

Industrial ScopeMeter®

Scope and Meter Mode

Auto Range/Manual Range

Push to toggle between the Manual and Auto

Ranging modes.

When Auto Range is active, the Information area shows

Auto and the Test Tool automatically adjusts the position,

range, time base, and triggering (Connect-and-View).

This ensures a stable display on nearly all waveforms.

The Status area shows the range, the time base for both

inputs, and the trigger information.

When Manual is active, the Information area shows

Manual.

Screen Graphic Adjustment

From Auto Range, use YZWX to manually change the

waveform trace. This turns off the Connect-and-View

function. Observe that Auto in the Information area

disappears.

Amplitude

The available amplitude settings are from 5 mV/div to

200 V/div with the use of test leads.

1. Push to enlarge the waveform.

2. Push to reduce the waveform.

Time Base

The available time base settings are 10 ns/div or

20 ns/div (depends on model) to 5 s/div in normal mode.

1. Push (s) to increase the number of periods.

2. Push (ns) to decrease the number of periods.

Waveform Position

You can move the waveforms around on the screen.

Repeatedly push until all menus and secondary

button bars close.

1. Push 1 to select Move A.

2. Use

The trigger identifier () moves horizontally and vertically

on the screen as the waveform moves.

WXYZ to move the A waveform on the

screen.

Note

The waveform positions are fixed for 3-phase

power measurements.

23

Page 34

123B/124B/125B

Users Manual

Noise Reduction

To view the waveform without higher frequency noise:

1. Push to open the Scope and Meter button bar.

2. Push 3 to open the INPUT SETTINGS menu.

3. Use YZ to highlight the Noise filter as ON.

4. Push to make the change.

This noise filter is a 10 kHz bandwidth limit filter.

hxv15.eps

Glitch Display

By default, the displayed waveform shows glitches. For

each time position the minimum and maximum values

since the last time position are shown. A glitch of 25 ns or

wider is still visible on the screen even when using a

slower timebase.

To disable this feature and see one sample/channel for

each sample time:

1. Push to open the Scope and Meter button bar.

2. Push 2 to open the SCOPE menu.

3. Use

4. Push to make the change.

5. Push 4 to exit the menu.

YZ to highlight the Type as Glitch Off.

This feature will be turned off for both channel A and

channel B.

24

Page 35

Industrial ScopeMeter®

Scope and Meter Mode

Waveform Smoothing

To smooth the waveform:

1. Push to open the Scope and Meter button bar.

2. Push 2 to open the SCOPE SETTINGS menu.

hxv16.eps

3. Use YZ to highlight the Type as Smooth. Both the

input A and input B waveforms are smoothed.

4. Push to make the change.

5. Push 4 to exit the menu.

Waveform smoothing suppresses noise without loss of

bandwidth. Waveform samples with and without

smoothing are shown in Figure 11. Smoothing is the

average of eight acquired waveforms. Glitch detect is

turned off in this mode.

hxv17.eps

Figure 11. Waveform Smoothing

25

Page 36

123B/124B/125B

Users Manual

Reading Smoothing

To smooth the readings on A:

1. Push to open the Scope and Meter button bar.

2. Push 3 to open the INPUT SETTINGS menu.

3. Use

4. Push to make the change.

5. Push 4 to exit the menu.

For best results, set Readings to:

• Fast for short averaging, fast response

• Normal is the default setting

• Smooth for long averaging, stable readings

YZ to highlight the Readings as Smooth.

How to Display the Envelope of a Waveform

The Test Tool records the envelope (minimum and

maximum) of the live waveforms for inputs A and B.

Repeat the first two actions of Smoothing the Waveform,

and then do the following:

To display the waveform envelope:

1. Push to open the Scope and Meter button bar.

2. Push 2 to open the SCOPE SETTINGS menu.

3. Use

YZ to highlight the Type as Envelope.

4. Push to make the change.

5. Push 4 to exit the menu.

The screen shows the resultant envelope waveform. You

can use Envelope to observe the variations in time or

amplitude of input waveforms over a longer time period.

hxv18.eps

26

Page 37

Industrial ScopeMeter®

Scope and Meter Mode

Waveform Acquisition

The Test Tool can be setup to acquire waveforms as

needed for a specific application. This section explains

the setup options.

Single Acquisition

To catch single events, you can perform a single shot

(one time screen update).

To set up the Test Tool for a single shot on the input A

waveform:

1. Connect the probe to the signal to be measured.

2. Push to open the Scope and Meter button bar.

3. Push 2 to open the SCOPE SETTINGS menu.

4. Use

5. Push to make the change.

6. Push 4 to exit the menu.

YZ to highlight the Update as Single.

The Test Tool will now show the acquisition screen

and the Information area updates:

Waiting

Run

Hold

Test Tool is waiting for a trigger

single acquisition is triggered

single acquisition is complete

hxv19.eps

To continue with the next single acquisition:

7. Push and wait for another single acquisition

trigger.

27

Page 38

123B/124B/125B

Users Manual

Slow Signals

The roll mode function supplies a visual log of waveform

activity. Use slow signals to measure lower frequency

waveforms.

1. Push to open the Scope and Meter button bar.

2. Push 2 to open the SCOPE SETTINGS menu.

3. Use

4. Push to make the change.

5. Push 4 to exit the menu.

6. Push to freeze the waveform in roll mode.

To capture longer waveform recordings, see Recorder

Mode.

YZ to highlight the Update as Roll.

The waveform moves across the screen from right to

left like a normal chart recorder. The Test Tool does

not make measurements while recording.

The measurement values show only after you push

.

hxv20.eps

28

Page 39

Industrial ScopeMeter®

Scope and Meter Mode

AC Coupling

Use AC-coupling to observe a small ac signal that rides

on a dc signal.

To select ac-coupling on input A:

1. Push to open the Scope and Meter button bar.

2. Push 3 to open the INPUT SETTINGS menu.

3. Use YZ to highlight the Coupling as AC.

4. Push to make the change.

5. Push 4 to exit the menu.

Waveform Trigger

The trigger tells the Test Tool when to start the waveform

trace. You can:

• select which input signal to use

• select which edge this should occur

• define the condition for a new update of the

waveform

The bottom line of the waveform area identifies the trigger

parameters in use. Trigger icons on the screen indicate

the trigger level and slope.

Note

The trigger settings are fixed for 3-phase power

measurements.

Set Trigger Level and Slope

For quick operation, use to automatically trigger on

nearly all signals. toggles between the Auto and

Manual mode. The current operating mode is shown in

the Information Area.

To optimize trigger level and slope manually:

1. Repeatedly push until all menus and

secondary button bars close.

2. Push 2 to enable and use WXYZ to set the

Trigger level and slope adjustment.

29

Page 40

123B/124B/125B

Users Manual

3. Use YZ to adjust the Trigger level continuously.

Observe that the trigger icon on the third time

division line indicates the trigger level.

4. Use WX for Trigger on either positive slope or

negative slope of the chosen waveform.

hxv21.eps

Select Trigger Parameters

To trigger on the Input A waveform and configure the auto

range trigger for waveforms down to 1 Hz:

1. Push to open the Scope and Meter button bar.

2. Push 2 to open the SCOPE SETTINGS menu.

30

hxv22.eps

Page 41

Industrial ScopeMeter®

Scope and Meter Mode

3. Push to highlight A in the Trigger Input group.

4. Use YZ to highlight the Update as On trig.

5. Push to make the change.

6. Push 4 to accept all trigger selections and return

to normal measurement.

To autorange on signals down to 1 Hz:

1. Push to open the MENU.

2. Use

3. Push to open the USER OPTIONS MENU.

4. Use

5. Push to open the USER > AUTOSET MENU.

6. Use

7. Push to make the change.

YZ to highlight USER OPTIONS.

YZ to highlight Autoset Settings.

YZ to highlight the Search For Signals as

> 1 Hz.

8. Push to close all menus.

Note

Setting the automatic triggering to >1 Hz will

slow down the auto range.

The Information area updates with:

Wait

ON TRIGGER

Gray text in a menu or button bar indicates that

the function is disabled or the status is not valid.

no trigger found

screen updates only when valid

triggers occur

Note

31

Page 42

123B/124B/125B

Users Manual

Cursor Measurements

Cursors allow you to make precise digital measurements

on waveforms. Cursors are disabled for 3-phase power

measurements.

Horizontal Cursors

Use horizontal cursors to measure the amplitude, high

and low value, or overshoot of a waveform.

To use the cursors for a voltage measurement:

1. Repeatedly push until all menus and

secondary button bars close.

2. Push 3 to select CURSOR ON.

3. Push 1 to select . Observe that two horizontal

cursor lines are shown on the screen.

4. Push 2 to select the upper cursor.

5. Use

6. Push 2 to select the lower cursor.

7. Use YZ to move the position of the lower cursor

YZ to move the position of the upper cursor

on the waveform.

on the waveform.

Note

Even when the key labels are not displayed at

the bottom of the screen, you can still use the

arrow keys.

The readout shows the voltage difference between the

two cursors and the voltages at the cursors in relation to

the zero icon (-).

hxv23.eps

32

Page 43

Industrial ScopeMeter®

Scope and Meter Mode

Vertical Cursors

Use vertical cursors to measure the time difference “t”

between the cursors and the voltage difference between

the two markers.

To use the cursors for a time measurement:

1. Push 3 to select CURSOR ON.

2. Push 1 to select . Observe that two vertical

cursor lines are shown on the screen. Markers (-)

identify the point where the cursors cross the

waveform.

3. Push 2 to select the left cursor.

4. Use

5. Push 2 to select the right cursor.

6. Use

WX to move the position of the left cursor on the

waveform.

WX to move the position of the right cursor on

the waveform.

hxv24.eps

33

Page 44

123B/124B/125B

Users Manual

Rise Time Measurements

To measure rise time:

1. Push 3 to select CURSOR ON.

2. Push 1 to select (rise time). Observe that two

horizontal cursors are displayed.

3. Push 4 if only one trace is displayed and select

MANUAL or AUTO. AUTO automatically does steps

5 to 7. For two traces, select the required trace A

or B.

4. Use YZ to move the upper cursor to 100% of the

trace height. A marker is shown at 90%.

5. Push 2 to select the other cursor.

6. Use

7. Push 3 to disable the cursors.

YZ to move the lower cursor to 0% of the

trace height. A marker is shown at 10%.

The reading now shows the risetime from 10%-90%

of the trace amplitude and the voltage at the cursors

in relation to the zero icon (-).

hxv25.eps

34

Page 45

Industrial ScopeMeter®

Power and Harmonics Mode

High Frequency Measurements with 10:1 Probe

Fluke recommends the VP41 10:1 Probe to measure high

frequency signals in circuits with high impedance. The

loading of the circuit by a 10:1 Probe is much lower than

that of a 1:1 Shielded Test Lead.

Probe attenuation and probe adjustment must be

observed when using a 10:1 Probe.

Probe Attenuation

The Probe attenuates the signal 10X. The example below

is for a Probe connected to input A.

To adapt the Test Tool’s voltage readout to this

attenuation:

1. Push to open the Scope and Meter button bar.

2. Push 3 to open the INPUT SETTINGS menu.

3. Use

4. Push to open the PROBE SELECT menu.

5. Use

6. Push to make the change.

Observe that the 10X attenuation of the Probe is

compensated in the voltage readout.

YZ to go to Select>.

YZ to highlight 10:1 V.

Probe Adjustment

The VP41 Probe is always adapted correctly to its inputs.

High frequency adjustment is not necessary.

Other 10:1 Probes however must be adjusted for optimal

High Frequency performance. See 10:1 Scope Probes for

information about how to adjust these Probes.

Power and Harmonics Mode

The Power and Harmonics mode offers:

• Single phase power measurements with waveform and

harmonics display

• Voltage RMS, Current RMS, frequency, and phase

measurements

• Active, apparent, and reactive power measurements

• Power factor, cos ϕ, and total harmonic distortion

measurements

This section is a step-by-step introduction to power and

harmonics measurements. It does not cover all of the

capabilities of the Test Tool but gives basic examples to

show how to use the menus and perform basic

operations.

To use the power and harmonics functions, connect the

voltage leads and current probe as shown in Figure 7

setup 2.

35

Page 46

123B/124B/125B

Users Manual

To select the power and harmonics mode:

1. Push to open the SETTINGS menu.

2. Use YZ to highlight POWER HARMONICS.

3. Push to open the Ampere Probe on B

SETTINGS menu.

If the voltage probe on A and current probe on B

have not been selected before, complete Step 4 to

Step 10.

4. Push 3 to select the probe settings.

hxv26.eps

5. Use YZ to highlight SELECT… in Probe A group.

6. Push to open the Probe A menu.

7. Use

8. Push to make the change.

9. Push 3 to select the probe settings.

10. Use

11. Push to make the change.

YZ to highlight the Probe A type.

YZ to highlight the Probe B (current clamp)

type.

Other settings stay the same.

Volts/Amps/Watt Measurements

This function simultaneously shows the voltage and

current signal. Use this function to get a first impression

of the voltage and current signal before you examine the

signal in more detail with the other functions.

To select the type of measurement:

1. Push 2 to select the waveform display.

2. Push 1 to toggle between the Voltage/Current or

Power readings.

36

Page 47

Industrial ScopeMeter®

Power and Harmonics Mode

Table 4 is a list of the visible readings when

Voltage/Current is selected.

Table 4. Volt/Amp Readings

hxv27.eps

Symbol Description

rms

v

Hz

rms

a

A<B

Deg

Voltage AC value on channel A

Frequency of voltage signal on channel A

Current AC value on channel B

Phase angle between voltage on channel A

and current on channel B

Table 5 is a list of the visible readings when Power is

selected.

Table 5. Watt Readings

hxv28.eps

Symbol Description

KW

VA

VAR

Hz

PF

Active power in Watt

Apparent power in Volt Ampere

Reactive power in Volt Ampere

Frequency

Power factor. The ratio between active power

and apparent power.

37

Page 48

123B/124B/125B

Users Manual

Harmonics Measurements

Harmonics are periodic distortions of voltage, current, or

power sine waves. A waveform can be considered a

combination of various sinewaves with different

frequencies and magnitudes. The contribution of each

component to the full signal is measured.

Harmonics power distribution systems are often caused

by non-linear loads such as switched mode DC power

supplies in computers, TVs, and adjustable speed motor

drives. Harmonics can cause transformers, conductors,

and motors to overheat.

In the Harmonics function, the Test Tool measures

harmonics to the 51

components, THD (Total Harmonic Distortion), and

K factor are measured.

You can display the harmonics of:

• Voltage measurements on Input A

• Current measurements on Input B

• Power measurements calculated from Voltage

measurements on Input A and Current

measurements on Input B.

st

. Related data such as DC

In the Harmonics mode the Test Tool always uses the

AUTO mode. The vertical sensitivity range and the time

base range are automatically adjusted to the most

suitable range for the applied input signal. The ranging

keys ( / / ) and are locked.

Input A is forced to measure voltage. Input B is forced to

measure current.

To make harmonics measurements:

1. Push 2 to select the harmonics display.

2. Push 1 to toggle between the voltage, current or

power readings.

3. Push 4 to turn on the cursor.

When the harmonics display with voltage measurements

is selected, the screen shows as in Table 6. For

harmonics display when current measurements are

selected, see Table 7. For harmonics display when watts

measurements are selected, see Table 8.

38

Page 49

Industrial ScopeMeter®

Power and Harmonics Mode

Table 6. Harmonics Voltage Measurements

Readout Description

rms V AC Voltage AC value on channel A

THD is the amount of harmonics in a signal as a percentage

of the total RMS value (THD%r) or as a percentage of the

fundamental (THD%f). It is a measure of the degree to which

a waveform deviates from a purely sinusoidal form. 0%

indicates that there is no distortion. You can select THD%r or

THD%f in the Settings menu (3).

The harmonics component as selected with the cursor. Use

WX to move the cursor. In the example screen this is the third

harmonic. The values to the right of this number will change

when the cursor is moved to another harmonic component.

The amount of the selected harmonic component in the

voltage signal as a percentage of the total RMS value

(THD%r) or as a percentage of the fundamental (THD%f). You

can select %r or %f in the Settings menu (3).

The phase angle between the harmonic component and the

fundamental voltage.

hxv29.eps

THD %f

Nr (3)

V Voltage of the harmonic component as selected by the cursor.

%f

Deg

39

Page 50

123B/124B/125B

Users Manual

Table 7. Harmonics Current Measurements

Readout Description

Rms AAc Current AC value on channel A

THD is the amount of harmonics in a signal as a percentage

of the total RMS value (THD%r) or as a percentage of the

THD %f

fundamental (THD%f). It is a measure of the degree to which

a waveform deviates from a purely sinusoidal form. 0 %

indicates that there is no distortion. You can select THD%r or

THD%f in the Settings menu (1).

40

hxv30.ep

KF

Nr (3)

A Current of the harmonic component as selected by the cursor.

%f

Deg

K-Factor indicates the losses in transformers due to harmonic

currents.

The harmonics component as selected with the cursor. Use

WX to move the cursor. In the example screen this is the third

harmonic. The values to the right of this number will change

when the cursor is moved to another harmonic component.

The amount of the selected harmonic component in the

current signal as a percentage of the total RMS value

(THD%r) or as a percentage of the fundamental (THD%f). You

can select %r or %f in the Settings menu (3).

The phase angle between the harmonic component and the

fundamental current.

Page 51

Industrial ScopeMeter®

Power and Harmonics Mode

Table 8. Harmonics Power Measurements

Readout Description

W Active power in Watts

hxv31.ep

KF

Nr (3)

W Power of the harmonic component as selected by the cursor.

%f

Deg

K-Factor indicates the losses in transformers due to harmonic

currents.

The harmonics component as selected with the cursor. Use

WX to move the cursor. In the example screen this is the third

harmonic. The values to the right of this number will change

when the cursor is moved to another harmonic component.

The amount of the selected harmonic component in the

current signal as a percentage of the total RMS value

(THD%r) or as a percentage of the fundamental (THD%f). You

can select %r or %f in the Settings menu (1).

The phase angle between the harmonic component and the

fundamental current.

41

Page 52

123B/124B/125B

Users Manual

Zooming Harmonics

If the harmonics bars screen is shown, you can zoom

vertically for a more detailed view. Use

or zoom out.

The scale at the left side changes when zooming in or

out.

YZ to zoom in

Fieldbus Mode

Fieldbuses are bi-directional, digital, serial control

networks used in process control and industrial

automation.

The Test Tool can indicate the status of the following

aspects of the OSI model Physical Layer:

• Voltage levels (bias, high level, low level)

• Bit width – baud rate

• Rise and fall time

• Distortion

The Test Tool can show the bus signal waveform in the

Eye-pattern mode, see page 47.

The Test Tool operates in full automatic (ranging and

triggering) mode. Test limits are preset, but can be

changed, see page 47.

For supported bus types and protocols see Table 9.

For extended information on Fieldbuses and fieldbus

measurement, see Appendix A of this manual.

Note

To check a suspected cable you can make

resistance measurements and capacitance

measurements using the Scope/Meter mode.

To do fieldbus measurements:

1. Push to open the MENU.

2. Use YZ to highlight BUSHEALTH.

3. Push to open the BUS HEALTH menu.

4. Use

5. Push to make the change.

6. Connect the inputs as shown in Figure 8, setup 4.

YZ to highlight the bus type.

Select User1 or User2 to create a customized set of

limits to test nonstandard bus systems. See page 48

for information about how to set the test limits.

Default settings are RS232 for User1 and Foundation

Fieldbus H1 for User2.

For bus types with additional options, a secondary

menu is available. Use

and to make the change.

An example of the screen is shown in Table 10.

YZ to highlight the option

42

Page 53

Industrial ScopeMeter®

Fieldbus Mode

Table 9. Bus Measurement Inputs

7. Use the BB120 Banana-to-BNC Adapter to connect a

BNC cable for bus measurements.

You can use the optional BHT190 Bushealth Test

adapter to easily connect the probe tip to a bus that

uses a DB9, RJ-45, or a M12 connector.

hxv32.eps

Bus Subtype

AS-i x - STL120

CAN x x STL120

Interbus S RS-422 x - VP41

DeviceNet x x STL120

Modbus

Foundation

fieldbus

Profibus

RS-232 x - STL120

RS-485 x x STL120

RS-232 x - STL120

RS-485 x x STL120

H1 x - STL120

DP/RS-485 x x STL120

PA/31.25 kBit/s x - STL120

Input

A B

Advised

Probe

43

Page 54

123B/124B/125B

Users Manual

How to Read the Screen

The bus test screen shows the status of the various signal

properties. To open, go the main screen and push 3.

Information is represented in four columns, see Table 10.

Table 10. Field Bus Test Screen

Item Description

Signal property under test, for example, VHigh. Rows show each

A

A B C D

hxv33.eps

signal property and corresponding data. See Table 11 for a description

of the signal properties for the bus types.

Status indicator. See Table 12 for a description of the indicators.

B

Most recent measurement value, for example, 3.5 V.

C

--OL

Used low (LOW) and high (HIGH) test limits (LIMIT), for example 18.5

D

31.6V.

LIMIT *

N/A

indicates that no reading is available

indicates that the signal is out of the measurement range

(overload)

The * indicates that one or more of the limits are not set to

the default value.

The limit does Not Apply to this bus type.

44

Page 55

Industrial ScopeMeter®

Fieldbus Mode

Table 11. Test Signal Properties

Property Explanation Property Explanation

VBias Bias voltage CAN-Rec. L CAN-recessive low level voltage

CAN-Rec. H-L

CAN-Rec. H CAN-recessive high level voltage Vpk-pk Peak to peak voltage

V-Level High-Bias High level to bias level voltage V Low Low level voltage

V-Level Bias-Low Bias level to low level voltage V-Level pk-pk Peak to peak voltage

CAN-DOM. H-L

CAN-DOM. H CAN-dominant high level voltage V-level low Low level voltage

CAN-DOM. L CAN-dominant low level voltage

Data

Rise Rise time as % of bit width

Fall Fall time as % of bit width

Distortion Jitter Jitter distortion Distortion Amplitude Amplitude distortion (AS-i bus)

Distortion Overshoot

CAN-recessive high to low level

voltage

CAN-dominant high to low level

voltage

Bit width Data Baud Baud rate

Signal distortion, over- and

undershoot

V High High level voltage

V-level high High level voltage

45

Page 56

123B/124B/125B

Users Manual

Table 12. Bus Test Screen Indicators

Indicator Description

Bus activity indicators

Bus activity indicator 1:

c No reading available.

f Test OK. Measurement results are within 80% of allowable range, see Figure 12.

d Warning. Measurement results are between 80% and 100% of allowable range, see Figure 12.

e Test failed. Measurement results are out of allowable range, see Figure 12.

(filled) voltage measured

(open) no voltage measured

Bus activity indicators 2 and 3:

(both open) no activity

(blinking)

Busy, the Test Tool is measuring/processing data.

activity

46

Page 57

Industrial ScopeMeter®

Fieldbus Mode

Figure 12 shows the bus health indicator boundaries. The

high level voltage of a bus must be between +3.0 V (MIN)

and +15.0 V (MAX). Depending on the measurement

result, the displayed indicator will be:

f

d

e

Result is between 4.2 and 13.8V. (10 % of

12 V = 1.2 V)

Result is between 3 V and 4.2 V, or between

13.8 V and 15 V.

Result is <3 V or >15 V.

hxv34.eps

Figure 12. Bus Health Indicator Boundaries

How to View the Bus Waveform Screen

To view the waveform eye pattern of the bus voltage:

1. Push 3. The screen shows the eye pattern. The

screen shows the waveforms of one bit time

triggered on a positive, as well as, on a negative

edge in persistence mode.

2. Push 1 to clear the persisted waveforms and

restart to show the waveform.

3. Push to freeze the screen. Push again to

clear the persistence waveform and restart the

waveform eye pattern.

hxv35.eps

47

Page 58

123B/124B/125B

Users Manual

Test Limits

The test limits apply to the selected bus type. To change

the test limits:

1. Push to open the MENU.

2. Use

3. Push to open the BUS HEALTH menu.

4. Use

5. Push to make the change.

6. From the BUSHEALTH main screen, push 1 to

7. Use

YZ to highlight BUSHEALTH.

YZ to highlight the bus type.

Select User1 or User2 to create a customized set of

limits to test nonstandard bus systems.

Default settings are RS232 for User1 and Foundation

Fieldbus H1 for User2.

open the SETUP LIMITS menu. The header shows

the bus type.

YZWX to highlight the property for the limit.

Note

Use 2 to set all limits to the default setting.

hxv36.eps

48

Page 59

Industrial ScopeMeter®

Recorder Mode

8. Edit the limit.

hxv37.eps

An asterisk (*) in the SETUP LIMITS screen

indicates that a signal property has limits that differ

from the default setting.

9. Push 3 to select N/A if a limit should not be

involved in the test.

10. Push 4 to accept the limits and return to the test

screen.

In the test screen the text LIMIT will be followed by

an * if any of the limits is not the default limit.

Note

Changed limits persist until a new change is

made or the Test Tool is reset.

Recorder Mode

The Test Tool offers recording and logging functionality:

• Meter Recorder to log meter readings over a long

period of time.

• Scope Recorder to continuously log waveforms for a

long period of time without time gaps (as is the case

in Scope and Meter mode).

49

Page 60

123B/124B/125B

Users Manual

The Meter Recorder makes the Test Tool act as a

paperless recorder that collects a series of parameter

measurements over time and shows the result as a graph

or a trend-line on screen. This is most useful to

understand the change of individual parameters over time

or the influence of environmental changes like

temperature over time.

The Scope Recorder captures waveforms. The applied

input voltage is registered over time and the resulting

waveform is stored in a long memory record. This can be

used to capture intermittent problems. Deviations from

the original signal are stored as events that can be easily

viewed after recording without the need to check all

information.

Start and Stop Meter Recording

Before you record, apply a stable signal to input A and B.

To set the parameters for recording:

1. Push to open the Recorder button bar.

2. Push 1 to open the RECORDING SETTINGS

menu.

50

hxv38.eps

3. Use YZ to highlight Set Duration.

4. Push to open the RECORDER SETTINGS >

DURATION menu.

hxv39.eps

Page 61

Industrial ScopeMeter®

Recorder Mode

5. Use YZWX and to enter the time in hours

and minutes.

Events are used to determine how often the

measured reading deviates from the initial reading

when recording starts. It is easy to see the time of a

deviation when you view the recording after it stops.

6. Use YZ to highlight Set Threshold.

7. Push and use YZ and to enter the

percentage deviation for meter readings.

8. Use

9. Push to accept the memory location.

10. Push 4 when done.

11. To start or stop a recording, push or 4.

The Test Tool continuously logs all readings to memory

and displays these as graphs. When both input A and

input B are on, the upper graph is input A.

YZ to highlight the memory type for recording

as either the internal memory of the Test Tool or an

SD memory card.

Note

The Test Tool beeps when an event occurs. If

no event is specified, a beep happens when a