Page 1

EchoPod®

Ultrasonic Level Transmitter

UG06 & UG12 Series Manual

Flowline, Inc. | 10500 Humbolt Street, Los Alamitos, CA 90720 p 562.598.3015 f 562.431.8507 w flowline.com MN310140 Rev A5

Page 2

Introduction / Table of Contents Step One

An ultrasonic sound wave is pulsed from the base of the transducer. The sound wave reflects against the

process medium below it. The sound wave energy is returned to the transducer. The microprocessor based

electronics measures the time of flight between the sound pulse generation and its receipt. This translates into

the distance or range between the transducer and process media below.

NEW FEATURES

Reflective Ultrasonic Technology

Simple configuration with push button or WebCal

®

software configuration

Increased temperature range

Increased output filtering

TABLE OF CONTENTS

Introduction: ...................................................................................................................................................... 2

Specifications: ........................................................................................................................................... 4

Dimensions: .............................................................................................................................................. 5

Reflective Technology: .............................................................................................................................. 6

About this manual: .................................................................................................................................... 7

Getting Started: ..................................................................................................................................................... 8

Setup Overview: ........................................................................................................................................ 8

Components: ............................................................................................................................................. 9

WebCal

®

vs. Display Configuration: ........................................................................................................ 10

Understanding Sensor Height (Height): .................................................................................................. 11

Understanding Fill-Height (Fill-H): ...................................................................................................... 12-13

Sensor Output to Local Display: ............................................................................................................. 14

Configuration (with WebCal

Step 1 – Install WebCal

WebCal

®

): ............................................................................................................................ 15

®

Software: ......................................................................................................... 16

®

System Requirements: ................................................................................................ 16

USB Fob Interface: ...................................................................................................................... 17

Step 2 – Measure the Tank: .................................................................................................................... 18

Step 3 – Sensor Configuration: ............................................................................................................... 19

Step 4 – Dimensional Entry: ................................................................................................................... 20

Step 5 – Tank Level Confirmation: .......................................................................................................... 21

Step 6 – Write to Unit: ............................................................................................................................. 21

Configuration

(

with Display): ................................................................................................................................ 22

Step1 – Measure Tank: ........................................................................................................................... 23

Step 2 – Setting the Units of Measurement: ........................................................................................... 24

Step 3 – Setting the Height: .................................................................................................................... 25

Step 4 – Setting the Fill-H: ...................................................................................................................... 26

Step 5 – Setting the Fail-Safe Current Output: ....................................................................................... 27

Installation: .......................................................................................................................................................... 28

Mounting Guide: ...................................................................................................................................... 28

Fitting Selection: ................................................................................................................................ 29-31

| 2 MN310140 Rev A5

Page 3

Introduction / Table of Contents Step One

Wiring: ................................................................................................................................................................ 32

Wiring Diagram – Sample: ...................................................................................................................... 32

Wiring EchoPod

Wire Connections: ................................................................................................................................... 33

General Notes for Electrical Connections, Usage and Safety: ............................................................... 33

Analog Output: ........................................................................................................................................ 34

Common Wiring to Displays, Controllers & PLCs: ............................................................................. 35-36

Voltage Output: ....................................................................................................................................... 37

WebCal

®

Appendix: ............................................................................................................................................ 38

Sensor Configuration: ........................................................................................................................ 38-39

Volumetric Configuration: ................................................................................................................... 40-42

Tank Level Confirmation: ........................................................................................................................ 43

“Write to Unit” .......................................................................................................................................... 44

Display Appendix: ............................................................................................................................................... 45

Air Gap vs. Liquid Level: ......................................................................................................................... 45

How to reverse the current output (Rev mA): ......................................................................................... 46

How to Setup to Start-up Power: ............................................................................................................ 47

Values Menu: .......................................................................................................................................... 48

SETUP: ....................................................................................................................................... 48

Diagnostic (DIAG) parameters: ................................................................................................... 48

Reset: .......................................................................................................................................... 49

Appendix: ............................................................................................................................................................ 50

Factory Settings: ..................................................................................................................................... 50

User Settings: ......................................................................................................................................... 50

Troubleshooting: ..................................................................................................................................... 51

Warranty: ............................................................................................................................................................ 52

®

: .................................................................................................................................... 32

MN310140 Rev A5 3 |

Page 4

Introduction (continued) Step One

SPECIFICATIONS

Electrical:

Supply Voltage: 14-28 Vdc

Signal: 4 to 20 mA current loop; 22 mA

max.

Mechanical:

Display Module: Removable via short cable and

plug

LCD: 6 characters, 10 mm (0.394”)

height

Buttons: Three, UP / OK / DN

Pin Connection: Display can be removed such

that the open connection allows

the sensor to be WebCal

®

capable.

Enclosure: Polypropylene head with skirt to

Environmental:

Temperature: -40 to 80 °C (-40 to 176 °F)

Pressure: 30 psi (2 bar)

Enclosure: IP68

Functional:

Range: UG06: 6.0m (19.69 feet)

UG12: 12.0m (39.4 feet)

Dead band: UG06: 20cm (8 inches)

UG12: 45.7cm (18 inches)

Accuracy: 0.2% of Range in air at 20 °C

Resolution: UG06: 2mm (0.079 inches)

UG12: 5mm (0..196 inches)

Beam width: UG06: 7.6cm (3 inches)

UG12: 15.2cm (6 inches)

Menu: Self-scrolling

support transducer w/ conduit

Conduit Connection: Single, 1/2 inch NPT

Transducer: Black, PVDF with Viton A

gasket

Process Mount: UG06: 2" NPT or 2” G

UG12: 3” NPT or 3” G

Gasket Viton A (G thread only)

Electrical Connections:

Power & Return: 2-pin quick connect terminal

block

WebCal Connect.: 2-pin quick connect terminal

block

Display Connect.: 5-pin plug & socket

| 4 MN310140 Rev A5

Page 5

Introduction (continued) Step One

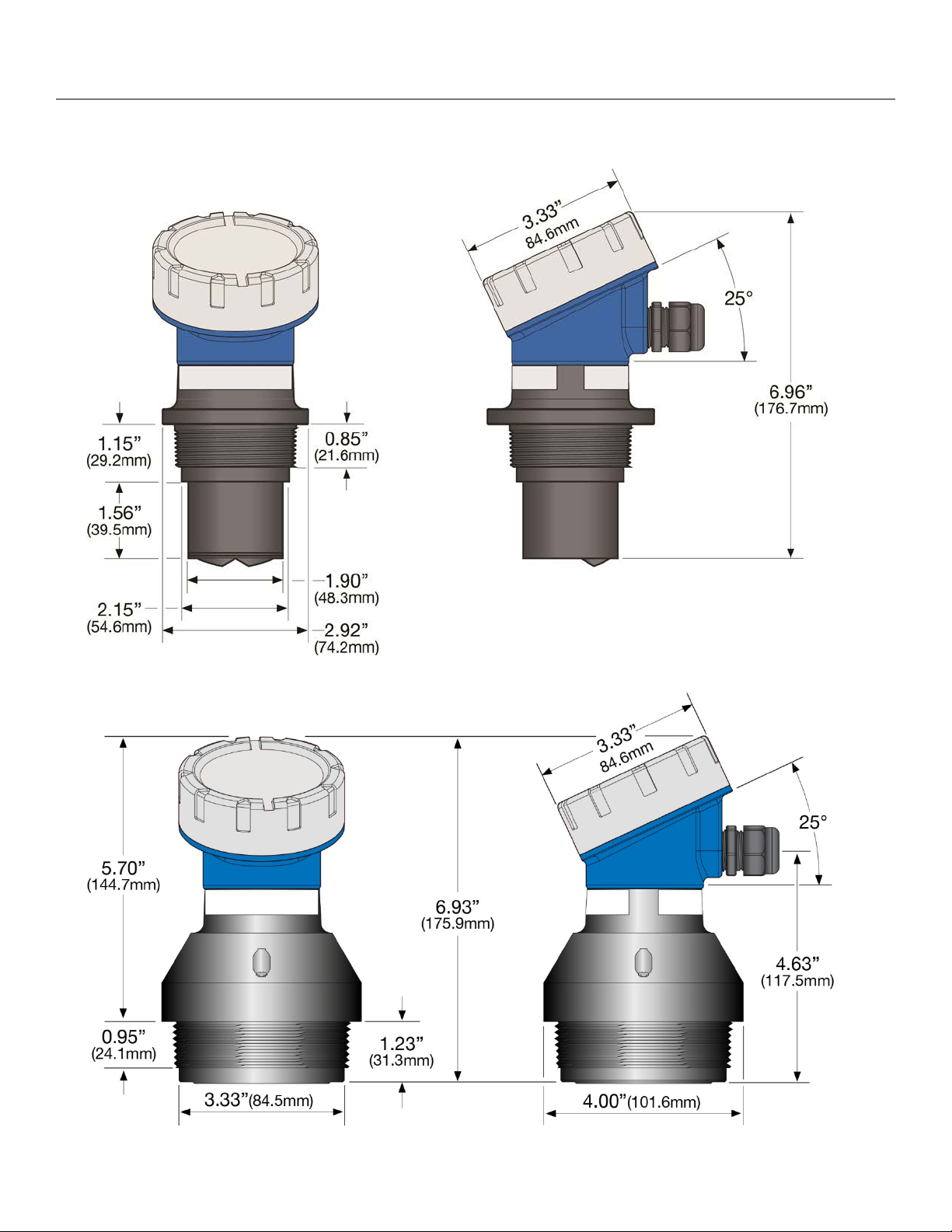

DIMENSIONS

Dimensions for UG06 Series

Dimensions for UG12 Series

MN310140 Rev A5 5 |

Page 6

Introduction (continued) Step One

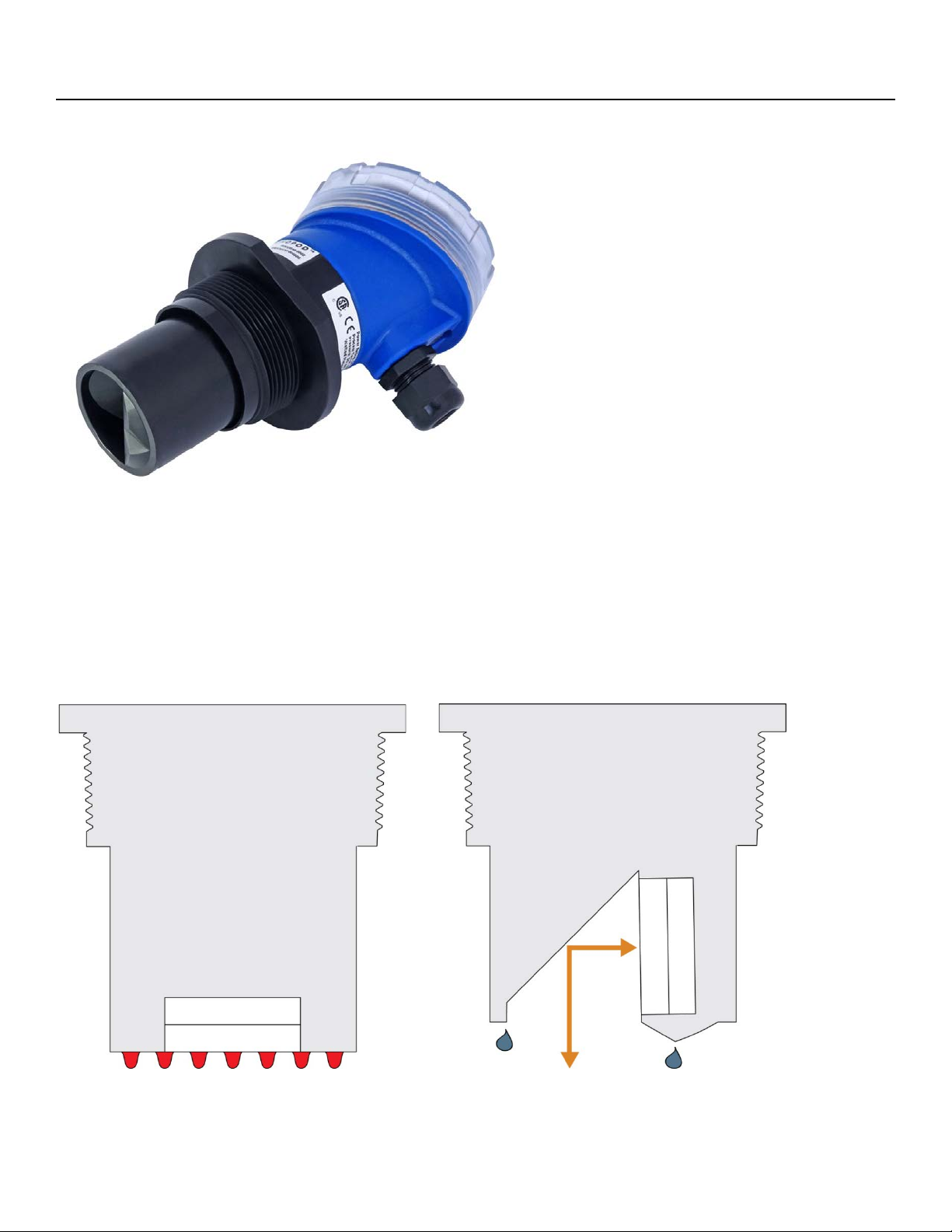

REFLECTIVE TECHNOLOGY

Condensation is the most common variable in liquid level applications. Condensation attenuates the acoustic

signal of ultrasonic sensors with horizontal transducers, weakening their signal strength and signal to noise

ratio by up to 50%, and substantially reducing their measurement reliability. At the core of Reflective

Technology™ is a simple fact. Unlike flat horizontal surfaces, significant water droplets cannot adhere to

smooth vertical surfaces. By orienting the transducer vertically, condensation runs off the transducer and does

not affect sensor performance. The unimpeded transmit and receive signals are redirected to and from the

liquid off a 45º reflector, delivering reliable level measurement.

FLAT TRANSDUCER REFLECTIVE TRANSDUCER

Signal Attenuation Reliable Measurement

| 6 MN310140 Rev A5

Page 7

Introduction (continued) Step One

About this Manual: PLEASE READ THE ENTIRE MANUAL PRIOR TO INSTALLING OR USING THIS

PRODUCT. This manual includes information on the EchoPod

®

series Ultrasonic Level Transmitter from

FLOWLINE. Please refer to the part number located on the switch label to verify the exact model

configuration, which you have purchased.

User’s Responsibility for Safety: FLOWLINE manufactures a broad range of level sensing technologies.

While each of these sensors is designed to operate in a wide variety of applications, it is the user’s

responsibility to select a sensor model that is appropriate for the application, install it properly, perform tests of

the installed system, and maintain all components. The failure to do so could result in property damage or

serious injury.

Proper Installation and Handling: Only professional staff should install and/or repair this product. Never

over tighten the sensor within the fitting. Always check for leaks prior to system start-up.

Wiring and Electrical: A supply voltage of 14 to 28 VDC is used to power the EchoPod®. Electrical wiring

of the transmitter should be performed in accordance with all applicable national, state, and local codes.

Material Compatibility: The enclosure is made of Polypropylene (PP). The transducer is made of

Polyvinylidene Fluoride (PVDF). Make sure that the model, which you have selected, is chemically compatible

with the application media.

Enclosure: While the sensor housing is liquid-resistant the EchoPod® is not designed to be operational

when immersed. It should be mounted in such a way that the enclosure and transducer do not come into

contact with the application media under normal operational conditions.

Note: If using the Flowline LM90-1001 (liquid tight fitting) on the ½” conduit, the cable minimum is 0.170”

(4.3mm) and the maximum is 0.450” (11.4mm).

Handling Static-Sensitive Circuits/Devices: When handling the transmitter, the technician should follow

these guidelines to reduce any possible electrostatic charge build-up on the technician’s body and the

electronic part.

1. Always touch a known good ground source before handling the part. This should be repeated while

handling the part and more frequently after sitting down from a standing position, sliding across the seat

or walking a distance.

2. Avoid touching electrical terminals of the part unless making connections.

3. DO NOT open the unit cover until it is time to calibrate.

Make a Fail-Safe System: Design a fail-safe system that accommodates the possibility of switch and/or

power failure. FLOWLINE recommends the use of redundant backup systems and alarms in addition to the

primary system.

Flammable, Explosive or Hazardous Applications:

EchoPod® should not be used within classified hazardous environments.

Warning: Always use the Viton gasket when installing “G” threaded versions of EchoPod®.

Warning: Make sure that all electrical wiring of the switch is in accordance with applicable codes.

MN310140 Rev A5 7 |

Page 8

Getting Started Section Two

SETUP OVERVIEW

Below highlights the initial steps in setting up your sensor for operation.

1. Check Part Number (Section Two)

a. Confirm that the sensor’s part number matches the ordered part number and all components

are provided with the model delivered.

2. Measurements, Installation & Software (Section Two)

a. Understand the location placement of the sensor relative to Measurement Range including

Sensor Height and Fill-Height settings.

b. Download the WebCal

3. Configure Sensor with WebCal

a. Section 3 contains information on using the WebCal

4. Configure Sensor with Push Button (Section Four)

a. Section 4 contains information on using the Push Button Display to configure the sensor.

5. Install the sensor (Section Five)

a. Section 5 contains information about the sensor location placement and its mechanical

installation.

6. Wire the sensor (Section Six)

a. Section 6 contains information about the sensor’s electrical wiring and power requirements.

Note: When configuring EchoPod

accomplish the goal of sensor configuration. Changes to the configuration can be made using the alternative

method. When beginning with one method, it is recommended to complete the configuration before using the

other method to make any adjustments.

®

software from www.flowline.com/webcal-software/.

®

(Section Three)

®

, choose either the WebCal® or Push Button method. Either method will

®

configuration software.

| 8 MN310140 Rev A5

Page 9

Getting Started (continued) Section Two

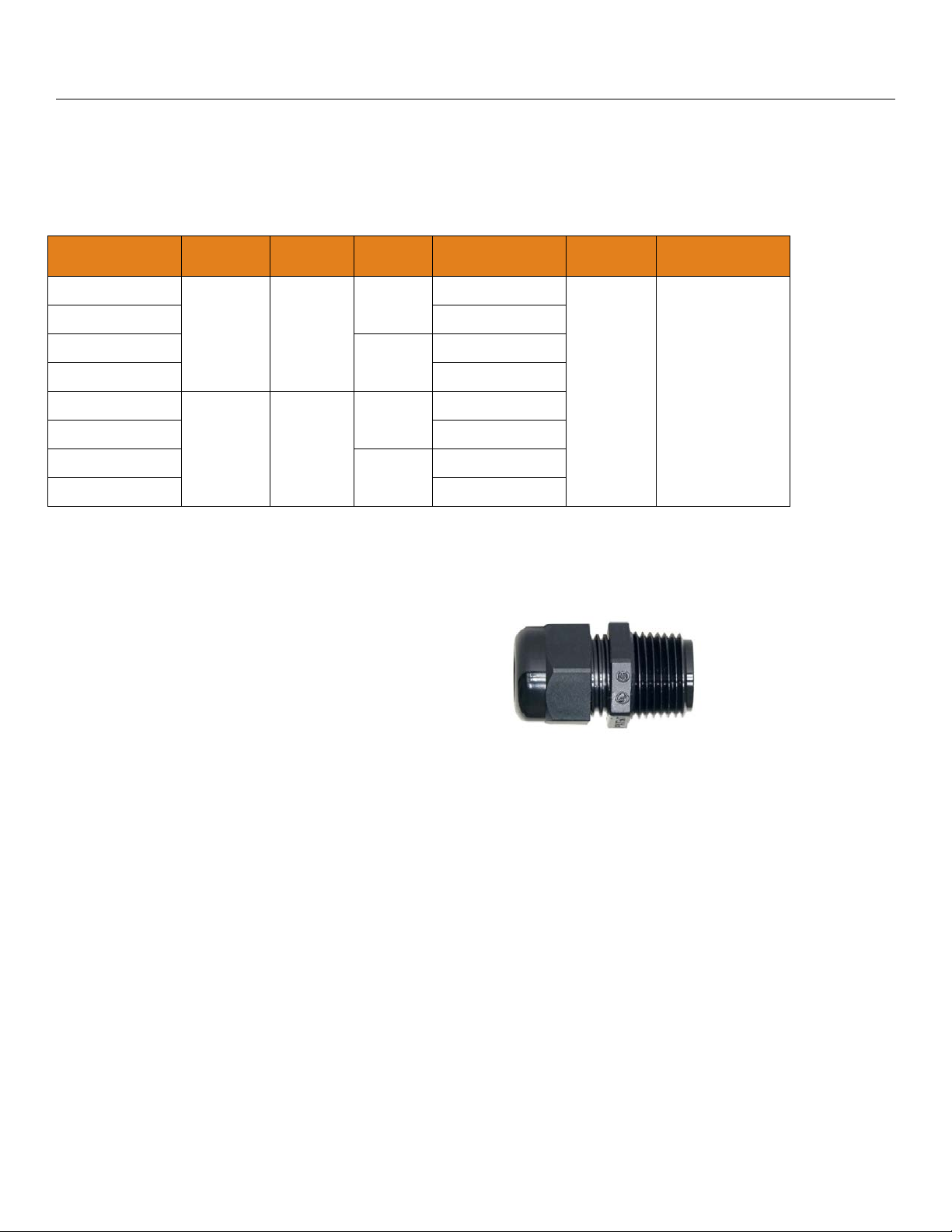

COMPONENTS

EchoPod® is offered in different models. Depending on the model purchased, you may or may not have been

shipped all the components shown below. All G threaded process mounts require a Viton

®

installation and operation of EchoPod

P/N

Max.

Range

Dead

Band

UG06-0001-00

.

Thread Fob Output Configuration

Not Included

®

gasket for

2” NPT

UG06-0001-01 Included

UG06-0011-00

UG06-0011-01 Included

UG12-0001-00

UG12-0001-01 Included

UG12-0011-00

19.7’

(6m)

39.4’

(12m)

8”

(20cm)

18”

(45.7cm)

2” G

3” NPT

Not Included

Not Included

Not Included

4-20 mA

Display

with

Push Button

or

®

WebCal

3” G

UG12-0011-01 Included

Viton Gasket (G threaded version only)

o Part # 200129 – (UG06-0011-0_ only)

o Part # 210157 – (UG12-0011-0_ only)

Liquid Tight Fitting

o Part # LM90-1001

o Note: If using the Liquid Tight Fitting on

the ½” conduit, the cable minimum is

0.170” (4.3mm) and the maximum is

0.450” (11.4mm).

Quick Start Guide

MN310140 Rev A5 9 |

Page 10

Getting Started (continued) Step Two

WEBCAL® VS. DISPLAY CONFIGURATION

EchoPod® can be configured using either the free WebCal® software and USB® Fob or with the internal display

module. Either method will accomplish the goal of sensor configuration. Changes to the configuration can be

made using the alternative method. Upon implementing one methodology, it is recommended to complete the

configuration before using the other methodology in making any adjustments.

EchoPod

®

can be configured before installation or after installation. The transmitter features non-volatile

memory, so any settings configured before installation will not be lost when the sensor is powered down. To

start, the following information is required:

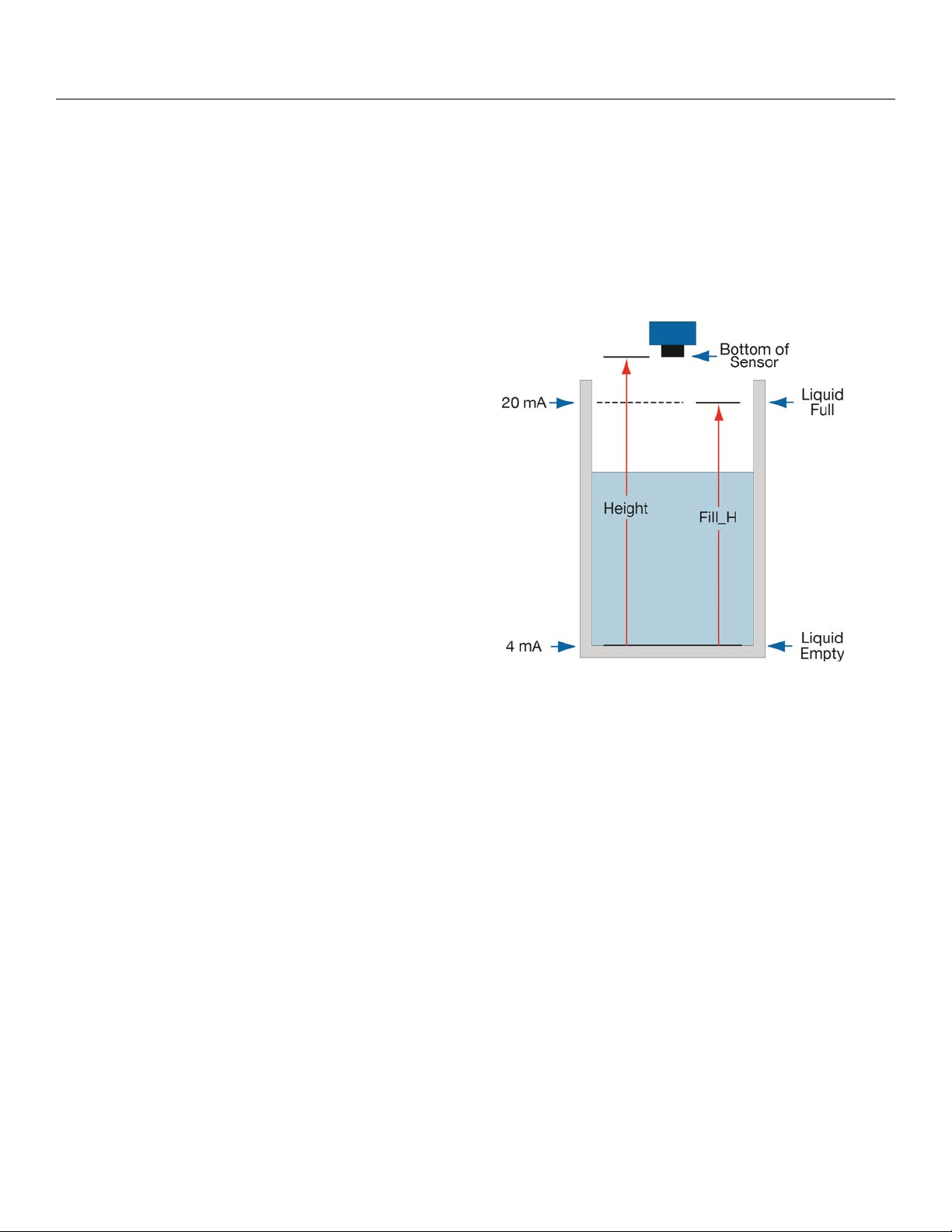

Basic Tank Information

o HEIGHT (Sensor Height) – Distance from

the bottom of the tank to the bottom of the

sensor.

o FILL-H (Fill-Height) – Distance from the

bottom of the tank to the fill-height of the

liquid.

Power:

o Provide input power to the EchoPod

®

Note: The HEIGHT and Fill-Height (FILL-H) settings also determine the 4 to 20 mA current span. The

HEIGHT setting determines the 4mA position and the FILL-H setting determines the 20 mA position.

| 10 MN310140 Rev A5

Page 11

Getting Started (continued) Step Two

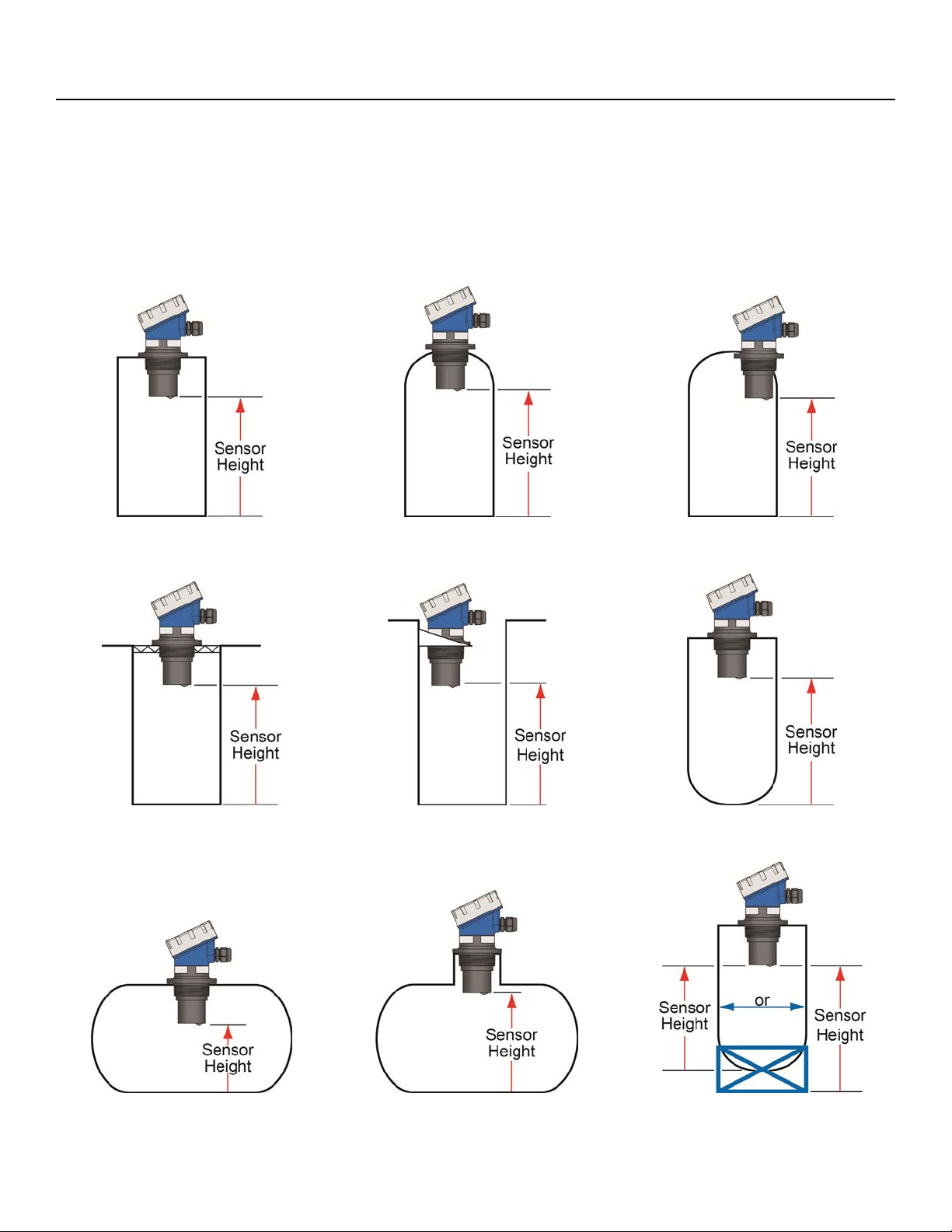

UNDERSTANDING SENSOR HEIGHT (HEIGHT)

This is a critical setting for EchoPod®. Sensor Height (SH) defines the location of the sensor from the bottom

of the tank. The value must take into account the shape of the tank and any risers, fittings, structures or

extensions associated with the tank or the installation (see examples below). The reference point for definition

of the Sensor Height is always the bottom of the mounting nut.

Sensor Off-center

Simple Vertical Tank Dome Top Raises HEIGHT

Changes HEIGHT

Simple Open Top Tank Sensor Extends into Sump

Simple Horizontal Tank Riser Elevates HEIGHT

Cone Bottom

Elevates HEIGHT

Mounting Fixture

Elevates HEIGHT

MN310140 Rev A5 11 |

Page 12

Getting Started (continued) Step Two

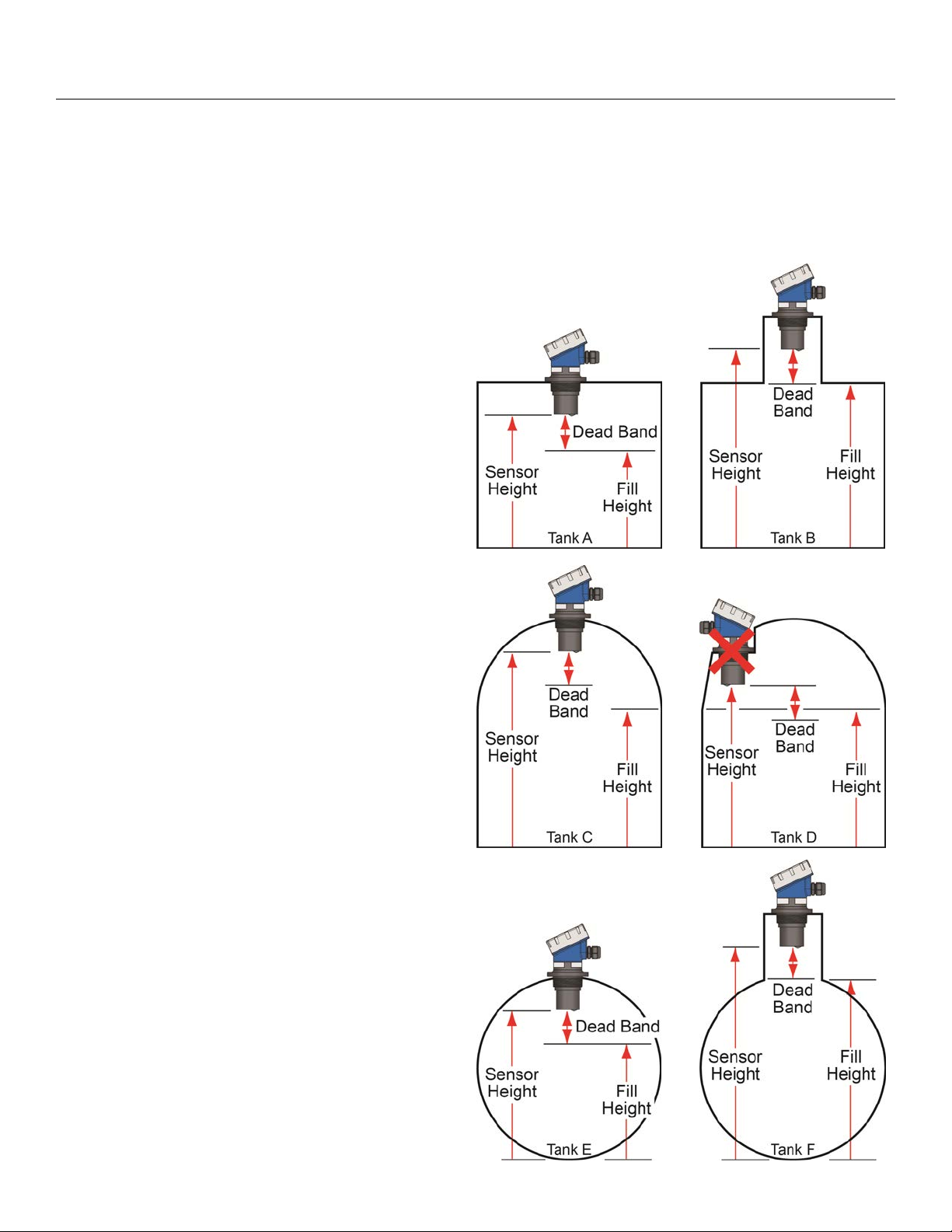

UNDERSTANDING FILL-HEIGHT (FILL-H)

This is another critical setting for EchoPod®. FILL-H (Fill-Height) defines the location of the highest point in the

tank where the sensor will read level changes. When the level rises above FILL-H, the sensor will read full

(as long as the level does not enter the dead band). The reference point for definition of FILL-H is always from

the bottom location of the Sensor Height. The value must take into account the sensors dead band, any risers,

fittings, structures or extensions associated with the tank or the installation as well as the tanks geometry.

Example #1 – Flat Top Tanks

Tank A is a vertical tank with a flat top. The highest

value for FILL-H can be calculated by subtracting

the Dead Band from the Sensor Height.

FILL-H = Sensor Height – Dead Band

Tank B is another vertical tank with a riser that

matches the dead band of the sensor. In this case,

the FILL-H will be set to the top of the tank.

Note: The ratio of height to diameter of the riser

must be no greater than 2:1. Any higher and the

sensor will target the inside wall of the riser.

Example #2 – Dome Top Tanks

Tank C has a tall enough dome whereas the Dead

Band is above the straight side of the tank. The

FILL-H can be set to the top of the straight side

(this is advantageous because the top of the

straight side is typically a known volume of liquid).

The sensor is moved to a flat part of Tank D. As a

result, the Dead Band is now below the straight

side of the tank. FILL-H cannot be set to match the

straight side of the tank. Calculate FILL-H as

follows:

FILL-H = Sensor Height – Dead Band

Example #3 – Horizontal Tanks

Tank E is a horizontal tank with a rounded top.

The highest value for FILL-H can be calculated by

subtracting the Dead Band from the Sensor

Height.

FILL-H = Sensor Height – Dead Band

Tank

F is another horizontal tank with a riser that

matches the dead band of the sensor. In this case,

the FILL-H will be set to the top of the tank.

Note: The ratio of height to diameter of the riser

must be no greater than 2:1. Any higher and the

sensor will target the inside wall of the riser.

| 12 MN310140 Rev A5

Page 13

Getting Started (continued) Step Two

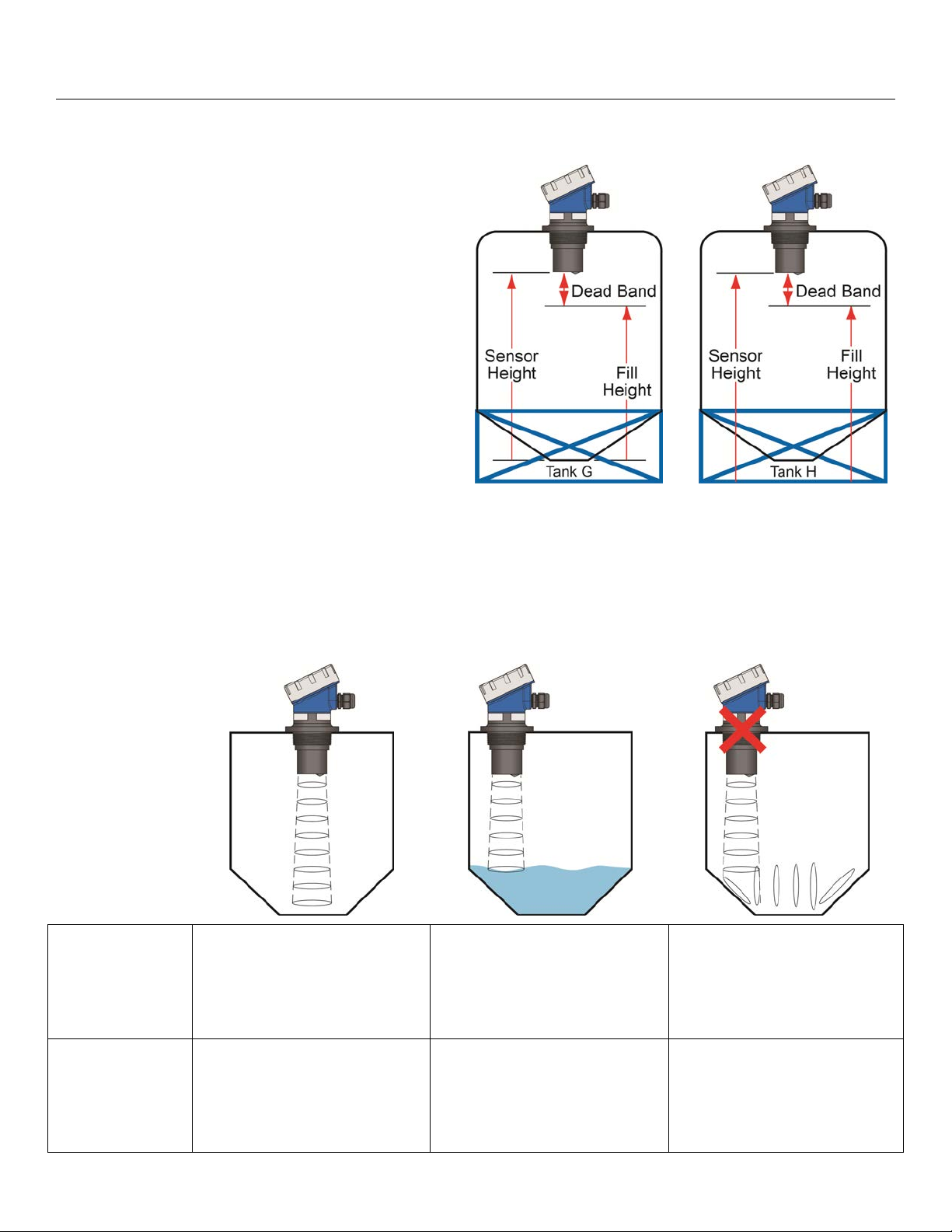

Example #4 – Cone Bottom Tank

Tank G and Tank H are both vertical tanks that are

being supported above ground level with tank

stands. The location of the Sensor Height (Tank

G - bottom of tank or Tank H – ground level) will

influence the FILL-H setting.

Note: FILL-H must always be referenced to the

lowest location of the Sensor Height.

Since Tank G is off of the ground, the lowest

location may be difficult to identify/measure. This

location is required if the Volumetric Mode in

WebCal

Tank H uses ground level as the main reference

location. This method is easiest to use and ideal

for using the Distance Mode of WebCal

®

is used.

®

.

Cone and Rounded Bottom Tanks

The location of an EchoPod

®

installed along the top of a cone or rounded bottom tank may have an effect on

the installation of the sensor. Be sure to understand the geometry directly underneath the sensor. Cone or

rounded bottom tanks will provide off angled surfaces that can reflect the ultrasonic sound energy away from

the sensor as the liquid level is lowered.

#1 Center of Cone #2 Above an Angled Tank

Bottom (straight side only)

#3 Above an Angled Tank

Bottom (full range)

Tank

Geometry

Does not impede sensor’s

performance. Sensor is able

to track the entire range of

the tank.

Does not impede sensor’s

performance as long as the

level remains within the

straight side of the tank wall.

Does impede sensor’s

performance. The angled

bottom will reflect ultrasonic

energy away from the

sensor.

HEIGHT is set to the bottom

of the tank; the sensor will

function as long as the level

is within the straight side of

Distance

Reading

HEIGHT is typically set to

the bottom of the tank.

Sensor will track the full

range of the tank.

HEIGHT is typically set to

the bottom of the straight

side. Sensor will only tack

the straight side of the tank.

the tank.

MN310140 Rev A5 13 |

Page 14

Getting Started (continued) Step Two

SENSOR OUTPUT TO LOCAL DISPLAY/CONTROLLER

EchoPod® outputs a 4-20 mA signal to a local display/controller or to remote devices such as PLCs, SCADA,

DCS or other displays/controllers. The 4-20 mA signal is set relative to the Sensor Height and Fill-Height

settings. These settings create an operational range that can be translated into a level reading in defined units

(i.e. inches, feet, gallons, meters, liters, etc.).

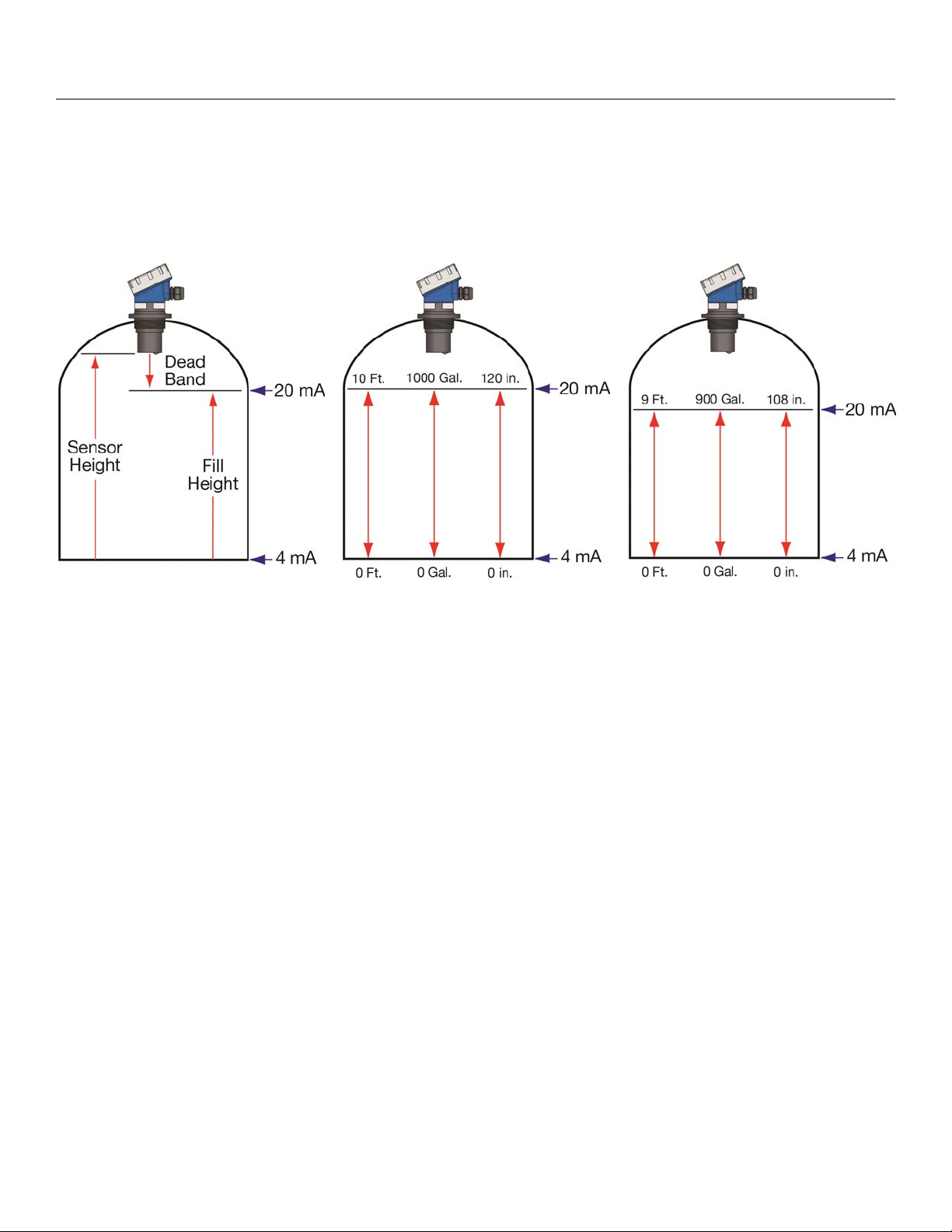

Tank A

In the Tank A example, the Sensor Height sets the 4mA to the bottom of the tank. Fill-Height sets the 20mA to

the top of the straight side of the tank.

In the Tank B example, the 4-20mA sensor range is correlated to actual units of level measurement. The

operational range now will have engineering values of 0 to 10 feet or 0 to 1000 gallons or 0 to 120 inches.

Tank B

Tank C

In the Tank C example, the 20mA setting was lowered by 1 foot, so the engineering values for the new shorter

operational ranges are either 0 to 9 feet, 0 to 900 gallons or 0 to 108 inches.

| 14 MN310140 Rev A5

Page 15

Configuration Using WebCal® Step Three

EchoPod

®

can be configured before installation. The transmitter features non-volatile memory, so any setting

configured before installation will not be lost when the switch is powered down. To configure, follow the steps

below:

1. Install WebCal

a. Go to www.flowline.com/webCal-software/

b. Review how USB

®

software

®

and select language version.

Fob interfaces with EchoPod® and your computer.

2. Measure the Tank

a. Begin by measuring the key tank and fitting dimensions.

b. Correct tank dimensions will result in accurate sensor measurement.

3. Sensor Configuration

a. Configures Loop Fail-Safe, Output at Empty & Startup Condition for the sensor.

4. Dimensional Entry

a. Distance Mode (default)

i. Basic information for operation (Sensor Height & Fill-Height).

5. Tank Level Confirmation

a. Confirm the values are accurate for the application.

6. Write to Unit

a. Uploads configuration into the sensor.

b. Access to a customer wiring diagram specific to the relay configuration.

Note: When configuring EchoPod

®

, choose either the WebCal® or Push Button method. Either

method will accomplish the goal of sensor configuration. Changes to the configuration can be

made using the alternative method. When beginning with one method, it is recommended to

complete the configuration before using the other method to make any adjustments.

MN310140 Rev A5 15 |

Page 16

Configuration Using WebCal

STEP 1 – INSTALL WEBCAL® SOFTWARE

®

(continued) Step Three

EchoPod® is configured through WebCal®*, a PC software program. WebCal® is a free download from

®

Flowline’s website. You must download and install WebCal

prior to plugging in the USB® Fob (LI99-

2001). Please go to .flowline.com/webcal-software/, and select your language version.

WEBCAL® SYSTEM REQUIREMENTS

Windows® XP, Vista, 7, 8, 10

32 or 64-bit system

1 USB

®

2.0 port

10 mB hard drive space

256 mB RAM

Internet connection

*

For complete information on the WebCal

®

software, please refer to the WebCal® manual located at

www.flowline.com/webcal-software/.

| 16 MN310140 Rev A5

Page 17

®

Configuration Using WebCal

USB® FOB INTERFACE

®

(continued) Step Three

EchoPod

(LI99-2001) into your computer’s USB

www.flowline.com/webcal-software/

Connect the red, green, white and black wires from EchoPod

the screws on the terminals. Plug your Fob into the USB

Wiring to Fob (LI99-2001)

®

communicates with WebCal®* through a USB® interface called a Fob. Before plugging your Fob

®

port, be sure that you have installed WebCal® (see

) on your computer.

®

port of your computer.

LI99-2001 USB

®

Wiring is identical for all EchoPod

The maximum cable distance

configuring the EchoPod

®

.

Series – Use only the Red, Black, Green and White wires.

between the computer and EchoPod® is 15’. This only applies for

®

into the correct terminals on the Fob. Tighten

Fob

Note: Only use the LI992001 USB

®

Fob (white).

The LI99-1001 USB

(black) will not work with

the EchoPod

®

series.

®

Fob

®

Once EchoPod

is configured and prior to installation, isolate the white and green terminals from active

power to prevent a short from the configuration circuit.

Note: When using the Fob, do not add VDC or VAC power. The Fob, when connected to the computer, will

provide the required power to the EchoPod

Note: When connecting the sensor to the WebCal

®

.

®

Software, you must remove the display or the software

will not connect. Once completed, you can re-connect the display to the terminal.

* For complete information on the WebCal

www.flowline.com/webcal-software/

.

®

software, please refer to the WebCal® manual located at

MN310140 Rev A5 17 |

Page 18

Configuration Using WebCal

STEP 2 - MEASURE THE TANK

®

(continued) Step Three

Measuring the tank is one of the most important aspects in

configuring the sensor. When measuring the tank, take

into account the location of the sensor with respect to

fittings, risers, dome tops and bottoms, and identify where

the measurements are taken from the sensor. The Sensor

Height is influenced by the installation location. Sensors

mounted along the sloped portion of the tank will result in a

lower (HEIGHT) value. On the other hand, sensors

installed in risers/nozzles will result in a higher (HEIGHT)

value.

The basic measurements (Height and Fill-H) for configuration are described below:

1. HEIGHT (Sensor Height) - Distance from the bottom of

the tank to the Bottom of Sensor.

a. The bottom of the tank will be the sensor’s zero

level / empty level.

b. This setting determines the 4mA location.

2. FILL-H (Fill-Height) - Distance from the bottom of the

tank to the level of liquid where the tank is full is FILL-H.

a. The FILL-H is typically set to the liquid full level.

b. This setting determines the 20 mA location.

c. 20mA cannot be set within the sensor’s dead

band [8” (20cm) from bottom of sensor]. Largest

FILL-H value will be as follows:

Largest FILL-H = HEIGHT – 8” (20cm)

| 18 MN310140 Rev A5

Page 19

Configuration Using WebCal

®

(continued) Step Three

With EchoPod

®

connected to your computer, open the WebCal®* software by clicking on the WebCal® icon.

Follow steps 3-6 to configure the transmitter. Click “Help” in the lower right hand corner and open the help

menu of WebCal

®

for instructions on WebCal®. If you need additional assistance using WebCal®, please

contact a Flowline applications engineer at (562) 598-3015. Note: For complete information on the WebCal

software, please refer to the WebCal

STEP 3 - SENSOR CONFIGURATION:

®

manual located at .flowline.com/webcal-software/.

Configures the Loop Fail-Safe, Output at Empty and Startup Condition for the sensor.

®

Note: When configuring EchoPod®, choose

either the WebCal® or Push Button method.

Either method will accomplish the goal of

sensor configuration. Changes to the

configuration can be made using the

alternative method. When beginning with

one method, it is recommended to

complete the configuration before using the

other method to make any adjustments.

Note: When connecting the sensor to the WebCal® Software, you must remove the display or the software will

not connect. Once completed, you can re-connect the display to the terminal.

MN310140 Rev A5 19 |

Page 20

Configuration Using WebCal

STEP 4 – DIMENSIONAL ENTRY:

Distance Mode (default): Output of sensor is based on the distance (height of liquid) in the tank. Any

change in liquid level will reflect linearly to the current output. Note: Most applications will fall into this

category. For Volumetric outputs, refer to VOLUMETRIC CONFIGURATION on page 40. The two

values (Sensor Height and Fill-Height) below set the 4-20 mA current span for the sensor. Both values

will be set in the units shown under Height Units.

Sensor Height: Sets the location for 4mA. It is based on the distance from the Empty level

position (bottom of tank) to the Measurement location for the sensor (bottom of sensor).

Fill-Height: Sets the location for 20mA. It is based on the distance from the Empty level

position (bottom of tank) to the Full level position (see below).

®

(continued) Step Three

| 20 MN310140 Rev A5

Page 21

Configuration Using WebCal

STEP 5 – TANK LEVEL CONFIRMATION:

Verify the Height Units, Sensor Height & Fill-Height. All values were calculated in the previous Dimensional

Entry window. To adjust these settings, click on Volumetric Modes.

®

(continued) Step Three

STEP 6 – WRITE TO UNIT:

This WebCal®* operation uploads configuration into the sensor. Other features in the section include providing

a custom wiring diagram specific to the signal output and saving the configuration file to your hard drive.

VolumetricSensorOutput

The Volumetric Mode

button will be highlighted

inBluewhenavolume

outputisselected.

®

* For complete information on the WebCal

software, please refer to the WebCal® manual located at

flowline.com/webcal-software/.

MN310140 Rev A5 21 |

Page 22

Configuration Using Display Step Four

EchoPod

®

can be configured before installation. The transmitter features non-volatile memory, so any setting

configured before installation will not be lost when the switch is powered down. To configure, follow the steps

below:

1. Measure the Tank

a. Begin by measuring the key tank and fitting dimensions.

b. Correct tank dimensions will result in accurate sensor measurement.

2. Set the Units of Measurement (UNITS)

a. Units can be configured in basic engineering units of length including Feet, Inches, Centimeters

or Meters.

3. Set the Sensor Height (HEIGHT)

a. This is the empty setting (4mA) for the tank.

4. Set the Fill-Height (FILL-H)

a. This is the full setting (20mA) for the tank.

5. Set the Fail-Safety (SAFE)

a. This is the maximum measurement range for the sensor. The sensor will ignore all echo returns

beyond this setting.

NOTE: When configuring EchoPod

accomplish the goal of sensor configuration. Changes to the configuration can be made using the alternative method.

When beginning with one method, it is recommended to complete the configuration before using the other method to

make any adjustments.

®

, choose either the WebCal® or Push Button method. Either method will

| 22 MN310140 Rev A5

Page 23

Configuration Using Display (continued) Step Four

STEP 1 - MEASURE THE TANK

Measuring the tank is one of the most important aspects in

configuring the sensor. When measuring the tank, take

into account the location of the sensor with respect to

fittings, risers, dome tops and bottoms, and identify where

the measurements are taken from the sensor. The Sensor

Height is influenced by the installation location. Sensors

mounted along the sloped portion of the tank will result in a

lower (HEIGHT) value. On the other hand, sensors

installed in risers/nozzles will result in a higher (HEIGHT)

value.

The basic measurements (Height and Fill-H) for configuration are described below:

1. HEIGHT (Sensor Height) - Distance from the bottom of

the tank to the Bottom of Sensor.

a. The bottom of the tank will be the sensor’s zero

level / empty level.

b. This setting determines the 4mA location.

2. FILL-H (Fill-Height) - Distance from the bottom of the

tank to the level of liquid where the tank is full is FILL-H.

a. The FILL-H is typically set to the liquid full level.

b. This setting determines the 20 mA location.

c. 20mA cannot be set within the sensor’s dead

band [8” (20cm) from bottom of sensor]. Largest

FILL-H value will be as follows:

Largest FILL-H = HEIGHT – 8” (20cm)

MN310140 Rev A5 23 |

Page 24

Configuration Using Display (continued) Step Four

TOP-LEVEL MENU

The TOP-LEVEL MENU will continue to scroll

through the items listed to the right until the OK

button is pressed.

To return to the Normal / Operational mode of

EchoPod

®

, press OK while RUN appears in the

display.

How to enter the TOP-LEVEL MENU

1. Press and hold OK (approximately 5 seconds) until

MENU is displayed.

2. The TOP-LEVEL MENU items will rotate through

display.

3. Use OK to choose a MENU item.

How to exit the TOP-LEVEL MENU

In TOP-LEVEL MENU, press OK when RUN appears.

STEP 2 - SETTING THE UNITS OF MEASUREMENT (UNITS)

1. In the TOP-LEVEL MENU mode, select UNITS.

2. Press OK to choose between INCHES, CM

(centimeter), FEET or METERS.

a. Press and hold OK on the selected setting for 2

seconds then release.

a. To cancel UNITS, Select EXIT.

3. Select EXIT to return to the TOP-LEVEL MENU.

®

Note: EchoPod

will adjust the display when measurement

units are changed under UNITS. Example: If you are in

inches and the display reads 60.0, the display will change to

5.00 when feet is selected as the unit of measurement.

| 24 MN310140 Rev A5

Page 25

Configuration Using Display (continued) Step Four

STEP 3 - SETTING THE HEIGHT (SENSOR HEIGHT)

1. In TOP-LEVEL MENU mode, select TANK.

2. Select HEIGHT.

3. Using the UP and DOWN buttons, set the HEIGHT of

the tank (transducer face to the bottom of the tank).

4. To enter the value, press and hold OK for 5 seconds

and release. SAVED will display.

5. Select EXIT to return to TOP-LEVEL MENU.

Note: The HEIGHT setting also determines the 4 mA current location. To reverse the current output with

20mA at the bottom of the tank, use the REV MA function.

Note: To speed up the scrolling of the values on the display, hold down the OK button while holding down the

UP or DOWN buttons.

MN310140 Rev A5 25 |

Page 26

Configuration Using Display (continued) Step Four

STEP 4 - SETTING THE FILL-H (FILL-HEIGHT)

1. In TOP-LEVEL MENU mode, select TANK.

2. Select FILL-H.

3. Using the UP and DOWN buttons, set the Fill Height

(FILL-H) of the tank (max. level of liquid to the bottom of

the tank).

4. To enter the value, press and hold OK for 5 seconds

and release. SAVED will display.

5. Select EXIT to return to TOP-LEVEL MENU.

Note: The Fill-Height (FILL-H) setting determines the 20 mA current span. To reverse the current output with

4mA being at the top of the tank, use the REV MA function.

Note: To speed up the scrolling of the values on the display, hold down the OK button while holding down the

UP or DOWN buttons.

| 26 MN310140 Rev A5

Page 27

Configuration Using Display (continued) Step Four

STEP 5 - HOW TO SELECT FAIL-SAFE CURRENT OUTPUT (LOST)

In the event the sensor does not receive an echo, the Fail-Safe Current Output or LOST setting can be set to

output a current of 4mA, 20mA, 21mA, 22mA or Hold (last known value). During fail-safe, the display will

read LOST.

2. In TOP-LEVEL MENU mode, select

OUTPUT.

3. Select SAFE.

4. Select 4mA, 20mA, 21mA, 22mA or

HOLD.

a. Press and hold OK on the

selected setting for 2 seconds

then release.

b. To cancel SAFE, Select EXIT.

5. Select EXIT to return to TOP-LEVEL

MENU.

MN310140 Rev A5 27 |

Page 28

t

o

k

n

c

U

D

L

S

D

b

D

D

d

a

e

h

r

h

o

D

n

d

n

n

n

n

o

t

s

2

i

n

s

e

b

u

t

.

t

-

h

m

b

d

l

d

m

h

t

o

h

L

a

q

n

s

a

t

re

l

a

e

b

o

c

a

r

o

r

a

n

e

n

.

e

A

e

g

a

Ins

allation

Ech

Pod® shou

gas

et for G th

wor

. Always

pro

ess conditi

MO

NTING GUI

1.

o not mou

2.

iquid shoul

3.

ide Wall:

4.

o not mou

eam width

5.

o not mou

6.

o not mou

7. I

n cone b

eepest par

Inst

llation in

larg

r than the

bus

ing such a

LM5

2-3800 (4” t

a. Mou

a. mou

ld always b

eaded vers

and-tighte

ns prior to

E

t at an angl

never ent

t at least 3”

nt where o

t at least 3”

t in a vacu

t in the cen

ttom tank,

of the tank

existing fi

threads of

the LM52

hread x 2” t

e mounted

ons only).

the trans

ystem start

e

r the dead

from the si

stacles wil

from the si

m

er of a do

position t

tings: If

the EchoP

2800 (3” t

read).

perpendicul

Make sure

itter within

up.

and

e wall

intrude on

e wall

e top tank.

e sensor

he existing

d®, select

read x 2” t

ar to the li

that the fitti

the fitting.

sensor’s

over the

fitting is

reducer

hread) or

uid surface

g and tran

Perform

Do no

angle

Do not

3” of t

Do no

obj

(use the p

mitter thre

n installed

install at a

lative to th

iquid.

install withi

nk sidewall

t install with

cts in the

eam.

ovided Vito

ds are not

leak test u

Step Fiv

n® mountin

damaged o

nder norm

r

l

Do n

t install in

appli

ations with

v

cuum.

LM52-

800

M52-3800

Do not

cente

t

install in th

of a dome

p tank.

| 28

MN310140 Rev

5

Page 29

4

t

c

a

“

1

2

o

T

n

d

d

8

Fth

A

A

k

2

n

C

a

D

e

d

d

f

.

e

u

a

d

n

:

e

w

o

c

C

m

n

m

5

d

c

d

a

a

d

u

n

R

8

r

Ap

a

)

m

i

f

g

d

u

-

a

w

p

m

n

e

t

N

a

o

f

p

k

o

n

h

s

9

e

s

u

o

A

T

3

c

m

e

p

s

n

e

s

d

a

e

T

e

n

h

e

d

A

n

e

1

e

p

l

l

i

a

d

t

e

y

g

e

0

s

u

e

e

e

k

y

w

f

n

t

h

Ins

allation

FITT

ING SELEC

Che

k the part

inst

lled in tank

the

G” threade

(continue

ION

umber to

adapters,

EchoPod

)

etermine th

langes, bra

®

e required

kets or sta

itting moun

ndpipes.

size and t

ote: Alway

read type.

include th

EchoPod®

gasket w

Step Fiv

is commonl

en installin

. Tank A

LM52-3

a.

b.

c.

2” Tan

Socket

(LM5

apter: Sel

90 for 3” se

or best res

read x thre

void tank a

lways mou

i. Note

insid

Adapter

x Thread

-2890)

ct a tank a

nsors.

lts, select

d, reducer

apter (thre

t the tank a

Never mo

the tank.

w/ 3”x2”

(LM52-3

apter fittin

3” tank a

bushing.

d x thread)

apter so th

nt the tank

k Adapter

Ta

educer B

90 w/LM52

, such as th

apter and

styles and/

e majority o

adapter u

shing

2800)

e LM52-28

dd a reduc

r pipe stop

fitting is o

side down

3” Tank

Socket x

(LM52-

0 tank ada

r bushing

forward of

tside the ta

r where th

dapter

hread

890)

ter for 2” s

uch as the

the installe

k.

bulk of th

Tank

Thread

Do

thread

nsors or th

LM52-280

transducer

e material i

dapter

x Thread

ot use

x thread

,

.

N

. Riser: I

a.

a. 2

te: Do not

stallations

ore Out C

c

n also be

iameter to

” (5 cm) dia

n

o taller than

Dia

4” (1

6” (1

xceed the

ith tall, na

ncrete:

onsidered

ore Height

eter risers

12” (30.5 c

R

iser Specif

In

er

eter

2” (

cm)

0cm)

5cm)

imensions

row risers c

plications

s a riser ty

for the dia

should be

).

cations

Maximum

Height

4” (10cm)

8” (20cm)

12” (30cm)

listed abov

n impede t

here a tan

e applicati

eter of the

o taller tha

.

he acoustic

with a con

n. In these

core.

4” (10.0 c

signal.

rete ceiling

application

). Larger

Note: If

sensor

to allow

avoid th

risers.

exceeds

the Ris

Use a la

takes i

Specific

that has be

follow a 2:

iameter ris

attempting

bove the to

for a higher

use of tal

he examp

the dimens

r Specific

rger tank a

to accoun

ations.

n cored o

ratio (Inn

rs should b

to raise th

of the tan

fill capacit

and narro

e to the le

ons listed i

tions char

apter whic

the Rise

t

r

,

t

.

r

MN3101

0 Rev A5

29

|

Page 30

t

g

”(LM

n

h

t

p

d

l

2

n

c

u

a

n

(

n

(

T

a

d

R

0

n

0

s

o

h

o

u

8

s

w

s

d

s

s

t

c

M

d

e

s

h

A

e

Ins

allation

(continue

)

Step Fiv

3. Flan

such

a

e: If instal

as the LM5

. Use a fla

ing on a fla

-2850.

ge with a 3

ge, select

” thread an

flange wit

add a 3” t

a thread th

2” reducer

at is above

bushing to

he plane of

omplete th

the flange,

installation

.

Flange

2

52-2850)

Flange w/

3”

LM52-385

educer B

w/LM52-2

shing

00)

3”

(LM

52-3850)

Flange

4. Side

mou

Mount Bra

t bracket.

ket: For i

stallations i

open tank

and sump

, use the L

50-1001 s

eries side

LM5

-1001 Sho

n

Note: T

method

stand pi

e Side Mo

o secure st

e.

nt Bracket

nd pipes.

LM50 serie

here are to

) is not de

few threa

igned for u

s to properl

e with stan

y hold the s

pipes or a

ensor and t

a

e

| 30

MN310140 Rev

5

Page 31

Installation (continued) Step Five

5. Stand Pipe: A standpipe maybe used to dampen turbulence or when foam is present in the

application.

a) Pipe can be constructed from any material.

b) Select a minimum 3” ID pipe or greater for the stand pipe.

i) Select a minimum 4” ID pipe for the UG12 series.

c) Use a coupling and reducer bushing to attach the

EchoPod

®

to the pipe.

i) Use a reducer bushing such as LM52-2400 (3” Thread

x 2” Thread) fitting or the LM52-2410 (3” Slip x 2”

Thread) fitting.

d) The pipe length should run the measurement span. The

bottom of the pipe should remain submerged at all times to

prevent foam from entering the pipe.

e) Cut a 45°notch at the bottom of the pipe. Drill a

1/4”pressure equalization hole in the dead band.

f) The pumps should not drive liquid past the open end of the

stand pipe which causes the liquid in the pipe to oscillate.

Note: Never allow the bottom of the stand pipe to become

exposed to air. This will break the liquid seal which will

prevent echoes from returning back to the sensor.

EchoPod

®

UG06

3” x 2”

Reducer Bushing

(TxT)

Vent Hole (1/4”)

3” Coupling

(S x T)

3” PVC Pipe

EchoPod

®

attached to a

LM52-2400 (3” x 2” reducer

bushing) to a Slip x Thread 3”

Coupling.

Avoid the use of a tee within the

stand pipe. A tee can create false

signals impeding the sensor’s

performance.

MN310140 Rev A5 31 |

Page 32

Wiring Step Six

WIRING DIAGRAM - SAMPLE

SampleWiringDiagram

Diagram will change based upon

the sensor’s configuration, use

WebCal®toviewappropriatewiring

diagram.

WIRING ECHOPOD

Once EchoPod

®

®

has been configured; follow the Wiring Diagram provided by the WebCal® software. A typical

wiring diagram is shown above. Flowline recommends using a qualified licensed electrician to wire EchoPod

with your application’s components.

Configure your EchoPod® with WebCal® and use the wiring diagram button to view the appropriate

diagram. Each configuration will have its own unique diagram. The diagram shown above is only a

sample and should not be used as a wiring diagram.

The analog output of the EchoPod® is a loop powered 4-20 mA control circuit. The typical way to use

this feature is to connect a positive supply to the (+) input and to sense the current flow out of the (-)

output.

®

| 32 MN310140 Rev A5

Page 33

Wiring (continued) Step Six

WIRE CONNECTIONS

(+) Power & (-) Return: (+) Power and (-) Return leads are for

connection to a 24 VDC power supply or to a 4-20 mA loop power

source. The (+) and (-) wires can be extended up to 1,000 feet

using a 22-gauge or larger wire.

(W) Tx (Out) & (G) Rx (In): (W) Tx and (G) Rx leads are reserved

for use with WebCal

®

and also to communicate to PodView®.

These wires should only be connected to one device at a time (i.e.

only to WebCal

be connected to WebCal

UG06 Series

other than the LI99 series Fob. The maximum cable distance

between the computer and EchoPod

®

or PodView®. In addition, these wires should not

®

while power is supplied from any source

®

is 15’. Note: Never allow the

white or green wires to touch any power supply.

GENERAL NOTES FOR ELECTRICAL CONNECTIONS, USAGE AND SAFETY

Where personal safety or significant property damage can occur due to a spill, the installation

must have a redundant backup safety system.

Wiring should always be completed by a licensed electrician.

Supply voltage should never exceed 28 VDC.

Protect the sensor from excessive electrical spikes by isolating the power, whenever possible.

The sensor materials must be chemically compatible with the liquids to be measured.

Design a fail-safe system for possible sensor and/or power failure.

o During power failure, relays will remain in their current state and will not change until power is

restored and the signal is reacquired.

Note: When connecting the sensor to the WebCal

®

Software, you must remove the display or the

software will not connect. Once completed, you can re-connect the display to the terminal.

Never use the sensor in environments classified as hazardous.

MN310140 Rev A5 33 |

Page 34

Wiring (continued) Step Six

ANALOG OUTPUT

The analog output of the EchoPod® is a loop powered 4-20 mA control circuit. The typical way to use this

feature is to connect a positive supply to the Power (+) input terminal and to sense the current flow out of the

Power (-) output terminal with a sampling resistor as shown in the following diagram.

The cabling should be a shielded twisted pair to minimize EMI interference. Typically 20 to 24 gauge wire is

used in this application. To access the terminals, gently remove the display from the housing.

When wiring is completed, restore the display to the housing and replace the cover.

The UG06 series can operate without the display. When wired and powered correctly, the sensor will

continue to provide a proportional 4-20 mA signal.

| 34 MN310140 Rev A5

Page 35

Wiring (continued) Step Six

COMMON WIRING TO DISPLAYS, CONTROLLERS & PLC’S

Below is a quick review of wiring the EchoPod® to common display, controllers and PLC’s.

DataView™ LI55 Series

Level Controller

Commander™ LI90 Series

Multi-Tank Level Controller

DataLoop™ LI23 Series

Level Indicator

without the backlight

DataLoop™ LI23 Series

Level Indicator

with the backlight

MN310140 Rev A5 35 |

Page 36

Wiring (continued) Step Six

COMMON WIRING TO DISPLAYX, CONTROLLERS & PLC’S (CONTINUED)

DataPoint™ LC52 Series

Level Controller

*JWA mode (Factory Setting)

DataPoint™ LC52 Series

Level Controller

*JWB mode

Generic Loop

Generic PLC

Powered Display

* Refer to the DataPoint™, LC52 Series, Level Controller manual for information on JWA mode and JWB mode

settings in the controller.

| 36 MN310140 Rev A5

Page 37

Wiring (continued) Step Six

VOLTAGE OUTPUT

EchoPod® can be configured as a 0 to 5 VDC or 0 to 10 VDC output. A resistor will need to be added to the

circuit to enable a voltage output (refer to the wiring diagram below).

0-5 VDC output

o Add a 250 Ohm resistor

o Actual output will be 1 to 5 VDC

0-10 VDC output

o Add a 500 Ohm resistor

o Actual output will be 2 to 10

VDC

MN310140 Rev A5 37 |

Page 38

WebCal® Appendix Section Seven

This section of WebCal

®

is where you select the sensor configuration settings. Start from the top and work to

the bottom, choosing the selections that are applicable to your application. All configuration settings must be

selected before you can continue to the next step.

SENSOR CONFIGURATION

LOOP FAIL-SAFE

This feature allows you to select the fail-safe current output if the

sensor looses echo confidence (LOST). When the sensor regains

echo confidence, the output current will revert back to the current level

condition.

Hold Last Value - The output will remain in the same state as

the last validated echo detected. Example: If the output was

6.7mA just prior to the lost signal, the sensor will continue to

output 6.7mA until echo confidence is regained.

Empty - The output will revert to the current value for an

empty condition. When 4 mA at Bottom is selected, the

sensor will output 4 mA during a fail-safe condition. If 20 mA

at Bottom is selected, the sensor will output 20 mA during a

fail-safe condition.

Full - The output will revert to the current value for a full

condition. When 4 mA at Bottom is selected, the sensor will

output 20 mA during a fail-safe condition. If 20 mA at

Bottom is selected, the sensor will output 4 mA during a fail-

safe condition.

Overfill (21mA) - The sensor will output 21mA during a fail-

safe condition.

Overfill (22mA) - The sensor will output 22mA during a fail-

safe condition.

OUTPUT AT EMPTY

This feature allows you to select the orientation of the 4 to 20mA output (4 to 20 mA or 20 to 4 mA). Choose

which output setting best fits the application. Factory default is 4mA at bottom and 20mA at top, as this

configuration scenario is an industry standard. When connecting your sensor to a display, you must account for

your output orientation setting.

4mA at Bottom - The output current will be 4mA when the sensor measures an empty tank and 20mA

when the sensor measures a full tank.

20mA at Bottom - The output current will be 20mA when the sensor measures an empty tank and 4mA

when the sensor measures a full tank.

Note: Right click on any item to open the help menu.

Note: To reset the configuration table, press the Clear Screen button

| 38 MN310140 Rev A5

Page 39

WebCal® Appendix (continued) Section Seven

SENSOR CONFIGURATION (CONTINUED)

STARTUP CONDITION

This feature allows you to select the startup current when power is

first applied to the sensor. The sensor will consume the selected

power while it is acquiring the liquid level. When the correct level

has been identified, the output will adjust to the level output. Use

this feature to avoid false alarms with the controller when power is

first applied to the sensor.

Empty - The current output will revert to the selected current

value for an empty condition.

o 4 mA at Bottom - The sensor will output 4 mA while

the sensor powers up.

o 20 mA at Bottom - The sensor will output 20 mA while

the sensor powers up.

Mid Tank (12 mA) – The sensor will output 12 mA while the

sensor powers up.

Full - The output will revert to the selected current value for a

full condition.

o 4 mA at Bottom - The sensor will output 20 mA while

powering up.

o 20 mA at Bottom - The sensor will output 4 mA while the

sensor powers up.

Overfill (22mA) - The sensor will output 22mA while the

Note: Right click on any tem to open the help menu.

Note: To reset the configuration table, press the Clear Screen button

sensor powers up.

MN310140 Rev A5 39 |

Page 40

WebCal® Appendix (continued) Section Seven

VOLUMETRIC CONFIGURATION

The sensor may be configured in volumetric units

(Gallons or Liters) or Distance (Height of Liquid)

units (inches, cm, feet or meters). WebCal

default to Distance (Height of Liquid) with units of

Inches. To change units or change from Distance

to Volume, press the Volumetric Mode button as

located near the center of the window.

Distance (Height of Liquid): When this is selected,

the sensor will always output a linear output

proportional to the height of liquid (regardless of the

tank shape). In the two drawings below, the Sensor

High is set to 64” and Fill-Height is set to 60”. If the

tank is empty, the sensor will output 4mA. If the level

is at 30”, then the sensor will output 12mA. Either

tank can be configured with a display from 0” to 60”

and the sensor will always output the height of liquid.

®

will

Volume: When volume is selected, the 4-20 mA output from the sensor will be proportional to the volume of

the tank, not the height of the tank. This means that the current output will track the volume of the tank (in

gallons or liters). Depending on the shape of the tank, the values may be a linear or non-linear scale. In the

same examples below, the sensors are also configured with SH = 64” and FH = 60”. The current output in a

linear tank will act as expected with volume increase matching equal changes to level. However, the current

output in the Non-Linear tank will reflect the actual changes in volume. So even though the liquid height

changes incrementally the same amount, the volume change will adjust throughout the entire span of the tank.

The advantage of this is that sensor does all the math so you can read tank volume using a simple two-point

display/controller such as the DataLoop

Linear Tank Example

™

LI25 series or DataView™ LI55 series.

Non-Linear Tank Example

Note: In the above illustration, 10” of liquid will

always be equal to 100 gallons of liquid (1” = 10

gallons).

Note: In the above illustration, 1” of liquid does not

equal 10 gallons. The 10” at the bottom represents a

rise of 62.8 gallons. As a change between 10” and

20” represents an increase of 109.6 gallons (i.e.

172.4 gallons – 62.8 gallons).

| 40 MN310140 Rev A5

Page 41

WebCal® Appendix (continued) Section Seven

Shape Selection Window: This window will shows the different tank shape options available in WebCal

Vertical Cylinder

Vertical Cylinder with Cone Bottom

Horizontal Cylinder with End caps

Horizontal Cylinder with Spherical Ends

Spherical

Rectangular

Strapping Table – Use this feature for manual entry

of measured tank distances and volumes.

Select any of the above tank shapes and press OK to

confirm.

A. Dimensional Entry – Vertical Cylinder Example: Choose the Sensor Output Units as Distance or

Volume. After choosing the Sensor Output Units, select the units of measurement in the pull down to

the left.

®

.

Units of Measurement

Distance Volume

Inches

Cm

Feet

Meters

Distance – Sensor Output Units (Vertical Cylinder Example):

Enter the dimensions of the tank. You must

enter data in all fields shown.

Sensor Height: Distance from the bottom of

the tank to the bottom of the sensor.

Fill Height: Distance from the bottom of the

tank to the operational full level of liquid

(20mA). This setting defines the location of

full current output and is the top of the

sensor’s measurement range.

Riser Height: Distance the sensor is above

the top of the tank (including all fittings).

Measured from the bottom of the sensor.

Gallons

Liters

MN310140 Rev A5 41 |

Page 42

WebCal® Appendix (continued) Section Seven

Volume – Sensor Output Units (Vertical Cylinder Example):

Enter the dimensions of the tank. You must

enter data in all fields shown.

Sensor Height: Distance from the bottom of

the tank to the bottom of the sensor.

Fill Height: Distance from the bottom of the

tank to the operational full level of liquid

(20mA). This setting defines the location of

full current output and is the top of the

sensor’s measurement range.

Riser Height: Distance the sensor is above

the top of the tank (including all fittings).

Measured from the bottom of the sensor.

Tank Height: Distance from the bottom of the tank to the top of the straight side wall.

Diameter: Distance of the inside tank diameter.

Volume – Tank Capacity (Vertical Cylinder Example): After entering the dimensions, press the Capacity

button to show the Calculated Capacity of the tank. If the Calculated Capacity is slightly different than the

expected capacity, click on the Adjust Capacity box and enter the expected capacity of the tank. If the

Adjusted Capacity is more than 10% of the Calculated Capacity, recheck the dimensions information entered

above.

When all dimensions are entered, press the Apply button to return to the previous Configuration window.

Apply – Transfers the dimensions to the original Configuration window.

Tanks – Returns to the previous Shape Selection window.

Cancel – Returns to the Configuration window without saving any information.

Help – Jumps to the Help menu.

| 42 MN310140 Rev A5

Page 43

WebCal® Appendix (continued) Section Seven

TANK LEVEL CONFIRMATION

This section of WebCal® is where you confirm the values set in the previous step. The values were entered

under the Dimensional entry window. To edit these settings, you must go back to the Dimensional entry

window via the Volumetric Mode button.

Height Units: Units selected for configuration. When used as a device to measure the distance (height

of liquid), the options are inches, cm, feet or m. When used as a device to measure the volume of

liquid, the options are gallons or liters.

Sensor Height: Distance from the bottom of the tank to the bottom of the sensor.

Fill-Height: Distance from the bottom of the tank to the operational full level of liquid (20mA). This

setting defines the location of full current output and is the top of the sensor’s measurement range.

Capacity: The total volume of the tank. Only shown when gallons or liters are selected.

Note: By extending the empty (4mA) to the bottom of the tank, the 4-20 mA output will track the volume of the tank.

This allows any local display to read the actual volume of liquid without the need for any unique configuration. This

feature is very useful with any non-linear tanks such as horizontal, spherical or tanks with cone bottoms.

HeightUnits

Capacity

SensorHeight

Fill‐Height

Volumetric Sensor Output: The

volumetric mode button will be

highlighted in Blue when a

volume output is selected.

MN310140 Rev A5 43 |

Page 44

WebCal® Appendix (continued) Section Seven

WRITE TO UNIT

After you have entered configurations, selected and

configured the Tank Shape and entered the Tank Values,

Write to Unit

Wiring diagram

Advanced

click “Write to Unit” and load the configuration into the

memory of the sensor. When completed, this configuration

will remain inside the sensor memory and will not change

unless the sensor is connected to WebCal

®

and a new

configuration is written to the sensor. Loss of power will not

change or lose the configuration within sensor memory.

Next, use the file management features to save your

Save Config File

configuration by clicking “Save Config File” and print your

wiring diagram by clicking “Wiring Diagram.”

“Save Config File” will save this configuration as a text file which can be loaded back into WebCal® by

pressing the “Open Config File” button. It is good practice to save the configuration file for each different

configuration with a unique name for easy identification. If using multiple sensors in identical applications, then

use of a single configuration file is recommended.

“Wiring Diagram” will display a PDF file showing the unique wiring for the specific configuration created in

WebCal™. The PDF can be printed or emailed. It is good practice to save the wiring diagram as a backup

.

“Advanced” is a feature setting designed to help solve performance or operational issues for specific

applications. Changing these setting will alter the factory default performance or operation, of your sensor.

Increase Output Filtering: Placing a check mark in the box will increase the filtering (averaging) of the

analog output. Use this filter if the 4 to 20 mA output requires a smoother output for the application

such as open channel flow measurement.

Decrease Output Filtering: Placing a check mark in the box

will eliminate all filtering (averaging) of the analog output

which enables a pulse by pulse level reading. Use this filter to

see changes in level after every echo pulse.

Note: Never check increase output filtering and decrease output

filtering at the same time.

Stabilize Output in Dead Band: Placing a check mark in the box will activate a filter to hold the output

at Full if the level enters the dead band of the EchoPod

®

. This filter requires the level to leave the dead

band at a smooth and steady rate.

Reduce Fast Level Jump Response Time: Changes the sensor’s response time from 60 seconds to

10 seconds. This filter prevents the sensor from making a quick jump in level if a false signal suddenly

appears. Change the response time if application involves expected quick level changes.

Increase LOST Response Time: Changes the sensor’s response time from 60 seconds to 180

seconds. This filter sets the time the sensor waits before entering a LOST state. Change the response

time if you want to delay the sensor from stating LOST.

| 44 MN310140 Rev A5

Page 45

Display Appendix Section Eight

AIR GAP VS. LIQUID LEVEL (HOW TO SELECT THE DISPLAY SETTING)

The display can be made to display either the height of liquid in the tank (LIQUID mode) or the amount of air in

the tank (AIR mode). This function does not influence the current output, just the display on the sensor.

1. In TOP-LEVEL MENU mode, select DISPLAY.

2. Select LIQUID or AIR.

a. Press and hold OK on the selected setting for

2 seconds then release.

b. To cancel DISPLAY, Select EXIT.

3. Select EXIT to return to TOP-LEVEL MENU.

Liquid Mode Air Mode

MN310140 Rev A5 45 |

Page 46

Display Appendix (continued) Section Eight

HOW TO REVERSE THE CURRENT OUTPUT

The factory setting for EchoPod® has 4mA set at the bottom of the tank and 20mA at the top. If the application

requires this output to be reversed (20mA at bottom and 4mA at top), then use the REV MA setting to reverse

the current output.

With REV MA set to NORM (factory default), 4mA will be at the bottom and 20 mA at the top of the tank.

With REV MA set to REV, 20mA will be at the bottom and 4mA at the top of the tank.

1. In TOP-LEVEL MENU mode, select

OUTPUT.

2. Select REV MA.

3. Select 4 BOTT or 4 TOP.

a. Press and hold OK on the selected

setting for 2 seconds then release.

b. To cancel REV MA, Select EXIT.

4. Select EXIT to return to TOP-LEVEL MENU.

| 46 MN310140 Rev A5

Page 47

Display Appendix (continued) Section Eight

HOW TO SETUP THE START-UP POWER (STRTUP)

During the window of time between when power is first applied to the sensor and the sensor acquires the level

reading, the output current can be preset in order to avoid any false alarms during this window. The options for

start-up are 4mA, 12mA, 20mA or 22mA.

1. In TOP-LEVEL MENU mode, select

OUTPUT.

2. Select STRTUP.

3. Select 4mA, 12mA, 20mA or 22mA.

a. Press and hold OK on the selected

setting for 2 seconds then release.

b. To cancel STRTUP, Select EXIT .

4. Select EXIT to return to TOP-LEVEL MENU.

MN310140 Rev A5 47 |

Page 48

Display Appendix (continued) Section Eight

VALUES MENU

Functions include providing setup information (SETUP), a diagnostic to be used in conjunction with a Flowline

Representative (DIAG) and the ability to reset the EchoPod

SETUP

®

(RESET).

Will display the configuration settings for

EchoPod

®

.

1. In TOP-LEVEL MENU mode, select

VALUES.

2. Select SETUP.

3. Setup will list the following information:

a. HEIGHT,

b. FILL-H

4. Select EXIT to return to TOP-LEVEL

MENU.

DIAGNOSTIC (DIAG) PARAMETERS

This mode runs diagnostic tests that confirm

®

operation of EchoPod

. This is a production

test feature used by the factory to confirm

operation.

1. In TOP-LEVEL MENU, select VALUES.

2. Select DIAG.

3. DIAG will list the following settings:

a. Display Test

b. RANGE

c. TEMP

d. ECHO

e. POWER

f. VER

4. Select EXIT to return to TOP-LEVEL

MENU.

Note: This mode should only be used when

supervised by a Flowline representative.

| 48 MN310140 Rev A5

Page 49

Display Appendix (continued) Section Eight

RESET

EchoPod® enables the end user to reset the entire configuration back to the original factory settings.

1. In TOP-LEVEL MENU mode, select

VALUES.

2. Select RESET.

3. Select YES.

a. To cancel the reset, Select NO.

4. Select EXIT to return to TOP-LEVEL

MENU.

MN310140 Rev A5 49 |

Page 50

®

®

Appendix Section Nine

FACTORY SETTINGS

EchoPod

®

Sensor Height Fill-Height

UG06 Series

UG12 Series

USER SETTINGS

236.2”

(600 cm)

472.4”

(1200 cm)

228.2”

(579.7 cm)

454.4”

(1154.3 cm)

Loop Fail-

Safe

Hold Last

Hold Last

Fill out the chart below and keep as a record of your configuration.

Tank

Height = Fill-H =

Units

Inches Feet cm Meter

Display

Air Liquid

Safe

Output @

Empty

4mA at

Bottom

4mA at

Bottom

Startup

Condition

Empty

Empty

22mA 21 mA 20mA Hold Last 4mA

Rev mA

4mA @ Bottom 4mA at Top

Start-up

4mA 12mA 20mA 22mA

TROUBLESHOOTING

PROBLEM SOLUTION

No Unit Detected in

WebCal

®

.

Cannot access some of

the configuration features

in WebCal

®

.

If WebCal

Check that the LI99-2001 Fob is connected to the USB

cannot detect EchoPod® when connected to the computer:

®

port.

Check that all four wires (Red, Black, White and Green) are securely

attached to the Fob.

Check Device Manager and confirm that both drivers (WebCal

®

Configuration & EchoFob) are present.

If the above do not work, reinstall the WebCal

®

software while the computer

is in Safe Mode.

As choices are made in Configuration, WebCal

will begin to eliminate

functions that are not applicable to a configuration. To reset Configuration or

get access to all the features, click on the Clear Screen button.

| 50 MN310140 Rev A5

Page 51

Appendix (continued) Section Nine

TROUBLESHOOTING

PROBLEM SOLUTION

Internet error. The server

name or address could not be

resolved.

Display shows FULL: Level of liquid is above the FILL-H setting: Check the FILL-H setting,

Display shows EMPTY: Level of liquid is beyond the HEIGHT setting: Check the HEIGHT setting,

Display shows WARMUP: Typically occurs when power is being applied to transmitter. Indicates a

Display shows LOST: Sensor is in a Fail-Safe state. The return sound pulses are not reaching the

Display is opposite of the