Page 1

EchoPod®

Ultrasonic Liquid Level Transmitter

UG06 & UG12 Series Quick Start

©2019 Flowline, Inc.

All Rights Reserved

Made in USA

Flowline, Inc. | 10500 Humbolt Street, Los Alamitos, CA 90720 p 562.598.3015 f 562.431.8507 w flowline.com QS310140 Rev A4

Page 2

WELCOME TO THE ECHOPOD® QUICK START

The EchoPod® Quick Start provides basic mounting, setup and use instructions for getting the EchoPod®

up and running quickly. If you have a non-standard installation or setup requirement that is not

addressed here, please refer to the EchoPod

®

Manual or other support documentation located at

flowline.com.

WE DO YOUR LEVEL BEST

Thank you for purchasing EchoPod

®

. The sensor provides integrated LCD and three push-button

configuration. This quick start includes everything you’ll need to get the sensor up and running.

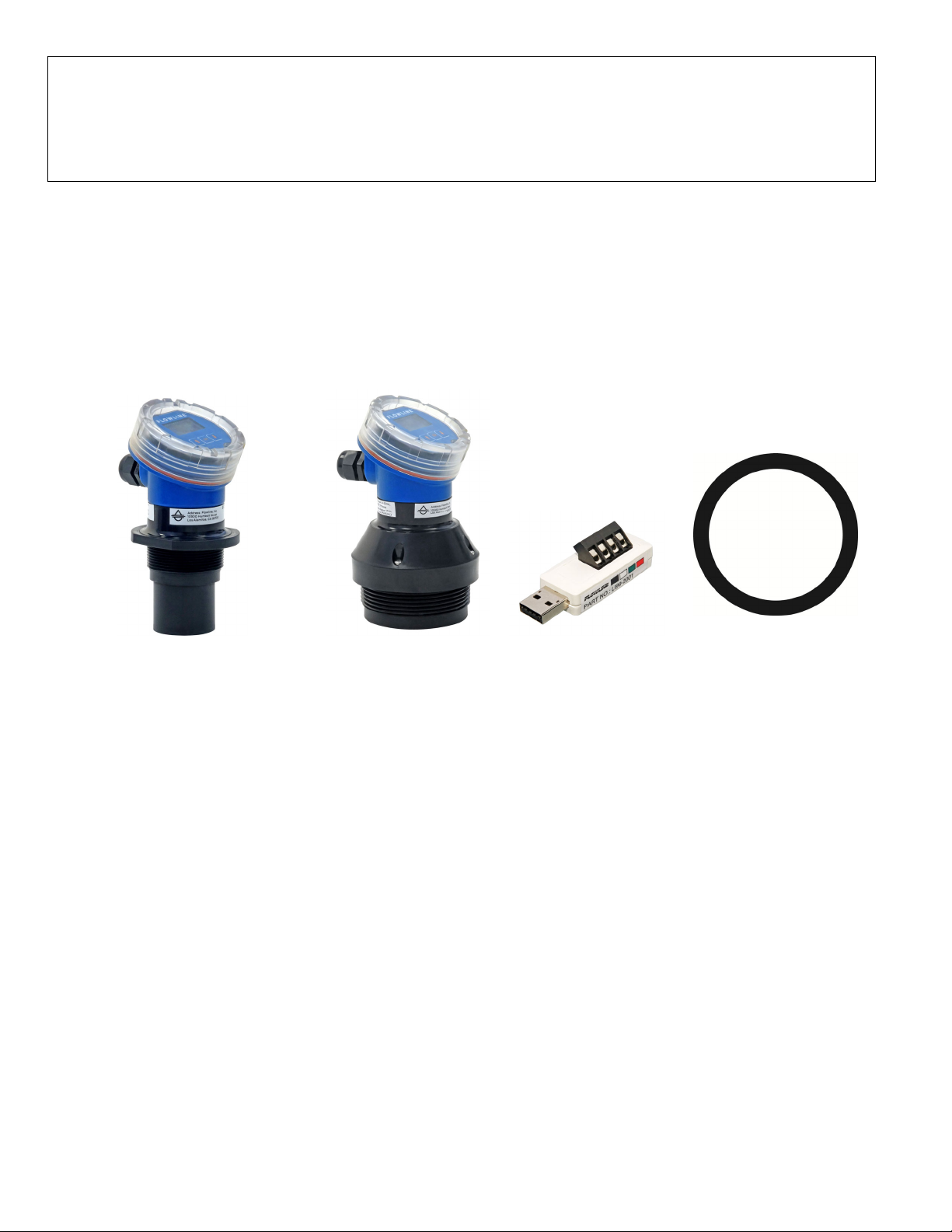

COMPONENTS

Depending on how the sensor part number that was shipped, EchoPod

®

comes with a Viton® gasket for

installation and the Quick Start.

®

EchoPod

UG06-0001-00

UG06-0001-01

UG06-0011-00

UG06-0011-01

EchoPod

®

UG12-0001-00

UG12-0001-01

UG12-0011-00

UG12-0011-01

®

USB

Key Fob

P/N: LI99-2001

Viton® gasket (2”)

G threaded version only

Viton® gasket (3”)

P/N: 200129

P/N: 210157

G threaded version only

ENCLOSURE

While the switch housing is liquid-resistant the EchoPod

®

is not designed to be operational when immersed. It

should be mounted in such a way that the enclosure and transducer do not come into contact with the

application media under normal operational conditions. Before closing the enclosure, make sure that the

enclosure gasket is properly seated, and that any conduit fittings, cable connectors or plugs are installed

correctly and sealed. Note: If using the Flowline LM90-1001 (liquid tight fitting) on the ½” conduit, the cable

minimum is 0.170” (4.3mm) and the maximum is 0.450” (11.4mm).

CONFIGURATION

When configuring EchoPod

®

, choose either the WebCal® or Push Button method. Either method will

accomplish the goal of sensor configuration. Changes to the configuration can be made using the alternative

method. When beginning with one method, it is recommended to complete the configuration before using the

other method to make any adjustments.

Note: When connecting the sensor to the WebCal

®

Software, you must remove the display or the software will

not connect. Once completed, you can re-connect the display to the terminal.

| 2 QS310140 Rev A4

Page 3

0

CO

N

o

o

P

w

c

d

a

P

e

e

c

B

c

E

n

L

C

a

b

C

o

n

n

u

n

o

n

o

t

w

W

o

r

t

e

B

F

e

x

®

p

t

p

)

i

o

W

a

q

E

w

a

e

e

c

h

o

t

e

p

r

s

e

n

w

U

f

e

2

w

n

t

n

u

o

M

C

w

y

t

g

u

o

.

t

m

n

g

o

o

t

W

o

p

b

u

s

e

g

d

s

c

e

y

d

FIGURING

Ech

perf

STE

Do

nload Web

spe

Win

Pod® is co

rmed prior

1: INSTAL

ifications:

ows® XP/V

CHOPOD® (

figured thr

to mounting

WEBCAL

al® softwa

ista/7/8/10,

EBCAL)

ugh WebC

, since it re

®

SOFTWAR

e from ww

10 MB stor

l®, a PC so

uires conn

.flowline.co

ge space,

tware progr

ction to yo

m/webcal-s

56 MB RA

am. Config

r PC.

ftware ont

, 1 USB® 2

ration of y

a PC with

0 port

ur sensor s

he followin

hould be

minimum

must have

You

inst

ll software

STE

2: CONNE

Not

: Do not c

Not

: When co

not

onnect. O

The

sensor com

®

US

the

omputer a

port, ens

1. Rem

from

n active In

efore proc

T THE US

nnect the

necting the

ce complet

municates t

re that all e

d EchoPod

ve the dis

the connec

ernet conn

eding to St

®

FOB

ob to your

sensor to t

d, you can

WebCal®

ternal pow

is 15’.

lay and un

or on the ci

ction to do

p 2. Install

omputer u

e WebCal®

re-connect

hrough the

r is discon

lug the cabl

cuit board.

nload Web

er program

til after you

Software,

he display

USB® Fob.

ected from

e

al®. Doubl

ill automa

’ve installed

ou must re

o the termi

Prior to plu

EchoPod®.

e-click the

ically install

WebCal

®

s

ove the dis

al.

ging the Fo

The maxim

ebCal® ins

any require

ftware.

lay or the

into your

m distanc

taller to

drivers.

oftware will

omputers

between

QS31

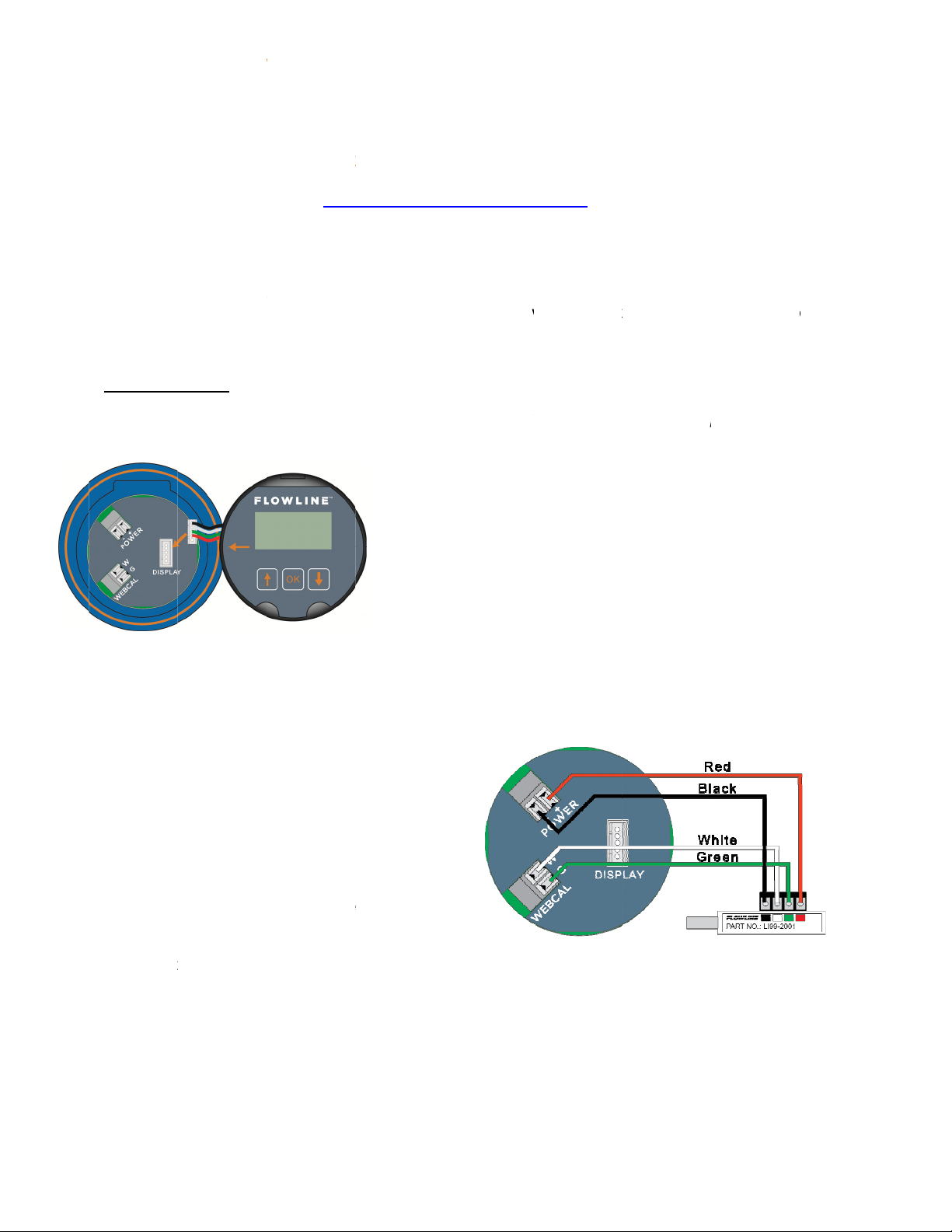

2. Con

3. Tigh

4. Plug

140 Rev A4

ect the pro

Ech

Pod® to the

nals on the

termi

. Power (+

a

. Power (-)

b

. WebCal (

c

. WebCal (

d

en the term

scre

the Fob int

driver.

er terminal

correspond

Fob.

to Red

to Black

W) to Whit

G) to Gree

nal screws

your PC’s

from the

ing colored

ith a slotte

SB® port.

d

Wirin

Black,

identical f

Green and

r all serie

White wir

– Use onl

s.

the Red,

3 |

Page 4

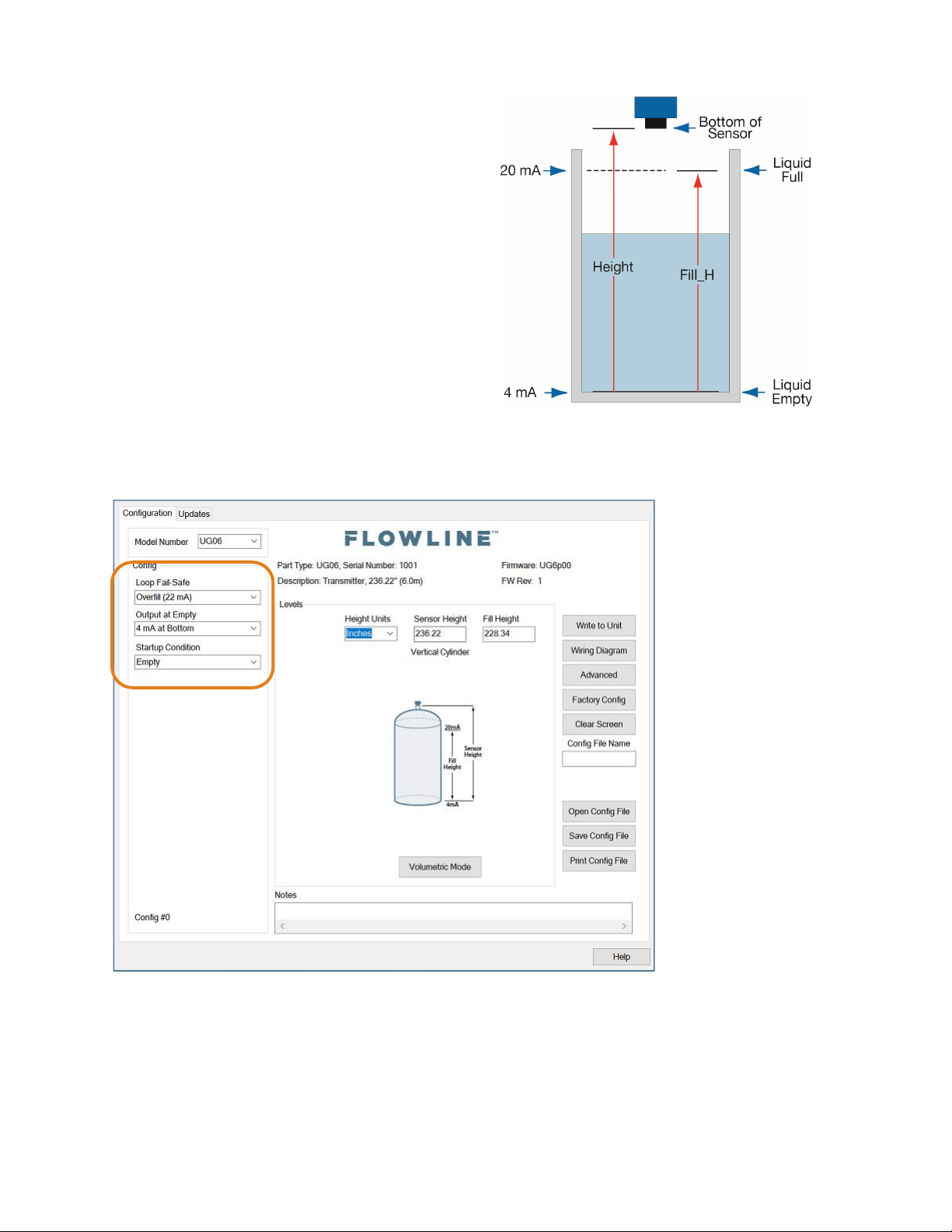

STEP 3 - MEASURE THE TANK

Measuring the tank is one of the most important aspects

in configuring the sensor. When measuring the tank,

take into account the location of the sensor with respect

to fittings, risers, dome tops and bottoms, and identify

where the measurements are taken from the sensor.

The HEIGHT and FILL-H settings determine the 420mA span and are always measured from the bottom

of the tank up.

STEP 4 - SENSOR CONFIGURATION

Configures the Loop Fail-Safe, Output at Empty and Startup Condition for the sensor.

| 4 QS310140 Rev A4

Page 5

STEP 5 – DIMENSIONAL ENTRY

Distance Mode (default): Output of sensor is based on the distance (height of liquid) in the tank. Any change

in liquid level will reflect linearly to the current output. The two values (Sensor Height and Fill-Height) below set

the 4-20 mA current span for the sensor. Both values will be set in the units shown under Height Units.

Height Units: Confirm units for use in Sensor Height and Fill-Height settings.

Sensor Height: Sets the location for 4mA. It is based on the distance from the Empty level position

(bottom of tank) to the Measurement location for the sensor (bottom of sensor).

Fill-Height: Sets the location for 20mA. It is based on the distance from the Empty level position

(bottom of tank) to the Full level position (see below).

STEP 6 - TANK LEVEL CONFIRMATION

Verify the Height Units, Sensor Height & Fill-Height. All values were calculated and set in the previous

Dimensional Entry window. Make any adjustments if required.

QS310140 Rev A4 5 |

Page 6

STEP 7 - WRITE TO UNIT

This WebCal®* operation uploads the configuration into the sensor, provides a custom wiring diagram specific

to the signal output and/or relay configuration, and saves the configuration file to your hard drive.

* For complete information on the WebCal

®

software, please refer to the WebCal® manual located at

flowline.com/webcal-software.

Before configuration can be completed:

You must click the Write to Unit button to save the settings to the unit.

Then, click Wiring Diagram for a hard copy of the sensor’s settings.

Finally, enter the file name under which you wish to save the configuration file and click Save Config

File.

Configuration is now complete.

Disconnect the USB

®

Fob before continuing to the next step: Mounting the EchoPod®.

| 6 QS310140 Rev A4

Page 7

CONFIGURING ECHOPOD® (DISPLAY)

TOP-LEVEL MENU

The sensor is configured with the three buttons on the sensor face (UP, DOWN and OK) and the sensor’s

LCD. To access the sensor’s Top-level menu, simply hold down the OK button for five seconds. The display

menu will automatically begin to scroll through the TOP-LEVEL MENU.

When the menu scrolls to an item you wish to configure, simply press the OK button to choose that item. The

TOP-LEVEL MENU will continue to scroll through the following (UNITS – TANK – dISPLY – OUTPUT –

VALUES – RUN), If you miss your selection, it will appear again shortly.

To return to the TOP-LEVEL MENU, press OK when EXIT appears.

To return to Operational Mode of the sensor, press OK when RUN appears in the TOP-LEVEL MENU.

Note: To speed up the scrolling of the values on the display, hold down the OK button while holding

down the UP or DOWN buttons.

STEP 1 - MEASURE THE TANK

Measuring the tank is one of the most important aspects in

configuring the sensor. When measuring the tank, take into

account the location of the sensor with respect to fittings, risers,

dome tops and bottoms, and identify where the measurements

are taken from the sensor. The HEIGHT and FILL-H settings

determine the 4-20mA span and are always measured from the

bottom of the tank up.

Height: Sets the location for 4mA. It is based on the distance

from the Empty level position (bottom of tank) to the

Measurement location for the sensor (bottom of sensor).

Fill-Height: Sets the location for 20mA. It is based on the

distance from the Empty level position (bottom of tank) to the

Full level position (see below).

#2 - SETTING THE UNITS OF MEASUREMENT (UNITS)

The EchoPod® displays information in the following units:

inches, feet, centimeters, meters or percentage. The value

shown on the display represents the amount of liquid in the

tank.

1) In TOP-LEVEL MENU mode, select UNITS.

2) Next, select INCHES, FEET, CM or METERS by holding

down OK button.

3) Finally, select EXIT to return to the TOP-LEVEL MENU.

QS310140 Rev A4 7 |

Page 8

#3 - SETTING THE HEIGHT (SENSOR HEIGHT) & #4 - SETTING THE FILL-H (FILL-HEIGHT)

This setting customizes the reading for your installation.

Follow these instructions to set the height and fill height for your tank:

1) In TOP-LEVEL MENU mode, select TANK.

2) Select HEIGHT.

3) Use the UP and DOWN buttons, set the

HEIGHT of your tank.

4) To enter the value, press and hold OK for 3

seconds and release. SAVED will display.

HEIGHT is now set.

5) Select FILL-H.

6) Use the UP and DOWN buttons, set the

HEIGHT of your tank.

7) To enter the value, press and hold OK for 3

seconds and release. SAVED will display.

FILL-H is now set.

8) Select EXIT to return to the TOP-LEVEL MENU.

9) Select RUN to return to Operational Mode.

Note: The Height and Fill Height settings also determine the 4 to 20 mA current span.

The Height setting determines the 4mA position and the Fill-H setting determines the 20 mA position.

#5 - HOW TO SELECT FAIL-SAFE CURRENT OUTPUT (LOST)

In the event the sensor does not receive an echo,

the Fail-Safe Current Output or LOST setting can

be set to output a current of 4mA, 20mA, 21mA,

22mA or HOLD (last known value). During failsafe, the display will read LOST.

1) In TOP-LEVEL MENU mode, select SAFE.

2) Select 4mA, 20mA, 21mA, 22mA or

HOLD by holding down OK button.

3) Select EXIT to return to the TOP-LEVEL

MENU.

TROUBLESHOOTING

If you face any issues not addressed in this Quick Start, please refer to the EchoPod

Flowline’s website at www.flowline.com.

®

Manual located on

| 8 QS310140 Rev A4

Page 9

0

MO

U

b

u

h

f

M

t

a

r

b

e

p

p

o

e

o

o

r

w

e

s

e

d

0

b

h

f

m

”

t

t

o

e

a

f

f

r

,

h

a

m

n

0

d

w

p

s

r

h

c

a

f

o

e

t

2

e

m

k

s

a

f

p

-

s

M

e

s

p

e

"

H

k

e

t

o

u

n

e

s

0

G

u

a

o

a

o

I

a

h

e

MLMLM

n

e

e

NTING ECH

The

sensor sho

or o

stacles in t

man

ual at www.

OPOD®

ld always

e path of t

lowline.co

e mounted

e acoustic

.

erpendicul

ignal. For

r to the liq

urther mou

id surface.

ting inform

nsure that t

tion, pleas

ere are no

refer to th

restrictions

EchoPod®

Installat

Use a L

slip x 3”

Basic T

Use a 2”

for the U

3890 for

Use a la

reducer

Use a 2”

UG06 s

for the U

Weld a

half cou

Mountin

Installati

2" diam

risers sh

Height t

Diamete

Installat

Use Flo

Not

for u

Ther

stan

ion in exist

52-2800 3

hread adap

nk Installa

bulkhead fi

G06 series

the UG12 s

ger bulkhe

ushing suc

flange with

ries or a 3”

G12 series.

lastic 2” hal

ling for the

g in Rise

ns with tall

ter risers s

uld be no t

Inner Dia

).

ion in ope

line's LM5

: The Side

e with stan

are too fe

pipe.

ing 3” fittin

thread x 2”

te

(UG06 s

ion:

ting, such a

r a 3” bulk

ries.

d fitting, su

h as the LM

a 2” thread,

lange with

coupling t

UG12.

:

narrow ris

ould be no

ller than 1

eter ratio (

tanks and

-1001 side

Mount Brac

pipes or a

threads to

gs:

thread ada

eries only).

s the LM52

ead fitting,

h as the L

52-2800.

such as th

3” thread

the tank to

rs can imp

aller than 4

". For best

xample: 8”

sumps:

ount brac

et (LM50 s

a method

properly h

ter or a LM

2890 bulkh

uch as the

52-3890 wi

LM52-285

uch as the

for the U

de the aco

. Larger di

results, foll

igh to 4” In

et.

ries) is not

o secure st

ld the sens

52-2810 3”

ad fitting

LM52-

th a

for the

LM52-3850

06 or a 3”

stic signal.

meter

w a 2:1

ner

designed

nd pipes.

r and the

L

52-2800

52-2890

52-2850

Mou

LM50-1

01

ting in Ris

QS31

140 Rev A4

9 |

Page 10

IMPORTANT MOUNTING GUIDELINES

1) Never mount the sensor at an angle.

2) Liquid should never enter the dead band.

3) Mount at least 3” from the side wall.

4) Never mount the sensor in a vacuum.

5) Do not obstruct the sensor’s beam width with objects underneath the sensor.

6) Do not mount in the center of a dome top tank.

7) In a cone bottom tank, position the sensor over the deepest part of the tank.

8) Avoid mounting in a riser where the sensor is recessed more than twice the diameter of the riser.

MOUNTING IN A STAND-PIPE

A stand-pipe may be used to dampen turbulence, separate surface foam from the point of measurement or

increase performance in heavy vapor. When mounting the sensor in a stand-pipe, the minimum diameter of the

pipe is 3”, minimum 4” for the UG12 series. Larger diameter pipes can be used. The pipe should be attached

with a coupling or tank adapter and reducer bushing. Avoid the use of multiple pipe fittings when possible. An

ideal mount would be to select a tank adapter (S x T or S x S) and connect the pipe to the inside slip and use a

reducer bushing to attach the sensor (see example below).

The pipe length should run the measurement span and the bottom of the pipe should remain submerged at all

times to prevent foam from entering the pipe. Cut the bottom end of the pipe at 45° and drill a 1/4” pressure

equalization hole within the sensor’s dead band. Locate the stand-pipe away from pump outlets and/or other

sources of substantial turbulence which might cause the liquid in the pipe to oscillate.

3” x 2”

Reducer Bushing

(TxT)

3” Tank

Adapter

(S x T)

3” PVC Pipe

Stand-Pipe Example

Stand-Pipe Mounting

| 10 QS310140 Rev A4

Page 11

WIRING THE ECHOPOD®

The following wiring diagram can be used for the 4-20 mA output of the EchoPod

®

.

Notes on Safety

Where personal safety or significant property damage can occur due to a spill, the installation must

have a redundant backup safety system installed.

Wiring should always be completed by a licensed electrician.

The sensor must be chemically compatible with the application.

Design a fail-safe system for possible sensor and/or power failure.

Never use the sensor in classified hazardous environments.

Wiring to Common Devices

Wiring to Loop Display Wiring to Generic PLC

Wiring to DataView™

LI55 series

QS310140 Rev A4 11 |

Page 12

WARRANTY

Flowline warrants to the original purchaser of its products that such products will be free from defects in

material and workmanship under normal use and service in accordance with instructions furnished by Flowline

for a period of two years from the date of manufacture of such products. Flowline's obligation under this

warranty is solely and exclusively limited to the repair or replacement, at Flowline's option, of the products or

components, which Flowline's examination determines to its satisfaction to be defective in material or

workmanship within the warranty period. Flowline must be notified pursuant to the instructions below of any

claim under this warranty within thirty (30) days of any claimed lack of conformity of the product. Any product

repaired under this warranty will be warranted only for the remainder of the original warranty period. Any

product provided as a replacement under this warranty will be warranted for the full two years from the date of

manufacture.

RETURNS

Products cannot be returned to Flowline without Flowline's prior authorization. To return a product that is

thought to be defective, go to flowline.com, and submit a customer return (MRA) request form and follow the

instructions therein. All warranty and non-warranty product returns to Flowline must be shipped prepaid and

insured. Flowline will not be responsible for any products lost or damaged in shipment.

LIMITATIONS

This warranty does not apply to products which: 1) are beyond the warranty period or are products for which

the original purchaser does not follow the warranty procedures outlined above; 2) have been subjected to

electrical, mechanical or chemical damage due to improper, accidental or negligent use; 3) have been modified

or altered; 4) anyone other than service personnel authorized by Flowline have attempted to repair; 5) have

been involved in accidents or natural disasters; or 6) are damaged during return shipment to Flowline. Flowline

reserves the right to unilaterally waive this warranty and dispose of any product returned to Flowline where: 1)

there is evidence of a potentially hazardous material present with the product; or 2) the product has remained

unclaimed at Flowline for more than 30 days after Flowline has dutifully requested disposition. This warranty

contains the sole express warranty made by Flowline in connection with its products. ALL IMPLIED

WARRANTIES, INCLUDING WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. The remedies of repair or

replacement as stated above are the exclusive remedies for the breach of this warranty. IN NO EVENT SHALL

FLOWLINE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND

INCLUDING PERSONAL OR REAL PROPERTY OR FOR INJURY TO ANY PERSON. THIS WARRANTY

CONSTITUTES THE FINAL, COMPLETE AND EXCLUSIVE STATEMENT OF WARRANTY TERMS AND NO

PERSON IS AUTHORIZED TO MAKE ANY OTHER WARRANTIES OR REPRESENTATIONS ON BEHALF

OF FLOWLINE. This warranty will be interpreted pursuant to the laws of the State of California. If any portion

of this warranty is held to be invalid or unenforceable for any reason, such finding will not invalidate any other

provision of this warranty.

For complete product documentation, video training, and technical support, go to flowline.com.

For phone support, call 562-598-3015 from 8am to 5pm PST, Mon - Fri.

(Please make sure you have the Part and Serial number available.)

| 12 QS310140 Rev A4

Loading...

Loading...