Page 1

Liquid and Solids Level Measurement and Control

Page 2

HVAC

Textile

Mining

Biofuel

Marine

Oil field

Printing

Cement

Farming

Hospital

Chemical

Lubricant

Aerospace

Agriculture

Water park

Automotive

Why Flowline

Flowline has twenty five years of proven success in level

measurement and control applications. We understand your

requirements, offer a breadth of measurement technologies,

and readily share our application expertise.

RELIABILITY

EASE OF USE

AVAILABILITY

QUALITY

Our advanced level sensing technologies

including pulse radar, guided wave

and ultrasonic provide accurate and

reliable measurement.

Our intuitive designs, powerful WebCal

configuration software and applicationsolution based website, make our level

products easy to use.

Our level products are locally stocked,

fulfilled and supported by our

global network of fluid handling and

process distributors.

Our ISO 9001 company and team of level

experts, stand behind our products and

services, and your satisfaction is our

highest concern.

Animal feed

Pulp & paper

Biotechnology

Environmental

Metal finishing

Transportation

Semiconductor

Paint & coating

Microelectronic

Pharmaceutical

Pool & fountain

Zoo & aquarium

Water treatment

Building material

Food & beverage

Power generation

Commercial laundry

Building automation

Wastewater treatment

Equipment manufacturer

2

Page 3

We Do Your Level Best

™

Flowline enables industrial manufacturers, chemical distributors, municipalities and energy or food providers

to safely and efficiently manage their contained liquid and solid assets. Our quality solutions measure tank

inventories, automate tank processes, ensure workplace safety and protect the environment. We design,

manufacture and market the best level measurement and control instruments for your chemical, water,

wastewater, oil and dry solid applications. Flowline products are sold and supported worldwide through our

stocking distribution partners. Our customers include design engineers, system integrators, original equipment

manufacturers, facility operations, engineering and maintenance decision makers. The leading criteria for

product selection are reliability, ease of use, availability and quality.

CHEMICAL

DISTRIBUTION

MUNICIPAL

WATER & WASTEWATER

INDUSTRIAL

MANUFACTURING

BU LK

SOLIDS

INDUSTRIAL

WATER & WASTEWATER

1

1

Page 4

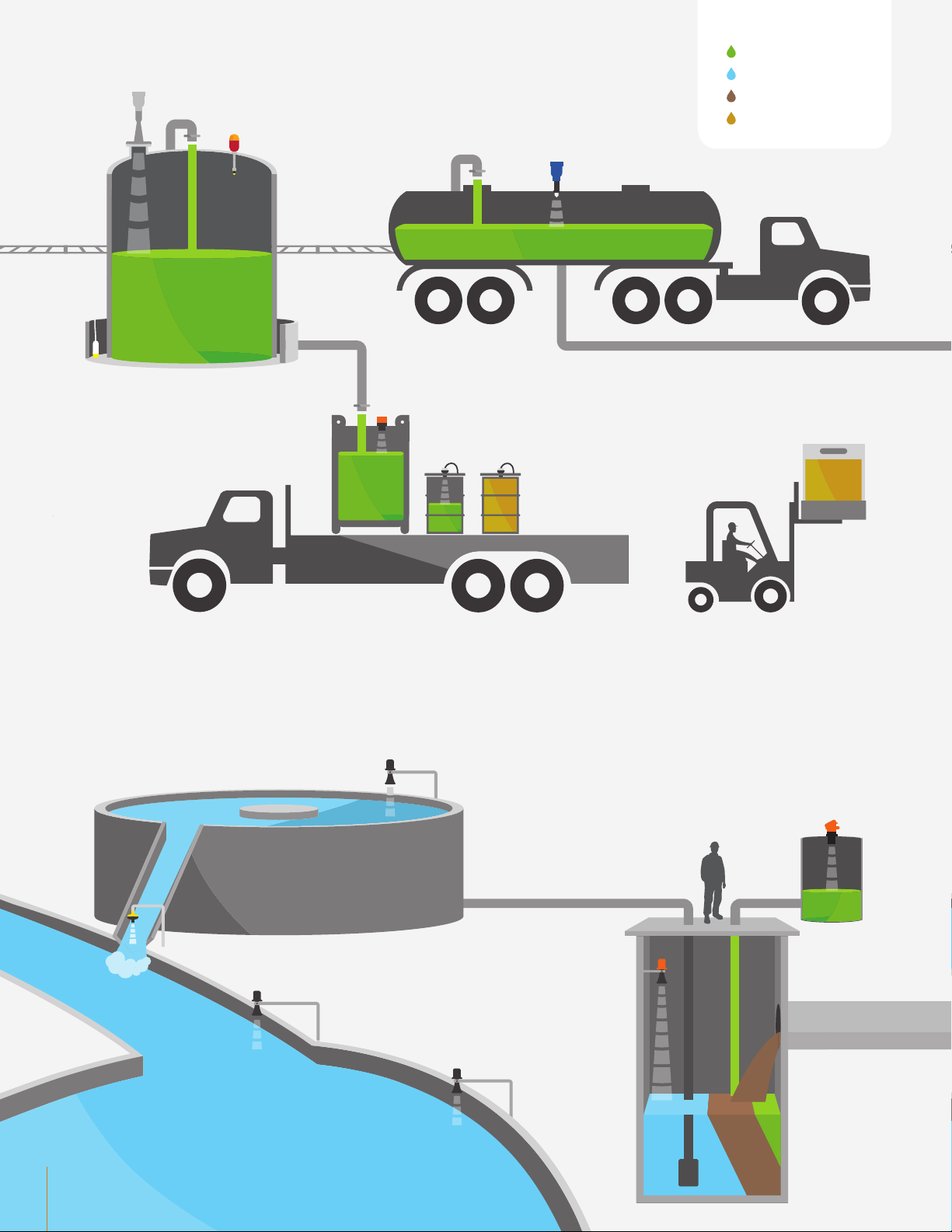

CHEMICAL DISTRIBUTION

Bulk Storage

IBC or Drum

CHEMICAL

WATER

WASTEWATER

OIL

Tanker Truck

Open

Channel

MUNICIPAL WASTEWATER

Wastewater Clarifier

Chemical Feed

Sewer / Storm

Lift Station

Canal

Reservoir

2

Page 5

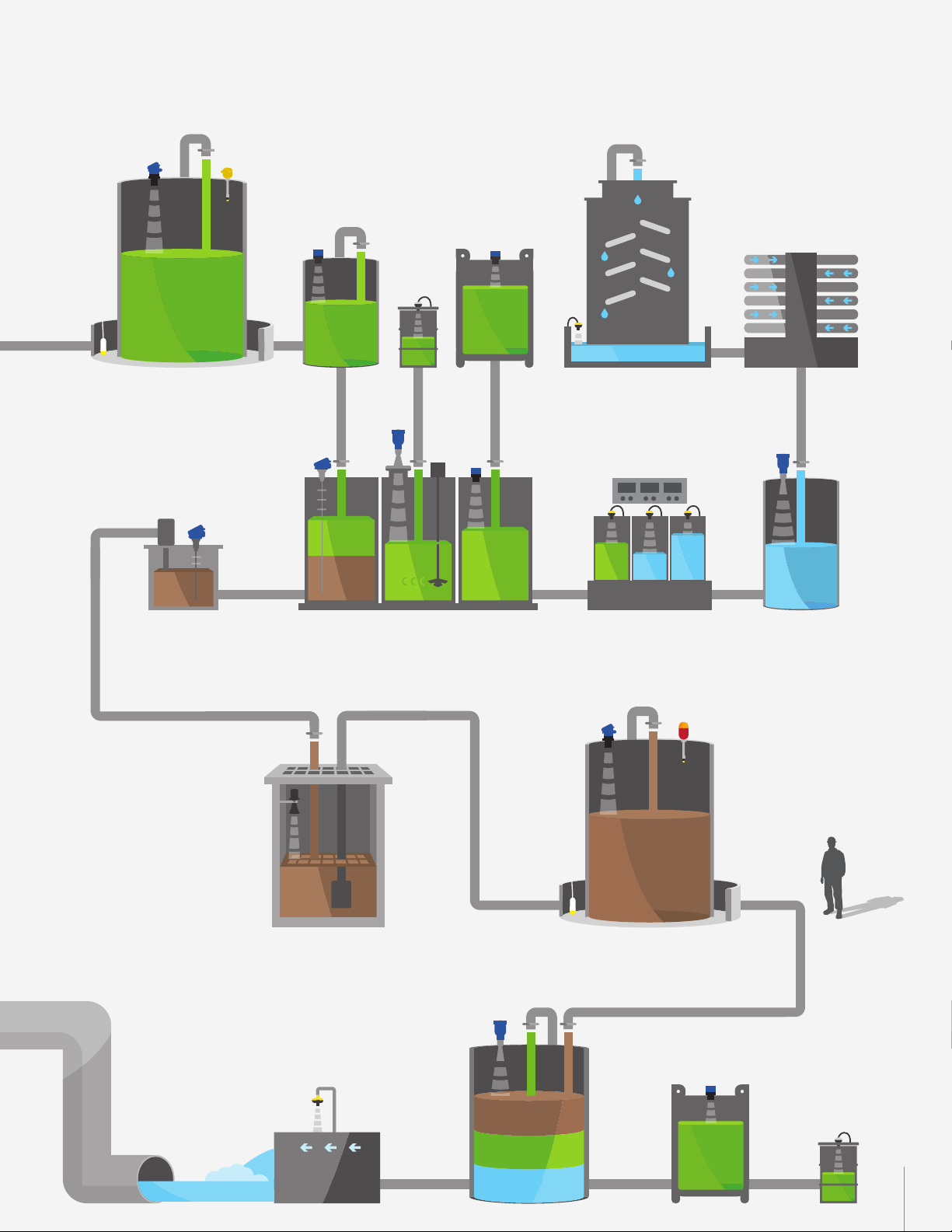

INDUSTRIAL MANUFACTURING

Bulk Storage

Day Tank IBC or Drum

RO System

Cooling Tower

Waste Sump

Process Tank Skid or Machine

INDUSTRIAL WASTEWATER

Waste Lift Station

Neutralization

Open Channel

RO Storage

Bulk Storage

IBC or Drum

3

Page 6

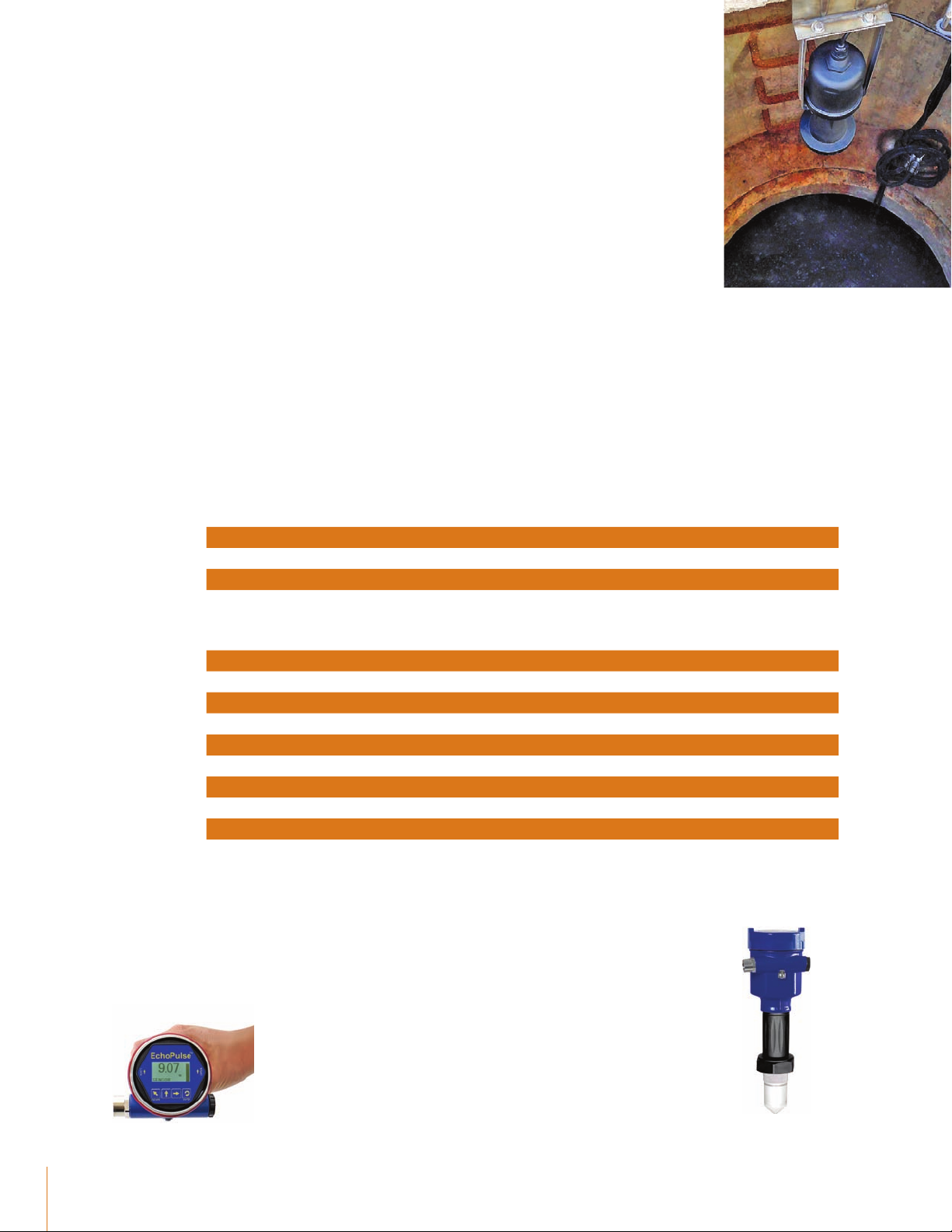

EchoPulse® General Purpose

Pulse Radar Liquid Level Transmitters

Best for Difficult Bulk Tank, Process or Sump Applications

These non-contact sensors are the reliable level measurement solution for your most

demanding storage, process and lift station applications.

WHY PULSE

Pulse radar is unaffected by process

conditions that cause other sensing

technologies to fail or require ongoing

maintenance. These include foam,

vapor, condensation, corrosion,

temperature, pressure, vacuum,

and coating or scaling liquids.

TECHNOLOGY

The radar sensor emits a 26 GHz or 6.3

GHz RF pulse from the base of the antenna.

The pulse travels through the free space,

reflects against the liquid dielectric material

and returns to the antenna. The sensor

measures the pulse time of flight and

translates it into liquid level distance.

The LR30 pulse radar

sensor is the reliable

level measurement

solution for municipal

and industrial pump

lift stations.

LR10 LR15 LR20 LR25 LR30

Classification General purpose

Application Storage Storage Storage Process Lift station

Proc. condition Easy Difficult Difficult Extreme Difficult

Tank location

and material

Corrosive Yes Diluted Ye s Yes Diluted

Range 32.8' (10m) 98.4' (30m) 65.6’ (20m) 114.8' (35m) 98.4' (30m)

Output 4-20 mA 4-20 mA 4-20 mA 4-20 mA 4-20 mA

Configuration Push button Push button Push button Push button Push button

Installation Tank adapter or flange Flange Flange Bracket

Mount 1 1/2" NPT 1 1/2” NPT 3", 4" ANSI 4", 6" ANSI Bolt

Max. temp. 266º F. (130º C.) 302º F. (150º C.) 302º F. (150º C.) 266º F. (130º C.) 212º F. (100º C.)

Max. pressure 43.5 PSI (3 bar) 150 PSI (10 bar) 72 PSI (5 bar) 580 PSI (40 bar) Atmospheric

Ant. material PFA 316L 316L & PTFE 316L & PTFE Nylon

Above grade metal or

below grade in any

tank material

Above or below

grade in any

tank material

Above or below

grade in any

tank material

Above grade metal or

below grade in any

tank material

Below grade

in any tank material

ECHOPULSE® LR10

LR10-0010

1 1/2” NPT, PFA horn

The general purpose 26 GHz. pulse radar level transmitter

provides continuous level measurement up to 32.8’ (10m)

with a 4-20 mA signal output, and is configured via its

integral push button display module. The non-contact

liquid level sensor is intended for chemical or water storage

applications in above grade metal or reinforced concrete

tanks or below grade tanks of any material. Select this

sensor for easy process conditions with corrosive media,

light agitation, condensation or vapor, and installation in a

low-profile tank adapter or flange fitting.

4

Page 7

ECHOPULSE® LR15

LR15-0010-20

2” (48mm) 316L horn

LR15-0010-30

3” (78mm) 316L horn

LR15-0010-40

4” (98mm) 316L horn

The general purpose 26 GHz. pulse radar transmitter provides

continuous level measurement up to 98.4’ (30m) with a 4-20

mA signal output, and is configured via its integral push button

display module. The non-contact liquid level sensor is intended

for petroleum, water, wastewater and diluted chemical storage

or process applications in above or below grade tanks of any

material. Select this sensor for challenging process conditions

with diluted or non-corrosive media, light surface foam or

agitation, higher temperature or pressure, condensation or

vapor, and installation in a tank adapter, flange fitting or metal

stand-pipe.

ECHOPULSE® LR 2 0

LR20-0310-30

3” ANSI with PTFE shield

LR20-0310-40

4” ANSI with PTFE shield

ECHOPULSE® LR 25

LR25-0310-40

4” ANSI with PTFE shield

LR25-0310-60

6” ANSI with PTFE shield

The general purpose 26 GHz. pulse radar transmitter provides

continuous level measurement up to 65.6’ (20m) with a 4-20

mA signal output, and is configured via its integral push button

display module. The non-contact liquid level sensor is intended

for chemical storage or process applications in above or below

grade tanks of any material. Select this sensor for challenging

process conditions with corrosive media, light surface foam

or agitation, higher temperature or pressure, condensation or

vapor, and installation in a flange fitting.

The general purpose 6.3 GHz. pulse radar transmitter provides

continuous level measurement up to 114.8’ (35m) with a 4-20

mA signal output, and is configured via its integral push button

display module. The non-contact liquid level sensor is intended

for chemical and petroleum storage or process applications in

above grade metal or reinforced concrete tanks or below grade

tanks of any material. Select this sensor for harsh process

conditions with corrosive or low dielectric media, heavy surface

foam or agitation, higher pressure, steam, condensation or

vapor, and installation in a flange fitting. Due to the wider beam

angle, special attention should be given to ensure that the

sensor is located with unobstructed measurement space.

ECHOPULSE® LR 3 0

LR30-0010-10

Nylon sensor, 304 bracket,

remote display

The general purpose 26 GHz. pulse radar transmitter provides

continuous level measurement up to 98.4’ (30m) with a 4-20

mA signal output, and is configured via its remote push button

display module. The non-contact liquid level sensor is intended

for industrial wastewater, municipal storm or sewer lift station,

reservoir, river, canal or flume applications located below

or above grade. Select this sensor for challenging process

conditions that may include light surface foam or agitation,

small trash or plant material, wind, condensation or vapor.

Each comes with a 32.8’ (10m) cable, mounting bracket and

display module. The sensor is intended for bracket mount

installation suspended above the liquid level.

5

Page 8

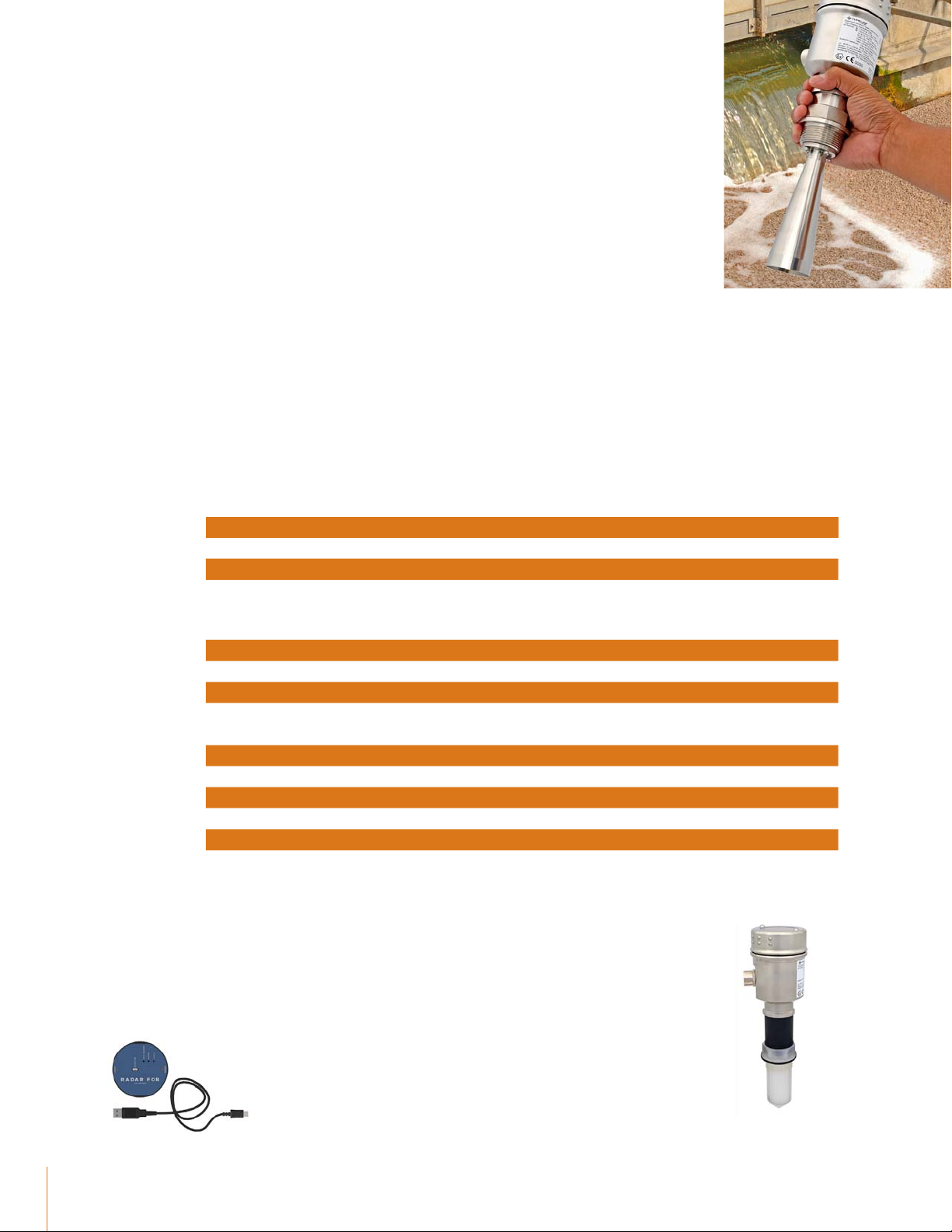

EchoPro® Intrinsically Safe

Pulse Radar Liquid Level Transmitters

Best for Difficult Bulk Tank, Process or Sump Applications

These non-contact sensors are the reliable level measurement solution for your most

demanding storage, process and lift station applications.

WHY PULSE

Pulse radar is unaffected by process

conditions that cause other sensing

technologies to fail or require ongoing

maintenance. These include foam,

vapor, condensation, corrosion,

temperature, pressure, vacuum,

and coating or scaling liquids.

TECHNOLOGY

The radar sensor emits a 26 GHz or 6.3

GHz RF pulse from the base of the antenna.

The pulse travels through the free space,

reflects against the liquid dielectric material

and returns to the antenna. The sensor

measures the pulse time of flight and

translates it into liquid level distance.

The LR16 pulse

radar sensor

delivers reliable

level measurement

in applications with

surface foam.

LR11 LR16 LR21 LR26 LR31

Classification Intrinsically safe

Application Storage Storage Storage Process Lift station

Proc. condition Easy Difficult Difficult Extreme Difficult

Tank location

and material

Corrosive Yes Diluted Ye s Yes Diluted

Range 32.8' (10m) 98.4' (30m) 65.6’ (20m) 114.8' (35m) 98.4' (30m)

Output 4-20 mA + HART 4-20 mA + HART 4-20 mA + HART 4-20 mA + HART 4-20 mA + HART

Configuration

Installation Tank adapter or flange Flange Flange Bracket

Mount 1 1/2" NPT 1 1/2” NPT 3", 4" ANSI 4", 6" ANSI Bolt

Max. temp. 266º F. (130º C.) 302º F. (150º C.) 302º F. (150º C.) 266º F. (130º C.) 212º F. (100º C.)

Max. pressure 43.5 PSI (3 bar) 150 PSI (10 bar) 72 PSI (5 bar) 580 PSI (40 bar) Atmospheric

Ant. material PFA 316L 316L & PTFE 316L & PTFE Nylon

Above grade metal or

below grade in any

tank material

Push button,

WebCal, HART

Above or below

grade in any

tank material

Push button,

WebCal, HART

Above or below

grade in any

tank material

Push button,

WebCal, HART

Above grade metal or

below grade in any

tank material

Push button,

WebCal, HART

Below grade

in any tank material

Push button,

WebCal, HART

ECHOPRO® LR 11

LR11-5421-00

1 1/2” NPT, PFA horn, w/o Fob

LR11-5421-01

1 1/2” NPT, PFA horn, w/Fob

The intrinsically safe 26 GHz. pulse radar level transmitter

provides continuous level measurement up to 32.8’ (10m)

with a 4-20 mA analog and HART digital signal output, and

is configured via its integral push button display module

or WebCal software. The non-contact liquid level sensor is

intended for chemical or water storage applications in above

grade metal or reinforced concrete tanks or below grade tanks

of any material. Select this sensor for easy process conditions

with corrosive media, light agitation, condensation or vapor,

and installation in a low-profile tank adapter or flange fitting.

6

Page 9

ECHOPRO® LR16

LR16-5021-20-00

2” horn, 316L, w/o Fob

LR16-5021-20-01

2” horn, 316L, w/Fob

LR16-5021-30-00

3” horn, 316L, w/o Fob

LR16-5021-30-01

3” horn, 316L, w/Fob

LR16-5021-40-00

4” horn, 316L, w/o Fob

LR16-5021-40-01

4” horn, 316L, w/Fob

The intrinsically safe 26 GHz. pulse radar transmitter provides

continuous level measurement up to 98.4’ (30m) with a 4-20 mA

analog and HART digital signal output, and is configured via its

integral push button display module or WebCal software. The

non-contact liquid level sensor is intended for petroleum, water,

wastewater and diluted chemical storage or process conditions

in above or below grade tanks of any material. Select this sensor

for challenging process conditions with diluted or non-corrosive

media, light surface foam or agitation, higher temperature or

pressure, condensation or vapor, and installation in a tank

adapter, flange fitting or metal stand-pipe.

ECHOPRO® LR 21

LR21-5321-30-00

3” ANSI, PTFE shield, w/o Fob

LR21-5321-30-01

3” ANSI, PTFE shield, w/Fob

LR21-5321-40-00

4” ANSI, PTFE shield, w/o Fob

LR21-5321-40-01

4” ANSI, PTFE shield, w/Fob

ECHOPRO® LR 26

LR26-5321-40-00

4” ANSI, PTFE shield, w/o Fob

LR26-5321-40-01

4” ANSI, PTFE shield, w/Fob

LR26-5321-60-00

6” ANSI, PTFE shield, w/o Fob

LR26-5321-60-01

6” ANSI, PTFE shield, w/Fob

The intrinsically safe 26 GHz. pulse radar transmitter provides

continuous level measurement up to 65.6’ (20m) with a 4-20 mA

analog and HART digital signal output, and is configured via its

integral push button display module or WebCal software. The

non-contact liquid level sensor is intended for chemical storage or

process applications in above or below grade tanks of any material.

Select this sensor for challenging process conditions with corrosive

media, light surface foam or agitation, higher temperature or

pressure, condensation or vapor, and installation in a flange fitting.

The intrinsically safe 6.3 GHz. pulse radar transmitter provides

continuous level measurement up to 114.8’ (35m) with a 4-20 mA

analog and HART digital signal output, and is configured via its

integral push button display module. The non-contact liquid level

sensor is intended for chemical and petroleum storage or process

applications in above grade metal or reinforced concrete tanks

or below grade tanks of any material. Select this sensor for harsh

process conditions with corrosive or low dielectric media, heavy

surface foam or agitation, higher pressure, steam, condensation

or vapor, and installation in a flange fitting. Due to the wider beam

angle, special attention should be given to ensure that the sensor

is located with unobstructed measurement space.

ECHOPRO® LR 31

LR31-0021-10-00

Nylon sensor, 304 bracket,

remote display, w/o Fob

LR31-0021-10-01

Nylon sensor, 304 bracket,

remote display, w/Fob

The intrinsically safe 26 GHz. pulse radar transmitter provides

continuous level measurement up to 98.4’ (30m) with a 4-20 mA

analog and HART digital signal output, and is configured via its

remote push button display module or WebCal software. The noncontact liquid level sensor is intended for industrial wastewater,

municipal storm or sewer lift station, reservoir, river, canal or open

channel applications located below or above grade. Select this

sensor for challenging process conditions that may include light

surface foam or agitation, small trash or plant material, wind,

condensation or vapor. Each comes with a 32.8’ (10m) cable,

mounting bracket and display module. The sensor is designed

for bracket mount installation suspended above the liquid level.

7

Page 10

WebCal® Configuration Software

Best for Fast and Easy Level Sensor Setup

WebCal software is a PC utility program that enables users to easily configure and test compatible Flowline

level sensors to their measurement and control requirements. Download your free copy at our website and

®

connect your sensor through our Fob USB

level configuration simple.

Configure your sensor,

update the firmware or

demo your configuration

prior to installation

adapter. Sensors are sold with and without Fobs. WebCal makes

LI99-3001

LI99-2001

View your sensor part

number, serial number,

description and firmware

Select from preprogrammed

drop down menus to create

your level configuration

Click to write your level

configuration to the sensors

non-volatile memory

View, print or email a PDF

wiring diagram of your level

configuration for use by

the installer

Available in both

English and Chinese

Supports up to 175

sensor configurations

Customize set points to

your level measurement

or control requirements

Add notes to your saved

configuration file for

future reference

8

Change the proportional signal

output from distance to linearized

volume using the standard tank

shapes or custom strapping table

Open an existing file, save a

new configuration file, or print

a copy of your configuration

to document your file revision

Page 11

9 9

Page 12

EchoPod® General Purpose

Ultrasonic Liquid Level Transmitters

Best for Corrosive Small to Medium Tank or Sump Applications

Reflective Technology

Patent

Pending

™

These non-contact sensors are the reliable level measurement solution for your ambient

storage, day tank, chemical feed, skid or machine, sump and neutralization applications.

WHY ULTRASONIC

Ultrasonic is unaffected by liquid

characteristics that cause contact

sensing technologies to fail or require

ongoing maintenance. These include

corrosive, dirty, coating or scaling type

liquids. If you have an ambient, foamless

application and require non-contact level

measurement, then you want ultrasonic

with Reflective Technology

™

.

TECHNOLOGY

Condensation attenuates the acoustic

signal of ultrasonic sensors with horizontal

transducers, weakening their signal strength,

and substantially reducing their measurement

reliability. By orienting the transducer vertically,

water droplets run off the transducer, and do

not affect sensor performance. The unimpeded

transmit and receive signals are reflected to

and from the liquid. Thanks gravity.

Unlike horizontal

transducers, water

droplets naturally

shed off the reflective

transducer face.

Horizontal Transducer

Reliable Measurement

Signal Attenuation

DL10 DL14 UG01 UG03 UG06 UG12

Classification General purpose

Application

Proc. condition Easy Easy Typical Typical Typical Typical

Range 49.2" (1.25m) 49.2” (1.25m) 4.9’ (1.5m) 9.8’ (3m) 19.6’ (6m) 39.3’ (12m)

Output 4-20 mA

Configuration WebCal WebCal WebCal WebCal

Display No No No No Ye s Ye s

Termination Cable Cable Cable Cable Conduit Conduit

Mount 1" NPT (G) 1" NPT (G) 2" NPT (G) 2” NPT (G) 2" NPT (G) 3" NPT (G)

Temperature 20º F. (-7º C.) to 140º F. (60º C.) -40º F. (-40º C.) to 176º F. (80º C.) -40º F. (-40º C.) to 176º F. (80º C.)

Max. pressure 30 PSI (2 bar)

Trans. type Horizontal Horizontal Reflective Reflective Reflective Reflective

Trans. material PVDF

Chemical feed, skid or machine, cooling tower,

IBC or drum, small waste sump

4-20 mA +

(4) SPST relays

4-20 mA +

(4) SPST relays

Mini bulk,

day tank, waste

sump

4-20 mA +

(4) SPST relays

Bulk storage,

day tank, waste

sump, clarifier,

neutralization

4-20 mA 4-20 mA

Push button,

WebCal

storage, waste

Push button,

Large bulk

sump

WebCal

10

ECHOPOD® DL10

DL10-00

1.25m, NPT, w/o Fob

DL10-01

1.25m, NPT, w/Fob

The general purpose ultrasonic transmitter provides continuous

level measurement up to 49.2” (1.25m) with a 4-20 mA analog

signal output, and is configured via our WebCal software. Select

this sensor for small tanks with non-foaming, non-condensing

or highly vaporous media such as chemical, water, wastewater

and oil. Typical applications include chemical feed, skid or

machine, IBC or drum and small waste sumps.

Page 13

ECHOPOD® DL14

DL14-00

1.25m, NPT, w/o Fob

DL14-01

1.25m, NPT, w/Fob

The general purpose ultrasonic multi-function level transmitter

provides continuous level measurement up to 49.2” (1.25m) with

a 4-20 mA analog signal output and four relays, and is configured

via our WebCal software. Each relay can be configured for alarm,

automatic fill or empty functions. Select this sensor for small tanks

with non-foaming, non-condensing or highly vaporous media

such as chemicals, water, wastewater and oil. Typical applications

include chemical feed, skid or machine, IBC or drum and small

waste sumps.

ECHOPOD® UG01

UG01-0001-40

1.5m, NPT, w/o Fob

UG01-0001-41

1.5m, NPT, w/Fob

ECHOPOD® UG03

UG03-0001-40

3m, NPT, w/o Fob

UG03-0001-41

3m, NPT, w/Fob

ECHOPOD® UG06

UG06-0001-00

6m, NPT, w/o Fob

UG06-0001-01

6m, NPT, w/o Fob

The general purpose reflective ultrasonic multi-function level

transmitter provides continuous level measurement up to 4.9’

(1.5m) with a 4-20 mA analog signal output and four relays, and is

configured via our WebCal software. Each relay can be configured

for alarm, automatic fill or empty functions. Select this sensor for

small tanks with non-foaming or highly vaporous media such as

chemicals, water, wastewater and oil. Typical applications include

cooling tower, chemical feed, skid or machine, IBC or drum and

small waste sumps.

The general purpose reflective ultrasonic multi-function level

transmitter provides continuous level measurement up to 9.8’

(3m) with a 4-20 mA analog signal output and four relays, and is

configured via our WebCal software. Each relay can be configured

for alarm, automatic fill or empty functions. Select this sensor

for mid-sized tanks with non-foaming or highly vaporous media

such as chemicals, water, wastewater and oil. Typical applications

include mini-bulk storage, day tank and waste sumps.

The general purpose reflective ultrasonic level transmitter provides

continuous level measurement up to 19.6’ (6m) with a 4-20 mA

analog signal output, and is configured via its integral push button

display module or WebCal software. Select this sensor for bulk

tanks with non-foaming or highly vaporous media such as chemi-

cals, water, wastewater and oil. Typical applications include bulk

storage, day tank, neutralization tank, clarifier and waste sumps.

ECHOPOD® UG12

UG12-0001-00

12m, NPT, w/o Fob

UG12-0001-01

12m, NPT, w/o Fob

The general purpose reflective ultrasonic level transmitter provides

continuous level measurement up to 39.3’ (12m) with a 4-20 mA

analog signal output, and is configured via its integral push button

display module or WebCal software. Select this sensor for large

bulk tanks with non-foaming or highly vaporous media such as

chemicals, water, wastewater and oil. Typical applications include

bulk storage tanks and waste sumps.

11

Page 14

EchoTouch® Intrinsically Safe

Ultrasonic Liquid Level Transmitters

Best for Corrosive Small to Medium Tank or Sump Applications

Reflective Technology

Patent

Pending

™

These non-contact sensors are the reliable level measurement solution for your ambient

storage, day tank, chemical feed, skid or machine, sump and neutralization applications.

WHY ULTRASONIC

Ultrasonic is unaffected by liquid

characteristics that cause contact

sensing technologies to fail or require

ongoing maintenance. These include

corrosive, dirty, coating or scaling type

liquids. If you have an ambient, foamless

application and require non-contact level

measurement, then you want ultrasonic

with Reflective Technology

™

.

TECHNOLOGY

Condensation attenuates the acoustic

signal of ultrasonic sensors with horizontal

transducers, weakening their signal strength,

and substantially reducing their measurement

reliability. By orienting the transducer vertically,

water droplets run off the transducer, and do

not affect sensor performance. The unimpeded

transmit and receive signals are reflected to

and from the liquid. Thanks gravity.

Unlike horizontal

transducers, water

droplets naturally

shed off the reflective

transducer face.

Horizontal Transducer

Reliable Measurement

Signal Attenuation

US01 US03 US06 US12

Classification Intrinsically safe

Chemical feed,

Application

Proc. condition Typical Typical Typical Typical

Range 4.9’ (1.5m) 9.8’ (3m) 19.6’ (6m) 39.3’ (12m)

Output 4-20 mA 4-20 mA 4-20 mA + HART 4-20 mA + HART

Configuration WebCal WebCal

Display No No Yes Yes

Termination Cable Cable Conduit Conduit

Mount 2" NPT (G) 2” NPT (G) 2" NPT (G) 3" NPT (G)

Temperature -40º F. (-40º C.) to 176º F. (80º C.) -40º F. (-40º C.) to 176º F. (80º C.)

Max. pressure 30 psi (2 bar) 30 psi (2 bar) 30 psi (2 bar) 30 psi (2 bar)

Trans. type Reflective Reflective Reflective Reflective

Trans. material PVDF

skid or machine, cool-

ing tower, IBC or drum,

small waste sump

Mini bulk, day tank,

waste sump

Bulk storage,

day tank, waste sump,

clarifier, neutralization

Push button,

WebCal, HART

Large bulk storage,

waste sump

Push button,

WebCal, HART

12

ECHOTOUCH® US01

US01-0001-00

1.5m, NPT, w/o Fob

US01-0001-01

1.5m, NPT, w/Fob

The intrinsically safe reflective ultrasonic level transmitter

provides continuous level measurement up to 4.9’ (1.5m) with a

4-20 mA analog signal output, and is configured via our WebCal

software. Select this sensor for small tanks with non-foaming or

highly vaporous media such as chemicals, water, wastewater and

oil. Typical applications include chemical feed, skid or machine,

IBC or drum, cooling tower and small waste sumps.

Page 15

By eliminating the affects of condensation on ultrasonic sensors,

Flowline has achieved a breakthrough in level measurement reliability.

ECHOTOUCH® US03

US03-0001-00

3m, NPT, w/o Fob

US03-0001-01

3m, NPT, w/Fob

ECHOTOUCH® US06

US06-0003-00

6m, NPT, w/o Fob

US06-0003-01

6m, NPT, w/o Fob

ECHOTOUCH® US12

US12-0003-00

12m, NPT, w/o Fob

US12-0003-01

12m, NPT, w/o Fob

The intrinsically safe reflective ultrasonic level transmitter

provides continuous level measurement up to 9.8’ (3m) with a

4-20 mA analog signal output, and is configured via our WebCal

software. Select this sensor for mid-sized tanks with non-foaming

or highly vaporous media such as chemicals, water, wastewater

and oil. Typical applications include mini-bulk storage, day tank

and waste sumps.

The intrinsically safe reflective ultrasonic level transmitter provides

continuous level measurement up to 19.6’ (6m) with a 4-20 mA

analog signal output, and is configured via its integral push button

display module, WebCal software or HART. Select this sensor for

bulk tanks with non-foaming or highly vaporous media such as

chemicals, water, wastewater and oil. Typical applications include

bulk storage, day tank, neutralization tank, clarifier and waste sumps.

The intrinsically safe reflective ultrasonic level transmitter provides

continuous level measurement up to 39.3’ (12m) with a 4-20 mA

analog signal output, and is configured via its integral push button display module, WebCal software or HART. Select this sensor

for large bulk tanks with non-foaming or highly vaporous media

such as chemicals, water, wastewater and oil. Typical applications

include bulk storage tanks and waste sumps.

13

Page 16

EchoWave® General Purpose

Guided Wave Liquid Level Transmitters

Best for Difficult Small to Medium Tank or Sump Applications

These contact sensors are the reliable level measurement solution for your day tank,

process tank, skid or machine and sump applications with challenging process conditions.

WHY GUIDED WAVE

Guided wave radar is unaffected by most

process conditions that cause other

sensing technologies to fail or require

ongoing maintenance. These include

foam, vapor, condensation, temperature,

pressure, vacuum, and light coating

or scaling liquids.

TECHNOLOGY

The guided wave sensor emits a RF pulse

from the base of the probe feed through.

The pulse travels down the probe, reflects

against the liquid dielectric material and

returns to the feed through. The sensor

measures the pulse time of flight and

translates it into liquid level height.

The LG10 guided

wave sensor is

the ideal level

measurement

solution for oil

storage and

reclamation

applications.

LG10-0 LG10-1 LG11-2

Classification General purpose

Tank location

and material

Application

Dirty, coating or

crystallizing liquid

Range 9.8’ (3m) 9.8’ (3m) 18’ (5.5m)

Output 4-20 mA 4-20 mA 4-20 mA

Probe type Rod Coaxial Cable

Probe material 316L 316L 316

Mount 3/4" NPT (G)

Max. temperature 302º F. (150º C.)

Max. pressure 250 PSI (17 bar)

Above grade metal or below

grade in any tank material

Day tank, IBC or drum, process tank,

skid or machine, cooling tower, waste sump

Yes No Yes

Above or below grade

in any tank material

Above grade metal or below

grade in any tank material

Bulk storage, waste sump

14

ECHOWAVE® LG10 -11

LG10-0003-01-036

.9m rod, NPT, w/Fob

LG10-0003-01-072

1.8m rod, NPT, w/Fob

LG10-0003-01-118

3m rod, NPT, w/Fob

LG10-1003-01-036

.9m coaxial, NPT, w/Fob

LG10-1003-01-072

1.8m coaxial, NPT, w/Fob

LG10-1003-01-118

3m coaxial, NPT, w/Fob

LG11-2003-01-216

5.5m cable, NPT, w/Fob

Offered in three probe types, the general purpose guided

wave transmitter provides continuous level measurement

up to 18’ (5.5m) with a 4-20 mA signal output, and is

configured via our WebCal software. This liquid level

sensor is applied in non-turbulent environments with foam,

vapor, condensation, temperature or pressure. Select the

rod or cable probe for use with clean, dirty, coating or

crystallizing liquids in above grade metal or below grade

tanks of any material. Select the coaxial probe for use with

clean, non-coating or crystallizing liquids in above or below

grade tanks of any material. Standard probe lengths may

be user cut in the field. Typical applications include small

bulk storage, day tank, skid or machine, IBC or drum,

process tank, cooling tower and waste sumps.

CableCoaxialRod

Page 17

15

15

Page 18

Switch-Tek™ General Purpose and Intrinsically Safe

Single and Multi-Point Liquid Level Switches

Best for Corrosive Level Switch or Leak Detection Applications

These contact sensors are the reliable level switch or control, pump protection, spill prevention,

leak detection or alarm solution for your chemical, water, wastewater and oil applications.

AXXX AX23 AX1X AX13 LU10 LZ12 LV10 LO10

Classification

Type Multi-point package Single-point package Ultrasonic Vibration Buoyancy Optic

Application

Function

Max. length 10' (3m) 10’ (3m) 10’ (3m) 10’ (3m) - - - - - - - - - - - -

Supply 12-36 VDC 120/240 VAC 12-36 VDC 120/240 VAC 12-36 VDC 12-36 VDC - - - 12-36 VDC

Contact

Rating

Enclosure

Mount 2" NPT (G) 2” NPT (G)

Temperature -40º F. (-40º C.) to 176º F. (80º C.)

Max. pressure Atmospheric

Material PP PP PP / PVDF PP / PVDF PP / PFA PP-Ryton PP / PVDF PP / PFA

Intrinsically

safe or gen.

purpose

Day tank, skid or machine,

cooling tower, waste sump,

process tank

Level

switches

(1-4) SPST

relay or

SPDT reed

60 VA

or 15 VA

NEMA 4X

(IP65)

General

purpose

Auto fill

or empty

(1) SPDT

latching

relay

250 VAC

@ 10A

NEMA 4X

(IP65)

Intrinsically

safe or gen.

purpose

Bulk storage, IBC or drum,

neutralization tank

Level

switch

(1) SPST

relay or

SPDT reed

60 VA

or 15 VA

NEMA 4X

(IP65)

2" NPT

(1 1/2" G)

150 PSI

(10 bar)

General

purpose

Level

shut off

(1) SPDT

relay

250 VAC

@ 10A

NEMA 4X

(IP65)

2” NPT

(1 1/2” G)

150 PSI

(10 bar)

Intrinsically

safe

Chemical Wastewater Water

Level

switch

(1) SPST

relay

32 VDC

(0.5A max)

NEMA 6

(IP68)

3/4"

NPT (G)

150 PSI

(10 bar)

General

purpose

Level

switch

(1) SPST

relay

60 VA

(1A max)

NEMA 6

(IP68)

3/4”

NPT (G)

150 PSI

(10 bar)

General

purpose

Level

switch

(1) SPDT

reed

15 VA

(0.25A max)

NEMA 6

(IP68)

3/4"

NPT (Rp)

25 PSI

(2 bar)

General

purpose

Secondary

containment

Leak

detection

(1) SPST

relay

60 VA

(1A max)

NEMA 6

(IP68)

3/4"

NPT (G)

150 PSI

(10 bar)

16

SMART TRAK™ AXXX

AV26

Buoyancy, NPT

AU25

Utrasonic, NPT

AZ28

Vibration, NPT

SMART TRAK™ A X23

AV23

Buoyancy, NPT

AU23

Ultrasonic, NPT

AZ23

Vibration, NPT

The intrinsically safe or general purpose level switch package

provides liquid level detection up to 10’ (3m) with 1-4 adjustable

level switch points and a compact junction box for wiring

termination. Offered in three sensor technologies, choose the

type based upon your application media. This PP level switch

package is selected for day tank, skid or machine, cooling

tower, waste sump or process tank applications, connected

to a PLC or remote relay controller.

The general purpose level switch package provides automatic

tank filling or emptying up to 10’ (3m) between two adjustable

level switch points. The compact relay controller with optional

strobe provides one latching 16A relay for pump or valve

control. Offered in three sensor technologies, choose the

type based upon your application media. This PP level switch

package is selected for day tank, skid or machine, cooling

tower, waste sump and process tank applications, requiring

detection and control.

Page 19

SWITCH-PAK™ AX1X

AV16

Buoyancy, PP, NPT

AU18

Ultrasonic, PP, NPT

AZ18

Vibration, PP, NPT

The intrinsically safe or general purpose level switch package

provides high or low liquid level detection with one relay or reed

switch output, and a compact junction box for wiring termination.

Available in three level sensor technologies, choose the sensor type

based upon your application media. This PP or PVDF level switch

package is selected for bulk storage, IBC or drum, and neutralization

tank applications, connected to a PLC or remote relay controller.

SWITCH-PAK™ AX13

AV13

Buoyancy, w/o strobe, PP, NPT

AU13

Ultrasonic, w/o strobe, PP, NPT

AZ13

Vibration, w/o strobe, PP, NPT

ULTRASONIC LU10

LU10-1305

PP, short, NPT

LU10-2305

PFA, short, NPT

LU10-1405

PP, long, NPT

VIBRATION LZ12

LZ12-1405

PP-Ryton

®

, NPT

The general purpose level switch package provides high or low liquid

level detection with one 16A compact relay controller for pump or

valve shut off. The optional flash alarm brings attention to alarm

conditions. Available in three level sensor technologies, choose the

sensor type based upon your application media. This PP or PVDF

level switch package is selected for bulk storage, IBC or drum, and

neutralization tank applications, requiring detection and control.

CSA approved for use in hazardous locations, the intrinsically safe

ultrasonic level switch provides high or low liquid level detection of

chemical, solvent or low viscosity petroleum based liquids with a

1A relay output. Media examples include hydrochloric acid, acetone

and diesel fuel oil. The submersible PP or PFA level switch sensor

is universally mounted through the tank wall or inside the tank, and

connected to a PLC or remote relay controller.

The general purpose vibration level switch provides high or low liquid

level detection of dirty liquids or those with light to medium coating

or scaling characteristics with a 1A relay output. Media examples

include wastewater, diluted caustic soda and copper sulfate. For

optimum performance, the sensor automatically adjusts for coating

build up, and if necessary, outputs a proactive maintenance alarm

to request cleaning. The submersible PP-Ryton

®

level switch sensor

is universally mounted through the tank wall or inside the tank, and

connected to a PLC or remote relay controller.

BU OYA NCY LV10

LV10-1301

PP, NPT

LV10-5301

PVDF, NPT

OPTIC LO10

LO10-1305

PP, short, NPT

LO10-2305

PFA, short, NPT

The general purpose buoyancy level switch provides high or low

liquid level detection of relatively clean water and chemical solutions

with a 15VA reed switch output. Media examples include potable

water and boric acid. The baffle body eliminates level switch chatter

caused by turbulence. The submersible PP or PVDF level switch

sensor is mounted vertically inside the tank, and connected to a PLC

or remote relay controller.

The general purpose optic leak switch provides leak detection in and

around secondary containment sumps, tanks and piping systems

with a 1A relay output. Media examples include sulfuric acid and

sodium hypochlorite. The submersible PP or PFA leak switch sensor

is mounted through the containment wall or within the interstitial

space, and connected to a PLC or remote relay controller.

17

Page 20

18

Page 21

19

Page 22

EchoPro® Intrinsically Safe

Pulse Radar Solids Level Transmitters

Best for Difficult Storage or Process Applications

These non-contact sensors are the reliable level measurement solution for your most

demanding silo, bin, stockpile, crusher and transfer station applications.

WHY PULSE

Pulse radar measures powders, grains,

aggregates, building materials or pellets,

and properly configured is unaffected

by process conditions that cause other

sensing technologies to fail or require

ongoing maintenance, such as dust,

material build-up or temperature.

SELECTION

TECHNOLOGY

The radar sensor emits a 26 GHz RF

pulse from the base of the antenna.

The pulse travels through the free space,

reflects against the solid dielectric material

and returns to the antenna. The sensor

measures the pulse time of flight and

translates it into solids level distance.

The LR36 and LR41

sensors are easily

installed with the

LR97 adjustable

mounting bracket.

To select the appropriate sensor for your application, consider that the stronger the RF signal, the greater the

sensors ability to overcome application variables such as process dust, low media reflectivity or dielectric value

and material buildup on the antenna. The RF signal strength increases by model and antenna size from the

LR36 with a 4” horn for easy process conditions to the LR46 with a 10” parabola for extreme processes.

LR36 LR41 LR46

Classification Intrinsically safe

Application Bin, transfer station, crusher

Process dust Minimal Moderate Significant

Range 49.2' (15m) 229.7' (70m) 229.7’ (70m)

Output 4-20 mA + HART 4-20 mA + HART 4-20 mA + HART

Configuration Push button, WebCal, HART Push button, WebCal, HART Push button, WebCal, HART

Installation Bracket or gimbal flange Bracket or gimbal flange Gimbal flange

Mount 1 1/2" NPT, 4” or 5” ANSI 1 1/2” NPT, 4” or 5” ANSI 4", 5" ANSI

Max. temp. 392º F. (200º C.) 752º F. (400º C.) 752º F. (400º C.)

Antenna type 4” horn 4” or 5” horn 8” or 10” parabola

Ant. air purge No Yes No

Ant. dust shield No Option No

Ant. material 316L 316L with optional PTFE dust shield 316L

Silo, stockpile, bin,

transfer station, crusher

Silo

20

ECHOPRO® LR36

LR36-5021-40-01

NPT, 316L, w/Fob

LR36-5321-44-01

4” ANSI, 316L, w/Fob

LR36-5321-45-01

5” ANSI, 316L, w/Fob

The intrinsically safe 26 GHz. pulse radar transmitter provides

continuous level measurement up to 49.2’ (15m) with a 4-20 mA

analog and HART digital signal output, and is configured via its

integral push button display module or WebCal software. The

non-contact solids level sensor is intended for dry solid media

including aggregates, grains, pellets, powders and building

materials. Select this sensor for easy process conditions with

minimal dust and installation with an adjustable mounting

bracket or gimbal flange. Typical applications include bins,

transfer stations and crushers.

Page 23

For extreme applications with significant dust, long ranges or

very low dielectric media, select the LR46 pulse radar sensor.

The parabolic antenna, adjustable gimbal flange and high gain

RF transceiver deliver reliable level measurement in the most

challenging conditions.

ECHOPRO® LR41

LR41-5021-40-01

4” horn, NPT, 316L, w/Fob

LR41-5021-50-01

5” horn, NPT, 316L, w/Fob

LR41-5321-44-01

4” horn, 4” ANSI, 316L, w/Fob

LR41-5321-45-01

4” horn, 5” ANSI, 316L, w/Fob

LR41-5321-54-01

5” horn, 4” ANSI, 316L, w/Fob

LR41-5321-55-01

5” horn, 5” ANSI, 316L, w/Fob

ECHOPRO® LR46

LR46-5321-84-01

8” parabola, 4” ANSI, 316L, w/Fob

LR46-5321-85-01

8” parabola, 5” ANSI, 316L, w/Fob

LR46-5321-04-01

10” parabola, 4” ANSI, 316L, w/Fob

LR46-5321-05-01

10” parabola, 5” ANSI, 316L, w/Fob

The intrinsically safe 26 GHz. pulse radar transmitter provides

continuous level measurement up to 229.7’ (70m) with a 4-20

mA analog and HART digital signal output, and is configured

via its integral push button display module or WebCal software.

The non-contact solids level sensor is intended for dry solid

media including aggregates, grains, pellets, powders and

building materials. Select this sensor for challenging process

conditions with moderate to significant dust, and installation

with an adjustable gimbal flange or mounting bracket. Typical

applications include silos, stockpiles, transfer stations and

crushers.

The intrinsically safe 26 GHz. pulse radar transmitter provides

continuous level measurement up to 229.7’ (70m) with a 4-20

mA analog and HART digital signal output, and is configured

via its integral push button display module or WebCal

software. The non-contact solids level sensor is intended

for dry solid media including aggregates, grains, pellets,

powders and building materials. Select this sensor for the

most difficult process conditions with significant to extreme

dust, and installation with an adjustable gimbal flange. For

ease of installation, the parabolic antenna can be unclamped,

inserted through the base of a riser, and reattached to the

sensor. Typical applications include silos.

21

Page 24

22

Page 25

Level Controllers and Indicators

Best for Tank, Sump or Silo Automation

Complete your level measurement solution with a panel or field mount relay controller or indicator.

LI55 LC52 LI25-1 LI25-2

Classification General purpose General purpose General purpose Intrinsically safe

Type Controller Controller Indicator Indicator

Application Display + control Display + control Display only Display only

Mount Panel mount Rail mount Panel mount Panel mount

Display 6-digit LED 3.5-digit LED 5-digit LCD 5-digit LCD

Supply 85-265 VAC, 12-24 VDC 120 / 240 VAC 12-30 VDC loop 12-30 VDC loop

Contact (0, 2, 4) SPDT relay 2 SPDT relays - - - - - -

Enclosure NEMA 4X faceplate NEMA 1 NEMA 4X faceplate NEMA 4X faceplate

DATAV IEW™ LI 5 5

LI55-1001

VAC, 0 relays, w/o repeater

LI55-1201

VAC, 2 relays, w/o repeater

LI55-1211

VAC, 2 relays, w/repeater

LI55-1401

VAC, 4 relays, w/o repeater

LI55-1411

VAC, 4 relays, w/repeater

DATA PO I NT ™ LC52

LC52-1001

VAC, 2 relays, w/repeater

DATA LO OP™ LI 25

LI25-1001

General purpose

The general purpose AC or DC powered level controller

displays engineering units with one 4-20 mA level transmitter

and is offered in three configurations with optional two or four

programmable relays and an isolated 4-20 mA repeater. Each

relay can be configured on a single set point as a high or low

level alarm, or latched on two set points for automatic fill or

empty control in simplex or duplex modes. Select this panel

mount controller for use with general purpose two or three-wire

level transmitters. For field mount installation, add a single or

double NEMA box.

The general purpose AC powered level controller displays

engineering units with one 4-20 mA level transmitter, two

programmable relays and an isolated 4-20 mA repeater. Relay

one is configurable on a single set point. Relay two can be

configured on a single set point or latched on two set points

for automatic fill or empty control in simplex mode. Select this

DIN rail mount controller for use with general purpose two or

three-wire level transmitters. For field mount installation, add

a single or double NEMA box.

The general purpose loop powered level indicator displays

engineering units connected in series with one 4-20 mA level

transmitter. Select this panel mount indicator for use with

general purpose two-wire level transmitters. For field mount

installation, add a single or double NEMA box.

DATA LO OP™ LI 25

LI25-2001

Intrinsically safe

FM and CSA approved, the intrinsically safe loop powered level

indicator displays engineering units connected in series with

one 4-20 mA level transmitter. Select this panel mount indicator

for use with intrinsically safe two-wire level transmitters. For

field mount installation, add a single or double NEMA box.

23

Page 26

Fittings and Enclosures

REDUCER BUSHING | THREAD X THREAD

LM51-2S00

LM52-1400

LM52-1800

LM53-2400

LM53-2800

LM53-2S10

LM53-3800

LM52-2400

LM52-2800

LM52-3800

REDUCER BUSHING | SOCKET X THRE AD

LM52-1410

LM52-1810

LM52-2410

LM52-2810

LM52-3410

LM52-3810

FLANGE | ANSI X THREAD

LM52-1850

LM52-2850

LM53-3S50

LM53-3850

LM52-3850

LM53-4S50

LM53-4850

LM53-6S50

LM53-6850

2” x 3/4” NPT, 316 stainless

2” x 1” NPT, PVC, schedule 40

2” x 1” NPT, PVC, schedule 80

2” x 1.5” NPT, PVC, schedule 40

2” x 1.5” NPT, PVC, schedule 80

2” x 1.5” NPT, 316 stainless

3” x 1.5” NPT, PVC, schedule 80

3” x 2” NPT, PVC, schedule 40

3” x 2” NPT, PVC, schedule 80

4” x 2” NPT, PVC, schedule 80

2” x 1” NPT, PVC, schedule 40

2” x 1” NPT, PVC, schedule 80

3” x 2” NPT, PVC, schedule 40

3” x 2” NPT, PVC, schedule 80

4” x 2” NPT, PVC, schedule 40

4” x 2” NPT, PVC, schedule 80

1” x 1” NPT, CPVC, schedule 80

2” x 2” NPT, CPVC, schedule 80

3” x 1.5” NPT, 316 stainless

3” x 1.5” NPT, CPVC, schedule 80

3” x 3” NPT, CPVC, schedule 80

4” x 1.5” NPT, 316 stainless

4” x 1.5” NPT, CPVC, schedule 80

6” x 1.5” NPT, 316 stainless

6” x 1.5” NPT, CPVC, schedule 80

24

TANK ADAPTER

LM52-1890

LM52-2890

LM52-3890

MOUNTING BRACKET

LM50-1001-1

LR97-S006

LM50-1001

NEMA ENCLOSURE

LM91-1001

LM91-2001

LM92-1002

LM92-2002

LM92-1202

LM92-2202

1” NPT bulkhead, PVC

2” NPT bulkhead, PVC

3” NPT bulkhead, PVC

1” NPT bracket, PP

1 1/2” NPT bracket, 316 stainless

2” NPT bracket, PP

Single NEMA box, non-windowed, 1/8 DIN, PC

Double NEMA box, non-windowed, 1/8 DIN, PC

Single NEMA box, windowed, 1/8 DIN, PC

Double NEMA box, windowed, 1/8 DIN, PC

Single NEMA box, windowed, 35mm rail, PC

Double NEMA box, windowed, 35mm rail, PC

Page 27

25

Page 28

10500 Humbolt Street

Los Alamitos, CA 90720 USA

562.598.3015 p

562.431.8507 f

flowline.com w

level.solution@flowline.com e

Volume 12

$5 USD

Loading...

Loading...