Page 1

Warranty, Service & Repair

WARRANTY

Flowline warrants to the original purchaser of its products that such

products will be free from defects in material and workmanship under

normal use and service for a period which is equal to the shorter of

one year from the date of purchase of such products or two years from

the date of manufacture of such products.

This warranty covers only those components of the products which

are non-moving and not subject to normal wear. Moreover, products

which are modified or altered, and electrical cables which are cut to

length during installation are not covered by this warranty.

Flowline’s obligation under this warranty is solely and exclusively

limited to the repair or replacement, at Flowline’s option, of the products (or components thereof) which Flowline’s examination proves to

its satisfaction to be defective. FLOWLINE SHALL HAVE NO

OBLIGATION FOR CONSEQUENTIAL DAMAGES TO PERSONAL OR REAL PROPERTY, OR FOR INJURY TO ANYPERSON.

This warranty does not apply to products which have been subject to

electrical or chemical damage due to improper use, accident, negligence, abuse or misuse. Abuse shall be assumed when indicated by

electrical damage to relays, reed switches or other components. The

warranty does not apply to products which are damaged during shipment back to Flowline’s factory or designated service center or are

returned without the original casing on the products. Moreover, this

warranty becomes immediately null and void if anyone other than service personnel authorized by Flowline attempts to repair the defective

products.

Products which are thought to be defective must be shipped prepaid

and insured to Flowline’s factory or a designated service center (the

identity and address of which will be provided upon request) within

30 days of the discovery of the defect. Such defective products must

be accompanied by proof of the date of purchase.

Flowline further reserves the right to unilaterally wave this warranty

and to dispose of any product returned to Flowline where:

a. There is evidence of a potentially hazardous material present

with product.

b. The product has remained unclaimed at Flowline for longer than

30 days after dutifully requesting disposition of the product.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND

THE DESCRIPTION ON THE FACE OF THIS WARRANTY. This

warranty and the obligations and liabilities of Flowline under it are

exclusive and instead of, and the original purchaser hereby waives, all

other remedies, warranties, guarantees or liabilities, express or

implied. EXCLUDED FROM THIS WARRANTY IS THE IMPLIED

WARRANTY OF FITNESS OF THE PRODUCTS FOR A PARTICULAR PURPOSE OR USE AND THE IMPLIED WARRANTY OF

MERCHANT ABILITY OF THE PRODUCTS.

This warranty may not be extended, altered or varied except by a written instrument signed by a duly-authorized officer of Flowline, Inc.

To register your product with the manufacturer, go to the Flowline

website for on-line registration. The website address is as follows:

www.flowline.com

On-line Warranty Registration can be found under Contact

Flowline on the Navigation Bar along the side of the home page.

If for some reason your product must be returned for factory service, go to

the Flowline website listed above. Online Factory Service can be found

under Contact Flowline on the Navigation Bar along the side of the home

page. Click on Return Authorization to begin the registration process.

You will need the following information at the time of registration:

1. Part Number and full Serial Number from product

2. Name and telephone number of someone who can answer

technical questions related to the product and its application.

3. Return Shipping Address

4. Brief Description of the Symptom

5. Brief Description of the Application

Once you have received a Material Return Authorization number,

ship the product prepaid in its original packing to:

Flowline Factory Service

MRA _____

10500 Humbolt Street

Los Alamitos, CA 90720

To avoid delays in processing your repair, write the MRA on the

shipping label. Please include the information about the malfunction with your product. This information enables our service technicians to process your repair order as quickly as possible.

®

Version 3.2A

© 2007 FLOWLINE Inc.

All rights reserved.

Manual # LV900001-LV10-09/07-M3-2

Vertical Buoyancy

Level Switch

LV10 Series

Owner’s Manual

Page 2

Step One

SPECIFICATIONS

Accuracy: ± 2 mm in water

Repeatability: ± 1 mm in water

Extreme orientation: ± 20° from vertical

Specific gravity: .8 minimum

Switch type: -_3_1: Dry contact, SPDT

-_2_1: Dry contact, SPST

Switch voltage: -_3_1: 120 VAC, 120 VDC @ 15 VA

-_2_1: 120 VAC, 120 VDC @ 50 VA

CE rating: 30 Vrms and 42.4 Vpeak or 60 VDC @15 VA

Switch output: Selectable NO or NC states

Temperature range: F: -40° to 176°(C: -40° to 80°)

Pressure range: 25 psi (2 bar) @ 25°C., derated @ 1.667 psi

(.113 bar) per °C. above 25° C.

Probe material: Polypropylene (PP)

Polyvinylidene Fluoride (PVDF)

Probe rating: NEMA 6 / IP68

Mounting threads: 3/4" NPT (3/4” BSP)

Cable type: 10 ft. (3 m), 3-wire, 22 gauge with ground,

shield & PP or PFA jacket

CE compliance: EN 61326 EMC

EN 61010-1 safety

Technology

The vertical buoyancy switch and the vertical float switch both consist of a float, magnet, reed switch and baffle body which dampens

turbulence and eliminates the negative effects of switch chatter. When

the probe is dry, the float rests on the bottom of the baffle body such

that the magnet does not influence the reed switch. As the probe

becomes immersed in liquid, the float becomes buoyant and the magnet elevates causing the reed switch to change state.

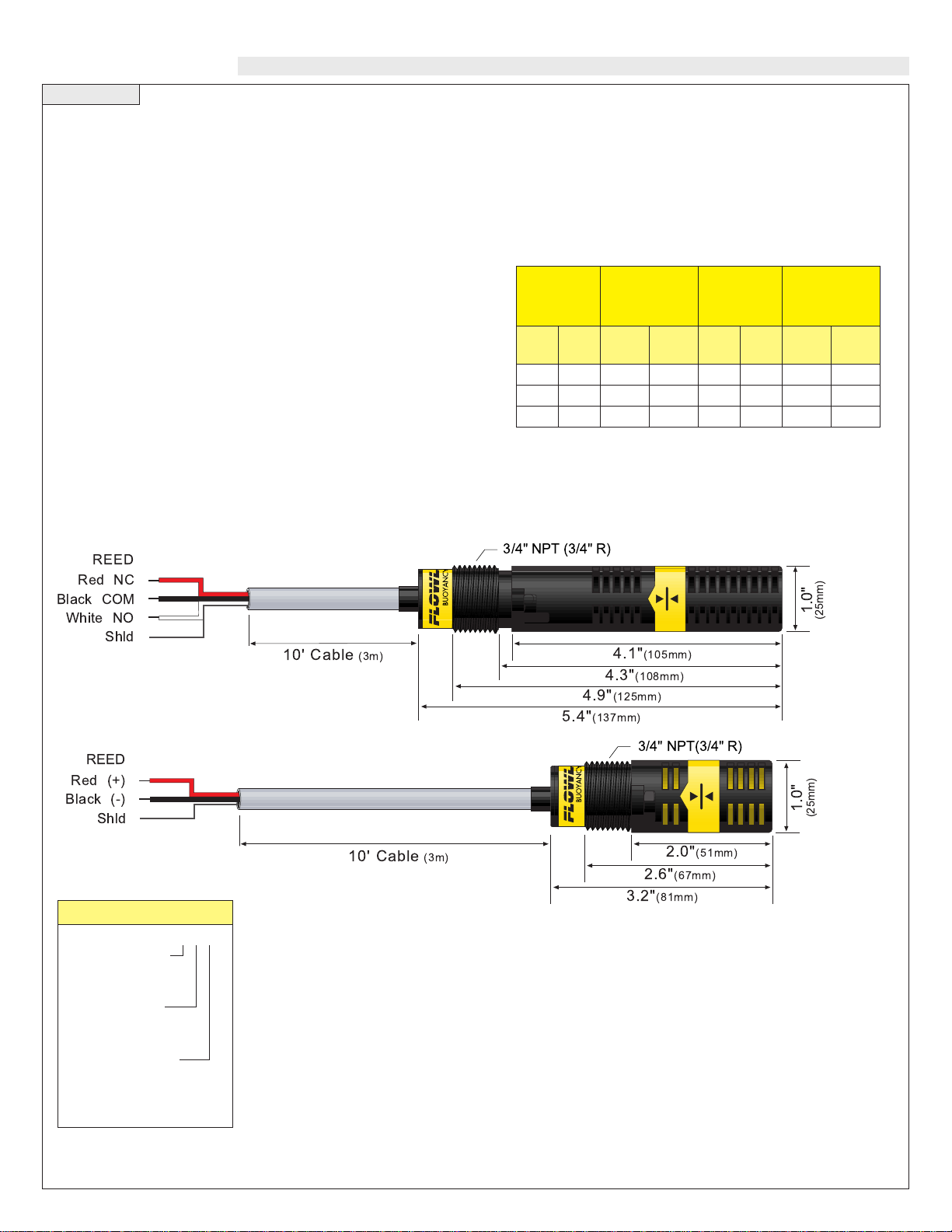

Dimensions

(LV10-1301, LV10-1351, LV10-5301, LV10-5351)

(LV10-1201, LV10-1251, LV10-5201, LV10-5251)

Reed

Switch

Rating

Max.

Resistive

Load

VA15Volts

0-50

120

240

Amps

AC

0.3

0.13

0.06

Amps

DC

0.21

0.09

0.04

Reed

Switch

Rating

Max.

Resistive

Load

VA50Volts

0-50

120

240

Amps

AC

0.5

0.4

0.2

Amps

DC

0.5

0.4

0.2

LV10 - _ _ _ 1

Sensor Material

1 - PP

5 - PVDF

Sensor Length

2 - 3.2" (81 mm)

3 - 5.4" (137 mm)

Mounting Thread

0 - 3/4" NPT

5 - 3/4" BSP

Vertical Buoy ancy & Float

4.1"(105mm)

4.3"(108mm)

1.0"

(25mm)

10' Cable (3m)

4.9"(125mm)

5.4"(137mm)

3/4" NPT (3/4" R)

NC

COM

NO

Shld

Red

Black

White

REED

2.0"(51mm)

1.0"

(25mm)

10' Cable (3m)

2.6"(67mm)

3.2"(81mm)

3/4" NPT(3/4" R)

(+)

(-)

Shld

Red

Black

REED

Page 3

Step Two Step Three

SAFETY PRECAUTIONS INSTALLATION

About this Manual:

PLEASE READ THE ENTIRE MANUAL PRIOR TO

INSTALLING OR USING THIS PRODUCT. This manual

includes information on the vertical buoyancy, model LV10-_3_1,

and vertical float switch, model LV10-_2_1. Please refer to the part

number located on the sensor label to verify the exact model which

you have purchased.

User's Responsibility for Safety:

FLOWLINE manufactures a wide range of liquid level switches

and technologies. While each of these switches are designed to

operate in a wide variety of applications, it is the user's responsibility to select a switch model that is appropriate for the application, install it properly, perform tests of the installed system, and

maintain all components. The failure to do so could result in property damage or serious injury.

Proper Installation and Handling:

Because this is an electrically operated device, only properly

trained staff should install and/or repair this product. Use a proper

sealant with all installations. Never overtighten the sensor within

the fitting, beyond a maximum of 80 inch-pounds torque. Always

check for leaks prior to system start-up.

Material Compatibility:

The LV10 level switch is available in two wetted material versions.

The switch and cable are made of Polypropylene (PP) for the

LV10-1__1. The switch is made of Polyvinylidene Fluoride

(PVDF) and cable is made of Perfluoroalkoxy (PFA) for the LV105__1. Make sure that the switch is compatible with the application

liquids. To determine the chemical compatibility between the sensor and its application liquids, refer to the Compass Corrosion

Guide, available from Compass Publications (858-589-9636).

Temperature and Pressure:

The LV10 series switch is designed for use in application temperatures up to 80 °C, and for use at pressures up to 25 psi (2 bar) @ 25

°C., derated @ 1.667 psi (.113 bar) per °C. above 25 °C.

Wiring and Electrical:

The supply voltage used for the LV10 switch should never exceed

120 volts AC @ 15 VA for the LV10-_3_1 and 120 volts AC @ 50

VA for the LV10-_2_1. For the CE versions, the supply voltage for

the LV10 switch should never exceed 30 Vrms and 42.4 Vpeak or

60 VDC. Electrical wiring of the switch should be performed in

accordance with all applicable national, state, and local codes.

Flammable, Explosive and Hazardous Applications:

The LV10 series switch should not be used within flammable or

explosive applications unless properly connected to a approved

control device. In hazardous applications, use redundant measurement and control points, each having a different sensing technology. Refer to the National Electrical Code (NEC) for all applicable

installation requirements in hazardous locations.

Through Wall Installation:

FLOWLINE’s LV10 switch may be installed through the top wall of

a tank. The sensor has male 3/4" NPT threads and a 3/4" bayonet

adapter on the LV10-_3_1. This enables the user to mount the LV10

using either FLOWLINE's Smart Trak™ or FLOWLINE's Switch

Pak™.

Note: Avoid installing the LV10 in magnetized metal

tanks. Doing so will activate the internal reed switch.

LV10-_3_1 LV10-_3_1

3/4” threads 3/4” bayonet

WARNING

Please observe the difference in wiring and operation between

the LV10-_3_1 and the LV10-_2_1.

Avoid installing the LV10 in tanks in magnetized metal tanks.

Doing so will activate the internal reed switch.

High Level Sensor

Model LV10-_2_1

Switch Pak

LC06

Junction

Box

Low Level Sensor

Model LV10-_3_1

1/2

Coupling

Smart Trak

Page 4

Step Four Step Five

INSTALLATION ELECTRICAL

Orientation:

Mounting orientation must be kept vertical for proper operation. The

vertical buoyancy and float switches are orientated in the vertical

position ±20°.

Voltage:

The input voltage to the LV10 switch should never exceed the maximum voltage rating. FLOWLINE controllers have a built-in 13.5

VDC power supply which provides power to all of FLOWLINE’s

level switches. Alternative controllers and power supplies may also be

used with the LV10 switch.

Cable Length:

Determine the length of cable required between the LV10 series sensor and its point of termination. Allow enough slack to ensure the easy

installation, removal and/or maintenance of the sensor. The cable

length may be extended up to a maximum of 1000 feet, using a wellinsulated, 18 gauge shielded wire.

Wire Stripping:

Using a 10 gauge wire stripper, carefully remove the outer layer of

insulation from the last 1-1/4" of the sensor's cable. Unwrap and discard the exposed foil shield from around the signal wires, leaving the

drain wire attached if desired. With a 20 gauge wire stripper, remove

the last 1/4" of the colored insulation from the signal wires.

Removing Baffle (LV10-_2_1 Only):

The vertical float, model LV10-_2_1, can be installed with out the

protective shield. To do so, remove the shield by twisting it off from

the bayonet adapter. Make sure the C-clip is added to the post to prevent the float from falling off.

Output Selection (LV10-_2_1 Only):

The selection of normally open or normally closed for the

LV10-_2_1 is made by the orientation of the float. The

switch arrives from the factory in the NO position (open circuit when dry). The top of the float is identified by the rough

edges at the end of the float. The smooth end is the bottom

of the float. To change to NC, rotate the float 180°.

+

20

3/4 NPT

FloatShield

C-Clip

?

1"

1/4"

Page 5

Step Six Step Seven

WIRING ORIENTATION

Note: Above wiring is for NO operation (open circuit when switch is dry and closed circuit when

switch is wet). To wire NC (closed circuit when dry

and open circuit when wet), use RED and BLACK

wires for the LV10-_3_1 or reverse the float for the

LV10-_2_1. Use the shield to protect the cable

from electrical noise. Attach to either the Shield

terminal or the ground terminal.

Buoyancy

Buoyancy

Float

Float

All Models:

Wiring to a FLOWLINE Controller

LC10 Series Controller

Vertical Buoyancy Level Switch (LV10-_3_1):

The LV10-_3_1 switch can be wired normally open or normally

closed for your application requirement.

Normally Open:

Use the Black and White wires for operating the LV10-_3_1 in a normally open state. Normally open is defined as the switch being open

when the float is dry and closed when the float becomes submersed.

This operation is typical for indicating a high level.

Normally Closed:

Use the Black and Red wires for operating the LV10-_3_1 in a normally closed state. Normally closed is defined as the switch being

closed when the float is dry and open when the float becomes submersed. This operation is typical for indicating a low level.

LC40 Series Controller

Black

White

Black

Red

White

Power

Supply

Black

White

Power

Supply

Black

Red

Power

Supply

Black

Red

Power

Supply

Black

STANDARD

CONTROLLER

RELAY 1 RELAY 2

POWER

INPUT 1 INPUT 2A INPUT 2B

-

+

-

+

INVERT

DELAY

INVERT

DELAY

LATCH

ON OFF

Black

White

Black

Red

AC

115 VAC

220 VAC

AC

GND

NC

C

NO

DELAY

INVERINVERT +/- +/-

P

R

Input 1A

(+)

(-)

LALATCHTCH

(+)

(-)

B

t 1

u

p

Input 1B

In

Page 6

Step Eight Step Nine

ORIENTATION MAINTENANCE

Vertical Float Level Switch (LV10-_2_1):

The LV10-_2_1 switch can be wired normally open or normally

closed for your application requirement.

Normally Open:

Only use the Black and Red wires with the LV10-_2_1. Orientate the

float upward so that the switch is in the normally open state. Normally

open is defined as the switch being open when the float is dry and

closed when the float becomes submersed. This operation is typical

for indicating a high level.

Normally Closed:

Only use the Black and Red wires with the LV10-_2_1. Orientate the

float downward so that the switch is in the normally closed state.

Normally closed is defined as the switch being closed when the float

is dry and open when the float becomes submersed. This operation is

typical for indicating a low level.

General:

While a filter shroud protects the float from particulate contamination, the switch may need to be cleaned periodically too prevent jamming or sticking. The vertical buoyancy and vertical float has no

scheduled maintenance requirement, except to clean off any deposits

or scaling from the switch as necessary. It is the responsibility of the

user to determine the appropriate maintenance schedule, based on the

specific characteristics of the application liquid.

Cleaning procedure:

1. Power: Make sure that all power to the switch, controller and/or

power supply is completely disconnected.

2. Switch removal:If necessary , make sure that the tank is drained

well below the switch prior to removal. Carefully, remove the sensor from the installation. Remove the outer screen by pushing on

the screen and turning is slightly to disconnect is from the bayonet connector so that the float is exposed.

3. Cleaning the switch:Using a soft bristle brush and mild deter-

gent, carefully wash the switch. Do not use harsh abrasives such

as steel wool or sandpaper, which might damage the surface of the

sensor. Do not use incompatible solvents which may damage the

sensor's PP or PVDF plastic body. Take particular care to remove

any scaling from the float body and make sure that it moves

freely.

4. Sensor installation: Follow the appropriate steps of installa-

tion as outlined in the Installation section of this manual.

Testing the installation:

1. Power:Turn on power to the controller and/or power supply.

2. Immersing the switch: Immerse the sensing tip in its applica-

tion liquid, by filling the tank up to the switches point of actuation. An alternate method of immersing the switch during preliminary testing is to hold a cup filled with application liquid up to

the switch's tip.

3. Test: With the switch being fluctuated between wet and dry

states, the switch indicator light in the controller should turn on

and off. If the controller doesn't have an input indicator, use a voltmeter or ammeter to ensure that the switch produces the correct

signal.

4. Point of actuation: Observe the point at which the rising or

falling fluid level causes the switch to change state, and adjust the

installation of the switch if necessary.

Red

Power

Supply

Black

Red

Power

Supply

Black

Red

Power

Supply

Black

Red

Power

Supply

Black

Loading...

Loading...