FlowLine LU71, LU72, LU73, LU75 Owner's Manual

Warranty, Service & Repair

WARRANTY

Flowline warrants to the original purchaser of its products that such

products will be free from defects in material and workmanship under

normal use and service for a period which is equal to the shorter of

one year from the date of purchase of such products or two years from

the date of manufacture of such products.

This warranty covers only those components of the products which

are non-moving and not subject to normal wear. Moreover, products

which are modified or altered, and electrical cables which are cut to

length during installation are not covered by this warranty.

Flowline’s obligation under this warranty is solely and exclusively

limited to the repair or replacement, at Flowline’s option, of the prod-

ucts (or components thereof) which Flowline’s examination proves to

its satisfaction to be defective. FLOWLINE SHALL HAVE NO

OBLIGATION FOR CONSEQUENTIAL DAMAGES TO PERSON-

AL OR REAL PROPERTY, OR FOR INJURY TO ANYPERSON.

This warranty does not apply to products which have been subject to

electrical or chemical damage due to improper use, accident, negli-

gence, abuse or misuse. Abuse shall be assumed when indicated by

electrical damage to relays, reed switches or other components. The

warranty does not apply to products which are damaged during ship-

ment back to Flowline’s factory or designated service center or are

returned without the original casing on the products. Moreover, this

warranty becomes immediately null and void if anyone other than ser-

vice personnel authorized by Flowline attempts to repair the defective

products.

Products which are thought to be defective must be shipped prepaid

and insured to Flowline’s factory or a designated service center (the

identity and address of which will be provided upon request) within

30 days of the discovery of the defect. Such defective products must

be accompanied by proof of the date of purchase.

Flowline further reserves the right to unilaterally waive this warranty

and to dispose of any product returned to Flowline where:

a. There is evidence of a potentially hazardous material present

with product.

b. The product has remained unclaimed at Flowline for longer than

30 days after dutifully requesting disposition of the product.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND

THE DESCRIPTION ON THE FACE OF THIS WARRANTY. This

warranty and the obligations and liabilities of Flowline under it are

exclusive and instead of, and the original purchaser hereby waives, all

other remedies, warranties, guarantees or liabilities, express or

implied. EXCLUDED FROM THIS WARRANTY IS THE IMPLIED

WARRANTY OF FITNESS OF THE PRODUCTS FOR A PARTIC-

ULAR PURPOSE OR USE AND THE IMPLIED WARRANTY OF

MERCHANT ABILITY OF THE PRODUCTS.

This warranty may not be extended, altered or varied except by a writ-

ten instrument signed by a duly-authorized officer of Flowline, Inc.

To register your product with the manufacturer, go to the Flowline

website for on-line registration. The website address is as follows:

www.flowline.com

On-line Warranty Registration can be found under Contact Us in

the Navigation Bar along the side of the home page.

If for some reason your product must be returned for factory service, contact Flowline Inc. at (562)598-3015 to receive a Material

Return Authorization number (MRA), providing the following

information:

1. Part Number, Serial Number

2. Name and telephone number of someone who can answer

technical questions related to the product and its application.

3. Return Shipping Address

4. Brief Description of the Symptom

5. Brief Description of the Application

Once you have received a Material Return Authorization number,

ship the product prepaid in its original packing to:

Flowline Factory Service

MRA _____

10500 Humbolt Street

Los Alamitos, CA 90720

To avoid delays in processing your repair, write the MRA on the

shipping label. Please include the information about the malfunction with your product. This information enables our service technicians to process your repair order as quickly as possible.

®

EchoSwitch Multi-Point

Ultrasonic Level Switch

Model LU71/72/73/75

Owner’s Manual

Version 2.1.5

© 2004 FLOWLINE Inc.

All rights reserved.

Manual # LU900014 - 0411-LU72M2_1_5

Step One

SPECIFICATIONS

Range: LU75: 2" to 4'

(5 cm to 1.2m)

LU72: 4" to 9.8'

(10 cm to 3m)

LU71: 4" to 16.4'

(10 cm to 5m)

LU73: 8" to 26.2'

(20 cm to 8m)

Repeatability: 0.25" (6 mm)

Adjustability: Over entire range

Hysteresis: LU72/5: 0.5" (1.2 cm)

(single set point)

LU71/3: 1" (2.5 cm)

(single set point)

Beam width: LU72/5: 2" (5 cm) dia.

LU71/3: 3" (7.6 cm) dia.

Dead band: LU75: 2" (5 cm)

LU71/2: 4" (10 cm)

LU73: 8" (20 cm)

LED indication: Power, relay and echo status

Calibration: Target, push button

Memory: Non-volatile

Supply voltage: 50_5: 95-250 VAC

58_5: 12-28 VDC

Consumption: 50_5: 20 watts max.

58_5: 100 mA @ 24 VDC

Contact type: (3) SPDT relays

Contact rating: 60 VA

Contact logic: Single point: alarm

Two point: latching or

out of bounds alarms

Duplex or Alternation:

(Relays 1 and 2 only)

Contact fail-safety: De-energizes during echo signal loss

Process temp.: F: -4° to 140°

C: -20° to 60°

Temp. comp.: Automatic

Electronics temp.: F: -40° to 160°

C: -40° to 71°

Pressure: 30 psi (2 bar) @ 25° C., derated @

1.667 psi (.113 bar) per °C. above

25° C.

Enclosure rating: NEMA 4X (IP65)

Enclosure vent: Water tight membrane

Encl. material: PC/ABS FR

Trans. material: PVDF Kynar®

Process mount: LU72/5: 1" NPT (1" G)

LU71/3: 2" NPT (2" G)

Mount. gasket: Viton®

Conduit entrance: Dual, 1/2" NPT

Classification: General purpose

CE compliance: EN 61326 EMC

(pending) EN 61010 safety

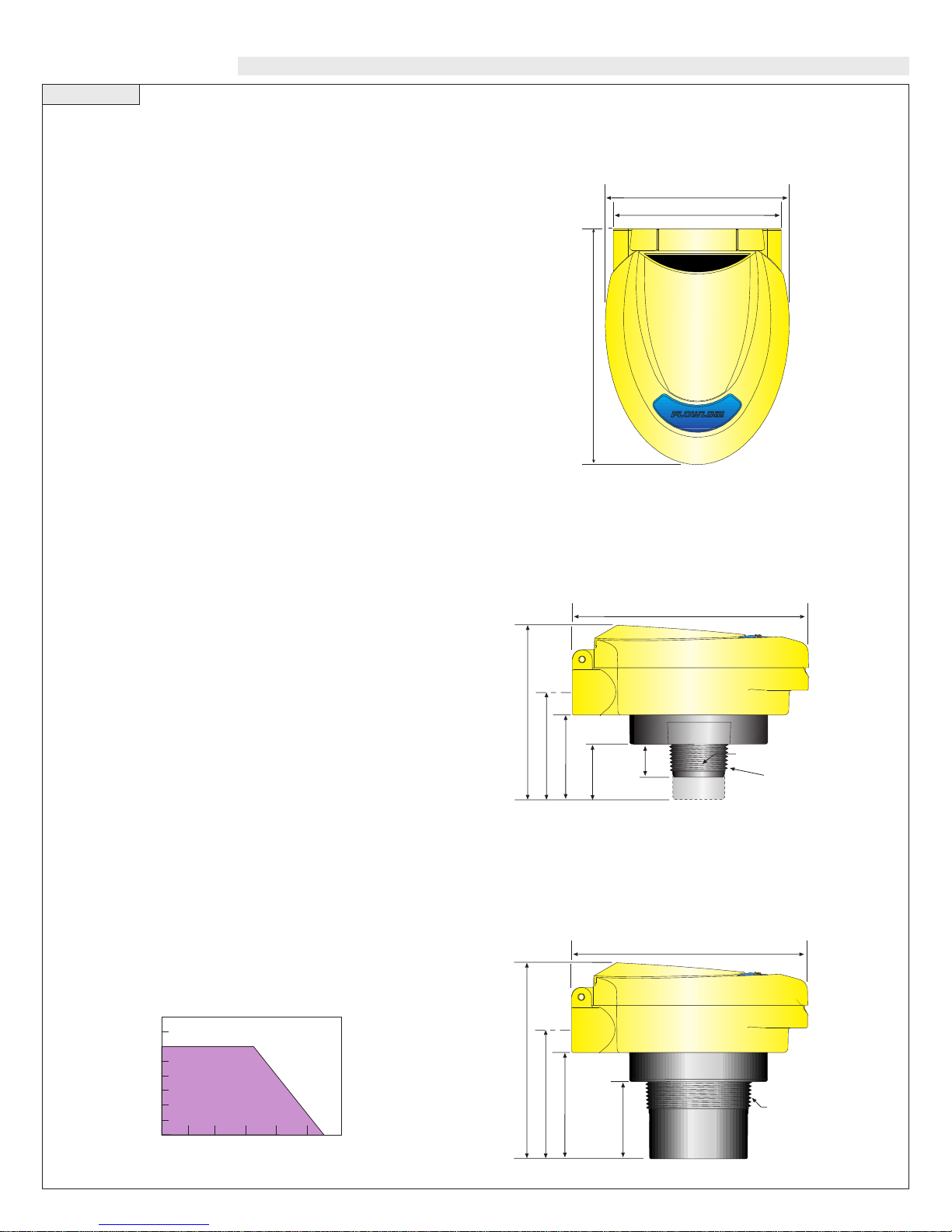

1.2"

(32 mm)

1.9" (49 mm)

3.9" (100 mm)

5.2" (133 mm)

2.4" (62 mm)

1" NPT (1" G)

0.75"

(19 mm)

LU75

LU72

2.5"(63 mm)

4.5" (114 mm)

5.2" (133 mm)

3.0"(76 mm)

2" NPT

(2" G)

1.7"(44 mm)

4.1" (104 mm)

5.2" (133 mm)

3.8" (96 mm)

40

30

20

10

00

-40 -20 00 20 40 60 80

Acceptable

Range

Unacceptable

Range

Temperature/Pressure Derating

Operating Pressure (psi)

Temperature (C¡)

LU71-5_ _5

LU73-5_ _5

Enclosure

Side View

LU75-5 _ _5

LU72-5 _ _5

Enclosure

Side View

LU7_-5 _ _5

Enclosure

Top View

INTRODUCTION TECHNOLOGY

Step Three

A. Application: The general purpose ultrasonic switch provides

non-contact level detection up to 26’ or 8m with 3 relays. Each relay

can be configured on a single set point alarm, two latched set points

for automatic fill or empty, two set points for out of bounds alarms or

three set point (relays 1 and 2 only) alternation / duplexing . The

switch is well suited for a wide range of corrosive, waste and slurry

type media, and is broadly selected for atmospheric day tank, pump

lift station and waste sump applications.

B. Part Number: The part and serial numbers are located on the

wrench flat. Check the part number on the product label and confirm

which of the below model configurations you have purchased:

Part Number

Range Supply Mount

LU75-5005 4’ (1.2m) 95-250 VAC 1” NPT

LU75-5065 4’ (1.2m) 95-250 VAC 1” G

LU75-5805 4’ (1.2m) 12-28 VDC 1” NPT

LU75-5865 4’ (1.2m) 12-28 VDC 1” G

LU72-5005 9.8’ (3m) 95-250 VAC 1” NPT

LU72-5065 9.8’ (3m) 95-250 VAC 1” G

LU72-5805 9.8’ (3m) 12-28 VDC 1” NPT

LU72-5865 9.8’ (3m) 12-28 VDC 1” G

LU71-5005 16.4’ (5m) 95-250 VAC 1” NPT

LU71-5065 16.4’ (5m) 95-250 VAC 1” G

LU71-5805 16.4’ (5m) 12-28 VDC 1” NPT

LU71-5865 16.4’ (5m) 12-28 VDC 1” G

LU73-5005 26.2’ (8m) 95-250 VAC 2” NPT

LU73-5065 26.2’ (8m) 95-250 VAC 2” G

LU73-5805 26.2’ (8m) 12-28 VDC 2” NPT

LU73-5865 26.2’ (8m) 12-28 VDC 2” G

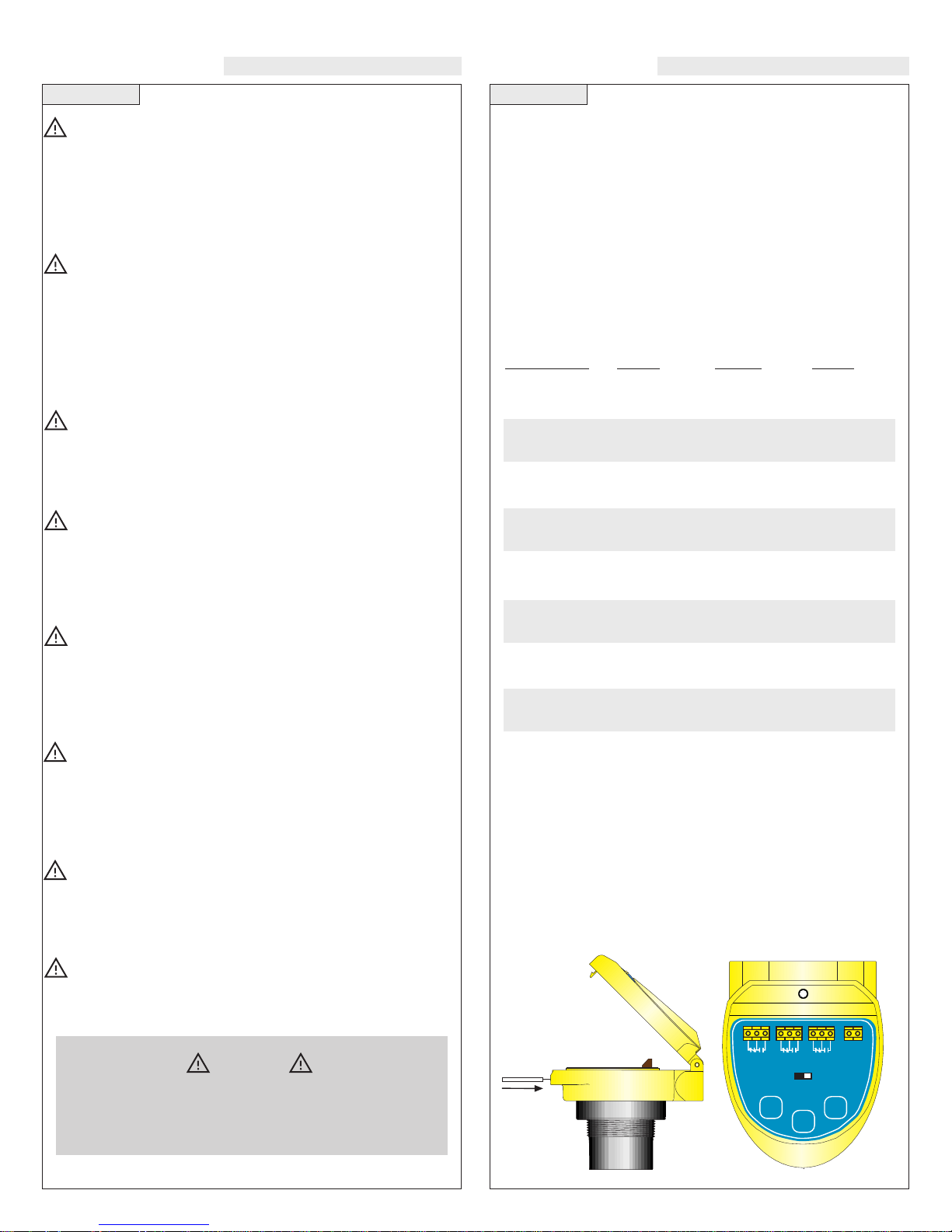

C. NEMA 4X Enclosure: The enclosure has a flip cover with two

1/2” NPT female conduit ports and an internal terminal strip for

wiring. To open the enclosure, you will need a small insertion tool

such as a screwdriver. Insert the tool into the hole located at the

front of the enclosure and gently push on the latching mechanism

to release the cover. Rotate the hinged cover up for 135° access to

the faceplate and terminal strips. Before closing the enclosure,

make sure that the enclosure gasket is properly seated, and

that any conduit fittings, cable connectors or plugs are

installed correctly and sealed.

Step Two

About this Manual: PLEASE READ THE ENTIRE MANU-

AL PRIOR TO INSTALLING OR USING THIS PRODUCT. This

manual includes information on the LU7_-5_ _5 Ultrasonic Level

Switch from FLOWLINE. Please refer to the part number located

on the switch label to verify the exact model configuration which

you have purchased.

User’s Responsibility for Safety: FLOWLINE manufac-

tures a broad range of level sensing technologies. While each of

these sensors is designed to operate in a wide variety of applications, it is the user’s responsibility to select a sensor model that is

appropriate for the application, install it properly, perform tests of

the installed system, and maintain all components. The failure to do

so could result in property damage or serious injury.

Proper Installation and Handling: Only properly trained

staff should install and/or repair this product. Install the switch with

the included Viton gasket and never overtighten the switch within

the fitting. Always check for leaks prior to system start-up.

Wiring and Electrical: A supply voltage of 95-250 VAC is

used to power the LU7_-50 _5 switch, and a supply voltage of 1228 VDC is used to power the LU7_-58_5 switch. Electrical wiring

of the switch should be performed in accordance with all applicable national, state, and local codes.

Material Compatibility: The LU7_-5_ _5 enclosure is made

of a flame retardant Polycarbonate (PC/ABS FR). The transducer is

made of Polyvinylidene Fluoride (PVDF). Make sure that the

model which you have selected is chemically compatible with the

application media.

Enclosure: While the switch housing is liquid-resistant the

LU7_-5 _ _5 is not designed to be operational when immersed. It

should be mounted in such a way that the enclosure and transducer do not come into contact with the application media under normal operational conditions.

Make a Fail-Safe System: Design a fail-safe system that

accommodates the possibility of switch and/or power failure.

FLOWLINE recommends the use of redundant backup systems

and alarms in addition to the primary system.

Flammable, Explosive or Hazardous Applications:

The LU7_-5_ _5 should not be used within classified hazardous

environments.

Warning

Always use the Viton gasket when installing the LU7_-5_ _5

switch, and make sure that all electrical wiring of the switch

is in accordance with applicable codes.

LU7_-5_ _1

Shown

RELAY

1

RELAY2RELAY

3

L

1 L2

POWER

Cal. Run

High Low

Select

EchoSwitch

™

Loading...

Loading...