FlowLine LP10 Series Owner's Manual

Warranty Service and Repair ®

To register your product with the manufacturer, fill out the enclosed

warranty card and return it immediately to:

Flowline Inc.

10500 Humbolt Street

Los Alamitos, CA 90720

If for some reason your product must be returned for factory service,

contact your Flowline distributor to receive a material return authorization number first, and provide them with the following information:

1.Part number, serial number

2.Name and telephone number of someone who can answer

questions related to the product and its application

3.Return shipping address

4.Brief description of the symptom

5.Brief description of the application

Intrusive RF Capacitance Level Switch

LP10 Series Owner’s Manual

Provided by:

www.KTHSales.com

Once you have received a return authorization number, ship the

product prepaid in its original packing to:

Flowline Factory Service

10500 Humbolt Street

Los Alamitos, CA 90720

Please include any related symptom and application information with

your product. This information enables our service technicians to

process your repair order as quickly as possible.

WARRANTY

Flowline warrants to the original purchaser of its products that such products will be free from defects in material and workmanship under normal use and service for a period which is equal to the shorter of one year

from the date of purchase of such products or two years from the date of

manufacture of such products.

This warranty covers only those components of the products which are

non-moving and not subject to normal wear. Moreover, products which

are modified or altered, and electrical cables which are cut to length

during installation are not covered by this warranty.

Flowline’s obligation under this warranty is solely and exclusively limited to the repair or replacement, at Flowline’s option, of the products

(or components thereof) which Flowline’s examination proves to its satisfaction to be defective. FLOWLINE SHALL HAVE NO OBLIGATION FOR CONSEQUENTIAL DAMAGES TO PERSONAL OR

REAL PROPERTY, OR FOR INJURY TO ANY PERSON.

This warranty does not apply to products which have been subject to

electrical or chemical damage due to improper use, accident, negligence,

abuse or misuse. Abuse shall be assumed when indicated by electrical

damage to relays, reed switches or other components. The warranty does

not apply to products which are damaged during shipment back to

Flowline’s factory or designated service center or are returned without

the original casing on the products. Moreover, this warranty becomes

immediately null and void if anyone other than service personnel authorized by Flowline attempts to repair the defective products.

®

NRTL/C

Version 3.0A

1998 Flowline Inc.

All rights reserved.

Part # LP900001 8/98

Products which are thought to be defective must be shipped prepaid and

insured to Flowline’s factory or a designated service center (the identity

and address of which will be provided upon request) within 30 days of

the discovery of the defect. Such defective products must be accompanied by proof of the date of purchase.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE OF THIS WARRANTY. This warranty

and the obligations and liabilities of Flowline under it are exclusive and

instead of, and the original purchaser hereby waives, all other remedies,

warranties, guarantees or liabilities, express or implied. EXCLUDED

FROM THIS WARRANTY IS THE IMPLIED WARRANTY OF FITNESS OF THE PRODUCTS FOR A PARTICULAR PURPOSE OR USE

AND THE IMPLIED WARRANTY OF MERCHANT ABILITY OF

THE PRODUCTS.

This warranty may not be extended, altered or varied except by a written

instrument signed by a duly-authorized officer of Flowline, Inc.

If FLOWLINE level transmitters or switches are used for process control

where failure of the transmitter or switch could result in personal injury

or property damage, an independent means such as a redundant FLOWLINE point level switch should be used. Where FLOWLINE level transmitters or switches are used as a part of a pressure vessel or pipe, care

should be taken to independently protect against personal injury or property damage should the FLOWLINE sensor fail or be mishandled. Contact FLOWLINE or your local distributor for additional information.

SPECIFICATIONS

Step One

Accuracy: ±1 mm in water

Repeatability: ± .5 mm in water

Dielectric range: > 20 constants

Conductive range: > 100 micromhos

Supply voltage: 12 - 36 VDC

Consumption: Relay: 25 mA

Relay rating: 60 VDC/VAC @ 1A

FET rating: 36 VDC max. @ 100 mA max.

Switch output: Selectable NO or NC

Temperature range: F: -40° to 194°

Pressure range: 150 psi (10 bar) @ 25 °C., derated @ 1.667

Sensor material:

Sensor rating: NEMA 6 (IP68)

Mounting threads: Short: 3/4" NPT (3/4" BSP)

Mounting gasket: Viton (3/4"), metric only

Cable type: 8 ft. (2.5 m), 4-wire (relay) or 3-wire (FET),

CSA approval: Class I, Groups A, B, C & D;

CSA entity parameters: V

Certificate number: LR 79326-4

CE compliance: EN 50082-2 immunity

LP10 - _ _ _ _

Sensor Material

1 - PP

2 - PFA

Sensor Length

3 - Short

4 - Long

Mounting Thread

0 - 3/4" NPT

2 - 3/4" G

Switch Output

0 - Intrinsically Safe

2 - FET, N-Channel

3 - FET, P-Channel

5 - Relay

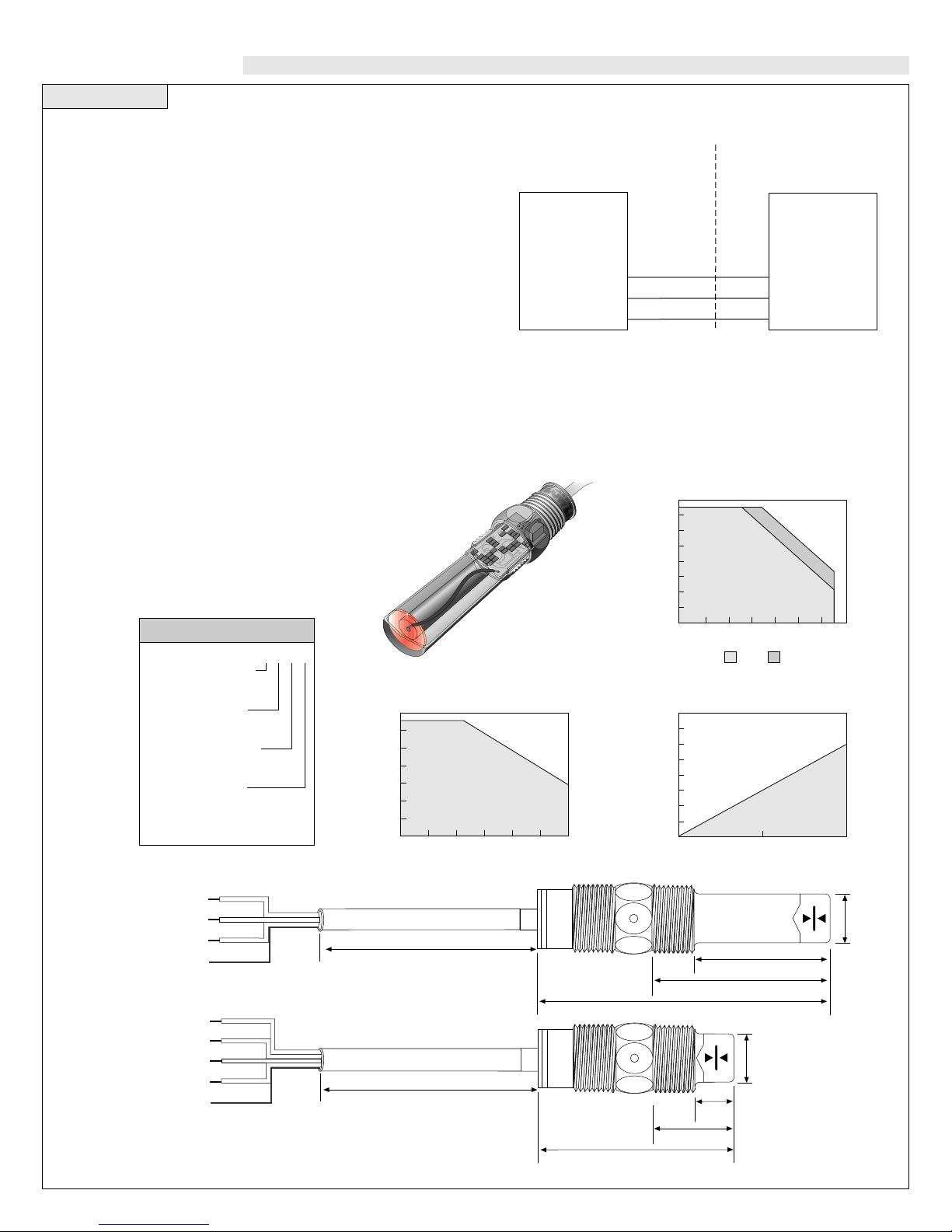

Dimensions

FET: 5mA, ± 1mA (dry)

19 mA, ± 1mA (wet)

C: -40° to 90°

psi (0.113 bar) per °C. above 25 °C.

Polypropylene (PP) or Perfluoroalkoxy (PFA)

Long: 3/4" NPT (3/4" G)

22 gauge with shield & PP or PFA jacket

Class II, Groups E, F & F; Class III

= 32 VDC

max

I

= 0.5 A

max

C

= 0 µF

i

L

= 0 mH

i

EN 55011 emission

Capacitance Switch

Maximum Temperature / Voltage Derating

100

80

60

40

20

00

-20

-40

Ambient Sensor Temperature (°C)

Intrinsically Safe Control Drawing

NON-HAZARDOUS LOCATION

Associated

Equipement

(see notes 2 and 5)

Notes:

LP50 series sensor suitable for Class I, Groups A, B, C, and

1.

D locations only.

CSA certified associated equipment with entity parameters.

2.

Vmax ≥ Voc, Imax ≥ Isc, Ci + Ccable ≤ Ca, Li + Lcable ≤ La.

3.

Installation should be in accordance with CEC Part I, or

4.

NFPA 70.

Associated equipment must be installed per manufacturers

5.

instructions

Continuous 20 mA Sinking Curve

Unacceptable

Range

Acceptable

Range

12 16 20 24 28 32 36

Operating Voltage (VDC)

HAZARDOUS LOCATION

Class I, Groups A,B, C, and D

Class II, Groups E, F, and G

Red Wire

Black Wire

Shield

Sensor Drawing: LSD1

Rev. A 7-21-95

Temperature / Pressure Derating

160

140

120

100

80

60

40

20

Operating Pressure (psi)

00

1,600

1,400

1,200

1,000

800

600

400

200

0

Max. Series Resistance (Ohms)

Acceptable

Range

-40 -20 00 20 40 60 80 100

12 24 36

Temperature (°C)

PP PFA

4-20 mA Sensor

Electrical Loading Limits

Unacceptable

Range

Supply Voltage (VDC)

Class III, (see note 1)

Sensor Models

LP10

LP50

LU10

LO10

Entity Parameters

V

max = 32V

Imax = 0.5A

Ci ≈ 0

Li ≈ 0

Unacceptable

Range

Acceptable

Range

(+)

(-)

FET

FET

Black

White

Wiring

Red

shld

Relay

Wiring

Red

Black

White

Green

(+)

(-)

NO/NC

COM

shld

8' Cable (2.5 m)

8' Cable

(2.5 m)

3.0"

4.5" (114 mm)

(76 mm)

1.3"

2.8" (70 mm)

0.7"

(19 mm)

(32 mm)

2.1" (54 mm)

0.7"

(19 mm)

0.7"

(19 mm)

*All dimensions

are nominal

Loading...

Loading...