Page 1

Commander

LI90 Series

Controller

User Manual

Flowline Inc.

10500 Humbolt Street

Los Alamitos, CA 90720

Tel: (562) 598-3015

Fax: (562) 431-8507

www.flowline.com

27 AUG 08 PRELIMINARY MANUAL 1 of 57

Rev 1_3 Commander LI90 Series

Page 2

2 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 3

Preface

This manual explains how to use the Commander LI90 series controller.

Warranty, Service & Repair

To register your product with the manufacturer, go to the Flowline website for on-line

registration. The website address is as follows:

www.flowline.com

On-line Warranty Registration can be found under Contact Us in the Navigation Bar along the

side of the home page.

If for some reason your product must be returned for factory service, go to the Flowline website

to receive a Material Return Authorization number (MRA), providing the following information:

1. Part Number, Serial Number

2. Name and telephone number of someone who can answer technical questions related

to the product and its application.

3. Return Shipping Address

4. Brief Description of the Symptom

5. Brief Description of the Application

On-line Material Return Authorization can be found under Contact Us in the Navigation Bar

along the side of the home page. Click on Return Authorization to begin the MRA request. Once

you have received a M RA number, ship the product prepaid in its original packing to:

Flowline Factory Service

MRA_____

10500 Humbolt Street

Los Alamitos, CA 90720

To avoid delays in processing your repair, write the MRA on the shipping label. Please include

the information about the malfunction with your product. This information enables our service

technicians to process your repair order as quickly as possible.

27 AUG 08 PRELIMINARY MANUAL 3 of 57

Rev 1_3 Commander LI90 Series

Page 4

Warranty

Flowline warrants to the original purchaser of its products that such products will be free from

defects in material and workmanship under normal use and service for a period which is equal to

the shorter of one year from the date of purchase of such products or two years from the date of

manufacture of such products.

This warranty covers only those components of the products which hare non-moving and not

subject to normal wear. Moreover, products which are modified or altered, and electrical cables

which are cut to length during installation are not covered by this warranty.

Flowline’s obligation under this warranty is solely and exclusively limited to the repair or

replacement, at Flowline’s option, of the products (or components thereof) which Flowline’s

examination proves to its satisfaction to be defective. FLOWLINE SHALL HAVE NO

OBLIGATION FOR CONSEQUENTIAL DAMAGES TO PERSONAL OR REAL

PROPERTY, OR FOR INJURY TO ANY PERSON.

This warranty does not apply to products which have been subject to electrical or chemical

damage due to improper use, accident, negligence, abuse or misuse. Abuse shall be assumed

when indicated by electrical damage to relays, reed switches or other components. The warranty

does not apply to products which are damaged during shipment back to Flowline’s factory or

designated service center or are returned without the original casing on the products. Moreover,

this warranty becomes immediately null and void if anyone other than service personnel

authorized by Flowline attempts to repair the defective products.

Products which are thought to be defective must be shipped prepaid and insured to Flowline’s

factory or a designated service center (the identity and address of which will be provided upon

request) within 30 days of the discovery of the defect. Such defective products must be

accompanied by proof of the date of purchase.

Flowline further reserves the right to unilaterally waive this warranty and to dispose of any

product returned to Flowline where:

a. There is evidence of a potentially hazardous material present with product.

b. The product has remained unclaimed at Flowline for longer than 30 days after dutifully

requesting disposition of the product.

THERE ARE NO WARRANTIES WHICH EXTEND BEYONDTHE DESCRIPTION ON THE

FACE OF THIS WARRANTY. This warranty and the obligations and liabilities of Flowline

under it are exclusive and instead of, and the original purchaser hereby waives, all other

remedies, warranties, guarantees or liabilities, express or implied. EXCLUDED FROM THIS

WARRANTY IS THE IMPLIED WARRANTY OF FITNESS OF THE PRODUCTS FOR A

PARTICULAR PURPOSE OR USE AND THE IMPLIED WARRANTY OF

MERCHANTABILITY OF THE PRODUCTS.

This warranty may not be extended, altered or varied except by a written instrument signed by a

duly-authorized officer of Flowline, Inc.

4 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 5

Table of Contents

Safety Warnings and Guidelines ..........................................................................................6

Introduction ..........................................................................................................................7

Installation............................................................................................................................9

Panel Mounting ........................................................................................................9

DIN Rail Mounting ................................................................................................10

Dimensions ........................................................................................................................11

Electrical ............................................................................................................................12

Wiring ................................................................................................................................13

Configuration .....................................................................................................................14

Specifications .....................................................................................................................15

Startup ................................................................................................................................16

Common Information.........................................................................................................19

Analog (Scaled Input) ............................................................................................19

Analog (Fixed Input)..............................................................................................20

Application #1 ....................................................................................................................21

Overview ................................................................................................................21

General (Open Functions) ......................................................................................22

General (Secured Functions) ..................................................................................24

Configuration of Inputs ..............................................................................25

Configuration of Outputs ...........................................................................27

Application #2 ....................................................................................................................29

Overview ................................................................................................................29

General (Open Functions) ......................................................................................30

General (Secured Functions) ..................................................................................32

Configuration of Inputs ..............................................................................33

Configuration of Outputs ...........................................................................35

Application #3 ....................................................................................................................38

Overview ................................................................................................................38

General (Open Functions) ......................................................................................39

General (Secured Functions) ..................................................................................40

Configuration of Inputs ..............................................................................41

Volume ...........................................................................................43

Configuration of Outputs ...........................................................................46

Appendix ............................................................................................................................51

Simulation mode ....................................................................................................51

Factory Reset .........................................................................................................53

Changing Applications...........................................................................................54

Removable Media for Data Transfer .....................................................................55

Micro SD Cards .........................................................................................55

Micro SD File System ................................................................................55

Using Removable Media to Log Data .......................................................56

27 AUG 08 PRELIMINARY MANUAL 5 of 57

Rev 1_3 Commander LI90 Series

Page 6

Safety Warnings and Guidelines

When found on the product, the following symbols specify:

Warning: Consult user documentation. Warning: Electrical Shock Hazard.

WARNING: To avoid the risk of electric shock or burns, always connect the safety (or

earth) ground before making any other connections.

WARNING: To reduce the risk of fire, electrical shock, or physical injury it is strongly

recommended to fuse the voltage measurement inputs. Be sure to locate fuses as close to

the source as possible.

WARNING: Replace fuse with the same type and rating to provide protection against risk

of fire and shock hazards.

WARNING: In the event of repeated failure, do not replace the fuse again as a repeated

failure indicates a defective condition that will not clear by replacing the fuse.

WARNING: Only qualified electrical personnel familiar with the construction and

operation of this equipment and the hazards involved should install, adjust, operate, or

service this equipment. Read and understand this manual and other applicable manuals in

their entirety before proceeding. Failure to observe this precaution could result in severe

bodily injury or loss of life.

• All applicable codes and standards need to be followed in the installation of this product.

• For I/O wiring (discrete), use the following wire type or equivalent: Belden 9918, 18

AWG or larger.

Adhere to the following safety precautions whenever any type of connection is made to the

module.

• Connect the green safety (earth) ground first before making any other connections.

• When connecting to electric circuits or pulse-initiating equipment, open their related

breakers. Do not

• Make connections to the module first; then connect to the circuit to be monitored.

• Route power wires in a safe manner in accordance with good practice and local codes.

• Wear proper personal protective equipment including safety glasses and insulated gloves

when making connections to power circuits.

• Ensure hands, shoes, and floors are dry before making any connection to a power line.

• Make sure the unit is turned OFF before making connection to terminals. Make sure all

circuits are de-energized before making connections.

• Before each use, inspect all cables for breaks or cracks in the insulation. Replace

immediately if defective.

make connections to live power lines.

6 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 7

Introduction

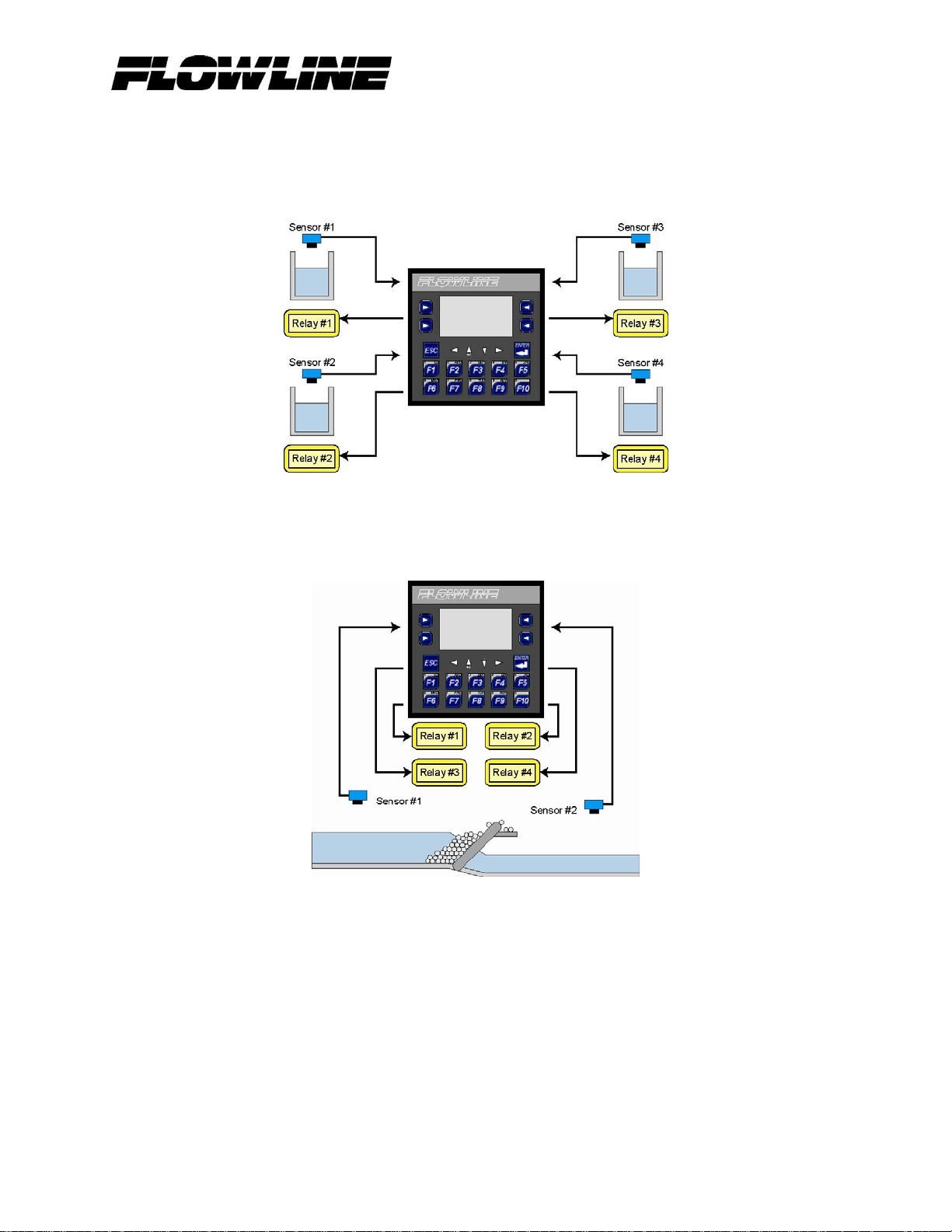

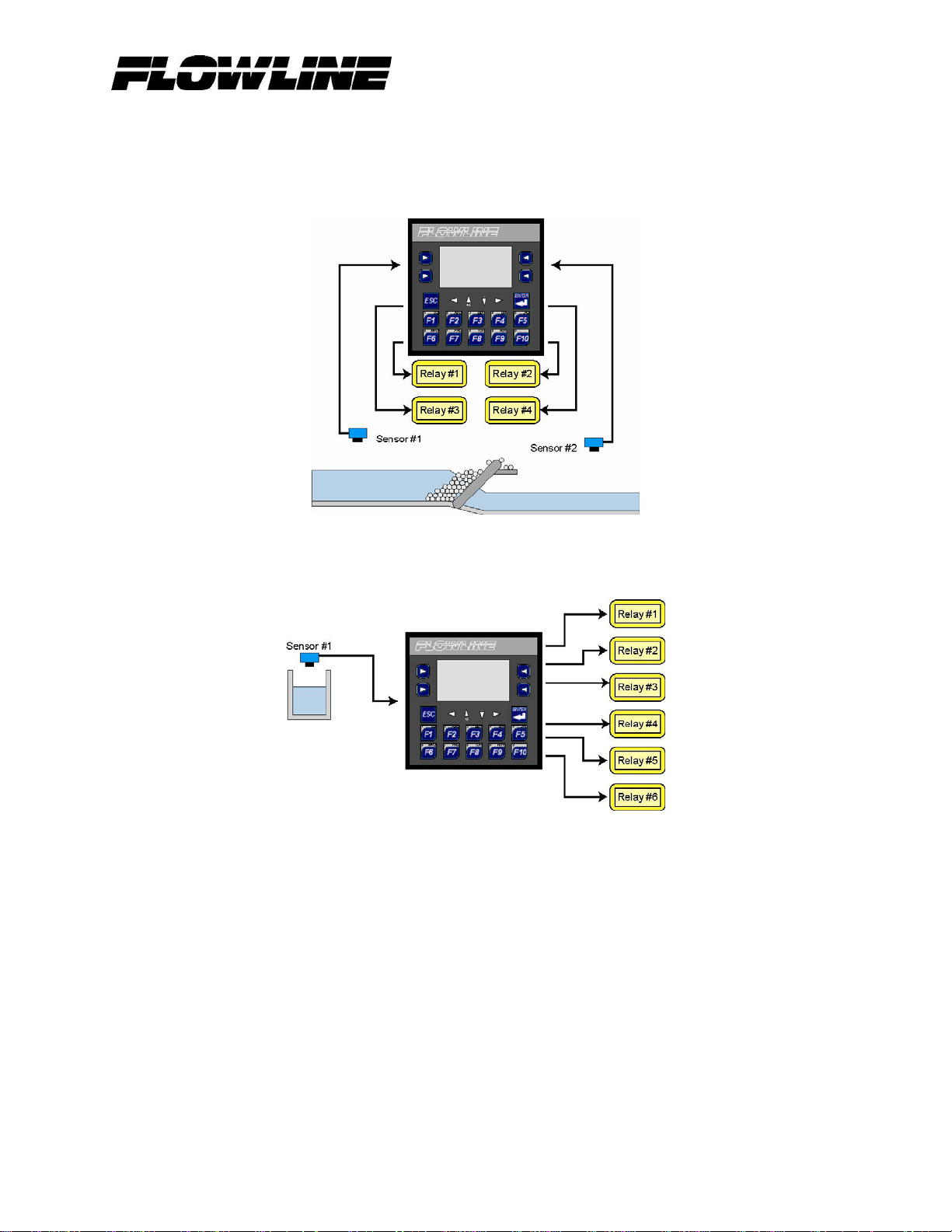

The Commander Series has three unique application configurations. The choice of application is

field selectable. The three configurations are:

• Multi-Tank Display (Application #1) – Commander will accept up to Four 4-20 mA input

transmitters and will provide a 3A SPST relay output for each input.

• Differential Level Controller (Application #2) – Commander will monitor the levels

above and below a rake and control a relay based upon the defined differential between

the two levels. In addition, a differential alarm can be programmed as well as individual

alarms for each input.

27 AUG 08 PRELIMINARY MANUAL 7 of 57

Rev 1_3 Commander LI90 Series

Page 8

• Pump Controller (Application #3) – Commander will accept a single 4-20 mA input

transmitter and will provide up to Six 3A SPST relay outputs.

8 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 9

Installation

• Overview

o The mechanical installation greatly affects the operation, safety and appearance of the

system. Information is provided to mechanically install the unit such as cut out sizes,

mounting procedures and other recommendations for the proper mechanical

installation of the unit.

• Components

o Commander Series display

o Terminal Strips

Power (3-pin black)

Inputs (15-pin Orange)

Outputs (15-Pin Black)

Optional Interface (5-pin Orange)

o Mounting Clips (set of four)

Quick Start Guide

• Mounting requirements

o Commander series can be mounted through a panel or on a DIN rail.

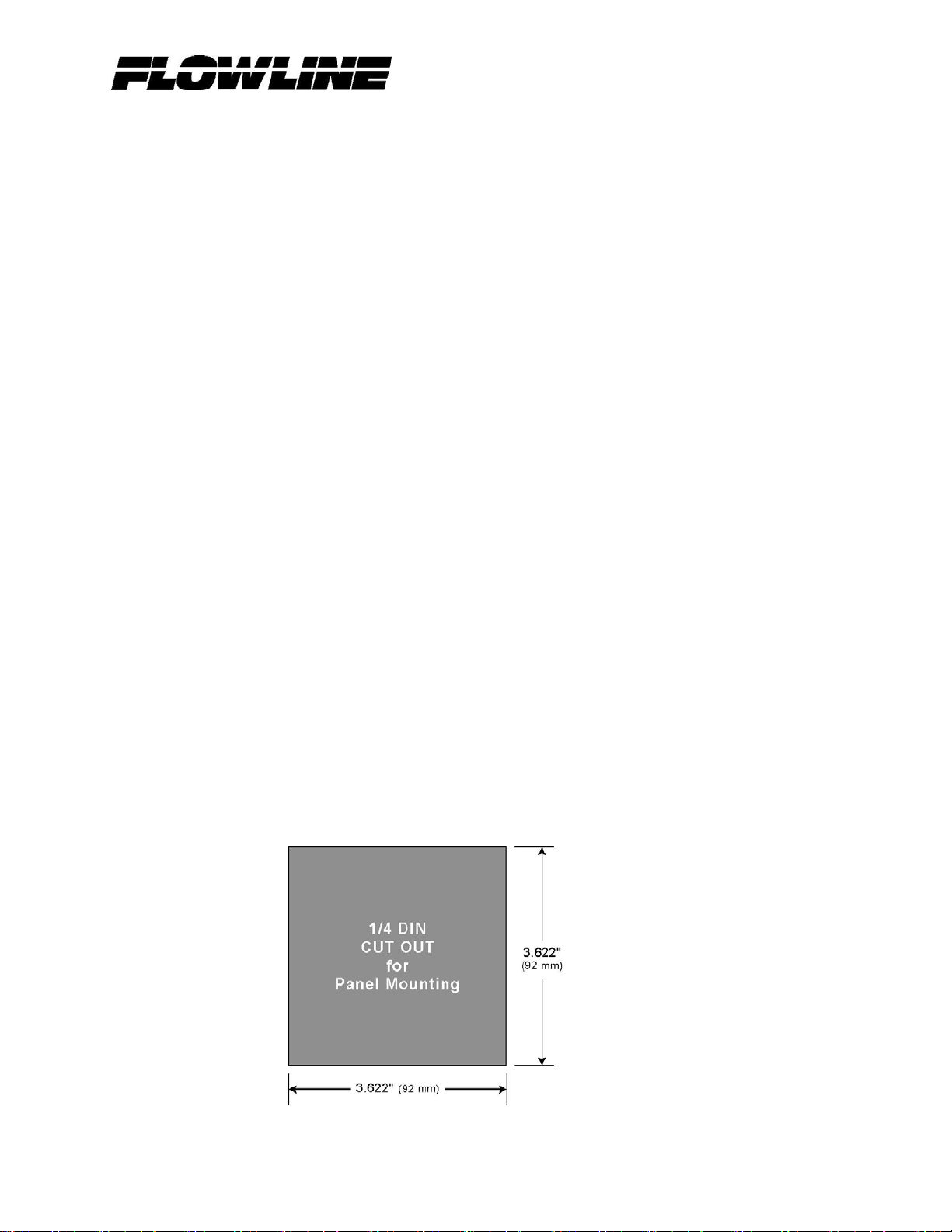

• Panel Mounting

o Once the panel design has been completed using the criteria and suggestions in the

following sections, use the following steps to panel mount the LI90 series.

Remove all connectors from the unit.

Press the DIN rail clip up to make passing the unit through the cutout easier.

Make sure the gasket is installed on the LI90 series and is free from dust and

debris. Check that the corners of the gasket are secure.

Pass the unit through the panel.

Insert the each of the four (4) mounting clips into the slots in the

Commander’s case. One clip should be installed on each corner. Lightly

tighten each screw so the clip is held in place.

Tighten the screws on the clips such that the gasket is compressed against the

panel.

o For panel mount, use the standard cutout for a ¼ DIN [3.622” (92 mm) x 3.622” (92

mm)]. Use the four mounting clips to secure the display to the panel. A mounting

clip will attach to all four sides of the display.

Not to Scale

27 AUG 08 PRELIMINARY MANUAL 9 of 57

Rev 1_3 Commander LI90 Series

Page 10

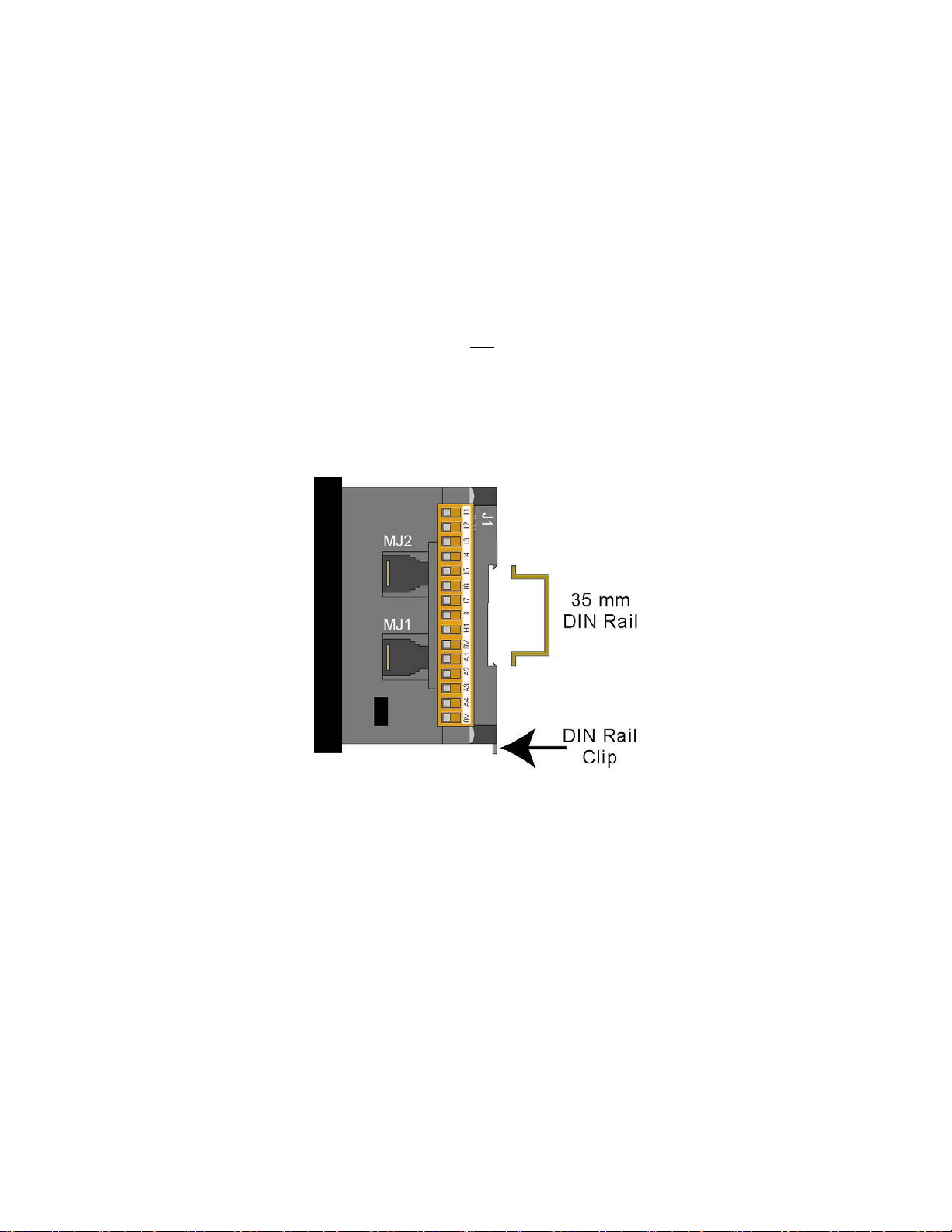

• DIN Rail Mounting

o The LI90 series is designed to clip onto standard 35 millimeter DIN rail. If your

installation requires liquid or dust protection, make sure the controller is placed in an

appropriate sealed panel when mounting on DIN rail. Use the following steps to

mount on DIN rail.

Move the DIN rail clip to the lower position.

Clip the “Top Clips” on the top of the DIN rail.

Press the unit into place and press the DIN rail clip up. A small flat-head

screwdriver can be used in the slot of the DIN rail clip if clearance is an issue.

o Note: The DIN rail connection does not

o For DIN rail, use a 35 mm DIN Rail.

Move the DIN rail clip to the lower position.

Clip the “Top Clips” on the top of the DIN rail.

Press the unit into place and press the DIN rail clip up. A small flat-head

screwdriver can be used in the slot of the DIN rail clip if clearance is an issue.

provide an earth ground.

10 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 11

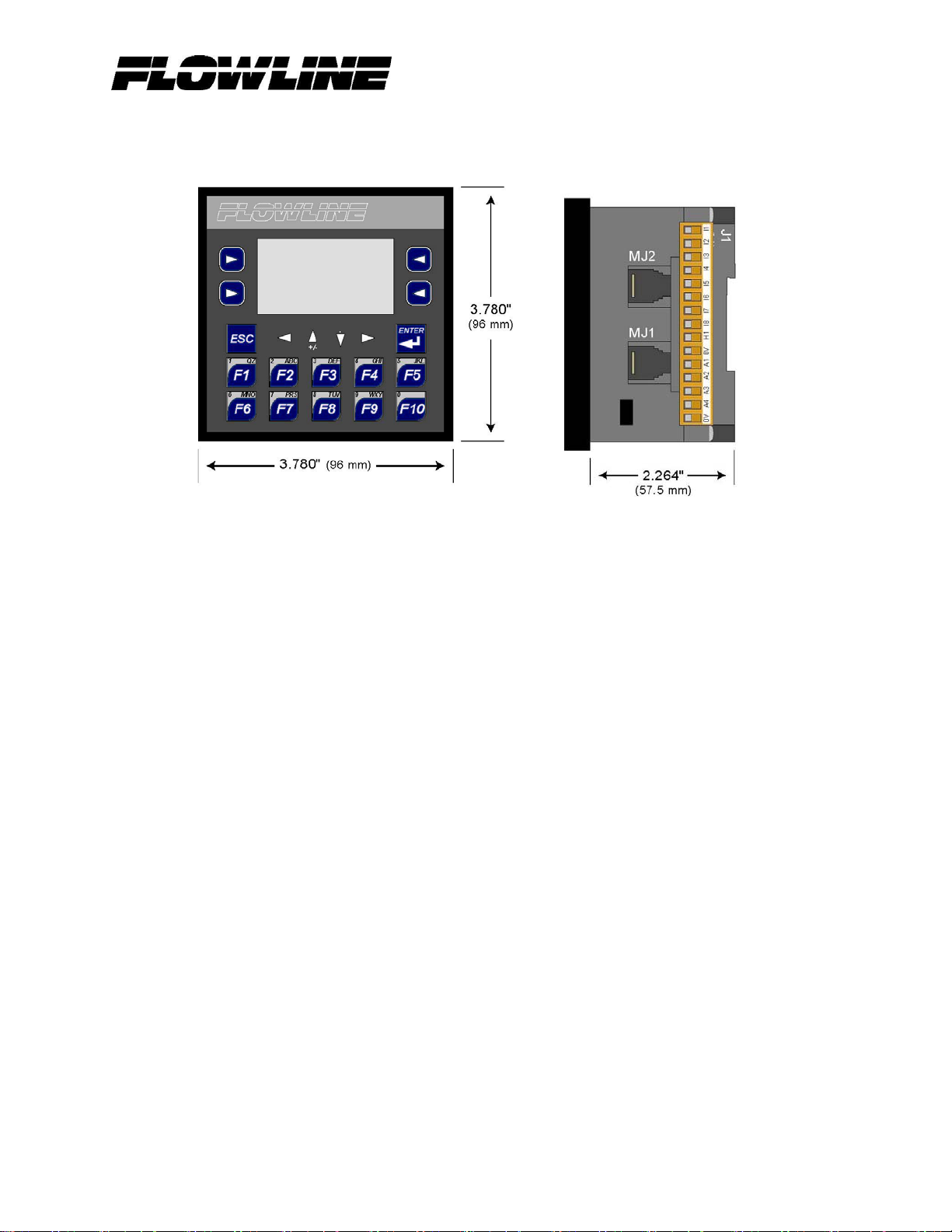

• Dimensions

Front View Side View

• Temperature / Ventilation

o Ensure that the panel layout design allows for adequate ventilation and maintains the

specified ambient temperature range. Consider the impact on the design of the panel

layout if operating at the extreme ends of the ambient temperature range. For

example, if it is determined that a cooling device is required, allow adequate space

and clearances for the device in the panel box or on the panel door.

• Orientation

o When panel-mounted, there are no orientation restrictions on the LI90 series.

• Noise

o Consider the impact on the panel layout design and clearance requirements if noise

suppression devices are needed. Be sure to maintain an adequate distance between

the controller and noisy devices such as relays, motor starters, etc.

• Shock and Vibration

o The LI90 series has been designed to operate in typical industrial environments that

may inflict some shock and vibration on the unit. For applications that may inflict

excessive shock and vibration please use proper dampening techniques or relocate the

Commander to a location that minimizes shock and/or vibration.

27 AUG 08 PRELIMINARY MANUAL 11 of 57

Rev 1_3 Commander LI90 Series

Page 12

Electrical

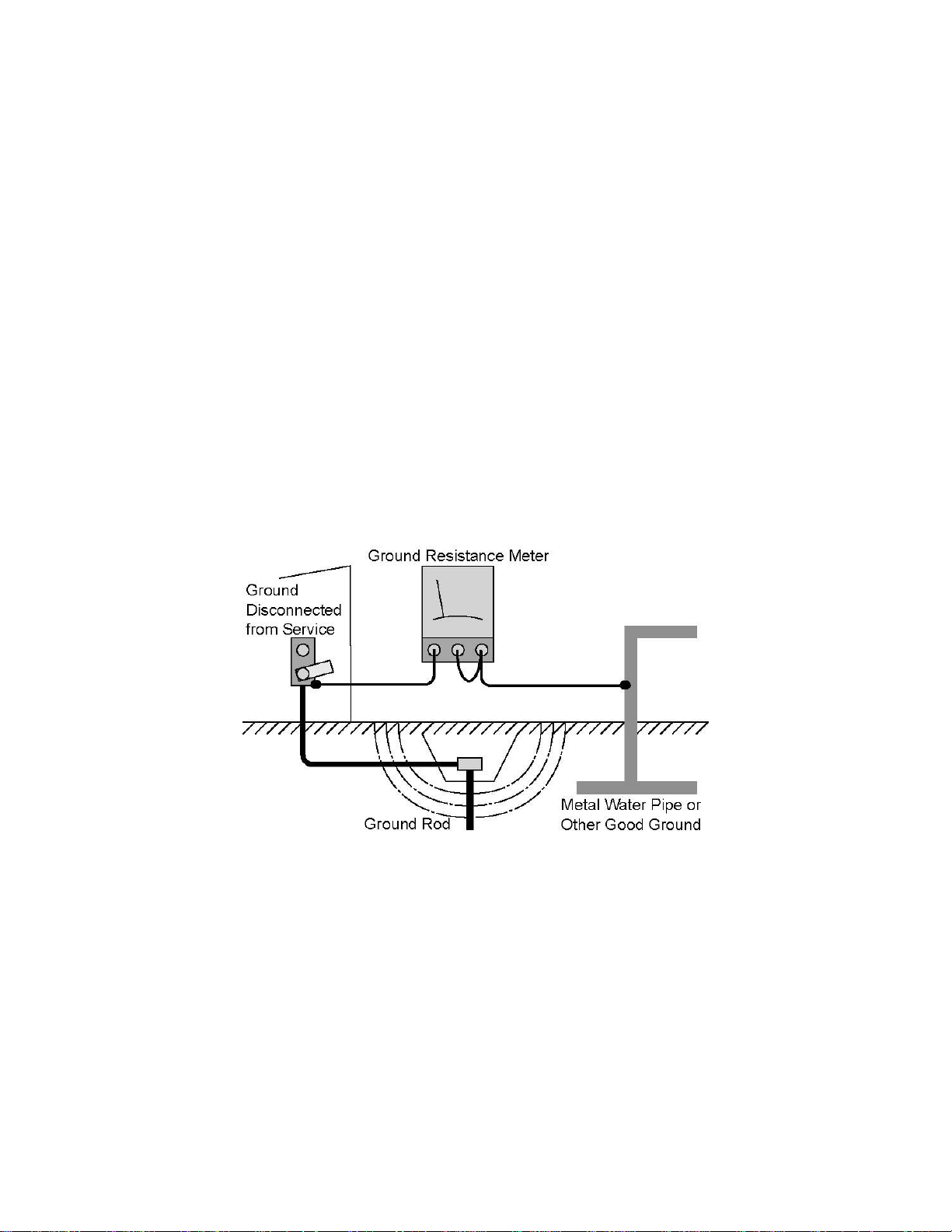

• Grounding Definition

o Ground: The term Ground is defined as a conductive connection between a

circuit or piece of equipment and the earth. Grounds are fundamentally used to

protect an application from harmful interference causing either physical damage

such as by lightning or voltage transients or from circuit disruption often caused

by radio frequency interference (RFI).

• Ground Specifications

o Ideally, a ground resistance measurement from equipment to earth ground is 0 ohms.

In reality it typically is higher. The U.S. National Electrical Code (NEC) states the

resistance to ground shall not exceed 25 ohms. Flowline recommends less than 15

ohms resistance from our equipment to ground. Resistance greater than 25 ohms can

cause undesirable or harmful interference to the device.

• How to Test for Good Ground

o In order to test ground resistance, a Ground Resistance Tester must be used. A

typical Ground Resistance Meter Kit contains a meter, two or three wire leads,

and two ground rods. Instructions are supplied for either a two-point or threepoint ground test. Below shows a two-point ground connection test.

12 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 13

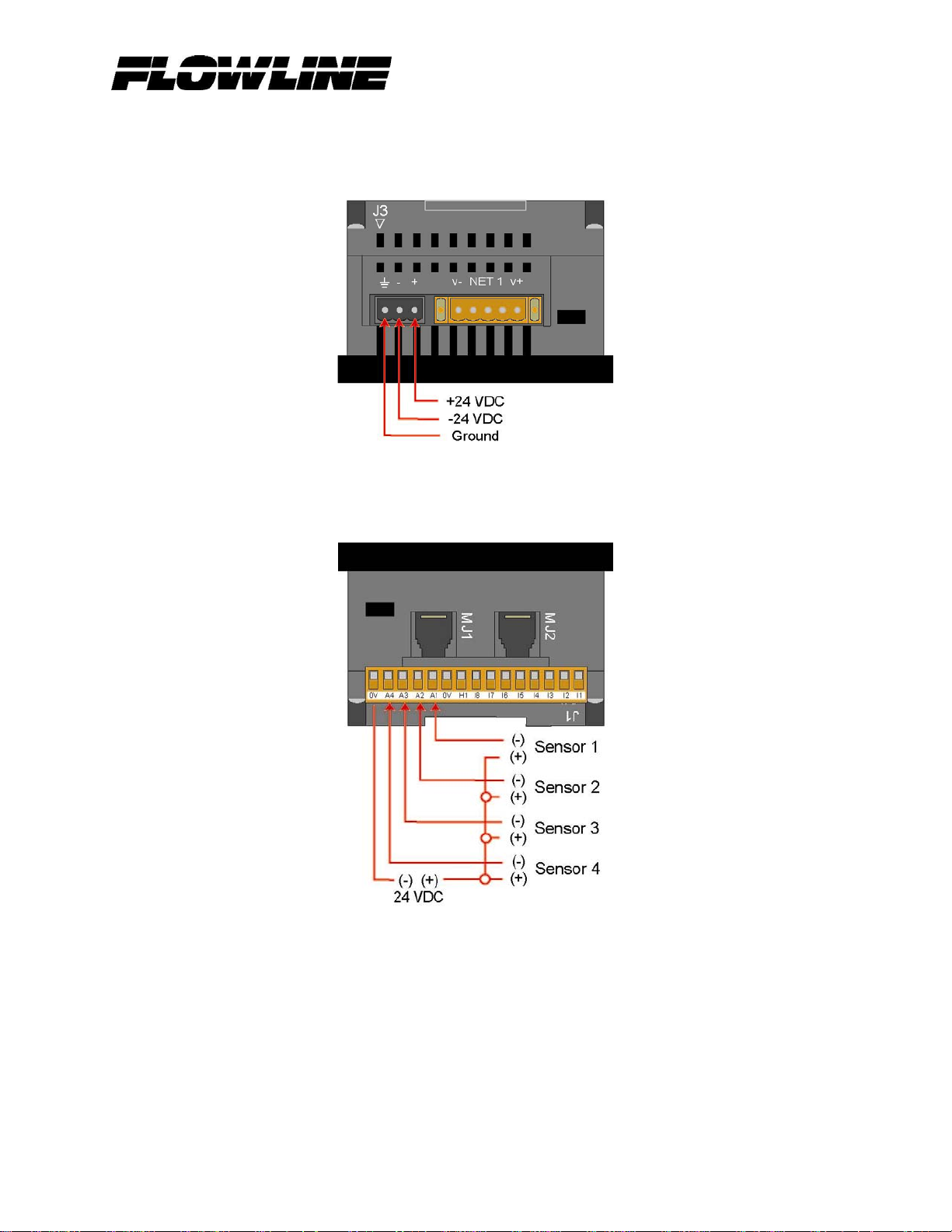

• Wiring

o Power

o Inputs

• Connect to Earth Ground. Apply 10 - 30 VDC.

• Commander can connect up to four 4-20 mA inputs.

27 AUG 08 PRELIMINARY MANUAL 13 of 57

Rev 1_3 Commander LI90 Series

Page 14

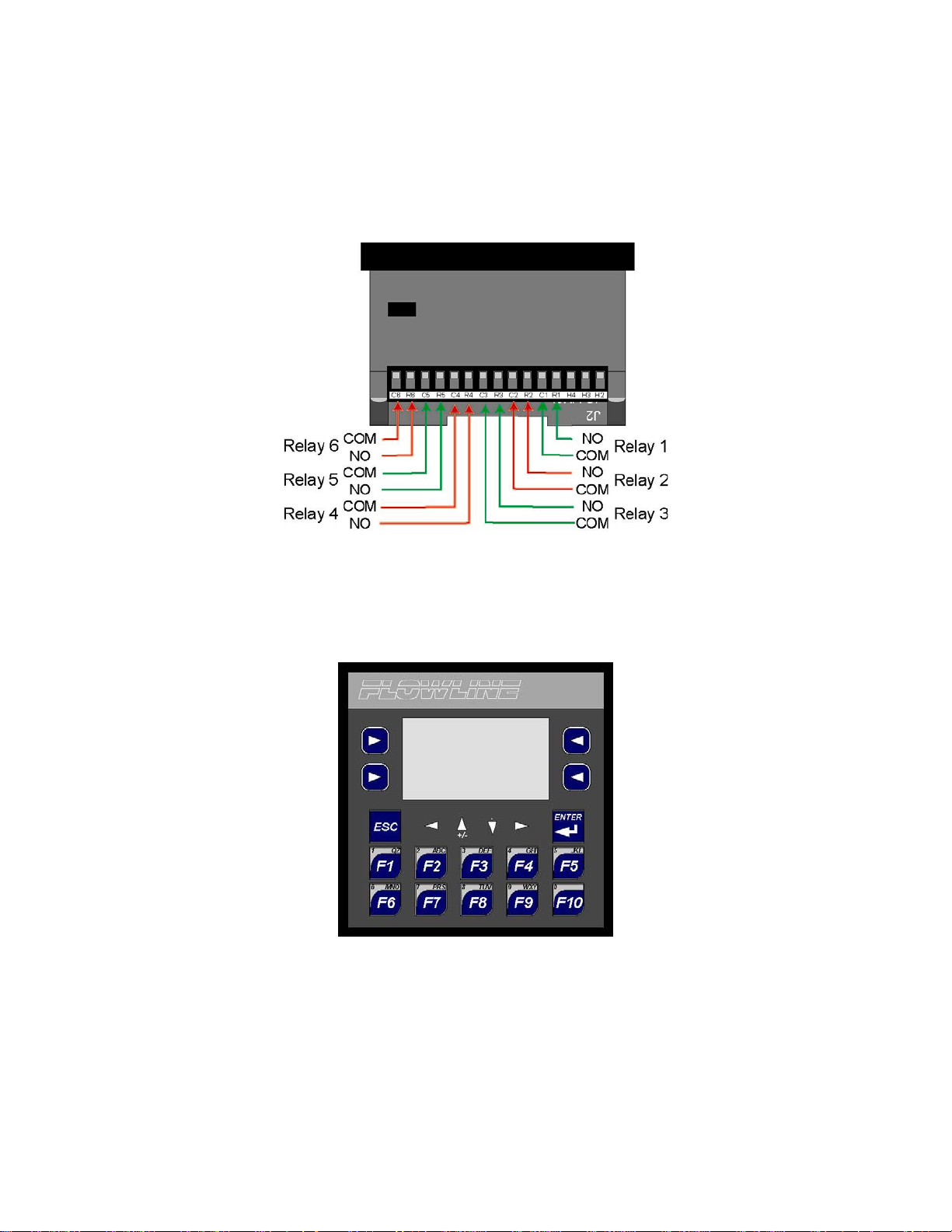

o Outputs

• Commander can connect up to 6 relays, depending on the application

selection.

• Relays can switch voltages up to 275 VAC, 30 VDC with a maximum

output current of 3 A at 250 VAC, resistive.

Configuration

• Commander Series is configured via the Human Machine Interface (HMI) located on the

front cover of the controller

14 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 15

Specifications

Display

Keypad Touch screen

Controller

General Specs

Analog Inputs

Relay Outputs

Graphics/Text: Yes / Yes

Pixels: 128 x 64

Display Technology: Backlit LCD

Total Keys: 20

Function Keys: 10

Memory: 256 KB

Logic Scan Rate: 1.2 mS/K

Memory Card Slot: Up to 1 GB

Height: 3.7” (95.1 mm)

Width: 3.7” (95.1 mm)

Depth: 2.5” (63.9 mm)

Weight: 12.5 oz (0.354 kg)

Environmental: 0 to 50 °C

Wash down: NEMA 4X

Max. panel thickness: 5 mm

Cut-out: 3.622” (92 mm) x 3.622” (92 mm)

Required Power

Steady State: 130 mA @ 24 VDC

Inrush: 30 A for 1 ms @ 24 VDC

Primary Power Range: 10 – 30 VDC

Relative Humidity: 5 to 95% Non-condensing

Clock Accuracy: +/- One Minute/Month at 20C

Operating Temp.: 0°C to +50°C

Terminal Type: Screw Type, 5 mm Removable

Certifications: CE UL

Number of Channels: 4

Input Ranges: 4 – 20 mA

Max. Over-Current: 35 mA

Outputs per Module: 6 relay

Commons per Module: 6

Max. Output Current: 3 A at 250 VAC, resistive

Max. Output Voltage: 275 VAC, 30 VDC

Max. Switched Power: 1250 VA, 150 W

Expected Life

No load: 5,000,000

Rated load: 100,000

Max. Switching Rate: 300 CPM at no load / 20 CPM at rated load

Type: Mechanical Contact

Response Time: One update per ladder scan plus 10 ms

27 AUG 08 PRELIMINARY MANUAL 15 of 57

Rev 1_3 Commander LI90 Series

Page 16

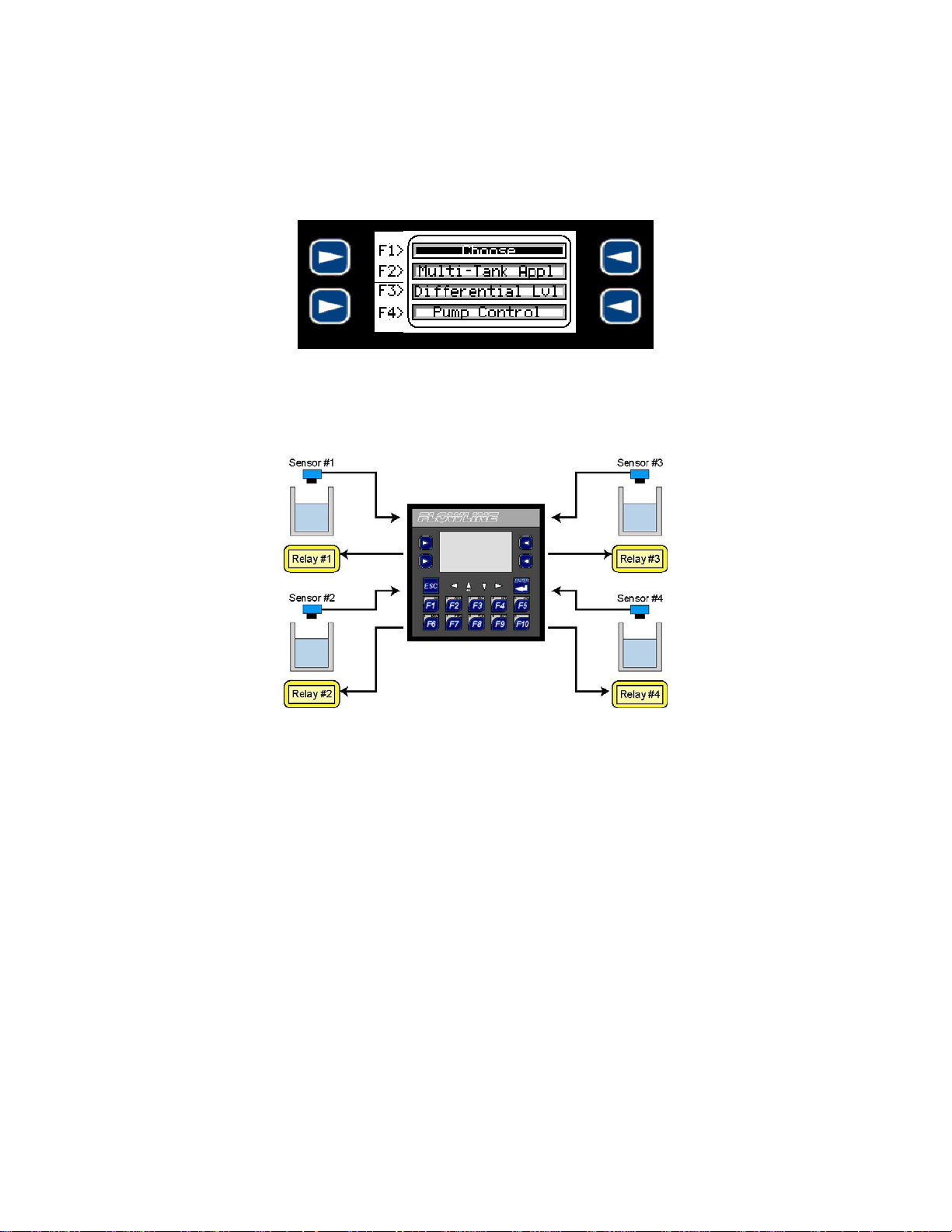

Startup

• When the Commander is powered for the first time, the LI90 series will allow the end

user to select the application to be used. Follow the instructions on the screen to choose

the application.

o Application #1 / Multi-Tank Display (Press F2) – Commander will accept up to

Four 4-20 mA input transmitters and will provide a 3A SPST relay output for each

input.

16 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 17

o Application #2 / Differential Level Controller (Press F3) – Commander will

monitor the levels above and below a rake and control a relay based upon the defined

differential between the two levels. In addition, a differential alarm can be

programmed as well as individual alarms for each input.

o Application #3 / Pump Controller (Press F4) – Commander will accept a single

4-20 mA input transmitter and will provide up to Six 3A SPST relay outputs.

27 AUG 08 PRELIMINARY MANUAL 17 of 57

Rev 1_3 Commander LI90 Series

Page 18

• If you need to change the application selection, press and hold the ESC button for 5

seconds. This will return you to the Selection Screen and allow for a new application to

be selected.

o The selection can be accessed at any time.

18 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 19

Common Information – There are several configuration aspects that are similar for all three

applications in the LI90 series.

• Analog Input

o The Commander accepts any 4-20 mA signal.

o The Commander has the ability to accept a 4-20 mA that has been scaled to the

size of the tank / vessel or with a 4-20 mA that is from a non-configured

transmitter (in its original factory setup).

o There are six parameters required to configure an analog input in the LI90 series.

o For a scaled output. Use this description when using a transmitter that has been

configured with 4 mA set to an empty tank/vessel and 20 mA set to a full

tank/vessel.

• Sensor Max. Range – This is the distance from the bottom of the tank to

the bottom of the installed sensor.

• Sensor Dead Band – This is the distance from the full level of liquid to

the bottom of the sensor.

• Sensor Height – This is the distance from the bottom of the tank to the

bottom of the installed sensor. This will be the same setting as the Sensor

Max. Range.

• Sensor Fill_H – This is the distance from the bottom of the tank to the

highest level of liquid. Adding the Fill_H value to the Dead Band value

will equal the Max. Range or Height values.

• Empty Setting – This is the display value when the tank is empty.

• Full Setting – This is the display value when the tank is full.

27 AUG 08 PRELIMINARY MANUAL 19 of 57

Rev 1_3 Commander LI90 Series

Page 20

o For a non-scaled output. Use this description when using a transmitter that is

either set with its original Factory Settings or with a transmitter that has a fixed

(non-configurable) 4-20 mA output:

• Sensor Max. Range – This is the maximum range of the sensor. This is

typically the 4 mA set point for the sensor. Use the sensor’s manual to

obtain the sensors maximum range (4 mA output).

• Sensor Dead Band – This is the dead band for the level sensor. Use the

sensor’s manual to obtain the sensors dead band (20 mA output).

• Sensor Height – This is the distance from the bottom of the tank to the

bottom of the installed sensor

• Sensor Fill_H – This is the distance from the bottom of the tank to the

highest level of liquid

• Empty Setting – This is the display value when the tank is empty.

• Full Setting – This is the display value when the tank is full.

20 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 21

Application #1

• Overview

o Multi-Tank Display – The LI90 series in this application is typically used to

eliminate the need of one display for each transmitter. This application can accept

up to Four 4-20 mA input transmitters and will provide a 3A SPST relay output

for each input.

• Power: Operate from 12 to 24 VDC power

• Inputs: Accept up to four 4-20 mA inputs, the inputs will be powered by

12 to 24 VDC power source

• Outputs: Each input channel has a relay assigned (4 relays total)

• Mounting: Commander can be ¼ DIN mounted and DIN rail mountable

27 AUG 08 PRELIMINARY MANUAL 21 of 57

Rev 1_3 Commander LI90 Series

Page 22

• General (Open Functions)

o Opening Screen indicates the Level of Liquid in the tank/vessel along with the

true analog (4-20 mA) input for channel #1 and the status of Relay #1

• Regardless on how the input level is configured, the bar graph will show

the true 4-20 mA input provided by the sensor

o Pressing the Lower Right Soft key will jump the display to a screen showing the

same information for Channel #2.

o Pressing the lower Right soft key will continue to Channels #3 and #4 and then

the Relay Status Page

• Sequence is as follows:

• Channel 1, Channel 2, Channel 3, Channel 4, Relay Info, Channel

1, …

Channel 1 Channel 2 Channel 3

Channel 4 Hand/Off/Auto (HOA)

o In the Relay Info screen, pressing the upper left soft key will jump the screen to

the HAND / OFF / AUTO (H.O.A.) functions for each relay.

22 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 23

• The H.O.A. screen for each relay will indicate each relay, the current

status of each relay and soft keys to jump back or to the next relay.

• The first time the LI90 series is powered up, all of the relays will be in the

OFF mode. To activate the relay, you will need to change the relay mode

to AUTO.

• AUTO – This mode places the relay in automatic. Relay will

energize based upon the ON setting and will De-energize based

upon the OFF setting.

• OFF – This mode turns the relay OFF (de-energized). The ON

and OFF settings are ignored in this mode. This mode is helpful in

taking a relay off-line for maintenance.

• HAND – This mode turns the relay ON (energized). This mode is

helpful in overriding a relay function. Relay will be energized

until

o The OFF is selected or

o When the AUTO mode is selected and the level drops

below the OFF setting

27 AUG 08 PRELIMINARY MANUAL 23 of 57

Rev 1_3 Commander LI90 Series

Page 24

• General (Secured Functions)

o The configuration of the display/input and relays/output are all under the secured

section of the display.

o To access these functions, press and hold the ENTER key for 5 seconds. The

display will jump to the configuration section.

o To leave the Secured Function section, press Exit

24 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 25

• Configuration of Inputs

o Once in the Secured Function Section, press the Config Inputs soft key

o Press the Next or Back soft keys to scroll to the input you would like to configure.

o Upon selecting an input channel, the controller will ask for the following 6

settings to configure the input. The first four settings must be in the same units

(i.e. inches, cm, feet, m, etc.) typically in units of length. The last two settings

can be in any engineering units as long as they are the same (i.e. inches, cm,

gallons, liters, etc.)

1. Sensor Max. Range 2. Sensor Dead Band 3. Sensor Height

4. Sensor Fill_H 5. Empty Setting 6. Full Setting

1. Sensor Max. Range –This is the distance from the bottom of the tank to

the bottom of the installed sensor with a scaled 4-20 mA output. For a

fixed output, this is the maximum range of the sensor. Use the sensor’s

manual to obtain the sensors maximum range (4 mA output)

2. Sensor Dead Band – This is the distance from the full level of liquid to

the bottom of the sensor with a scaled 4-20 mA output. For a fixed output,

this is the dead band for the level sensor. Use the sensor’s manual to

obtain the sensors dead band (20 mA output).

3. Sensor Height – This is the distance from the bottom of the tank to the

bottom of the installed sensor.

4. Sensor Fill_H – This is the distance from the bottom of the tank to the

highest level of liquid.

5. Empty Setting – This is the display value when the tank is empty.

6. Full Setting – This is the display value when the tank is full.

• Use the Next soft key to advance to the next setting.

• Use the Back soft key to return to the previous setting.

27 AUG 08 PRELIMINARY MANUAL 25 of 57

Rev 1_3 Commander LI90 Series

Page 26

Scaled 4-20 mA Output Fixed 4-20 mA Output

o To change a value, first press the Enter key

• The value will be highlighted

• Use the 10-digit keypad to enter the desired value

• I.e. for 123.4, press the following keys: <F1>, <F2>, <F3>, <▼>,

<F4>,

• Press Enter when completed to store this value to memory

• Follow the sequence above:

• 1. Press Enter to begin

• 2. Press F1 for number 1

• 3. Press F2 for number 2

• 4. Press F3 for number 3

• 5. Press ▼ for “.”

• 6. Press F4 for number 4

• 7. Press Enter to save setting

• The screen cannot change until a value is stored in memory.

26 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 27

• Configuration of Outputs

o Once in the Secured Function Section, press the Config Outputs soft key

o Each relay will ask for a Relay ON and Relay OFF level. These settings must be

in the same units used for the Empty and Full settings

Relay ON Relay OFF

• If you are reading between 0 to 500 gallons, then the relay set points must

be in gallons

• For Pumps and Valves, use both settings as the ON/OPEN and

OFF/CLOSE points for the device

• For Alarms, use the ON point where the relay will start and the OFF as a

hysteresis to prevent chattering of the relay

High Alarm Low Alarm Automatic Fill Automatic Empty

o To change a value, first press the Enter key

• The value will be highlighted

• Use the 10-digit keypad to enter the desired value

• I.e. for 123.4, press the following keys: <F1>,

<F2>,<F3>,<.>,<F4>,

• Press Enter when completed to store this value to memory

27 AUG 08 PRELIMINARY MANUAL 27 of 57

Rev 1_3 Commander LI90 Series

Page 28

• Follow the sequence above:

• 1. Press Enter to begin

• 2. Press F1 for number 1

• 3. Press F2 for number 2

• 4. Press F3 for number 3

• 5. Press ▼ for “.”

• 6. Press F4 for number 4

• 7. Press Enter to save setting

• The screen cannot change until a value is stored in memory.

o Use the Next soft key to advance to the next setting

o Use the Back soft key to return to the previous setting

o When done, press Exit to leave the Secured Function Section

28 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 29

Application #2

• Overview

o Differential Level Controller – Commander will monitor the levels above and

below a rake and control a relay based upon the defined differential between the

two levels. In addition, a differential alarm can be programmed as well as

individual alarms for each input.

• Power: Operate from 12 to 24 VDC power

• Inputs: Accept up to two 4-20 mA inputs, the inputs will be powered by

12 to 24 VDC power source

• Outputs: Two alarm relays (one for each channel) and two relays that

activate based upon the differential value between the two inputs.

• Mounting: Commander can be ¼ DIN mounted and DIN rail mountable

27 AUG 08 PRELIMINARY MANUAL 29 of 57

Rev 1_3 Commander LI90 Series

Page 30

• General (Open Functions)

o Opening Screen indicates the Level of Liquid in the tank/vessel along with the

true analog (4-20 mA) input for both input channel#1 and #2

• Regardless on how the input level is configured, the bar graph will show

the true 4-20 mA input provided by the sensor

o Pressing the Lower Right Soft Key will jump the display to show the following:

• Channel 1 and 2, Channel 1 only, Channel 2 only, Relay Info…

Channel 1 & 2 Channel 1 only

Channel 2 only Relay info

30 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 31

o In the Relay Info screen, pressing the upper right soft key will jump the screen to

the HAND / OFF / AUTO (H.O.A.) functions for each relay.

• The H.O.A. screen for each relay will indicate each relay, the current

status of each relay and soft keys to jump back or to the next relay

• AUTO – This mode places the relay in automatic. Relay will

energize based upon the ON setting and will De-energize based

upon the OFF setting.

• OFF – This mode turns the relay OFF (de-energized). The ON

and OFF settings are ignored in this mode. This mode is helpful in

taking a relay off-line for maintenance.

• HAND – This mode turns the relay ON (energized). This mode is

helpful in overriding a relay function. Relay will be energized

until

o The OFF is selected or

o When the AUTO mode is selected and the level drops

below the OFF setting

o Pressing the lower right soft key (Next) will return the controller to the opening

screen

27 AUG 08 PRELIMINARY MANUAL 31 of 57

Rev 1_3 Commander LI90 Series

Page 32

• General (Secured Functions)

o The configuration of the display/inputs and relays/outputs are all under the

secured section of the display

o To access these functions, press and hold the ENTER key for 5 seconds. The

display will jump to the configuration section.

o To leave the Secured Function section, press Exit

32 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 33

• Configuration of Inputs

o Once in the Secured Function Section, press the Config Inputs soft key

o Press the Next or back soft keys to scroll to the input you would like to configure.

o Upon selecting an input channel, the controller will ask for the following 6

settings to configure the input. The first four settings must be in the same units

(i.e. inches, cm, feet, m, etc.) typically in units of length. The last two settings

can be in any engineering units as long as they are the same (i.e. inches, cm,

gallons, liters, etc.)

1. Sensor Max. Range 2. Sensor Dead Band 3. Sensor Height

4. Sensor Fill_H 5. Empty Setting 6. Full Setting

1. Sensor Max. Range –This is the distance from the bottom of the tank to

the bottom of the installed sensor with a scaled 4-20 mA output. For a

fixed output, this is the maximum range of the sensor. Use the sensor’s

manual to obtain the sensors maximum range (4 mA output)

2. Sensor Dead Band – This is the distance from the full level of liquid to

the bottom of the sensor with a scaled 4-20 mA output. For a fixed output,

this is the dead band for the level sensor. Use the sensor’s manual to

obtain the sensors dead band (20 mA output).

3. Sensor Height – This is the distance from the bottom of the tank to the

bottom of the installed sensor.

4. Sensor Fill_H – This is the distance from the bottom of the tank to the

highest level of liquid.

5. Empty Setting – This is the display value when the tank is empty.

6. Full Setting – This is the display value when the tank is full.

• Use the Next soft key to advance to the next setting.

• Use the Back soft key to return to the previous setting.

27 AUG 08 PRELIMINARY MANUAL 33 of 57

Rev 1_3 Commander LI90 Series

Page 34

Scaled 4-20 mA Output Fixed 4-20 mA Output

o To change a value, first press the Enter key

• The value will be highlighted

• Use the 10-digit keypad to enter the desired value

• I.e. for 123.4, press the following keys: <F1>, <F2>, <F3>, <. >,

<F4>,

• Press Enter when completed to store this value to memory

• Follow the sequence above:

• 1. Press Enter to begin

• 2. Press F1 for number 1

• 3. Press F2 for number 2

• 4. Press F3 for number 3

• 5. Press ▼ for “.”

• 6. Press F4 for number 4

• 7. Press Enter to save setting

• The screen cannot change until a value is stored in memory.

34 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 35

• Configuration of Outputs

o Once in the Secured Function Section, press the Config Outputs soft key

• Relays #1 and #2 will ask for a Relay ON and Relay OFF level. These

settings must be in the same units used for the Empty and Full settings

Relay ON Relay OFF

• If you are reading between 0 to 500 gallons, then the relay set points

must be in gallons

• For Pumps and Valves, use both settings as the ON/OPEN and

OFF/CLOSE points for the device

• For Alarms, use the ON point where the relay will start and the OFF as

a hysteresis to prevent chattering of the relay

High Alarm Low Alarm Automatic Fill Automatic Empty

27 AUG 08 PRELIMINARY MANUAL 35 of 57

Rev 1_3 Commander LI90 Series

Page 36

• To change a value, first press the Enter key

• The value will be highlighted

• Use the 10-digit keypad to enter the desired value

o I.e. for 123.4, press the following keys: <F1>, <F2>, <F3>,

<.>, <F4>,

• Press Enter when completed to store this value to memory

• Follow the sequence above:

• 1. Press Enter to begin

• 2. Press F1 for number 1

• 3. Press F2 for number 2

• 4. Press F3 for number 3

• 5. Press ▼ for “.”

• 6. Press F4 for number 4

• 7. Press Enter to save setting

• The screen cannot change until a value is stored in memory.

36 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 37

• Relays #3 and #4 will ask for a Differential ON and Differential OFF level.

These settings must be in the same units used for the Empty and Full settings.

Differential ON Differential OFF

• This allows the end use to select a differential level between the two

analog inputs

• Channel #1 must be the upstream level and Channel #2 the

downstream level

• Typically, Relay #3 is used for the main differential control and Relay

#4 is for an alarm differential

• Use the Next soft key to advance to the next setting

• Use the Back soft key to return to the previous setting

• When done, press Exit to leave the Secured Function Section

27 AUG 08 PRELIMINARY MANUAL 37 of 57

Rev 1_3 Commander LI90 Series

Page 38

Application #3

• Overview

o Pump Controller – The LI90 series in this application is typically used to provide

multiple relay contacts for a single 4-20 mA input. Relays 5 and 6 can be combined

to be programmed as duplexing / alternating relays.

• Power: Operates from 12 to 24 VDC power

• Inputs: Accepts a single 4-20 mA input, the input will be powered by 12

to 24 VDC power source

• Outputs: 6 relays are available to program as alarms, pumps or valves

• Enclosure: Front panel must be NEMA 4X rated

• Mounting: Panel must be ¼ DIN mounted and DIN rail mountable

• Volumetric: Display can indicate level in either Gallons or Liters for

vertical and horizontal tanks

• Simulation mode: Use this mode to simulate the level of liquid and test

relay operation without changing the true liquid level

38 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 39

• General (Open Functions)

o Opening Screen indicates the Level of Liquid in the tank/vessel along with the

true analog (4-20 mA) input

• Regardless on how the input level is configured, the bar graph will show

the true 4-20 mA input provided by the sensor

o Pressing the Lower Left Soft key will jump the display to indicate the relay status.

Above the relay status will be the liquid level.

• Pressing the lower left soft key will return the display back to the opening

screen

• Pressing the upper left soft key will jump the screen to the HAND / OFF /

AUTO (H.O.A.) functions for each relay.

o The H.O.A. screen for each relay will indicate each relay, the current status of

each relay and soft keys to jump back or to the next relay

• AUTO – This mode places the relay in automatic. Relay will energize

based upon the ON setting and will De-energize based upon the OFF

setting.

• OFF – This mode turns the relay OFF (de-energized). The ON and OFF

settings are ignored in this mode. This mode is helpful in taking a relay

off-line for maintenance.

• HAND – This mode turns the relay ON (energized). This mode is helpful

in overriding a relay function. Relay will be energized until

• The OFF is selected or

• When the AUTO mode is selected and the level drops below the

OFF setting

27 AUG 08 PRELIMINARY MANUAL 39 of 57

Rev 1_3 Commander LI90 Series

Page 40

• General (Secured Functions)

o The configuration of the display, relays and simulations are all under the secured

section of the display

o To access these functions, press and hold the ENTER key for 5 seconds. The

display will jump to the configuration section.

o To leave the Secured Function section, press Exit

40 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 41

• Configuration of Inputs

o Once in the Secured Function Section, press the Config Inputs soft key

o Next, select if the application will show a Scaled Input or a Volumetric Input

• Scaled Input – Allows for the current inputs to display in any engineering

units the linear scale from the current

• Volumetric Input – Calculates the total volume (gallons or liters) for both

vertical or horizontal tanks

• Scaled Inputs

o The controller will ask for the following 6 settings to configure the input. The

first four settings must be in the same units (i.e. inches, cm, feet, m, etc.) typically

in units of length. The last two settings can be in any engineering units as long as

they are the same (i.e. inches, cm, gallons, liters, etc.)

1. Sensor Max. Range 2. Sensor Dead Band 3. Sensor Height

4. Sensor Fill_H 5. Empty Setting 6. Full Setting

• Sensor Max. Range – This is the maximum range of the sensor located on

top of the tank.

• Sensor Dead Band – This is the dead band for the level sensor

• Sensor Height – This is the distance from the bottom of the tank to the

bottom of the sensor

• Sensor Fill_H – This is the distance from the bottom of the tank to the

highest level of liquid

27 AUG 08 PRELIMINARY MANUAL 41 of 57

Rev 1_3 Commander LI90 Series

Page 42

• Empty Setting – This is the display value when the tank is empty

• Full Setting – This is the display value when the tank is full

• Use the Next soft key to advance to the next setting

• Use the Back soft key to return to the previous setting

Scaled 4-20 mA Output Fixed 4-20 mA Output

o To change a value, first press the Enter key

• The value will be highlighted

• Use the 10-digit keypad to enter the desired value

• I.e. for 123.4, press the following keys: <F1>, <F2>, <F3>, <. >,

<F4>,

• Press Enter when completed to store this value to memory.

• Follow the sequence above:

• 1. Press Enter to begin

• 2. Press F1 for number 1

• 3. Press F2 for number 2

• 4. Press F3 for number 3

• 5. Press ▼ for “.”

• 6. Press F4 for number 4

• 7. Press Enter to save setting

• The screen cannot change until a value is stored in memory.

42 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 43

• Volumetric Inputs

o The controller will ask basic shape and dimensional information in order to

display either the gallons or liters within the tank or vessel.

o Select between either Vertical Tanks or Horizontal Tanks.

• Dimensional information must be entered as either inches or cm.

• Dimensional inches must show gallons and cm must show liters.

• Transmitter must be configured such that tank empty is 4 mA and tank full

is 20 mA.

Vertical Tanks Horizontal Tanks

o Choose between Gallons or Liters for the display output.

• When choosing Gallons, make sure all dimensional information entered is

in inches.

• When choosing Liters, make sure all dimensional information entered is in

cm.

27 AUG 08 PRELIMINARY MANUAL 43 of 57

Rev 1_3 Commander LI90 Series

Page 44

o Vertical Tanks – Select among Rectangular, Round Bottom or Cone Bottom.

Rectangular Round Bottom Cone Bottom

1. Sensor Height 2. Tank Height

3. Tank Width/Diameter 4. Tank Length/Cone

• Sensor Height – This is the distance from the bottom of the tank to the

bottom of the sensor

• Tank Height – This is a dimension for either the Height of the Tank or

the Height of the Straight Side of the cone bottom tank.

• Tank Width / Diameter – This is either the width of the tank or the

diameter of the tank

• Tank Length / Cone – This is either the length of the tank or the Height

of the Cone. You do not need to configure this setting for the Round

Bottom tank.

• Use the Next soft key to advance to the next setting

• Use the Back soft key to return to the previous setting

44 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 45

o Horizontal Tanks – Select among Flat Ends or Round Ends.

Length

Diameter

Flat Ends Round Ends

1. Sensor Height 2. Tank Length

3. Tank Diameter 4. End Cap Length

• Sensor Height – This is the distance from the bottom of the tank to the

bottom of the sensor

• Tank Length – This is a length of the tank.

• Tank Diameter – This is diameter of the tank.

• End Cap Length – This is the distance for one of the end caps. You do

not need to configure this setting for the Flat End Tank.

• Use the Next soft key to advance to the next setting

• Use the Back soft key to return to the previous setting

27 AUG 08 PRELIMINARY MANUAL 45 of 57

Rev 1_3 Commander LI90 Series

Page 46

• Configuration of Outputs

o Once in the Secured Function Section, press the Config Outputs soft key

o Each relay will ask for a Relay ON and Relay OFF level. These settings must be

in the same units used for the Empty and Full settings

Relay ON Relay OFF

• If you are reading between 0 to 500 gallons, then the relay set points must

be in gallons

• For Pumps and Valves, use both settings as the ON/OPEN and

OFF/CLOSE points for the device

• For Alarms, use the ON point where the relay will start and the OFF as a

hysteresis to prevent chattering of the relay

High Alarm Low Alarm Automatic Fill Automatic Empty

46 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 47

o To change a value, first press the Enter key

• The value will be highlighted

• Use the 10-digit keypad to enter the desired value

• I.e. for 123.4, press the following keys: <F1>, <F2>, <F3>, <. >,

<F4>,

• Press Enter when completed to store this value to memory

• Follow the sequence above:

• 1. Press Enter to begin

• 2. Press F1 for number 1

• 3. Press F2 for number 2

• 4. Press F3 for number 3

• 5. Press ▼ for “.”

• 6. Press F4 for number 4

• 7. Press Enter to save setting

• The screen cannot change until a value is stored in memory.

o Use the Next soft key to advance to the next setting

o Use the Back soft key to return to the previous setting

o Option – Relays 5 and 6 can be used as a Duplex / Alternation function

o Select Config. Relay #5 and #6 to configure relays #5 and #6. This setting will

always configure both relays #5 and #6.

27 AUG 08 PRELIMINARY MANUAL 47 of 57

Rev 1_3 Commander LI90 Series

Page 48

o Select either an Independent Relay #5 and #6 or Duplexing Relays #5 and #6.

Independent

Relay #5 & #6

o Independent Relays – Relays #5 and #6 perform the same as relays #1 through

#4. The two relays are not linked together.

o Duplex Relays – Relays #5 and #6 are linked together with two unique start

levels and a common off position. The relays will also alternate between each

LEAD start. If the level ever reaches the LAG start, the remaining relay will

activate.

o Alternating Relays – Relays #5 and #6 will switch back and forth each time the

ON level is reached. This is used to maintain a common use/life cycle for

equipment.

o Relay settings must be in the same units used for the Empty and Full settings

1. Relay #5 ON or LEAD ON 2. Relay #5 OFF or ALL OFF

Duplex

Relay #5 & #6

Alternate

Relay #5 and #6

3. Relay #6 ON or LAG ON 4. Relay #6 OFF

48 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 49

•

•

• To use as Independent Relay mode, press the IND soft key and then press

Next.

Independent Relays #5 and #6

Enter the Relay #5 ON set point (where Relay

#5will energize) and press Next

• Enter the Relay #5 OFF set point (where

Relay #5 will de-energize) and press Next

• Enter the Relay #6 ON set point (where Relay

#6 will energize) and press Next.

• Enter the Relay #6 OFF set point (where

Relay #6 will de-energize) and press Next.

• To change to a Duplex mode, press the DUP soft key and then press Next.

Duplex Relays #5 and #6

Enter the LEAD ON relay set point (where

the lead relay will energize) and press Next

• Enter the ALL OFF relay set point (where

both relays will de-energize) and press Next

• Enter the LAG ON relay set point (where the

lag relay will energize) and press Next.

o You do not need to provide a value for

Relay #6 OFF.

o Duplex can be used as a Filling or

Emptying configuration.

o Always make sure that the LAG ON is

above the LEAD ON for an Empty

configuration or below the LEAD ON for

a Fill configuration.

27 AUG 08 PRELIMINARY MANUAL 49 of 57

Rev 1_3 Commander LI90 Series

Page 50

• To change to an Alternation mode, press the DUP soft key and then press

•

Next.

Alternate Relays #5 and #6

Enter the LEAD ON relay set point (where

relay #5 will energize) and press Next

• Enter the ALL OFF relay set point (where

both relays will de-energize) and press Next

• Enter the LAG ON relay set point (where

relay #6 will energize) and press Next.

o You do not need to provide a value for

Relay #6 OFF.

• To return Relays 5 and 6 back to an independent mode, press the IND soft

key

o When done, press Exit to leave the Secured Function Section

o Alternate can be used as a Filling or

Emptying configuration.

o Always make sure that the LAG ON is

the same as the LEAD ON. This will

enable Relays 5 and #6 to alternate

each time a relay is to become

energized.

50 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 51

Appendix

Simulation Mode

This mode enables the end user to simulate changes in level without having the level of liquid

move. The display will simulate level of liquid and will turn the relays ON and OFF according

to how they were configured. For example, if Relay 1 is set as a Pump Empty with an ON

setting for 100.0 inches and an OFF setting of 30.0 inches, then when the display goes above

100.0, Relay 1 will energize and when the level falls below 30.0, Relay 1 will de-energize. This

function can be used to test the wiring and to verify if the configuration is set accordingly.

Please note: Simulation mode will energize and de-energize all configured relays. Any devices

wired to the relays will become active during simulation mode. To turn off individual relays,

Select OFF in the H.O.A. section before entering the Simulation mode.

• Simulation Mode I sunder the secured section of the display

o To access this function, press and hold the ENTER key for 5 seconds. The

display will jump to the configuration section.

o Once in the Secured Function Section, press the Simulation Mode soft key

27 AUG 08 PRELIMINARY MANUAL 51 of 57

Rev 1_3 Commander LI90 Series

Page 52

o Next, press the Begin Simulation soft key to proceed or the Back soft key to

return

o Next press the YES soft key to begin the Simulation

o Simulation mode will begin after a short count down

o Once in Simulation mode, use the two soft keys on the left to increase and

decrease the level per your requirements

o Check all active relays to verify operation

o To exit from Simulation mode, press the Exit soft key in the lower right corner of

the screen

52 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 53

Factory Reset

• At anytime, the Commander Series can be reset to its original factory settings. To do so

perform the following:

o Press and hold the F10 button for 10 seconds

o Release the F10 button when the Factory Reset? Screen appears.

o To reset, press the soft key for Yes and press F10 to enter

o The LI90 series will be reset to its original setting

o Pressing Enter with NO active will return the display back to it current setting and

nothing will be reset.

27 AUG 08 PRELIMINARY MANUAL 53 of 57

Rev 1_3 Commander LI90 Series

Page 54

Changing Applications

• If you need to change the application selection, press and hold the ESC button for 5

seconds. This will return you to the Selection Screen and allow for a new application to

be selected.

o The selection can be accessed at any time.

54 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 55

Removable Media for Data Transfer

Overview

• All Commander models provide a Removable Media slot, labeled Memory, which

supports standard Micro SD Flash memory cards. Micro SD cards can be used to save

and load applications, to capture graphics screens and to log data for later retrieval.

Micro SD Cards

• When the Micro SD card format was introduced, it was originally called TransFlash.

Cards labeled either Micro SD or TransFlash, with up to 2.0 GB of Flash memory, are

compatible with the Commander’s Memory slot.

• The Memory slot is equipped with a “push-in, push-out” connector and a Micro SD

card can be safely inserted into the Memory slot whether the power is On or Off.

o To install a Micro SD card: Align its 8-pin gold edge connector down,

facing the front of the unit as shown below; then carefully push it all the

way into the Memory slot. Ensure that it clicks into place.

o To remove the Micro SD card: Push down on the top of the card gently to

release the spring. The card pops up for removal.

Installing Removable Memory Card

Micro SD File System

• The Micro SD Memory slot uses the PC-compatible FAT16 File System. This means

that a PC, with a Micro SD-compatible card reader, can read files that have been written

by the Commander and can write files that can be read by the Commander.

• However, the Commander does not

8.3 filename format. This means that all file and directory names must consist of up to 8

characters, followed by an optional dot, and an optional extension with up to 3

characters.

• Directories and sub-directories can be nested up to 16 levels deep as long as each

pathname string does not exceed 147 characters.

support long filenames, but instead implements the

27 AUG 08 PRELIMINARY MANUAL 55 of 57

Rev 1_3 Commander LI90 Series

Page 56

Using Removable Media to Log Data

• The Commander has the feature of logging data to a Micro SD card in the form of

comma-delimited files, with a .CSV extension. These files are compatible with

standard database and spreadsheet PC programs.

• To activate the data log in the commander, press and hold the Left Arrow (shown above)

for 10 seconds. When Data Log Activated appears, release the button. The unit will log

the four analog inputs at rate of once per 15 seconds.

• When completed, follow the previous instructions for removing the Micro SD card.

• The data in the card will appear in five folders. Folder A_Inputs contains the raw and

scaled data for the four analog inputs (see chart below).

Data Folder

Raw analog input

(referenced between

0 to 32,000 units)

Scaled input

(referenced between

Empty and Full settings)

Channel 1 Channel 2 Channel 3 Channel 4

A_Inputs A_Inputs A_Inputs A_Inputs

%AI0001 %AI0002 %AI0003 %AI0004

%R0107 %R0207 %R0307 %R0407

• Folders AI1_Set, AI2_Set, AI3_Set and AI4_Set contain the configuration information

for the analog inputs (see below).

Data Folder

Sensor Max. Range

Sensor Dead Band

Sensor Height

Sensor Fill_H

Empty Setting

Full Setting

Channel 1 Channel 2 Channel 3 Channel 4

AI1_Set AI2_Set AI3_Set AI4_Set

%R0123 %R0223 %R0323 %R0423

%R0125 %R0225 %R0325 %R0425

%R0133 %R0233 %R0333 %R0433

%R0135 %R0235 %R0335 %R0435

%R0103 %R0203 %R0303 %R0403

%R0105 %R0205 %R0305 %R0405

56 of 57 PRELIMINARY MANUAL 27 AUG 08

Commander LI90 Series Rev 1_3

Page 57

Troubleshooting

PROBLEM SOLUTION

No power to the

transmitters

No power from the relay

contacts

Relays stays OFF all the

time

The Analog Inputs are not internally powered. Power for

transmitters must be provided from an alternative source.

Typically, it is the same power supply that is providing

power to the LI90-1001.

All of the relays are dry contact relays. Power for the

device the relays are switching must come from an

alternative source.

Make sure that the Hand, OFF Auto for the relay is set

for Auto. The OFF setting will keep the relay OFF until

this setting has been changed.

27 AUG 08 PRELIMINARY MANUAL 57 of 57

Rev 1_3 Commander LI90 Series

Loading...

Loading...