Flotec FPSC1725X Owner's Manual

© 2011 FP579 (6/17/2011)

FPSC1725X

OWNER’S MANUAL

Submersible Utility Pump

NOTICE D’UTILISATION

Pompe submersible à usage

général

MANUAL DEL USUARIO

Bomba sumergible de uso general

Installation/Operation/Parts

For further operating, installation, or

maintenance assistance:

Call 1-800-365-6832

English . . . . . . . . . . . . . . . Pages 2-6

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 365-6832

Français . . . . . . . . . . . . Pages 7-11

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-365-6832

Español . . . . . . . . . . .Paginas 12-16

293 Wright Street, Delavan, WI 53115

Phone: 1-800-365-6832

Fax: 1-800-526-3757

Web Site: FlotecWater.com

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

DESCRIPTION

This Submersible Utility Pump is designed for draining

water from basement floors, stock tanks, window wells,

boats, flat roofs and cisterns. Unit is equipped with a

3-prong grounding-type power cord. Shaded-pole motor

is oil filled and sealed for cooler operation. Sleeve bearings on the motor shaft never need lubrication.

Automatic reset thermal protection.

NOTICE: This unit is not designed for applications involv-

ing salt water or brine! Use with salt water or brine will

void warranty.

SPECIFICATIONS

Power supply required...............................120V, 60 HZ.

Motor duty...................................................continuous*

Liquid Temp. Range................. Less Than 120° F (50° C)

Individual Branch Circuit Required (min.).........15 Amps

Pump Discharge............................................1-1/4" NPT

Adapter...............................................3/4" Garden Hose

NOTICE: For continuous operation, the pump must be

submerged to prevent motor overheating.

Risk of fire or explosion. Do not use in

explosive atmospheres. Pump water only with this

pump.

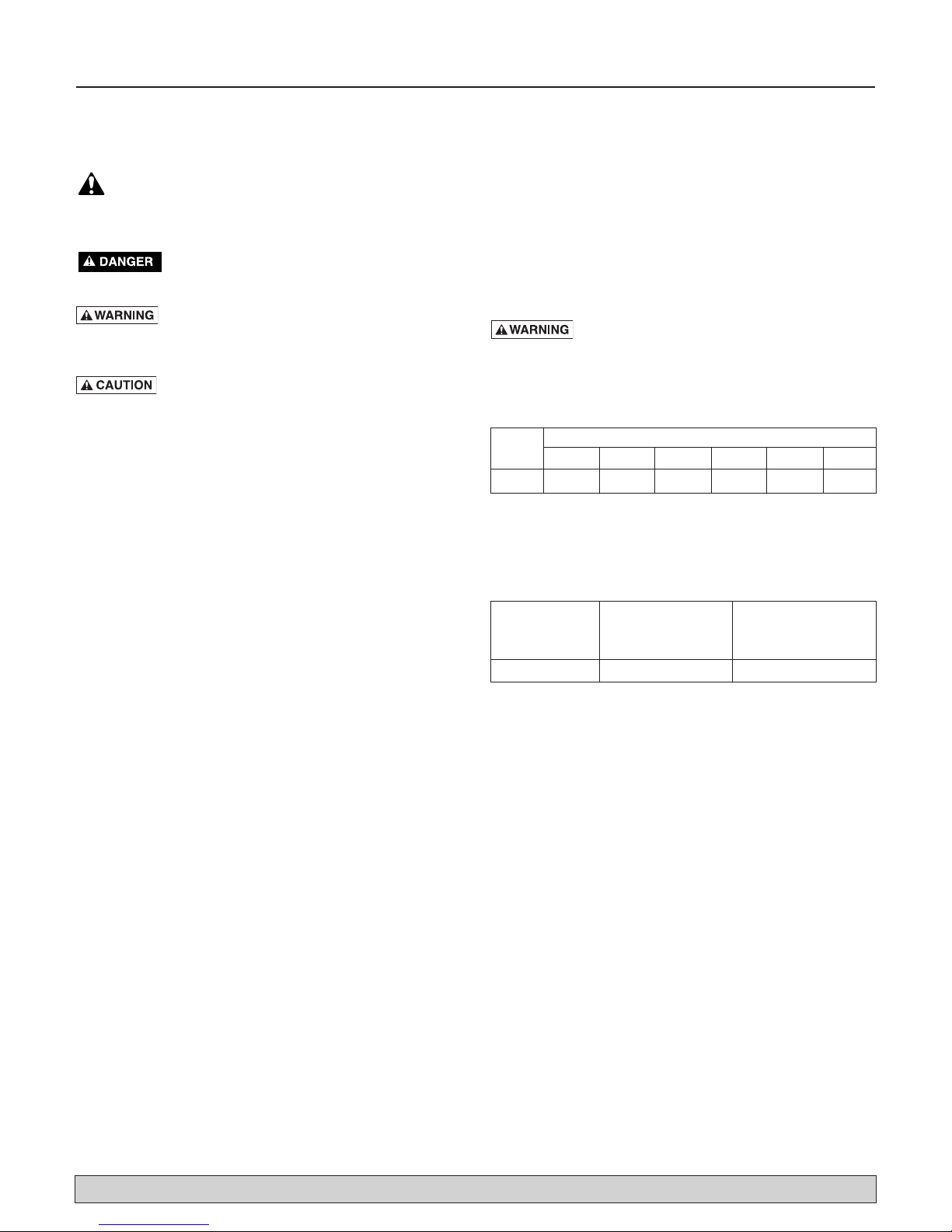

PERFORMANCE

ELECTRICAL & SWITCH

SPECIFICATIONS

Discharge Feet of Head

0 5 10152025

GPH 1320 1170 1020 810 510 0

Safety 2

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Motor Individual Branch

Full Load Circuit Required

Motor HP Amps (Amps)

1/4 5.6 15

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

General Information / Installation 3

GENERAL SAFETY INFORMATION

Electrically powered utility pumps normally give many

years of trouble-free service when correctly installed,

maintained, and used. See the “Troubleshooting Chart”

in this manual for information about common utility

pump problems and remedies. For more information,

see your retailer, or call Flotec customer service at

1-800-365-6832.

1. Know the pump application, limitations, and poten-

tial hazards.

2. Do not use in water where fish are present.

3. Disconnect the power before servicing.

4. Release all pressure within the system before servic-

ing any component.

5. Drain all water from the system before servicing.

6. Secure the discharge line before starting the pump.

An unsecured discharge line will whip, possibly

causing personal injury and/or property damage.

7. Check hoses for weak or worn condition before each

use. Making certain all connections are secure.

8. Periodically inspect the pump and system compo-

nents. Keep free of debris and foreign objects.

Perform routine maintenance as required.

9. Provide a means of pressure relief for pumps whose

discharge line can be shut-off or obstructed.

10.Personal Safety:

a. Wear safety glasses at all times when working

with the pumps.

b. Keep work area clean, uncluttered and properly

lighted – replace all unused tools and equipment.

c. Keep visitors at a safe distance from the work

area.

d. Make the workshop child-proof – with padlocks,

master switches, and by removing starter keys.

11.When wiring an electrically driven pump, follow all

of the electrical and safety codes that apply.

12.This equipment is only for use on 120 volt (single

phase) and is equipped with an approved 3-conductor cord and 3-prong, grounding-type plug.

Hazardous voltage. Can shock, burn or

cause death. To reduce the risk of electric shock,

pull the plug before servicing. This pump has not

been investigated for use in swimming pool areas.

The pump is supplied with a grounding conductor

and grounding-type attachment plug. Be sure it is

connected only to a properly grounded groundingtype receptacle.

Where a 2-prong wall receptacle is encountered, it

must be replaced with properly grounded 3-prong

receptacle installed in accordance with the codes

and ordinances that apply.

Do not walk on wet area until all power has been

turned off. If the shut-off box is in the basement,

call the electric company or hydro authority to shut-

off the service to house, or call your local fire

department for instructions. Failure to follow this

warning can result in a fatal electrical shock.

Do not lift the pump by the power cord.

13.All wiring should be performed by a qualified

electrician.

14.Make certain the power source conforms to the

requirements of your equipment.

15. Protect the electrical cord from sharp objects, hot surfaces, oil, and chemicals. Avoid kinking the cord.

Replace or repair damaged or worn cords immediately.

16.Do not touch an operating motor. Motors are

designed to operate at high temperatures.

17.Do not handle the pump or pump motor, or change

fuses with wet hands or when standing on wet or

damp surface, or in water.

INSTALLATION

1. Set the pump on a hard surface in at least 2” of

water.

2. Connect the discharge line with the fittings provided.

3. The pump should not be installed on clay, dirt, mud

or sand surfaces. Although the pump will usually

pass small particles suspended in water, clean the

area to be pumped of small stones and gravel which

could clog the pump.

NOTICE: Grass, mud, sand or pea gravel can clog the

pump and reduce it’s performance. Keep the pump inlet

screen clean.

4. To reduce motor noise and vibrations when using rigid

pipe, a short length of rubber hose (e.g. radiator hose)

can be connected into the discharge line near the

pump using suitable clamps.

5. Power Supply: Pump is designed for 120 V., 60 Hz.,

operation and requires a minimum 15 amp. individual branch circuit. Pump is supplied with a 3-wire

cord with grounding-type plug.

Hazardous voltage. Can shock, burn or

cause death. Pump should always be electrically

grounded to a suitable electrical ground such as a

grounded water pipe or a properly grounded metallic

raceway, or ground wire system. Do not cut off

round ground pin.

6. If the pump discharge line is exposed to an outside

sub-freezing atmosphere, the line exposed must be

installed so any water remaining in pipe will drain to

the outfall by gravity. Failure to do this can cause

water trapped in the discharge line to freeze which

could result in damage to pump.

7. Check the operation of pump by observing through

one complete cycle.

Risk of flooding. Failure to make this

operational check may lead to improper operation,

premature failure, and flooding.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Operation 4

OPERATION

Hazardous voltage. Can shock, burn or

cause death. Do not handle a pump or pump motor

with wet hands or when standing on wet or damp surface, or in water.

1. The shaft seal depends on water for lubrication and

for cooling. Do not operate the pump unless it is submerged in water. The seal may be damaged if allowed

to run dry.

2. The pump will not remove all water. During manual

operation the pump will pump down to within 1/8”

of the pumping surface. If the optional switch is used,

the final water level is determined by placement of

the switch.

NOTICE: For continuous operation, the pump must

be submerged to prevent the motor from overheating.

A fully submerged pump is preferred for proper cooling when a pump runs continuously.

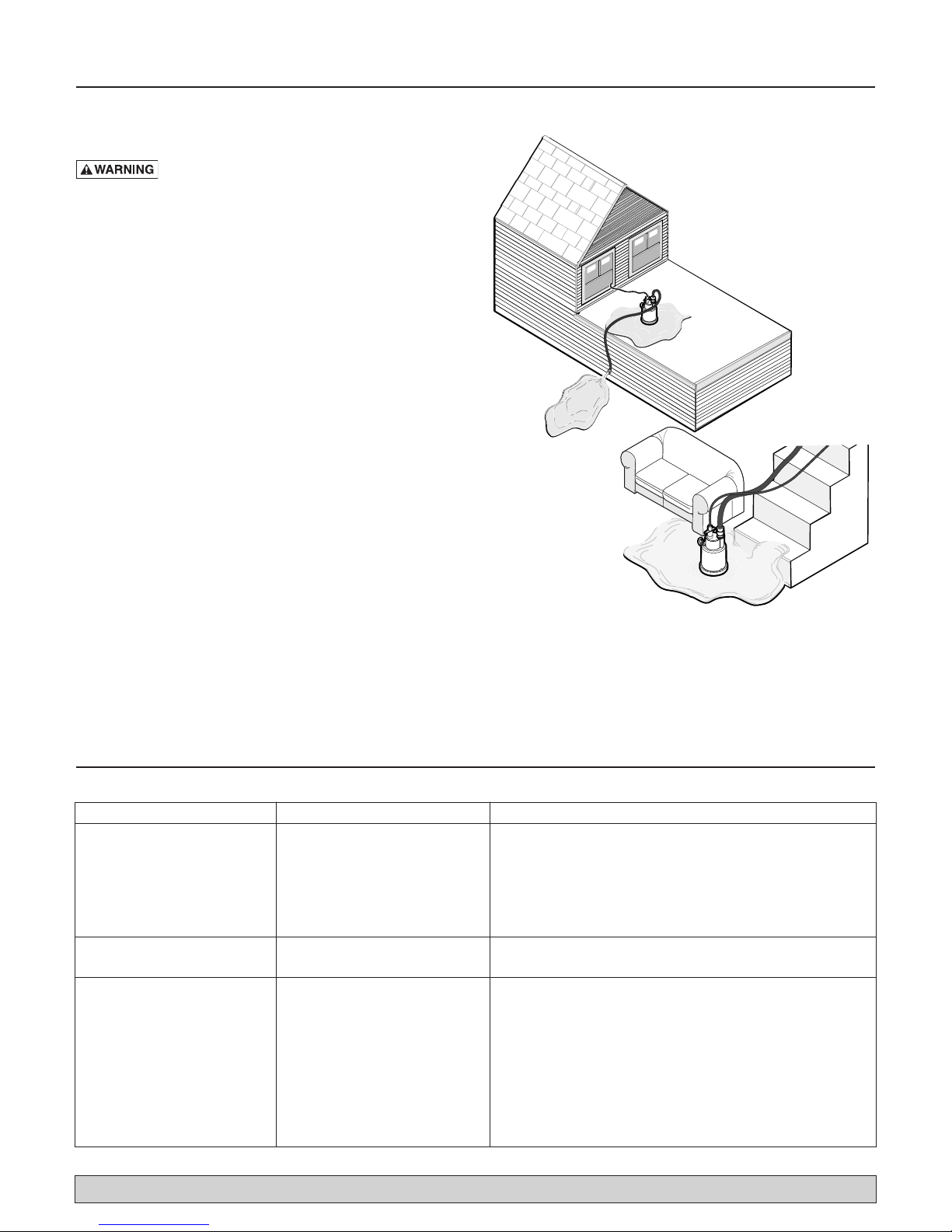

AIRLOCKS

When a pump airlocks, it runs but does not move any

water. An airlock will cause the pump to overheat and

fail. This pump has a built in anti-airlock hole. See the

exploded view on the repair parts page for the location

of the hole. Leakage from the anti-airlock hole is normal.

If you suspect an airlock, unplug the pump, clean out the

anti-airlock hole with a paper clip or a piece of wire,

and restart the pump.

Troubleshooting

SYMPTOM PROBABLE CAUSE(S) CORRECTIVE ACTION

Pump won’t start or run. Pump is not plugged in. Check and see if pump is plugged in to a proper outlet.

Blown fuse or breaker. If blown, replace with fuse of proper size or reset breaker.

Low line voltage. If voltage under recommended minimum, check size of

wiring from main switch on property. If OK, contact power

company or hydro authority.

Defective motor. Replace pump.

Pump starts and stops. Motor is overheating. Discharge or intake are obstructed. Pump is in too

shallow of water.

Pump operates but Restricted discharge Remove pump and clean pump and piping.

delivers little or no water. (obstacle or ice in piping).

Restricted intake. Remove the pump and clean out the intake screen.

Low line voltage. If voltage under recommended minimum, check size of

wiring from main switch on property. If OK, contact power

company or hydro authority.

Worn or plugged impeller. Replace pump.

Anti-airlock hole is plugged. Turn off the pump, clean out the anti-airlock hole, and

restart the pump.

Roofs

3696 0500 NEW

.3

Basements

.3

Repair Parts 5

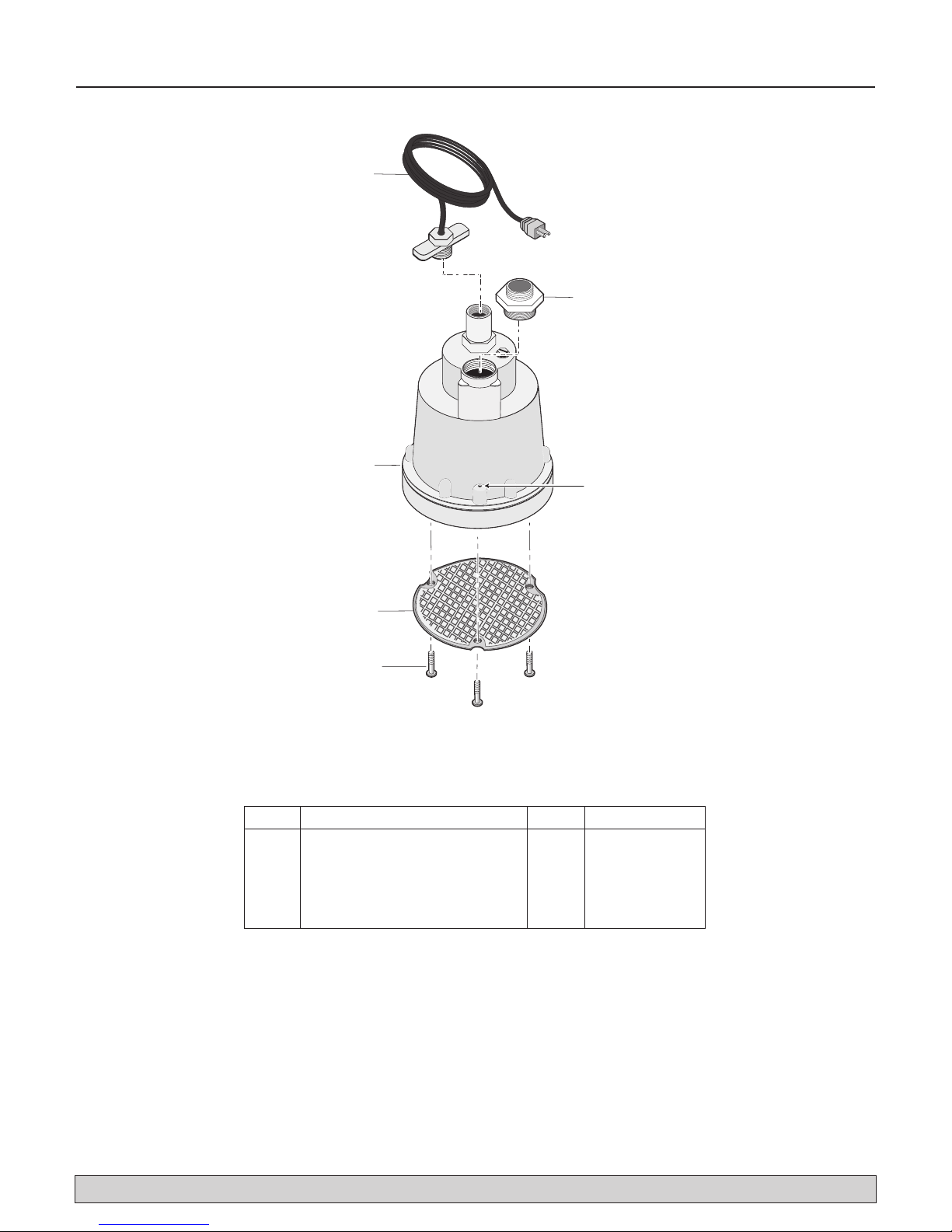

4

1

2

3

5

Anti-airlock Hole

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

REPAIR PARTS

Key Part Description Qty. FPSC1725X-02

1 Power Cord 1 PS117-54-TSU

2 Adapter 1 007-031

3 Motor Assembly 1 **

4 Inlet Screen 1 667-016

5 Screws, Screen 3 670-793

** If the motor fails, replace the entire pump.

Loading...

Loading...