Flotec FPPM3600D, FPPSS3000 Owner's Manual

OWNER’S MANUAL

Pedestal Sump Pump

NOTICE D’UTILISATION

Pompe d’assèchement

sur pied

MANUAL DEL USUARIO

Bomba de Pie para

Sumideros

Installation/Operation/Parts

For further operating,

installation, or maintenance

assistance:

Call 800-365-6832

English ....................... Pages 2-6

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le 1 (800) 365-6832

Français ................. Pages 7-11

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 800-365-6832

Español .................Paginas 12-16

©2012 FP263 (Rev. 06/28/12)

5097 0705

293 Wright Street, Delavan, WI 53115

Phone: 800-365-6832

Fax: 800-526-3757

www.flotecwater.com

FPPM3600D, FPPSS3000

Warranty 2

Retain Original Receipt For Warranty Eligibility

Limited Warranty

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

FLOTEC warrants to the original consumer purchaser (“Purchaser” or “You”) that its products are free from defects in material

and workmanship for a period of twelve (12) months from the date of the original consumer purchase. If, within twelve (12)

months from the original consumer purchase, any such product shall prove to be defective, it shall be repaired or replaced at

FLOTEC’s option, subject to the terms and conditions set forth herein. Note that this limited warranty applies to manufacturing

defects only and not to ordinary wear and tear. All mechanical devices need periodic parts and service to perform well. This

limited warranty does not cover repair when normal use has exhausted the life of a part or the equipment.

The original purchase receipt and product warranty information label are required to determine warranty eligibility. Eligibility

is based on purchase date of original product – not the date of replacement under warranty. The warranty is limited to repair

or replacement of original purchased product only, not replacement product (i.e. one warranty replacement allowed per

purchase). Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store - contact FLOTEC Customer Service at

800-365-6832.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail outlet

where it was purchased or to the factory immediately after the discovery of any alleged defect. FLOTEC will subsequently take

corrective action as promptly as reasonably possible. No requests for service will be accepted if received more than 30 days

after the warranty expires. Warranty is not transferable and does not apply to products used in commercial/rentalapplications.

Sewage Pumps

DO NOT return a sewage pump (that has been installed) to your retail store. Contact FLOTEC Customer Service. Sewage pumps

that have seen service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wearrubbergloveswhenhandlingthepump;

• Forwarrantypurposes,returnthepump’scordtagandoriginalreceiptofpurchasetotheretailstore;

• Disposeofthepumpaccordingtolocaldisposalordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product - Model Warranty Period

FP0F360AC, FP0FDC 90 days

FP0S1775A, FP0S1790PCA, FP0S2400A, FP0S2450A, FP0S4100X, FP2800DCC, FPCP-20ULST,

FPPSS3000, FPSC2150A, FPSC3150A, FPSC3350A

2 Years

4” Submersible Well Pumps, FP0S3200A, FP0S3250A, FP0S6000A, FPSC1725X, FPSC2200A,

FPSC2250A, FPSE3601A, FPPSS5000

3 Years

FP7100 Series Pressure Tanks, E100ELT, E3305TLT, E3375TLT, E5005TLTT, E50TLT, E50VLT,

E75STVT, E75VLT, FPSC3200A, FPSC3250A, FPSC4550A

5 Years

General Terms and Conditions; Limitation of Remedies

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does not

applytothefollowing:(1)actsofGod;(2)productswhich,inFLOTEC’ssolejudgment,havebeensubjecttonegligence,abuse,

accident,misapplication,tampering,oralteration;(3)failuresduetoimproperinstallation,operation,maintenanceorstorage;

(4)atypicalorunapprovedapplication,useorservice;(5)failurescausedbycorrosion,rustorotherforeignmaterialsinthe

system, or operation at pressures in excess of recommended maximums.

This warranty sets forth FLOTEC’s sole obligation and purchaser’s exclusive remedy for defective products.

FLOTEC SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an

implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal

rights and You may also have other rights which vary from state to state.

FLOTEC • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 800-365-6832 • Fax: 800-526-3757 • www.flotecwater.com

For parts or assistance, call Flotec Customer Service at 800-365-6832

Safety 3

For parts or assistance, call Flotec Customer Service at 800-365-6832

Im portant Safety

Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided,

will result in death or serious injury.

indicates a hazard which, if not

avoided, could result in death or serious injury.

indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE addresses practices not related to

personalinjury.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition. Replace missing

or damaged safety labels.

This unit is not designed for applications involving salt water

or brine! Use with salt water or brine will void warranty.

California Proposition 65 Warning

This product contains chemicals known

to the State of California to cause cancer or birth

defects or other reproductive harm.

1. Know the pump application, limitations, and

potentialhazards.

Risk of explosion. Do not ground to a gas

supply line. Pump water only with this pump. Failure to

follow this warning can result in personal injury and/or

property damage.

2. Disconnect power before servicing.

3. Release all pressure within system before servicing

anycomponent.

4. Drain all water from system before servicing.

Risk of flooding. Can cause personal

injury and/or property damage. If a flexible discharge

hose is used, pump may move when motor starts. If

it moves far enough so that switch hits side of sump,

switch may stick and prevent pump from starting.

Make sure pump is secured so it cannot move around

in sump.

5. Secure discharge line before starting pump. An

unsecured discharge line will whip, possibly

causing personal injury and/or property damage.

6. Check hoses for weak or worn condition before

each use, making certain all connections are

secure.

7. Inspect sump, pump and system components

monthly. Keep free of debris and foreign objects.

Perform routine maintenance as required.

Risk of fire. Do not store or rest objects

on or near motor or switch linkage. Keep all flammable

objects or liquids away from motor.

8. Provide means of pressure relief for pumps whose

discharge line can be shut-off or obstructed.

9. Personal Safety:

a. Wear safety glasses at all times when working

with pumps.

b. Keep work area clean, uncluttered and properly

lighted replace all unused tools and equipment.

c. Keep visitors at a safe distance from work area.

d. Make workshop child-proof – with padlocks,

master switches, and by removing starter keys.

10. When wiring an electrically driven pump, follow all

electrical and safety codes, as well as most recent

National Electrical Code (NEC) and Occupational

Safety and Health Act (OSHA).

11. This equipment is only for use on 115 volt

(single phase) and is equipped with an approved

3-conductor cord and 3-prong, grounding-type

plug.

Risk of electric shock. Can shock, burn

or kill. Be certain that it is connected to properly

grounded, grounding-type receptacle.

Never connect green (or green and yellow) wire in cord

to a live terminal! Where a 2-prong wall receptacle

is encountered, it must be replaced with properly

grounded 3-prong receptacle installed in accordance

with the National Electrical Code and local codes and

ordinances.

12. All wiring should be performed by a qualified

electrician.

13. Make certain that power source conforms to

requirements of your equipment.

14. Protect electrical cord from sharp objects, hot

surfaces, oil, and chemicals. Avoid kinking

cord. Replace or repair damaged or worn cords

immediately.

15. Do not touch an operating motor. Modern motors

can operate at high temperatures.

16. Do not handle pump or pump motor with wet

hands or when standing on wet or damp surface,

or in water.

Risk of flooding. Can cause personal

injury and/or property damage. If your basement has

water or moisture on floor, do not walk on wet area

until all power has been turned off. If shut-off box is

in basement, call electric company to shut-off service

to house, or call local fire department for instructions.

Remove pump and repair or replace. Failure to follow

this warning can result in fatal electrical shock.

Specifications

Power supply required ..............................115V, 60 HZ.

Horsepower .............................................................. 1/3

Motor duty ...................................................Intermittent

Liquid Temp. Range ..................... 32°F to 70°F(0°-21°C)

Individual Branch Circuit

Required GFCI Class A .....................................15 Amps

Motor full load (maximum ..............................3.5 Amps

Discharge: Plastic Models ......................... 1-1/4” FNPT

Cast Iron Models ..................... 1-1/2” FNPT

Installation 4

For parts or assistance, call Flotec Customer Service at 800-365-6832

Performance

Installation

1. This unit can be installed in sump pit with

minimum diameter of 12” (30cm) and depth of

12” (30cm). Sump pit may be constructed of tile,

concrete, steel or plastic. Check local codes for

approved materials.

2. Install pump on solid, level foundation, as near as

possible to center of sump pit. Do not hang pump

from discharge pipe or power cord.

NOTICE Pump must be level (column must be vertical)

when operating. If motor is tilted, internal start/run

switch may overheat and damage motor.

3. Pump should not be installed on clay, earth or sand

surfaces. Clean sump pit of small stones and gravel

which could clog the pump. Keep pump inlet

screenclear.

4. Thread discharge pipe into pump body carefully to

avoid stripping or crossing threads.

NOTICE Do not use ordinary pipe joint compound on

plastic pipe or pump. Pipe joint compound can attack

plastics and damage pump.

5. To reduce motor noise and vibrations, a short

length of rubber hose (1-5/8” (41mm) I.D., e.g.

radiator hose) can be connected into discharge line

near pump using suitable clamps.

Risk of electric shock. Can shock, burn

or kill. Pump is designed for 115V., 60 HZ operation

and requires an individual branch circuit of 15 amperes

capacity. It is supplied with a 3-wire cord set with

grounding-type plug for use in a 3-wire, grounded

outlet. Do not cut off the round grounding prong. For

safety, outlet must always be electrically grounded to

a suitable electrical ground such as a grounded water

pipe or a properly grounded metallic raceway or

ground wire system.

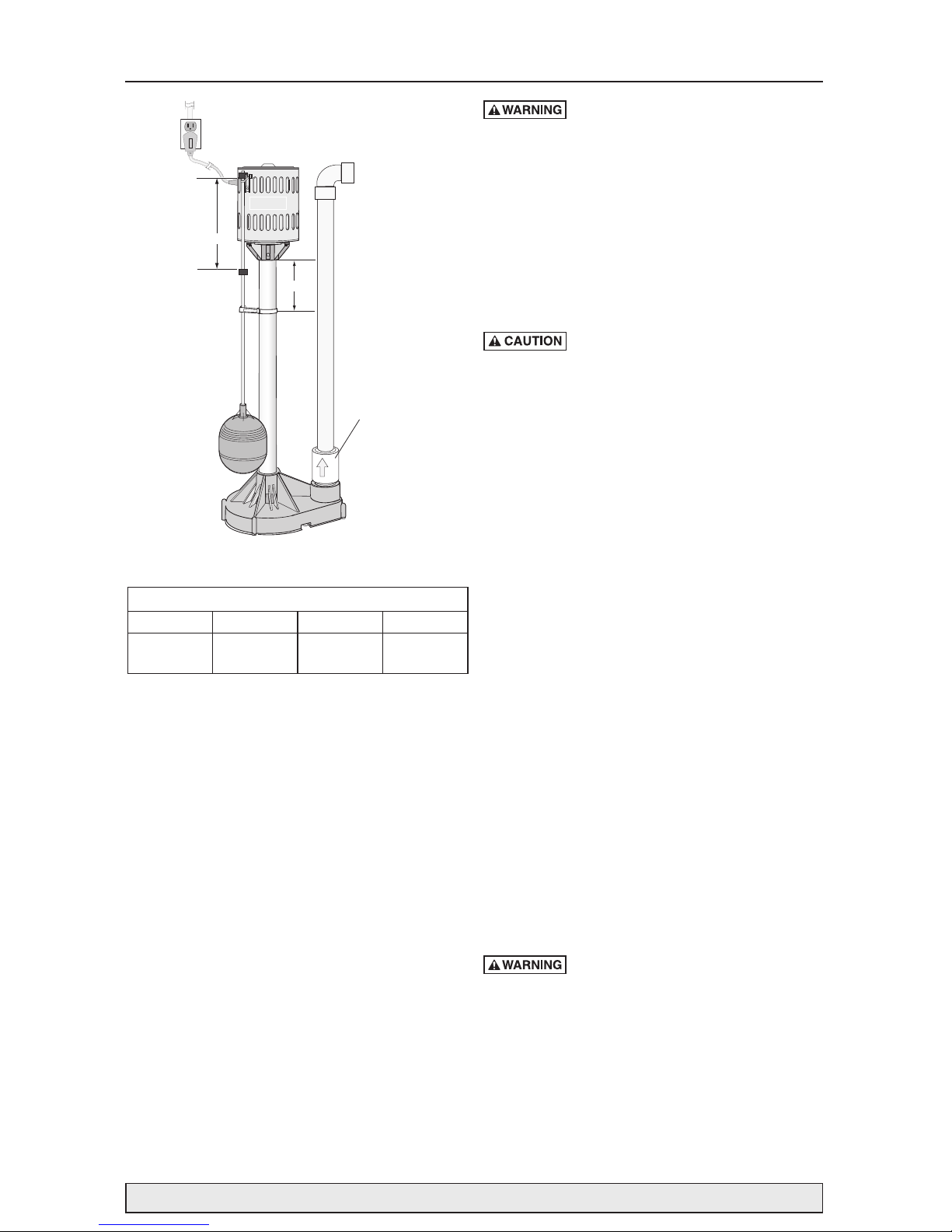

6. Locate Float Rod Guide (Key No. 6) about 6”

(16cm) below motor. Clamp guide to column with

screwprovided.

Risk of flooding. Be sure that guide is

securely clamped so that float rod is vertical and can

move up and down freely. If float is angled or binds,

pump may not start, allowing flooding to occur.

7. Screw float onto threaded end of rod. Threads on

rod will cut threads into corrosion resistantfloat.

8. Insert plain end of float rod up through eye of

rodguide.

9. Slide one rod stop on float rod before passing rod

through eye of pump switch. Slide 2nd rod stop on

rod after passing through eye of switch. Position

2nd rod stop flush with top of rod.

10. Position lower rod stop to within 8”(20cm) of

switch lever arm. With lower rod stop in this

position, pump will automatically cycle at

approximately 2-1/2” (6cm) off and 10-12” (2530cm) on. For faster cycling, move lower rod stop

closer to switch lever arm.

11. If pump discharge line is exposed to outside

subfreezing atmosphere, then portion of line

exposed must be installed so any water remaining

in pipe will drain to outfall by gravity. Failure to do

this can cause water trapped in discharge to freeze

which could result in damage to pump.

12. Install an in-line check valve (Flotec No. FP0026-

6D) to prevent flow backwards through pump after

pump shuts off.

NOTICE Flotec check valve FP0026-6D is equipped

with an air bleed hole to prevent airlocking the pump.

If using a check valve without an air bleed hole, drill a

1/8” (3.2mm) hole in discharge pipe just above pump

body but below the check valve to prevent air locks.

13. After all piping and controls have been installed,

unit is ready for operation.

14. Run pump through one cycle to check float

switchoperation.

Risk of sudden starts. Can cause

electrical shock and personal injury. The pump motor

is equipped with automatic resetting thermal protector

and may restart unexpectedly. Protector tripping is an

indication of motor overloading as a result of operating

pump at low heads (low discharge restriction),

excessively high or low voltage, inadequate wiring,

incorrect motor connections, or a defective motor.

Discharge

About 6"

About 8"

Check

Valve

(Purchase

Separately)

GPH (LPH) at total feet (M)

5 ft (1.52) 10 ft (3.05) 15ft (4.57) 20 ft (6.09)

3000 (11

355L)

2460 (9

312L)

1620 (6

131L)

0 (0L)

Operation 5

Troubleshooting

For parts or assistance, call Flotec Customer Service at 800-365-6832

Risk of electric shock. Can shock, burn or kill. Unplug pump from power source before working on

pump.

Operation

Risk of electric shock. Can shock,

burn or kill. Do not touch sump pump, pump motor,

water, or discharge piping when pump is connected to

electrical power. Always disconnect pump cord (power)

before handling.

1. Plug this unit into a 115V outlet, on an individual

branch circuit, with a Class A, 15 amp GFCI

(Ground Fault Circuit Interrupter). Consult your

local electrician for information and availability.

2.

Fill sump pit with water, pump will start automatically

when lower rod stop actuates switch lever arm. When

upper rod stop actuates switch lever arm, pump will stop.

NOTICE Do not allow pump to run dry.

3. The motor is equipped with an automatic reset

thermal protector to protect unit from overheating.

When motor has cooled sufficiently, switch will reset

automatically and restart motor. Repeated tripping

could be caused by low voltage, long extension cords,

clogged impeller, very low head or lift, etc. Cycling of

protector will cause eventual motor burnout.

Symptom Probable Cause(s) Corrective Action(s)

Motor will

not run

No electrical power Check fuse, circuit breaker, power cord and electircal outlet.

Low line voltage

If voltage wiring under recommended minimum, check size of

wiring from main source. If OK, contact Electric Comapny or local

Hydro authority.

Faulty automatic switch Operate switch manually and replace if inoperative.

Float or float rod stuck

Check to see float is not rubbing sump wall or float rod rubbing or

stuck against sump cover.

Waterlogged float Replace float if filled with water.

Motor overload tripped

IF pump has been running and stops before sump is emptied,

automatic overload may have tripped. Check inlet screen to be

sure impeller is not jammed. If so, free impeller of obstruction.

Electrical malfunction

Check power cord, automatic switch and motor. Replace faulty

parts as needed.

Motor runs

but pump

will not

pump

Inlet clogged Check inlet and clean if needed.

Discharge line plugged Clear discharge line and check valve for obstruction.

Low line voltage Refer Corrective Actionon low line voltage in above section.

Pump airlocked

Dril a 1/8” (3.2mm) hole in discharge pipe just above pump body

but below the check valvee.

Broken impeller or shaft Replace impeller or shaft as needed.

Pump starts

and stops

too often

Improper positioning of float

rodstop

Lower float rod stop.

Faulty automatic switch Replace automatic switch.

Pump is

noisy

Impeller installation Refer to No. 5 in Insallation instructions.

Noisy motor Replace pump.

Pump will

not stop

running

Debris around float or float

rodstuck

Remove debris from sump. Check to see float is not rubbing sump

wall or float rod rubbing or stuck against sump cover.

Faulty automatic switch Replace switch.

Motor defective Replace Pump

Loading...

Loading...