Flotec FPDC30 Owner's Manual

OWNER’S MANUAL

Battery Backup System

NOTICE D’UTILISATION

Système de secours à batterie

Device ID Key

MANUAL DEL USUARIO

Sistema de batería de respaldo

Test System

Tester

Probar sistema

System Alert

Alerte du système

Alerta del sistema

AC Power

Courant AC

CA

Pump Activity

Activité de pompe

Actividad de la bomba

Power

Reset System

Alarm Silenced

Courant

Réinitialise

Encendido

Alarme arrêtée

Restrablecer sistema

Alarma apagada

Interrupteur à otteur

Float Switch

Interruptor del otador

Silence Alarm

Charging

Arrêter l’alarme

Recharge

Apagar alarma

En carga

Battery Status

État de batterie

Estado de la batería

Light

Lumière

Luz

Pump

Pompe

Bomba

Circuit Breaker

Disjoncteur

Disyuntor

+

FPDC30

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Call 800-365-6832

English ........................... Pages 2-16

©2014 FP979 (04/08/14)

Composer le

(800) 365-6832

Français .................... Pages 17-31

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 800-365-6832

Español ..................... Paginas 32-46

Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided,

will result in death or serious injury.

indicates a hazard which, if not avoided,

can result in death or serious injury.

indicates a hazard which, if not avoided,

can or may result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition. Replace missing or

damaged safety labels.

To avoid risk of serious bodily injury due to electrical

shock or burns and property damage due to flooding,

read the safety instructions carefully before installing

pump.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and

disconnect DC output terminals only after removing the

charger from the AC outlet. Never allow the DC

terminals to touch each other.

Hazardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be sure

one hand is free when plugging in or unplugging charger.

If basement floor is wet, disconnect power to basement

before walking on floor.

Risk of flooding. Do not run pump dry. To

do so will damage seals and can cause leaking and

property damage.

Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault circuit

interrupter (GFCI) is recommended for use on any

electrical appliance submerged in water.

Use this system only for backup sump pump duty in a

residential application. It is not designed as a primary

sump pump.

Do not lift pump by electrical cord.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

Pump clear water only with this pump.

Pump is permanently lubricated at the factory. Do not try

to lubricate it!

Keep battery charger and battery box off of the floor and

in a dry, cool, well ventilated area.

NOTICE: If a Carbon Monoxide (CO) sensor is installed,

it must be at least 15 feet away from battery charger

in order to avoid nuisance CO alarms. Please refer

to your CO detector’s installation guidelines for more

information.

To avoid danger of fire or explosion, keep sparks and

flame (pilot light) away from battery.

Maximum vertical pumping distance is 15 feet (4.6M) for

Model FPDC30.

Make sure sump is clear of debris. Debris can damage

the pump which can result in flooding.

GENERAL INFORMATION

The battery backup sump system is not a substitute for

your primary sump pump. It is designed to temporarily

backup your primary sump pump during a power outage

or other problem which prevents normal operation of

the primary pump. Do not use this system to pump

flammable liquids or chemicals. Pump clear water only

with this pump.

Keep the battery charger dry and protected from damage.

This system is designed to work with a deep cycle sealed

maintenance free lead-acid AGM battery. It will also

work with a flooded lead acid battery. Gell and Sealed

flooded lead acid batteries are not recommended. In

an emergency (such as an extended power outage)

which depletes the system deep cycle battery, your

automobile battery may be temporarily substituted. Be

sure to replace the system deep cycle battery as soon

as possible. Use of an automobile battery instead of a

deep cycle battery in this system will significantly reduce

the system’s total performance. Automobile batteries

are not designed for this type of application and will be

quickly ruined by the repeated charge/discharge cycling.

NOTICE: This system is not designed for applications

involving salt water, brine, or where fish may be present!

Use with these will void warranty.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Installation 3

BASIC TOOLS AND PARTS NEEDED

(Purchase Separately)

Channel locks or large adjustable pliers

Tape measure

Socket wrench or 5/16” nut driver

Side cutters

Hacksaw (to cut PVC pipe)

Medium size pliers

Slotted screwdriver

Phillips head screwdriver

Pencil or marker

PTFE pipe thread sealant tape

PVC glue (solvent weld)

PVC pipe cleaner

Cloth towel

Plastic fittings

Check valve(s) - 1 or 2 depending on installation

38-120 Ampere-Hour Storage or Deep Cycle Battery

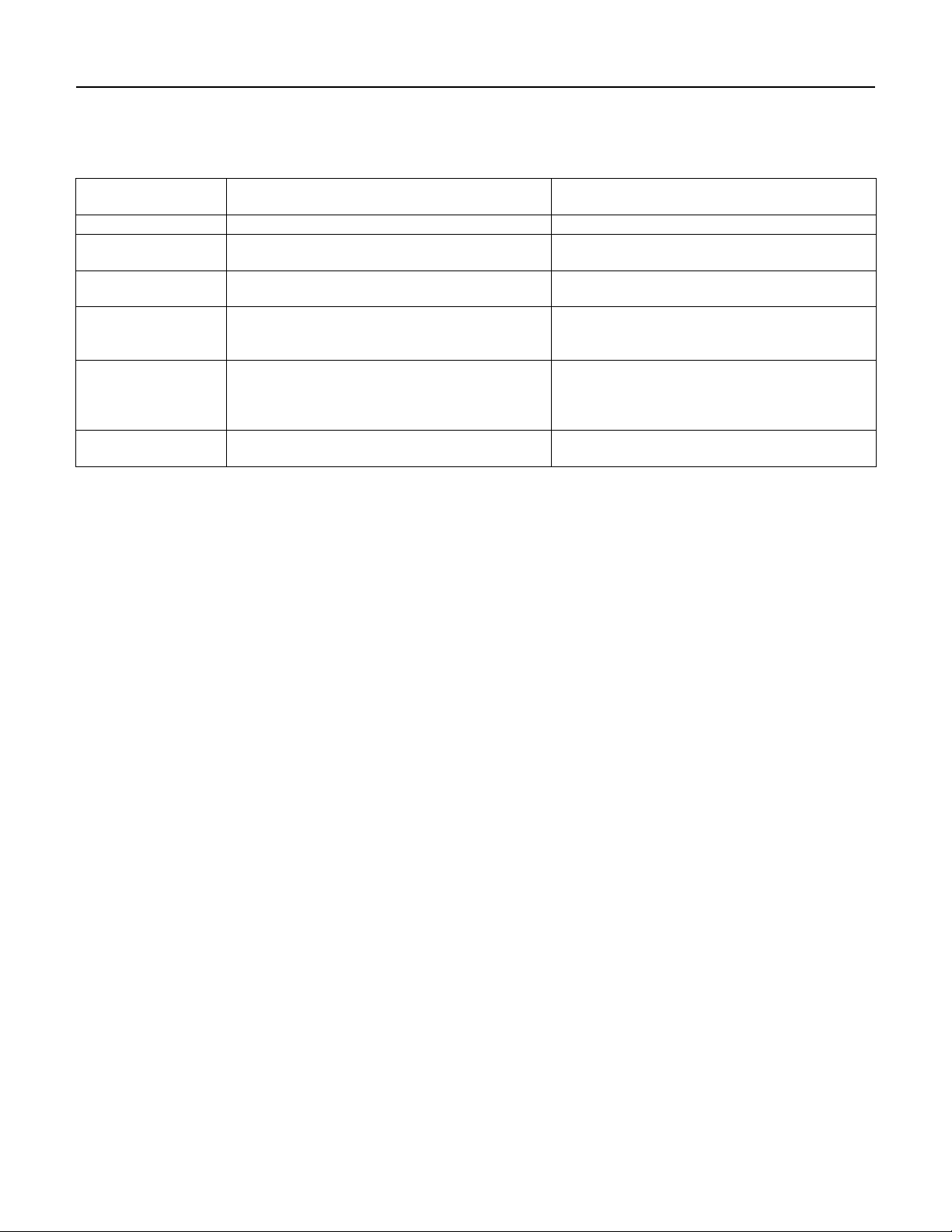

Required Battery Capacity:

For best results, use the following AGM Storage Batteries:

Gal/Charge

Part Amp-Hour

BAT40 40 4,800 5 Hours

BAT75 75 11,500 11.5 Hours

• Unit equipped with dual battery capability

• Maximum amp-hour: 120

NOTICE: The charger will not fully charge batteries with

excessive amp hour ratings without resetting system.

at 10’

Approx Run

Time

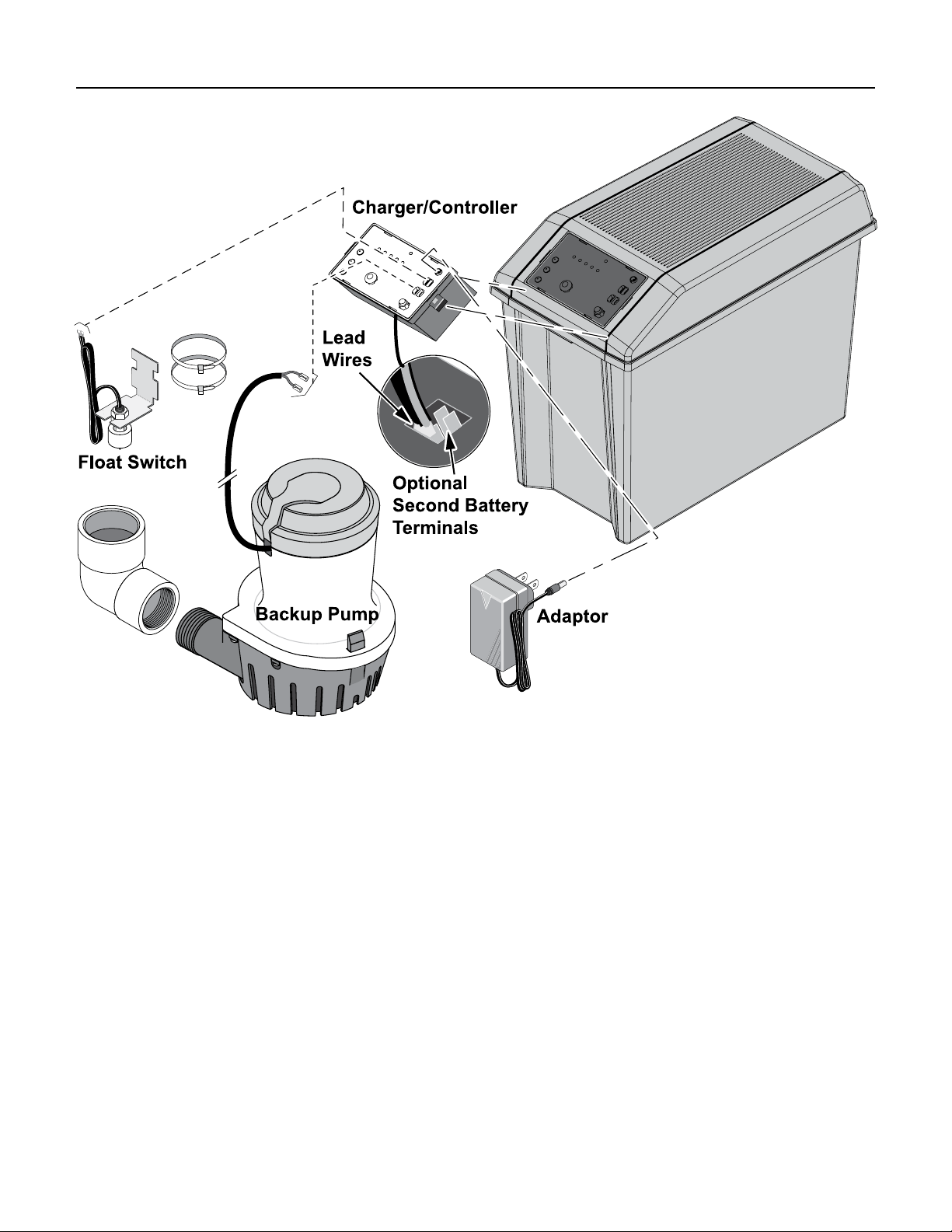

BATTERY BACKUP SYSTEM (BBU)

INSTALLATION AND OPERATION

NOTICE:

• Install this system during a time when the primary

pump will not be needed. Gather all supplies before

starting. Read all warnings and installation steps

before you start.

• Be prepared for water to leak from the coupling or

piping when disassembling or cutting the discharge

pipe. Protect system components, tools and supplies

from getting wet. Dry any work areas that get wet.

NOTICE: Study pages 4-6 to determine which installation

method will be best for you. The “Separate Discharge”

(Figure 2, Page 4), installation is recommended.

NOTICE: Check your local codes and ordinances

regarding waste water disposal (especially when running

the pump discharge outside the house) before you start.

The installation must conform to all legal requirements.

If possible, install the BBU so that the discharge goes

directly outdoors (separate discharge pipe from the

primary sump pump discharge pipe). If this is not a

practical option, see the “Common Discharge” (Figure 3,

Page 4) option.

NOTICE: For ALL installations, once the installation is

complete, run both the primary sump pump and the BBU

through at least one complete cycle to make sure that

everything operates correctly.

Personal injury and flood hazard. Do not

turn the pump on until all the fittings are glued and the

glue has dried. Loose fittings can explode off of pipes

and cause personal injury and flooding.

Risk of electrical shock. At the circuit breaker

or fuse box, turn off the electrical power to the sump

pump before beginning this installation.

Setup

1. Locate the high water level in your sump pit (the

water level at which the existing (primary) sump

pump starts - see Figure 1). Turn off power to pump

and mark this point on the discharge pipe with a

pencil or marker.

2. Drain the sump pit as far as possible without running

the pump dry. Do this by:

A. Piggyback switch: Unplug the pump and switch

from the outlet, then unplug the pump from the

piggyback switch. Reset the circuit breaker or

reinstall the fuse and plug the pump directly into

the outlet. The pump will start. Drain the pit and

unplug the pump. OR

b. No piggyback switch: Reset the circuit breaker

or reinstall the fuse and use a non-conducting

broom handle or stick to raise the float switch;

the pump should start. Drain the pit and then

release the switch.

3. When the pit has drained, turn off (open) the circuit

breaker or remove the fuse again to avoid electrical

shock while working on the installation.

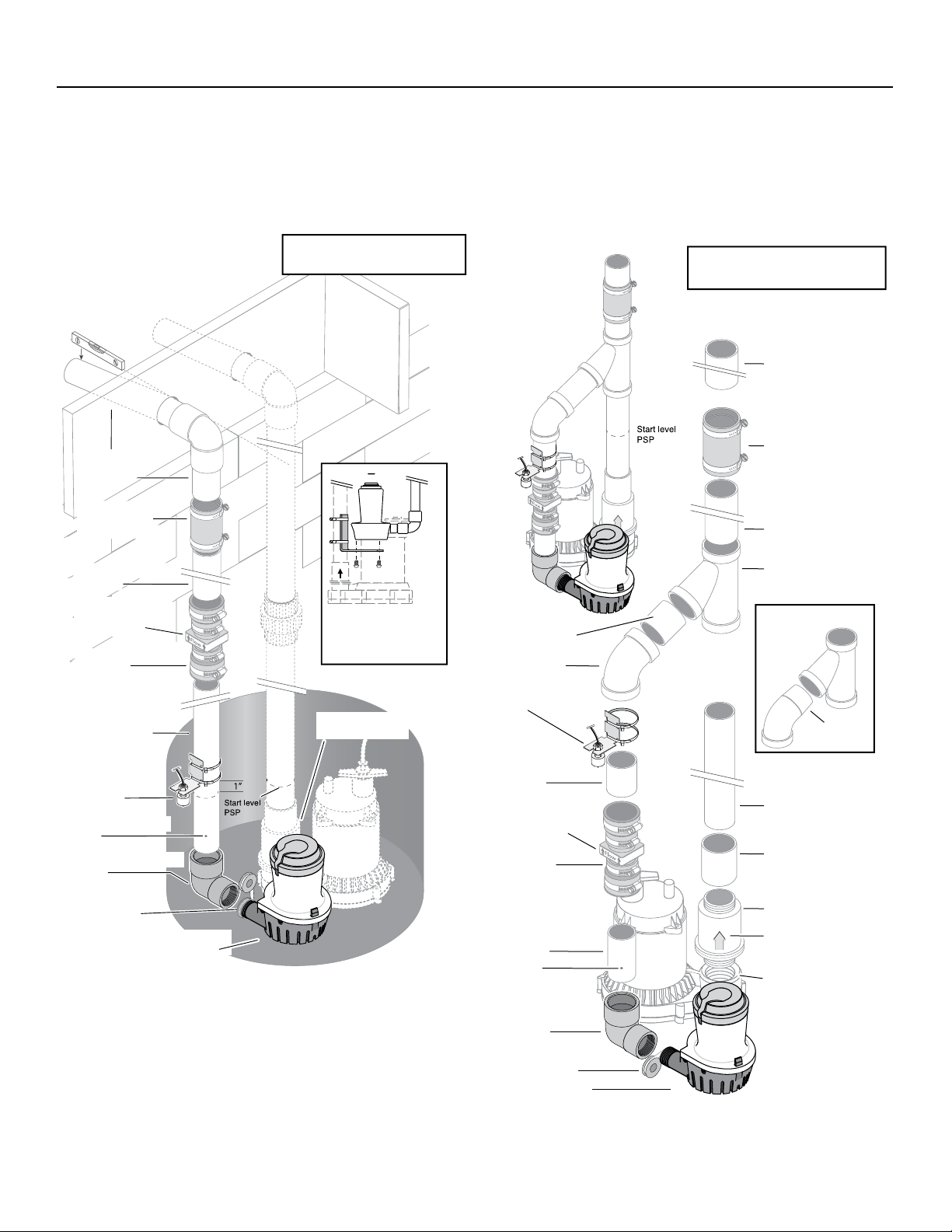

Figure 1: Mark pipe at ‘start’ water level

Installation 4

“Separate Discharge”

“Common Discharge”

NO

c

as sho

kup

System. Chec

AWA

T

T

assembled

Both check v

must be installed

on the pump side

of the

6783 0313a

NOTICE:

Check Valve Flapper(s) must swing AWAY and flow arrow(s) must point

AWAY from pump being protected.

The water level when the switch shuts off must be above the BBU

pump intake.

* Supplied with the Battery Backup System.

Items in italics must be purchased separately.

Slope DOWN

to outlet

1-1/2” PVC Upper

Discharge Pipe

(cut to fit)

U74-68 Hose and

Clamp Assembly

(Purchase Separately)

1-1/2” PVC Riser Pipe

(cut to fit)

Flow Arrow; Must point

AWAY from Pump

being Protected

FP0026-10

Check Valve

(Purchase

Separately)

Lower Discharge Pipe

1-1/2” PVC Pipe

(cut to fit)

Not to scale.

Wiring omitted for clarity.

Sill

Floor

Joist

If the sump is small,

hang the BBU from

the Primary discharge

pipe on an angle bracket.

Primary Sump Pump

Check Valve

TICE: In this installation, if the Primary Sump Pump (PSP) does not have a

heck valve installed below the wye, you MUST install a check valve for the PSP

wn. This prevents backflow of water into the sump from the Battery Bac

k Valve Flapper(s) must swing AWAY and flow arrow(s) must point

Y from the pump being protected.

he water level when the switch shuts off must be above the BBU pump intake.

ypical installation,

.

alves

wye.

Optional 1-1/2”

PVC Pipe (cut to fit)

45º Slip Elbow

Battery Backup

Switch*

FLOW

Not to scale.

Wiring omitted for clarity.

Supplied with the Battery Backup System.

*

Items in italics must be purchased separately

1-1/2” PVC Upper

Discharge Pipe

(cut to fit)

U74-68 Hose and

Clamp Assembly

(Purchase Separately)

1-1/2” PVC Riser Pipe

(cut to fit)

45 degree Slip Wye

AlternateWye/Elbow

Setup

45º Slip Street

Elbow

Battery Backup

Switch*

Drill 1/8” Anti-Airlock

Hole

1-1/4” FNPTx1-1/2” Slip

Elbow*

PTFE pipe thread

sealant tape on all

threaded joints

Battery Back Up

Sump Pump*

FLOW

Figure 2: Typical installation with separate

discharge pipes.

6782 0313a

1-1/2” PVC Pipe

(cut to fit)

Flow Arrow; Must point

AWAY from Pump

being Protected

FP0026-10

Check Valve

(Purchase

Separately)

Lower Drischarge Pipe

1-1/2” PVC Pipe

(cut to fit)

Drill 1/8”

Anti-Airlock Hole

1-1/4” FNPTx1-1/2”

Slip Elbow*

PTFE pipe thread

sealant tape on all

threaded joints

Battery Back Up

Sump Pump*

FLOW

Primary Pump

Discharge Pipe

(cut to fit)

Thread to Slip

Adapter

Primary Pump

Check Valve

Flow Arrow; Must point

AWAY from Pump

being Protected

Primary Sump Pump

Discharge Port

Figure 3: Typical installation with common

discharge pipe.

Installation 5

INSTALLATION (Typical): Separate Discharge

Risk of electrical shock. Can shock, burn, or

kill. Unplug the primary sump pump before beginning this

procedure.

NOTICE: Allow for overlap when cutting piping and run a

trial (dry) fitting before you glue.

1. Use PTFE pipe thread sealant tape on male ends of

discharge pipe. Thread the 1-1/4” x 1-1/2” elbow

(supplied) onto the discharge. When tight, the elbow

must point up.

2. If possible, install the Battery Backup Unit (BBU) on

the floor of the sump; be sure that the two pumps do

not touch each other and do not interfere with switch

operation.

NOTICE: If debris or gravel is present in the bottom of

the sump pit that could get sucked up into the pump, set

both the primary sump pump and the BBU up on bricks

or cinder blocks to prevent clogging.

3. If the sump is too small to allow both pumps to sit on

the bottom of the sump, install an angle bracket on the

primary sump pump’s discharge pipe with stainless steel

hose clamps. Mount the backup pump on the angle

bracket. See Figure 1, “Separate Discharge”.

4. Cut a piece of 1-1/2” PVC pipe to reach from the backup

pump discharge elbow to about one (1) foot above the

basement floor. This is the lower discharge pipe.

5. To prevent airlocking the pump during operation, drill a

1/8” hole in the lower discharge pipe about 2” above the

bottom of the pipe (below floor level).

6. Install FP0026-10 check valve (purchase separately)

on the upper end of the pipe. Tighten the hose clamps

securely. BE SURE that the flow arrows point UP (away

from the BBU). If they point down, the valve will not

pass water and the pump will not work.

7. Cut a short length of 1-1/2” PVC pipe for a riser pipe and

clamp it into the top of the check valve.

8. Install a U74-68 Hose and Clamp Assembly on the top

of the riser pipe. For 1-1/2” pipe, remove and discard

the short piece of 1-1/4” hose in the Hose and Clamp

Assembly. Leave the hose clamps loose and slide the

Assembly down below the top of the riser pipe.

9. Determine where you want the discharge to exit the

basement. At that point, drill the necessary holes (large

enough to have clearance for a 1-1/2” pipe) to allow you

to run the discharge pipe from above the sump to the

outdoors.

10. Install the horizontal discharge pipe. Install a 90° elbow

on the inside end but do not glue.

11. Cut another short piece of 1-1/2” PVC for the Upper

Discharge Pipe to run from the top of the riser pipe up to

the 90° elbow. Be sure to allow enough overlap for the

glue joint in the elbow.

12. Do a trial fit with NO GLUE, installing the 1-1/2” upper

discharge pipe in the 90° elbow and the upper discharge

pipe in the vertical end of the 90° elbow. The upper

discharge pipe should just fit between the riser pipe and

the elbow.

13.

Whenever using PVC primer and PVC cement, follow

the glue manufacturer’s instructions.

14. Make sure that the BBU will clear the primary sump

pump and its switch. If there isn’t room for both pumps

to sit on the floor of the sump, the BBU will have to be

raised (depending on your particular situation).

15. Clean, prime and glue the upper discharge pipe into the

90º elbow. When the glue has set, slide the Hose and

Clamp Assembly up to cover the joint and tighten all the

hose clamps.

16. Install the Battery Backup Switch as shown, 1” above

start water level of primary pump. Fasten it to the pipe

with cable ties.

17. Tape the pump cord to the riser pipe so that the plug

cannot fall into the sump.

18. Go to “BBU WIRING AND SETUP” (Page 8) for wiring

instructions.

19. Once all wiring is complete, fill your pit with water

and verify that the PSP removes the water and the BBU

doesn’t run. Then, unplug your PSP and refill your pit

with water. Verify that the BBU pump removes the water.

20. Make sure that the power is on to both pumps, and your

system is ready to use.

Risk of fire and chemical inhalation.

Installation 6

INSTALLATION (Typical): Common Discharge

Risk of electrical shock. Can shock, burn, or

kill. Unplug the primary sump pump before beginning this

procedure.

NOTICE: Allow for over lap when cutting piping and run a

trial (dry) fitting before you glue.

NOTICE: If there is no check valve in the primary sump

pump’s discharge, you will need to install one. You must also

install one in the BBU’s discharge pipe (Figure 3, Page 4). Make

sure that the check valve flow arrow points AWAY from the

pump it is protecting.

1. Use PTFE pipe thread sealant tape on male ends of

discharge pipe. Thread the 1-1/4” x 1-1/2” elbow

(supplied) onto the discharge. When tight, the elbow

must point up.

2. If possible, position the BBU on the floor of the sump;

be sure that the two pumps do not touch each other and

do not interfere with switch operation.

NOTICE: If debris or gravel is present in the bottom of

the sump pit that could get sucked up into the pump, set

both the primary sump pump and the BBU up on bricks

or cinder blocks to prevent clogging.

3. If the sump is too small to allow both pumps to sit on the

bottom of the sump, find a raised position that doesn’t

interfere with the PSP switch.

4. Cut a piece of 1-1/2” PVC pipe to reach from the backup

pump discharge elbow to about one (1) foot above the

basement floor. This is the lower discharge pipe.

5. To prevent airlocking the pump during operation, drill a

1/8” hole in the lower discharge pipe about 2” above the

bottom of the pipe (below floor level).

6. Install FP0026-10 check valve (purchase separately)

on the upper end of the pipe. Tighten the hose clamps

securely. BE SURE that the flow arrows point UP (away

from the backup pump). If they point down, the valve

will not pass water and the pump will not work.

7. Cut the discharge pipe for the primary sump pump (PSP)

above the union and check valve (if any). Make this cut

about 18” above the top of the BBU’s riser pipe with the

backup pump sitting as installed.

8. If the PSP does not have a check valve installed in the

discharge pipe, install one now.

9. Cut a length of discharge pipe for the PSP to fit between

the check valve and a 45° slip wye. Be sure to allow for

the overlap needed for gluing joints.

10. Install the 45° wye on the PSP’s discharge pipe.

11. Install a 45° elbow on the 1-1/2” BATTERY BACKUP

discharge pipe.

NOTICE: You may need to insert a piece of straight pipe

between the elbow and the wye. If so, use a standard

45° elbow. If you do not need to insert a piece of straight

pipe between the elbow and the wye (elbow goes

directly into the wye), use a 45° slip street ell.

12. Fit the upper discharge pipe to the upper end of the wye.

NOTICE: It is good practice to cut a short length of

pipe to go into the wye and install a union on the pipe.

Continue the discharge pipe from the outlet side of

the union. This will allow easier removal of the system

for cleaning or service. A U74-68 Hose and Clamp

Assembly can be used for this.

13. Make sure that the BBU will clear the primary sump

pump and its switch. If there isn’t room for both pumps

to sit on the floor of the sump, the BBU will have to be

raised (depending on your particular situation).

14. Do a trial assembly to make sure that everything is

going to fit. This may require a helper to assist in holding

everything together while you check the fit without glue.

Mark all joints before gluing.

Risk of fire and chemical inhalation. Follow the

glue manufacturer’s instructions regarding fire hazards and

ventilation when using PVC solvents, primer, and cement.

15. Take all the pipe apart, clean all joints, and then

reassemble the system, gluing it with PVC primer and

glue.

16. Install the Battery Backup Switch as shown, 1” above

start water level of primary pump. Fasten it to the pipe

with the cable ties provided.

17. Tape the pump cord to the riser pipe so that the plug

cannot fall into the sump.

18. Go to “BBU WIRING AND SETUP” (Page 8) for wiring

instructions.

19. Once all wiring is complete, fill your pit with water

and verify that the PSP removes the water and the BBU

doesn’t run. Then, unplug your PSP and refill your pit

with water. Verify that the BBU pump removes the water.

20. Make sure that the power is on to both pumps, and your

system is ready to use.

Battery Requirements 7

BATTERY REQUIREMENTS

Hazardous electric current. Can cause

severe burns and start a fire if the battery terminals are

short circuited. Install the battery in the battery case. To

prevent accidental shorting across battery terminals,

close and latch the battery case securely. Do not leave

the battery uncovered.

Do not allow children to play around the battery

backup system installation.

The performance of your backup sump pump depends on

the battery used with it for power. We recommend using

our BAT40 or BAT75. You can also use a group 24M or

27M Deep Cycle battery. They will provide acceptable

performance and will stand up well to long periods of

little or no use.

This system is designed to work with either a sealed

lead-acid AGM battery or a flooded lead-acid battery.

Use of a true Gell Cell (often confused for AGM) or a

standard automotive battery with this charger is not

recommended. An automotive battery may require

charging after only 1-2 hours of continuous use, and the

repeated charging cycles may cause early plate failure in

the battery.

Use only lead-acid batteries. This unit is not designed to

use with Li-Ion, NiMh, NiCAD, Liquid Polymer, etc.

Use only the recommended battery or one of the same

type and size so it will fit in the battery box (maximum

size: 13” long x 7” wide x 10” tall (330.2mm x 177.8mm

x 254mm) including terminals) and supply enough

voltage for full performance.

BATTERY MAINTENANCE

Severe burn hazard. An acid-filled standard

lead-acid battery contains sulfuric acid. Avoid contact with

skin, eyes or clothing.

NOTICE: To protect the battery case from chipping and

gouging, do not let the battery sit on a concrete floor.

Install the battery on a shelf or protective pad (plywood,

2x4s, etc.). Always install the battery in a dry location

that is protected from flooding.

Pre-Qualification Test – 1 and 2

Charger is charging at a very low level to try to bring a

dead battery back to life. If the battery is taking too long,

try resetting the charger once or twice (push the ‘SYSTEM

TEST’ and ‘SILENCE ALARM’ buttons together to reset the

charger).

Special Features:

The charger is equipped with reverse battery, short

circuit, and “runaway charge” protection.

Possible Problems and Remedies

1. Wrong Battery Voltage

Reconnect charger to a 12 volt battery.

2. Reversed Battery Connections

Check all connections. The negative (black) on the

battery must connect to the negative (black) on

the charger, and the positive (red) on the battery

must connect to the positive (red) on the charger.

Reversing the battery connections will cause the

‘SYSTEM ALERT’ and ‘SILENCED AUDIBLE ALARM’

LEDs to flash.

3. Thermal Runaway Condition

“Thermal Runaway” is the technical term for the

condition of the battery when some (or all) of the

cells have deteriorated to the point that they won’t

take a charge. In this case, replace the battery.

4. Charge Time Monitor – 1 and 2

Battery took too long to complete its charge. The

“Charge Time Monitor” will shut down the charger

after 84 hours of continuous charging.

Possible causes are:

A) Pump ran for a long period of time during

charging, or

B) Battery is too large for the charger (including

several batteries connected in a parallel circuit).

Excessive Battery Drain

Pump may have run for a very long time, discharging the

battery. In this case:

1. If 115VAC power is OFF, the charger shuts down

until the power comes back on, but the pump will

run as long as the battery charge lasts. You may need

to replace the battery afterwards.

2. If 115VAC power is ON, the charger/controller

continues to try to charge the battery at a charging

rate of .5 AH until the battery charge is more

than 20%, at which point the charger will resume

charging at a rate of 2 AH.

3. If the pump is running and the AC power is on, you

may need to stop the pump to allow the battery to

charge.

Follow the battery manufacturer’s recommendations for

maintenance and safe use of the battery.

Wiring • Setup 8

BBU WIRING AND SETUP

1. Connect the positive (+) charger/controller lead

wire (red) to the positive (+) battery terminal (red).

Connect the negative (–) charger/controller lead

wire (black) to the negative (–) terminal (black) on

the battery. If you are using two batteries, use the

set of optional terminals and connect the second

battery. Use lead wires (not included) to connect

the positive (+) charger/controller terminal to the

positive (+) battery terminal and the negative (–)

charger/controller terminal to the negative (–) battery

terminal.

2. The backup pump leads are polarity sensitive;

connect the positive pump lead to the terminal

labeled Pump ‘+’ and the negative pump lead to the

terminal labeled Pump ‘–’.

NOTICE: If the leads are reversed, the pump will run

backward and not pump water.

3. The float switch leads are not polarity sensitive;

connect the float switch leads to the ‘Float Switch’

tabs on the charger/controller.

4. Test the float and the pump by lifting and holding

the float. The system alert LED will blink while

the float is up. The ‘PUMP STATUS’ LED will light

continuously and the buzzer will beep steadily. The

pump should start after 3 seconds. If the pump does

not run, check all the connections and remake them

as necessary.

5. To stop the pump, lower the float; after 25 seconds

the pump should stop, the ‘PUMP STATUS’ LED

should flash, and the buzzer should beep.

6. With the pump operating, test the ‘SILENCE ALARM’

button; hold for one second; release. The ‘ALARM

SILENCED’ LED should illuminate and the buzzer

should stop sounding. To reset the buzzer (allow it to

sound) and extinguish the ‘ALARM SILENCED’ LED,

press the ‘SILENCE ALARM’ button again for one

second.

Depress the ‘TEST SYSTEM’ button; hold it for one

second; release. The ‘PUMP STATUS’ LED should stop

flashing.

Wiring • Setup 9

NOTICE: During normal operation, the flashing

‘PUMP STATUS’ LED indicates that the pump has

run in your absence.

1. Press and hold ‘TEST SYSTEM’ button. All LEDs will

light up, pump will run and buzzer will sound.

Release the button and LEDs should go off, pump

should stop, buzzer should stop.

2. The ‘BATTERY STATUS’ LED indicates the battery

capacity when the A.C. power is off.

A. Continuously ON - the battery voltage is above

10.9 Volts Direct Current (10.9VDC) and

capacity is above 20%.

B. Slow Beep/Slow LED Flash - the battery’s

capacity is between 0 and 20%.

LED Display and Control Buttons

C. Fast Beep/Fast LED Flash - the battery is severely

discharged. The battery will continue to charge

(as long as the 115V AC power to the charger is

on) at the rate of .5 AH until the battery’s charge

is above 20%.

When the first warning occurs (slow beep/slow

flash), you will have approximately 2 hours (or less)

of pump operation left. The actual time of operation

will depend on the condition of the battery and may

be as little as 15 minutes.

4. Connect the Power Supply cable (supplied) to the

Charger/Controller’s Power Input jack.

NOTICE: When the unit is first plugged in, or when it first receives power from the battery, the ‘BATTERY STATUS’

LED will flash for 3 seconds.

NOTICE: To activate any Control Button, press and hold it for 1 second.

Virtual Water Assistant Setup 10

Battery Backup Internet Connection and

Alerts Configuration

Before setting up the Virtual Water Assistant (VWA), make

sure your Battery Backup Unit - FPDC30 is installed correctly, refer to Owner’s Manual for instruction. Make sure

the primary pump and battery backup unit has power.

Verify the system is operational by pressing the ‘TEST

SYSTEM’ button and observing the test sequence.

1. Find an open network connection on your internet

router or other hard-wired connection. Rotate the

antennae up on the gateway.

NOTICE: We recommend the use of an uninterrupted

power supply for your internet modem, home router

and the gateway power supply.

2. Using the supplied 1 meter Ethernet cable (or longer

cable if necessary), connect the gateway to an open

network port.

3. Connect the gateway power supply to a 115 VAC

outlet, plug into the back of the gateway.

• The LED will blink red for a few seconds.

• When the LED becomes solid green or solid

green with an occasional blink your gateway is

connected to the VWA servers.

If not, refer to Gateway Troubleshooting.

4. Once the gateway LED is green, go to the BBU and

verify that the AC power LED is solid green. If not, the

gateway will have to be moved closer to the BBU.

5. Log onto the website www.VirtualWaterAssistant.com

• Select “Sign Up”

• Follow the online instructions and enter the

required personal information to create a user

account. The Alerts will use the e-mail addresses

and phone numbers entered here.

• Enter the Unique Device ID Key included with

the FPDC30 - located on BBU case and manual

cover.

6. Test installation by clicking the “Test” icon on the

web page and verify the unit has run the test.

7. Using the drop down menu configure the desired

method of Alerts you want to receive (Text or E-mail).

8. Alerts can be tested by activating the pump with the

float switch.

Virtual Water Assistant Setup 11

Gateway Troubleshooting

IF GATEWAY LED LIGHT IS NOT GREEN (GREEN, SLOW BLINK) FIRST TRY TO “POWER CYCLE” THE GATEWAY (UNPLUG THE

POWER CORD, WAIT 15+ SECONDS, THEN RE-APPLY POWER).

Gateway Status

Indicator (LED Color)

Green Power on: gateway connected to servers. OK - Connection complete and operational

Green, quick blink Power on: data traffic to servers. OK - Operating, data is moving between BBU and

Green, slow blink

(1-2 blinks per second)

Red Power on: gateway has no local connection to

Red, slow blink

(1-2 blinks per second)

Off Power off or product fault. Check power source, verify power adapter is

Definition Action Needed

Server

Power on: gateway connected to local router, but

not connected to Internet or servers.

router. The gateway does not "recognize/see" that it

is connected to the router.

Power on: gateway communicating with router, but

router cannot assign Dynamic Host Configuration

Protocol (DHCP) or Domain Name System (DNS) to

gateway.

System is online and scanning for destination/server

(add a network switch inline to help define unit).

Check Ethernet cable connections and/or quality or

cable. Try a different router port. Is the router turned

on.

Router is not permitting the gateway to access the

internet (add a network switch inline to help define

unit).

functioning. Defective gateway.

Charger/Controller LED Display 12

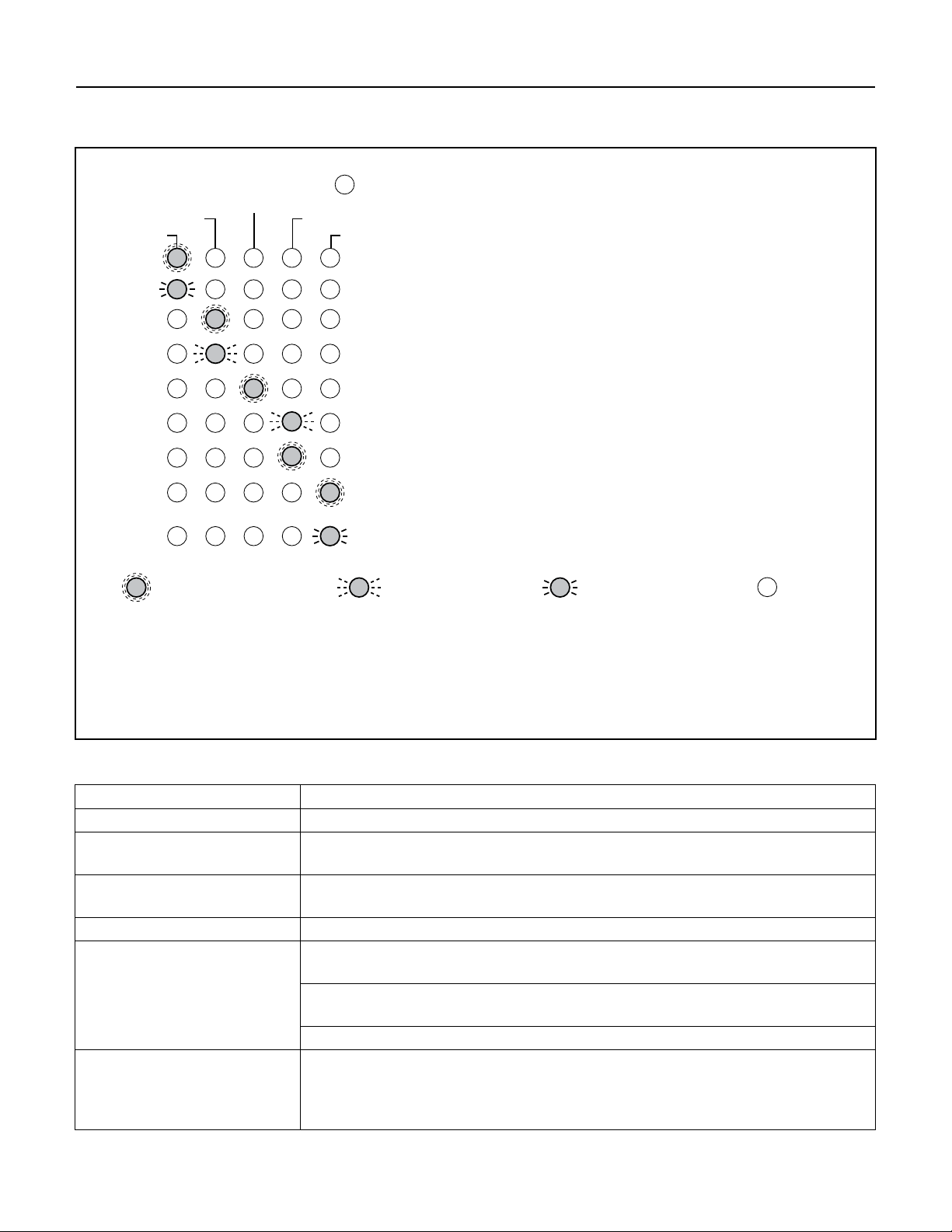

LED Operating Code Display

System Operating Condition

6790 0313

TABLE II – Operating Code Displays (LEDs Lighted Continuously or Flashing)

SYSTEM ALERT

ALARM SILENCED

PUMP ACTIVITY

AC POWER

CHARGING

BATTERY STATUS

Indicates 115V AC Power is connected / Unit online

Indicates 115V AC Power is connected / Unit offline

Indicates Pump is running (continuous LED)

Indicates Fast flashing LED: Pump has run

Indicates Audible alarm is switched off

Indicates Fast flashing LED: Battery pre-qualification test is running

Indicates Battery is charging normally

Indicates Continuous LED: battery charge is above 20%,

system is maintaining charge

Indicates Slow flashing LED: battery charge is below 20%

= =

LED is ON Continuously

=

LED is Flashing (Fast)

=

LED is Flashing (Slow)

LED is OFF

NOTICE: All of the situations listed above indicate normal system operation; no action is required.

However, if the BBU pump is running or has run, check the primary pump and actively monitor the

charger status for battery life. Always reset the charger after the pump runs.

During normal system operation, the ‘SYSTEM ALERT’ LED blinks while the float switch is on,

indicating the pump should start within 3 seconds. The “AC POWER” LED is lighted

(solid or blinking) as long as the system is plugged in to an operating AC power circuit.

TABLE III – LED Function Displays (LEDs Lighted Continuously)

Control LED: Continuous Illumination Indicates Normal Operation:

AC Power AC power is present. Unit is online.

Pump Status

Silenced Audible Alarm Audible Alarm has been silenced. Press and release the ‘SILENCE ALARM’ button

Charging

Battery Status A. Continuous ON - the battery voltage is above 10.9 Volts DC and capacity is

System Alert Flashing (in unison with the buzzer) indicates that the charger has entered ‘Failure

The float switch has been activated. The LED remains on (flashing) after the pump

has stopped. Depress the ‘SYSTEM TEST’ button to reset it.

to reset (activate) the audible alarm and turn OFF the LED.

Indicates that the battery is charging – see Table II, above.

above 20%.

B. Slow Beep/Slow LED Flash - the battery’s capacity is below 20%, and voltage is

between 8.2VDC and 10.9VDC.

C. Fast Beep/Fast LED Flash - the battery has been discharged to less than 8.2VDC.

Mode’. Press the ‘SYSTEM TEST’ and ‘SILENCE ALARM’ buttons to reset it.

NOTICE: If the source of the failure is not corrected, the charger will reenter

“Failure Mode”. See Table IV for error code information.

Charger/Controller LED Display 13

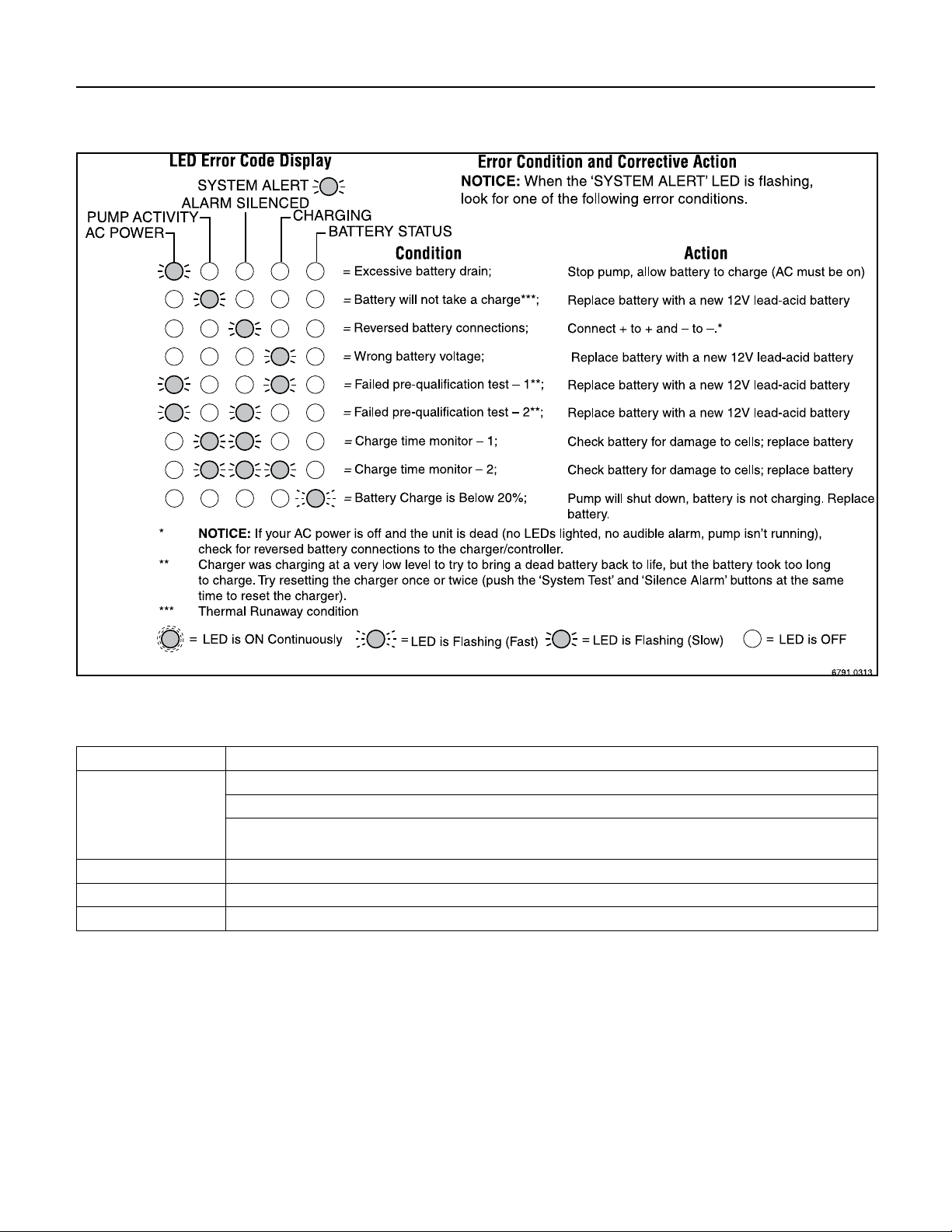

TABLE IV – Error Code Displays (LEDs Flashing)

TABLE V – Control Button Functions

Control Button: Result of Pushing Button:

System Test Pump starts and all LEDs light up.

Will reset the ‘PUMP ACTIVITY’ LED.

When pushed with the ‘SILENCE ALARM’ button, the Charger/Controller microprocessor resets

and error code resets.

Silence Alarm Toggle; Prevents the audible alarm sounding. Press and release to reset.

Light Toggles the light on the Charger/Controller on and off.

System Reset Press and release ‘TEST SYSTEM’ and ‘SILENCE ALARM’ to reset system.

Troubleshooting 14

TROUBLESHOOTING - PUMP

Pump won’t run: Check all the wiring connections.

Check for a low or defective battery.

Check that the automatic switch is free to move up and down.

Press the circuit breaker reset button on the control panel.

Motor hums but pump won’t run: Check for low or defective battery.

Pump runs but pumps very little or no water: Make sure a check valve is installed and functioning between the

primary pump discharge and the Battery Backup wye.

Check for an obstruction in the discharge pipe.

The discharge pipe length and/or height exceeds the capacity of the

pump.

Check for a low or defective battery.

The Positive (+) and negative (–) pump wires are reversed.

Disconnect them and reconnect correctly.

Pump cycles too frequently: The check valve located between the discharge of the primary

pump and the Battery Backup wye is not installed or is not

working properly. Install an auxiliary check valve or replace the

existing check valve as required.

Loading...

Loading...