Flotec FP5455 Owner's Manual

OWNER’S MANUAL

Engine Drive Self-Priming Pump

NOTICE D’UTILISATION

Motopompe à amorçage

automatique

MANUAL DEL USUARIO

Bomba autocebante

accionada a motor

Installation/Operation/Parts

DO NOT return this pump to the store

where you purchased it.

For questions or problems about pump

operation, call 1-800-365-6832.

English . . . . . . . . . . . . . . . Pages 2-8

Installation/Fonctionnement/Pièces

NE PAS ramener cette pompe au

magasin ou elle a été achetée.

Pour toute question ou tout problème

concernant le fonctionnement de la

pompe, appeler le 1 800 365-6832.

Français . . . . . . . . . . . . Pages 9-15

Instalación/Operación/Piezas

No devuelva esta bomba a la tienda

donde la compró.

Para preguntas o problemas acerca de

la operación de la bomba llame al

1-800-365-6832.

Español . . . . . . . . . . .Paginas 16-22

FP753 (Rev. 2/11/05)

Model FP5455

®

P.O. Box 342, Delavan, WI 53115

Phone: 1-800-365-6832

Fax: 1-800-526-3757

E-Mail: info@flotecwater.com

Web Site: http://www.flotecwater.com

4584 0504

IMPORTANT

For best possible performance and continuous, satisfactory operation, read these instructions before installing your new pump. Should service be required, this

manual can be a valuable guide, it should be kept near the

installation for ready reference.

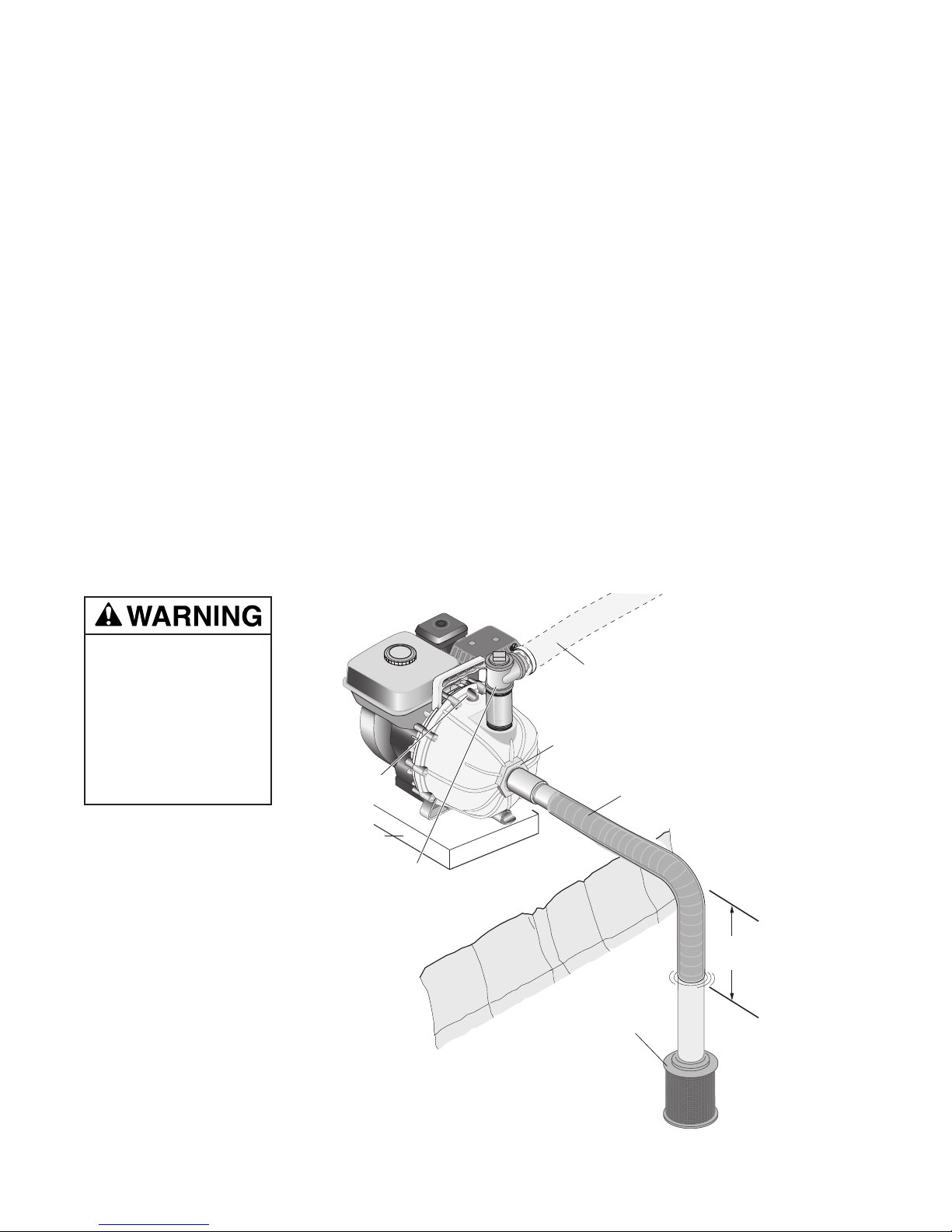

INSTALLATION

LOCATION

Place unit as close to water source as possible to minimize

suction lift, obtain the best pumping performance, and aid in

priming. A typical portable installation is shown in Figure 1.

For permanent installation, mount unit on a foundation that

will support the weight of pump and engine and also provide

stability while the pump is running. For most permanent

installations, it is advisable to bolt unit directly to foundation.

NOTICE: Settling and/or shifting during operation can cause

piping to place excessive strain on the pump and may damage pump case. Set pump on hard level surface.

SUCTION CONNECTION

Connect either rigid pipe or flexible suction hose to pump

suction as shown in Figure 1. If hose is selected, hose must

be rated to hold the suction pressure and prevent collapse

while the pump is running.

Make the suction line a continuous rise from the water

source to the pump. High spots can trap air and also make

priming difficult. Make sure all connections are tight and free

of air leaks.

NOTICE: Suction pipe or hose must be at least as large as the

pump suction inlet in order for the pump to operate properly.

Minimum depth for the suction inlet is determined by the

diameter of the suction line. See Figure 1.

NOTICE: Use a suction screen to keep debris out of pump.

DISCHARGE CONNECTIONS

Your pump is equipped with a single port discharge. Select

the appropriate size for the application. Install a “T” as

shown to allow priming the pump without disconnecting the

piping.

OPERATION

NOTICE: Do not start or run pump dry or damage to the

mechanical seal will result.

NOTICE: Add engine oil before startup. Refer to the

engine operation manual before startup.

PRIMING THE PUMP

A self priming pump only needs to be manually primed at the

first start-up. Once primed, under normal conditions the

pump will reprime automatically at each subsequent start-up.

If the pump is used in portable applications and the water has

been drained from the pump case, reprime before start-up

To prime, remove plug from top discharge outlet and fill

pump with water. Replace plug and start pump. The pump

will require a few minutes to evacuate air from the suction

line. After several minutes of operation, pump will be fully

primed and pumping water. Priming time will vary depending

on length and diameter of suction line.

2

Figure 1 – Typical Installation

Hazardous Suction.

Can trap persons

against suction inlet.

Always use strainer

on suction hose to

prevent entrapment.

Use pipe or reinforced hose to make

suction connection.

Hose must be strong enough to

not collapse during operation.

Suction screen area must be at least four

times suction pipe area.

All suction piping must slope up toward the

pump inlet.

Support the piping and fittings to reduce strain

on the pump case.

Priming Plug

Provide rigid

platform for pump.

Customer-supplied

Priming tee, plug

and nipple.

Discharge pipe not

smaller than the pump

discharge opening.

(2" x 25' Discharge hose

included in kit FP2731)

Pump Inlet

Suction hose

(2" x 15' Suction hose

included in kit FP2735).

Support pipe and

fittings.

Strainer or foot valve

(2" strainer included

in kit FP2735)

Depth of suction inlet at least

four (4) times the diameter of suction

pipe to avoid forming vortexes.

Example:

2" Pipe x 4 = 8" minimum depth.

25' Max

RUNNING THE ENGINE

Refer to engine operation part of this manual for starting and

operating instructions.

Pump performance varies depending on engine R.P.M.

Refer to engine operation to adjust engine speed.

MAINTENANCE

PUMP LUBRICATION

Pump liquid end does not require any grease or oil for lubrication. The mechanical seal is lubricated by water when the

pump is operating.

3

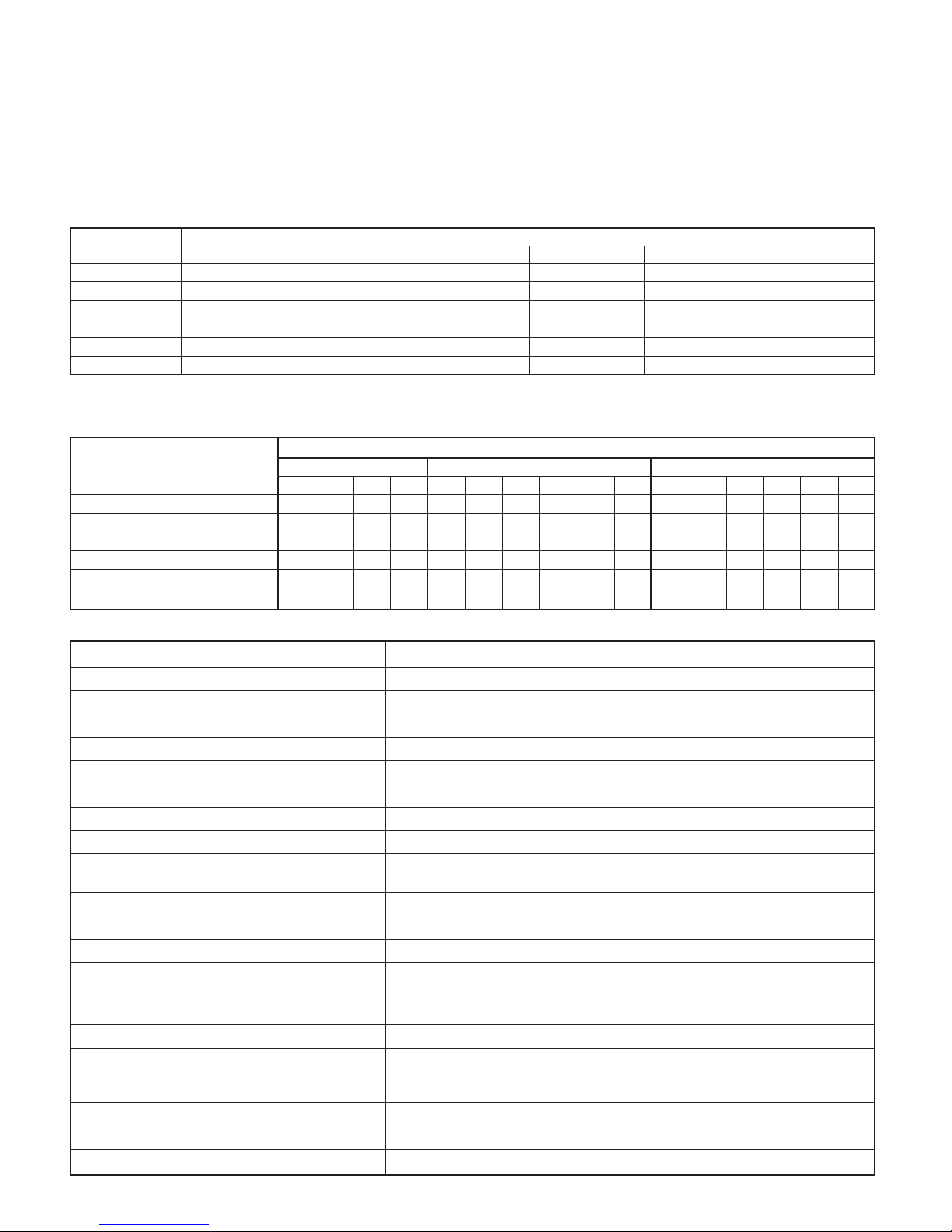

CAUSE CORRECTIVE ACTION

1. ENGINE

A. Speed too low Refer to engine section

B. Rotating and/or reciprocating parts drag Refer to engine section

C. Speed too high Maximum engine speed not to exceed engine manufacturer’s recommendation.

D. Loose or broken parts Refer to engine section

2. PUMP

E. Not primed Reprime, inspect suction system for air leaks, and or clack assembly.

F. Pump takes too long to prime Check for air leaks or defective check valve.

G. Flow through pump completely Locate and remove obstruction. Attach strainer.

or partially blocked

H. Internal leakage Check clearances between face of vanes and case. Should not exceed 1/32".

I. Rotating parts drag Inspect. Repair.

J. Loose or broken parts Inspect. Repair.

3. SYSTEM

K. Pressure required by system at design Compare pump pressure and flow rate against pump performance chart.

flow rate exceeds pressure rating of pump Reduce system pressure requirement. Increase pressure capability of pump.

L. Obstruction in suction piping Locate and remove obstruction. Attach strainer.

M. Suction lift too high Check with gauge or measure vertical distance between water surface and

center line of pump, allowing for friction loss in suction pipe. Reduce rate of

flow to obtain desired lift. Refer to pump performance chart.

N. Discharge head too low Decrease rate of flow

O. Suction inlet not immersed deep enough Refer to “Installation”

P. Leaky suction line or connection admitting air Repair or replace suction line. Tighten connections.

PROBABLE CAUSE

SYMPTOM ENGINE PUMP SYSTEM

ABCDEFGH I JKLMNOP

No water delivered X X X X X X X

Not enough water delivered X X X X X X X

Not enough pressure X X X X X X

Engine heats excessively X X X X X X X

Abnormal noise and/or vibration X X X X X X X

Pump works for a while, then stops XXXXXX

Depth Gallons per Minute at Discharge Pressure Maximum

to Water 15 PSI 25 PSI 35 PSI 45 PSI 50 PSI PSI

0 ft. 141 120 95 65 50 58

5 ft. 130 110 85 55 40 55

10 ft. 121 100 75 45 25 52

15 ft. 113 90 65 30 2 50

20 ft. 105 80 55 7 – 48

25 ft. 80 60 40 2 – 45

Troubleshooting Guide

Performance Chart

4

Pump Exploded View

• Not illustrated.

† Purchase locally.

* If needed, replace entire pump.

Item Description Qty. Part Number

1 Engine 1 *

2 Engine Mount Screws, 5/16-24 x .75 4 †

3 Seal Plate 1 M13906

4 O-Ring, Pump Body 1 M13910

5 Diffuser Gasket (O-Ring Segment) 1 M13918

6 Mechanical Seal 1 M13914

7Impeller 1 M13908

8 Impeller screw, 5/16-24 x 1.25 1 S23562

9 Rubber Washer for Impeller Screw 1 M13913

10 Diffuser 1 M13907

11 Flapper Valve 1 M13909

12 Plug 2 M13911

12A O-Ring, Plug 2 M13912

13 Pump Housing 1 M13905

14 Screw, 1/4-20x2.5 hex Head Machine Screw 10 †

15 Nuts, 1/4-20 10 †

16 Lockwasher 10 †

• Screw, Diffuser, #6 x 1/2 Self-Tapping 2 †

• Screw, Diffuser, #10 x 1-1/2 Self-Tapping 1 †

1

3

4

5

7

2

10

15

16

9

12

12A

13

6

8

11

12A

12

14

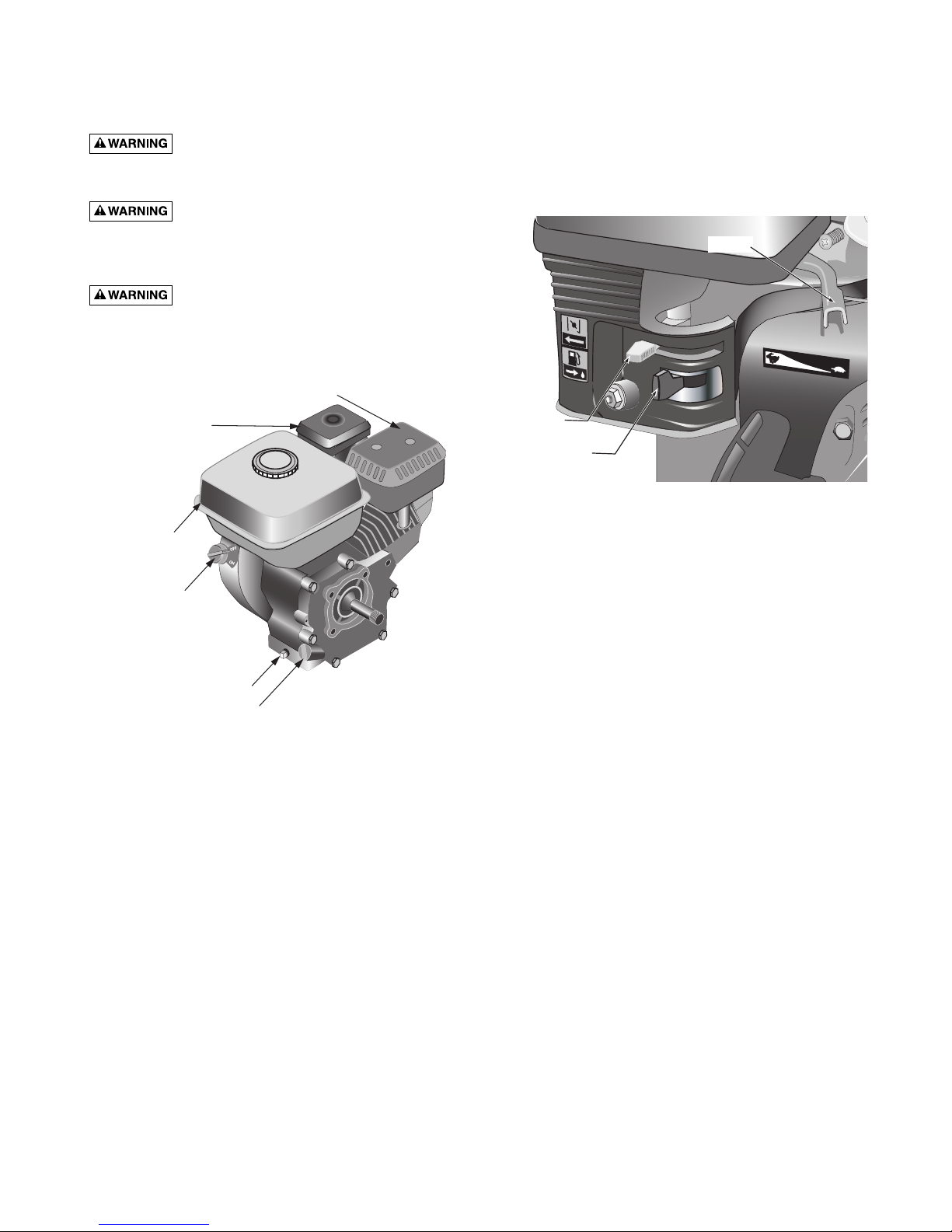

Engine Safety Precautions:

Fire and explosion hazard. Gasoline can

explode. Store gasoline away from the engine. Add gasoline

to the engine only when the engine is off.

Burn hazard. Hot surface.The engine gets

very hot during operation. Do not touch the engine surfaces.

Keep children away. Allow the engine to cool before moving

it indoors.

Deadly fumes. Carbon monoxide. Never run

the engine in an enclosed space. Only use outdoors with

plenty of ventilation.

Engine Operation

Before starting the engine:

Check and Fill Oil

The engine is shipped without oil. It must be filled before

starting the engine.

Fill oil by removing the fill cap / dipstick. Add oil until the

level reaches the bottom of the opening. Check the oil level

by pushing the cleaned dipstick into the oil fill opening. DO

NOT SCREW IT IN. Remove the dipstick and inspect it. Add

oil if needed. Reinstall the cap / dipstick.

Oil capacity is 0.63 quarts (0.6 liter). 10W-30 oil should be

used in normal conditions. Use 10W-40 oil if the engine is to

be run in temperatures over 90°F (32°C) .

Note that the engine has a low-oil monitoring system. If the

oil level drops too low, the system will automatically turn off

the engine.

Add Gasoline

Fill gas tank with clean fresh gasoline. This should be

unleaded fuel that has an octane rating of 86 or higher.

Do not fill the tank to overflowing. Clean up any spilled gasoline before starting the engine.

Open Fuel Valve

Move the fuel valve to the right to allow fuel to the engine.

Close Choke

When starting a cold engine, move the choke control to the

left (closed). As the engine warms up move it towards the

right (open). A warm engine should start with the choke

open.

Position Throttle

Move the throttle (speed control) slightly to the left.

Turn Engine Switch On

The engine switch controls the ignition. turn it to the ON

position to start the engine. The same control is used to stop

the engine.

Pull Starter

Pull the handle on the recoil starter. Adjust throttle to desired

speed. Move the choke to the right as engine warms.

Stopping the Engine

Stop the engine by turning the engine switch to OFF.

Turn the fuel control to OFF (left).

5

PUMP ENGINE OPERATION AND MAINTENANCE

Muffler

Air Filter

Gas Tank

Engine On / Off Switch

Throttle

Engine Choke

Fuel Valve

Oil Drain Plug

Oil Fill and Dipstick

4646 0704

Engine Maintenance

Air filter

The air filter should be checked every month for dust and

dirt accumulation. Every 6 months the filter element should

be removed and cleaned. Clean the foam element with

detergent and warm water. Squeeze out excess water and

let it dry. Before reinstalling the filter element, soak it with

engine oil, and squeeze out the excess. Reinstall the filter.

The engine will smoke upon startup if too much oil is left in

the filter element.

Oil level

The oil level should be checked before each use.

Oil Change

The oil should be changed in the first month, and then every

6 months (or 100 hours of operation). To drain the oil, run

the engine until warm. Turn off the engine, remove the oil

drain plug, and let the the oil drain into a pan. Reinstall the

plug and fill with oil.

NOTE: Dispose of used oil responsibly. DO NOT pour it

down drains, onto the ground or put it in the trash. Most

communities have collection points for used oil.

Spark Plug

The spark plug should be checked and cleaned every 6

months or 100 hours.

The sparkplug should be replaced if it is damaged, or excessively worn.

The sparkplug is type BPR6ES (NGK) or equivalent. The

plug gap should be 0.030 in. (0.75 mm)

Engine Troubleshooting

If the engine won’t start:

• Check that there is gas in the tank

• Make sure the fuel valve is ON and that the engine switch

is ON

• Make sure there is enough oil in the engine to reset the

low-oil sensor

• Check that fuel is getting to the carburetor*

• Check for spark at the sparkplug*

* These checks to be done by persons with small-engine

experience.

Extended storage

If the pump will be stored for more than a month or two, follow the steps below.

• Drain Gasoline

• Change oil

• Squirt oil (or a chemical made for storing engines) in the

spark plug hole.

• Rotate engine slowly until resistance is felt (this indicates

that both valves are closed).

• Install spark plug

• Cover engine

6

7

1

Engine Replacement Parts

Item Description Qty. Part Number

1 Muffler Cover 1 2545-0011

2 Muffler 1 2545-0010

3 Spark Plug (use NGK brand #BPR6ES) 1 *

4 Air Filter Cover 1 2545-0018

5 Air Filter Cartridge 1 2545-0001

6 Starter Assembly 1 2545-0005

(includes rope,handle and recoil assembly)

7 Wing-nut for Air Filter 1 2545-0019

8 Muffler Cover Mounting Hardware 2 2545-0020

9 Oil Fill Cap 1 2545-0003

10 Oil Drain Plug and Washer 1 2545-0021

11 On / Off Switch and Cover 1 2545-0004

12 Fuel Tank 1 2545-0009

13 Fuel Tank Cap 1 2545-0002

* Purchase locally.

2

4 & 5

3

6

7

8

13

12

11

9

10

8

FLOTEC LIMITED WARRANTY

FLOTEC warrants to the original consumer purchaser (“Purchaser”) of its products that they are free from defects in material or

workmanship.

If within twelve (12) months from the date of the original consumer purchase any such product shall prove to be defective, it

shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below. Your original receipt of

purchase is required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Ninety (90) Day Warranty:

If within ninety (90) days from original consumer purchase any Drill Pump, Pitcher Pump, or In-Line Water Filter Cartridge

shall prove to be defective, it shall be replaced, subject to the terms set forth below.

Two (2) Year Warranty:

If within two (2) years from original consumer purchase any 1/3 HP Submersible Sump Pump shall prove to be defective, it

shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below.

Three (3) Year Warranty:

If within three (3) years from original consumer purchase any 4” Submersible Well Pump, or 1/2 HP Submersible Sump Pump,

shall prove to be defective, it shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth

below.

Four (4) Year Warranty:

If within four (4) years from original consumer purchase any FLOODMATE 7000

TM

Submersible Sump Pump shall prove to be

defective, it shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below.

Five (5) Year Warranty:

If within five (5) years from original consumer purchase any Pre-Charge water system tank shall prove to be defective, it shall

be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below.

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty shall

not apply to acts of God, nor shall it apply to products which, in the sole judgement of FLOTEC, have been subject to negligence, abuse, accident, misapplication, tampering, alteration; nor due to improper installation, operation, maintenance or storage; nor to other than normal application, use or service, including but not limited to, operational failures caused by corrosion,

rust or other foreign materials in the system, or operation at pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective product to the Retail outlet or to FLOTEC as

soon as possible after the discovery of any alleged defect. FLOTEC will subsequently take corrective action as promptly as reasonably possible. No requests for service under this warranty will be accepted if received more than 30 days after the term of

the warranty.

This warranty sets forth FLOTEC’s sole obligation and purchaser’s exclusive remedy for defective products.

FLOTEC SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WAR-

RANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE DURATION OF THE APPLICABLE EXPRESS WARRANTIES

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an

implied warranty lasts, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

FLOTEC • P.O. Box 342 • Delavan, WI U.S.A. 53115

Phone: 1-800-365-6832 • Fax: 1-800-526-3757

E-Mail: info@flotecwater.com • Web Site: http://www.flotecwater.com

ENGINE

Refer to engine manufacturer’s operating manual for complete maintenance and warranty.

Loading...

Loading...