Flotec FP4210, FP4207, FP4205, FP4157, FP4150 Owner’s Manual

OWNER'S MANUAL

®

293 Wright Street, De[avan, Wl 53115

Phone: 1-800-365-6832

Fax: 1-800-526-3757

Web Site: F[otecWater.com

Water

isOur

Business'

Jet Pumps

NOTICE D'UTILISATION

Pompes acc_l_ratrices

MANUAL DEL USUARIO

Bombas de chorro

Shallow Well Pump Models

Pompe Pour Puits Peu Profond

Bomba De Pozo Poco Profundo

FP4155 1/2 HP/ch

FP4157 3/4 HP/ch

FP4150 I HP/ch

installation/Operation/Parts

For further operating_ installation,

or maintenance assistance:

Call 1-800-365-6832

English ............. Pages 2-12

Pompe Pour Puits Profond

Bomba De Pozo Profundo

installation/Fonctionnement/

Pi_ces

Pour plus de renseignements

concernant I'u tilL_ation,

l'installation ou l'entretien,

Composer ie I (800) 365-6832

Fran_ais .......... Pages 13=23

DeepWell Pump Models

FP4205 1/2 HP/ch

FP4207 3/4 HP/ch

FP4210 I HP/ch

instalaci6n/Operaci6n/Piezas

Para mayor informacidn sobre el

funcionamiento, instalacidn o

mantenimiento de/a bomba:

Llame al 1-800-365-6832

Espaffo[ ........... P_ginas 24-34

@2011 FP933 (4/5/11)

Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS -This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product,

Save this manual for future reference.

_, This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

E_WARNiNGI indicates a hazard which, if not avoided,

could result in death or serious injury.

E_CAUTION[ indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Electrical Safety

I_WARNINGI Capacitor voltage may be hazardous.

To discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor

terminals together. Do not touch metal screwdriver blade

or capacitor terminals. [f in doubt, consult a qualified

electrician.

General Safety

[_ CAUTION1Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for

20 minutes after shut-down before handling.

Do not allow pump or any system component to freeze.

To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

[_WARNING] Pump body may explode if used as a

booster pump unless relief valve capable of passing full

pump flow at 75 psi is installed.

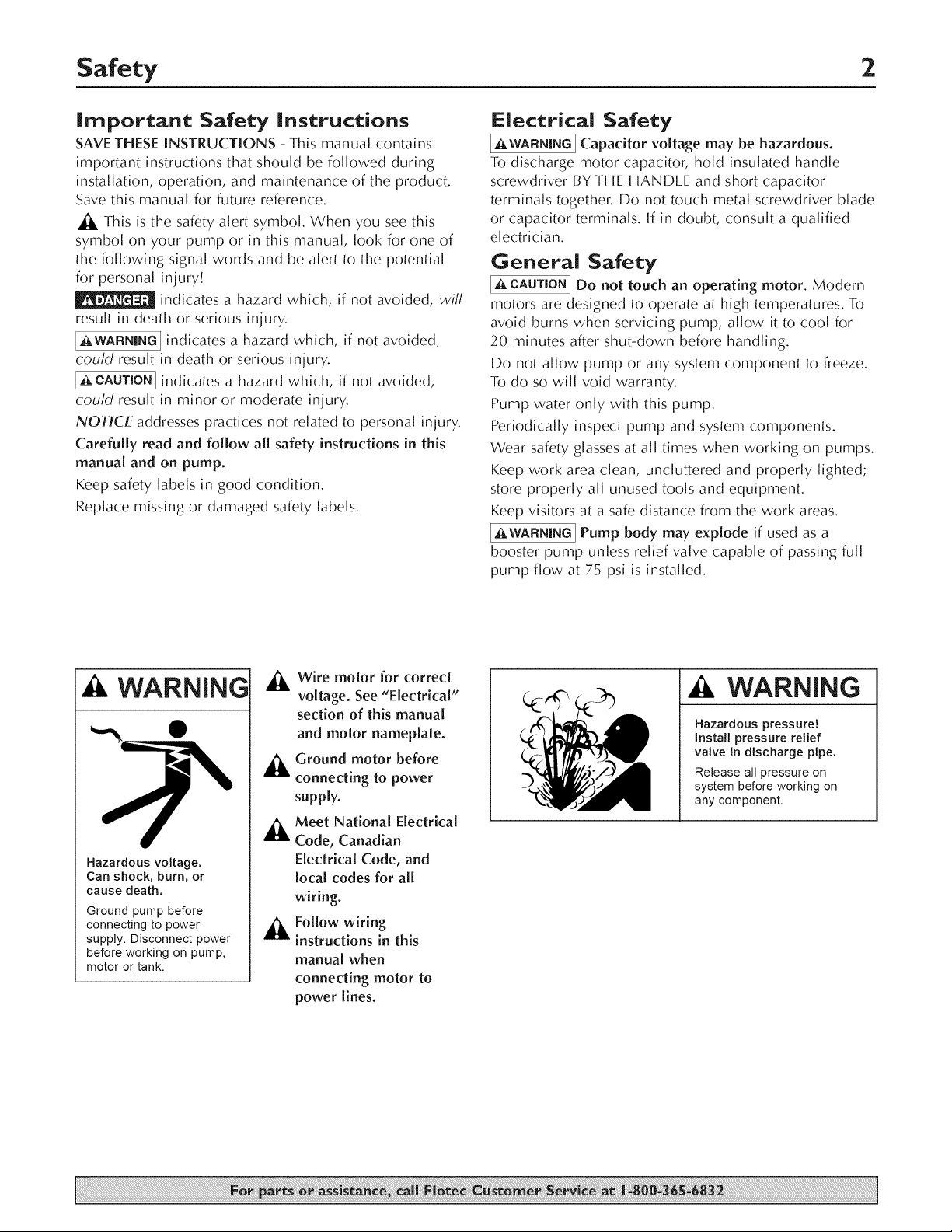

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

_, Wire motor for correct

voltage. See "Electrical"

section of this manual

and motor nameplate.

_ round motor before

connecting to power

supply.

,_ Meet Natlona[ Electrical

Code, Canadian

Electrical Code, and

local codes for all

wiring.

_k Follow wiring

instructions in this

manual when

connecting motor to

power lines.

WARNING

Hazardous pressure!

Instal[ pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

Warranty 3

Retain Original Receipt For Your Records

Limited Warranty

FLOTECwarrantstotheoriginalconsumerpurchaser("Purchaser"or"You")ofitsproductsthattheyarefreefromdefectsinmaterialandworkmanship

foraperiodoftwelve(12)monthsfromthedateoftheoriginalconsumerpurchase.

If,withintwelve(12)monthsfromtheoriginalconsumerpurchase,anysuchproductshallproveto bedefective,itshallberepairedorreplacedat

FLOTEC'soption,subjecttothetermsandconditionssetforthbelow.Theoriginalpurchasereceiptandproductwarrantyinformationlabelarerequired

todeterminewarrantyeligibility.Eligibilityisbasedonpurchasedateof originalproduct- notthedateofreplacementunderwarranty.Thewarrantyis

limitedtorepairor replacementofproductonly- Purchaserpaysall removal,installation,labor,shipping,andincidentalcharges.

Forpartsor troubleshootingassistance,DONOTreturnproducttoyourretailstore.ContactFLOTECCustomerServiceat1-800-365-6832.

Claimsmadeunderthiswarrantyshallbemadebyreturningtheproduct(exceptsewagepumps,seebelow)totheretailoutletwhereitwaspurchased

immediatelyafterthediscoveryofanyallegeddefect.FLOTECwill subsequentlytakecorrectiveactionaspromptlyasreasonablypossible.Norequests

forservicewill beacceptedif receivedmorethan30daysafterthewarrantyexpires.

Sewage Pumps

DONOTreturnasewagepump(thathasbeeninstalled)toyourretailstore.ContactFLOTECCustomerService.Sewagepumpsthathaveseenservice

andbeenremovedcarryacontaminationhazardwiththem.

Ifyoursewagepumphasfailed:

- Wearrubbergloveswhenhandlingthepump;

- Forwarrantypurposes,returnthepump'scordtagandoriginalreceiptofpurchasetotheretailstore;

- Disposeofthepumpaccordingtolocaldisposalordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

DrillPump,PitcherPump,In-lineWaterFilterCartridge,Utility Pump(ModelFPOF360AC,FPOFDC) 90 days

1/3 HPSubmersibleSumpPumps,PoolCoverPump(ModelFPOS1790PCA),UtilityPump(ModelFPOS4100X),Condensate 2Years

Pump(ModelFPCP-2OULST),IntelliPump(ModelFPOS1775A),Back-upSumpPumpSystem(ModelFP2800DCC)

4" SubmersibleWellPumps,1/2 HPSubmersibleSumpPumps,1/3 HPSumpPumpModels(FPSC2200A-10,FPSC2250A-10) 3Years

Pre-OhargeWaterSystemTank(FP7100Series),1/2 HPSumpPump(ModelsFPSC3200A-10,FPSC3250A-10),Submersible 5Years

SolidsHandlingPumps(ModelsFPSE9000,E75STVT),SubmersibleSumpPumps(ModelsESOTLT,ESOVLT,E75VLT,

EIOOELT,FPSC5OOOA)

Floodmate®7000(ModelFPOS6OOOA),PedestalSumpPump(ModelFPPSS5000),SewageEjector(ModelFPSE3601A), Lifetime

SubmersibleSewagePump(ModelFPSES2700A),Utility Pump(ModelFPSC1725X),SubmersibleSumpPump(Model

FPSC4550A-10)

General Terms and Conditions

Youmustpayall laborandshippingchargesnecessaryto replaceproductcoveredbythiswarranty.Thiswarrantydoesnotapplytothefollowing:

(1)actsofGod;(2)productswhich,in FLOTEC'ssolejudgement,havebeensubjecttonegligence,abuse,accident,misapplication,tampering,or

alteration;(3)failuresduetoimproperinstallation,operation,maintenanceorstorage;(4)atypicalor unapprovedapplication,useorservice;(5)failures

causedbycorrosion,rustorotherforeignmaterialsinthesystem,oroperationatpressuresinexcessofrecommendedmaximums.

ThiswarrantysetsforthFLOTEC'ssoleobligationandpurchaser'sexclusiveremedyfordefectiveproducts.

FLOTECSHALLNOTBELIABLEFORANYCONSEQUENTIAL,INCIDENTAL,ORCONTINGENTDAMAGESWHATSOEVER.

THEFOREGOINGWARRANTIESAREEXCLUSIVEANDINLIEUOFALLOTHEREXPRESSANDIMPLIEDWARRANTIES,INCLUDINGBUTNOTLIMITED

TOTHEIMPLIEDWARRANTIESOFMERCHANTABILITYANDFITNESSFORA PARTICULARPURPOSE.THEFOREGOINGWARRANTIESSHALLNOT

EXTENDBEYONDTHEDURATIONPROVIDEDHEREIN.

Somestatesdonotallowtheexclusionorlimitationofincidentalor consequentialdamagesorlimitationsonhowlonganimpliedwarrantylasts,sothe

abovelimitationsorexclusionsmaynotapplyto You.ThiswarrantygivesYouspecificlegalrightsandYoumayalsohaveotherrightswhichvaryfrom

statetostate.

FLOTEC. 293 Wright Street • Delavan, Wl U.S.A. 53115

Phone: 1-800-365-6832 " Fax: 1-800-526-3757

Web Site: FIotecWater.com

Installation 4

Process A. Determine the Depth of

YourWell

Shallow wells are less than 25 feet to water; deep wells are up

to 70 feet to waten Tie a small but heavy weight to the end of

a piece of string (be sure there is enough string; some wells are

very deep). J.ower the weight into the well until it reaches the

bottom. Take up the slack and mark the string at ground level.

Pull the weight out of the well and measure from the bottom of

the weight to the ground level mark. This is the depth of your

well. Subtract five feet from the depth of your well. This number

should not exceed the maximum rated depth for your pump. If

it does, it will greatly hinder or prevent the proper operation of

the pump.

Process B. Correctly Select Your Pump

Voltage

[_WARNING[ Hazardous voltage. Disconnect power to pump

before working on pump or motor. Disconnect pump from

power source before changing the pump voltage. To change the

voltage, the selector switch is located underneath the plastic

access cover on top of the motor. To access the switch, remove

the eight screws holding the plastic coven To change the voltage

setting, slide the switch as shown until desired voltage is visible

on the switch. The voltage number that appears is the voltage

setting for the pump. Be sure the switch is completely engaged.

Replace the cover and secure it with the eight screws.

VOLTAGE SELECTION DIRECTIONS

Warning!

Disconnect pump from power

source before servicing or

handling pump.

Be sure that incoming power

supply is same as voltage

selector switch setting.

Wiring Your Pump

I_kWARNING] Hazardous voltage. Disconnect power to pump

before working on pump or match Disconnect pump from

power before servicing or handling pump. Remove the cover

from the pressure switch. Connect the bare copper ground to

the ground screw in the pressure switch. Connect the power

supply to the terminals marked "Line" in the diagram below.

____ fTo Motor

Ground

Connections -_

From Line

5907 1108

Piping

Plastic- PVC pipe is shown in the illustrations, but galvanized

steel pipe may be used if desired. All piping must be clean and

free of all foreign matter to prevent clogging. ALL JOINTS AND

CONNECTIONS IN THE WE[_[. ASSEMBLY MUST BE AIRTIGHT.

Even a pinhole leak will prevent the proper operation of

the pump (this is the most common problem). Use thread

compound on all threaded joints unless specified otherwise.

slide switch as shown

To change voltage settings

until desired voltage is

visible on switch.

Be sure switch is completely

engaged.

Replace capacitor housing cover

and secure cover with screws.

Do not overtighten screws.

Wiring Chart - Recommended Wire And Fuse Sizes

Distance In Feet(Meters) From Motor To Supply

0- 100 101 - 200 201 - 300 301 - 400

Model HP Volts

Motor

FP4155 1/2 115/230

FP4157 3/4 115/230

FP4150 1 115/230

FP4205 1/2 115/230

FP4207 3/4 115/230

FP4210 1 115/230

Nameplate

Amps

8.5/4.2

11.0/5.5

12.0/6.0

7.0/3.5

11.0/5.5

11.0/5.5

Branch Fuse

Rating Amp

15/15

20/15

20/15

15/15

20/15

20/15

(0- 30) (31 - 61) (62 - 91) (92 - 122)

14/14(2/2)

12/14(3/2)

12/14(3/2)

14/14(2/2)

12/14(3/2)

12/14(3/2)

AWG Wire Size (mmO

12/14(3/2)

10/14(5.5/2)

10/14(5.5/2)

12/14(3/2)

10/14(5.5/2)

10/14(5.5/2)

10/14(5.5/2)

8/14(8.4/2)

8/14(8.4/2)

10/14(5.5/2)

8/14(8.4/2)

8/14(8.4/2)

8/14(8.4/2)

6/14(14/2)

6/14(14/2)

10/14(5.5/2)

6/14( 14/2 )

6/14(14/2)

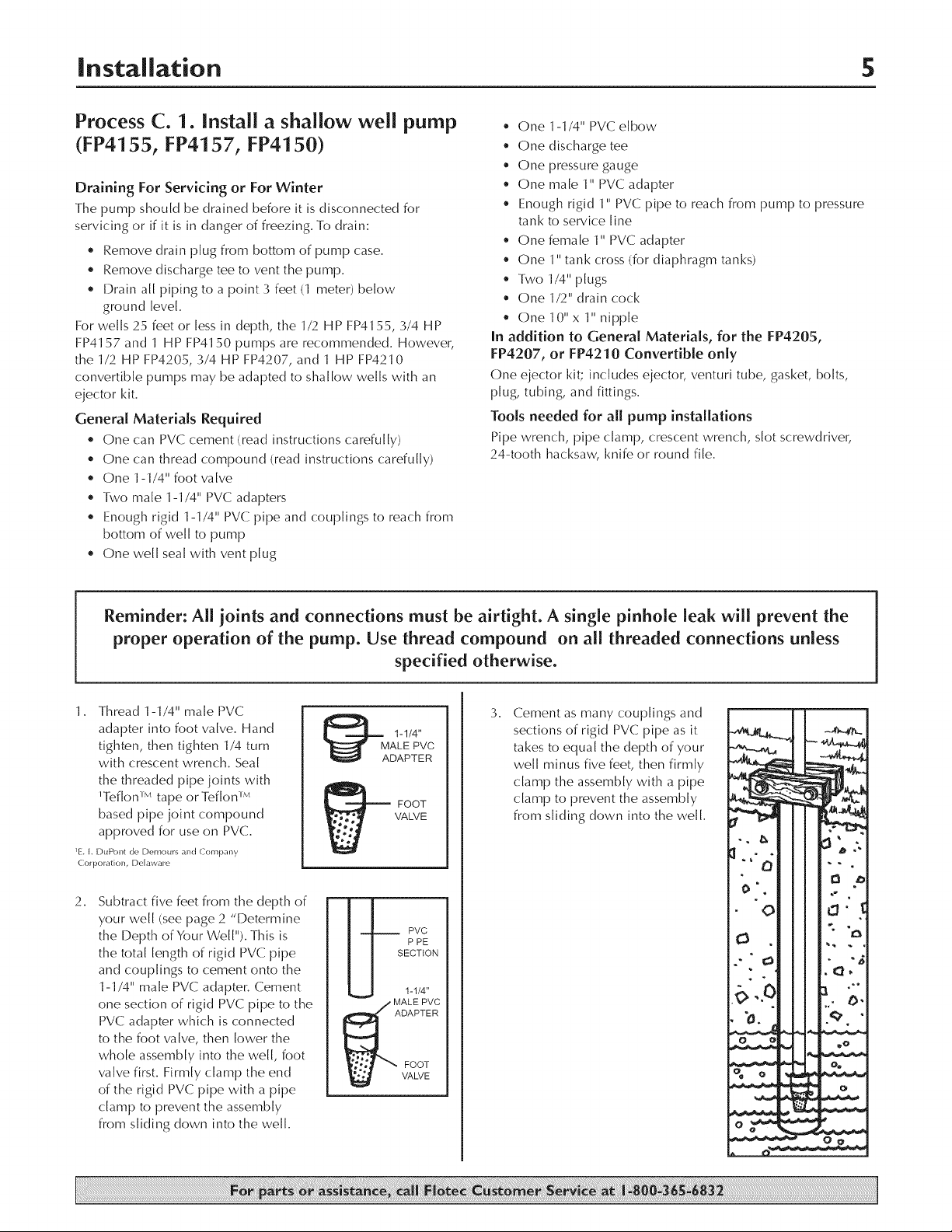

Process C. 1. install a shallow well pump

(FP4155, FP4157, FP4150)

Draining For Servicing or For Winter

The pump should be drained before it is disconnected for

servicing or if it is in danger of freezing. To drain:

Remove drain plug from bottom of pump case.

• Remove discharge tee to vent the pump.

• Drain a[[ piping to a point 3 feet (1 meter) below

ground [eve[.

For we[is 25 feet or less in depth, the 1/2 HP FP4155, 3/4 HP

FP4157 and 1 HP FP4150 pumps are recommended. However,

the 1/2 HP FP4205, 3/4 HP FP4207, and 1 HP FP4210

convertible pumps may be adapted to shallow wells with an

ejector kit.

General Materials Required

• One can PVC cement (read instructions carefully)

• One can thread compound (read instructions carefully)

• One 1-1/4" footva[ve

• Two male 1-1/4" PVC adapters

• Enough rigid 1-1/4" PVC pipe and couplings to reach from

bottom of we[[ to pump

• One we[[ sea[ with vent plug

• One 1-1/4" PVC elbow

• One discharge tee

One pressure gauge

• One male 1" PVC adapter

• Enough rigid 1" PVC pipe to reach from pump to pressure

tank to service line

• One female 1" PVC adapter

• One 1" tank cross (for diaphragm tanks)

Two 1/4" plugs

• One 1/2" drain cock

• One 10"x 1" nipple

In addition to General Materials, for the FP4205,

FP4207, or FP4210 Convertible only

One ejector I<it; includes ejector, venturi tube, gasket, bolts,

plug, tubing, and fittings.

Tools needed for all pump installations

Pipe wrench, pipe damp, crescent wrench, slot screwdriver,

24-tooth hacksaw, knife or round file.

Reminder: All joints and connections must be airtight. A single pinhole leak will prevent the

proper operation of the pump. Use thread compound on all threaded connections unless

specified otherwise.

1. Thread 1-1/4" male PVC

adapter into foot valve. Hand

tighten, then tighten 1/4 turn

with crescent wrench. Seal

the threaded pipe joints with

'Teflon ''_ tape or Teflon ''_

based pipe joint compound

approved for use on PVC.

1E. L DuPout de Demours aud (ompany

( orporatiou, Ddaware

2.

Subtract five feet from the depth of

your well (see page 2 "Determine

the Depth of Y0ur We[["). This is

the total length of rigid PVC pipe

and couplings to cement onto the

1-1/4" male PVC adapter. Cement

one section of rigid PVC pipe to the

PVC adapter which is connected

to the foot valve, then lower the

whole assembly into the we[[, foot

valve first. Firmly (_-[amp the end

of the rigid PVC pipe with a pipe

damp to prevent the assembly

from sliding down into the we[[.

M 1-1/4 '

ALE PVC

DAPTER

VALVE

_ FOOT

m

P PE

SECTION

_ VC

1-I/4"

MAL E PVC

DAPTER

FOOT

VALVE

3. Cement as many couplings and

sections of rigid PVC pipe as it

takes to equal the depth of your

well minus five feet, then firmly

clamp the assembly with a pipe

clamp to prevent the assembly

from sliding down into the well.

0 O _0

% o o.

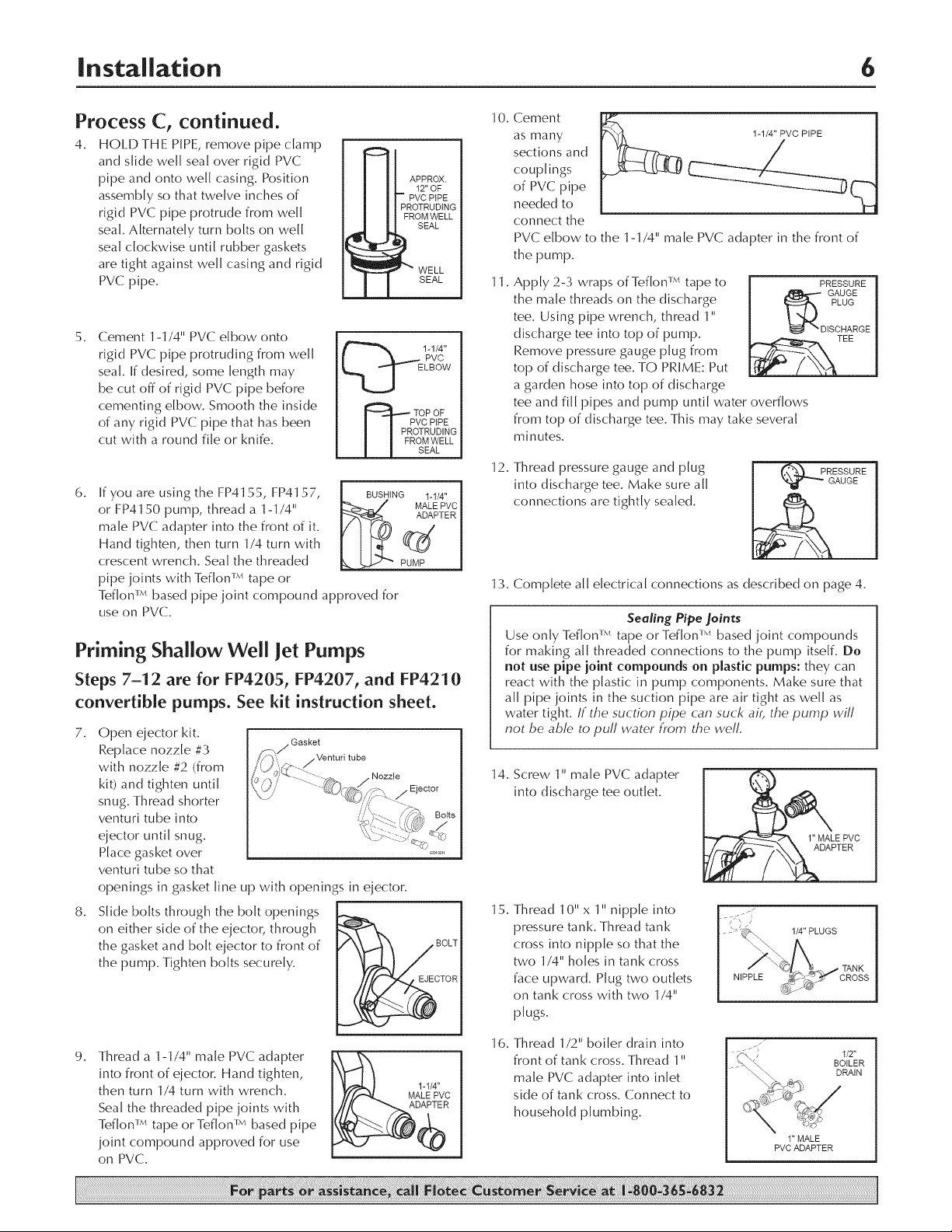

Installation 6

10.

Process C, continued.

4. HOI.DTHE PIPE, remove pipe clamp

and slide well seal over rigid PVC

pipe and onto well casing. Position

assembly so that twelve inches of

rigid PVC pipe protrude from well

seal. Alternately turn bolts on well

seal clockwise until rubber gaskets

are tight against well casing and rigid

PVC pipe.

2. Cement 1-1/4" PVC elbow onto

rigid PVC pipe protruding from well

_E 1-1/4"

seal. If desired, some length may

be cut off of rigid PVC pipe before

cementing elbow. Smooth the inside

of any rigid PVC pipe that has been

cut with a round file or knife.

6.

If you are using the FP4155, FP4157,

or FP4150 pump, thread a 1-1/4"

male PVC adapter into the front of it.

Hand tighten, then turn 1/4 turn with

crescent wrench. Sea[ the threaded

pipe joints with Teflon _'* tape or

Teflon i.,, based pipe joint compound approved for

use on PVC.

Priming Shallow Well Jet Pumps

Steps 7-12 are for FP4205, FP4207, and FP4210

convertible pumps. See kit instruction sheet.

7.

Open ejector kit.

Replace nozzle #3

with nozzle #2 (from

kit) and tighten until

snug. Thread shorter

venturi tube into

ejector until snug.

Place gasket over

venturi tube so that

openings in gasket line up with openings in ejector.

8.

Slide bolts through the bolt openings

on either side of the ejector, through

the gasket and bolt ejector to front of

the pump. Tighten bolts securely.

Gasket

_J

_O BOLT

APPROX.

12" OF

-- PVC PiPE

PROTRUDING

FROM WELL

SEAL

_WELL

SEAL

PVC

LBOW

TOP OF

PVC PiPE

OTRUDING

OMWELL

SEAL

BUSHING 1-1/4"

PUMP

Nozzle

TOR

Cement

as many

sections and

couplings

of PVC pipe

needed to

connect the

PVC elbow to the 1-1/4" male PVC adapter in the front of

the pump.

11.

Apply 2-3 wraps of Teflon _'* tape to

the male threads on the discharge

tee. Using pipe wrench, thread 1"

discharge tee into top of pump.

Remove pressure gauge plug from

top of discharge tee. TO PRIME: Put

a garden hose into top of discharge

tee and fill pipes and pump until water overflows

from top of discharge tee. This may take several

minutes.

12.

Thread pressure gauge and plug

into discharge tee. Make sure all

connections are tightly sealed.

13. Complete all electrical connections as described on page 4.

Sealing Pipe Joints

Use only Teflon i.,, tape or Teflon i_, based joint compounds

for making all threaded connections to the pump itself. Do

not use pipe ioint compounds on plastic pumps: they can

react with the plastic in pump components. Make sure that

all pipe joints in the suction pipe are air tight as we[[ as

water tight. If the suction pipe can suck ai;, the pump wift

not be able to puff water from the weft.

14. Screw 1" male PVC adapter

into discharge tee outlet.

15.

Thread 10" x 1" nipple into

pressure tank. Thread tank

cross into nipple so that the

two 1/4" holes in tank cross

face upward. Plug two outlets

NIPPLE

on tank cross with two 1/4"

plugs.

PRESSURE [

GAUGE |

I_ PLUG I

_ DISCHARGE |

GAUGE

PRESSURE I

1/4" PLUGS

9.

Thread a 1-1/4" male PVC adapter

into front of ejector. Hand tighten,

then turn 1/4 turn with wrench.

Seal the threaded pipe joints with

Teflon _* tape or Teflon _'* based pipe

joint compound approved for use

on PVC.

m

I_ 1-1/4"

16.

Thread 1/2" boiler drain into

front of tank cross. Thread 1"

male PVC adapter into inlet

side of tank cross. Connect to

household plumbing.

1"MALE

PVC ADAPTER

1/2"

BOILER

DRAIN

|nstallation 7

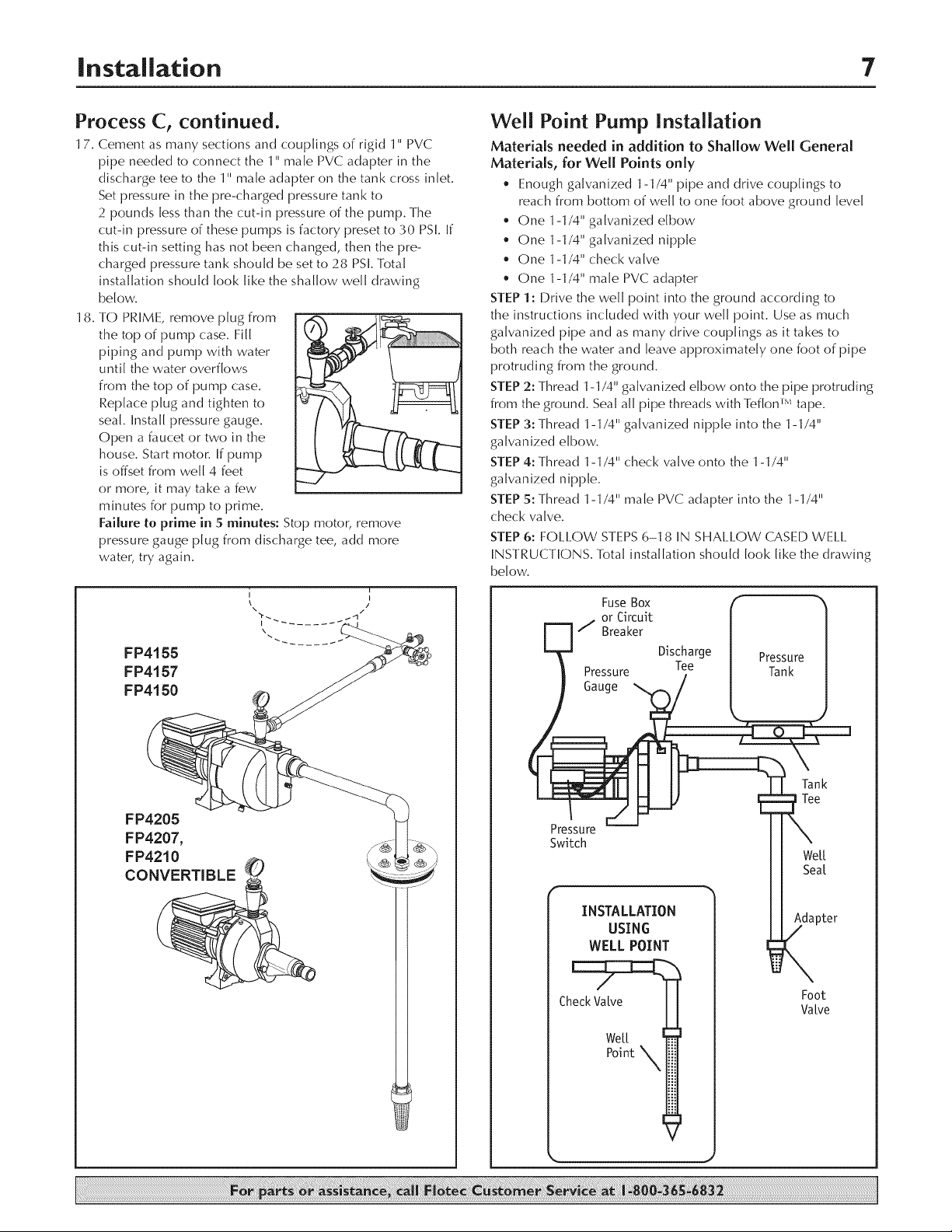

Process C, continued,

17. Cement as many sections an(] couplings of rigid 1" PVC

pipe needed to connect the 1" male PVC adapter in the

discharge tee to the 1" male adapter on the tank cross inlet.

Set pressure in the pre-charged pressure tank to

2 pounds less than the cut-in pressure of the pump. The

cut-in pressure of these pumps is factory preset to 30 PSI. If

this cut-in setting has not been changed, then the pre-

charged pressure tank should be set to 28 PSI. Total

installation should look like the shallow well drawing

below.

18. TO PRIME, remove plug from

the top of pump case. Fill

piping and pump with water

until the water overflows

from the top of pump case.

Replace plug and tighten to

seal. Install pressure gauge.

Open a faucet or two in the

house. Start motor. If pump

is offset from well 4 feet

or more, it may take a few

minutes for pump to prime.

Failure to prime in 5 minutes: Stop motor, remove

pressure gauge plug from discharge tee, add more

water, try again.

j i

X\ /I

\

FP4155

FP4157

FP4150

Well Point Pump Installation

Materials needed in addition to Shallow Well General

Materials, for Well Points only

• Enough galvanized 1-1/4" pipe and drive couplings to

reach from bottom of we[[ to one foot above ground [eve[

• One 1-1/4" galvanized elbow

• One 1-1/4" galvanized nipple

• One 1-1/4" check valve

• One 1-1/4" male PVC adapter

STEP 1: Drive the we[[ point into the ground according to

the instructions included with your we[[ point. Use as much

galvanized pipe and as many drive couplings as it takes to

both reach the water and leave approximately one foot of pipe

protruding from the ground.

STEP 2: Thread 1-1/4" galvanized elbow onto the pipe protruding

from the ground. Sea[ all pipe threads with Teflon r'* tape.

STEP 3: Thread 1-1/4" galvanized nipple into the 1-1/4"

galvanized elbow.

STEP 4: Thread 1-1/4" check valve onto the 1-1/4"

galvanized nipple.

STEP 5: Thread 1-1/4" male PVC adapter into the 1-1/4"

check valve.

STEP 6: FOLLOW STEPS 6-1 8 IN SHALLOW CASED WEI.I_

INSTRUCTIONS. Total installation should look like the drawing

below.

or Circuit

/ Breaker

Fuse Box ]

Pressure Tee Tank

Gauge

Discharge Pressure

FP4205

FP4207,

FP4210

CONVERTIBLE

Pressure

Switch

INSTALLATION

WELL POINT

Check Vatve

Tank

Tee

We[[

Sea[

USING

Foot

Valve

Weft

Point X

Installation 8

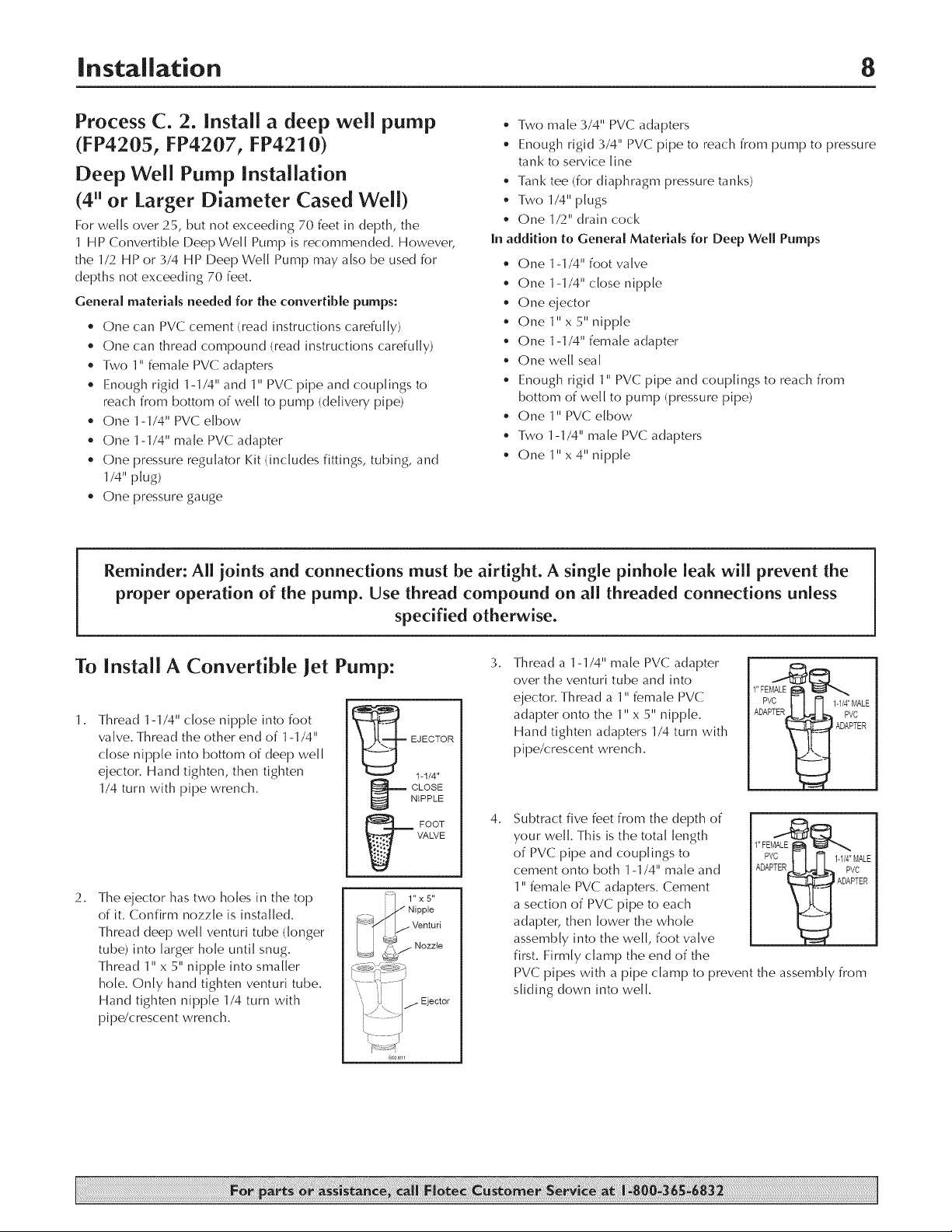

Process C. 2. install a deep well pump

(FP4205, FP4207, FP4210)

Deep Well Pump Installation

(4" or Larger Diameter Cased Well)

For weLLs over 25, but not exceeding 70 feet in depth, the

1 HP ConvertibLe Deep We[[ Pump is recommended. However,

the 1/2 HP or 3/4 HP Deep We[[ Pump may also be used for

depths not exceeding 70 feet.

Genera[ materials needed for the convertible pumps:

* One can PVC cement (read instructions carefuLLy)

* One can thread compound (read instructions carefuLLy)

* Two 1" female PVC adapters

* Enough rigid 1-1/4" and 1" PVC pipe and couplings to

reach from bottom of we[[ to pump (deLivery pipe)

* One 1-1/4" PVC elbow

* One 1-1/4" male PVC adapter

* One pressure regulator Kit (incLudes fittings, tubing, and

1/4" pLug)

* One pressure gauge

• Two male 3/4" PVC adapters

• Enough rigid 3/4" PVC pipe to reach from pump to pressure

tank to service Line

• Tank tee (for diaphragm pressure tanks)

Two 1/4" pLugs

• One 1/2" drain cock

In addition to Genera[ Materia[s fur Deep Weft Pumps

• One 1-1/4" foot valve

• One 1-1/4" close nipple

• One ejector

• One 1" x 5" nipple

• One 1-1/4" female adapter

• One we[[ sea[

• Enough rigid 1" PVC pipe and couplings to reach from

bottom of well to pump (pressure pipe)

• One 1" PVC elbow

• Two 1-1/4" male PVC adapters

• One 1" x 4" nipple

Reminder: ALl joints and connections must be airtight. A single pinhole Leak wiLL prevent the

proper operation of the pump. Use thread compound on all threaded connections unless

specified otherwise.

To Install A Convertible Jet Pump:

1.

Thread 1-1/4" close nipple into foot

valve. Thread the other end of 1-1/4"

dose nipple into bottom of deep we[[

ejector. Hand tighten, then tighten

1/4 turn with pipe wrench.

2.

The ejector has two holes in the top

of it. Confirm nozzle is installed.

Thread deep well venturi tube (longer

tube) into larger hole until snug.

Thread 1" x 5" nipple into smaller

hole. Only hand tighten venturi tube.

Hand tighten nipple 1/4 turn with

pipe/crescent wrench.

_ EJECTOR

.... _ Nipple

/ [ _9/Nezzte

_J _A

1-1/4"

NIPPLE

_ CLOSE

._ FOOT

VALVE

i 1"x5"

ve tur,

Ejector

3.

Thread a 1-1/4" male PVC adapter

over the venturi tube and into

ejector. Thread a 1" female PVC

adapter onto the 1" x 5" nipple.

Hand tighten adapters 1/4 turn with

pipe/crescent wrench.

4.

Subtract five feet from the depth of

your we[[. This is the total length

of PVC pipe and couplings to

cement onto both 1-1/4" male and

1" female PVC adapters. Cement

a section of PVC pipe to each

adapter, then lower the whole

assembly into the we[[, foot valve

first. Firmly clamp the end of the

PVC pipes with a pipe clamp to prevent the assembly from

sliding down into well.

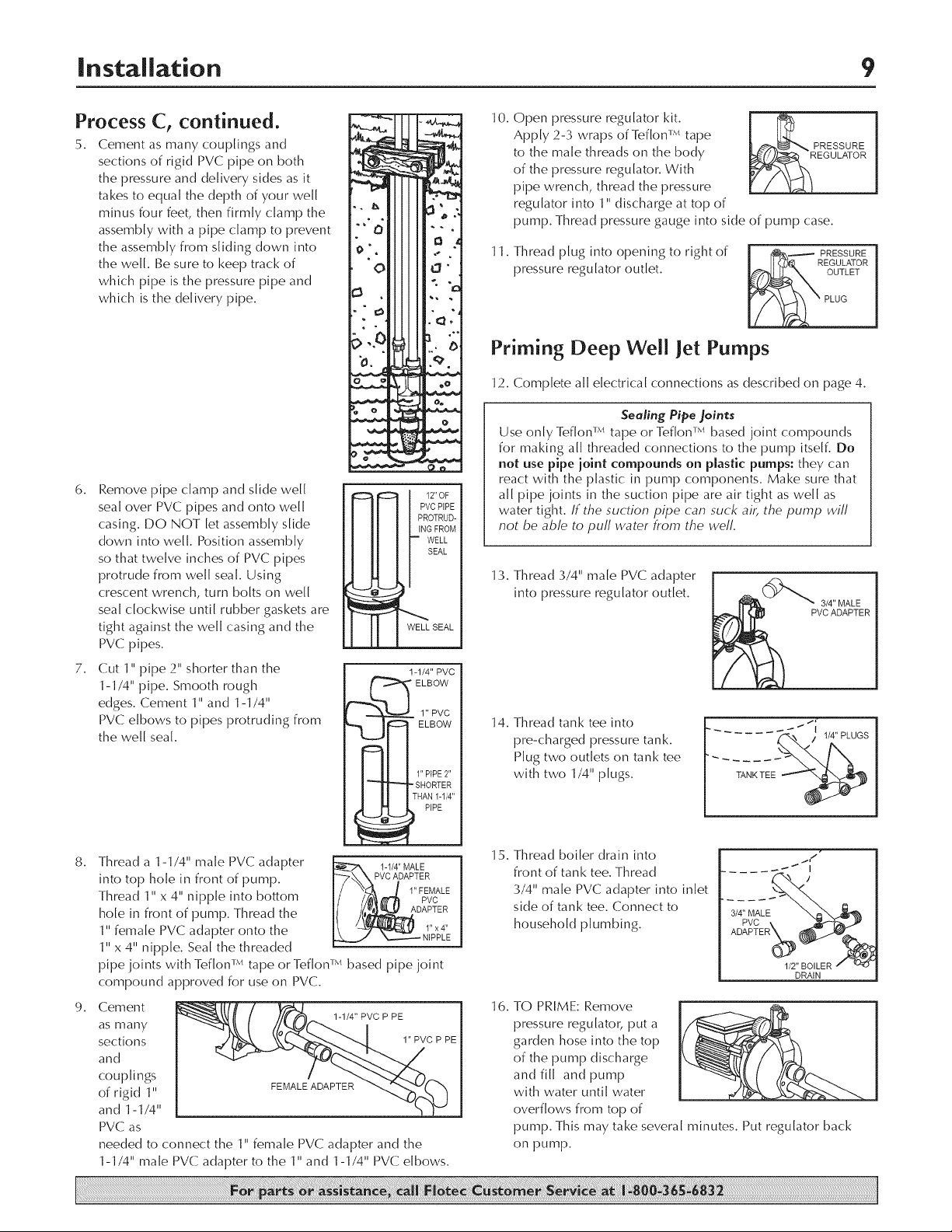

ProcessC, continued.

5. Cement as many couplings and

sections of rigid PVC pipe on both

the pressure and delivery sides as it

takes to equal the depth of your we[[

minus four feet, then firmly damp the

assembly with a pipe clamp to prevent

the assembly from sliding down into

the we[[. Be sure to keep track of

which pipe is the pressure pipe and

which is the delivery pipe.

6.

Remove pipe clamp and slide well

seal over PVC pipes and onto well

casing. DO NOT let assembly slide

down into well. Position assembly

so that twelve inches of PVC pipes

protrude from we[[ sea[. Using

crescent wrench, turn bolts on we[[

sea[ clockwise until rubber gaskets are

tight against the we[[ casing and the

PVC pipes.

7.

Cut 1" pipe 2" shorter than the

1-1/4" pipe. Smooth rough

edges. Cement 1" and 1-1/4"

PVC elbows to pipes protruding from

the well seal.

12"OF

PVCPIPE

PROTRUD-

ING FROM

• WELL

SEAL

-LL SEAL

1-1/4" PVC

_ ELBOW

_ ELBOW

r_l 11,, PIPE2"

1" PVC

10.

Open pressure regulator kit.

Apply 2-3 wraps of Teflon v,, tape

PRESSURE

to the male threads on the body

of the pressure regulator. With

pipe wrench, thread the pressure

EGULATOR

regulator into 1" discharge at top of

pump. Thread pressure gauge into side of pump case.

11.

Thread plug into opening to right of

pressure regulator outlet.

OUTLET

Priming Deep Well Jet Pumps

12. Complete all electrical connections as described on page 4.

Sealing Pipe joints

Use only Teflon v'_ tape or Teflon _ based joint compounds

for making all threaded connections to the pump itself. Do

not use pipe ioint compounds on plastic pumps: they can

react with the plastic in pump components. Make sure that

all pipe joints in the suction pipe are air tight as well as

water tight. If the suction pipe can suck air, the pump will

not be able to puff water hem the well.

13. Thread 3/4" male PVC adapter

into pressure regulator outlet.

14, Thread tank tee into

pre-charged pressure tank.

Plug two outlets on tank tee

with two 1/4" plugs.

...... ,' ,4"PLUCS

8.

Thread a 1-1/4" male PVC adapter

into top hole in front of pump.

VCADAPTER

Thread 1" x 4" nipple into bottom

hole in front of pump. Thread the

1" female PVC adapter onto the

t -1/4" MALE I

1" x 4" nipple. Seal the threaded

pipe joints with Teflon L'*tape or Teflon L'*based pipe joint

compound approved for use on PVC.

9. Cement

as many

sections

and

couplings

of rigid 1" FEMALEADAPTER

and 1-1/4"

PVC as

needed to connect the 1" female PVC adapter and the

1-1/4" male PVC adapter to the 1" and 1-1/4" PVC elbows.

1-1/4" PVC P PE

1" FEMALE

PVC

DAPTER

1"x4"

NIPPLE

1" PVC P PE

15. Thread boiler drain into

front of tank tee. Thread

3/4" male PVC adapter into inlet

side of tank tee. Connect to

household plumbing.

'4'pv ;LE,

ADAPTERX_ @FJ_b..

1/2" BOILER _

16. TO PRIME: Remove

pressure regulator, put a

garden hose into the top

of the pump discharge

and fill and pump

with water until water

overflows from top of

pump. This may take several minutes. Put regulator back

on pump.

._ i#

DRAIN

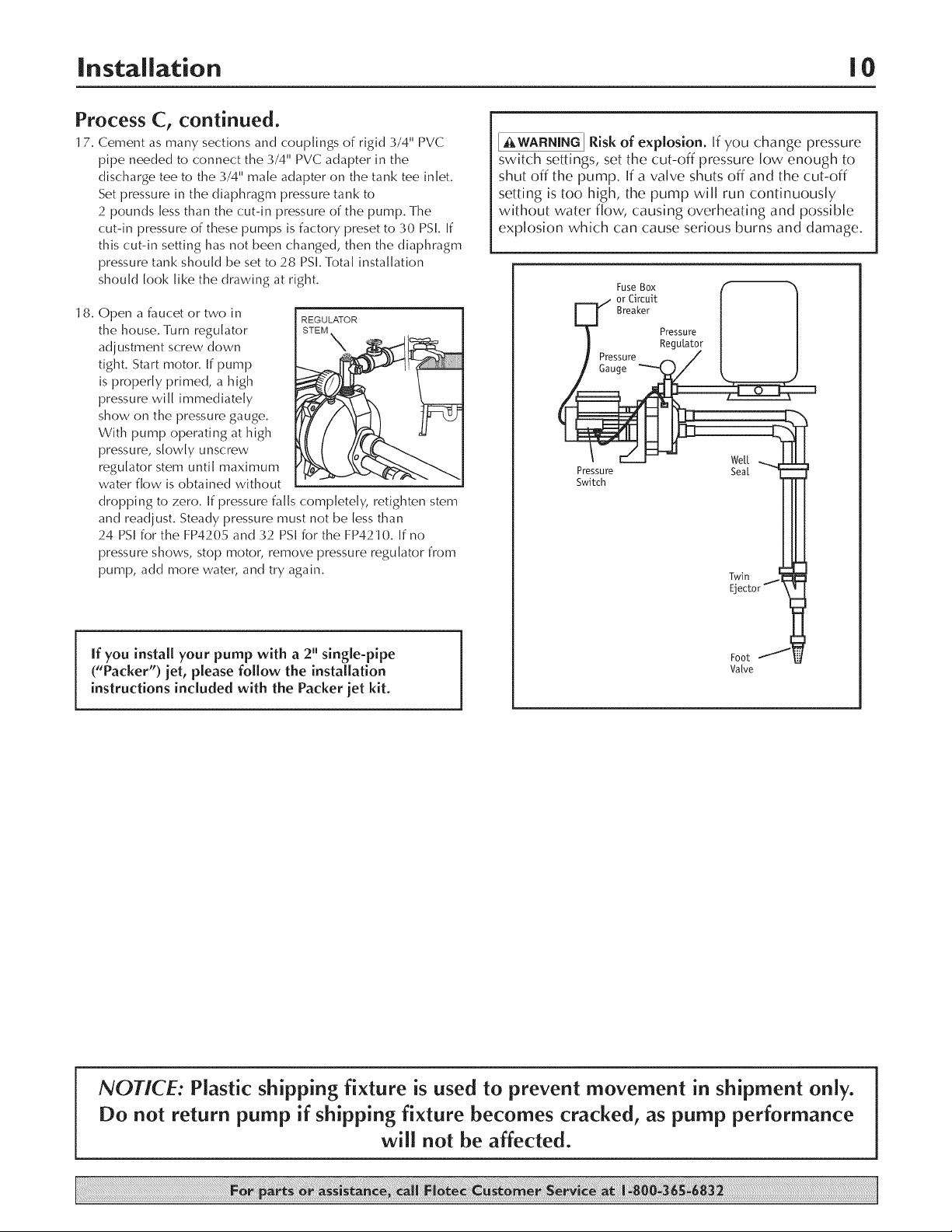

Process C, continued.

17. Cement as many sections and couplings of rigid 3/4" PVC

pipe needed to connect the 3/4" PVC adapter in the

discharge tee to the 3/4" male adapter on the tank tee inlet.

Set pressure in the diaphragm pressure tank to

2 pounds less than the cut-in pressure of the pump. The

cut-in pressure of these pumps is factory preset to 30 PSI. If

this cut-in setting has not been changed, then the diaphragm

pressure tank should be set to 28 PSI. Total installation

should look like the drawing at right.

18. Open a faucet or two in

the house. Turn regulator STEM

adjustment screw down N

tight. Start motor. If pump

is properly primed, a high

pressure will immediately

show on the pressure gauge.

With pump operating at high

pressure, slowly unscrew

regulator stem until maximum

water flow is obtained without

dropping to zero. If pressure falls completely, retighten stem

and readjust. Steady pressure must not be less than

24 PSI for the FP4205 and 32 PSI for the FP4210. If no

pressure shows, stop motor, remove pressure regulator from

pump, add more water, and try again.

REGULATOR

[_WARNING] Risk of explosion. [f you change pressure

switch settings, set the cut-off pressure low enough to

shut off the pump. If a valve shuts off and the cut-off

setting is too high, the pump will run continuously

without water flow, causing overheating and possible

explosion which can cause serious burns and damage.

FuseBOX ( '_

_=._/ or Circuit [ [

U Br0aker | |

/ Pressure | |

] ReguLator | |

Pressure / ] [

/ Ga'uge _ L_

Pressure Sea[

Switch

Twin

If you install your pump with a 2" slngle-pipe

("Packer") jet, please follow the installation

Foot

Valve

instructions included with the Packer jet kit.

NOTICE: Plastic shipping fixture is used to prevent movement in shipment only.

Do not return pump if shipping fixture becomes cracked, as pump performance

will not be affected.

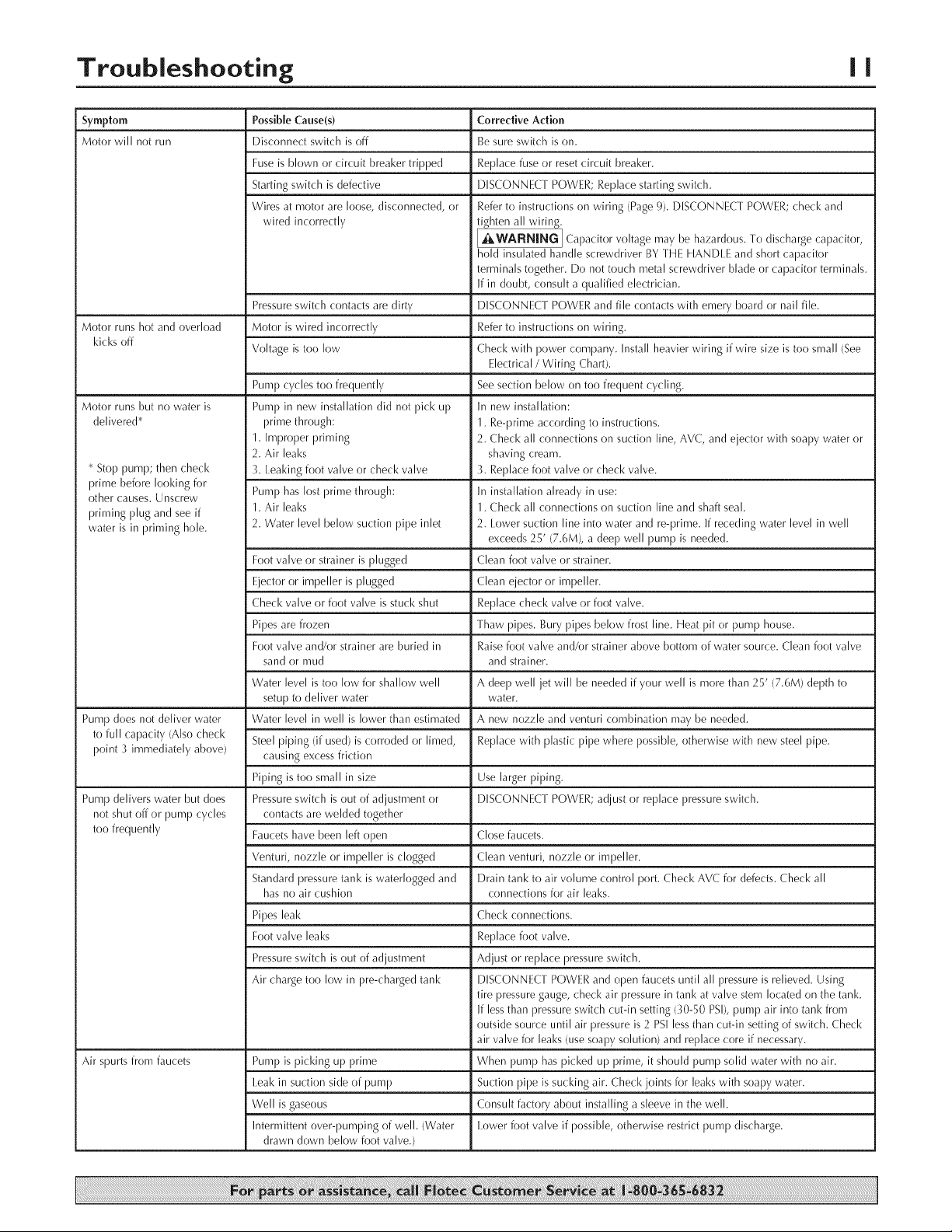

Troubleshooting II

Symptom

Motor will not run

Possible Cause(s)

Disconnect switch is off

Fuse is blown or circuit breaker tripped

Starting switch is defective

Wires at motor are loose, disconnected, or

wired incorrectly

Pressureswitch contacts aredirty

Motor runs hot and overload Motor is wired incorrectly

kicksoff

Motor runs but no water is

delivered*

* Stop pump; then check

prime before looking for

other causes. Unscrew

priming plug and see if

water is in priming hole.

Pump does not deliver water Water level in well is lower than estimated

to full capacity (Also check

point _¢immediately above)

Pump delivers water but does Pressure switch is out of adjustment or DISCONNECT POWER; adjust or replace pressure switch.

not shut off or pump cycles contacts are welded together

too frequently Faucets have been left ol)en Close faucets.

Air spurts from faucets Pump is picking up prime When pump has picked up prime, it should pump solid water with no air.

Voltage is too low

Pump cycles too frequently

Pump in new installation did not pick up

prime through:

1. Improper priming

2. Air leaks

_¢.Iealdng foot valve or check valve

Pump has lost prime through:

1. Air leaks

2. Water level below suction pipe inlet

Foot valve or strainer is plugged

Ejector or impeller is plugged

Check valve or foot valve is stuck shut

Pipes are frozen

Foot valve and/or strainer are buried in

sand or mud

Water level is too low for shallow well

setup to deliver water

Steel piping (if used) is corroded or limed,

causing excess friction

Piping is too small in size Use larger piping.

Venturi, nozzle or impeller is clogged Clean venturi, nozzle or impeller.

Standard pressure tank is waterlogged and Drain tank to air volume control port. Check AVC for defects. Check all

has no air cushion connections for air leaks.

Pipes leak Check connections.

Foot valve leaks Replace foot valve.

Pressure switch is out of adjustment Adjust or replace pressure switch.

Air charge too low in pre-charged tank DISCONNEC[ POWER and (}pen faucets until all pressure is relieved. Using

leak in suction side of pump Suction pipe is sucking air. Check joints for leaks with soapy water.

Well is gaseous Consult factory about installing a sleeve in the well.

Intermittent over-pumping of well. (Water lower foot valve if possible, otherwise restrict pump discharge.

drawn down below foot valve.)

Corrective Action

Be sure switch is on.

Replace fuse or reset circuit breaker.

DISCONNECT POWER; Replace starting switch.

Refer to instructions on wiring (Page 9). DISCONNECT POWER; check and

tighten all wiring.

I ,_WARNING I Cal)acitor voltage may be hazardous. To discharge capacitor,

hold insulated handle screwdriver BY IHE HANDLE and short capacitor

terminals together. Do not touch metal screwdriver blade or capacitor terminals.

If in doubt, consult a qualified electrician.

DISCONNECT POWER and file contacts with emery board or nail file.

Refer to instructions on wiring.

Check with power company. Install heavier wiring if wire size is too small (See

Electrical / Wiring Chart).

See section below on too frequent cycling.

In new installation:

1. Re-prime according to instructions.

2. Check all connections on suction line, AVC, and ejector with soapy water or

shaving cream.

_¢.Replace foot valve or check valve.

In installation already in use:

1. Check all connections on suction line and shaft seal.

2. lower suction line into water and re-prime. If receding water level in well

exceeds 25' (7.6M), a deep well pump is needed.

Clean foot valve or strainer.

Clean ejector or impeller.

Replace check valve or foot valve.

Thaw pipes. Bury pipes below frost line. Heat pit or pump house.

Raise foot valve and/or strainer above bottom of water source. Clean foot valve

and strainer.

A deep well jet will be needed if your well is more than 25' (7.6M) depth to

water.

A new nozzle and venturi combination may be needed.

Replace with plastic pipe where possible, otherwise with new steel pipe.

tire pressure gauge, check air pressure in tank at valve stem located on the tank.

If less than pressure switch cut-in setting (30-50 PSI), pump air into tank from

outside source until air pressure is 2 PSI less than cut-in setting of switch. Check

air valve for leaks/use soapy solution) and replace core if necessary.

Loading...

Loading...