Flotec FP0S400X Owner's Manual

®

P.O. Box 342, Delavan, WI 53115

Phone:

1-800-365-6832

Fax:

1-800-526-3757

E-Mail:

flotec@flotecpump.com

Web Site:

http://www.flotecwater.com

OWNER’S MANUAL

Submersible Pool Cover

Pump

NOTICE D’UTILISATION

Pompe submersible

pour couverture de

piscine

MANUAL DEL USUARIO

Bomba sumergible para

cubiertas de piscinas

Installation/Operation/Parts

For further operating,

installation, or maintenance

assistance:

Call 1-800-365-6832

English ...................... Pages 2-3

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 365-6832

Français ................... Pages 4-5

Instalación/Operación/Piezas

Para mayor información sobre

el funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-365-6832

Español....................Paginas 6-7

© 2007 FP545 (Rev. 5/14/07)

FP0S400X

Safety / Operation 2

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

ATTENTION: Read carefully before attempting to

install, operate or service your pump. Protect yourself and others by observing all safety information

and additional instructions included with this equipment. Failure to comply with instructions could

result in personal injury and/or property damage!

Retain for future reference.

DESCRIPTION

This submersible pump is intended for water removal

from swimming pool covers. Unit is constructed of

hi-impact corrosion resistant plastic. Screened inlet

prevents large solids from entering pump.

SPECIFICATIONS

Power supply required........................115V, 60 HZ.

Motor ..........................................................16 Watt

Motor duty.............................................Continuous

Thermal Protector ....................................Automatic

Liquid Temp. Range......................Max. 77°F (25°C)

Operation Position ..................................Horizontal

Circuit Requirement (min.)..........................10 Amp

Dimensions (Overall)................6-3/8" x 4-7/8” x 3”

Power Cord Set .................................Vinyl, 3-prong

Discharge.....Horizontal Male Garden Hose Thread

PERFORMANCE

NOTICE: This unit is not designed for applications involving salt water or brine!

GENERAL SAFETY

INFORMATION

1. Know the pump application, limitations, and

potential hazards.

Do not use in explosive

atmospheres. Pump water only with this pump.

Failure to follow this warning can result in personal injury and/or property damage.

2. Make certain that the power source conforms to

the requirements of your equipment.

3. Disconnect power before servicing.

4. Secure the discharge line before starting the

pump. An unsecured discharge line will whip,

possibly causing personal injury and/or property

damage.

5. Check hoses for weak or worn condition before

each use, making certain that all connections are

secure.

6. Periodically inspect pump and system components. Perform routine maintenance as required

(See MAINTENANCE Section).

7. Provide a means of pressure relief on pumps

whose discharge line can be shut-off or obstructed.

8. Personal Safety:

a. Wear safety glasses at all times when work-

ing with pumps.

b. Keep work area clean, uncluttered and prop-

erly lighted – replace all unused tools and

equipment.

c. Keep visitors at a safe distance from the work

area.

d. Make workshop child-proof – with padlocks,

master switches, and by removing starter

keys.

9. This equipment is only for use on 115 volt (single phase) and is equipped with an approved 3conductor cord and 3-prong, grounding-type

plug.

To reduce the risk of electric

shock, be certain that it is connected to a properly grounded, Ground Fault Circuit Interrupter

(GFCI) protected, grounding-type receptacle.

Do not lift pump by the power cord; always lift

it by the handle.

Where a 2-prong wall receptacle is encountered, it must be replaced with a properly

grounded, GFCI protected, 3-prong receptacle

installed in accordance with all applicable

codes and ordinances.

10. Protect electrical cord from sharp objects, hot

surfaces, oil, and chemicals. Avoid kinking the

cord. Replace or repair damaged or worn cords

immediately.

11. Do not touch an operating motor. Modern motors

are designed to operate at high temperatures.

12. Power Supply: Pump is designed for 115V., 60

HZ. operation and requires a circuit of 10

amperes or more capacity. It is supplied with a

3-wire cord set with grounding-type plug for

use in a 3-wire, grounded outlet. To reduce risk

of electrical shock, plug pump into a Ground

Fault Circuit Interrupter (GFCI). Consult a local

electrician for availability and installation. For

safety, circuit should always be electrically

grounded to a suitable electrical ground such as

a grounded water pipe or a properly grounded

metallic raceway, or ground wire system. Do

not cut off the round grounding prong.

OPERATION

Risk of electric shock. Do not handle a pump or pump motor with wet hands or when

standing on wet or damp surface, or in water.

1. Hand tighten 90-degree garden hose discharge

adapter into top of pump.

2. Thread garden hose onto adapter hand tight.

Then turn one quarter turn tighter with pliers to

seal. Make sure the washer is in the end of the

garden hose.

3. Straighten out the garden hose as much as

possible.

GPH IN TOTAL FEET

3' 5' 7'

FP0S400X 300 170 0

Maintenance / Repair Parts 3

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

4. Use the hose, not the power cord, to position the

pump on the pool cover and to retrieve the

pump when finished. Make sure that the pump

stands on its feet while running and that it is in at

least 2-1/2” of water (the pump loses prime at 21/4”).

5. With pump submersed in the water, plug the

pump into a GFCI outlet.

6. Monitor water level on the pool cover to be

ready to unplug the pump before it runs dry.

7. The motor is thermally protected. This means

that the pump will shut off before damage from

overloading can be done to the motor. Low voltage, long extension cords, clogged impeller, very

low head or lift, etc., could cause cycling.

8. This pump will pump water down to 2-1/4"; this

means that it will not remove all water. If unit has

been operating and suddenly no water comes

out of discharge hose, shut off unit immediately.

Water level is probably very low and unit has

broken prime. Use mop or squeegee to remove

remaining water.

9. Pump depends on water for lubrication. Do not

operate pump unless it is in at least 2-1/4” of

water as pump may be damaged if allowed to

run dry.

Risk of electric shock. Before

attempting to check why unit has stopped operating, disconnect power from unit. Do not handle pump with wet hands or when standing on

wet or damp surfaces, or in water. Failure to follow this precaution can result in personal injury

or death and/or property damage.

MAINTENANCE

Risk of electric shock. Make certain that the pump is unplugged before attempting to

service or remove any component.

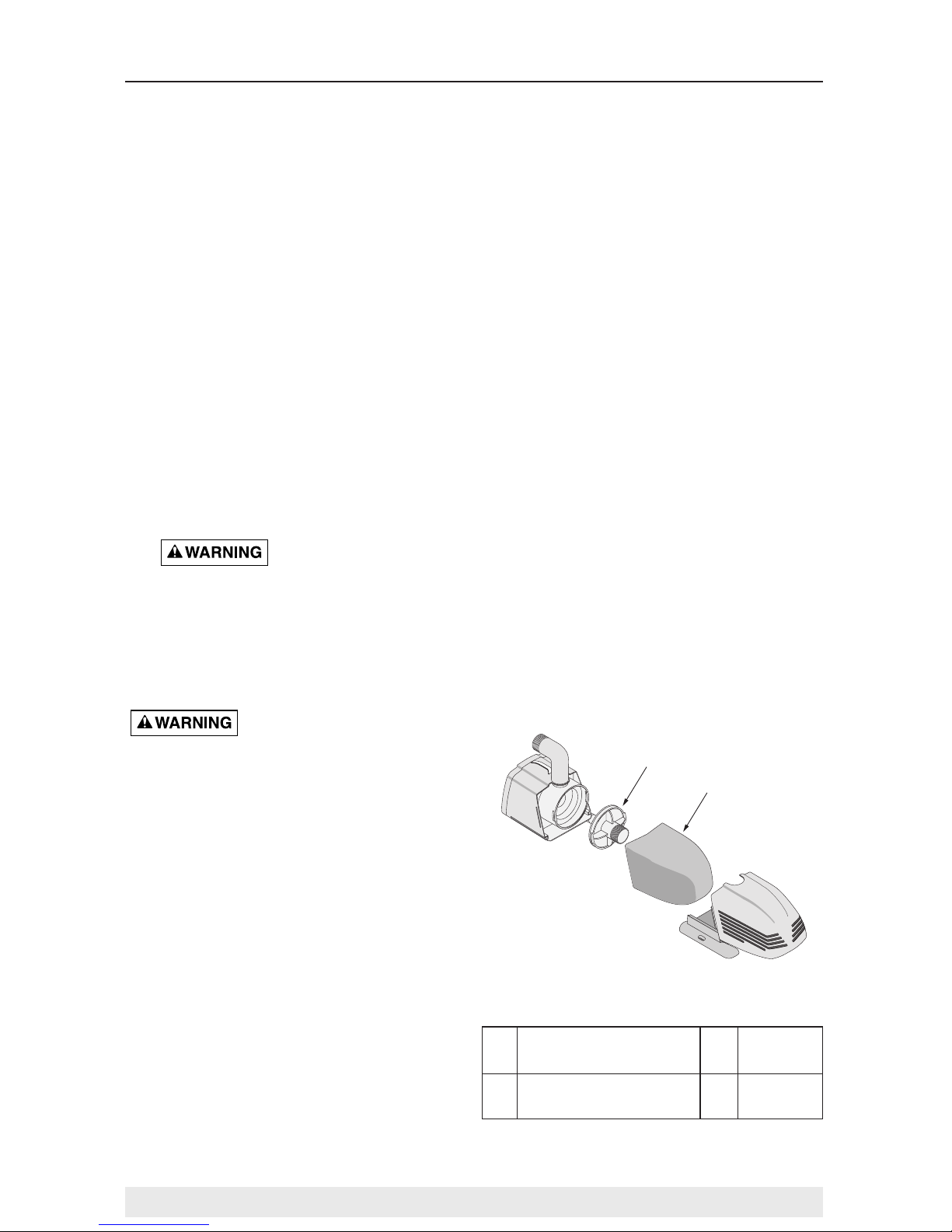

To clean the screen and filter:

1. Unplug the pump and remove it from the pool

cover.

2. Remove the hose.

3. Dry the pump and cord.

4. Squeeze the sides of the screen together (Key

No. 4) and pull it away from the pump. Screen

will unsnap and come off.

5. Remove foam filter (Key No. 3) and wash in

soapy water.

6. Rinse and reassemble.

To clean the impeller:

1. Remove screen (Key No. 4) as described above.

2. Grasp nose of pump (Key No. 2) and twist coun-

terclockwise. Front plate will come off, bringing

impeller with it.

3. Clean impeller and replace front plate of pump.

Twist clockwise to lock it in place.

4. Replace screen and filter. Pump is ready for

operation.

TROUBLESHOOTING

Pump won’t start or run.

1.

Blown fuse:

If blown, replace with fuse of prop-

er size.

2.

Low line voltage:

If voltage under recommended

minimum, check size of wiring from main switch

on property. If OK, contact power company.

3.

Obstructed impeller:

Unplug pump and clear the

impeller (Key No. 2) .

4.

Pump Unplugged:

Plug in pump.

5.

Defective motor:

Replace pump.

Pump operates but delivers little or no

water.

1.

Garden hose is air-locked:

Remove the garden

hose from the pump and hold the hose up while

walking all of the water out of the hose.

Emptying the hose of water should restore the

flow.

2.

Low line voltage:

If voltage under recommended

minimum, check size of wiring from main switch

on property. If OK, contact power company.

3.

Something caught in impeller:

Follow instructions under “To Clean Impeller” under

“Maintenance”.

4.

Plugged filter or screen:

Remove parts and clean;

replace if necessary.

5.

Worn or defective parts or plugged impeller:

Clean parts; if required, replace parts or pump.

Key Part Part

No. Description Qty. No.

1 Impeller Assembly 1 57R101

2 Foam Filter 1 500S66

REPAIR PARTS

1

2

Loading...

Loading...