Flotec FP0S1790PCA Owner's Manual

®

OWNER’S MANUAL

Submersible Electronic

P.O. Box 342, Delavan, WI 53115

Phone:

Fax:

E-Mail:

Web Site:

1-800-365-6832

1-800-526-3757

info@flotecwater.com

http://www.flotecwater.com

Pool Cover Pump

NOTICE D’UTILISATION

Pompe submersible

électronique pour couverture

de piscine

MANUAL DEL USUARIO

Bomba sumergible electrónica

para cubierta de piscina

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-365-6832

English . . . . . . . . . . . . . . . Pages 2-5

©2008 FP822 (Rev. 1/3/08)

MODEL FP0S1790PCA

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

Français . . . . . . . . . . . . . Pages 6-9

1 (800) 365-6832

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-365-6832

Español . . . . . . . . . . .Paginas 10-13

Safety / Installation 2

GENERAL SAFETY

IMPORTANT SAFETY

INSTRUCTIONS

When installing and using this electrical equipment,

basic safety precautions should always be followed,

including the following:

READ AND FOLLOW

ALL INSTRUCTIONS

To reduce the risk of injury, do not

permit children to use this product unless they are

closely supervised at all times.

Risk of Electric Shock. Connect only

to a properly-grounded, grounding type receptacle.

The pump requires 115 volt, single phase current.

The pump is protected by a ground-fault circuit

interrupter (GFCI) built into the plug. Do not modify

the cord, plug, or GFCI.

Do not bury cord. Locate cord to minimize abuse

from lawn mowers, hedge trimmers, and other

equipment.

To reduce the risk of electric shock,

replace damaged cord immediately.

To reduce the risk of electric shock, do

not use an extension cord to connect the unit to the

electrical supply; provide a properly located outlet.

SAVE THESE

INSTRUCTIONS

The pump motor is equipped with an automati-

cally resetting thermal protector and may restart unexpectedly.

DO NOT plug in the pump while standing in water or on a wet

or damp surface.

DO NOT use in water where fish are present (oil in motor can

kill fish).

DO NOT pick up the pump by the power cord.

Protect the electrical cord from sharp objects, hot surfaces, oil,

and chemicals. Avoid kinking the cord.

Unplug the pump before servicing it or attempting to clean it.

Secure the discharge hose before starting the pump. An unse-

cured discharge hose may whip, which can cause personal

injury and property damage.

Keep the pump, base, and inlet screen free of debris and foreign objects.

SPECIFICATIONS

Power supply required..........................................115V, 60 HZ.

Liquid Temp. Range........................................Max. 77°F (25°C)

Operation Position.........................................................Vertical

Individual Branch Circuit Required ..............................15 Amp

Operating Depth Beginning min...............................3/4"

(water level) Ending max...................................1/4"

Discharge.........................................................1" NPT (25 mm)

DESCRIPTION

The submersible pump is designed for water removal from pool

covers in home swimming pool applications. Unit is constructed

of hi-impact corrosion resistant plastic. Screened inlet and base

prevent large solids from entering pump and protect pool cover.

NOTICE: This unit is not designed for applications involving salt

water or brine! Use with salt water or brine will void warranty.

PERFORMANCE

GPH (LPH) AT TOTAL FEET (M)

3' 5' 10' 15' 18' 20' 22'

(0.91) (1.52) (3.05) (4.57) (5.49) (6.09) (6.70)

1600 gal 1524 gal 1260 gal 924 gal 648 gal 372 gal 0 gal

(6 057 L) (5 769 L) (4 770 L) (3 498 L) (2 453 L) (1 408 L) (0 L)

INSTALLATION

Hazardous voltage. Can shock, burn or cause

death. Do not use power cord to lift motor. Always use handle.

1. Pump should always stand upright on base when operating.

Do not suspend pump by means of discharge hose or

power cord. Keep pump inlet screen clear.

2. To install a garden hose, first install adapter provided with

pump.

NOTICE: To keep friction as low as possible, hose must be

5/8" or larger. Keep hose as short as possible.

3. If, in your application, backflow is a problem when the

pump stops, prevent it by installing a 1” NPT check valve

in the pump discharge.

4. Power Supply: Pump is designed for 115V., 60 HZ.

operation and requires an individual branch circuit of

15 amperes or more capacity. It is supplied with a 3-wire

cord set with grounding-type, GFCI protected plug for use

in a 3-wire, grounded outlet. For safety, pump should

always be electrically grounded to a suitable electrical

ground such as a grounded water pipe or a properly

grounded metallic raceway or ground wire system. Do not

cut off the round grounding prong.

Risk of sudden starts. Can result in an

electrical shock or the pinching of hands or tools. The

pump motor is equipped with automatic resetting thermal

protector and may restart unexpectedly. Protector tripping is

indication of motor overloading as a result of operating

pump at high pressure, excessively high or low voltage,

inadequate wiring, incorrect motor connections, or a defective motor or pump.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Operation 3

OPERATION

Risk of electrical shock. Can burn or cause

death. Do not handle pump or pump motor with wet hands or

when standing on wet or damp surface, or in water.

Disconnect power from pump before handling, servicing, or

attempting to repair pump.

NOTE: The power cord for this pump is equipped with a

Ground Fault Circuit Interrupter (GFCI). The GFCI will shut

down the pump in the event of leakage of electrical current

from the pump motor or cord to ground. If the pump does not

respond when plugged in, unplug it, reset the GFCI (push the

RESET button on the plug) and plug it in again. If it still doesn’t

respond, make sure that the circuit breaker for the branch circuit is in the ‘on’ position (closed). if the circuit breaker is

closed and the pump doesn’t respond, consult a licensed electrician. DO NOT TRY TO MODIFY the cord or plug, and do

not remove the GFCI.

The Electronic Pool Cover Pump is fully automatic in operation. The “smart” controller starts the pump every 2-1/2 minutes

and causes it to run for 5 seconds. If it senses that there is no

water to the pump, it stops. If it senses water, it continues to

run until the water is pumped down to 1/4" deep, and then

it stops. It then goes into a 7-minute quick-detection cycle,

starting 4 times the first minute, twice the second minute, and

once a minute for the next 5 minutes. If by the last check it

has not detected water, it resumes its cycle (running 5 seconds

every 2-1/2 minutes) until it senses water again.

NOTICE: When you plug the pump into the outlet, it will start

and run for 5 seconds. It will then cycle as described above.

If the unit is put in the water and started, interrupting the water

flow into the pump during the 5-second water-sensing run will

cause it to wait 2-1/2 minutes before restarting.

1. The motor is equipped with an automatically resetting

thermal overload protector. If the motor gets too hot, the

overload protector will stop the motor before it is damaged. When the motor has cooled sufficiently, the overload

protector will reset itself and the motor will restart.

NOTICE: If the overload protector stops the pump repeatedly, disconnect the power from the pump and check it to

find the problem. Low voltage, clogged impeller, too much

back pressure in the discharge hose (as when pumping

through 50’ (15 M) of coiled hose), or extended running of

pump with no load, can all cause overheating.

2. The water being pumped cools the motor, allowing the

pump to run continuously at any depth of water above 1/4".

However, if the motor overload stops the pump, allow it to

cool for one hour before restarting. The motor will not restart

before the overload has cooled.

LOCKED ROTOR

1. If the pump tries to start and senses that the rotor is locked,

it will shut off, wait 2-1/2 minutes, and try to restart.

2. If the rotor has unlocked, the pump will resume normal

operation. If the rotor is still locked, the pump will shut off

again and wait through another 2-1/2 minute cycle.

3. After 2-1/2 minutes, the pump will again try to start. If the

rotor has unlocked, the pump will resume normal operation. If the rotor is still locked, the pump will shut off and

will not restart automatically.

4. To restart the pump manually, unplug it and plug it in

again.

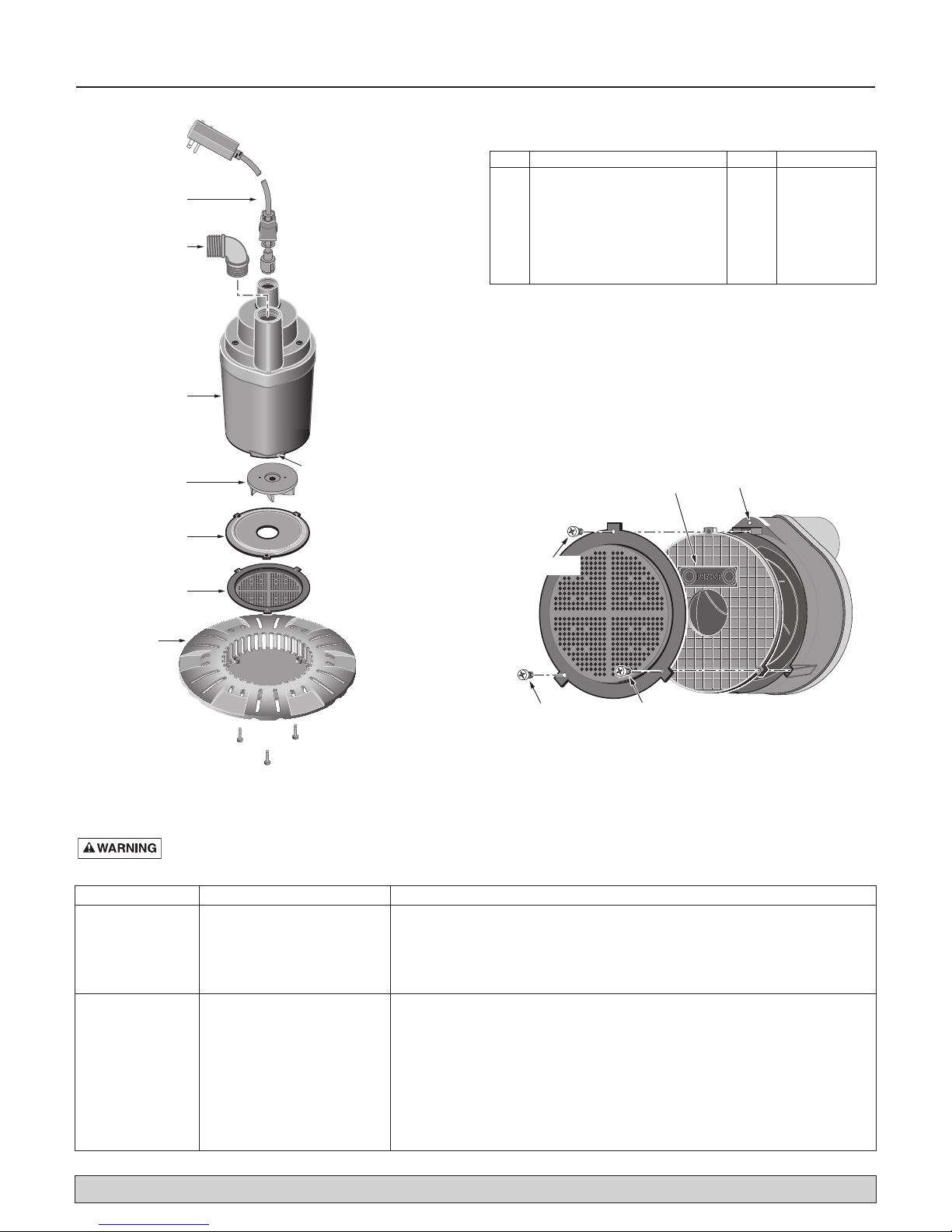

5. If the rotor is still locked, UNPLUG THE PUMP, remove

the base, shield, and screen, and clean out the rotor.

Risk of dangerous or fatal electrical shock.

Disconnect the pump from the power source before

disassembling the pump or cleaning out the rotor.

6. See Page 4 for important information about the alignment

of the screen and shield when you reassemble them. Note

that the pump will not operate correctly if these parts are

not correctly installed.

7. Once you have reassembled the pump, reset it on the pool

cover and plug it in again to resume normal operation.

AIRLOCKS

When a pump airlocks, it runs but does not move any water.

An airlock will cause the pump to overheat and fail. This

pump has an anti-airlock hole in the bottom of the pump

body. If you suspect an airlock, unplug the pump, clean out

the anti-airlock hole with a paper clip or piece of wire, and

restart the pump.

NOTICE: If the outlet of the discharge hose is submerged you

must have a 1/8" hole in the discharge hose to prevent airlock.

This hole must be open to air.

NOTICE: If you move the pump or the pump airlocks, be sure to

drain the hose before trying to restart the pump.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Repair Parts / Troubleshooting 4

3rd

2nd

Insert Screws through base.

REPAIR PARTS

Key Part Description Qty. Part No.

1 Base 1 PS70-81

7

6

5

2 Screen 1 PS8-6P

3 Shield 1 PS70-3P

4 Impeller 1 PS5-25P

5 Motor 1 **

6 90° Garden Hose Adapter 1 PS74-78

7 Power Cord 1 PS17-1505

NOTICE: To purchase a check valve, call Customer Service at

1-800-365-6832 and order part number PW73-63.

** If motor fails, replace entire pump.

(Base omitted for clarity)

4

3

2

1

TROUBLESHOOTING

Risk of electrical shock and sudden start.

Disconnect electrical power to pump before attempting to troubleshoot or work on it.

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Pump won’t Blown fuse If blown, replace with fuse of proper size

start or run

Pump operates Low line voltage Call power company

but delivers little

or no water

Anti-Airlock

Hole

5635 0607

Low line voltage If voltage under recommended minimum, check size of wiring

from main switch on property. If OK, contact power company.

Defective motor Replace pump

Impeller Remove base and screen, locate source of binding

Something caught in impeller Clean out impeller

Small diameter garden hose Use larger diameter garden hose or 1" flexible pipe. Eliminate any

or long discharge line excess hose. Short hoses work best

Check valve installed without Drill a 1/16" - 1/8" (1.6 - 3.2 mm) dia. hole between pump

vent hole discharge & check valve

Air lock Turn off pump for a few seconds, clean out anti-airlock hole and restart pump

Coils or bends in hose Straighten hose

Orient Part Number with

Anti-Airlock Hole as shown

Tighten 1st

Assemble Screen and Shield as shown.

Anti-Airlock

Hole

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Warranty 5

ATTACH ORIGINAL RECEIPT HERE FOR WARRANTY CONSIDERATION.

FLOTEC warrants to the original consumer purchaser (“Purchaser”) of its products that they are free from defects in

material or workmanship.

If within twelve (12) months from the date of the original consumer purchase any such product shall prove to be defective, it shall be repaired or replaced at FLOTEC’s option, subject to the terms and conditions set forth below.Your original receipt of purchase is required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Product Warranty Period

Drill Pump, Pitcher Pump,

In-line Water Filter Cartridge

1/3 HP Submersible Sump Pumps

NTELLIPUMP (Model FP0S1775A)

I

Pool Cover Pump (Model FP0S1790PCA)

Back-up Sump Pump System (Model FP2800DCC)

4" Submersible Well Pumps

1/2 HP Submersible Sump Pumps 3 Years

Models FPSC2200A-10 and FPSC2250A-10

Pre-Charge Water System Tank

Models FPSC3200A-10 and FPSC3250A-10

®

Floodmate

Ironmate

Sewage Ejector (Model FPSE3601A) Lifetime

Pedestal Sump Pump (Model FPPSS5000)

Utility Pump (Model FPSC1725X)

Submersible Sump Pump (Model FPSC4550A-10)

7000 (Model FP0S6000A)

®

(Model FPSC4550A)

90 days

2 Years

5 Years

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product covered by this warranty.This warranty

shall not apply to acts of God, nor shall it apply to products which, in the sole judgement of FLOTEC, have been subject

to negligence, abuse, accident, misapplication, tampering, alteration;nor due to improper installation, operation, maintenance or storage; nor to other than normal application, use or ser vice, including but not limited to, operational failures

caused by corrosion, rust or other foreign materials in the system, or operation at pressures in excess of recommended

maximums.

Requests for service under this warranty shall be made by returning the defective product to the Retail outlet or to

FLOTEC as soon as possible after the discovery of any alleged defect.FLOTEC will subsequently take corrective action

as promptly as reasonably possible.No requests for service under this warranty will be accepted if received more than

30 days after the term of the warranty.

This warranty sets forth FLOTEC’s sole obligation and purchaser’s exclusive remedy for defective products.

FLOTEC SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHAT-

SOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long

an implied warranty lasts, so the above limitations or exclusions may not apply to you.This warranty gives you specific

legal rights and you may also have other r ights which vary from state to state.

FLOTEC • P.O. Box 342 • Delavan,WI U.S.A. 53115

Phone: 1-800-365-6832 • Fax: 1-800-526-3757

E-Mail: info@flotecwater.com • Web Site: http://www.flotecwater.com

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Loading...

Loading...