Page 1

Direct Acting Pressure Reducing Valve Specification Sheet

Model C150E

FEATURES:

Sizes: □½” □¾” □1” □1¼”

Maximum pressure 400psi

Maximum water temperature 180ºF

Reduced pressure ranges 15psi to 75psi

15psi to 150psi

Factory preset 50psi

Standard thread connections (FNPT) ANSI B 1.20.1

APPLICATION:

Designed for installation on potable water lines to

reduce high inlet pressure to a lower outlet pressure.

The integral strainer screen makes this device most

suitable for residential and commercial water systems

that require frequent cleaning of sediment and debris.

The direct acting integral by-pass design prevents

buildup of excessive system pressure caused by

thermal expansion. The balance piston design enables

the regulator to react in a smooth and responsive

manner to changes in system flow demand, while at the

same time, providing protection from inlet pressure

changes.

STANDARDS COMPLIANCE:

● ASSE® Listed 1003

● IAPMO

● CSA

®

Listed

®

Listed ½” thru 1”

● City of Los Angeles Approved

● LEAD PLUMBING LAW COMPLIANCE

.25% Max Weighted Average Lead Content

Certified by IAPMO R&T Lab

● Manufactured in compliance with

NSF/ANSI 61-2010

Certified by IAPMO R&T Lab

MATERIALS:

Body

Cover UV Resistant Polymer Composite

Cartridge Delrin™, NSF Listed

Internals Stainless Steel 300 Series

Stem Stainless Steel 300 Series

Elastomers EPDM (FDA approved)

Strainer screen Stainless Steel, 300 Series

Spring Steel

C

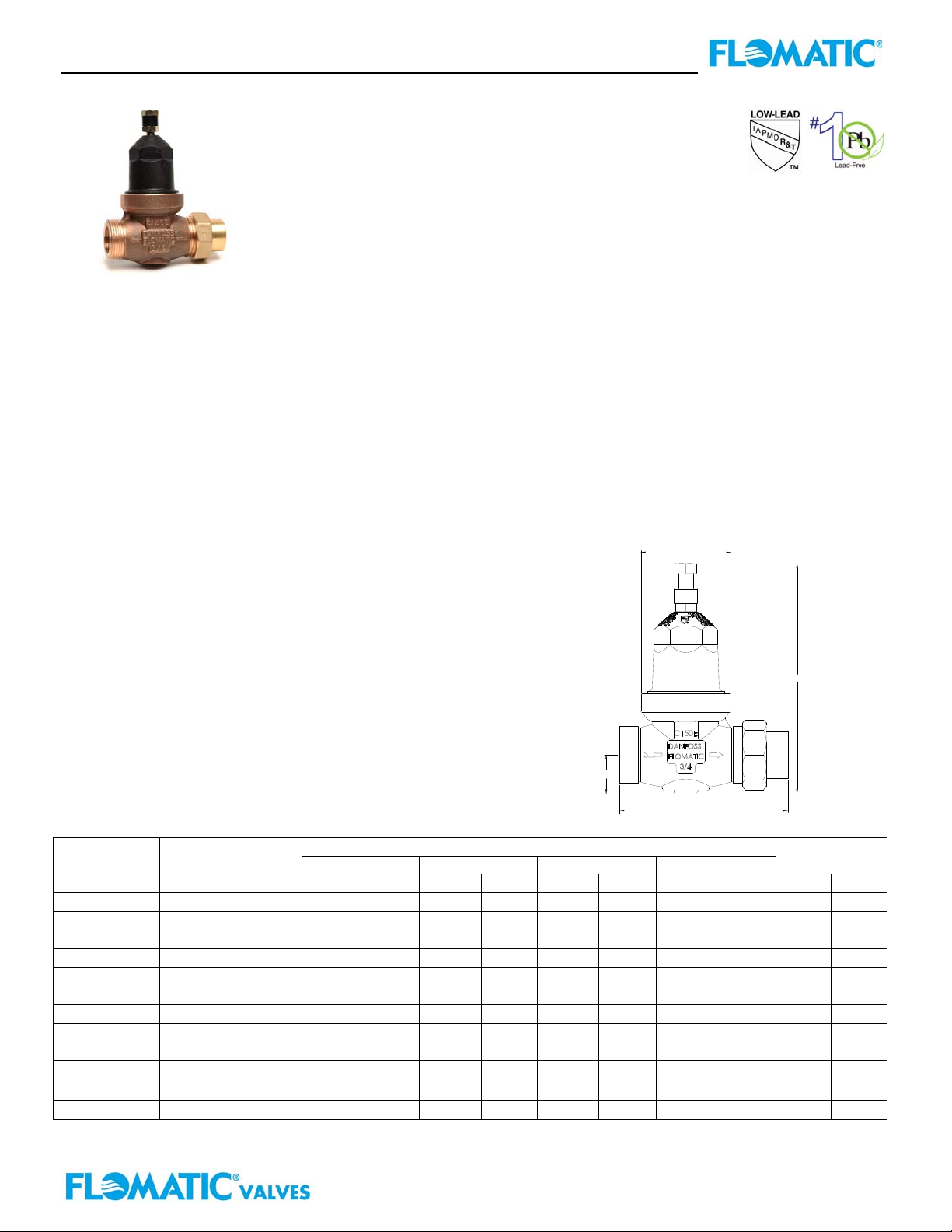

DIMENSIONS

SIZE CONNECTIONS A B C D WEIGHT

in mm in mm in mm in mm in mm lbs kg

½ 15 Single Union 4-3/8 111 6-1/8 156 1-1/32 26 2-3/8 60 3 1.5

½ 15 Less Union 3-1/2 89 6-1/8 156 1-1/32 26 2-3/8 60 3 1.5

½ 15 Double Union 5-1/4 133 6-1/8 156 1-1/32 26 2-3/8 60 3 1.5

¾ 20 Single Union

4-7/16

113 6-1/8 156 1-1/32 26 2-3/8 60 3 1.5

¾ 20 Less Union 3-1/2 89 6-1/8 156 1-1/32 26 2-3/8 60 3 1.5

¾ 20 Double Union 5-3/8 137 6-1/8 156 1-1/32 26 2-3/8 60 3 1.5

1 25 Single Union

4-15/16

125 7-5/8 194 1-1/8 29 3 76 4 2.0

1 25 Less Union 4 102 7-5/8 194 1-1/8 29 3 76 4 2.0

1 25 Double Union 5-7/8 150 7-5/8 194 1-1/8 29 3 76 4 2.0

1-¼”

1-¼”

1-¼”

* Consult factory for copper sweat and barbed end connections

32 Single Union

32 Less Union 5 125 8-3/8 213 1-9/16 40 3 76 5.3 2.4

32 Double Union 7-3/8 187 8-3/8 213 1-9/16 40 3 76 5.3 2.4

6-3/16

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

157 8-3/8 213 1-9/16 40 3 76 5.3 2.4

Flomatic Corporation

Bronze C89833

Buna Nitrile (FDA approved)

D

B

A

May 3,2004 Rev. H (7/13)

Specification Sheet C150E-2

Page 2

Direct Acting Pressure Reducing Valve Specification Sheet

Model C150E

P

k

138 14

S

S

O

L

E

R

U

S

35 53.5

S

E

R

P

C

i

a

s

W

/

p

M

20

1510.5103

1069 7

0

1.1452.27

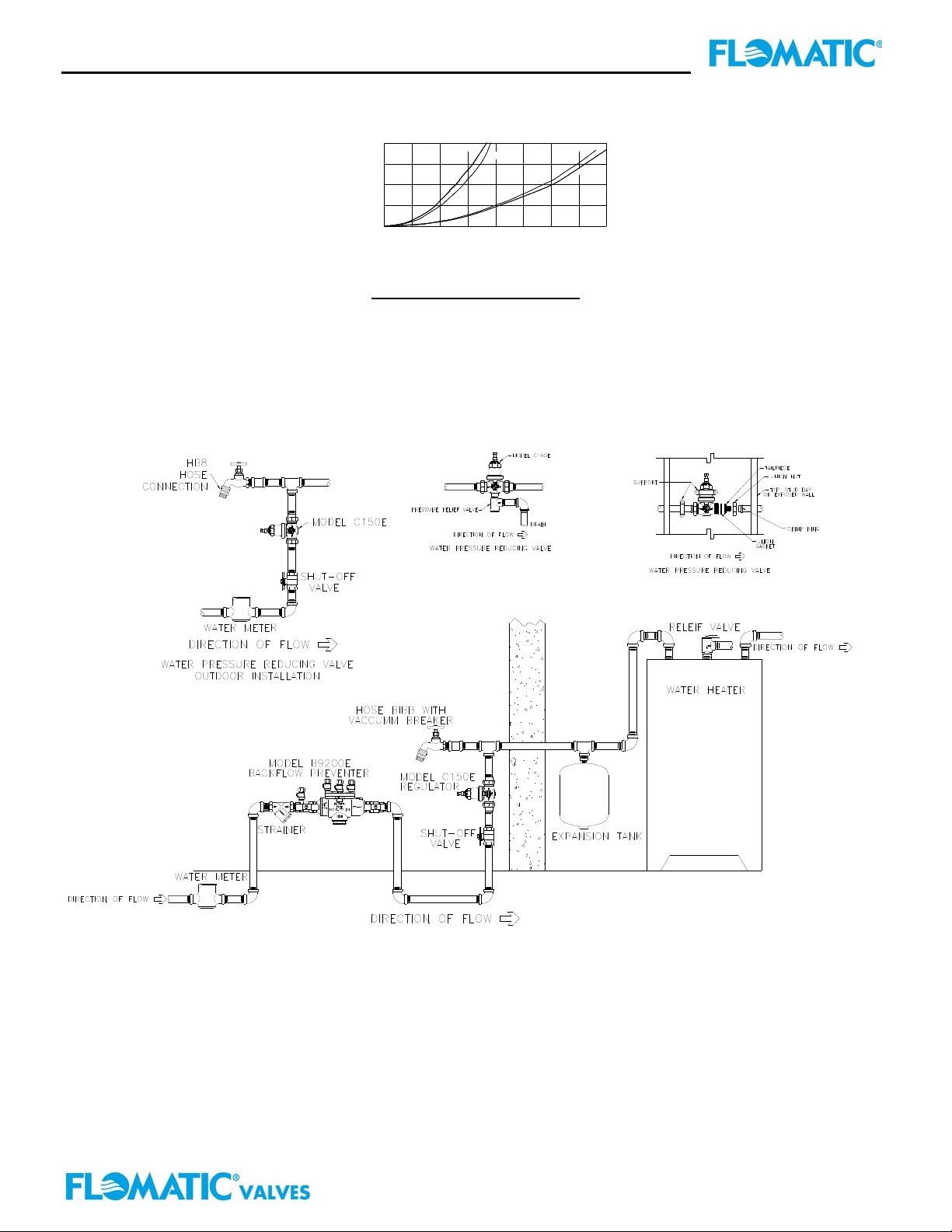

FLOW CURVES

1/2" (15mm)

10 15

3.41

.95.63.32

3/4" (20mm)

FLOW RATE

5.684.54 6.81

1.891.581.26

1" (25mm)

1-1/4" (32 mm)

7.95

2.21

40 gpm35302520

9.08 M /H

2.52 lps

3

TYPICAL INSTALLATION:

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

Local codes shall govern installation requirements. Unless otherwise specified, the assembly shall be mounted in

accordance with the latest edition of the Uniform Plumbing Code. The Model C150E may be installed in any position.

The assembly shall be installed with sufficient side clearance for testing and maintenance. Multiple installations are

recommended for wide demand variations or where the desired pressure reduction is more than 4 to 1 (i.e. 200 psi inlet

reduced to 50 psi outlet). CAUTION: Anytime a reducing valve is adjusted, a pressure gauge must be used

downstream to verify correct pressure setting. Do not bottom out adjusting screw on cover.

SPECIFICATIONS:

The Water Pressure Reducing Valve shall be ASSE

®

Listed 1003, and available with single union, double union and less

union end connections. The main body shall be Bronze C89833. The cover shall be composite plastic. The cartridge

shall be Delrin and incorporate an integral seat. The disc elastomer shall be EPDM. The assembly shall be

accessible for maintenance without removing the device from the line. The pressure reducing valve shall be a Flomatic

Model C150E

WARRANTY: Flomatic valves are guaranteed against defects of materials or workmanship when used for the services

recommended. If in any recommended service, a defect develops due to material or workmanship, and the device is returned, freight

prepaid, to Flomatic Corporation within 12 months from the date of purchase, it will be repaired or replaced free of charge. Flomatic

Corporations’ liability shall be limited to our agreement to repair or replace the valve only.

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Flomatic Corporation

May 3,2004 Rev. H (7/13)

Specification Sheet C150E-2

Page 3

Pressure Reducing Valve Specification Sheet

Model C150E

FEATURES:

Sizes: □1-½” □2”

Maximum pressure 400psi

Maximum water temperature 180ºF

Reduced pressure ranges 15psi to 75psi

15psi to 150psi

Factory preset 50psi

Standard thread connections (FNPT) ANSI B 1.20.1

APPLICATION:

Designed for installation on potable water lines to

reduce high inlet pressure to a lower outlet pressure.

The integral strainer screen makes this device most

suitable for residential and commercial water systems

that require frequent cleaning of sediment and debris.

The direct acting integral by-pass design prevents

buildup of excessive system pressure caused by

thermal expansion. The balance piston design enables

the regulator to react in a smooth and responsive

manner to changes in system flow demand, while at the

same time, providing protection from inlet pressure

changes.

STANDARDS COMPLIANCE:

● ASSE

● IAPMO

®

Listed 1003

®

Listed

● City of Los Angeles Approved

● LEAD PLUMBING LAW COMPLIANCE

.25% Max Weighted Average Lead Content

Certified by IAPMO R&T Lab

MATERIALS:

Body & Cover Bronze C89833

Cartridge Delrin™, NSF Listed

Internals Stainless Steel 300 Series

Stem Stainless Steel 300 Series

Elastomers EPDM (FDA approved)

Strainer screen Stainless Steel, 300 Series

Spring Steel

DIMESIONS

SIZE CONNECTIONS A B C D WEIGHT

in mm in mm in mm in mm in mm lbs kg

1-1/2 40 Single Union 7-5/64 180 9-15/16 252 2-3/16 56 5-3/16 132 14.5 6.6

1-1/2 40 Less Union 5-13/16 148 9-15/16 252 2-3/16 56 5-3/16 132 13.5 6.2

1-1/2 40 Double Union 8-11/32 212 9-15/16 252 2-3/16 56 5-3/16 132 15.5 7

2 50 Single Union 7-5/64 180 9-15/16 252 2-3/16 56 5-3/16 132 15.3 6.9

2 50 Less Union 5-13/16 148 9-15/16 252 2-3/16 56 5-3/16 132 14.3 6.5

2 50 Double Union 8-11/32 212 9-15/16 252 2-3/16 56 5-3/16 132 16.3 7.4

Flomatic Corporation

Buna Nitrile (FDA approved)

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

April 29,2004 Rev. D (6/11)

Specification Sheet C150

Page 4

Pressure Reducing Valve Specification Sheet

Models C150E

S

a

S

P

k

O

L

E

R

U

S

M

138 2014

103 10.5 15

69 107

S

E

R

P

C

i

s

W

/

p

3.5 535

0

20 40

1.26 3.792.52

FLOW CURVES

9.08

60

13.64.54

1-1/2" (40mm)

80

18.17

5.04

2" (50mm)

100

22.71

6.31

TYPICAL INSTALLATION:

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

Local codes shall govern installation requirements. Unless otherwise specified, the assembly shall be mounted in

accordance with manufacture’s instructions and the latest edition of the Uniform Plumbing Code. The Model C150E

may be installed in any position. The assembly shall be installed with sufficient side clearance for testing and

maintenance. Multiple installations are recommended for wide demand variations or where the desired pressure

reduction is more than 4 to 1 (i.e. 200 psi inlet reduced to 50 psi outlet). CAUTION: Anytime a reducing valve is

adjusted, a pressure gauge must be used downstream to verify correct pressure setting. Do not bottom out adjusting

bolt on bell housing.

SPECIFICATIONS:

The Water Pressure Reducing Valve shall be ASSE

union end connections. The main body shall be Bronze C89833. The cover shall be composite plastic. The cartridge

shall be Delrin and incorporate an integral seat. The disc elastomer shall be EPDM. The assembly shall be

accessible for maintenance without removing the device from the line. The pressure reducing valve shall be a Flomatic

Model C150E

WARRANTY: Flomatic valves are guaranteed against defects of materials or workmanship when used for the services

recommended. If in any recommended service, a defect develops due to material or workmanship, and the device is

returned, freight prepaid, to Flomatic Corporation within 12 months from the date of purchase, it will be repaired or

replaced free of charge. Flomatic Corporations’ liability shall be limited to our agreement to repair or replace the valve

only.

FLOW RATE

®

Listed 1003, and available with single union, double union and less

Flomatic Corporation

120 gpm

3

27.25 M /H

7.56 lps

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

April 29,2004 Rev. D (6/11)

Specification Sheet C150

Loading...

Loading...