Flomatic 89598PO Installation Manual

UNLEADED

BACKFLOW PREVENTERS

OPERATION & MAINTENANCE MANUAL

LEAD

High Quality Valves Built to Last...

Table of Contents

Features and Operating Procedures.....1

Specification Sheet RPZE 1/2" - 2".....2

Installation Guidelines & Procedures.....3

Trouble Shooting Procedures & Guide.....4

Trouble Shooting Solutions.....5

General Service Procedures RPZE/DCVE.....6

Check Valve Service Procedures.....7

Relief Valve Service Procedures.....8

Pressure Vacuum Breaker Service Instructions.....9

Repair Kits for PVB.....10

Repair Kits for RPZE & DCVE.....11

How to Contact & Warranty.....12

OPERATING AND MAINTENANCE PROCEDURES

Reduced Pressure Backflow Preventer

Flomatic has a consistent backflow design that

ranges from 1/2"-10", (15mm-250mm). The Flomatic

Model RPZE II design is a more compact/economical

model and is used when space is limited. The

Flomatic Model RPZE is available in size 3/4"-2",

(19mm-50mm) with a unleaded bronze body and

cover as standard. The 2 1/2"-10", (64mm-250mm)

are manufactured with epoxy coated ductile iron

for strength.

The Flomatic backflow preventer includes tightly

closing resilient seated shut-off valves on each end

of the body. The assembly has two independent and

internally loaded check valves with a pressure

differential relief valve between them.

The pressure drop across the first check valve is

approximately 6.0 PSID (41 kPa). The relief valve

consists of a hydraulically balanced diaphragm.

The high-pressure side of the first check valve is

connected to the top of the diaphragm through an

access hole in the body of the casting. The low-pressure

side is connected to the reduced pressure zone

keeping the relief valve closed during normal

operation. This is spring loaded to force the relief

valve open when the pressure drop across the first

check reduces to approximately 2.5 PSID (17 kPa).

NORMAL FLOW CONDITION

High Quality Valves Built to Last...

Flow Direction

LEGEND

Inlet Pressure

Outlet Pressure

Intermediate Zone Pressure

1

SPECIFICATION SHEET RPZE (1/2"-2") (12mm-50mm)

Features

•Unleaded body, test cocks and ball valves

•Ultimate mechanical protection of potable water,

against hazards of cross connection contamination.

•Meets all specifications of

AWWA,ASSE and USC Foundation for Cross

Connection Control and Hydraulic Research.

•Non-Interchangeable check valve assembly

•Replaceable check valve and removable 316 stainless

steel relief valve seats

•Top entry single access cover

•Vertical test cocks

•Low Head loss

•Simple construction, fewer parts

Operation

The backflow preventer shall be a Reduced Pressure

Principle and shall include a tightly closing resilient

seated shut-off valve on each end of the body.

The assembly shall be fitted with four (4) properly

located resilient seated test cocks.

The assembly shall have two (2) independent and

internally loaded check valve with a pressure differential

relief valve located between the check valves.

The backflow preventer shall meet the requirements of

the following standards:USC’s FCCC& Hr Manual,

Sec. 10, ASSE 1013 and CSA B64.4. Australia &

New Zealand AS/NZS 2845-1

FLOMATIC SPECIFICATIONS

The Reduced Pressure Principle backflow preventer

shall protect against backflow by either backpressure

or backsiphonage from a cross-connection between

potable water systems and substances that are

considered to have health hazards.

It shall consist of two (2) mechanically independent,

spring loaded, center guided check valves. It shall also

have a hydraulically dependent differential pressure

relief valve, set in an integral cast unleaded bronze

body, with a single access cover. The assembly shall

have four (4) vertical test cocks and two shut off

valves which are quarter-turn, full-port, resilient

seated and ball type.

The seat of each check valve and the relief valve

shall be replaceable. The check valves shall be held

into place by stainless steel clips and the check

valve assemblies shall be non-interchangeable with

silicone discs.

The backflow preventer shall be suitable for supply

pressure up to 175 psi (1205kPa) and water temperatures from 33 to 180 F.

2

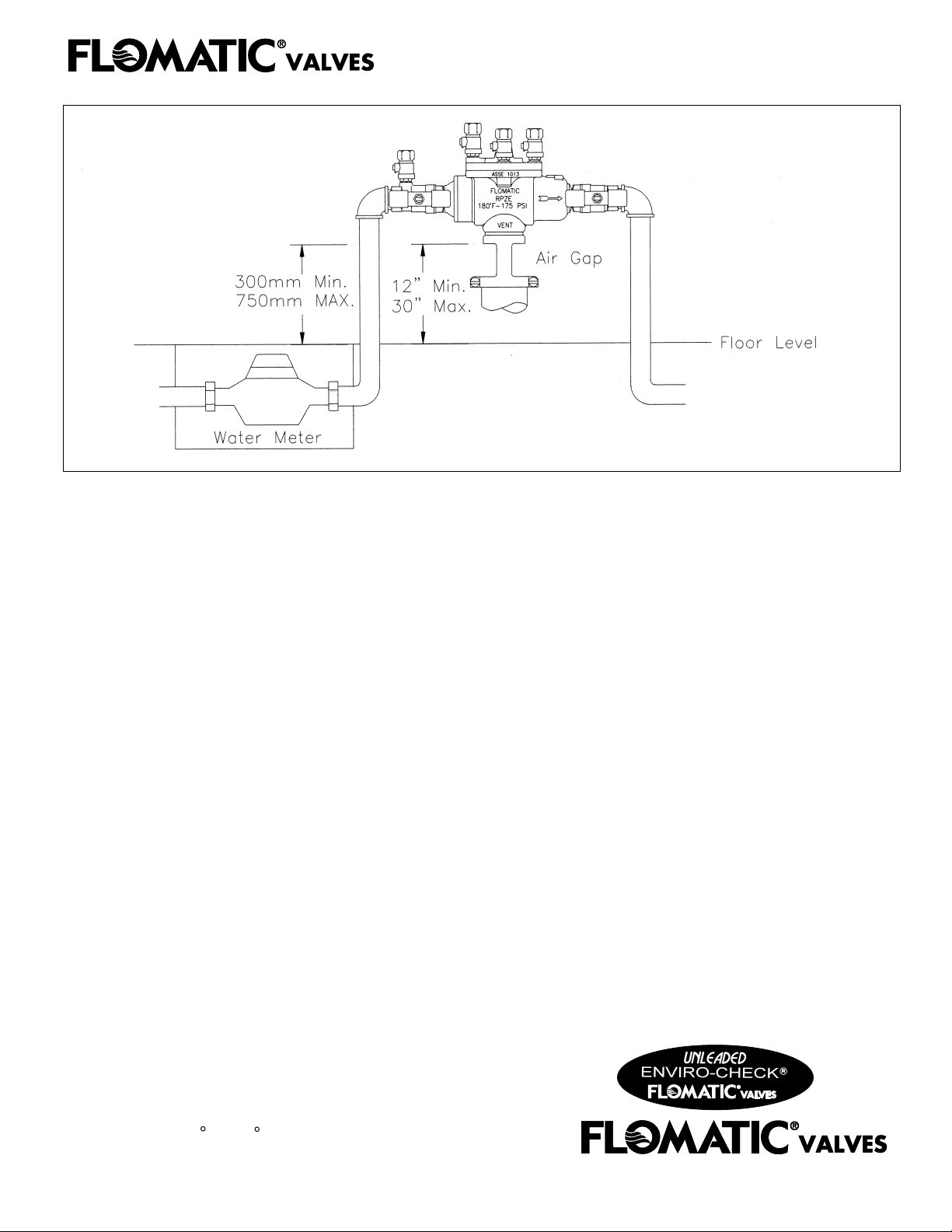

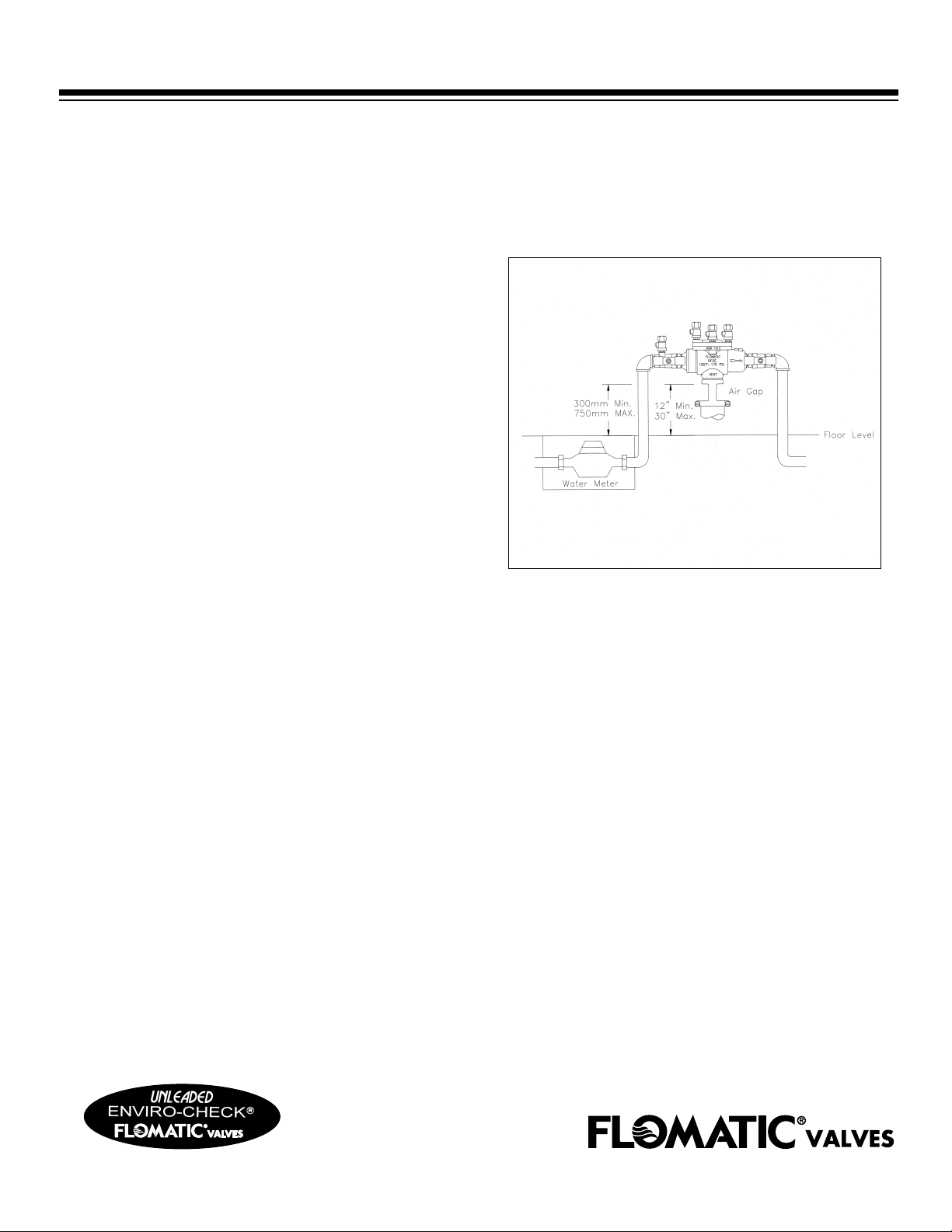

INSTALLATION GUIDELINES & PROCEDURES

Proper installation of the assembly is essential to the correct function of the assembly.

The following instructions are important characteristics of a proper installation.

1. Before installing any of Flomatic's backflow

assemblies, flush the lines thoroughly to

remove all debris, chips and other foreign

objects. Failure to do so may make any of these

assemblies inoperable.

2. Allow sufficient clearance around the installed

assembly to conduct testing (minimum 18"

(450mm) around). The assembly should be

installed in a horizontal position with a minimal

clearance of 12" (300mm) between the relief

valve discharge port and the flood level. The

maximum height should be 30" (762mm) to

allow for testing at a reasonable height.

3. Flomatic's RPZE assemblies are approved by

national approval agencies and are to be installed

in a horizontal position. Approval agencies do

not recommend installation of a RPZE in a pit.

Flooding of the pit can result in a cross

connection contamination. If local codes permit

installation of a RPZE in a pit, adequate drainage

must be provided to prevent the pit from flooding.

4. Placement of the assembly should be planned

where water discharge from the relief valve will

not be objectionable or cause property damage.

5. Insure that the water supply pressure does not

exceed the manufacturer’s maximum water

pressure or temperature. The unit should also be

protected against thermal water expansion,

extreme backpressure and/or water hammer.

6. The most common cause of field problems

for RPZE’s is dirt or debris in the system.

At the time of installation dirt or debris will

become trapped in the first check seating area,

resulting in a continuous discharge from the

relief valve in a static or backflow condition.

THEREFORE THE SYSTEM SHOULD

ALWAYS BE FLUSHED BEFORE THE

ASSEMBLY IS INSTALLED.

7. To effectively flush the systems after the assembly

has been installed, remove the internal components

and open the inlet shutoff valve to flush all debris

from the line and assembly. If debris in the water

continues to cause problems, a strainer should be

installed upstream of the assembly.

3

Loading...

Loading...