Page 1

This grease duct is ETL listed to standard UL

-

1978 and does not have to be

welded in the field.

Non

-

Welded Grease Duct Systems

Installation, Operation, and Maintenance Manual

FOR YOUR SAFETY

TWO MAJOR CAUSES OF GREASE DUCT RELATED FIRES: (1) FAILURE TO MAINTAIN

REQUIRED CLEARANCE (AIR SPACE) TO COMBUSTIBLE MATERIALS AND (2) FAILURE TO

CLEAN GREASE LADEN DUCTS. IT IS OF UTMOST IMPORTANCE THAT THIS GREASE DUCT

BE INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS. DO NOT INSTALL

GREASE DUCT WITHOUT FIRST READING THESE INSTRUCTIONS VERY CAREFULLY.

Grease duct installed in accordance with these installation instructions will comply with

national safety standards and building codes.

This booklet contains complete information on details concerning dimensions, installation and

clearances to combustibles. For any additional construction information, refer to Duct Work

Catalog.

February 2014 Rev. 20

A0011047

Page 2

TABLE OF CONTENTS

WARRANTY ............................................................................................................................................ 3

LISTINGS ................................................................................................................................................ 4

APPLICATION ......................................................................................................................................... 4

MECHANICAL ......................................................................................................................................... 5

Joint Sealant ....................................................................................................................................... 5

Sealant Features ............................................................................................................................. 5

Table 1 – Sealant Usage Chart ....................................................................................................... 5

Grease Duct Standard Connection ...................................................................................................... 6

Fig.1 – Joint Assembly .................................................................................................................... 6

Collar & Adjustable Duct Connections ................................................................................................. 7

Fig. 2 – Adjustable Duct Overlap ..................................................................................................... 7

Collar & Adjustable Duct Vertical Installation ........................................................................................ 7

Table 2 – Minimum Overlap ............................................................................................................. 7

Fig. 2a – Adjustable Duct Overlap ................................................................................................... 7

Fig. 2b – Collar & Adjustable Duct Installation.................................................................................. 8

Risers – Factory & Field (Bolted & Welded) Risers .............................................................................. 8

Fig. 3 – Field Installed Riser - Bolted ............................................................................................... 9

Fig. 4 – Duct Drain .......................................................................................................................... 9

Duct Drains ......................................................................................................................................... 9

Grease Manifold Tee ........................................................................................................................... 9

Fig. 5 - Grease Manifold Tee Position .............................................................................................. 9

Access Door (Tee Cap) Assembly ..................................................................................................... 10

Fig. 6 – Access Door Assembly ..................................................................................................... 10

Fan Adapter Plate ............................................................................................................................. 11

Fig. 7 – Fan Adapter Plate ............................................................................................................. 11

Prevention of Grease Accumulation in Horizontal Grease Duct .......................................................... 11

Alignment & Bracing of Grease Duct .................................................................................................. 11

Table 3 – Horizontal Support Spacing ........................................................................................... 11

Horizontal Support & Support Spacing .......................................................................................... 11

Fig. 8 – Horizontal Support Details ................................................................................................ 12

Wall Guide Support & Support Vertical Spacing ............................................................................. 12

Table 4 – Vertical Support Spacing................................................................................................ 12

Fig. 9 – Vertical Support Details .................................................................................................... 13

Grease Duct Assembly Examples ...................................................................................................... 14

Fig. 10 - Grease Duct Installation Guide ........................................................................................ 14

Fig. 11 - Grease Duct Installation Guide ........................................................................................ 15

Fig. 12 - Grease Duct Installation Guide ........................................................................................ 16

CLEARANCES ...................................................................................................................................... 17

Table 5 – Clearance – Grease Duct ................................................................................................... 17

Zero Clearances to Combustibles ...................................................................................................... 18

METHODS USED TO TEST DUCT AFTER ASSEMBLY ....................................................................... 18

Method 1 – Light Test per IMC 506.3.3.1 ........................................................................................... 18

Method 2 – Smoke Test .................................................................................................................... 18

GENERAL DUCT WEIGHT ................................................................................................................... 18

Formula 1 – 20 Gauge Duct............................................................................................................... 18

Formula 2 – 18 Gauge Duct............................................................................................................... 18

NOTES .................................................................................................................................................. 19

CLEANING & MAINTENANCE RECORD .............................................................................................. 20

2

Page 3

WARRANTY

This duct work system is warranted to be free from defects in material and workmanship, under normal

use and service, for a period of 12 months from the date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per this installation guide, this guide should

be kept with the equipment once installation is complete.

2. The equipment is not installed in accordance with federal, state and local codes and regulations.

3. The equipment is misused or neglected.

4. The equipment is not operated within its published capacity.

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such parts will be repaired or replaced by the MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

3

Page 4

LISTINGS

This grease duct is ETL listed to standard UL-1978 when installed in accordance with these installation

instructions and National Fire Protection Association Standard “NFPA 96, Standard for Ventilation Control

and Fire Protection of Commercial Cooking Operations”.

APPLICATION

The listed grease duct is suitable for use in commercial cooking installations for the removal of smoke

and grease laden vapors. The grease duct system includes all components for a complete exhaust

system from the hood to the exhaust fan inlet.

Grease duct installations require provisions for cleaning the interior of the duct. NFPA 96 cleanout

requirements are as follows:

1. A cleanout must be provided at each change of direction except where the entire length of duct

can be inspected and cleaned from either the hood or the discharge end.

2. On horizontal duct runs, at least one (1) 20” diameter opening must be provided. Where the

opening is smaller than 20” diameter, openings large enough to permit cleaning must be provided

at intervals of no more than 12’.

3. Openings must be at the side or the top, whichever is more accessible. When the opening is on

the side of the duct, the lower edge of the opening must be at least 1 ½” above the bottom of the

duct. For the listed grease duct, this is accomplished by the use of the grease manifold tee and

cleanout cap.

4. On vertical duct runs where personnel entry is possible, access must be from the top of the riser.

Where entry is not possible, access must be provided at each floor.

NOTE: ACCESS REQUIREMENTS ARE SUBJECT TO CHANGE IN ACCORDANCE WITH LOCAL

CODE. LOCAL AUTHORITIES SHOULD BE CONSULTED FOR EXACT REQUIRMENTS. GREASE

DUCT MAY BE CONNECTED ONLY TO HOODS IN A SINGLE FIRE ZONE ON ONE FLOOR. DO

NOT CONNECT GREASE DUCTS TO ANY OTHER PART OF THE BUILDING VENTILATION OR

EXHAUST SYSTEM.

When grease duct is installed in accordance with these installation instructions and the joints are sealed

properly with the recommended sealant, the system will contain a grease fire within the duct. A grease

fire can burn at extremely high temperatures. This system should be dismantled and inspected after any

exposure to a grease fire. Any section that is distorted or discolored should be replaced. All joints in the

system should be examined. Because the sealant expands to assure a positive seal in the case of a fire,

any sealant that has been exposed to high temperature must be replaced. This will ensure that the

system maintains its integrity against fire conditions in the future. The manufacturer of this grease duct

can not be responsible for grease duct systems that are not properly maintained or have been subjected

to one or more grease fires.

Grease duct systems size and capacity information may be obtained from the “ASHRAE Handbook –

Fundamentals” or from the “Air Pollution Engineering Manual” of the “US Environmental Protection

Agency”. Refer to the grease duct systems catalog for descriptions and dimensional data of parts.

4

Page 5

MECHANICAL

Joint Sealant

The joint sealant used to seal all joint assemblies is a 3M product. 3M Fire Barrier 2000 + Silicone

Sealant is a ready-to-use, gun-grade, one-component silicone elastomer that cures upon exposure to

atmospheric humidity to form a flexible seal. 3M Fire Barrier 2000 + Silicone Sealant, when installed

properly, will control the spread of fire before, during and after exposure to open flames. It will stop the

spread of noxious gas, smoke and water and maintain the integrity of fire rated assemblies and

construction. NO SEALANT SUBSTITUTES MAY BE USED.

Sealant Features

1. Superior adhesion.

2. Capable of withstanding 2000 °F + temperatures.

3. Class 25 sealant, per ASTM 920.

4. Re-enterable/repairable.

5. Provides up to 4-hours fire-rating.

6. Cures upon exposure to atmospheric humidity.

7. Working time 30 minutes.

8. Cure time 14 to 21 days.

9. Applied with a standard caulk gun.

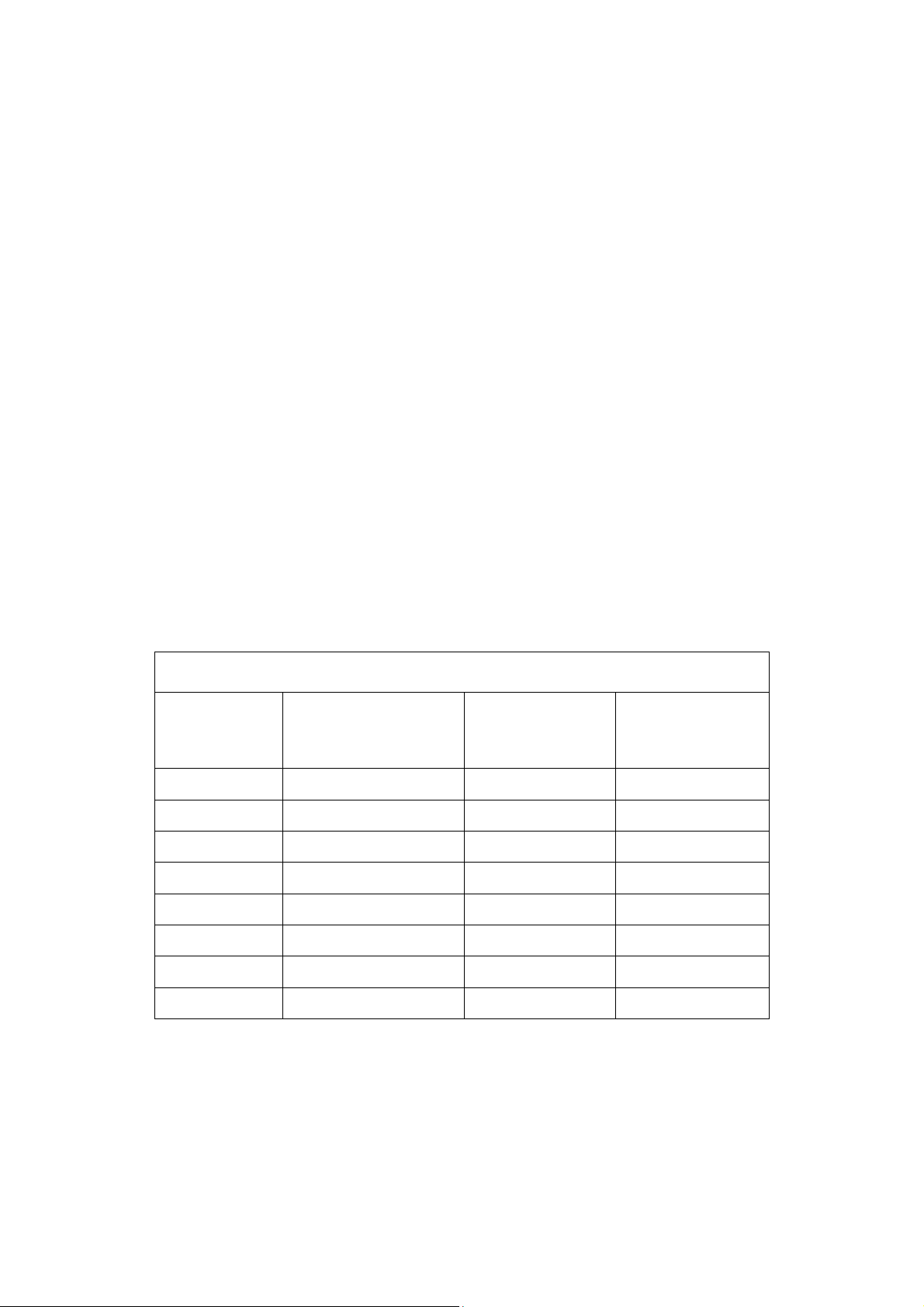

Table 1 – Sealant Usage Chart

DIAMETER DUCT PERIMETER FT

8" 2.16 30 7

10" 2.68 30 6

12" 3.21 30 5

14" 3.73 30 4

16" 4.25 30 3.5

18" 4.78 30 3

20" 5.30 30 3

24" 6.35 30 2.5

3M FIRE BARRIER 2000 PLUS USAGE

AVERAGE FEET

PER TUBE

NUMBER OF

JOINTS PER TUBE

5

Page 6

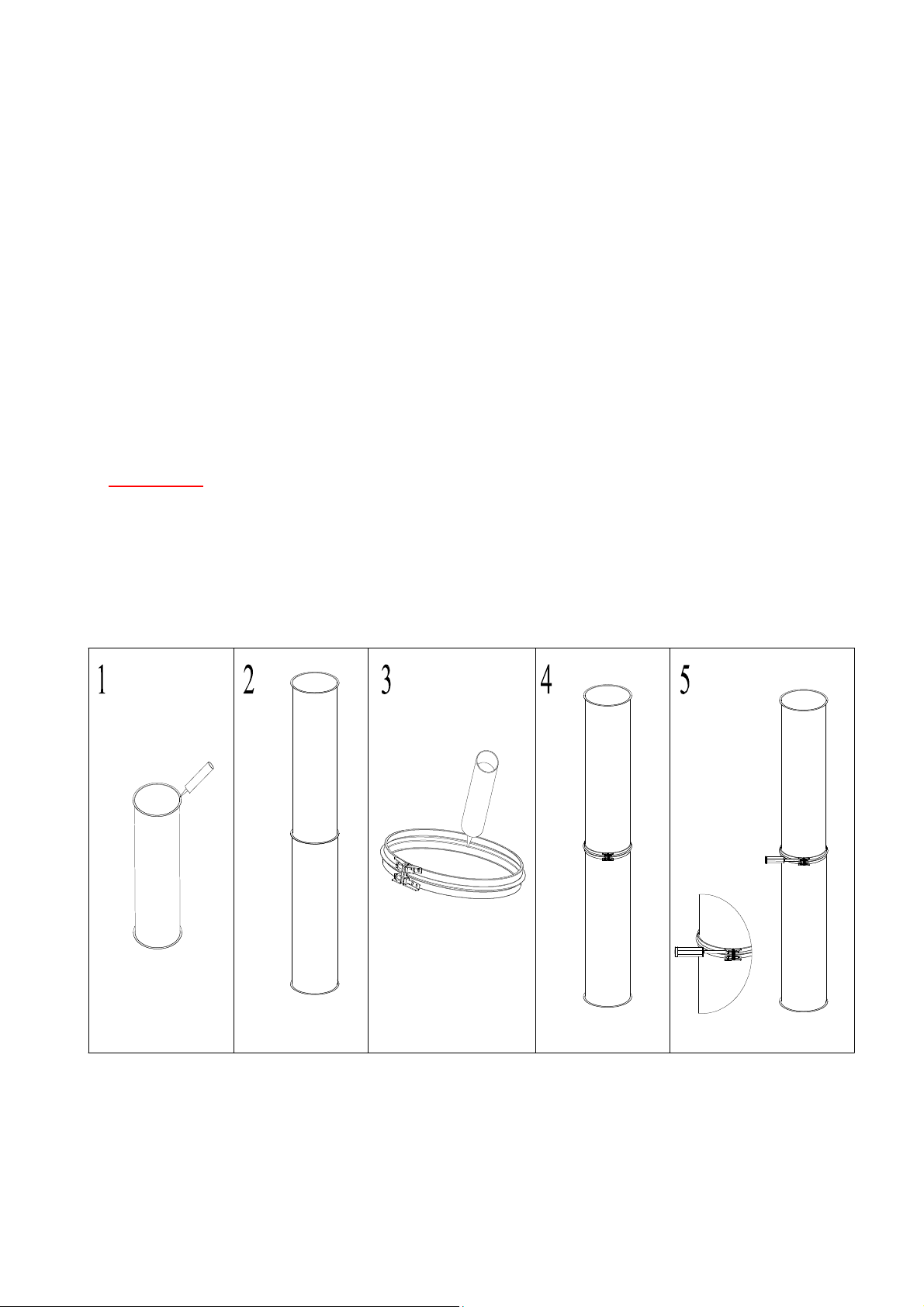

Grease Duct Standard Connection

1. Apply a continuous bead of proper sealant around the flange to be joined. The bead should be

¼” thick and continuous.

2. Join the two flanged ends of the duct section together.

3. Fill the “V” clamp with the proper sealant. The bead should be inside the “V”.

4. Install the “V” clamp around the duct sections. Both duct flanges should be inside the “V”.

5. For horizontal duct runs, the “V” clamp hardware should be located on the top side of the duct

and be orientated between the 3 and 9 o’clock position on the duct.

6. NEVER install the “V” clamp with the hardware orientated on the bottom side of the duct on

horizontal runs.

7. Secure the “V” clamp around the duct by tightening the ¼-20 hardware to 85 in-lbs.

8. See Fig. 1 below for details.

9. Remove any excess sealant from the inside of the duct surface.

IMPORTANT: THE HARDWARE USED TO ASSEMBLE THIS DUCTWORK IS SPECIFICALLY

DESIGNED FOR THIS APPLICATION. NO SUBSTITUTE HARDWARE IS ALLOWED. ALL

REPLACEMENT HARDWARE MUST BE PURCHASED FROM THE DUCTWORK FACTORY.

Fig.1 – Joint Assembly

6

Page 7

Collar & Adjustable Duct Connections

The collar and the adjustable length duct have two major

functions: (1) Make up odd lengths of duct as needed in short

runs as in termination of the duct at the exhaust fan. (2) Serve as

an expansion joint for thermal expansion in larger runs of duct.

When used in systems of any orientation, it can perform both

functions simultaneously. The adjustable duct section is overlapped

to allow grease to drain back to the hood in both vertical and

horizontal installations See Fig.10. The adjustable duct is flanged

at one end only. The collar is constructed of the same material as

the duct, and is also designed with a ½” flange that is connected to

the standard duct section using the joint assembly method listed

above See Fig.1. Collars are also sealed using high temperature

silicone that compresses around the adjustable duct when the collar

hardware is tightened. The collar is designed to securely hold the

adjustable duct, while allowing for thermal expansion.

Fig. 2 – Adjustable Duct Overlap

Adapter plate

Adjustable

duct

Collar

"V" clamp

Main duct

Vented curb

per NFPA96

See Table 2

min overlap

Collar & Adjustable Duct Vertical Installation

When the adjustable length duct and collar are installed in the vertical position between two fixed points,

such as the beginning support and the ending support, it should be installed just below the higher support. To

ensure proper axial alignment, wall guide support assemblies must be installed below the duct joint

immediately below the adjustable duct. This combination of parts will force the sliding inner and outer parts

of the adjustable duct to overcome collar friction allowing movement along the axis of the duct and thus

relieving expansion stresses which would otherwise develop between the fixed points of the heated vertical

duct.

1. Slide the adjustable collar over the adjustable duct. Flanges

should be opposite.

2. Slide the adjustable duct into the standard duct to the point

that the collar flange and the standard duct flange meet.

3. The adjustable collar and standard duct are joined and

sealed using the method listed above in Fig.1.

4. Slide the adjustable duct into the standard duct to the

desired length. The minimum overlap dimension depends

on the duct diameter. See Table 2. for proper overlap

dimensions.

5. The collar is sealed to duct using high temperature silicone.

6. Once the desired overlap has been met, tighten the ¼-20

hardware on the “V” clamp and the outside of the adjustable

collar to 85 in-lbs.

7. Inspect the connection for gaps in silicone.

Table 2 – Minimum Overlap

DIAMETER

8" 4”

10" 5”

12" 6”

14" 6”

16" 6”

18" 6”

20" 6”

24" 6”

MIN OVERLAP FOR

ADJUSTABLE DUCT

Fig. 2a – Adjustable Duct Overlap

See table 2

Adjustable duct

Adjustable collar

7

Page 8

Fig. 2b – Collar & Adjustable Duct Installation

Risers – Factory & Field (Bolted & Welded) Risers

There are two options for the riser (connection to hood plenum); Factory welded and field welded or bolted.

Dimensional data identifying the size and location of the riser must be provided for factory installation. The

riser is fully welded to the hood plenum.

When field installed, the riser is shipped loose allowing the installer at the jobsite to decide on the final

location of the riser. Field installed risers help when the final location is not known or adjustments may have

to be made due to duct misalignments. Field installed risers may be welded or bolted in place.

1. Bolted risers come with two rings that are used for the connection to the hood plenum, one is

connected to the riser and one will be loose.

2. Locate the desired position of the riser on the top of the hood. Use the riser as a guide when

marking the top of the hood. Make sure that the hole location is inside the plenum area before

cutting.

3. Since the riser is going to be bolted on, a bolt hole circle is required. Use the loose ring as a guide.

4. Use the high temperature silicone provided to seal above and below the cut hole, there should be no

gaps in the silicone either around the cut hole or the bolt hole circle.

5. Center the riser over the cut hole and push down into the silicone. The silicone should be visibly

coming through the bolt hole circle on the riser ring.

6. Align the loose riser ring over the hole on the inside of the plenum and push into the silicone. Align

with the riser ring above the hood and bolt the two rings together using ¼-20 hardware.

7. Excess silicone should be removed, and the connection should be inspected for gaps and loose

hardware.

8. When joining standard duct to the riser use the method shown in Fig. 1 – JOINT ASSEMBLY.

8

Page 9

"V " clam p

Fig. 3 – Field Installed Riser - Bolted

Standard du ct

Riser w ith

reta ining ring

R e taining

rin g

To p o f ho o d

1/4-20 H ard w a re

Duct Drains

Drains are used to provide a point at which low points in the duct system can be

drained. Condensation and low lying water left over from duct cleaning can be

drained easily with the installation of the ball valve drain. Drains are designed to

aid in duct cleaning and can be used to drain grease into an approved grease

collection reservoir. Drains can be hard piped to an approved grease collection

reservoir, remove the cap and connect to the 1-1/2” NPT threads. See Fig. 4. for

details.

Grease Manifold Tee

The grease manifold tee is used to provide access for cleanout to comply with

NFPA 96 requirements. It is equipped with an internal blank that acts as a grease

dam and gasket. The access port is then closed with a cleanout cap or tee cap.

The location of the access port in the tee is dependent on the orientation of the tee

in the final installation. Access port location is coded as Position 1, 2, 3, 4 see

Fig. 5. Access ports are never located where grease can build up and fall out

once the cleanout cap is removed.

Fig. 4 – Duct Drain

Tee

Adapter

Drain

Fig. 5 - Grease Manifold Tee Position

Position #1 Position #2

Grease Dam

Position #3 Position #4

9

Incorrect

Installation

Access Door

Removed for Clarity

Page 10

Access Door (Tee Cap) Assembly

Access doors (tee caps) are available 8” to 24”. They work in conjunction with the manifold tee as previously

shown in Fig. 5. The tee joint connection is shown in Fig. 1 – JOINT ASSEMBLY; however, the installation

of the access door is slightly different so read the following instructions very carefully. Consult NFPA 96,

Chapter 7, Section 7.3.1 “Openings shall be provided at the sides or at the top of the duct, whichever is more

accessible, and at change of directions”.

1. Select the location and the position of the access door.

2. All tee joints will be connected as shown in Fig. 1 – JOINT ASSEMBLY except for the access door.

3. Apply the proper sealant to the flange of the tee that will be used for access to the duct system.

4. Apply a ¼” continuous bead around the flange.

5. Center the inside blank (grease dam) over the opening of the tee and apply pressure. Pushing the

inside blank down onto the tee flange sealant, securing the inside blank to the tee flange.

6. Apply enough pressure to create a positive bond between the tee flange and the inside blank.

Remove excess sealant after making parts concentric (centered).

7. Apply a ¼” continuous bead around the inside blank 1” from the outside edge.

8. Center the listed gasket over the inside blank and push the gasket down into the sealant securing the

gasket to the inside blank.

9. Sealant will begin to cure upon exposure to atmospheric humidity. It will form a flexible seal.

10. Once the sealant is dry attach the access door using a “V” clamp. Ensure flanges are in the “V”

before tightening ¼-20 hardware to 80 in-lbs.

Fig. 6 – Access Door Assembly

10

Page 11

Fan Adapter Plate

The fan adapter plate (Transition Plate) is designed to

connect to a roof curb. The duct section is welded to

the underside of the adapter plate. The adapter plate

is formed to provide a slope to allow grease deposits

to flow back towards the duct. When connected, see

Fig. 7, the plate mounts on top of the fan curb, which

supports the fan housing. The plate may be

positioned off center within the curb provided that the

minimum distance to combustibles is maintained. In

the event that the plate is positioned off center, trim

off excess plate material to allow for fan placement.

Secure the plate to the curb using a minimum of three

fasteners per side. A suitably sized fastener provided

by others is used. The fan adapter plate can be used

to maintain distance to combustibles and also for

vertical support.

Adapter plate

(Optional)

Adjustable duct

Fig. 7 – Fan Adapter Plate

Exhaust fan

Secured to

curb by others

Ceramic

gasket

Vented curb

Prevention of Grease Accumulation in Horizontal Grease Duct

Duct systems serving Type 1 hoods shall be constructed and installed so that grease cannot collect in any

portion of the duct system. The duct system shall slope not less than ¼” per linear foot towards the hood or

toward an approved grease collection reservoir. Where horizontal ducts exceed 75 feet in length, the slope

shall not be less than 1” per linear foot. Offset collars have been designed to meet the above specification.

The collar is used in conjunction with other accessories such as tee’s and elbows to maintain the above

listed slope in horizontal duct runs. The “V” clamp hardware should be located on the top side of the duct and

be orientated between the 3 and 9 o’clock position on the duct. Never install the “V” clamp with the hardware

orientated on the bottom side of the duct on horizontal runs.

Alignment & Bracing of Grease Duct

Grease duct has the characteristics of a continuous stainless steel pipe and it will expand and contract along

its entire length with changes in its temperature. For this reason, conventional methods of attaching guides

and braces to the outer wall of the grease duct cannot be used. Correctly installed support rings, saddles

and wall guide assemblies will serve to keep the duct aligned, provide for adequate resistance to lateral

loads and allow the free axial expansion and contraction movement. A simplified rule for duct expansion is

that the axial growth will be approximately 1 inch per 100 feet of pipe length for each 100 degrees Fahrenheit

the exhaust vapor temperature is above the surrounding air temperature.

Horizontal Support & Support Spacing

Horizontal duct runs are supported using either 2 X 2 X 1/8” angle

or Unistrut, horizontal support spacing is shown in Table 3. When

cutting the angle or Unistrut to length there must be a minimum of 2”

on either side of the duct or duct wrap. It’s important that the 3/8”

threaded rod suspending the angle or Unistrut does not rub against

the duct or duct wrap. Once the angle has been cut to length it is

suspended using 3/8” threaded rod (minimum). Appropriate sized

holes are drilled/punched in either end of the angle. The 3/8”

threaded rod is secured to the angle or Unistrut using appropriate

sized hardware, washers are used on the top and bottom before

installing nuts, double nuts are used to make sure bottom nuts do not

come loose, see Fig. 8.

Table 3 – Horizontal Support Spacing

HORIZONTAL

DIAMETER

8" 10'

10" 10'

12" 10'

14" 10'

16" 10'

18" 10'

20" 10'

24" 10'

SUPPORT SPACING

(FEET)

11

Page 12

Fig. 8 – Horizontal Support Details

IMPORTANT: VERTICAL & HORIZONTAL SUPPORTS SHOWN IN THIS MANUAL ARE

RECOMMENDED. SUPPORTS BY OTHERS MUST BE APPROVED BY THE MANUFACTURER AND

AHJ. SUPPORT SPACING MUST BE AS STATED IN THIS MANUAL.

Wall Guide Support & Support Vertical Spacing

Angle / Unistrut

The wall guide is to be attached to Non-Combustible and Combustible surfaces. The wall guide is

constructed of 12 gauge steel and is comprised of a full ring, brackets, angle struts, wall support plates and

hardware for assembly (Includes mounting hardware to secure supports to gypsum walls constructed using

25 gauge steel studs), see Fig. 9. The ring, which is split in two halves for ease of assembly, is constructed

of 12 gauge steel. With the addition of a spacer between the two halves, the diameter is 1/8” larger than the

outside diameter of the duct. This is to allow for thermal expansion.

The wall support should be installed at the joint of the duct and below the “V” clamp so the “V” clamp moves

away from the support ring. The wall guide assembly is designed for 2 to 18 inches clearance from duct to

non-combustible / combustible walls. The side struts may be placed either up or down as is convenient. This

assembly is intended to resist lateral or side loads only and is not for carrying the weight of the vertical

grease duct. The horizontal struts allow for attachment to the wall after the grease duct has been positioned.

The angle of attachment may vary as needed for the duct to wall clearance. Wall supports shall be used at

the proper spacing shown in Table 4 for vertical duct support, with appropriate expansion joints to allow for

thermal expansion and wall guides for lateral stability.

OD + 4"

3/8" Threaded Rod

Duct

Duct Wrap

Inner Layer

Duct Wrap

Outer Layer

See table 3

6" Collar

Table 4 – Vertical Support Spacing

DIAMETER VERTICAL SUPPORT SPACING (FEET)

8" 10'

10" 10'

12" 10'

14" 10'

16" 10'

18" 10'

20" 10'

24" 10'

12

Page 13

Fig. 9 – Vertical Support Details

IMPORTANT: VERTICAL & HORIZONTAL SUPPORTS SHOWN IN THIS MANUAL ARE

RECOMMENDED. SUPPORTS BY OTHERS MUST BE APPROVED BY THE MANUFACTURER AND

AHJ. SUPPORT SPACING MUST BE AS STATED IN THIS MANUAL.

13

Page 14

Grease Duct Installation:

Grease Duct Assembly Examples

Fig. 10 - Grease Duct Installation Guide

Adjustable ducts and standard

ducts can be used to terminate

at the transition plate. The duct

is fully welded to the transition

plate at the factory.

The illustration shown provides useful information

on the installation of grease duct systems. Each

installation is specific to the application and the job

site. When duct systems are installed outside,

welded seams must be painted with corrosion

resistant high temperature paint. If you encounter a

situation not covered by this illustration, refer to the

guide or consult the factory. Remember, if the

distance to a combustible surface is less than 18

INCHES you will need to wrap the duct in a listed

duct wrap to get “ZERO CLEARANCE TO

COMBUSTIBLES”.

Exhaust fan

Vented curb per NFPA-96

IMPORTANT INFORMATION

PLEASE READ BEFORE INSTALLING

This duct is designed to be installed

in application where the duct system

is a minimum of 18" to combustible

surfaces, duct installations that cannot

maintain 18" minimum clearance to a

combustible surface must be insulated

using a clearance reducing, listed grease duct

insulation, see details in this guide.

Offset collar

Tee assembly with access door

has been used due to offset in

the duct. Access doors are used

when there is a change in direction

or where areas of duct are not accessible.

Adjustable duct

Adustable

collar

The vertical support assembly is

designed for 2" to 18" clearance

from duct to non-combustable

surface.

Offset collar used to

pictch horizontal duct runs

See table 2

Riser

Fan adapter plate

with ceramic gasket

Tee - Access door

3/8" Threaded Rod

Minimum.

First vertical support

at joint #1 after change

in direction

45 degree elbow

Standard duct

Adapter

Y Tee

Adjustable duct

Adustable

collar

Standard duct

temperature above the surrounding air temperature.

Offset collar

Unistrut / Angle

Adjustable ducts are used

on runs over 100 ft to compensate

for thermal expansion. The duct will

grow approximately 1" per 100 ft of

duct length for each 100 °F exhaust vapor

See table 3

Standard duct

Adustable

collar

Adjustable duct

Standard duct

Offset collar

Tee - Access door

Riser

14

Page 15

Grease Duct Installation:

Fig. 11 - Grease Duct Installation Guide

Adjustable ducts and standard

ducts can be used to terminate

at the transition plate. The duct

is fully welded to the transition

plate ate the factory.

Fan adapter plate

with ceramic gasket

Exhaust fan

Adjustable duct

Vented curb per NFPA-96

Adustable

collar

The illustration shown provides useful information

on the installation of grease duct systems. Each

installation is specific to the application and the

job site. When duct systems are installed outside,

welded seams must be painted with corrosion

resistant high temperature paint. If you encounter

a situation not covered by this illustration, refer to

the guide or consult the factory. Remember, if the

distance to a combustible surface is less than 18

INCHES you will need to wrap the duct in a listed

duct wrap to get “ZERO CLEARANCE TO

COMBUSTIBLES”.

The vertical support assembly is

designed for 2" to 18" clearance

from duct to non-combustable

walls.

Standard duct

Standard duct

"V" clamp

Tee assembly with access door

has been used due to offset in

the duct. Access doors are used

when there is a change in direction

or where areas of duct are not accessible.

See table 2

See table 4

The vertical support assembly

is used at the first connection

after the change of direction.

45 degree elbow

Tee - Access door

Standard duct

Adjustable ducts are used

on runs over 100 ft to compensate

for thermal expansion. The duct will

grow approximately 1" per 100 ft of

duct length for each 100 °F exhaust vapor

temperature above the surrounding air temperature.

Exhaust

hood

Hood width

Riser

Height

33" min / 48" max

IMPOTANT INFORMATION

PLEASE READ BEFORE INSTALLING

Hood

height

Height

78"

This duct is designed to be installed

in application where the duct system

is a minimum of 18" to combustible

surfaces, duct installations that can not

maintain 18" minimum clearance to a

combustible surface must be insulated

using a clearance reducing, listed grease duct

insulation, see details in this guide.

Cooking

equipment

15

Page 16

Grease Duct Installation:

Fig. 12 - Grease Duct Installation Guide

Adjustable ducts and standard

ducts can be used to terminate

at the transition plate. The duct

is fully welded to the transition

plate at the factory.

The illustration shown provides useful information on the

installation of grease duct systems. Each installation is

specific to the application and the job site. When duct

systems are installed outside, welded seams must be

painted with corrosion resistant high temperature paint. If

you encounter a situation not covered by this illustration,

refer to the guide or consult the factory. Remember, if the

distance to a combustible surface is less than 18 INCHES

you will need to wrap the duct in a listed duct wrap to get

“ZERO CLEARANCE TO COMBUSTIBLES”.

Adjustable duct

Adustable

collar

The vertical support assembly is

designed for 2" to 18" clearance

from duct to non-combustable

walls.

The vertical support assembly is

mounted under the "V" clamp and

adjustable collar. This will allow

the vertical movement of the duct

system.

Adjustable ducts are used

on runs over 100 ft to compensate

for thermal expansion. The duct will

grow approximately 1" per 100 ft of

duct length for each 100 °F exhaust vapor

temperature above the surrounding air temperature.

Fan adapter plate

with ceramic gasket

Standard duct

"V" Clamp

Standard duct

Riser

Exhaust fan

Vented curb per NFPA-96

Adjustable duct

Adustable

collar

See table 2

Standard duct

"V" Clamp

PLEASE READ BEFORE INSTALLING

Standard duct

Riser

IMPOTANT INFORMATION

This duct is designed to be installed

in application where the duct system

is a minimum of 18" to combustible

surfaces, duct installations that can not

maintain 18" minimum clearance to a

combustible surface must be insulated

using a clearance reducing, listed grease duct

insulation, see details in this guide.

16

Page 17

CLEARANCES

This grease duct is primarily intended for use in non-combustible surroundings, when installed in a room

where enclosure is not required. Grease duct may be located at clearance to combustibles in accordance

with Table 5. Grease duct may be located in a corner formed by two combustible walls provided the

minimum clearance is maintained.

In all buildings more than one story in height and in buildings where the roof-ceiling assembly is required to

have a fire resistance rating, the duct must be enclosed in a continuous enclosure from the lowest fire-rated

ceiling or floor above the hood, through any concealed spaces, to or through the roof to maintain the integrity

of the fire separations required by the applicable building code provisions. If the building is less than 4

stories in height, the enclosure shall have a fire resistance rating of not less than 1 hour. If the building is 4

stories or more in height, the enclosure shall have a fire resistance rating of not less than 2 hours. The

clearance between the outside of the duct and the inside of the rated enclosure must be a minimum of 6

inches or required by code.

Combustible roofs or roof-ceiling assemblies may be penetrated using the vertical support assembly when

distance to combustible surfaces is maintained.

Table 5 – Clearance – Grease Duct

CLEARANCE TO

LIMITED

COMBUSTIBLES

DIAMETER

CLEARANCE TO

COMBUSTIBLES

8" 18" 3" 0"

10" 18" 3" 0"

12" 18" 3" 0"

14" 18" 3" 0"

16" 18" 3" 0"

18" 18" 3" 0"

20" 18" 3" 0"

24" 18" 3" 0"

The above figures represent air space, in inches, to surrounding

NOTE: See NFPA 96, 2004 EDITION, Chapter 3, Definition of Combustible, Limited Combustible and Non-

Combustible.

CLEARANCE TO

NON

COMBUSTIBLES

17

Page 18

Zero Clearances to Combustibles

This duct is to be used in non-combustible surroundings. Where the duct does not require an enclosure, it

must have a minimum clearance to adjacent combustible walls as shown above in Table 5 – CLEARANCES.

In cases where the ducting extends through any story of a building above the location at the connected

appliances, it must be enclosed in the upper stories with walls having a fire resistance rating of not less than

one hour for buildings of two or three stories in height. If the building is four stories or more in height, the

enclosure wall shall have a fire resistance rating of not less than two hours.

METHODS USED TO TEST DUCT AFTER ASSEMBLY

Prior to the concealment of any portion of a grease duct system, a leakage test shall be performed in the

presence of the code official. Duct shall be considered to be concealed where installed in shafts or covered

by coatings or wraps that prevent the ductwork from being visually inspected on all sides. A light test or

approved equivalent test method (smoke test) shall be performed to determine that all joints are liquid tight.

The smoke test is used for longer duct runs while the light test is used for short duct runs, both methods are

approved for use.

Method 1 – Light Test per IMC 506.3.3.1

A light test shall be performed by passing a lamp having a power rating of not less than 100 watts through

the entire section of ductwork to be tested. The lamp shall be open so as to emit light equally in all directions

perpendicular to the duct walls. The test shall be performed for entire duct system, including the hood-toduct connection. The ductwork shall be permitted to be tested in sections, provided that every joint is tested.

Method 2 – Smoke Test

After the ductwork has been installed allow the listed sealant to cure for a minimum of 24 hours. Smoke

bombs are lit and placed at the bottom of the duct system, natural upwards drafts will pull the smoke to the

top of the duct system. Various length duct runs may require multiple smoke bombs. Once the smoke has

reached the top of the duct run, cap the duct, making sure it’s secure. Inspect all joints for leakage.

GENERAL DUCT WEIGHT

Two different material gauges are available, 20 gauge is the minimum / 18 gauge is the maximum allowable

material per this listed duct. Both gauges have been tested by ETL and comply with standard UL-1978. 20

gauge is the standard material used in application with 18 inches or more to combustible surfaces. 20 gauge

duct may also be wrapped using a listed duct wrap for zero clearance to combustibles, 18 gauge is required

in some JHA when duct needs to be wrapped using a listed duct wrap for zero clearance to combustibles.

Weight – 20 Gauge Duct

The following formula can be used to approximate the weight of total lengths of duct for 20 GA duct (.0327 x

“L” x “D”). “L” and “D” should be calculated in inches, where L is the length and D is the diameter. Example:

A total length of duct is 25 ft long, 14” diameter (.0327 x (25’ x 12”) x 14” = 137 LBS).

Weight – 18 Gauge Duct

The following formula can be used to approximate the weight of total lengths of duct for 18 GA duct (.0417 x

“L” x “D”). “L” and “D” should be calculated in inches, where L is the length and D is the diameter. Example:

A total length of duct is 25 ft long, 14” diameter (.0417 x (25’ x 12”) x 14” = 175 LBS).

18

Page 19

NOTES

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

19

Page 20

Factory Service Department

CLEANING & MAINTENANCE RECORD

Date Service Performed

Phone: 1-866-784-6900

Fax: 1-919-554-2415

20

Loading...

Loading...