Page 1

FOR YOUR SAFETY

Modular Packaged Unit

Installation, Operation and Maintenance Manual

Modular Packaged Cooling Unit

Save these instructions

RECEIVING AND INSPECTION

WARNING!!

FOR YOUR SAFETY

The use and storage of gasoline or other flammable

vapors and liquids in open containers in the vicinity

of this appliance is hazardous.

If you smell gas:

1. Open windows.

2. Do not touch electrical switches.

3. Extinguish any open flames.

4. Immediately call your gas supplier.

Warning!!

while hoisting this unit. All lifting lugs must be utilized while hoisting. Manufacturer is

not liable for any damage or injuries resulting from failure to do so.

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free. Turn the blower wheel by hand to verify free rotation and check the damper (if

supplied) for free operation.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment. ALWAYS disconnect power and gas

prior to working on heater.

Spreader Bar with length matching that of this entire unit Must be used

. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

July 2014 Rev. 12

Page 2

TABLE OF CONTENTS

WARRANTY .................................................................................................................................................. 3

INSTALLATION ............................................................................................................................................. 4

Mechanical ................................................................................................................................................ 4

Site Preparation .................................................................................................................................... 4

Assembly .............................................................................................................................................. 4

Curb and Ductwork ............................................................................................................................... 4

Optional Moisture Eliminator Panel ...................................................................................................... 5

Typical Roof Mount Installation ............................................................................................................ 6

Typical Roof Mount Installation with Exhaust Fan ............................................................................... 6

Plumbing Connections ......................................................................................................................... 7

Typical Cooling Coil Drain Trap ............................................................................................................ 7

Gas ........................................................................................................................................................... 7

Electrical ................................................................................................................................................... 7

Copper Wire Ampacity ......................................................................................................................... 8

MUA/Condenser Fan to Building Wiring Connection ........................................................................... 9

OPERATION ............................................................................................................................................... 10

Start Up ................................................................................................................................................... 10

Special Tools Required ...................................................................................................................... 10

Start Up Procedure ............................................................................................................................. 10

Checking the Refrigerant Charge ....................................................................................................... 11

Superheat and Adjusting TXVs .......................................................................................................... 12

Checking Heating Mode for Units with Heat Pumps .......................................................................... 13

Sequence of Operation-Cooling with Direct, Indirect, or Electric Heat ................................................... 14

Sequence of Operation-Reheat .......................................................................................................... 15

Sequence of Operation-Liquid Bypass ............................................................................................... 15

Sequence of Operation-Cooling Only or Heat Pump.............................................................................. 15

Board Menu ............................................................................................................................................ 18

Troubleshooting Chart ............................................................................................................................ 20

MAINTENANCE .......................................................................................................................................... 21

General Maintenance ............................................................................................................................. 21

2 weeks after startup .............................................................................................................................. 21

Every 3 months ....................................................................................................................................... 21

Yearly ...................................................................................................................................................... 22

Start-Up and Maintenance Documentation ............................................................................................ 23

Job Information ................................................................................................................................... 23

Unit Information .................................................................................................................................. 23

Maintenance Record .......................................................................................................................... 24

Factory Service Department ............................................................................................................... 24

Page 3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

3

Page 4

INSTALLATION

CLEARANCES

It is imperative that this unit is installed and operated with the designed airflow, gas, and electrical supply

in accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, BLOWER OR

MOTOR SHAFT, OR BEARINGS – USE ALL LIFTING LUGS PROVIDED WITH A

SPREADER BAR OR SLINGS UNDER THE UNIT – USE CARE NOT TO DAMAGE

EXPOSED REFRIGERATIION LINES.

Site Preparation

1. Provide clearance around installation site to safely rig and lift

equipment into its final position. Supports must adequately

support equipment. Refer to manufacturer’s estimated weights.

2. Consider general service and installation space when locating

unit.

3. Locate unit close to the space it will serve to reduce long, twisted

duct runs.

4. Do not allow air intake to face prevailing winds. Support unit

above ground or at roof level high enough to prevent precipitation

from being drawn into its inlet. The inlet must also be located at

least 10 feet away from any exhaust vents. The unit inlet shall be

located in accordance with the applicable building code provisions

for ventilation air.

The top, back and front

surfaces of this unit may

not be installed less than 6”

from combustible materials.

The base may be installed

on combustible surfaces.

Allow 24” minimum service

clearance on both sides of

this unit. Do not enclose

top of condensers blocking

airflow.

Assembly

Intakes and curbs are shipped unassembled. Upon unit arrival, follow the following procedure to

assemble the intake to the heater:

1. Apply silicone or weatherproof gasket on the backside of the flanges of the intake hood or v-bank

intake.

2. Screw the flanges of the intake hood or v-bank to the unit with the supplied sheet metal screws.

If the unit is a modular unit with a v-bank or evaporative cooler section, the v-bank or evaporative

cooler will bolt to the main unit with the bolts provided. Place caulk on the outside of the screws

to prevent water leaks.

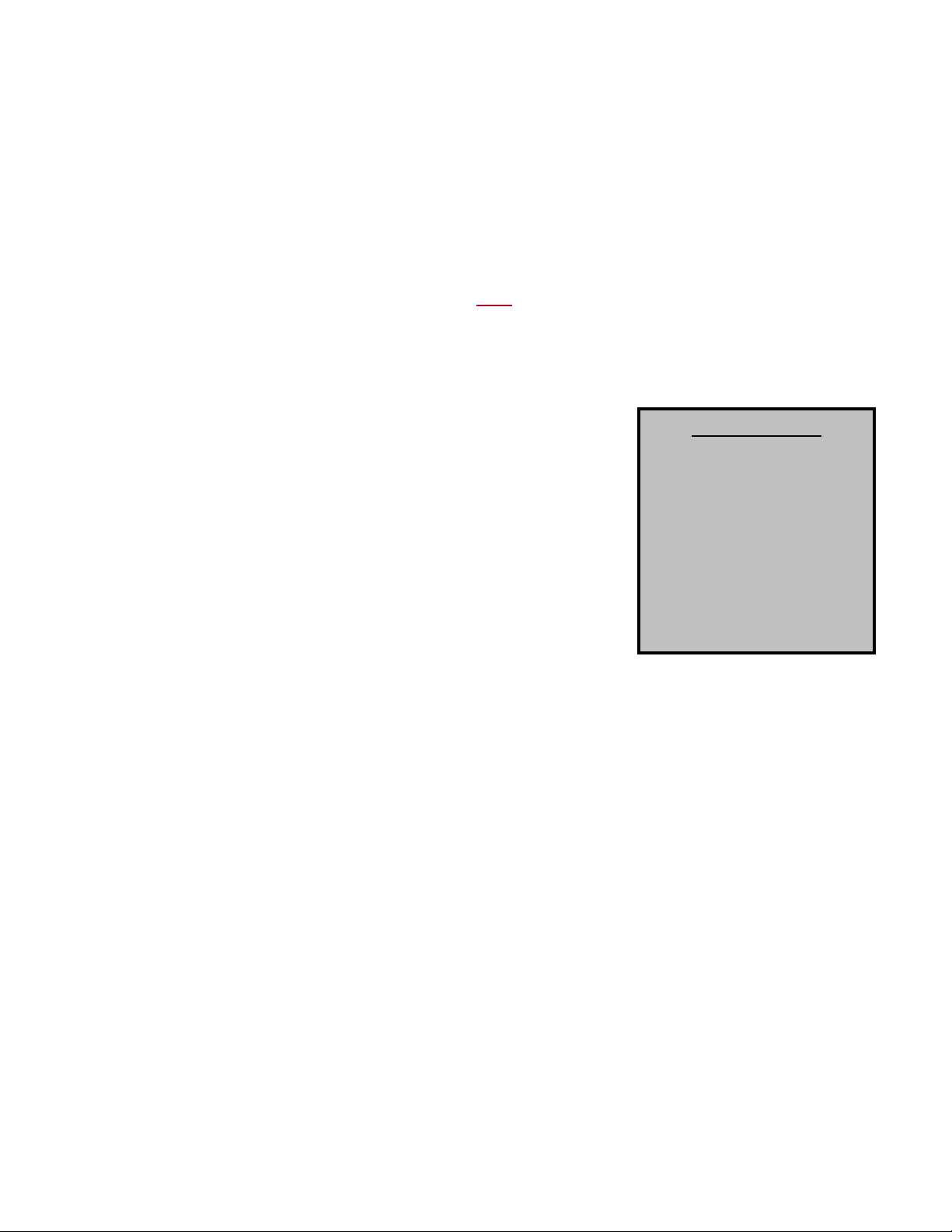

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect the airflow performance. Flexible ductwork and square elbows should not be used.

Also, transitions and turns in ductwork near the fan outlet will cause system effect and will drastically

increase the static pressure and reduce airflow. Follow SMACNA guides and recommendations for

the remaining duct run. Fans designed for rooftop installation should be installed on a prefabricated or

factory built roof curb. Follow curb manufacturer’s instructions for proper curb installation. The unit

should be installed on a curb and/or rail elevated not less than 20” above any surface. Be sure duct

connection and fan outlet are properly aligned and sealed. Secure fan to curb through vertical portion of

the ventilator base assembly flange using a minimum of eight (8) lug screws, anchor bolts or other

suitable fasteners (not furnished). Shims may be required depending upon curb installation and roofing

material. Check all fasteners for tightness. The diagrams below show different mechanical installation

configurations.

4

Page 5

Optional Moisture Eliminator Panel

If the unit is equipped with an optional moisture eliminator panel, the maximum face velocity of the coil

may be increased to 650 FPM. Moisture eliminator panels require minimal maintenance. Visual

inspection is recommended periodically. Scale or clogging will impair performance. If scale or clogging

occurs, remove the panel and flush with steam or water. Flushing should not have sufficient force to

dislodge the media from the panel. Scale removal may require a vinegar or detergent application

followed by rinsing.

5

Page 6

Typical Roof Mount Installation

Typical Roof Mount Installation with Exhaust Fan

6

Page 7

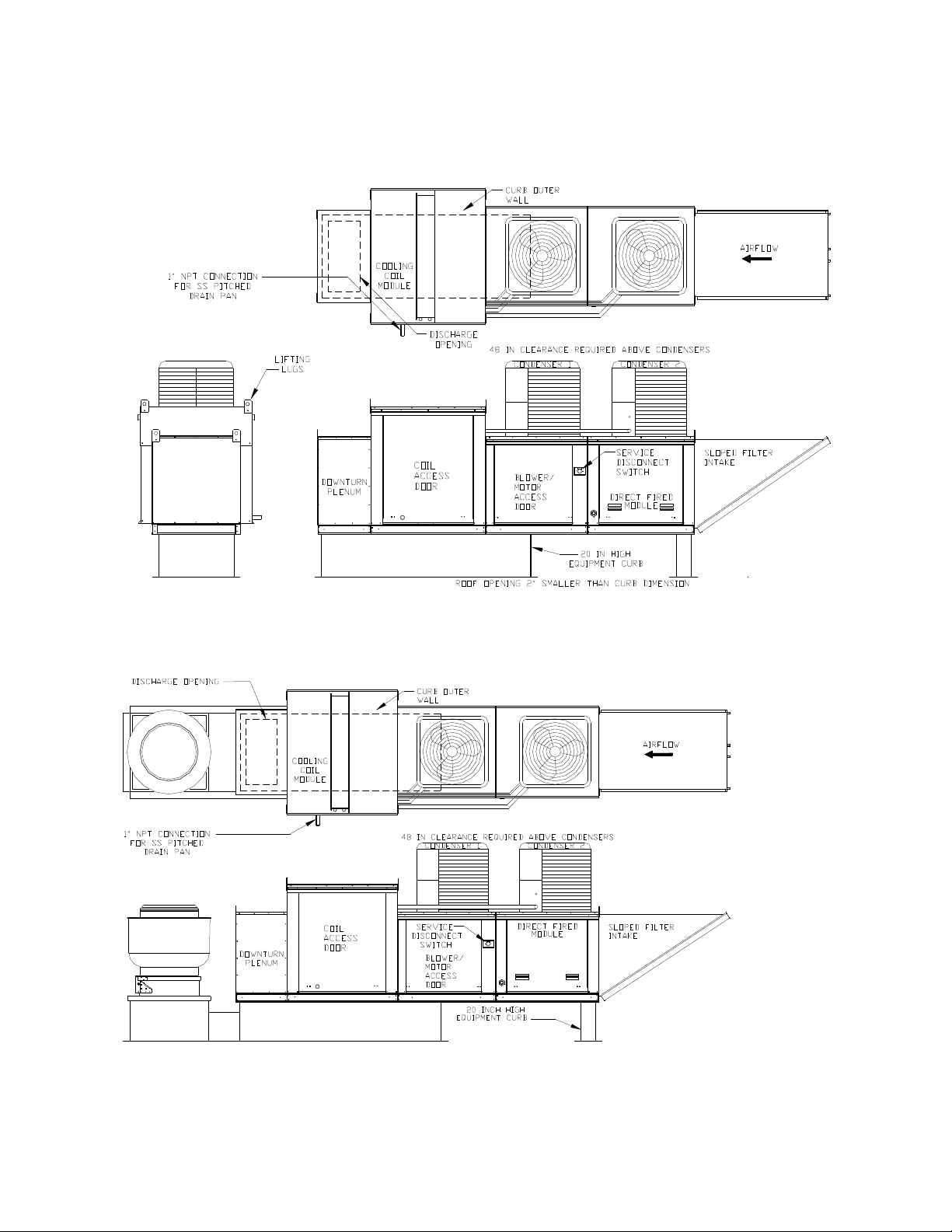

Plumbing Connections

WARNING!!

There is one field plumbing connection required for proper DX coil operation. This is the drain pan

located under the DX coil. Depending on the size of the unit, the coil can generate 5 gallons of water per

hour. It is imperative that the plumbing be sized accordingly. Also, it’s recommended that all plumbing

connections be sealed with Teflon tape or pipe dope.

Only 1” diameter PVC Pipe and low profile couplings should be used. Additionally, the top horizontal

length on the P-Trap should be a minimum of 12”. No unions should be used. Add a clean out as shown

in the picture below.

The P-Trap drain should be attached to the end of the drain pipe on the side of the unit. The trap is

important for two reasons. First, it can be piped to drain in the most convenient area. Second, it keeps

air from being drawn through the drain hole in the side of the pan, impeding drainage.

Typical Cooling Coil Drain Trap

Gas

Refer to the Make-up air (MUA) manual that shipped with this unit for gas installation details.

Electrical

Before connecting power to this unit, read and understand the

entire section of this document. As-built wiring diagrams are

furnished with each fan by the factory and are attached to the

door of the unit.

Electrical wiring and connections should be done in accordance

with local ordinances and the National Electric Code,

ANSI/NFPA70. Be sure the voltage and phase of the power

supply and the wire amperage capacity is in accordance with the

motor nameplate. For additional safety information refer to AMCA publication 410-96, Recommended

Safety Practices for Users and Installers of Industrial and Commercial Fans.

Disconnect power before

installing or servicing fan. High

voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

7

Page 8

1. Always disconnect power before working on or near

this unit. Lock and tag the disconnect switch or breaker

to prevent accidental power up.

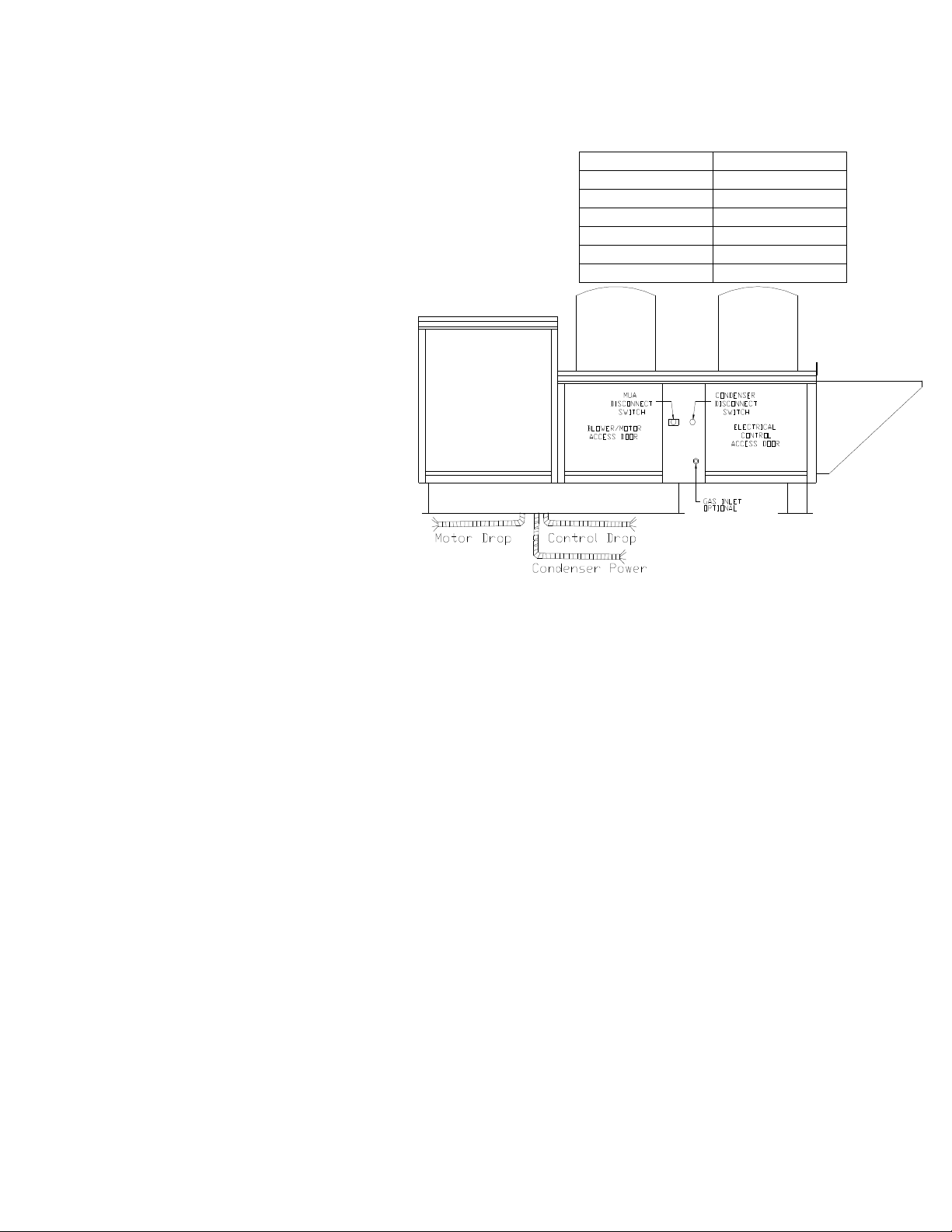

2. This unit contains 2 or 3 disconnect switches and

multiple wiring connections. 1 disconnect is for the mua

blower. The second disconnect is used for units with 2

condensers. A third disconnect is added for units with 3

condensers. An electrical drop containing the motor

power wiring and a separate

drop containing condenser

power is shipped with every

fan. The electrical drops

should be brought through

one of the conduit openings

located in the base of the unit,

run through the curb and

connected to a junction box

inside the building.

3. A dedicated branch circuit

should supply the motor circuit

with short circuit protection

according to the National

Electric Code. This dedicated

branch should be run to the

junction box mentioned above

and connected as shown in a

following illustration labeled “Fan to Building Wiring Connection”.

4. Make certain that the power source is compatible with the requirements of your equipment. The

heater nameplate identifies the proper phase and voltage of the motor. 3 phase condensers

have circuit boards that protect the compressor from running backwards. The board (located

under the condenser wiring panel) will produce a fault light if the 3 phase input needs to be

reversed to that condenser.

5. Units shipped with an optional remote panel have three electrical circuit drops. It is important to

run the motor wires in a separate conduit from the remote control wiring. The DC wires from the

unit temperature controller, located in the control drop, should either be shielded cable or be run

in a separate conduit.

6. Before connecting unit to the building power source, verify power line wiring is de-energized.

7. Secure the power cables to prevent contact with sharp objects.

8. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

9. Before powering up the heater, check fan wheel for free rotation and make sure that the interior of

the heater is free of loose debris or shipping materials.

10. If any of the original wire supplied with the heater must be replaced, it must be replaced with type

THHN wire or equivalent.

Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 15

12 20

10 30

8 50

6 65

4 85

8

Page 9

MUA/Condenser Fan to Building Wiring Connection

Single Phase Condenser: Condenser 1 is the Blue/Blue lines; Condenser 2 is the Red/Red lines;

Condenser 3 is the Grey/Grey lines.

Three Phase Condenser: Condenser 1 is the Blue/Blue/Blue lines; Condenser 2 is the Red/Red/Red

lines; Condenser 3 is the Grey/Grey/Grey lines.

9

Page 10

10

OPERATION

Prior to starting up or operating this unit, check all fasteners for tightness. In particular, check the set

screw in the wheel hub, bearings and the fan sheaves (pulleys). With power and/or gas OFF or prior to

connecting ventilator to power, turn the fan wheel by hand to be sure it is not striking the inlet or any

obstacles. Re-center if necessary.

WARNING: GLOVES AND SAFTEY GLASSES MUST BE WORN WHEN SERVICING

REFRIGERATION EQUIPMENT.

Start Up

Special Tools Required

• AC Voltage Meter

• Tachometer

• Standard Hand Tools

• Refrigeration Gauge Set

Start Up Procedure

• Amperage Meter

• Manometer

• Differential Pressure Gauge

• Thermometer

1. Check all electrical connections for tightness and continuity.

2. Check pulley alignment and belt tension as described below.

3. Inspect the condition of the intake damper and damper linkage, if

provided.

4. Inspect the air-stream for obstructions and install intake filters if

missing.

5. Compare the supplied motor voltage with the fan’s nameplate

motor voltage. If this does not match, correct the problem.

6. Start the fan up, by turning the external MUA disconnect to the ON

position, and shut it OFF immediately to check rotation of the

wheel with the directional arrow on the blower scroll. Reversed

rotation will result in poor air performance, motor overloading and

possible burnout. For units equipped with a single-phase motor,

check the motor wiring diagram to change rotation. For 3-phase

motors, any two power leads can be interchanged to reverse motor

direction.

7. When the fan is started up, observe the operation and check for

any unusual noises.

8. Once the fan is operating properly, turn the condenser disconnect

to the ON position. If the outside air temperature is below 55°F,

the condensers should not operate for an extended period of time.

9. Connect a refrigerant gauge set as shown below to the right.

10. Turn the cooling thermostat down to energize the first condenser.

11. Let the condenser operate for about 15 minutes and check refrigerant operating temperature and

pressure. For R410-A refrigerant, the proper suction temperature is approximately 45°F and the

proper liquid temperature is approximately 100°F. Set the refrigerant level to the proper

subcooling as indicated on the condenser label. Also, adjust the TXV to 10 degrees of superheat.

12. Disconnect the gauge set and repeat these steps on the other condensers if needed. The cooling

thermostat will need to be turned down further to energize the second or third condenser.

Page 11

11

13. If the unit is a cooling only unit, adjust the air proving switch such that prevailing winds cannot

start the condensers without the blower operating. With the unit operating, turn the adjustment

screw clockwise until condensers stop operating. Then turn the adjustment screw

counterclockwise until condensers operate. Turn the screw one half turn more counterclockwise.

14. Refer to the MUA manual to complete the startup of the MUA unit.

Checking the Refrigerant Charge

Subcooling can still be used to identify an over or under-charged system. Typical systems will run

between 10F and 20F of subcooling. If lower than 10F, the system is likely undercharged. If over 20F, the

system is probably overcharged. These "rules of thumb" are approximate. For the condensers used on

this system, the appropriate subcooling is shown below: (First number in unit size is tonnage x 12)

Subcooling is desirable because it increases the efficiency of an air conditioning system. However, too

much subcooling will back liquid up in the condenser causing increased head pressures. This will cause

the system to operate inefficiently and in extreme cases may cause the compressor to trip on its high

pressure control or its internal protector.

In the example below, a standard gauge set is connected (blue to suction and red to liquid) to a system

operating on R410A refrigerant.

The liquid line saturation temperature is reading approximately 98°F from the gauge. The surface

temperature of the liquid line is reading 83.5°F. The surface temperature reflects the actual temperature

of the refrigerant. To calculate subcooling, subtract the surface temperature from the gauge temperature:

Page 12

12

98°F – 83.5°F = 14.5°F of subcooling

This should be compared to the condenser nameplate

subcooling, which in this case is 14°F as shown to the

right.

As a reminder, to increase subcooling, add refrigerant charge and to decrease subcooling, remove

refrigerant charge.

R410A can be added to a system the same as previous R22 systems, such that it can be added as a

liquid into the suction side if done slowly to allow the refrigerant to evaporate before entering the

compressor.

Superheat and Adjusting TXVs

Ideally, the best way to check the operation of the TXV is to measure the superheat at the evaporator

outlet. In many cases this is not convenient for the technician, since there may be no gauge ports

available. A superheat check at the condensing unit can be used instead. Since suction line lengths can

vary, so too can the superheat measured at the condensing unit. With short line lengths (less than 30 ft.),

the superheat should be between 10F and 15F. With longer suction line lengths (between 30 and 50 ft.)

superheats of 15F to 20F are normal.

In the example below, a standard gauge set is connected (blue to suction and red to liquid) to a system

operating on R410A refrigerant.

The suction line saturation temperature is reading approximately 44°F from the gauge. The surface

temperature of the suction line is reading 54.1°F. The surface temperature reflects the actual

temperature of the refrigerant. To calculate superheat, subtract the gauge temperature from the surface

temperature:

54.1°F – 44°F = 10.1°F of superheat

This should be compared to the unit recommendation, which in this case is 10°F.

Page 13

13

If the superheat is too low, and an adjustable-type valve is supplied, the superheat can be increased by

turning the adjustment stem in a clockwise direction. It's a good practice to wait for 15 to 20 minutes after

adjusting the valve, to allow for the system to balance out before determining the effect of the adjustment.

If the superheat is too high, it can be lowered by turning the stem in a counter-clockwise direction.

To adjust the superheat, first remove the bottom cap from the TXV. Next, turn the adjustment screw

clockwise to increase superheat or counterclockwise to decrease superheat. Adjust about ½ turn at a

time and allow system to stabilize. Once proper superheat is set, replace the TXV cap.

Checking Heating Mode for Units with Heat Pumps

Refrigerant charge in heat pumps should be checked while the unit is in cooling mode with the same

Subcooling and Superheat method described above. However, it is also important to check heating mode

to make sure the unit is operating properly.

Attach the refrigerant gauges to the heat pump with the

red high pressure line connected to the suction line and

the blue low pressure line connected to the middle access

port as shown below.

Turn the heating thermostat up until the first heat pump

comes on. Allow the heat pump to run for 15 minutes and

check the high side pressure. The pressure should not

exceed the maximum operating pressure listed on the unit

name plate. If the pressure is high, refrigerant will need to

be removed. Removing refrigerant will also affect cooling

mode subcool and superheat, so they will need to be

checked again also.

Page 14

14

Sequence of Operation-Cooling with Direct, Indirect, or Electric Heat

This unit is most easily understood when broken down into smaller individual systems. There are two

main systems, a make-up air (MUA) fan and a cooling system. The make-up air fan consists of a blower

and motor. The cooling system consists of a condenser(s), DX coil, filter/dryer, and thermal expansion

valve.

Basic cooling units include 2 thermostats for proper operation. The first thermostat is an intake air

thermostat that prevents heating and cooling from occurring simultaneously. This is typically labeled

“Burner ON/Off Intake Air Thermostat.” This thermostat will allow the burner to operate when the outside

air temperature falls below the set point and prevents the burner from operating when the outside air

temperature rises above the set point. It also allows the cooling circuit to receive power when the outside

air temperature rises above the set point. This thermostat is typically set at 45° F and is adjustable.

The second thermostat is a cooling thermostat. The cooling thermostat allows the cooling circuit to

energize when the outside air rises above the set point. This is a 2 stage, differential thermostat; one set

point that energizes where the thermostat is set and a second stage that energizes at a factory setting of

10° F higher. The main set point controls the first stage of cooling and the differential controls the second

stage of cooling. This thermostat is factory set at 85° F; the factory setting and subsequent differential

setting are both adjustable.

With the blower already running and the airflow switch proven;

The air temperature rises above the setting of intake air thermostat and the cooling

thermostat

OR

The optional remote panel is set to “Manual” and “Cool” mode, and the temperature rises

above both thermostats as mentioned above.

• The first stage condenser energizes and cooling starts.

• The air temperature continues to rise above the cooling thermostat differential and the second stage

of cooling (if equipped) is energized.

• Once the air temperature falls below the differential, the second stage of cooling is de-energized.

• Once the air temperature falls below the cooling thermostat set point, both stages of cooling are de-

energized.

Cooling Thermostat on Left, Burner/Heat Thermostat on Right

***AN OPTIONAL PROGRAMMABLE THERMOSTAT

IS AVAILIBLE. WHEN THIS IS PROVIDED, AN AS

BUILT SCHEMATIC AND A SEPARATE MANUAL IS

PROVIDED FOR THE THERMOSTAT***

Page 15

15

Sequence of Operation-Reheat

The unit can be equipped with an optional reheat coil downstream from the DX coil. When this option is

installed, warm, liquid refrigerant will flow through a reheat coil before it enters the DX coil. This warms

the cooled air discharged from the DX coil and helps to lower the relative humidity of the airstream.

Reheat is always activated in this system, and only uses refrigerant from stage 1.

Sequence of Operation-Liquid Bypass

This system can be installed with a Liquid Bypass option. This option helps prevent coil freezing by

injecting warm liquid refrigerant directly into the DX coil, bypassing the TXV. The system is controlled by

a Bypass Thermostat whose sensing bulb is strapped to the vertical portion of the stage 1 suction line.

When the Bypass Thermostat reads a temperature below 35º F, it sends a signal to a 24V solenoid valve.

The valve opens and allow warm liquid refrigerant to bypass the TXV and go directly into the DX coil.

Once the thermostat reads a temperature above 35º F in the suction line, it shuts off the solenoid valve

and the system continues to operate normally.

Sequence of Operation-Cooling Only or Heat Pump

Onboard HMI

• MENU – Used to revert back one screen each

time it is pressed. If any value has been altered

and the menu button is pressed, that value will

save.

• UP – Used to navigate up through the current

list of items.

• DOWN – Used to navigate down through the

current list of items

• ENTER – Used to advance once screen each

time it is pressed. If any value has been altered

and the enter button is pressed, that value will

save.

(If any value has been changed, the board will automatically reboot when the user exits to the

home screen)

Info

• Temperature – Contains values for Discharge, Return, Outside Intake, Space, Mixed Air,

Outdoor-Discharge ∆T, and Return-Discharge ∆ T. Will show disconnected if there is no sensor

present.

• Date/Time – Displays time and date based on real time clock (RTC).

• Outputs – Output voltage to RTU out 0-10V #1.

• Timers – Displays uptime of the board.

• Mixed Air Info – Displays live outdoor air % and return air %.

Configuration

• Modbus Address – This address which will be used to communicate with the board.

• # Of Stages – Configurable to 1, 2, or 3 stages.

• Control Mode – Auto (heat/cool), heat, cool, off.

• Staged Based On – Outside, space.

• Activate Based On – Outside, space, both, either.

Page 16

16

Faults

• Space Cool SP – Stage 1 space cooling set point.

• Space Cool SP #2 – Stage 2 space cooling set point.

• Space Cool SP #3 – Stage 3 space cooling set point.

• Space Heat SP – Stage 1 space heating set point.

• Space Heat SP #2 – Stage 2 space heating set point.

• Space Heat SP #3 – Stage 3 space heating set point.

• Outdoor Cool SP – Stage 1 outdoor cooling set point.

• Outdoor Cool SP #2 – Stage 2 outdoor cooling set point.

• Outdoor Cool SP #3 – Stage 3 outdoor cooling set point.

• Outdoor Heat SP – Stage 1 outdoor heating set point.

• Outdoor Heat SP #2 – Stage 2 outdoor heating set point.

• Outdoor Heat SP #3 – Stage 3 outdoor heating set point.

(All tempering set points may not be available depending on the selected # of

stages and staging/activation selections)

• Min. Outdoor Air Temp – This value is in place to ensure that a unit is not trying to cool

when the ambient outside temperature is too low. This will help prevent coils from

freezing. It is factory set at 60° F and adjustable between 55-65° F.

• O/B Output Mode – This option allows you to choose whether the output energizes during

cooling or heating. This output is driven by what company heat pump is being utilized.

Carrier’s standard is to energize with cooling.

• Mode Change Time – This time dictates how long the unit must wait before switching

from heating to cooling or vice versa. Factory set at 5 minutes. Adjustable between 1-10

minutes.

• Heat Hysteresis – Factory set a 1° F, adjustable between 1-5° F.

• Cool Hysteresis – Factory set a 1° F, adjustable between 1-5° F.

• Min. Heat On Time – Time any heating stage must stay on after being activated. Factory

set at 2 minutes. Adjustable between 1-5 minutes.

• Min. Cool On Time – Time any cooling stage must stay on after being activated. Factory

set at 2 minutes. Adjustable between 1-5 minutes.

• Min. Heat Off Time – Time any heating stage must stay off after being de-activated.

Factory set at 2 minutes. Adjustable between 1-5 minutes.

• Min. Cool Off Time – Time any cooling stage must stay off after being de-activated.

Factory set at 2 minutes. Adjustable between 1-5 minutes.

• Mixing Box Type – Selectable between none, external, and adjustable. Choosing

external or adjustable both enables the use of return and mixed air sensors. When

adjustable is chosen it also enables the 0-10V damper position output on the board.

• Damper Position – This is a user selectable 0-100 percent, and once set, the board will

try to maintain that percentage of outdoor air by altering its output voltage to the damper.

• MB Deadband – This relates to the absolute value of the delta T between outdoor air and

return air. If the delta T falls within the deadband range, the board will not alter its output

voltage to the damper. The voltage will be a constant 0-10V directly related to the 0-100

damper position. Factory set at 5° F and adjustable between 1-10° F.

• Return As Space – This option is enabled when a mixing box is selected. If an adequate

space sensor can’t be mounted within the space, the board has the ability to treat the

return air sensor as the space sensor.

• Startup Time – Delay upon powering up until the board allows any pins to be active.

Factory set at 5 seconds.

• Reboot – Reboots the board.

• Factory Reset – Resets the board to the last commissioned settings.

• View Faults – This menu will store faults even once the board has lost power. Possible

faults include airflow, alarm 1 (float switch), heating discharge, and cooling discharge.

Heating and cooling discharge faults occur when there has been no ∆T for 30 minutes.

Page 17

17

Diagnostics

• Clear Faults – Once the faults have been resolved, choosing this option will wipe them

from the board’s memory. If the fault has not been resolved, it could re-appear on the

view faults screen.

• RTU Y1 – Option to enable or disable Y1 (stage 1) output.

• RTU Y2 – Option to enable or disable Y2 (stage 2) output.

• RTU Y3 – Option to enable or disable Y3 (stage 3) output.

• RTU O/B – Option to enable or disable O/B output.

• RTU 10V Out 1 – 0-10V adjustable output

• Exit – In order to back out of diagnostics mode, this menu item must be selected.

Page 18

18

Board Menu

Page 19

19

Components

The following image outlines the typical modular packaged unit components. Systems are available with

heating modules, mixing boxes and 1, 2 or 3 condensers.

Thermal Expansion Valves Filter/Dryer

Page 20

20

Troubleshooting

Problem

Potential Cause

Corrective Action

The following tables list causes and corrective actions for possible problems with the units. Review these

lists prior to consulting manufacturer.

Troubleshooting Chart

Fan Inoperative Blown fuse or open circuit breaker Replace fuse or reset circuit breaker

Disconnect switch in “Off” position Turn to “On” position

Motor wired incorrectly Check motor wiring to wiring diagram

Broken fan belt Replace belt

Motor starter overloaded Reset starter and check amps

Remote panel set to “Off” Position Set Remote Panel to “Manual” or “Auto”

Motor Overload Fan rotating in the wrong direction Be sure fan is rotating in the direction

Fan speed is too high Reduce fan RPM

Motor wired incorrectly Check motor wiring to wiring diagram

Overload in starter set too low Set overload to motor FLA value

Motor HP too low Determine if HP is sufficient for job

Duct static pressure lower than design Reduce fan RPM

Insufficient Airflow Fan rotating in the wrong direction Be sure fan is rotating in the direction

Poor outlet conditions There should be a straight clear duct at

Intake damper not fully open Inspect damper linkage and replace

Duct static pressure higher than design Improve ductwork to eliminate or reduce

Blower speed too low Increase fan RPM. Do not overload

Supply grills or registers closed Open and adjust

Dirty or clogged filters Clean and/or replace

Belt slippage Adjust belt tension

Excessive Airflow Blower speed too high Reduce fan RPM

Filters not installed Install filters

Duct static pressure lower than design Reduce fan RPM

Excessive Vibration and Noise Misaligned pulleys Align pulleys

Damaged or unbalanced wheel Replace wheel

Fan is operating in the unstable region of

the fan curve

Bearings need lubrication or replacement Lubricate or replace

Fan speed is too high Reduce fan RPM

Belts too loose, worn or oily Inspect and replace if needed

No Cooling Condenser Disconnect is Off Turn Disconnect to ON Position

Outside Air Temp is cooler then

thermostat setting

Frozen Coil Ensure airflow through unit is correct

Refrigerant Leak Ensure refrigerant has not leaked out of

Insufficient Cooling Excessive Airflow Reduce the airflow volume

Incorrect Refrigerant Charge Refrigerant charge must be checked by

and check amps

located on fan motor

Position

shown on rotation label

located on fan motor

shown on rotation label

the outlet

damper motor if needed

duct losses

motor

Refer to performance curve for fan

Turn thermostat to desired cooling

activation set point. Do not turn below

55° F.

and refrigeration charge is correct. Low

airflow will cause the coil to freeze.

unit.

a refrigeration contractor

Page 21

21

MAINTENANCE

To guarantee trouble free operation of this unit, the manufacturer suggests following these guidelines.

Most problems associated with fan failures are directly related to poor service and maintenance.

Please record any maintenance or service performed on this fan in the documentation section located at

the end of this manual.

WARNING: DO NOT ATTEMPT MAINTENANCE ON THE UNIT UNTIL THE

ELECTRICAL SUPPLY HAS BEEN COMPLETELY DISCONNECTED AND THE

MAIN GAS SUPPLY VALVE (IF REQUIRED) HAS BEEN TURNED OFF.

General Maintenance

1. Fan inlet and approaches to ventilator should be kept clean and free from any obstruction.

2. Motors are normally permanently lubricated. Check bearings periodically. If they have grease

fittings, lubricate each season. Use caution when lubricating bearings - wipe the fittings clean and

the unit should be rotated by hand while lubricating. Caution: Use care when touching the

exterior of an operating motor. Motors normally run hot and may be hot enough to be

painful or cause injury.

3. All fasteners should be checked for tightness each time maintenance checks are performed prior

to restarting unit.

4. Blowers require very little attention when moving clean air. Occasionally, oil and dust may

accumulate causing imbalance. If the fan is installed in a corrosive or dirty atmosphere,

periodically inspect and clean the wheel, inlet and other moving parts to ensure smooth and safe

operation.

5. Do not block or cover airflow to condensing units. Do not allow grass clippings, leaves or other

debris to accumulate on the sides or top of the unit.

6. Do not operate the air conditioning system when the outdoor air is less then 55° F.

2 weeks after startup

1. Belt tension should be checked after the first 2 weeks of fan operation. Belts tend to stretch and

settle into pulleys after an initial start-up sequence. Do not tension belts by changing the

setting of the motor pulley, this will change the fan speed and may damage the motor. To retension belts, turn the power to the fan motor OFF. Loosen the fasteners that hold the blower

scroll plate to the blower. Rotate the motor to the left or right to adjust the belt tension. Belt

tension should be adjusted to allow 1/64” of deflection per inch of belt span. Exercise extreme

care when adjusting V-belts, as not to misalign pulleys. Any misalignment will cause a sharp

reduction in belt life and produce squeaky noises. Over-tightening will cause excessive belt and

bearing wear, as well as noise. Too little tension will cause slippage at startup and uneven wear.

Whenever belts are removed or installed, never force belts over pulleys without loosening

motor first to relieve belt tension. When replacing belts, use the same type as supplied by the

manufacturer. On units shipped with double groove pulleys, matched belts should always be

used.

2. All fasteners should be checked for tightness each time maintenance checks are performed prior

to restarting unit.

Every 3 months

1. Belt tension should be checked quarterly. See instructions in the previous maintenance section.

Over-tightening will cause excessive bearing wear and noise. Too little tension will cause

slippage at startup and uneven wear.

Page 22

22

2. Filters need to be cleaned and/or replaced quarterly, and more often in severe conditions.

Washable filters can be washed in warm soapy water. When re-installing filters, be sure to install

with the airflow in the correct direction as indicated on the filter.

3. Check for and remove debris that has settled around the base of the condenser. This will ensure

proper water drainage from the condenser.

Yearly

1. Inspect bearings for wear and deterioration. Replace if necessary.

2. Inspect belt wear and replace torn or worn belts.

3. Inspect bolts and set screws for tightness. Tighten as necessary.

4. Inspect motor for cleanliness. Clean exterior surfaces only. Remove dust and grease from the

motor housing to ensure proper motor cooling. Remove dirt and grease from the wheel and

housing to prevent imbalance and damage.

Page 23

23

Start-Up and Maintenance Documentation

START-UP AND MEASUREMENTS SHOULD BE PERFORMED AFTER THE SYSTEM HAS BEEN

AIR BALANCED AND WITH THE COOLING ON (Warranty will be void without completion of this

form).

Job Information

Job Name Service Company

Address Address

City City

State State

Zip Zip

Phone Number Phone Number

Fax Number Fax Number

Contact Contact

Purchase Date Start-Up Date

Unit Information

Refer to the start-up procedure in this manual to complete this section.

Name Plate and Unit Information

Model Number

MUA Serial Number

Motor Volts

Motor Hertz

Motor Phase

Motor FLA

Motor HP

Blower Pulley

Motor Pulley

Belt Number

Gas Type

Min. Btu/Hr

Max. Btu/Hr

COND 1 Serial Number

COND 2 Serial Number

COND 3 Serial Number

**

If measured amps exceed the FLA rating on the nameplate, fan RPM must be reduced to decrease the

measured amps below the nameplate FLA rating.

Field Measured Information

Motor Voltage

Motor Amperage**

MUA Blower RPM

Ambient Wet Bulb Temp °F

Ambient Dry Bulb Temp °F

COND 1 Suction Pressure PSI

COND 1 Suction Temperature °F

COND 1 Liquid Pressure PSI

COND 1 Liquid Temperature °F

COND 1 Subcooling °F

COND 1 Superheat °F

COND 2 Suction Pressure PSI

COND 2 Suction Temperature °F

COND 2 Liquid Pressure PSI

COND 2 Liquid Temperature °F

COND 2 Subcooling °F

COND 2 Superheat °F

COND 3 Suction Pressure PSI

COND 3 Suction Temperature °F

COND 3 Liquid Pressure PSI

COND 3 Liquid Temperature °F

COND 3 Subcooling °F

COND 3 Superheat °F

Cooling Thermostat Set-Point °F

Airflow Direction Correct

Incorrect

Page 24

24

Maintenance Record

Date Service Performed

Factory Service Department

Phone: 1-866-784-6900

Fax: 1-919-554-9374

Loading...

Loading...