Page 1

Modular DX System

Installation Instructions

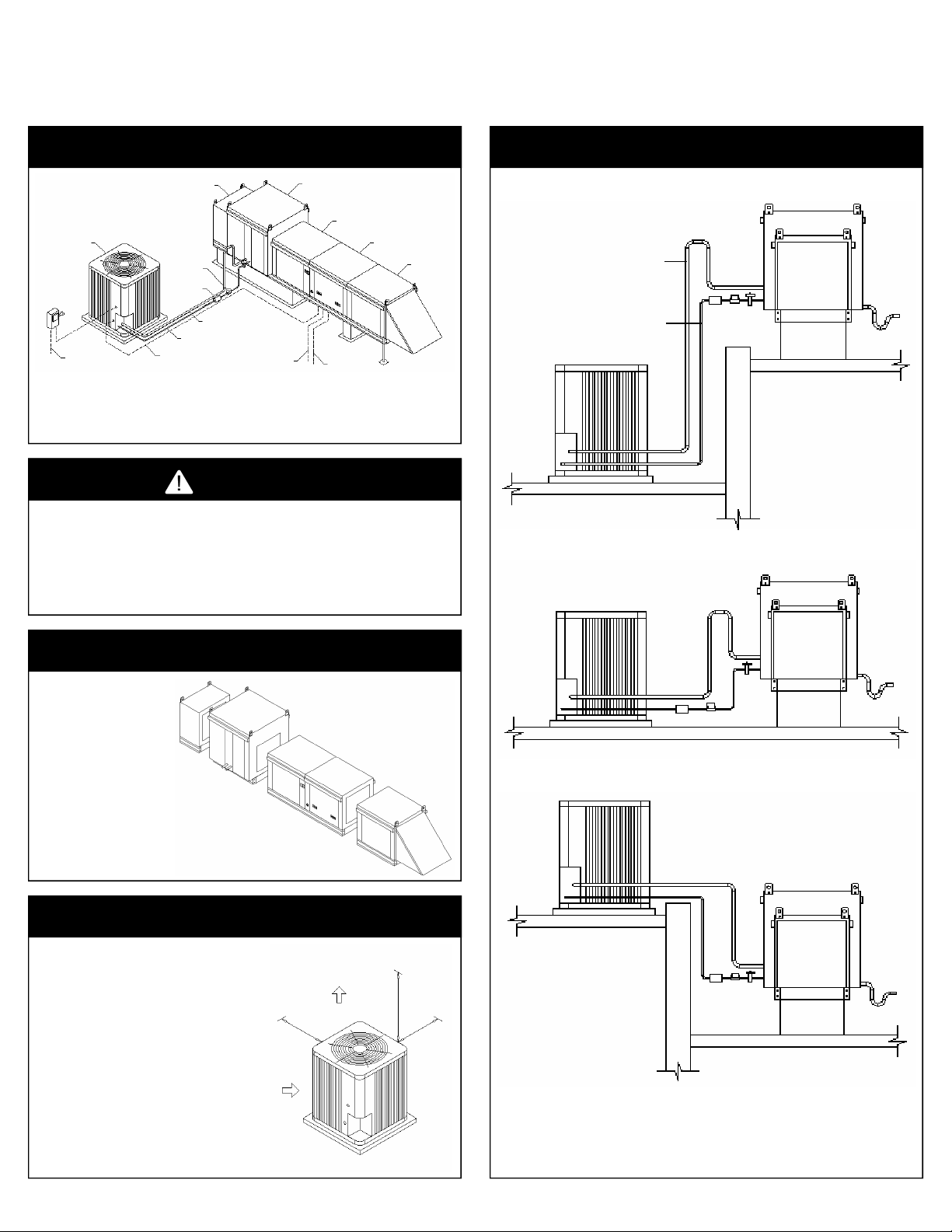

TYPICAL PIPING AND WIRING

Downturn

Plenum

Condensing

Unit

Weatherproof

Fused

Disconnect

Per NEC

Field Wired

Power Supply

Notes:

1. Read the equipments “Installation and Operation Guide” before installing this equipment.

2. All Piping must follow standard refrigerant piping techniques.

3. All wiring must comply with all local and national codes.

4. Call the factory service department with any installation questions.

Sight Glass

Filter Drier

Liquid Line

Field Wired

Control Wires

Suction Line

Field Wiring

Power Supply

Per NEC

DX Coil Module

Field Wiring

Remote Panel

(Optional)

Blower Module

WARNING

• Installing, start-up, and servicing air-conditioning

equipment can be dangerous due to system pressures,

electrical components, and equipment locations.

• Only trained, qualified installers and service technicians

should install, start-up, and service this equipment.

• Untrained personal can perform basic maintenance

functions such as cleaning coils. All other operations

should be performed by trained service personnel.

• When working on the equipment, observe precautions

in the literature and on decals, labels, and tags attached

to the equipment.

• Follow all safety codes. Wear safety glasses and work

gloves. Keep quenching cloth and fire extinguisher

nearby when braising.

• Use safe lifting practices when lifting and setting

equipment.

Heater Module

Filter

Section

REFRIGERANT PIPING PRACTICES

Typical Piping When Condenser Is Below The AMU

Suction Line

with a 16”

Refrigerant

Trap

Liquid Line

Condenser

Roof

Typical Piping On Same Level

Condenser

AMU

Curb

Roof

Condensate

Trap

INSPECT UNIT

• Inspect unit for damage.

• Look for damage done to the

casing, coils, or ship loose

components.

• Contact factory service depart-

ment if damage is found on the

unit.

• Verify that the power and gas

supply to the unit matches the

unit nameplate ratings.

• Call the factory service depart-

ment with any installation

questions.

INSTALL CONDENSING UNIT

• Read the customer supplied Condenser Installation manual

before attempting to install, pipe, or wire the unit. The

manufacturer of the Condenser may have special instructions for installing that is not mentioned in this document.

• Contact the Condenser manufacturer with any installation

questions.

• Mount the Condenser in a location where adequate air flow

and service space is available.

• The Condensing units comes with a factory refrigerant

charge. Do not open the ball valves until the plumbing has

been completed and tested for leaks.

• Refer to the Condenser Installation manual for suction and

liquid line sizes and maximum lengths.

• Refer to the Condenser Installation manual for general wiring

practices. All wiring must comply with all local and national

codes.

• Refer to the Cooling Circuit Wiring in this document for

instructions on connecting to the Make-Up Air unit electrical

panel.

Air Flow

Minimum

Clearance

24”

Air Flow

Minimum

Clearance

60”

Minimum

Clearance

24”

Suction Line

with a 16”

Refrigerant

Trap

Liquid Line

Roof

Typical Piping When AMU Is Below Condenser

Condenser

Suction Line

Roof

Notes:

1. Maximum refrigerant line length 100 feet.

2. Do not bury refrigerant lines underground.

3. Accumulators are required on refrigerant line lengths of 75 to 100 feet.

4. Maximum refrigerant liquid lift 60 feet.

5. Dual circuit systems require two suction and liquid lines.

Liquid

Line

AMU

Curb

AMU

Roof

Curb

Condensate

Trap

Condensate

Trap

Page 2

WARNING

Disconnect power before installing or servicing fan. High voltage electrical input is needed for this

Electrical wiring must be done in accordance with local ordinances and the National Electric Code, ANSI/

NFPA70. Be sure the voltage and phase of the power supply and the wire amperage capacity conform to those

listed on the units nameplate. For additional safety information, refer to AMCA publication 410-96,

equipment. This work should be performed by a qualified electrician.

“Recommended Safety Practices for Users and Installers of Industrial and Commercial Fans.”

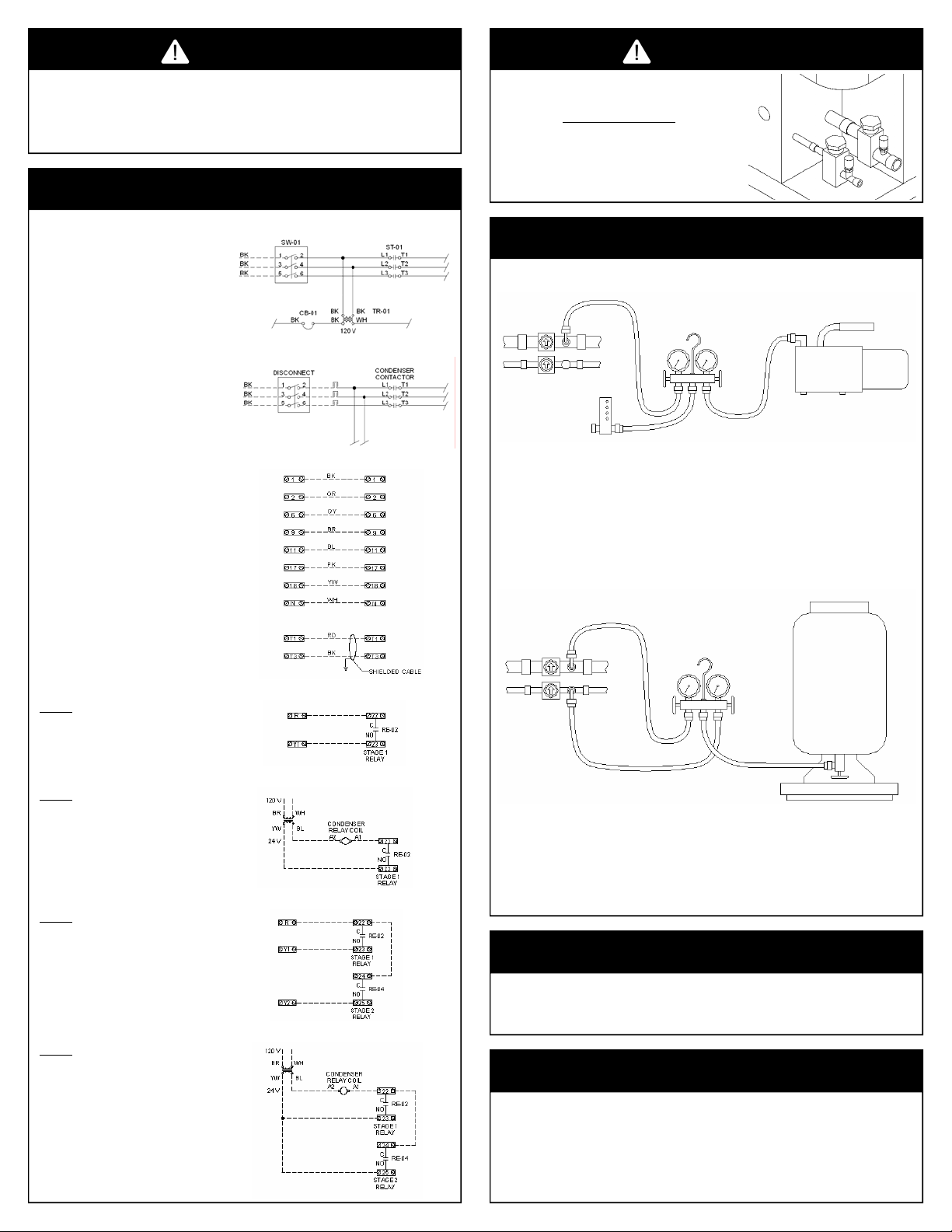

ELECTRICAL CONNECTIONS

AMU POWER SUPPLY

Check that the power supply matches the units

nameplate rating.

Wire the disconnect using NEC and local

codes. Size the wire according to the units

minimum circuit amps.

SW-01 MAIN DISCONNECT SWITCH

ST-01 SUPPLY MOTOR CONTACTOR

CB-01 CIRCUIT BREAKER

TR-01 POWER TRANSFORMER

CONDENSER POWER SUPPLY

Check that the power supply matches the units

nameplate rating.

Wire the disconnect using NEC and local

codes. Size the wire according to the units

minimum circuit amps.

CAUTION

Condensing units contain a factory holding charge of refrigerant .

Opening the liquid or suction line shut-off valves before the piping

has been braised, evacuated, and leak tested may result in

Section 608 of the “Clean Air Act”, prohibits individuals from

knowingly venting ozone-depleting compounds (refrigerant) into the

atmosphere while installing, maintaining, servicing, repairing, or

EPA performs random inspections, responds to tips, and pursues

potential violators. Under the Act, EPA is authorized to fine up to

releasing the holding charge.

EPA Section 608 Clean Air Act

disposing of air-conditioners or refrigeration equipment.

$32,000 per day for any violation of these regulations.

EVACUATION & REFRIGERANT CHARGING

EVACUATION

Suction Line

Valve

Liquid Line

Valve

Micron Gauge

Refrigerant Gauge

Vacuum Pump

AMU units that ship with a optional remote

panel must be field wired before starting the

unit.

The AMU terminal block will correspond with

the remote panel terminal block.

Use shielded cable on the wires for T1 and T3

for the remote set-point dial, or run the wired in

a separate conduit from the power wiring.

CONDENSER SINGLE COMPRESSOR (A)

Option A

Wire single compressor condensers with R-GY-W-C terminals to the AMU as shown.

Refer to the condensers installation manual for

additional wiring directions.

CONDENSER SINGLE COMPRESSOR (B)

Option B

Wire single compressor condensers without RG-Y-W-C terminals to the AMU as shown.

Refer to the condensers installation manual for

additional wiring directions.

CONDENSER DUAL COMPRESSOR (A)

Option A

Wire dual compressor condensers with R-G-YW-C terminals to the AMU as shown.

Refer to the condensers installation manual for

additional wiring directions.

REMOTE PANEL

• Leave suction and liquid line valves closed

• Open both refrigerant gauge valves and turn the vacuum pump ON

• Evacuate the system until the micron gauge reads less than 500 microns

• Repair leaks or check the hose connections if the micron gauge does not reach 500 microns

• Close the refrigerant gauge valves and turn the vacuum pump OFF

CHARGING

Check the condensing unit Installation Manual and documentation on charging instructions.

Some condensing unit come with the full operating refrigerant charge.

Suction Line

Valve

Liquid Line

Valve

Check the condensing units Installation Manual and documentation on charging information, some condensing

•

units come with the full operating refrigerant charge

• After evacuating the system, charge the system with 80% of the operating charge shown on the condensing units

name plate

• After starting the unit add the remaining refrigerant charge and fine tune the charge so the units super-heat is

around 8 to 12 F

Refrigerant Gauge

Refrigerant Tank

Scale

• Remove the gauge lines and replace the suction and liquid line valve caps.

START-UP

CONDENSER DUAL COMPRESSOR (B)

Option B

Wire dual compressor condensers without RG-Y-W-C terminals to the AMU as shown.

Refer to the condensers installation manual for

additional wiring directions.

Read the condensing unit and AMU installation, start-up, and operation guides

Fill out the start-up check lists and send them to the Factory Service Department

TECHNICAL SERVICE

Need additional help or have other questions?

Contact the factory service department.

715-595-4225 office

919-227-5959 fax

Loading...

Loading...