FloAire F-D User Manual

FOR YOUR SAFETY

Standard and Modular

Direct Fired

Re-Circulating

Heater

s

Installation, Operation, and Maintenance Manual

Save these instructions

RECEIVING AND INSPECTION

WARNING!!

FOR YOUR SAFETY

WARNING

Modular Direct Fired Re-Circulating Heater

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flames.

4. Immediately call your gas supplier.

The use and storage of gasoline or other flammable vapors and liquids in open containers in the

vicinity of this appliance is hazardous.

If you smell gas:

On heaters that recirculate room air, outside

ventilation air must be provided in accordance

with the information shown on the heater name

plate.

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free. Turn the blower wheel by hand to verify free rotation and check the damper (if

supplied) for free operation.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment. ALWAYS disconnect power and gas

prior to working on heater.

. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

August 2013 Rev. 1

A0020936

TABLE OF CONTENTS

WARRANTY ...................................................................................................................................................................................... 4

INSTALLATION ................................................................................................................................................................................. 5

Mechanical ................................................................................................................................................................................... 5

Site Preparation ...................................................................................................................................................................... 5

Assembly ................................................................................................................................................................................ 6

Curb and Ductwork ................................................................................................................................................................. 6

Indoor (INLINE) Installation ..................................................................................................................................................... 7

Roof Mount Installation ........................................................................................................................................................... 7

Gas .............................................................................................................................................................................................. 8

Gas Connection Sizes ............................................................................................................................................................ 8

Gas Pressure Table ................................................................................................................................................................ 8

Gas Connection Diagram ........................................................................................................................................................ 8

Electrical ...................................................................................................................................................................................... 9

Copper Wire Ampacity ............................................................................................................................................................ 9

PSC (Permanent Split Capacitor) Motor Speed Control ........................................................................................................ 10

ECM (Electronically Controlled Motor) Speed Control ........................................................................................................... 10

Motorized Intake Damper ...................................................................................................................................................... 10

Electric Cabinet Heater ......................................................................................................................................................... 10

Remote Control Panel ........................................................................................................................................................... 11

Fan to Building Wiring Connection ........................................................................................................................................ 11

Start Up ...................................................................................................................................................................................... 12

Special Tools Required ......................................................................................................................................................... 12

Start Up Procedure ............................................................................................................................................................... 12

Pilot Adjustment .................................................................................................................................................................... 12

Pilot Assembly ...................................................................................................................................................................... 12

Main Burner Adjustment ........................................................................................................................................................ 13

Maxitrol M511 and M611 Low Fire Bypass Screw ................................................................................................................. 13

Heater Start Up Summary ..................................................................................................................................................... 14

Final Start Up Procedure ....................................................................................................................................................... 15

Pulley Adjustment ................................................................................................................................................................. 15

Pulley Alignment ................................................................................................................................................................... 15

Proper Belt Tension .............................................................................................................................................................. 15

Pulley Setscrew Torque ........................................................................................................................................................ 15

Pulley Combination Chart ..................................................................................................................................................... 16

Sequence of Operation ............................................................................................................................................................... 17

Flame Safety Control ............................................................................................................................................................ 17

Air Flow Switch ..................................................................................................................................................................... 17

DC Flame Signal ................................................................................................................................................................... 17

Modulating Gas System ........................................................................................................................................................ 18

High Temperature Limit......................................................................................................................................................... 18

Operation Summary .............................................................................................................................................................. 18

Optional Remote Panel Circuit .............................................................................................................................................. 19

Re-Circulating Control Options ........................................................................................................................................................ 20

Manual Positioning Control (Potentiometer) .......................................................................................................................... 20

Two Position Control ............................................................................................................................................................. 20

Static Pressure Control (Photohelic) ..................................................................................................................................... 21

A306 Outdoor Sensor ........................................................................................................................................................... 22

Building Signal Damper Control ............................................................................................................................................ 22

Components .................................................................................................................................................................................... 23

Remote Panel Option ............................................................................................................................................................ 24

Troubleshooting ............................................................................................................................................................................... 25

Airflow Troubleshooting Chart ............................................................................................................................................... 25

Burner Troubleshooting Chart ............................................................................................................................................... 26

Remote Panel Troubleshooting Chart ................................................................................................................................... 27

Troubleshooting Flowcharts .................................................................................................................................................. 28

MAINTENANCE .............................................................................................................................................................................. 29

General Maintenance ................................................................................................................................................................. 29

2 weeks after startup .................................................................................................................................................................. 30

Every 3 months .......................................................................................................................................................................... 30

Filter Quantity Chart .............................................................................................................................................................. 30

Yearly ......................................................................................................................................................................................... 31

Burner Orifice Drill Size ........................................................................................................................................................ 31

Start-Up and Maintenance Documentation ................................................................................................................................. 32

Job Information ..................................................................................................................................................................... 32

Heater Information ................................................................................................................................................................ 32

Maintenance Record ............................................................................................................................................................. 32

Factory Service Department.................................................................................................................................................. 32

3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

4

INSTALLATION

CLEARANCES

It is imperative that this unit is installed and operated with the designed airflow, gas, and electrical supply

in accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

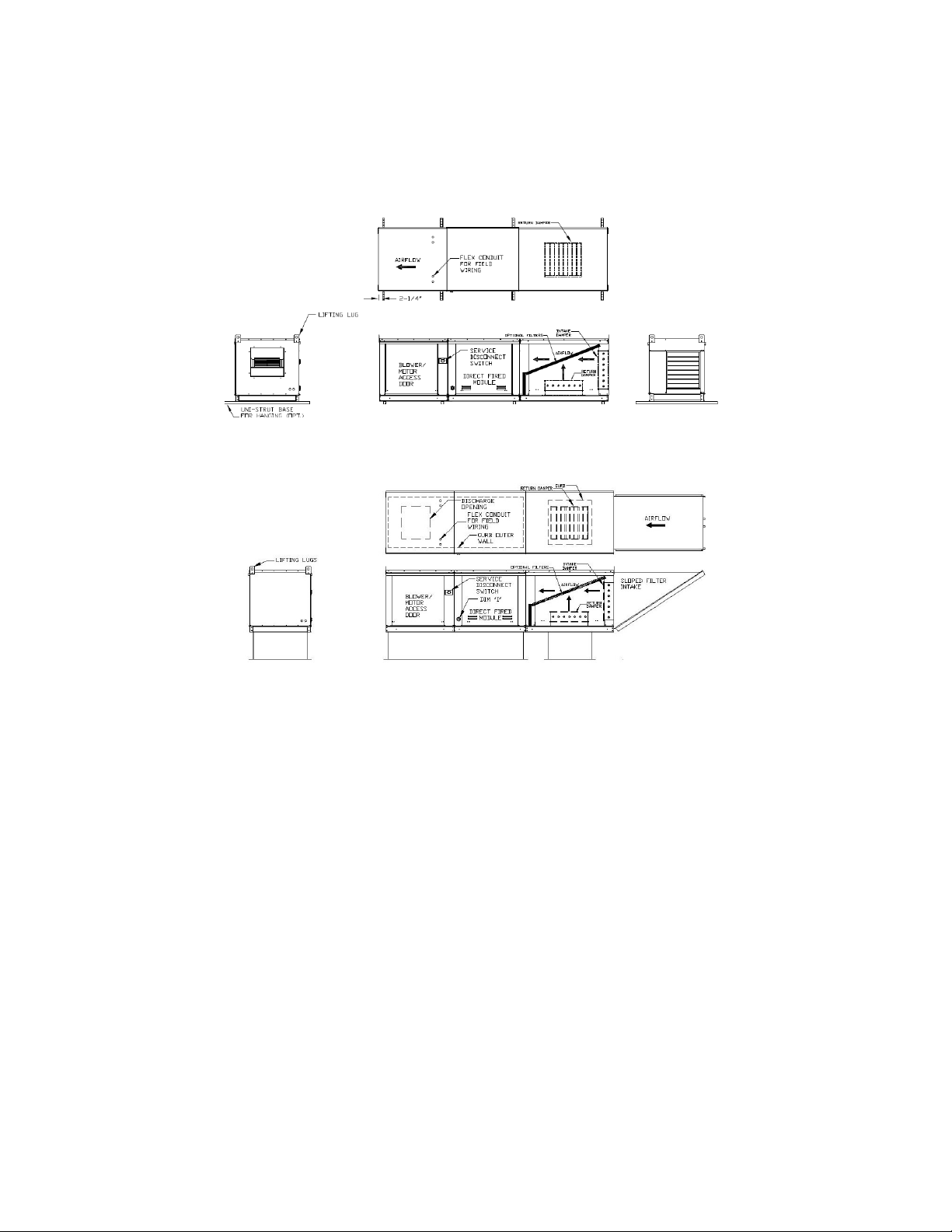

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, BLOWER OR

MOTOR SHAFT, OR BEARINGS – USE LIFTING LUGS PROVIDED OR A SLING

Site Preparation

1) Provide clearance around installation site to safely rig and

lift equipment into its final position. Supports must

adequately support equipment. Refer to manufacturer’s

estimated weights.

2) Consider general service and installation space when

locating unit.

3) Locate unit close to the space it will serve to reduce long,

twisted duct runs.

4) Do not allow air intake to face prevailing winds. Support

unit above ground or at roof level high enough to prevent

precipitation from being drawn into its inlet. The inlet must

also be located at least 10 feet away from any exhaust

vents. The heater inlet shall be located in accordance with the applicable building code

provisions for ventilation air. If in doubt regarding the application, consult the manufacturer. All

ventilation air to the heater shall be ducted directly from the outdoors.

5) Recirculation of room air may be hazardous in the presence of:

a) Flammable solids, liquids and gases

b) Explosive materials (e.g., grain dust, coal dust, gunpowder, etc.)

c) Substances which may become toxic when exposed to heat (e.g., refrigerants, aerosols, etc.)

6) Recirculation is not recommended in uninsulated buildings where outside temperatures fall below

32°F (0°C).

7) Excessive recirculation or insufficient ventilation air, which results in inadequate dilution of the

combustion products generated by the heater, may create hazardous concentrations of carbon

dioxide, carbon monoxide, nitrogen dioxide, and other combustion products in the heated space.

8) If gas fork trucks or other fossil fuel powered equipment are utilized in the conditioned area,

additional ventilation requirements for the facility must be addressed separately.

9) If the heater utilizes room sensors for limiting room CO2 concentration:

a) The CO2 control set-point shall be no greater than the maximum allowable room

concentration of 5000 ppm less the sensor’s published accuracy tolerance. The control shall

prevent the CO2 concentration in room air from exceeding 5000 ppm.

b) A minimum of one sensor shall be installed per room served by the heater.

c) When a room area, served by a single heater, does not exceed 10,000 ft2 (929 m2) and height

does not exceed 20 ft (6 m), a duct sensor may be installed in the return air opening of the

heater.

d) Sensors shall be calibrated per the sensor manufacturer’s recommended procedure and

frequency or annually, whichever is more frequent.

e) Sensors shall not be place near sources of CO2.

f) Each heater shall require its own CO2 sensor(s).

The top, back, and front

surfaces of this heater may not

be installed less than 6” from

combustible materials. The

heater base may be installed

on combustible surfaces.

Allow 24” minimum service

clearance on both sides of this

heater.

5

Assembly

Mixing Box Size

Duct Size

1

19 x 15

2

25 x 24

331 x 2

9

5

44 x 44

Intakes and curbs are shipped unassembled. Upon unit arrival, follow the following procedure to

assemble the intake to the heater:

1. Apply silicone or weather-proof gasket on the back

side of the flanges of the intake hood or v-bank

intake.

2. Screw the flanges of the intake hood or v-bank to

the unit with the supplied sheet metal screws.

Place caulk on the outside of the screws to prevent

water leaks. If the unit is a modular unit with a vbank or evaporative cooler section, the v-bank or

evaporative cooler will bolt to the heater with the bolts provided.

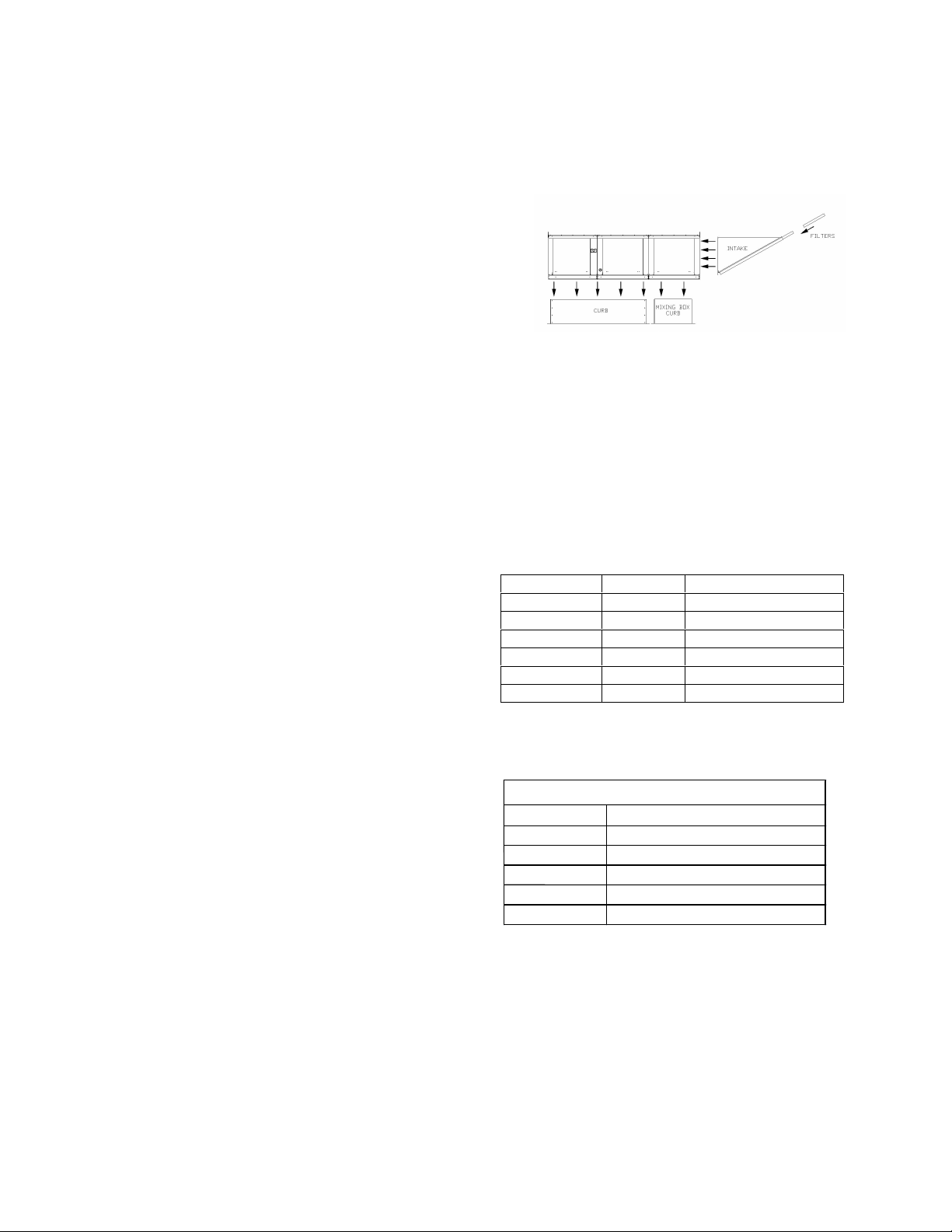

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect the airflow performance. Flexible ductwork and square elbows should not be used.

Also, transitions and turns in ductwork near the fan outlet will cause system effect and will drastically

increase the static pressure and reduce airflow. The chart below shows the minimum fan outlet duct

sizes and straight lengths recommended for optimal fan performance. Follow SMACNA guides and

recommendations for the remaining duct run. Fans designed for rooftop installation should be

installed on a prefabricated or factory built roof curb.

Follow curb manufacturer’s instructions for proper

curb installation. The unit should be installed on a

curb and/or rail elevated not less than 20” above

any surface. Be sure duct connection and fan outlet

are properly aligned and sealed. Secure fan to curb

through vertical portion of the ventilator base

assembly flange using a minimum of eight (8) lug

screws, anchor bolts, or other suitable fasteners (not

furnished). Shims may be required depending upon

curb installation and roofing material. Check all

fasteners for tightness. The diagrams below show

different mechanical installation configurations.

Adequate building relief shall be provided so as to not

over pressurize the building when the heating system

is operating at its rated capacity. This can be

accomplished by taking into account, through standard

engineering methods, the structure’s designed

infiltration rate; by providing properly sized relief

openings; or by interlocking a powered exhaust

system; or by a combination of these methods.

Heaters installed with intake ductwork must be purged to replace at least four air changes of the volume

of the intake duct.

If the failure or malfunction of this heater creates a hazard to other fuel burning equipment in the building

(e.g. when the heater is providing make up air to a boiler room), the unit is to be interlocked to open inlet

air dampers or other such devices.

Units being installed in airplane hangars should be installed in accordance with the Standard for Aircraft

Hangars, ANSI/NFPA 409. Units being installed in public garages should be installed in accordance

Recommended Supply Ductwork Sizes

Blower Size Duct Size Straight Duct Length

10 14 x 14 48 in.

12 16 x 16 54 in.

15 20 x 20 72 in.

18 24 x 24 86 in.

20 26 x 26 108 in.

25 32 x 32 168 in.

Recommended Return Ductwork Sizes

4 37 x 34

6

with the Standard for Parking Structures, ANSI/NFPA 88A, or the Standard for Repair Garages,

ANSI/NFPA 88B, and with CAN/CGA B149 Installation Codes.

Indoor (INLINE) Installation

Roof Mount Installation

7

NOTICE

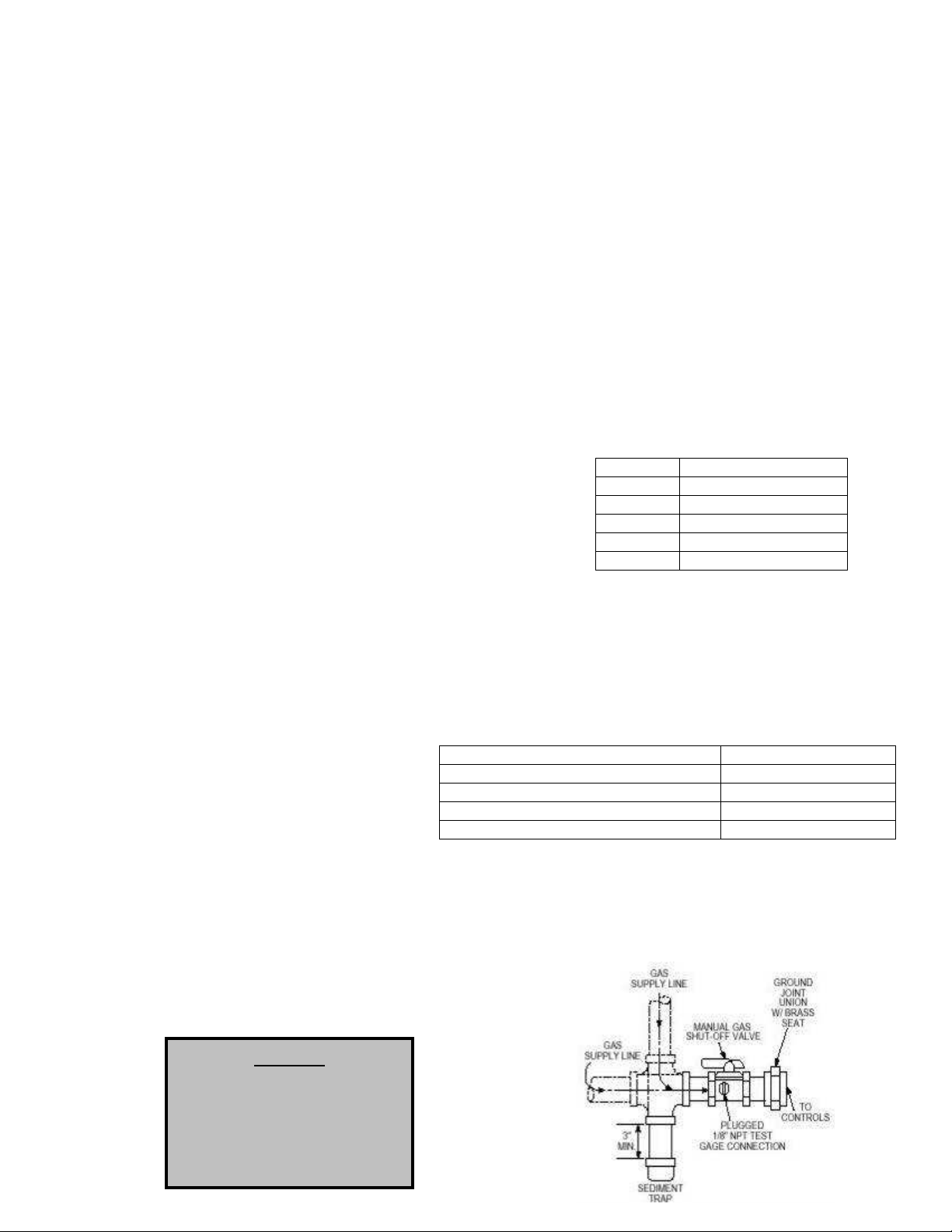

Gas

Installation of gas piping must conform with local building codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest edition. In Canada, installation must be in

accordance with CAN/CGA-B149.1 for natural gas units and CAN/CGA-B149.2 for propane units.

WARNING: INLET GAS PRESSURE MUST NOT EXCEED PRESSURE INDICATED

ON NAMEPLATE. SEE UNIT NAMEPLATE FOR PROPER GAS SUPPLY

PRESSURE AND GAS TYPE.

1. Always disconnect power before working on or near a heater. Lock and tag the disconnect

switch or breaker to prevent accidental power up.

2. Piping to the unit should conform with local and national requirements for type and volume of gas

handled, and pressure drop allowed in the line. Refer to the Gas Engineer’s Handbook for gas

line capacities.

3. The incoming pipe near the heater should be sized to

match the connection on the outside of the unit. Unit inlet

sizes are shown in the table to the right. Avoid multiple

taps in the gas supply so the unit has a steady supply of

gas at all times.

4. Install a ground joint union with brass seat and a manual

shut-off valve external to the unit casing, as shown below,

adjacent to the unit for emergency shut-off and easy

servicing of controls.

5. Provide a sediment trap, as shown below, before each

unit and where low spots in the pipe line cannot be avoided.

6. Blow out the gas line to remove debris before making connections. Purge line to remove air

before attempting to start unit. Purging of air from gas lines should be performed as described in

ANSI Z223.1-latest edition “National Fuel Gas Code”, or in Canada in CAN/CGA-B149.

7. All field gas piping must be pressure/leak tested prior to unit operation. Use a non-corrosive

bubble forming solution or equivalent

for leak testing. The heater and its

individual shut-off valve must be

disconnected from the gas supply

piping system during any pressure

testing of that system at test

pressures in excess of ½ psi. The

heater must be isolated from the gas

supply piping system by closing its

individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less

than ½ psi.

8. This unit requires a constant 7 in. w.c. minimum

natural gas supply, when the unit is operating at

maximum gas flow. If the gas supply exceeds 14 in.

w.c. (5 psi. for sizes 4-5 housings) it will damage the

internal valve components, and if it is below 7 in.

w.c., the heater may not perform to specifications.

Max. Manifold Pressure - Natural Gas 5 in. w.c. maximum

Max. Manifold Pressure - Propane 2.5 in. w.c. maximum

Gas Pressure Type Gas Pressure

Size 1-3 Inlet Pressure 7 in. w.c. – 14 in. w.c.

Size 4-5 Inlet Pressure 7 in. w.c. – 5 psi.

Gas Connection Sizes

Unit Size Gas Pipe Size (NPT)

Size 1 ¾”

Size 2 1”

Size 3 1”

Size 4 1-1/4”

Size 5 1-1/2”

Gas Pressure Table

Gas Connection Diagram

Refer to the heater rating

plate for determining the

minimum gas supply

pressure for obtaining the

maximum gas capacity for

which this heater is specified.

8

WARNING!!

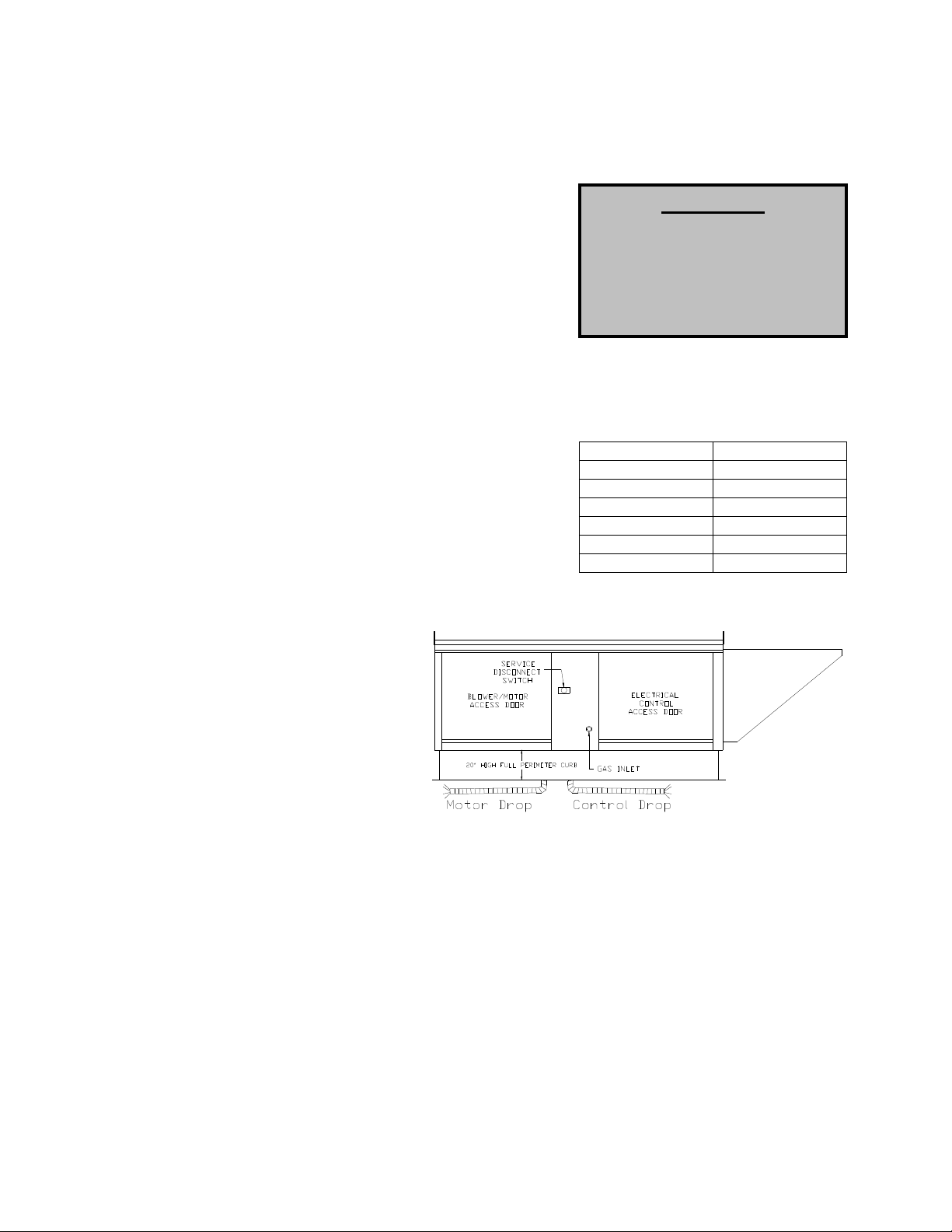

Electrical

Before connecting power to the heater, read and understand this

entire section of this document. As-built wiring diagrams are

furnished with each fan by the factory, and are attached to the

door of the unit.

Electrical wiring and connections should be done in accordance

with local ordnances and the National Electric Code,

ANSI/NFPA70. Be sure the voltage and phase of the power

supply and the wire amperage capacity is in accordance with the

motor nameplate. For additional safety information refer to AMCA publication 410-96, Recommended

Safety Practices for Users and Installers of Industrial and Commercial Fans.

Disconnect power before

installing or servicing fan. High

voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

1. Always disconnect power before working on or near a

heater. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

2. An electrical drop containing the motor power wiring is

shipped with every fan. The electrical drop should be

brought through one of the conduit openings located in

the base of the unit, run through the curb, and connected

to a junction box inside the building.

3. A dedicated branch circuit should supply the motor circuit

with short circuit protection according to the National

Electric Code. This dedicated branch should be run to the junction box mentioned above and

connected as shown in a following

illustration labeled “Fan to Building

Wiring Connection”.

4. Make certain that the power source

is compatible with the

requirements of your equipment.

The heater nameplate identifies

the proper phase and voltage of

the motor.

5. Units shipped with an optional

remote panel have two electrical

circuit drops. It is important to run

the motor wires in a separate conduit from the remote control wiring. The DC wires from the unit

temperature controller, located in the control drop, should either be shielded cable or be run in a

separate conduit.

6. Before connecting heater to the building power source, verify power line wiring is de-energized.

7. Secure the power cables to prevent contact with sharp objects.

8. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

9. Before powering up the heater, check fan wheel for free rotation and make sure that the interior of

the heater is free of loose debris or shipping materials.

10. If any of the original wire supplied with the heater must be replaced, it must be replaced with type

THHN wire or equivalent.

Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 15

12 20

10 30

8 50

6 65

4 85

9

10

PSC (Permanent Split Capacitor) Motor Speed Control

Some single phase direct drive fans contain speed controls that regulate the amount

of voltage going to the motor. Specific PSC motors must be used in conjunction

with speed controls. The speed control has a knob with an off position, and high to

low range. At high speed, the speed control allows all of the line voltage to pass

right to the motor.

A minimum speed adjustment is provided to allow independent control of the

minimum speed setting. Minimum speed adjustment ensures motor runs with

sufficient torque to prevent stalling. To adjust this:

1) Motor must be in actual operating conditions to achieve proper speed

adjustment. Motor will not slow down unless proper load is applied.

2) Turn main control knob to lowest speed position.

3) Locate and adjust minimum speed setting and adjust with small screw driver. This can be found

under the speed control faceplate. (rotate clockwise to decrease minimum speed; counterclockwise to increase minimum speed).

4) Motor will now operate from this preset minimum speed to full speed.

The lowest minimum voltage that may be applied to these motors is 65VAC. Running lower

voltages to the motor can cause premature failure and overheating problems.

ECM (Electronically Controlled Motor) Speed Control

ECM motors and control allows accurate manual adjustment of fan speed.

The benefit of ECM motors is exceptional efficiency, performance, and

motor life.

The control used with ECM motors features a 4 digit LED numerical

display. The blue knob on the control allows the user to set the flow index

with a screwdriver. Twenty seconds later, the display shows the motor

RPM. Then, the display periodically alternates between the flow index and

motor RPM. The flow index has a range of 0 to 100% and is typically linear with motor RPM.

The ECM control requires a 24 VAC input and can locally turn the motor on and off. The motor can be

adjusted between 300 RPM and maximum speed with this control.

NOTE: To adjust the speed of 3 phase direct drive motors, a variable frequency

drive is required.

Motorized Intake Damper

On units shipped with the optional motorized intake damper, a power transformer is supplied with the unit

if the main incoming voltage is greater than 120V. The damper motor is automatically energized when

the main disconnect switch is in the ON position. No external wiring to the damper motor is required.

Electric Cabinet Heater

On units shipped with an optional electric cabinet heater, ensure that the heater is wired to a separate

120V, 15 amp input, the thermostat sensing bulb is mounted correctly in the control vestibule where the

heater is located, and the thermostat set to 0 Degrees Fahrenheit.

Loading...

Loading...