Page 1

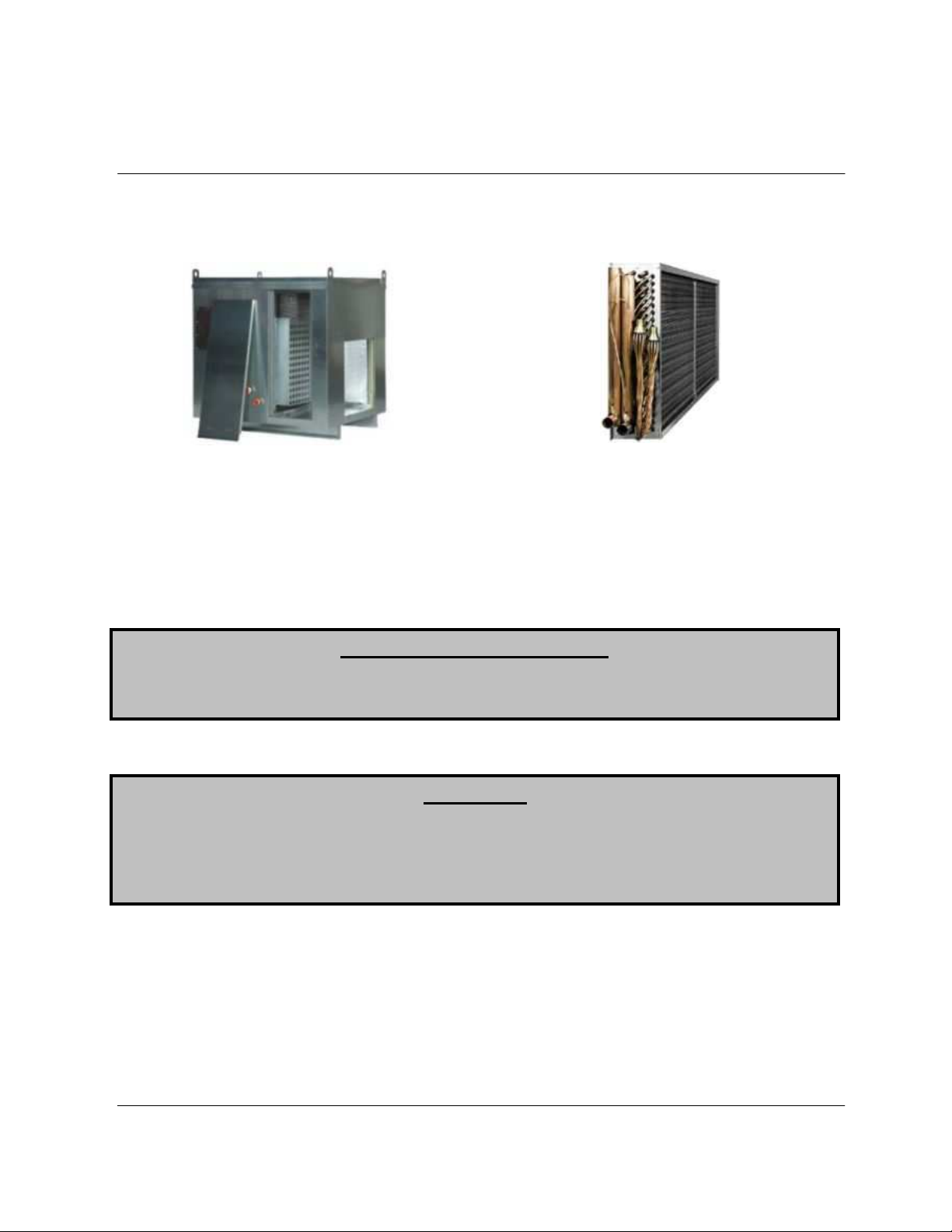

Direct Expansion Coil

Modules

Installation, Operation, and Maintenance Manual

Save these instructions

RECEIVING AND INSPECTION

WARNING!!

Direct Expansion Coil Module

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

Installation of this module should only be performed by a qualified professional who has read

and understands these instructions and is familiar with proper safety precautions. Improper

installation poses serious risk of injury due to electric shock, and other potential hazards.

Read this manual thoroughly before installing or servicing this equipment. ALWAYS

disconnect power prior to working on module.

Direct Expansion Coil

. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

A0011048

April 2013 Rev. 12

Page 2

Page 3

TABLE OF CONTENTS

WARRANTY .................................................................................................................................................. 4

INSTALLATION ............................................................................................................................................. 5

Mechanical ................................................................................................................................................ 5

Site Preparation .................................................................................................................................... 5

Assembly .............................................................................................................................................. 5

Plumbing Connections ......................................................................................................................... 6

Typical Cooling Coil Drain Trap ............................................................................................................ 6

Compressor Installation and Connection ............................................................................................. 6

Optional Moisture Eliminator Panel .................................................................................................... 10

Roof Mount Installation with Blower Only Unit ................................................................................... 10

Indoor Installation with Direct Fired Unit............................................................................................. 10

Electrical ................................................................................................................................................. 11

Copper Wire Ampacity ....................................................................................................................... 11

Dry Contacts for Condensing Unit. ..................................................................................................... 11

Located in Pre-wire or Heated Make-up-air unit. ............................................................................... 11

Terminals on Condensing Unit ........................................................................................................... 11

OPERATION ............................................................................................................................................... 12

Start Up ................................................................................................................................................... 12

Special Tools Required ...................................................................................................................... 12

Start Up Procedure ............................................................................................................................. 12

Component Description .......................................................................................................................... 13

Typical Installation of an AC system .................................................................................................. 13

Troubleshooting ...................................................................................................................................... 14

Troubleshooting Chart ........................................................................................................................ 14

MAINTENANCE .......................................................................................................................................... 15

General Maintenance ............................................................................................................................. 15

Every 6 months ....................................................................................................................................... 15

Yearly ...................................................................................................................................................... 15

Start-Up and Maintenance Documentation .............................................................................................. 2

Job Information ..................................................................................................................................... 2

DX coil Information ............................................................................................................................... 2

Maintenance Record ............................................................................................................................ 2

Factory Service Department ................................................................................................................. 2

3

Page 4

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

4

Page 5

INSTALLATION

Sloped

DX

Air

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, FILTER

TRACKS, OR PIPING – USE LIFTING LUGS PROVIDED OR A SLING

Site Preparation

1. Provide clearance around installation site to safely rig and lift equipment into its final position.

Supports must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Compressor Unit must be within 75 Ft of air handler unit.

3. Compressor Unit must not be near intake of air handler unit.

4. Consider general service and installation space when locating unit.

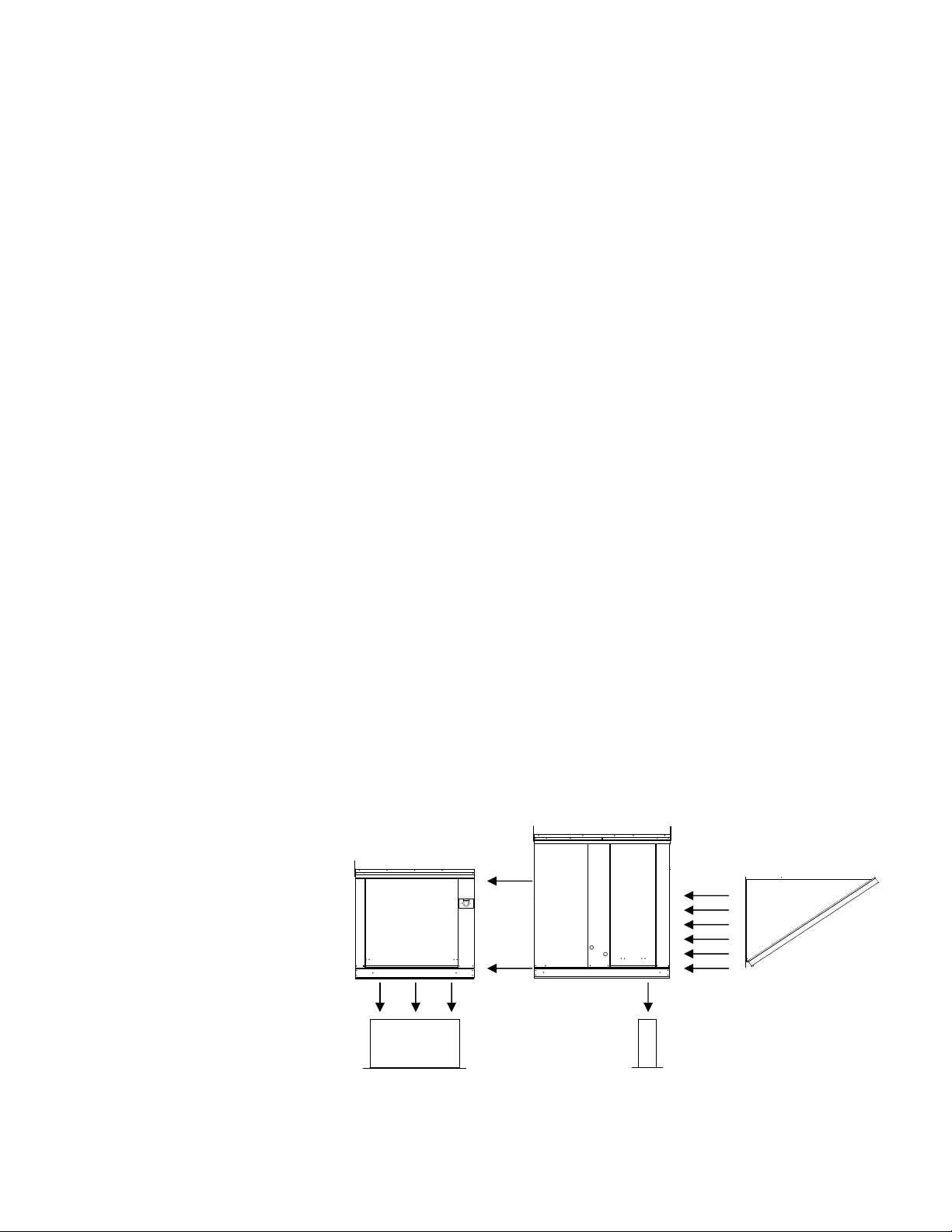

Assembly

There are several items shipped loose with the DX coil modules. These items include sheet metal

screws, nuts and bolts, and foam gaskets. It is important to know where the coil is to be installed. For

direct fired heaters and electric coil modules, the DX coil module mounts to the end discharge side of the

air handling unit. This keeps any refrigerant leaking from burning, avoiding the creation of toxic gasses.

Place caulk on the outside of any external screws used to prevent water leaks.

Upon unit arrival, follow the following procedure to assemble the DX coil.

For use with a direct fired or electric heater:

1. Attach the DX coil module to the discharge side of the air handler using the nuts, bolts and angle

bracket washers included. Apply the foam gasket to the air handler to ensure that there is a liquid

tight seal formed between the DX coil module and the air handling unit.

2. Attach the down discharge plenum to the end of the DX coil module using the supplied foam

gasket, nuts and bolts. Or, attach ductwork directly to the end of the unit using sheet metal

screws following SMACNA guidelines.

For use without a direct fired

or electric heater:

1. Attach the DX coil

module to the intake

side of the air handler

using the nuts, bolts and

Handler

Coil

Module

Intake Hood

angle washers included.

Apply the foam gasket to

the air handler to ensure

that there is a liquid tight

seal formed between the

DX coil module and the

air handling unit.

Curb Rail

2. Complete installation of

ductwork per SMACNA

standard installation.

5

Page 6

The airflow distribution screen is located on the incoming air side of the coil. This screen evens out the

airflow across the coil and allows for greater cooling efficacy. Removal of this screen may cause the coil

to freeze or more serious damage.

Plumbing Connections

There is one field plumbing connection required for proper DX coil operation. This is the drain pan

located under the DX coil. Depending on the size of the unit, the

coil can generate 5 gallons of water per hour. It is imperative that

the plumbing be sized accordingly. Also, it’s recommended that all

plumbing connections be sealed with Teflon tape or pipe dope.

Only 1” diameter PVC Pipe and low profile couplings should be

used. Additionally, the top horizontal length on the P-Trap should

be a minimum of 12”. No unions should be used. Add a clean out

as shown in the picture below.

The P-Trap drain should be attached to the end of the drain pipe on

the side of the unit. The trap is important for two reasons. First, it

can be piped to drain in the most convenient area. Second, it

keeps air from being drawn through the drain hole in the side of the

pan, impeding drainage.

Module

DXM1-1 1.625/1.125 3

DXM1-2 1.625/1.125 5

DXM1-3 1.625/0.875 10

DXM1-4 1.625/0.875 12.5

DXM2-1 1.625/0.875 5

DXM2-2 1.625/0.875 10

DXM2-3 1.625/0.875 15

DXM2-4 1.625/0.875 20

DXM3-1 1.625/0.875 10

DXM3-2 1.625/0.875 15

DXM3-3 1.625/0.875 20

DXM3-4 1.625/1.125 25

DXM4-1 1.625/0.875 20

DXM4-2 1.625/0.875 25

DXM4-3 1.625/1.125 30

DXM4-4 2.125/1.125 40

DXM5-1 2.125/1.375 30

DXM5-2 2.125/1.375 40

DXM5-3 2.125/1.375 50

All Coils are 2 circuit coils, except for

Connection size

(suction/liquid)

DXM1-1 and DXM1-2.

Tonnage

Typical Cooling Coil Drain Trap

Compressor Installation and Connection

There are several connections that need to be completed before the unit will function. Depending on the

module you have selected, you may have only one suction line and one liquid line to connect. Otherwise,

there are two sets that will need to be connected.

6

Page 7

Depending on the distance between the condenser and the module, there may be other components

installed in the lines. Here is a short list of components found in the lines. A filter dryer, which removes

any moisture from the refrigerant, needs to be installed close to the compressor section. A sight glass

should be installed close to the thermal expansion valve. This will help in diagnosing any problems with

the air conditioning (A/C) setup. A solenoid is required when the liquid line exceeds 75 Ft. This will

prevent the build up liquid refrigerant from entering the compressor while the unit is off. If the suction line

exceeds 75 Ft, an accumulator will need to be installed to prevent any liquid refrigerant from entering into

the compressor.

LOW PRESSURE LIQUID

EVAPORATOR CONDENSER

THERMAL

EXPANSION

VALVE SENSING BULB

LOW PRESSURE VAPOR

LOW TEMP / PSI SWITCH

SUCTION PORT

BASIC REFRIGERANT PIPING

I. There are two different types of thermal expansion valves. Internally equalized

valves will have 2 connections, one for liquid to the valve and one to the

distributor of the coil. The externally equalized will have an additional fitting for

the capped line from the coil.

II. If the coil has a hot gas bypass, install this now with the instructions included in

the kit.

B. Braze the joints. These joints will be under great pressure, so proper joint construction is

imperative. All joints need to be made using Silver-Phosphorus or Copper-Phosphorus

brazing filler, available from a local welding store. DO NOT USE SOFT SOLDER, this

material does not produce a strong enough joint. It is also recommended to flow dry

nitrogen through the lines to prevent joint oxidation while brazing.

I. Clean both mating surfaces with Emory cloth.

II. Fit both pieces together. If there are multiple joints within a short distance, clean

and fit them together as well.

III. There are some parts in the lines that cannot be overheated. Parts like the

thermal expansion valves, solenoid valves, sight glasses, and accumulators

cannot exceed 200° F. Place a wet rag around these parts to cool them while

you braze the joints, and avoid pointing the torch flame directly on these devices.

IV. Heat using a TurboTorch® or equivalent torch using MAPP gas or Acetylene.

Move the torch back and forth on the pipes. This will distribute the heat more

evenly around the part. When the parts glow a dull red, pull the torch away

slightly. Be careful not to over heat the pipe. Smaller pipes, if overheated, will

begin to melt and burn.

V. Add brazing wire until the entire joint is covered. On larger diameters of pipe,

you may need to move your torch around the diameter of the pipe.

THERMAL

EXPANSION

VALVE

SIGHT GLASS

COMPRESSOR

DRIER FILTER

HIGH-PRESSURE LIQUID

HIGH-PRESSURE VAPOR

HIGH TEMP / PSI SWITCH

HOT GAS PORT

1. Plumb Liquid and

Suction Lines.

A. Run the

lines. Keep

the lines as

short and as

straight as

possible.

Also, keep

the lines

away from

any sharp

edge. The

lines may

vibrate some

during

normal use

and this will

keep the

lines from

breaching.

7

Page 8

VI. If there are multiple joints to be made, move the torch and begin heating the next

joint. This will save time and fuel.

VII. Let the joints cool naturally. Cooling the joints with water could cause the joints

to fail prematurely.

2. Pressure testing the lines.

A. Charge the lines with Dry Nitrogen to design operating PSI.

B. If the pressure changes

drastically, you have a leak. If

the pressure drops slowly, you

may have a leak. If the

pressure holds for 15 minutes,

proceed to the next step.

I. Ultrasonically leak

check all joints.

II. After all joints have

been tested, bleed off

the excess pressure,

and repair the joints.

You will have trouble

repairing the joints if

there is pressure in the

lines.

III. Start the pressure

testing over.

MIC ROM ETE R

CO MPR ESS OR

GA UGE

SU CTIO N LIN E

To Vac uum Pum p (Y ellow)

LE A K TEST A N D P R EP

FOR REFRIG E R A NT C H A R G E

VA CUUM PU MP

8

Page 9

3. Vacuum the lines

A. Find and install the valve cores located on your compressor unit. If you cannot find the

taps, check the owner’s manual.

B. Install the pressure gauge manifold. Make sure both valves are closed on the manifold.

The blue line goes to the suction line and micron gauge. The yellow line connects to a

vacuum pump. Start the vacuum pump. To start vacuuming the system, open the blue

line side of the manifold. You should see the pressure start to drop.

C. Continue to vacuum the lines for 15 minutes, and then stop. If the vacuum on the lines

doesn’t hold, you have a leak. Repeat step 2 to fix the problem. If it holds, read the

micron gauge. If the gauge does not read below 500, continue to vacuum the lines until

the gauge does. You are now removing the moisture from the lines. This is very

important!!! The more moisture you remove now, the more efficiently your system will

run. Close the valves to the pump and the system should be able to maintain a 1000

micron vacuum continuously.

4. Installing the refrigerant. You will need a tank of

refrigerant and a scale. The scale must be able to

read ounces and have a max capacity of 50 Lbs.

The refrigerant will come from a HVAC professional.

Make sure to read the condenser owners manual

C OM P RE SS OR

for what kind of refrigerant and how much you will

need for your system. This step will be done while

the condenser is off.

A. Attach the red line to the liquid line

B. Open the valves on the unit. This will

release the holding charge into the circuit.

C. Attach the yellow hose to the tank of

refrigerant, open the valve on the tank, and

invert the cylinder on the scale.

G AU GE

SU C TIO N LI NE

To T ank (Y el low )

C H A R G IN G S Y S T E M

D. Open the blue valve on the manifold,

slightly. This will allow charge to enter into

the circuit.

S CA LE

E. Close the valve on the manifold after 80% (by weight) of the charge has been introduced.

F. RECORD THE WEIGHT OF THE TANK. This will tell you how much charge is left in the

tank.

5. Trimming the refrigerant charge. Once the initial charge has been introduced into the system,

allow the compressor to run for 15 minutes. This will balance the charge and help ensure

accurate readings.

A. Locate the charging chart in the compressor owner’s manual. Each chart will be different

depending on the manufacturer of condenser unit. Most require a liquid pressure and

temperature to be known.

B. Record the liquid line temperature and pressure. With the charging chart, plot the point

where the system is operating. Note if it falls into the Add Charge or Reduce Charge.

I. Add charge. Slowly turn the Blue side of the pressure gauge manifold. This will

allow the charge from the tank to enter the suction side of the compressor. After

a sufficient amount of refrigerant has been added, close the blue side valve and

allow the system to stabilize. Recheck temperature and pressure; re-plot the

point on the chart, and repeat the process if necessary.

II. Reduce charge. In the case of overfilling the circuitry, the excess refrigerant

must be recovered into an approved cylinder. Seek professional help for this

step.

C. Weight the tank and record the changes.

9

Page 10

10

Optional Moisture Eliminator Panel

If the unit is equipped with an optional moisture eliminator panel, the maximum face velocity of the coil

may be increased to 650 FPM. Moisture eliminator panels require minimal maintenance. Visual

inspection is recommended periodically. Scale or clogging will impair performance. If scale or clogging

occurs, remove the panel and flush with steam or water. Flushing should not have sufficient force to

dislodge the media from the panel. Scale removal may require a vinegar or detergent application

followed by rinsing

Roof Mount Installation with Blower Only Unit

Indoor Installation with Direct Fired Unit

Page 11

11

Electrical

WARNING!!

or Electrical Package

Before connecting power to the module, read and understand

the entire section of this document. As-built wiring diagrams

are furnished with each module by the factory, and are

attached either to the door of the unit or provided with a

paperwork packet.

Electrical wiring and connections should be done in

accordance with local ordnances and the National Electric

Disconnect power before

installing or servicing module.

High voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

Code, ANSI/NFPA70. Be sure the voltage and phase of the

power supply and the wire amperage capacity is in accordance

with the unit nameplate. For additional safety

information refer to AMCA publication 410-96, Recommended

Safety Practices for Users and Installers of Industrial and

Commercial Fans.

1. Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

2. Make certain that the power source is compatible with

the requirements of your equipment. The Air handler

wiring schematic and the compressor documentation

identifies the proper phase and voltage of the

equipment.

3. Secure the power cable to prevent contact with sharp

objects.

4. Do not kink power cable and never allow the cable to

come in contact with oil, water, grease, hot surfaces or

Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 20

12 25

10 30

8 40

6 55

4 70

3 85

2 95

1 110

0 125

00 145

chemicals.

5. There are RC, Y1, and Y2 terminals for cooling in the

electrical control package or heated make up air. These terminals must be connected to the

matching terminals in the condenser.

6. Before powering up the DX module and compressing unit, make sure that the interior of the unit is

free of loose debris or shipping materials, and all refrigerant piping is complete.

Connect to Terminal RC in Heater

Stage Y1 connects to Terminal Y1

in Heater or Electrical Package

Stage Y2 connects to Terminal Y2

in Heater or Electrical Package

Terminals on Condensing Unit

Dry Contacts for Condensing Unit.

Located in Pre-wire or Heated Make-

up-air unit.

Page 12

12

OPERATION

Prior to starting up or operating the DX module, check all fasteners for tightness. Ensure that the coil is

clean and that the interior of the module is free of loose debris. Also, check the drain pan for proper

drainage. This will guarantee proper operation during the cooling season.

Start Up

Special Tools Required

• AC Voltage Meter

• Amperage Meter

• Standard Hand Tools

Start Up Procedure

1. Remove the access door and check all electrical connections for tightness and continuity.

2. Inspect the air-stream for obstructions.

3. Compare the supplied voltage with the unit’s nameplate voltage. If this does not match, correct

the problem.

4. Set the thermostat to a set-point cooler than the entering air temperature for start-up purposes.

The cooling circuit will be energized when the entering air temperature is hotter than the

thermostat set-point.

5. Install the access door and apply power to the unit. If the entering air temperature is hotter than

the thermostat set-point, the cooling circuit will be energized the first stage of the compressor

should turn on.

6. Locate the sight glass and observe the refrigerant flow for a few minutes. This run time will allow

the unit to stabilize. If the line has is foaming, a large quantity of bubbles, you may need to add

charge to your unit.

7. Adjust the thermostat so that the second stage turns on, a difference of 10°F (typical) is required .

Repeat step 6.

8. Set the thermostat back to the desired cooling temperature (typically about 75°F-85°F).

Remember, the cooling circuit will only be energized when the entering air temperature is higher

than the set-points.

Page 13

13

Component Description

Component Number

Component

Description of Operation

2 3

4

Compressor

Suction Line(s)

Liquid Line(s)

DX Coil Module

Air Handler

Intake Hood

The following table lists common components and their function inside the AC system.

1 Filter Dryer Removes moisture and small

particulate from the refrigerant

2 Sight Glass with Moisture Indicator

(optional)

3 Solenoid Valve

(required for liquid line lengths in

excess of 75 FT)

4 Thermal Expansion Valve Controls the amount of liquid

5 Thermal Expansion Valve Bulb Senses the suction line

Allows for viewing of refrigerant

flow and moisture content

Valve, wired in parallel to the

signal lines, blocks the flow of

liquid refrigerant back into the

compressor during reset.

refrigerant flowing into the coil,

with the use of a capillary bulb.

temperature and adjusts

refrigerant flow accordingly

lines

1

5

Typical Installation of an AC system

Page 14

14

Troubleshooting

The following table lists causes and corrective actions for possible problems with DX coil modules.

Review this list prior to consulting manufacturer.

Troubleshooting Chart

Problem

Insufficient Cooling Frozen coil Reduce refrigerant charge.

Insufficient Airflow

Excessive Airflow

Water in ductwork Drip pan full Check drip pan for obstructions.

* Air velocity should be maintained between 200 and 550 FT per Minute through the coil.

Potential Cause

Charge is low Add refrigerant charge.

Excessive air flow Slow blower RPM down.

Contaminated refrigerant Have refrigerant replaced.

Frozen coil Reduce refrigerant charge.

Coil sized too small *

Overestimation of static pressure Reduce blower rpm.

Coil sized too large *

Excessive airflow Slow blower RPM down.

Ductwork is not insulated

Corrective Action

Check for proper airflow across

coil.

Increase airflow across coil.

Replace module with larger coil.

Change motor HP.

Slow blower RPM down.

Check drip pan plumbing for

clogs.

Insulate ductwork to reduce

condensation.

Page 15

15

MAINTENANCE

To guarantee trouble free operation of this DX coil module, the manufacturer suggests following these

guidelines. Most problems associated with unit failures are directly related to poor service and

maintenance.

Please record any maintenance or service performed on this equipment in the documentation section

located at the end of this manual.

WARNING: DO NOT ATTEMPT MAINTENANCE ON THE DX MODULE OR

COMPRESSOR UNIT UNTIL THE ELECTRICAL SUPPLY HAS BEEN COMPLETELY

DISCONNECTED

General Maintenance

1. Inlet and approaches to DX module and compressor unit should be kept clean and free from any

obstruction.

2. All fasteners should be checked for tightness each time maintenance checks are preformed prior

to restarting unit.

3. DX coil modules require little attention when moving clean air. Occasionally, dust may

accumulate on the coil causing low airflow or reduced cooling. The DX coil should be inspected

and cleaned every 6 months during the cooling season.

Every 6 months

1. Check and clean the drainage pan and drain.

2. Clean the DX coil from the entering air side. This will keep any grit or particulate from lodging it’s

self deeper into the coil. The air deflection screen must be removed before cleaning.

Yearly

1. Check the coil for damage. If there is evidence of a leak, seek professional help.

2. Check the moisture indicator inside the sight glass. If the indicator reads wet, call a professional

for more information and repair.

Page 16

Start-Up and Maintenance Documentation

START-UP AND MEASUREMENTS SHOULD BE PERFORMED AFTER THE SYSTEM HAS BEEN

AIR BALANCED (Warranty will be void without completion of this form)

Job Information

Job Name Service Company

Address Address

City City

State State

Zip Zip

Phone Number Phone Number

Fax Number Fax Number

Contact Contact

Purchase Date Start-Up Date

DX coil Information

Refer to the start-up procedure in this manual to complete this section.

Name Plate and Unit Information

Model Number

Serial Number

Volts

Hertz

Phase

Tonnage

Refrigerant Line

Suction(1/ 2) /

Field Measured Information

Refrigerant type

Refrigerant volume Lbs.

Airflow Direction Correct

Incorrect

Pressures

Liquid (1/ 2) /

Maintenance Record

Date Service Performed

Factory Service Department

Phone: 1-866-784-6900

Fax: 1-919-554-9374

16 April, 2013 Rev. 12

Loading...

Loading...