Page 1

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

WARNING!!

Installation of this control panel should only be performed by a qualified professional who has

read and understands these instructions and is familiar with proper safety precautions.

Improper installation poses serious risk of injury due to electric shock and other potential

hazards. Read this manual thoroughly before installing or servicing this equipment. ALWAYS

disconnect power prior to working on module.

Demand Control Ventilation System

Installation, Operation, and Maintenance Manual

Save these instructions. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

A0023662

May 2014 Rev. 5

Page 2

2

TABLE OF CONTENTS

Demand Control Ventilation System ............................................................................................................. 1

Installation, Operation, and Maintenance Manual ........................................................................................ 1

WARRANTY .................................................................................................................................................. 3

SAFETY INFORMATION .............................................................................................................................. 4

General ................................................................................................................................................. 4

Installation............................................................................................................................................. 4

Control board (ECPM03) Technical Information .................................................................................. 4

INSTALLATION ............................................................................................................................................. 6

Mechanical ................................................................................................................................................ 6

Site Preparation .................................................................................................................................... 6

Assembly .............................................................................................................................................. 6

Room Sensor Installation ..................................................................................................................... 6

Utility Cabinet Installation (Typical) ...................................................................................................... 6

Wall Mount Installation (Optional) ........................................................................................................ 7

Duct Sensor Installation ........................................................................................................................ 7

Electrical ................................................................................................................................................... 7

Copper Wire Ampacity .......................................................................................................................... 8

High Voltage Wiring .............................................................................................................................. 8

Low Voltage Wiring ............................................................................................................................... 9

Variable Frequency Drive (VFD) Installation Instructions .................................................................. 10

OPERATION ............................................................................................................................................... 12

Start-Up Procedure ................................................................................................................................. 12

Sequence of Operation ........................................................................................................................... 13

Functionality ............................................................................................................................................ 15

Fan Control ......................................................................................................................................... 15

Preparation Time Mode ...................................................................................................................... 15

Hood Lights ........................................................................................................................................ 15

Electric Gas Valve Reset .................................................................................................................... 15

High Temperature Automatic Appliance Shutdown ........................................................................... 15

Make-Up Air Interlock ......................................................................................................................... 15

Appliances Pilot Check Warning: ....................................................................................................... 16

Building Management System (Dry Contact) ..................................................................................... 16

Minimum Room Temperature ............................................................................................................. 16

Self-Cleaning (Optional) ..................................................................................................................... 16

Fan Proving Interlock (Optional) (i.e. Loss of Load Interlock/Airflow Fault Interlock) ........................ 17

CORE Protection Fire System (Optional) ........................................................................................... 17

PCU Advanced Filter Monitoring (AFM) (Optional) ............................................................................ 17

Electric Gas Valve Follow Fans (optional) .......................................................................................... 17

Shunt Trip Follow Fans (Optional) ...................................................................................................... 18

Dimmable HMI (Optional) ................................................................................................................... 18

CO Censor Input (Optional) ................................................................................................................ 18

PCU CORE ONLY (Optional) ............................................................................................................. 18

Energy Saving Graph (optional) ......................................................................................................... 18

Configuration and Diagnostics ................................................................................................................ 19

Security ............................................................................................................................................... 19

Setup Options ..................................................................................................................................... 19

Component Description ............................................................................................................................... 28

Variable Frequency Drive ................................................................................................................... 28

ECPM03 board ................................................................................................................................... 28

Temperature Sensor ........................................................................................................................... 30

Room Temperature Sensor ................................................................................................................ 30

HMI ..................................................................................................................................................... 30

Troubleshooting .......................................................................................................................................... 31

MAINTENANCE .......................................................................................................................................... 33

A0023662

May 2014 Rev.5

Page 3

3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

A0023662

May 2014 Rev.5

Page 4

4

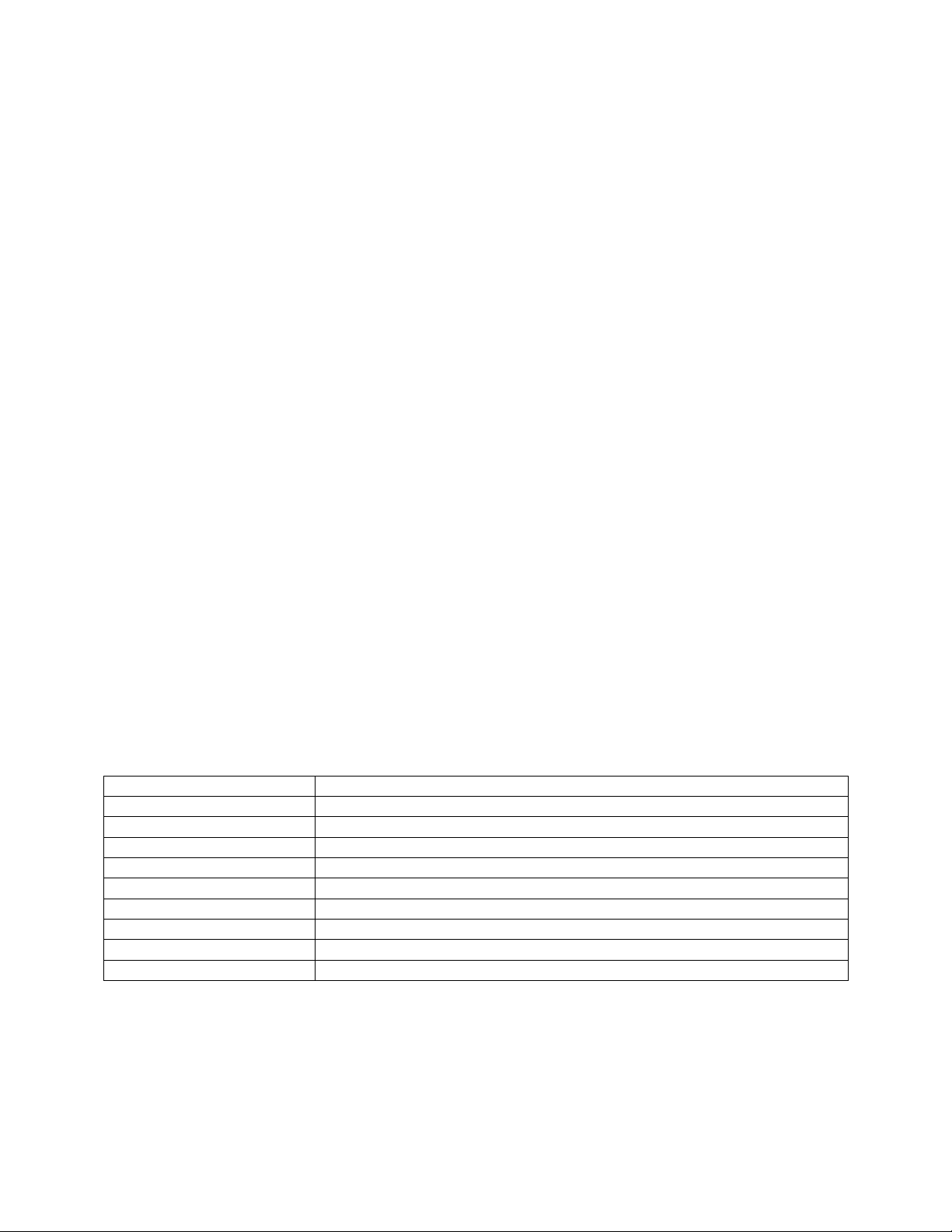

Ratings

24VDC, 10-20Watts

Other Ratings

On-board relay contacts are 120VAC with 4Amps Max

Flammability

FR4 board with 94V0 flammability rating

IP rating

IPX0

Fuse on board

Slo-Blo 4 Amp fuse, 5x20mm

Humidity

< 95% non-condensing

Temperature range

-10 to +55°C or +15 to +130 °F

Battery

Model 2032 - Lithium Coin Cell, 3VDC, 0.043mA

Dimensions

203mm L x 140mm W x 46mm H

Weight

0.6 lbs.

SAFETY INFORMATION

General

This control panel utilizes a mixture of traditional controls along with a “smart” digital circuit board

controller, referred to as the ECPM03 control board. It is intended to be installed within a UL508A

electrical control package. The board is powered by 24 Volts DC, which is provided by an approved 10-20

Watt class 2 power supply included inside the panel.

Some parts of the ECPM03 circuit board can be electrically live and some surfaces can be hot.

Inappropriate use and incorrect installation or operation creates the risk of injury to personnel and/or

damage to equipment. All operations concerning installation, commissioning and maintenance must be

carried out by qualified, skilled person who is familiar with the installation, assembly, commissioning, and

operation of the control panel and the application for which it is being used.

Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components during

transport, handling, installation or maintenance. Do not touch any electronic components or contacts. This

board contains electrostatically sensitive components, which can easily be damaged by inappropriate

handling. Static control precautions must be adhered to during installation, testing, servicing and repairing

of this board. Component damage may result if proper procedures are not followed.

To ensure proper operation, do not install the board where it is subjected to adverse environmental

conditions such as combustible, oily, or hazardous vapors; corrosive chemicals; excessive dust, moisture

or vibration; direct sunlight or extreme temperatures.

The ECPM03 may be mounted by means of DIN rail clips and board standoffs or by standoffs alone. It

will be mounted in a NEMA 1 enclosure for indoor use only.

When working on live panel controllers, applicable national safety regulations must be observed. The

electrical installation must be carried out according to the appropriate regulations (e.g. cable crosssections, circuit breaker, protective earth [PE] connection). While this document does make

recommendations in regards to these items, national and local codes must be adhered to.

Control board (ECPM03) Technical Information

May 2014 Rev.5

A0023662

Page 5

5

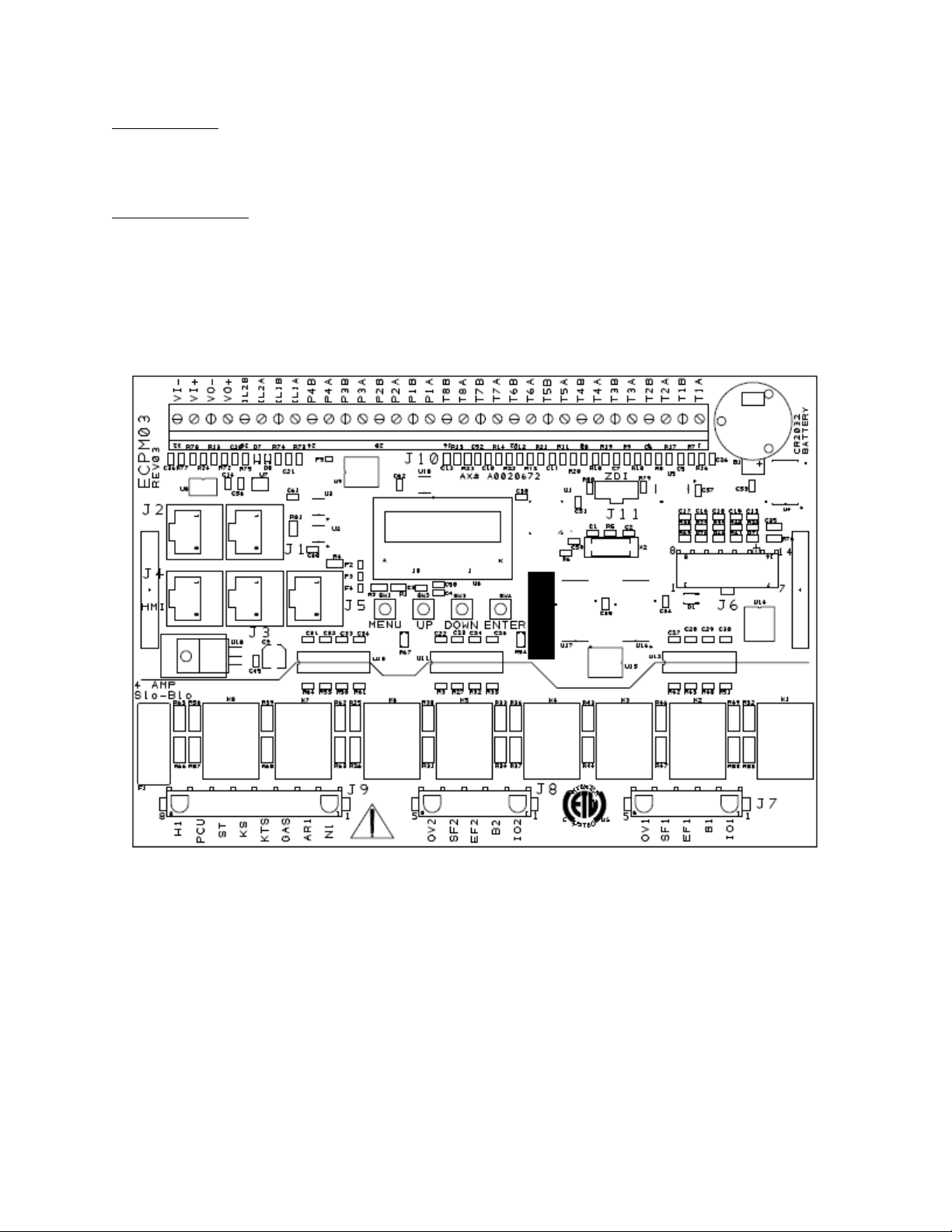

FIELD WIRING: The following is for reference only. All 120 Volt AC field wiring is landed on terminal

blocks, not on the board itself. See Installation section for details. Low voltage class 2 field wiring may be

landed at J3, J4, J5, or J10 connectors only, as indicated by the panel labeling and installation schematic.

Provision for spacing and routing of the field wiring is provided in the panel.

FACTORY WIRING:

The connectors below are intended to be used for factory wiring only by a UL508A panel shop:

J7, J8, J9 are provided for the control of 120 Volt AC relays, contactors, solenoids and shunt trip

breakers. Under no circumstances shall any lighting or motor loads be directly connected to these

connectors.

J1, J2, J6, are reserved for low voltage class 2 factory wiring.

Control Board (ECPM03) diagram

A0023662

May 2014 Rev.5

Page 6

6

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with these manual and applicable codes. If there are any questions about any items, please

call the service department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT LIFT CONTROL BY WIRING COMPONENTS

Site Preparation

1. Provide clearance around installation site to safely install equipment into its final position.

Supports must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Consider general service and installation space when locating unit.

Assembly

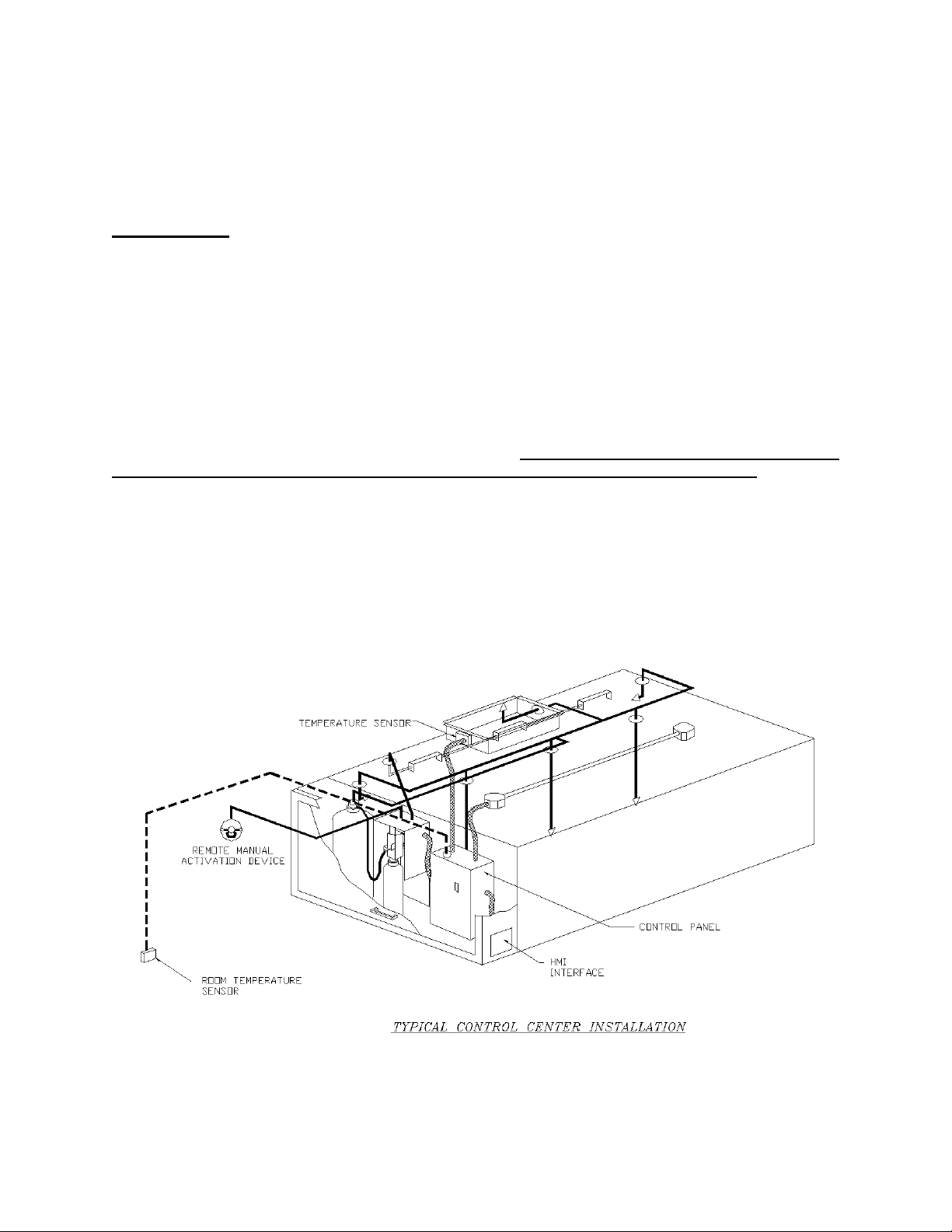

When the control panel is ordered in a utility cabinet installed on the hood, there is no mechanical

assembly required by the installer. If the control panel is ordered as a wall mounted panel, the enclosure

must be secured to a fixed wall near the exhaust hoods. Be certain to maintain adequate clearance

from excessive heat sources such as appliances to prevent damage of the components.

Room Sensor Installation

A room temperature sensor is provided with the panel. It should be installed in a safe location, free of

influence from external heat sources. It should be indicative of the average kitchen temperature away

from the appliances. The room sensor will always be landed at terminals T1A, T1B on the J10 connector

of the ECPM03.

Utility Cabinet Installation (Typical)

A0023662

May 2014 Rev.5

Page 7

7

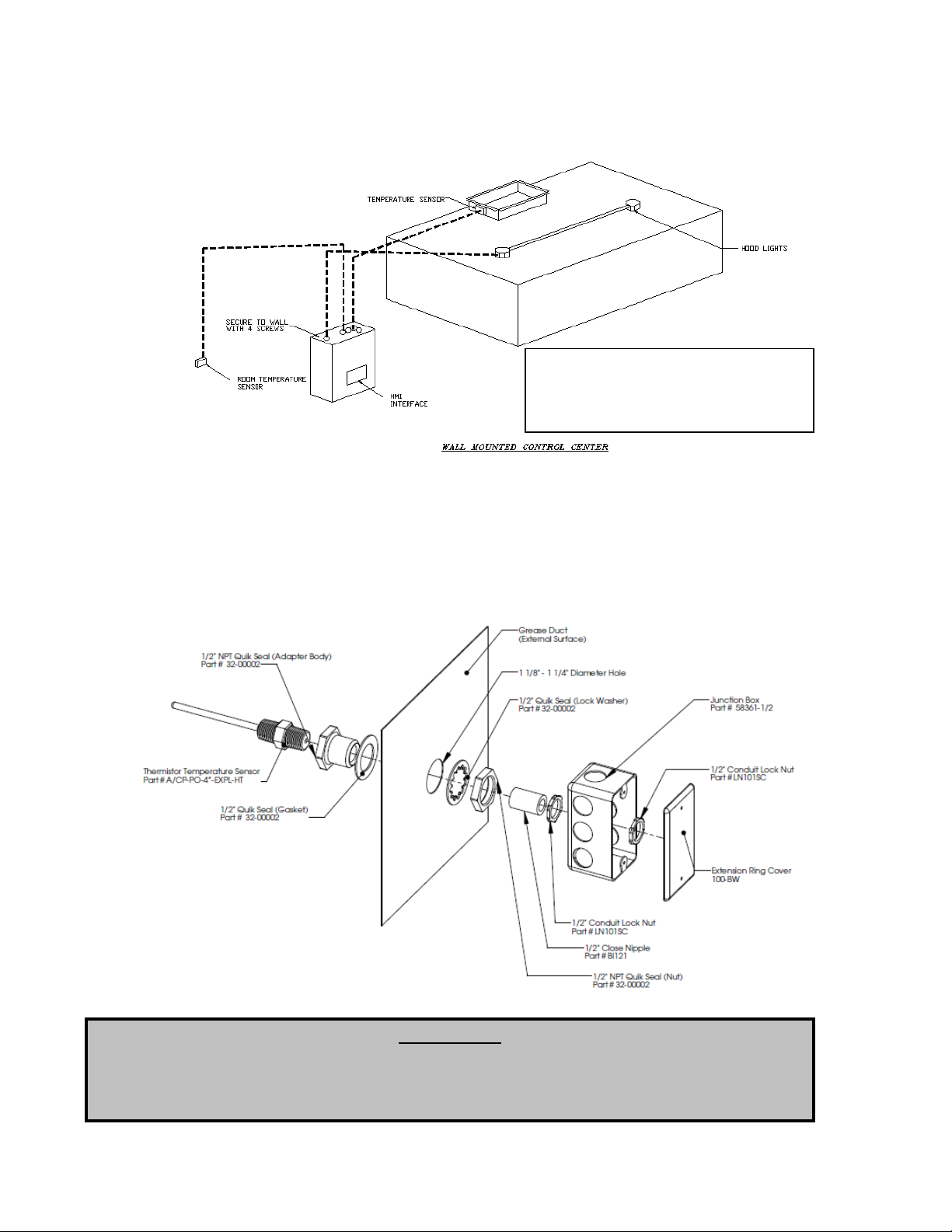

Mount control panel with adequate

clearance from excessive heat

sources such as appliances to prevent

damage of the components.

IMPORTANT!!

When exhaust duct connections are located and cut in the field, duct temperature probes are

shipped loose in the electrical package enclosure. These must be installed in the duct

immediately above the hood for proper system operation.

Wall Mount Installation (Optional)

Duct Sensor Installation

When the control panel is ordered, the system typically consists of one duct sensor per hood exhaust

riser. These sensors are typically shipped factory installed in factory assembled hood risers. If the risers

are field cut, the sensor and other components are shipped loose for field installation as shown below. A

hole must be cut in the grease duct, and the quick seal and sensor must be assembled as shown below.

A 2-wire plenum rated thermistor cable (18 gauge typical), run in conduit, should be used to wire the

sensors back to the controller and landed on connector J10 as indicated on the installation schematic.

A0023662

May 2014 Rev.5

Page 8

8

Copper Wire Ampacity

Wire Size AWG

Maximum Amps

14

15

12

20

10

30 8 50 6 65 4 85

WARNING!!

Disconnect power before

installing or servicing control.

High voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

Electrical

Before connecting power to the control, read and

understand this entire document. As-built wiring

diagrams are furnished with each control by the factory

and are attached either to the door of the unit or

provided within a paperwork pouch internal to the panel.

Electrical wiring and connections should be done in

accordance with local ordinances and the National

Electric Code, ANSI/NFPA70. Be sure the voltage and

phase of the power supply and the wire amperage

capacity is in accordance with the unit nameplate.

1. Always disconnect power before working on or near this

equipment. Lock and tag the disconnect switch or breaker

to prevent accidental power up.

2. Make certain that the power source is compatible with the

requirements of your equipment. The installation wiring

schematic identifies the proper phase and voltage of the

source breakers.

3. Before connecting control to power source, verify power

line wiring is de-energized.

4. Secure all wiring to prevent contact with sharp objects.

5. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

6. Before powering up the system, make sure that the interior of the control is free of loose debris,

metal shavings, or shipping materials. `

7. If any of the original wire supplied with the system must be replaced, it must be replaced with type

THHN wire or equivalent.

High Voltage Wiring

terminals as indicated on the installation diagram, typically “C1” and “AR1”. C1 is the common

and connects to terminal 1 on the micro-switch. AR1 is the armed state and connects to terminal

2 on the micro-switch. If a CORE fire system is present, this connection is not required.

1. All high voltage wiring shall be terminated

on the right side of the vertical terminal blocks

located on the right hand side.

2. There are multiple electrical power

sources required for this panel. Refer to

Installation diagrams for details.

3. The hood light wiring will also need to be

wired to terminals as indicated on the installation

diagram.

4. If an ANSUL fire system is present, the

fire system micro-switch will need to be wired to

A0023662

May 2014 Rev.5

Page 9

9

Low Voltage Wiring

Low voltage field wiring consists of Duct and Room Temperature sensors, ECM motors, 0-10VDC output,

24VDC input, or Modbus communication over CAT-5 cables for HMI(s) and remote equipment.

Additionally, panels can be ordered with Building Management Options. Refer to the Building

Management Owner’s Manual, if equipped, for low voltage building management wiring requirements.

Low voltage wiring must be run on the left hand side and directly terminated on the terminals located on

the ECPM03 board.

WARNING: Low voltage wires should never be run together with high voltage wires.

1- Room temperature sensor(s): For all installations, at least 1 room temperature sensor must be

installed in a safe location, free of influence from external heat sources. It should be indicative of the

average kitchen temperature away from the appliances. 2-wire 18 AWG thermistor cable must be

used. The room temperature sensor shall be wired according to the installation wiring schematic,

terminals “T1A” and ”T1B”.

2- Duct temperature sensors: For all installations excluding a single hood with factory risers and a

hood mounted panel, duct mounted temperature sensors will need to be wired in the field. 2-wire 18

AWG plenum rated thermistor cable must be used. The temperature sensor should be wired to

terminal blocks as indicated on the installation wiring schematic.

3- HMI is connected to the ECPM03 board through a CAT-5 cable. The HMI has two RJ-45 connectors

connected together for Modbus. The HMI connects to port J4 or J5 (RJ-45) of the ECPM03 board.

The other RJ-45 port of the HMI will typically be occupied by a RJ-45 end-of-line terminator (Part #

EOL120A).

4- Two end-of-line terminators (Part # EOL120A) are included in each panel. They are typically

plugged in at the factory on J3 and either on port J4 or in the back of the first HMI. If another HMI or

other equipment need to connect to a port occupied by an end-of-line terminator, it shall be removed

and place on the HMI or equipment that became connected at the end of the Modbus network.

5- If other pieces of equipment such as PCU Advanced Filter Monitoring (AFM) are connected to this

panel, a cat-5 cable will also be used to run the Modbus communication between these devices. The

cable would be plugged in port J3 of the ECPM03 board. The end-of-line terminators should then be

relocated from J3 to the PCU AFM module.

A0023662

May 2014 Rev.5

Page 10

10

Variable Frequency Drive (VFD) Installation Instructions

Input AC Power

1. Circuit breakers feeding the VFDs are recommended to be thermal-magnetic and fast acting.

They should be sized 1.25 to 1.5 times the input amperage of the drive. Refer to the installation

schematic for breaker sizing.

2. Each VFD should be fed by its own breaker. If multiple VFDs are to be combined on the same

breaker, each drive should have its own protection measure (fuses or miniature circuit breaker)

downstream from the breaker.

3. Input AC line wires should be run in conduit from the breaker panel to the drives. AC input power

to multiple VFDs can be run in a single conduit if needed.

4. The VFD should be grounded on the terminal marked PE.

STOP!

DO NOT connect incoming AC power to output terminals U, V, W. Severe damage to the drive

will result. Input power must always be wired to the L terminal connections (L1, L2, L3)

Output Power

1. Motor wires from each VFD to its respective motor MUST be run in a separate steel

conduit away from control wiring and incoming AC power wiring to avoid noise and

crosstalk between drives.

2. Load reactors: If the distance between the VFD and the motor is great, a load reactor should be

used between the VFD and the motor. The output reactor should be sized accordingly.

208/230V – Load reactor should be used when distance exceeds 250 feet.

460/480V – Load reactor should be ordered when distance exceeds 50 feet.

575V– Load reactor should be ordered when distance exceeds 25 feet.

3. If the distance between the VFD and the motor is between 500 and 1000 FT, a dV/dT filter should

be used.

4. No contactor should be installed between the drive and the motor. Operating such a device while

the drive is running can potentially cause damage to the power components of the drive.

5. When a disconnect switch is installed between the drive and motor, it should only be operated

when the drive is in a STOP state.

Programming

Most VFD parameters are preprogrammed at the factory when proper information about the fan

motors is provided. However the 2 parameters below should be verified in the field during startup.

1. The Drive should be programmed for the proper motor voltage. Refer to parameter P107 in the

“Component Description - Variable Frequency Drive” chapter below.

P107 is set to 0 (Low) if motor voltage is 120 VAC, 208 VAC or 400 VAC. P107 is set to 1 (High)

if motor voltage is 230 VAC, 480 VAC or 575 VAC.

2. The Drive should be programmed for the proper motor overload value. Refer to parameter P108

in the “Component Description - Variable Frequency Drive” chapter below.

P108 is calculated as Motor FLA x 100 / Drive Output Rating (available in table below). P108 is

also indicated on the factory wiring schematic under the “Motor Power Circuit” column.

NOTE: Do NOT adjust minimum and maximum frequency on the VFD. Communication errors will

result between the control board and the VFD. These parameters should be adjusted through the

control panel only.

A0023662

May 2014 Rev.5

Page 11

11

Model Number

Volts

1Ø

input

3Ø

input

HP

Input

Amps

1Ø

120VAC

Input

Amps

1Ø

240VAC

Output

Amps

Breaker

1Ø

120VAC

Breaker

1Ø

240VAC

ESV751N01SXB571

120/

240V X 1 16.6

8.3

4.2

25

15

ESV112N01SXB571

120/

240V X

1.5

20

10 6 30

20

Input

Amps

1Ø

Input

Amps

3Ø

Breaker

1Ø

Breaker

3Ø

ESV371N02YXB571

240V X X

0.5

5.1

2.9

2.4

15

15

ESV751N02YXB571

240V X X 1 8.8 5 4.2

15

15

ESV112N02YXB571

240V X X

1.5

12

6.9 6 20

15

ESV152N02YXB571

240V X X 2 13.3

8.1 7 25

15

ESV222N02YXB571

240V X X 3 17.1

10.8

9.6

30

20

ESV402N02TXB571

240V X 5

18.6

16.5 30

ESV552N02TXB571

240V X

7.5 26

23 40

ESV752N02TXB571

240V X

10 33

29 50

ESV113N02TXB531

240V X

15 48

42 80

ESV153N02TXB531

240V X

20 59

54 90

ESV751N04TXB571

480V X 1

2.5

2.1 15

ESV112N04TXB571

480V X

1.5 3.6 3

15

ESV152N04TXB571

480V X 2

4.1

3.5 15

ESV222N04TXB571

480V X 3

5.4

4.8 15

ESV402N04TXB571

480V X 5

9.3

8.2 15

ESV552N04TXB571

480V X

7.5 12.4

11 20

ESV752N04TXB571

480V X

10 15.8

14 25

ESV113N04TXB531

480V X

15 24

21 40

ESV153N04TXB531

480V X

20 31

27 50

ESV183N04TXB531

480V X

25 38

34 60

ESV223N04TXB531

480V X

30 45

40 70

ESV751N06TXB571

600V X 1 2 1.7 15

ESV152N06TXB571

600V X 2

3.2

2.7 15

ESV222N06TXB571

600V X 3

4.4

3.9 15

ESV402N06TXB571

600V X 5

6.8

6.1 15

ESV552N06TXB571

600V X

7.5 10.2 9

20

ESV752N06TXB571

600V X

10 12.4

11 20

ESV113N06TXB531

600V X

15 19.7

17 30

ESV153N06TXB531

600V X

20 25

22 40

ESV183N06TXB531

600V X

25 31

27 50

ESV223N06TXB531

600V X

30 36

32 60

ACTECH SMV VFD CROSS-REFERENCE TABLE

A0023662

May 2014 Rev.5

Page 12

12

Button

Associated

function

OPERATION

Start-Up Procedure

NOTE: FIRE system must be in ARMED state before proceeding.

1. Once all required connections have been completed as indicated on the installation schematic,

startup can begin. Apply power to the panel. The ECPM03 board and the HMI(s) will power up

and beep. If that is not the case, check all power connections. Verify that there is no alarm

message displayed on any HMI. If there are alarms present, you can press the MUTE button to

silence the alarm and then work to resolve them.

The HMI has 4 buttons; function is displayed adjacent to them on the LCD. These functions will

change depending on the status of the panel. If no text is adjacent to the button, it does not have

a function.

Typically LIGHTS and FANS functions

are shown on the bottom 2 buttons.

The status of those elements is shown

by the shading used inside the box

associated with the function. An empty

box around the FAN function means

that the FANS are turned OFF. A dark

box around the FAN function means

that the FANS are turned ON. The

same applies to LIGHTS.

Note: For the rest of the document, the

term button will be used to refer to

either the actual button or the function

associated with it.

The center two lines of the LCD are reserved for displaying informational or fault messages

When a fault occurs, an audible alarm is triggered and a message is displayed on the HMI(s).

The Audible Alarm can be silenced by pushing the Mute button that appears on the top right

corner.

2. Press the LIGHTS button on the HMI to energize the hood lights. If the lights do not come on,

make sure the light bulbs are installed and/or check the lighting circuit.

3. Press the FANS button on the HMI to energize the fans. Also press the PREP OFF button to run

all exhaust and supply fans.

4. If cooking appliances are connected to an Electric gas valve controlled by the control panel, the

gas valve can be turned ON by pressing the GAS RESET button on the top right corner of the

HMI. The icon will only show if the Gas Valve Option is turned ON under the ECPM03 menu:

Configuration / Misc. Options / Set Gas Valve. , or if a CORE fire protection system is enabled.

5. Turn the Fans off. Turn on the cooking appliance(s) and allow them to reach idle temperature.

The fans should automatically activate as the cooking appliance(s) heats up. The factory set

activation point for duct temperature override of the fan switch is 10 degrees above kitchen room

temperature. Each duct temperature sensor has its own temperature offset setting. These values

should be adjusted based on the cooking appliances and cooking load. Refer to paragraph (e)

under the Configuration section for further details.

A0023662

May 2014 Rev.5

Page 13

13

6. If the controls include the Self Cleaning or CORE Protection Fire System option, a WASH button

will be displayed on the HMI. Push the button to start the wash cycle. Water will be sprayed in the

plenum and duct of the hood and surfactant will be injected at a predetermined frequency. The

wash cycle will stop when the wash timer expires or when the Stop Wash button is pressed.

Make sure Hood filters remain in place during the wash cycle.

NOTE: The hood self-cleaning function will occur automatically at predetermined intervals after the

system detects a hood use period (heated duct sensors). Refer to paragraph (10) to (13) under

miscellaneous configuration section(h) of this manual for adjustment information.

7. If the Proving Interlock Option is enabled, a calibration step is required at startup. Please refer to

the Fan Proving Interlock section below under Functionality for further details about this function.

To perform the calibration, refer to paragraph (e) under the Configuration section.

Sequence of Operation

Preparation Time mode:

Turn on the cooking appliances and allow

Temperature to rise. The exhaust fans will

automatically be energized in Preparation

Time mode at first (Supply off). The

factory set Prep activation point is 7.5

degrees above kitchen room temperature.

LIGHTS will automatically be turned on as

well. LIGHTS can be turned ON and OFF

manually by pressing the LIGHTS button.

Manual method: The FANS button can be

pressed to energize the exhaust fans in

Preparation Time mode (supply off).

Full Modulation:

As the cooking appliances heat up, the

system will go into modulation mode with

supply fan ON. The factory set activation

point for modulation is 10 degrees above

kitchen room temperature. This function

allows the system to meet the

requirements of IMC 507.2.1.1, which

require exhaust fans to activate when

cooking is occurring. The fans take a few

seconds to come up to speed; this setting

is programmed into the panel for a soft

motor startup to prolong the fan motors.

The VFDs should all indicate 48Hz. Once

the cooking process begins, the VFDs will

begin to modulate typically between 48 Hz and 60 Hz based on the Duct temperature. This results in

a 20% reduction in airflow when operation is in low speed, which is equivalent to a 48% reduction in

electrical consumption by the fan motors.

For every exhaust fan, there are two possible factory settings for the temperature control: 450

degree rated hoods are programmed for a modulation range of 5F, while the 600-700 degree rated

hoods are programmed for a modulation range of 45F. All temperature ranges are adjustable as

needed for the application.

Manual Method: The PREP OFF button can be pressed to go into modulation mode and energize the

supply fan. VFDs for all fans will typically run at 48 Hz to start with and modulate based on

temperature from that point on.

A0023662

May 2014 Rev.5

Page 14

14

Max Air Flow:

By manually pressing the MAX AIR button, the fans will run at High Frequency, typically 60 Hz for a

factory set time of 30 minutes. This time is adjustable under the Misc Options section of the

configuration menu. Once the time period has expired or if the MAX AIR button is pressed again, the

VFDs will go back to operating based on the duct temperature.

Cool Down mode:

The fans will go into Cool Down mode when the duct temperature goes below the activation point

minus the temperature hysteresis of 2 degrees. For example, if the activation temperature is at 85 F

and the hysteresis is set to 2F, Cool Down mode will start at 83F.

In Cool Down mode, the exhaust fans will run at the same speed than in Preparation Time mode and

the supply fans will turn off.

NOTE: The hysteresis timer, factory set at 30 minutes, is used to prevent the fans from cycling on

and off too often due to small appliances generating just enough heat to turn on the fans but not

enough to keep them ON for a long time. The Hysteresis Timer will maintain the fans on after they

have been activated by temperature for a minimum time set by this timer, even if the temperature in

the duct cools back down.

Manual Method: If the duct temperature is in the Cool Down mode range, the Hysteresis timer can be

bypassed by pressing the FANS button.

Fans Off:

If the system was in automatic operation, the fans will turn off when the duct temperature goes below

the Prep activation point minus the temperature hysteresis of 2 degrees. For example, if the Prep

activation temperature is at 80F and the temperature hysteresis is set to 2F, then the fans will turn

off at 78F.

NOTE: The Prep hysteresis timer, factory set at 30 minutes, is used to prevent the fans from cycling

on and off too often due to small appliances generating just enough heat to turn on the fans but not

enough to keep them ON for a long time. The Hysteresis Timer will maintain the fans on Cool Down

mode after they have been activated by temperature for a minimum time set by this timer, even if the

temperature in the duct cools back down.

Manual Method: If the duct temperature is below the Cool Down mode range, the Hysteresis timer

can be bypassed by pressing the FANS button. This will also turn the lights off. If the temperature

never went above the Prep activation point and the fans were turned on only by pressing the FANS

button, the pressing the FANS button will directly turn off the fans.

A0023662

May 2014 Rev.5

Page 15

15

Functionality

Fan Control

The control panel controls fans through VFDs. They are used to adjust the speed of 3 phase motors and

frequency is proportional to airflow. There is one VFD for each fan in the system.

Preparation Time Mode

1. This option is enabled by default from the factory.

It can be disabled under Configuration → Factory options.

2. Preparation Time Mode is available for morning operation when appliances are off or when very light

food preparation is performed. Dedicated make-up air will be locked out only allowing the use of

transfer air during this mode. Exhaust fan(s) will run at low CFM while maintaining a balanced kitchen

pressure.

3. Preparation Time mode can be initiated by different means:

By pressing the FANS button on the HMI

When the duct temperature exceeds Prep activation point =Room Temperature + Temp Offset/2

(Factory Default: 7.5 °F).

4. The fans will go back to running in modulation mode if the PREP OFF button is pressed or if the

temperature sensors in the duct measure a temperature above the activation Temperature value.

5. The speed of the exhaust fan(s) in Preparation Time is calculated automatically and is equal to

the speed that will produce the same amount of CFM than the Transfer CFM when the fans are

running in full speed in normal operation. If there is no dedicated supply fan in the system, the

exhaust fans will run at the set High Frequency divided by 4 (typically 15 Hz).

NOTE: If the calculated value falls below the set minimum frequency, then the value will be adjusted

to the lowest allowable frequency.

Hood Lights

1. A control panel can have 1 HMI light switch but potentially controls multiple light circuits. Each

light circuit can feed with a maximum of 1400W. If more than 1400 watts of lights are needed,

additional 15 amp circuits can be brought to the panel. Panel specific lighting limitations are

indicated on the installation schematic.

2. Hood lights can be controlled manually through the LIGHTS button on the HMI. They will also be

automatically turned ON or OFF when the fans assigned to that same fan zone turn ON or OFF.

Manual light switch command on the HMI always takes priority.

Electric Gas Valve Reset

If the Gas Valve option is turned ON or the system is equipped with CORE Fire Protection, an additional

button (GAS RESET/GAS ON) is displayed on the HMI to allow the user to reset or re-energize an electric

gas valve connected to the panel. The gas valve is de-energized at initial startup, when the Fire System is

triggered or in other conditions as well.

Refer to paragraph (h) under Configuration section to turn this option ON or OFF.

High Temperature Automatic Appliance Shutdown

When any of the duct temperature sensors reads a temperature above the Appliance Shutdown

Temperature threshold settings (Factory Default: 250 Degrees °F), any electric gas valve wired to the

panel will shut down and the shunt trip output of the panel will activate. This is intended to prevent

potential fires. The activation threshold set point can be adjusted under Configuration/Fire Options.

Make-Up Air Interlock

When the dedicated supply fan is a Tempered Make-up Air unit, the blower inside the supply unit can be

interlock so that it will not run unless the safety controls (Freezestat, CO sensor, Smoke Detector etc.)

inside the supply fan are armed and until the internal motorized damper has reached its end limit switch.

A0023662

May 2014 Rev.5

Page 16

16

If the signal from the make-up air is not received by the DCV 90 Sec (factory default) after the start signal

is sent to the supply fan, an alarm will appear on the HMI. The DCV panel ships with a jumper between

terminals IL1A and IL1B for supply #1 and IL2A and IL2B for supply #2 if present. The jumper has to be

removed first before wiring the interlock from a make-up air unit.

Appliances Pilot Check Warning:

Every time an electronic gas valve is reset, a warning message will be displayed on the HMI for 1 minute.

A CLEAR button will be displayed on the HMI to clear the warning message and stop the beeps. If after 1

minute, the clear button is not pressed, the message disappears. This message is normal and provided

as a reminder only. There is no need to take any action.

Building Management System (Dry Contact)

1. All controls are equipped with the ability to control the fans via a dry contact BMS interlock.

Terminal IO1 should be energized by closing a dry contact placed between terminals H1 and IO1.

NOTE: the CO Censor option must be disabled for BMS dry contact functionality.

2. Removing the signal from IO1 will typically cause the fans to turn off. However, if the duct

thermostat sensors are hot or if the fans are energized through the fan button on the HMI, then

the fans will continue to run.

NOTE: If the panel is ordered with a digital building management option, such as CASlink,

BACnet, or Lonworks, please refer to the Building Management Owner’s Manual for alternative

fan interlock scheduling.

Minimum Room Temperature

This option is designed to prevent unnecessary automatic fan activation due to excessively cold room

temperatures. This value is adjustable between 50 degrees and 85 degrees. As long as the room

temperature reading is above the Min Room Temp set value, the package will use the actual room

temperature sensor reading to calculate the duct thermostat offset. However, if the room temperature

sensor reading is below the Min Room Temp set value, the package will ignore the actual room temp

reading and use the Min Room Temp set value as a reference instead. This prevents a system from

activating the fans unnecessarily, due to a large gap between room temperature and the hood duct

temperature. This option can also help alleviate fan activation troubles with lower temperature

appliances, which are not satisfying the minimum temperature requirements for fan activation.

Self-Cleaning (Optional)

1. During the wash cycle, water will be sprayed in the plenum and duct and surfactant will be

injected at a set frequency. The wash cycle will stop when the wash timer expires or when the

Wash button is pressed again.

2. The wash timer is factory set to 3 minutes and is adjustable through the Configuration Menu. The

surfactant is injected for 1 second at the start of each minute of Wash. This setting is not

adjustable. If equipped with CORE Fire Protection, the wash timer is not configurable through the

ECPM03 control board. Refer to the CORE Owner’s Manual for further information.

3. Hood filters MUST remain in place during the wash cycle.

4. The wash cycle can be initiated in several ways:

a. Manually, when the WASH button is pressed on the HMI.

b. Automatically, if the following conditions are met

Fans will need to go out of modulation mode either with the FANS button being

pressed or by the duct temperature cooling down and hysteresis value and timer

are met.

The fans will need to have effectively run cumulatively for a period of time longer

than the “Wash Min Fan Runtime” value configured under “Misc Options”.

Preparation Time mode and Cool Down mode fan time do not count towards

runtime. The runtime is reset to zero when the wash cycle is run.

A0023662

May 2014 Rev.5

Page 17

17

The amount of time elapsed since the previous wash cycle is greater than the

“Wash Min Interval time” value configured under “Misc Options”. That elapsed

time is reset to zero when the wash cycle is run.

c. If a Building Management System (BMS) is remotely controlling the fans through the

external input terminal IO1, when the Fans are turned ON and then OFF through the IO1

terminal, granted that the fans are not maintained on by the duct temperature sensors or

the fan button.

d. Through a digital Building Management System. Refer to the Building Management

Owner’s Manual for more information.

5. If the surfactant level is too low, an alarm will be triggered on the HMI. If the wash cycle is

initiated while this alarm is active, water will be sprayed but no surfactant will be injected. Refill

Surfactant as soon as possible for best results. (Refer to Self-Cleaning or CORE Manual for

additional information)

Fan Proving Interlock (Optional) (i.e. Loss of Load Interlock/Airflow Fault Interlock)

1. This function is designed to prevent exhaust fans from running if the supply fans are not running,

which in turn would shut off the cooking equipment. In practical terms, this means that all fans will

shut off along with cooking equipment if any of the exhaust or supply fans are not properly

running. Examples of reasons why a fan would not be properly running are: overload tripped,

broken fan belt, defective motor, disconnect switch off, etc.

2. This function requires calibration, which can be performed through the Calibration setting on the

ECPM03 LCD.

3. If this option is enabled, the load on all the exhaust and supply fans is constantly monitored. If the

load for an exhaust fan or the load for a supply fan drops below the threshold calculated after

calibration for more than the 35 sec, all exhaust and supply fans will shut down.

4. If an electric gas valve and shunt trip are attached to the system, they will shut down as well.

5. To reset the system after a Proving fault, press the Fault Reset button on the HMI.

CORE Protection Fire System (Optional)

1. If a CORE Protection Fire system is connected to the control panel, alarms from the CORE

system will automatically be displayed on the HMI.

2. Multiple CORE systems can be connected to the same control panel. Refer to the CORE Manual

for setup of CORE Interlock Network addressing to prevent communication conflicts.

PCU Advanced Filter Monitoring (AFM) (Optional)

1. If a PCU AFM is connected to the control panel through Modbus, alarms from the PCU will

automatically be displayed on the HMI.

2. To connect the AFM system to the HMI, run a CAT-5 connection from terminal J3 to the RJ45

port on the PCU AFM internal to the PCU. This is outlined in the installation schematics.

3. Up to 8 PCU AFM can be connected to the same Control panel. . Note that each additional PCU

AFM must be assigned a unique Modbus address. Refer to the PCU AFM manual for more

information. Note that each additional PCU AFM must be assigned a unique Modbus address.

Refer to the PCU AFM manual for more information.

Electric Gas Valve Follow Fans (optional)

This option is only available when an electric gas valve is enabled. If this option is ON, the gas valve is

shut off whenever the fans are off and requires a reset when the fans are turned ON. This is meant to

prevent gas cooking appliances to run when the fans are off and is only required in some jurisdictions.

This option can be enabled under Configuration/Misc Options/Gas Follow Fans. Factory Default Setting is

OFF. NOTE: Appliance pilots must be relit after each fan cycle when this option is enabled.

A0023662

May 2014 Rev.5

Page 18

18

Shunt Trip Follow Fans (Optional)

If this option is ON, the shunt trip will be energized whenever the fans are off. This is meant to prevent

electric cooking appliances from running when the fans are off and is only required in some jurisdictions.

This option can be enabled under Configuration/Misc Options/Shunt trip Follow Fans. Factory Default

Setting is OFF.

Dimmable HMI (Optional)

This option allows the backlight on all HMIs to turn off whenever a timer is satisfied. The timer is refreshed

every time the HMI button is pressed. This option is factory set to be disabled, and can be enabled under

Configuration/Misc Options/ Set HMI Dimming.

CO Censor Input (Optional)

If a CO Sensor is wired to the DCV and the CO sensor is triggered, all exhaust fans will be turned ON and

will ramp up to their high speed. All supply fans will be turned OFF, the gas valve will be shut off, and the

shunt trip will be energized. This option is only accessible through terminal IO1. Terminal IO1 should be

energized by closing a dry contact placed between terminals H1 and IO1, also CO sensor should be

enabled; otherwise, the IO1 terminal will function as BMS input. Factory Default Setting is OFF.

PCU CORE ONLY (Optional)

This option can only be enabled if CORE Hood is disabled. If this option is enabled, all the faults

occurring on a connected PCU CORE system will be displayed on the HMI. A cat5 cable will be needed

to connect the PCU CORE to the slave side of the network, typically J3. Factory Default Setting is OFF.

Energy Saving Graph (optional)

The % Savings graph on the HMI provides information on how much fan energy is saved by the system

when running the fans at lower speed. It is calculated based on the actual Kilowatts measured from each

Variable Frequency Drive controlling the fans. However, it doesn’t include the additional savings resulting

from the lower CFM of Make-up air and HVAC air that require heating or cooling. This option is factory set

to be enabled, and can be disabled under Configuration/Misc Options/Hide Energy Savings.

A0023662

May 2014 Rev.5

Page 19

19

Configuration and Diagnostics

Security

1. To access the Configuration / Factory, the password 1111 must be used.

2. To access the Configuration / Fire Options, the password 1234 must be used.

Setup Options

The ECPM03 board allows the user to monitor the system and configure a broad range of options

associated with the functionality of the system. Monitoring is done through the setup menus on the

ECPM03 LCD as shown above. Configuration is done through the HMI after calling for Configuration

through the ECPM03 menu.

Below the ECPM03 LCD are 4 buttons for navigation: MENU, UP, DOWN, ENTER. When in configuration

mode, the four buttons on the HMI will be labeled the same. See picture above.

The MENU button typically takes you up one level in the menu tree while the ENTER button takes you

down one level. UP and DOWN navigate through the same level of the menu tree and also allow the user

to change the value of a parameter.

After changing some parameters in the configuration menus, the user needs to press MENU multiple

times on the HMI until the screen displays the message “Saving. Wait for reboot” As indicated, the

processor will reboot. This allows the board to correctly process the parameters changed.

NOTE: a reboot of the board will cause the electric gas valve (if equipped) to shut off. Confirm that

gas/pilot lights are re-lit if necessary. It will also cause the VFDs to stop if not in Auto mode.

The 4 items below can be accessed through the ECPM03 LCD:

a. Display System Information

Starting from the Main menu, press the DOWN button, press DOWN again. Screen displays “Info”.

Press the ENTER button. Screen displays “Fault History”. Press DOWN to View the Version number.

Press DOWN to view the package Type, which should be “DCV”.

b. Display Fault History

Starting from the Main menu, press the DOWN button, press DOWN again. Screen displays “Info”.

Press the ENTER button. Screen displays “Fault History”. Press ENTER. Press UP and DOWN to

scroll through the fault history, with 1 being the most recent fault. To clear the fault history, please

ENTER and press ENTER again when prompted “Clear Fault History”. Or press MENU to go back

without clearing.

A0023662

May 2014 Rev.5

Page 20

20

c. Display temperature readings

Starting from the Main menu, press the DOWN button. Screen displays “Temperatures”. Press the

ENTER button. Press the UP and DOWN buttons to view all temperatures measured by the room and

duct temperature sensors.

d. Display Fan Monitoring data: Fan Frequencies and Motor Amps

Starting from the Main menu, press the DOWN button until the screen displays “Monitoring”. Press

the ENTER button. Press the UP and DOWN buttons to alternate between “Fan Frequencies” and

“Motor Amps”. Press enter for either one to view Frequency of each VFD or amps drawn by the motor

on each fan.

e. Fan Proving Interlock: Calibration

If the Fan Proving Interlock option is enabled, Calibration is required at startup. To perform

calibration, make sure Test and Balance has been performed on the entire system first. Filters should

be in place.

Starting from the Main menu, press DOWN until the screen displays “Calibration”. Press ENTER. The

screen should display “Proving Calib. Calibrate?” Press ENTER again to start the Calibration process

which takes about 40 sec. Press MENU once when calibration is complete.

If Calibration is unsuccessful, the message “Calibration Fail” will appear. Make sure the VFDs are

running and the MUA interlock signal is wired correctly to ILxA ILxB.

All the items below are for Configuration and are accessed by putting the HMI into Configuration mode.

To do this, starting from the Main menu on the ECPM03 LCD, press the MENU button. Screen displays

“Configuration” Press the ENTER button. Screen will display “Config Menu

on HMI”. From there, the rest can be done on the HMI.

f. Configure Temperature Sensor Assignments

Starting from the Main menu of HMI, screen displays “Temp Sensor

Assignment”. Press ENTER. Screen displays “Select Temp Sens to

assign: 1”.

To navigate to another Temperature sensor, press the UP button. To

configure the assignment for a Temperature Sensor, press ENTER.

1. For Temperature sensor 1, the options are either to follow the room sensor wired to terminal T1A,

T1B (“Room Temp 1”) or to assign a preset room temperature (75°F by default). Press UP or

DOWN to choose the proper option. Press MENU to confirm the selection. To change the default

preset value, press the ENTER button when displaying the Preset Temperature. Press UP or

DOWN to change the preset value. Press MENU multiple times to get out to main menu.

2. For Temperature sensor 2 and above, the options are either control or monitor. To control the fan

the choice should be capture volume or riser followed by the fan number. To monitor the

temperature. The decision should be one out of the list: Auxiliary Temp, Hood Coil Input, Hood

Coil Output, PSP Discharge, or ACPSP Discharge.

Press MENU multiple times to get back to the main menu or one more time to reboot the processor.

g. Configure Temperature Sensor Offset values (Factory Default: 15 Degrees °F)

Starting from the Main menu of HMI, press DOWN once so screen displays “Temp Sensor Offset”.

Press ENTER. Screen displays “Select Temp Sens to Offset: 2”

Press UP or DOWN to navigate between the different Duct Temperature sensors. Press ENTER to

select one. Then press UP or DOWN to adjust the offset Temperature.

Press MENU multiple times to get back to the main menu or one more time to reboot the processor.

A0023662

May 2014 Rev.5

Page 21

21

h. Configure Misc. Options:

1. Enable Electric Gas Valve control

This option will be enabled by default if the system is equipped with CORE Protection Fire

system.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Gas Valve”. Press ENTER.

Press UP or DOWN to turn this option ON or OFF. Press ENTER.

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

2. Enable Electric Gas Valve Follow Fans (Factory Default: OFF)

This option is only available when Gas Valve is turned ON or CORE is enabled.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Gas Valve Follow Fans”. Press

ENTER. Press UP or DOWN to turn this option ON or OFF.

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor

3. Enable Shunt Trip Follow Fans (Factory Default: OFF)

Starting from the Main menu of HMI, press the MENU button. Press DOWN or UP until the

screen displays “Misc Options”. Press ENTER. Press UP or DOWN until the screen displays

“Shunt Trip Follow Fans”. Press ENTER. Press UP or DOWN to turn this option ON or OFF.

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor

4. Adjust the Temperature Hysteresis (Factory Default: 2°F):

The hysteresis is used to prevent the fans from cycling ON and OFF when the temperature in the

duct is near the activation value. The fans will turn ON when the duct temperature exceeds the

activation value, but they will only turn off when the duct temperature goes below the activation

temperature minus the temperature hysteresis. For example, if the activation Temperature is at

85 °F and Temperature Hysteresis is set to 2 °F, the fans will turn ON at 85 °F and will turn OFF

at 83 °F.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Screen displays “Set Temp Hyst”. Press ENTER. Press UP or DOWN to adjust

the Hysteresis value. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

5. Adjust the Hysteresis Timer (Factory Default: 30 min):

The hysteresis is used to prevent the fans from cycling on and off too often due to small

appliances generating just enough heat to turn on the fans but not enough to keep them ON for a

long time. The Hysteresis Timer will maintain the fans on after they have been activated by

temperature for a minimum time set by this timer, even if the temperature in the duct cools back

down.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Hyst Timer”. Press ENTER.

Press UP or DOWN to adjust the Timer value. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

6. Adjust the Max Air Time (Factory Default: 30 min):

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Max Air Time”. Press UP or

DOWN to adjust the Timer value. Press ENTER.

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

A0023662

May 2014 Rev.5

Page 22

22

7. Set 0-10VDC output (Factory Default: Exhaust CFM Ratio):

In addition to each variable frequency drive (VFD) in the DCV system providing a 0-10 VDC

analog output from its terminals 30 and 2 directly proportional to its Fan Speed Ratio (Fan

Frequency / Fan High Frequency), the ECPM03 also offers a 0-10VDC output from terminals VO-

and VO+. This output can be configured depending on the type of signal needed by the building

management system or the equipment receiving it.

Three (3) types of signal are available:

- Total Exhaust CFM Ratio = Total Operating Exh CFM / Total Design Exh CFM

- Total Supply CFM Ratio = Total Operating Sup CFM / Total Design Sup CFM

- Total Transfer CFM Ratio = Total Operating Transfer CFM / Total Design Transfer CFM

Total Exhaust CFM Ratio could be sent to a Roof Top Unit providing make-up air to the hood.

Total Transfer CFM Ratio could be sent to a HVAC unit indicating how much transfer air is

needed for the kitchen. This selection takes in consideration the Preparation Time Mode where

the same amount of transfer air is used as when the fans are all running at maximum speed.

Total Supply CFM Ratio is only available if a Supply fan is present in the DCV system. In

Preparation Time, Total Supply CFM Ratio would be 0.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “0-10VDC output”. Press UP or

DOWN to set the option needed. Press ENTER.

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

8. Fan Proving Interlock: Proving Percentage (factory default 80%)

If the Fan Proving Interlock option is enabled, the Proving Percentage setting is available.

Its value can range between 50% and 100%. The greater the ratio, the tighter the limits will be for

fault detection, which also means the greater likelihood of false positive.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Proving Percent”. Press

ENTER. Press UP or DOWN to adjust the ratio value. Press ENTER. Press MENU multiple times

to get back to the main menu or one more time to reboot the processor.

9. Adjust Wash Time (Min) (Factory Default: 3 min):

This option is available if the control system includes self-cleaning option from the factory. The

wash time value is setup in minutes with a maximum value of 30 minutes.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Wash Time”. Press ENTER.

Press UP or DOWN to adjust the time value. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

10. Adjust Wash Frequency (Hz) (Factory Default: 15 Hz):

This option is available if the control system includes self-cleaning option from the factory. This

value is the frequency at which all exhaust fans will run in wash mode. The Supply fan will be

stopped during Wash.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Wash Frequency”. Press

ENTER. Press UP or DOWN to adjust the frequency value. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

A0023662

May 2014 Rev.5

Page 23

23

11. Set Wash Min Fan Runtime (Factory Default: 480 min):

This option is available if the control system includes self-cleaning option from the factory. Its

maximum value is 1440 minutes or 24 hours. Refer to the Self-Cleaning Section under

Functionality for more details about this option.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Wash Min Fan Runtime”. Press

ENTER. Press UP or DOWN to adjust the time value. Press ENTER.

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

12. Set Wash Min Interval Time (Factory Default: 720 min):

This option is available if the control system includes self-cleaning option from the factory. Its

maximum value is 1440 minutes or 24 hours. Refer to the Self-Cleaning Section under

Functionality for more details about this option.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Wash Min Interval time”. Press

ENTER. Press UP or DOWN to adjust the time value. Press ENTER. Press MENU multiple times

to get back to the main menu or one more time to reboot the processor.

13. Adjust the number of PCU Advanced Filter Monitoring (AFM) Units

If PCU AFM units are connected to the control panel (through Modbus), the number of units has

to be adjusted through this parameter. Refer to the PCU AFM manual for additional information

on how to setup the PCU AFM unit number at the unit control panel.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Number of PCU AFM”. Press

ENTER. Press UP or DOWN to adjust the number of units. Press ENTER.

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

14. Set External input to interlock Fans option

This option is used when the DCV panel is used in conjunction with a third party panel handling a

wash sequence. Based on the value selected for this option, the fans will behave differently when

an input is received on the OV2 terminal.

- OFF: no action.

- WASH CYCLE: Exhaust fans will run at the wash frequency and supply fans will stop.

This is used when a third party panel is washing the hood.

- DRY CYCLE: Exhaust fans will run at High frequency and supply fans will stop. This is

used when a third party panel requires the exhaust fan to run at full speed for drying

purposes.

15. Set HMI Dimming (Factory Default :OFF)

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set HMI Dimming”. Press ENTER.

Press UP or DOWN turn this option ON or OFF. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

16. Set Dim Delay Time (Factory Default: 60sec)

This option is only accessible when HMI Dimming is ENABLED. It allows the user to modify the

time for which the backlight of the HMI remains on before it will turn off. The Dim Delay Time is

factory set to 60 sec, and is refreshable every time a button on the HMI is pressed. The Dim

Delay Time is adjustable between 10sec and 5 minutes.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Dim Delay Time”. Press

ENTER. Press UP or DOWN to adjust the time value. Press ENTER

A0023662

May 2014 Rev.5

Page 24

24

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

17. Set Min Prep Frequency(Factory Default: 10Hz)

This option is only displayed when Prep Time Mode is enabled. Its maximum value is the

minimum of the low frequencies of all the fans controlled by the package and minimum value is

5Hz.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Min Prep Frequency”. Press

ENTER. Press UP or DOWN to adjust the Min Frequency. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

18. Hide Energy Savings(Factory Default: NO)

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Hide Energy Saving”. Press

ENTER. Press UP or DOWN to choose YES or NO. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

19. CO Sensor Input(Factory Default:OFF)

Starting from the Main menu of HMI, press UP or DOWN until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “CO Sensor Input”. Press ENTER.

Press UP or DOWN to choose: ON or OFF. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

20. Set Min Room Temp(Factory Default: 50 Degrees °F)

Starting from the Main menu of HMI, press UP or DOWN until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set Min Room Temp”. Press

ENTER. Press UP or DOWN to adjust the set value. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor.

21. PCU CORE Only(Factory Default: OFF)

Starting from the Main menu of HMI, press UP or DOWN until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “PCU CORE Only ON/OFF”. Press

ENTER. Press UP or DOWN to choose: ON or OFF. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the

processor. NOTE: This will not be present if HOOD CORE is enabled under the Factory Options

menu.

i. Set IO1 Delay Time (Factory Default: 0 min)

This option is intended for applications that require the fans to keep running for a specific amount of

time right after the BMS signal is turned OFF. The delay time value is set in minutes with a maximum

value of 15 minutes. The fans will remain ON for the set time after the BMS is de-energized.

Starting from the Main menu of HMI, press UP or DOWN until the screen displays “Misc Options”.

Press ENTER. Press UP or DOWN until the screen displays “Set IO1 Delay Time”. Press ENTER.

Press UP or DOWN to adjust the set value. Press ENTER

Press MENU multiple times to get back to the main menu or one more time to reboot the processor.

A0023662

May 2014 Rev.5

Page 25

25

j. Configure Fan Options

This sub-menu contains all options related to Fan configuration.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Fan Options”.

Press ENTER. Press UP or DOWN until one of the options below is displayed. Press ENTER to

access that option. Press UP or DOWN to select the fan (EXH1, EXH2, SUP1 etc.). Press ENTER.

Press UP or DOWN to change the value of that option for that fan. Press ENTER Press UP or DOWN

to select another fan or press MENU and then UP or DOWN to move on to the next option.

1. Set Fan Direction (Factory Default: FWD):

If the fan is running in the wrong direction at startup, the direction can be changed here without

having to change the wiring of the 3-phase motor.

Fan direction can be changed between Forward (FWD) and Reverse (REV).

2. Set Fan Design CFM

This is the design CFM value specified for each fan. This value is internally matched to the High

Frequency set for this fan and used to calculate the Supply fan frequency, as well as the

Preparation Time Frequency. This value should be adjusted after Test and Balance has been

performed on the hood.

NOTE: Changing this value will NOT automatically change the actual CFM exhausted by the fan.

This is achieved by changing the High Frequency. This value is to report to the Controller what

the design CFM is so it is used for internal calculation.

3. Set High Frequency

The High Frequency is the maximum frequency at which an exhaust fan will be running in

modulation mode. This corresponds to the design CFM of the exhaust fan. This value can be

adjusted during Test and Balance of the hood, if needed to adjust the amount of CFM exhausted

at the hood when the adjustment is smaller than what can be achieved with a pulley change. The

value can be increased up to 80 Hz and lowered down all the way to the Low Frequency setting.

4. Set Low Frequency (Exhaust fans only)

The Low Frequency is the minimum frequency at which an exhaust fan will be running in

modulation mode. The fan can still run slower in Wash mode or in Preparation Time. By default

this value is set to 48 Hz which represents a minimum of 80% of full speed when High Frequency

is left at 60 Hz. 20% is the recommended modulation value to ensure capture and containment at

the hood during cooking. Lowering this value is possible but should be carefully evaluated.

5. Set Modulation (Exhaust fans only)

This value is used to calculate the high temperature of the modulation range for each exhaust

fan. The low temperature is the value at which the fan will come on automatically and at which it

runs at the Low Frequency value. Low temperature = Room temperature measured + Temp

Offset. The high temperature is the value at which the fans are running at full speed or High

Frequency. High temperature = Room temperature measured + Temp Offset + Modulation

Range.

Press MENU multiple times to get back to the main menu or one more time to reboot the processor.

A0023662

May 2014 Rev.5

Page 26

26

k. Configure the Fire Options

This sub-menu is Password protected and changes should not be made after passing an

inspection.

Starting from the Main menu of HMI, press DOWN or UP until the screen displays “Fire Options”.

Press ENTER. When prompted, enter the password specified under the security section of this manual

above. Press UP or DOWN until one of the options below is displayed. Press ENTER to access that

option. Press UP or DOWN to change the value of that option. Press ENTER to move on to the next

option.

1. Exhaust On in Fire (Factory Default: ON): When this option is turned ON, the exhaust fans will be

turned ON in a fire condition. If the option is turned OFF, the exhaust fans will stay in whatever

state they were before the fire condition.

2. Lights Out in Fire (Factory Default: ON): When this option is turned ON, the hood lights will be

turned OFF in a Fire condition. If the option is turned OFF, the hood lights will stay in whatever

state they were before the fire condition.

3. Supply Off in Fire (Factory Default: OFF): When this option is turned OFF, the Supply fans will be

turned OFF in a Fire condition. If the option is turned ON, the Supply fans will turn ON in a fire

condition.

4. Appliance Shutdown Temp Threshold (Factory Default: 250 Degrees °F): When any of the duct

temperature sensors reads a temperature above that threshold, the gas valve shuts down and

shunt trip output is activated.

Press MENU multiple times to get back to the main menu or one more time to reboot the processor.

l. Configure Factory Options

This sub-menu is password protected and should only be accessed by the factory since all the

settings under it are directly related to the hardware configuration of the system. Only access this

page if instructed by the manufacturer.

Starting from the Main menu of HMI, press the DOWN button until the screen displays “Factory”.

Press ENTER. When prompted, enter the password specified under the security section of this

manual above. Press UP or DOWN until one of the options below is displayed. Press ENTER to

access that option. Press UP or DOWN to change the value of that option. Press ENTER to move on

to the next option.

1. Set Number of Temp Sensors

This includes all Room Temperature Sensors and Duct Temperature sensors conneted to the

ECPM03 board. Valid values range from 2 to 32.

2. Set Number of Exhaust Fans:

This defines the number of exhaust VFDs controlled the system. There can be up to 8 exhaust

fans.

3. Set Number of Supply Fans

This defines the number of exhaust VFDs controlled the system. There can be up to 2 supply

fans.

NOTE: Based on the number of Exhaust fans, number of Supply fans, and size of VFDs you may be

required to use an expansion box.

A0023662

May 2014 Rev.5

Page 27

27

4. Set Number of Fan Switches

This defines the number of fan switches controlled by the system. There can be 0 or 1 fan

switch. A fan switch will be displayed on the HMI accordingly. If 0 is selected, the fans will be

only controlled by the temperature sensors.

5. Set Number of Light switches

This defines the number of hood light switches controlled by the system. There can be 0, or 1

light switch. A light switch will be displayed on the HMI accordingly.

6. Set Proving Interlock

This option enables or disables the Fan Proving Interlock. Refer to the Fan Proving Interlock

paragraph under Functionality for further details. If this option is enabled, Proving calibration is

required. Refer to paragraph e under Setup Options.

7. Set Hood CORE