Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

ThermaCAM™ P65 HS

User’s manual

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 2

Legal disclaimer

All products manufactured by FLIR Systems are warranted against defective materials and workmanship for a period of one (1) year fromthe

delivery date of the original purchase, provided such products have been under normal storage, use and service, and in accordance with

FLIR Systems instruction.

All products not manufactured by FLIR Systems included in systemsdelivered by FLIR Systems to the original purchaser carrythe warranty,

if any, of the particular supplier only and FLIR Systems has no responsibilitywhatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It is not applicable to any product which has been subjected to

misuse, neglect, accident or abnormal conditions of operation. Expendable parts are excluded from the warranty.

In the case of adefect in a product coveredby this warranty theproduct must not be furtherused in order toprevent additional damage. The

purchaser shall promptly report any defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, at its option, repair or replace any such defective product free of charge if, upon inspection, it proves to be defective in

material or workmanship and provided that it is returned to FLIR Systems within the said one-year period.

FLIR Systems has no other obligation or liability for defects than those set forth above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims the implied warranties of merchantability and fitness for a

particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidentalor consequential loss or damage, whether based on contract, tort

or any other legal theory.

Copyright

© FLIR Systems,2006. All rights reservedworldwide. No parts ofthe softwareincluding sourcecode may be reproduced, transmitted,transcribed

or translated into any language or computer language in any form or by any means, electronic, magnetic, optical, manual or otherwise,

without the prior written permission of FLIR Systems.

This manual must not, in whole or part, be copied, photocopied, reproduced,translated or transmitted to any electronicmedium or machine

readable form without prior consent, in writing, from FLIR Systems.

Names and marks appearing on the products herein are either registered trademarks or trademarksof FLIR Systems and/or its subsidiaries.

All othertrademarks, tradenames or company namesreferenced herein are usedfor identification only and arethe propertyof their respective

owners.

Quality assurance

The Quality Management System under which these products are developed and manufactured has been certified in accordance with the

ISO 9001 standard.

FLIR Systems is committed to a policy of continuous development; therefore we reserve the right to make changes and improvements on

any of the products described in this manual without prior notice.

Patents

This product is protected by patents, design patents, patents pending, or design patents pending.

One or several of the following patents, design patents, patents pending, or design patents pending apply to the products and/or features

described in this manual:

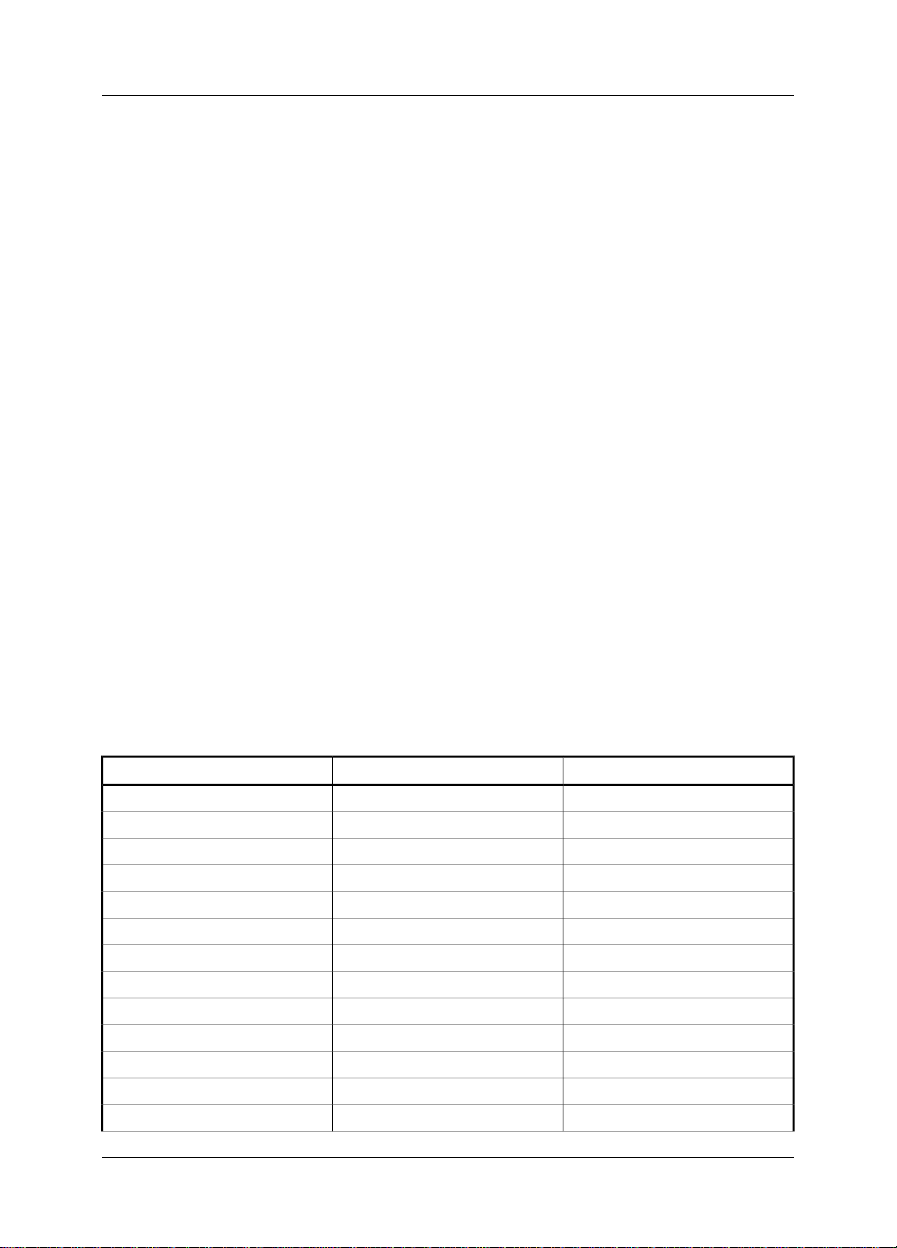

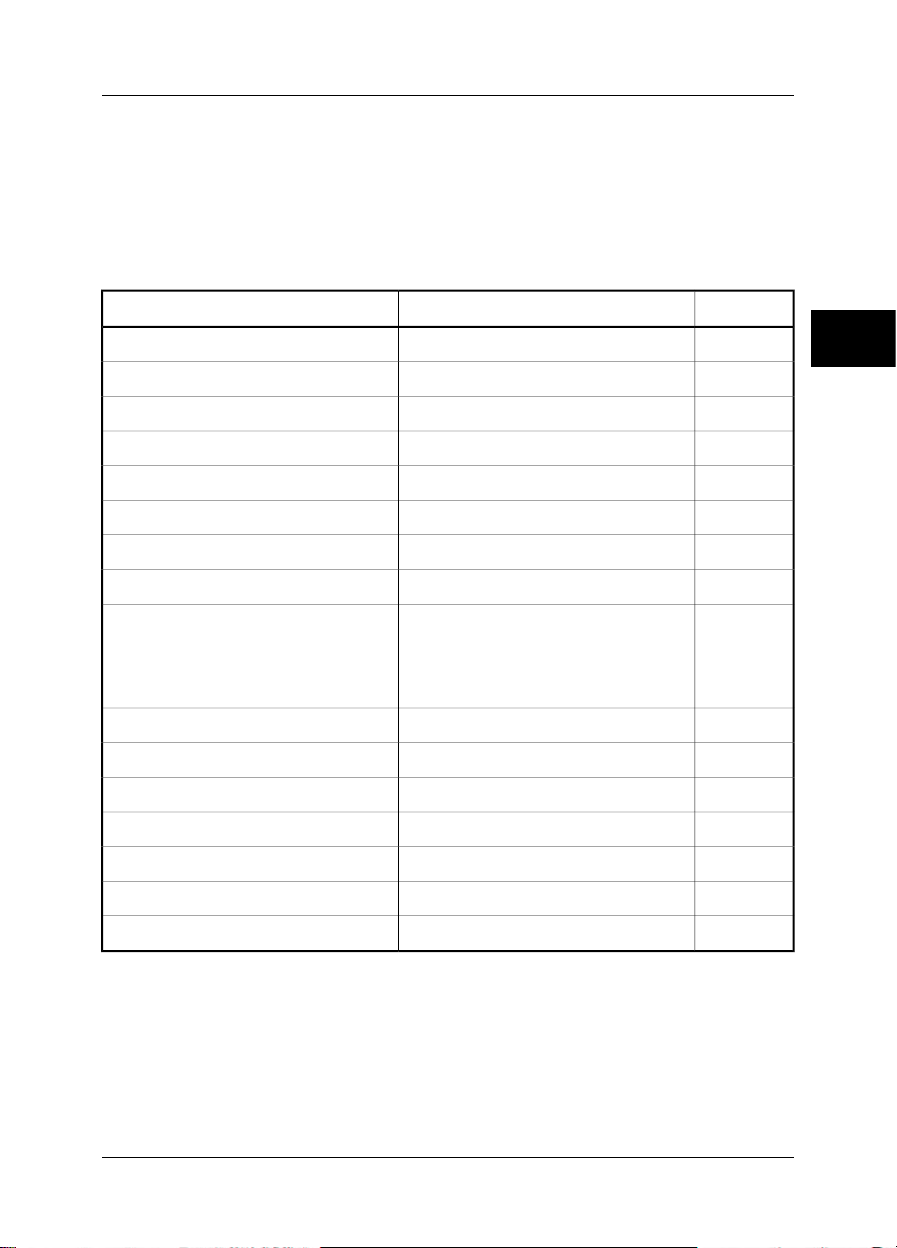

Reg. No.StatusDesignation

00809178.1ApplicationChina

01823221.3ApplicationChina

01823226.4ApplicationChina

235308Design PatentChina

ZL02331553.9Design PatentChina

ZL02331554.7Design PatentChina

200530018812.0PendingChina

1188086PatentEPC

01930377.5ApplicationEPO

01934715.2ApplicationEPO

27282912ApplicationEPO

000279476-0001Design PatentEU

1188086PatentFrance

viii Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 3

Reg. No.StatusDesignation

60004227.8PatentGermany

106017Design PatentGreat Britain

3006596Design PatentGreat Britain

3006597Design PatentGreat Britain

1188086PatentGreat Britain

DM/057692Design PatentInternational

DM/061609Design PatentInternational

2000-620406ApplicationJapan

2002-588123ApplicationJapan

2002-588070ApplicationJapan

1144833Design PatentJapan

1182246Design PatentJapan

1182620Design PatentJapan

2005-020460PendingJapan

PCT/SE01/00983ApplicationPCT

PCT/SE01/00984ApplicationPCT

PCT/SE02/00857ApplicationPCT

PCT/SE03/00307ApplicationPCT

PCT/SE/00/00739ApplicationPCT

0302837-0ApplicationSweden

68657Design PatentSweden

75530Design PatentSweden

518836PatentSweden

522971PatentSweden

524024PatentSweden

09/576266ApplicationU.S.

10/476,217ApplicationU.S.

10/476,760ApplicationU.S.

466540Design PatentU.S.

483782Design PatentU.S.

484155Design PatentU.S.

5,386,117PatentU.S.

5,637,871PatentU.S.

5,756,999PatentU.S.

6,028,309PatentU.S.

6,707,044PatentU.S.

6,812,465PatentU.S.

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 4

Reg. No.StatusDesignation

29/233,400PendingU.S.

x Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 5

Table of contents

11 Warnings & cautions ......................................................................................................................

32 Important note about this manual .................................................................................................

53 Welcome! .........................................................................................................................................

63.1 About FLIR Systems .............................................................................................................

83.1.1 A few images from our facilities ............................................................................

103.2 Comments & questions ........................................................................................................

114 Packing list ......................................................................................................................................

135 System overview .............................................................................................................................

176 Connecting system components ..................................................................................................

176.1 Front connectors ..................................................................................................................

186.2 Rear connectors ...................................................................................................................

196.3 Finding the IP address for cameras connected via FireWire: Method 1 .............................

206.4 Finding the IP address for cameras connected via FireWire: Method 2 .............................

217 Introduction to thermographic inspections of electrical installations ......................................

217.1 Important note ......................................................................................................................

217.2 General information ..............................................................................................................

217.2.1 Introduction ...........................................................................................................

227.2.2 General equipment data .......................................................................................

237.2.3 Inspection .............................................................................................................

237.2.4 Classification & reporting ......................................................................................

247.2.5 Priority ...................................................................................................................

247.2.6 Repair ....................................................................................................................

257.2.7 Control ..................................................................................................................

267.3 Measurement technique for thermographic inspection of electrical installations ...............

267.3.1 How to correctly set the equipment .....................................................................

267.3.2 Temperature measurement ...................................................................................

287.3.3 Comparative measurement ..................................................................................

297.3.4 Normal operating temperature .............................................................................

307.3.5 Classification of faults ...........................................................................................

327.4 Reporting ..............................................................................................................................

347.5 Different types of hot spots in electrical installations ...........................................................

347.5.1 Reflections ............................................................................................................

347.5.2 Solar heating .........................................................................................................

357.5.3 Inductive heating ...................................................................................................

357.5.4 Load variations ......................................................................................................

367.5.5 Varying cooling conditions ...................................................................................

377.5.6 Resistance variations ............................................................................................

377.5.7 Overheating in one part as a result of a fault in another ......................................

397.6 Disturbance factors at thermographic inspection of electrical installations ........................

397.6.1 Wind ......................................................................................................................

397.6.2 Rain and snow ......................................................................................................

407.6.3 Distance to object .................................................................................................

417.6.4 Object size ............................................................................................................

437.7 Practical advice for the thermographer ................................................................................

437.7.1 From cold to hot ...................................................................................................

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 xi

Page 6

8.2.4 Navigating between the internal camera memory and external CompactFlash™

card .......................................................................................................................

437.7.2 Rain showers ........................................................................................................

437.7.3 Emissivity ..............................................................................................................

447.7.4 Reflected apparent temperature ...........................................................................

447.7.5 Object too far away ...............................................................................................

458 Tutorials ...........................................................................................................................................

458.1 Switching on & switching off the camera .............................................................................

468.2 Working with images & folders .............................................................................................

468.2.1 Acquiring an image ...............................................................................................

468.2.2 Opening an image ................................................................................................

468.2.3 Deleting one or several images ............................................................................

46

478.2.5 Navigating in folders .............................................................................................

478.2.6 Create a new folder ...............................................................................................

488.2.7 Freezing & unfreezing an image ...........................................................................

488.2.8 Saving an image ...................................................................................................

488.3 Working with measurements ................................................................................................

488.3.1 Laying out & moving a spot ..................................................................................

488.3.2 Laying out & moving an box .................................................................................

498.3.3 Laying out & moving a circle ................................................................................

498.3.4 Laying out & moving a line ...................................................................................

498.3.5 Creating & changing an isotherm ........................................................................

508.3.6 Resizing a measurement marker ..........................................................................

508.3.7 Moving a measurement marker ............................................................................

528.4 Working with alarms .............................................................................................................

528.4.1 Setting the reference temperature ........................................................................

538.4.2 Setting up a silent alarm .......................................................................................

538.4.3 Setting up an audible alarm .................................................................................

558.5 Creating a text comment file ................................................................................................

568.6 Changing level & span .........................................................................................................

568.6.1 Changing the level ................................................................................................

568.6.2 Changing the span ...............................................................................................

578.7 Changing system settings ....................................................................................................

578.7.1 Changing the language ........................................................................................

578.7.2 Changing the temperature unit .............................................................................

578.7.3 Changing the date format .....................................................................................

578.7.4 Changing the time format .....................................................................................

588.7.5 Changing date & time ...........................................................................................

598.8 Working with the camera ......................................................................................................

598.8.1 Mounting an additional lens .................................................................................

608.8.2 Camera setup when using the Protective Window (P/N 1 194 977) ....................

608.8.3 Focusing the camera using autofocus .................................................................

608.8.4 Focusing the camera manually ............................................................................

608.8.5 Using the electronic zoom ....................................................................................

618.8.6 Inserting & removing the battery ..........................................................................

618.8.6.1 Inserting the battery ..........................................................................

618.8.6.2 Removing the battery ........................................................................

628.8.7 Removing & attaching the remote control from the camera handle ...................

628.8.7.1 Removing the remote control ...........................................................

628.8.7.2 Attaching the remote control ............................................................

659 Camera overview ............................................................................................................................

659.1 Camera parts ........................................................................................................................

xii Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 7

759.2 Keypad buttons & functions .................................................................................................

779.3 Autofocus ..............................................................................................................................

789.4 IrDA infrared communication link .........................................................................................

799.5 Camera status LCD ..............................................................................................................

809.6 Laser LocatIR ........................................................................................................................

819.7 Visual camera .......................................................................................................................

8310 Camera program .............................................................................................................................

8310.1 Screen objects ......................................................................................................................

8310.1.1 Result table ...........................................................................................................

8410.1.2 Status bar ..............................................................................................................

8410.1.3 Temperature scale ................................................................................................

8410.1.4 System messages .................................................................................................

8410.1.4.1 Status messages ...............................................................................

8510.1.4.2 Warning messages ...........................................................................

8610.2 Menu system ........................................................................................................................

8610.2.1 Navigating in the menu system ............................................................................

8710.2.2 File menu ..............................................................................................................

8710.2.2.1 Images ...............................................................................................

8810.2.2.2 Save ...................................................................................................

8910.2.2.3 Copy to card ......................................................................................

8910.2.2.4 Periodic save .....................................................................................

8910.2.2.5 Burst recording ..................................................................................

9110.2.2.6 Voice comment .................................................................................

9210.2.2.7 Text comment ....................................................................................

9710.2.2.8 Image description .............................................................................

9810.2.3 Analysis menu .......................................................................................................

9810.2.3.1 Edit mode ..........................................................................................

9810.2.3.2 Add spot ............................................................................................

10010.2.3.3 Add box .............................................................................................

10210.2.3.4 Add circle ..........................................................................................

10410.2.3.5 Add line .............................................................................................

10710.2.3.6 Add isotherm .....................................................................................

10910.2.3.7 Add diff ..............................................................................................

10910.2.3.8 Ref temp ............................................................................................

10910.2.3.9 Remove all .........................................................................................

11010.2.3.10 Obj par ...............................................................................................

11010.2.3.11 Deactivate local par. ..........................................................................

11110.2.4 Image menu ..........................................................................................................

11110.2.4.1 Visual/IR .............................................................................................

11110.2.4.2 Freeze/Live ........................................................................................

11110.2.4.3 Range ................................................................................................

11110.2.4.4 Level/Span .........................................................................................

11210.2.4.5 Manual adjust / Continuous adjust ...................................................

11210.2.4.6 Palette ................................................................................................

11210.2.4.7 Hide graphics ....................................................................................

11210.2.4.8 Add visual marker .............................................................................

11310.2.5 Setup menu ...........................................................................................................

11310.2.5.1 Image .................................................................................................

11610.2.5.2 Difference ..........................................................................................

11710.2.5.3 Save ...................................................................................................

11910.2.5.4 Alarm .................................................................................................

12010.2.5.5 Digital video .......................................................................................

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 xiii

Page 8

12010.2.5.6 Bluetooth® ........................................................................................

12110.2.5.7 Power .................................................................................................

12210.2.5.8 Status bar ..........................................................................................

12310.2.5.9 Buttons ..............................................................................................

12410.2.5.10 Date/time ...........................................................................................

12410.2.5.11 Local settings ....................................................................................

12510.2.5.12 Camera info .......................................................................................

12510.2.5.13 Profile .................................................................................................

12510.2.5.14 Factory default ...................................................................................

12711 Folder and file structure ...............................................................................................................

12912 Electrical power system .................................................................................................................

13012.1 Internal battery charging ......................................................................................................

13112.2 External battery charging .....................................................................................................

13212.3 Battery safety warnings ........................................................................................................

13513 A note on LEMO connectors .........................................................................................................

13513.1 How to connect & disconnect LEMO connectors ................................................................

13714 Maintenance & cleaning ................................................................................................................

13714.1 Camera body, cables & accessories ....................................................................................

13714.2 Lenses ...................................................................................................................................

13915 Troubleshooting ..............................................................................................................................

14116 Technical specifications & dimensional drawings ......................................................................

14116.1 Imaging performance ...........................................................................................................

14116.2 Detector ................................................................................................................................

14116.3 Image presentation ...............................................................................................................

14116.4 Temperature ranges .............................................................................................................

14216.5 Correction parameters ..........................................................................................................

14216.6 Laser LocatIR ........................................................................................................................

14216.7 Electrical power system ........................................................................................................

14216.8 Environmental specifications ...............................................................................................

14316.9 Physical specifications .........................................................................................................

14316.10 Interfaces & connectors .......................................................................................................

14416.11 Pin configurations .................................................................................................................

14416.11.1 RS-232/USB connector ........................................................................................

14516.11.2 Remote control connector ....................................................................................

14616.11.3 Power connector ...................................................................................................

14616.11.4 CVBS connector ...................................................................................................

14616.11.5 FireWire connector ...............................................................................................

14816.12 Relationship between fields of view and distance ...............................................................

16316.13 Basic dimensions – battery charger .....................................................................................

16416.14 Basic dimensions – battery ..................................................................................................

16516.15 Basic dimensions – remote control ......................................................................................

16616.16 Basic dimensions – camera .................................................................................................

16716.17 Basic dimensions – camera .................................................................................................

16816.18 Basic dimensions – camera .................................................................................................

16916.19 Basic dimensions – video lamp ............................................................................................

17117 Glossary ...........................................................................................................................................

17518 Thermographic measurement techniques ...................................................................................

xiv Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 9

17518.1 Introduction ..........................................................................................................................

17518.2 Emissivity ..............................................................................................................................

17618.2.1 Finding the emissivity of a sample .......................................................................

17618.2.1.1 Step 1: Determining reflected apparent temperature .......................

17818.2.1.2 Step 2: Determining the emissivity ...................................................

17918.3 Reflected apparent temperature ..........................................................................................

17918.4 Distance ................................................................................................................................

17918.5 Relative humidity ..................................................................................................................

17918.6 Other parameters ..................................................................................................................

18119 History of infrared technology ......................................................................................................

18520 Theory of thermography ................................................................................................................

18520.1 Introduction ...........................................................................................................................

18520.2 The electromagnetic spectrum ............................................................................................

18620.3 Blackbody radiation ..............................................................................................................

18720.3.1 Planck’s law ..........................................................................................................

18820.3.2 Wien’s displacement law ......................................................................................

19020.3.3 Stefan-Boltzmann's law .........................................................................................

19020.3.4 Non-blackbody emitters .......................................................................................

19320.4 Infrared semi-transparent materials .....................................................................................

19521 The measurement formula .............................................................................................................

20122 Emissivity tables .............................................................................................................................

20122.1 References ............................................................................................................................

20122.2 Important note about the emissivity tables ..........................................................................

20122.3 Tables ....................................................................................................................................

217Index ................................................................................................................................................

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 xv

Page 10

xvi Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 11

1 Warnings & cautions

10474103;a1

■ This equipment generates, uses, and can radiate radio frequency energy and if

not installed and used in accordance with the instruction manual, may cause interference to radio communications. It has been tested and found to comply with the

limits for a Class A computing device pursuant to Subpart J of Part 15of FCC Rules,

which are designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference in which case the user at his own

expense will be required to take whatever measures may be required to correct

the interference.

■ An infrared camera is a precision instrument and uses a very sensitive IR detector.

Pointing the camera towards highly intensive energy sources – such as devices

emitting laser radiation, or reflections from such devices – may affect the accuracy

of the camera readings, or even harm – or irreparably damage – the detector. Note

that this sensitivity is also present when the camera is switched off and the lens

cap is mounted on the lens.

■ Each camera from FLIR Systems is calibrated prior to shipping. It is advisable that

the camera is sent in for calibration once a year.

■ For protective reasons, the LCD (where applicable) will be switched off if the detector

temperature exceeds +60 °C (+149 °F) and the camera will be switched off if the

detector temperature exceeds +68 °C (+154.4 °F).

■ The camera requires a warm-up time of 5 minutes before accurate measurements

(where applicable) can be expected.

■ In certain outdoor conditions, the sun can enter the eyepiece and cause damage

to the LCD. Use an eyepiece protector when you expect to be using the camera

for extended periods of time in outdoor sunlit environments.

■ Changes or modifications not expressly approvedby FLIR Systemsvoids the user’s

authority to operate the equipment.

■ Note regarding Bluetooth® option MA9C: This equipment has been tested and

found to comply with the limits for a Class B digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonableprotection against

1

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 1

Page 12

1 – Warnings & cautions

1

harmful interference in a residential installation.This equipment generates, uses

and can radiate radio frequencyenergy and, ifnot installed andused in accordance

with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna

□

Increase the separation between the equipment and receiver

□

Connect the equipment into an outlet on a circuit different from that to which the

□

receiver is connected

Consult the dealer or an experienced radio/TV technician for help

□

Containing FCC ID: RZQ1195256.

2 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 13

2 Important note about this manual

As far as it is practically possible, FLIR Systems configures each manual to reflect

each customer’s particular camera configuration. However, please note the following

exceptions:

■ The packing list is subject to specific customerconfiguration and maycontain more

or less items

■ FLIR Systems reserves theright to discontinue models,parts and accessories, and

other items, or change specifications at any time without prior notice

■ In some cases, the manual may describe features that are not available in your

particular camera configuration

■ Depending on your camera configuration, Bluetooth® may be an extra option.

2

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 3

Page 14

2 – Important note about this manual

2

INTENTIONALLY LEFT BLANK

4 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 15

3 Welcome!

Thank you for choosing the ThermaCAM™ P65 HS infrared camera.

The ThermaCAM™P65 HS infrared condition monitoring system consistsof an infrared

camera with a built-in 36 mm lens, a visual color camera, a laser pointer, an IrDA (infrared communications link), a 4" color LCD on a removable remote control, and a

range ofaccessories. The infrared camerameasures and images the emitted infrared

radiation from an object. The fact that radiation is a function of object surface temperature makes it possible for the camera to calculate and show this temperature.

The ThermaCAM™ P65 HS camera is dust- and splash-proof and tested for shock

and vibration for use in the most demanding field conditions. It is a handheld, truly

portable camera, which is lightweight and operates for more than two hours on one

battery pack. A high-resolution color image (infrared & visual) is provided in real-time

either in the integral viewfinder or on the remote control LCD.

The camera is very easy to use and is operated by using a few buttons which are

conveniently placed on the camera, allowing fingertip control of major functions. A

built-in menu system also gives easy access to the advanced, simple-to-use camera

software for increased functionality.

To document the object under inspection it is possible to capture and store images

on aremovable CompactFlash card or in the camera's internal flash memory. It is also

possible to store, together with every image, voice comments by using the headset

connected tothe camera, ortext comments, byselecting these from a file with predefined text comments. The images can be analyzed either in the field by using the realtime measurement markers built into the camera software, or in a PC by using FLIR

Systems's software for infrared analysis and reporting.

3

The ThermaCAM™ P65 HS also features recording of infrared images at a very high

speed, using FireWire.

In the PC, the images can not only be viewed and analyzed, but the voice comments

can also be played back. FLIR Systems’s software makes it very easy to create

complete survey reports (containing numerous infrared images, photos, tables etc.)

from the inspections.

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 5

Page 16

3 – Welcome!

3.1 About FLIR Systems

With over 40 years experience in IR systems and applications development, and over

30 000 infrared cameras in use worldwide, FLIR Systems is the undisputed global

commercial IR industry leader.

10380703;a2

3

Figure 3.1 FLIR Systems, Boston, USA, FLIR Systems, Danderyd, Sweden, and FLIR Systems, Portland,

USA.

10570303;a2

Figure 3.2 Indigo Operations,Niceville, USA, and Indigo Operations,Santa Barbara,USA. Indigo Operations

is a division of FLIR Systems.

As pioneers in the IR industry, FLIR Systems has a long list of ‘firsts’ the world of infrared thermography:

■ 1965: 1st thermal imaging system for predictive maintenance (Model 650).

■ 1973: 1st battery-operated portable IR scanner for industrial applicationspredictive

maintenance (Model 750).

■ 1975: 1st TV compatible system (Model 525).

■ 1978: 1st dual-wavelength scanning system capable of real-time analog recording

of thermal events (Model 780). Instrumental in R & D market development.

■ 1983: 1st thermal imaging and measurement system with on-screen temperature

measurement.

■ 1986: 1st TE (thermo-electrically) cooled system.

■ 1989: 1st single-piece infrared camera system for PM (predictive maintenance)

and R & D (research & development) with on-board digital storage.

■ 1991: 1st Windows-based thermographic analysis and reporting system.

■ 1993: 1st Focal Plane Array (FPA) system for PM and R & D applications.

■ 1995: 1st full-featured camcorder style FPA infrared system (ThermaCAM).

■ 1997: 1st: uncooled microbolometer-based PM/R & D system.

6 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 17

3 – Welcome!

■ 2000: 1st thermography system with both thermal and visual imaging.

■ 2000: 1st thermography system to incorporate thermal/visual/voice and text data

logging.

■ 2002: 1st automated thermography system (model P60) to feature detachable re-

motely controllable LCD, JPEG image storage, enhanced connectivity including

USB and IrDA wireless, thermal/visual/voice and text data logging.

■ 2002: 1st low-cost ultra-compact hand-held thermography camera (E series).

Revolutionary, ergonomic design, lightest IR measurement camera available.

■ 2003: 1st low-cost, ultra-compact infrared camera for fixed installation intended for

automation and security applications. Exceptionally user-friendly due to standard

interfaces and extensive built-in functionality.

■ 2004: 1st camera models specially designed for building thermography (B1, B2

and B20)

10401603;a3

3

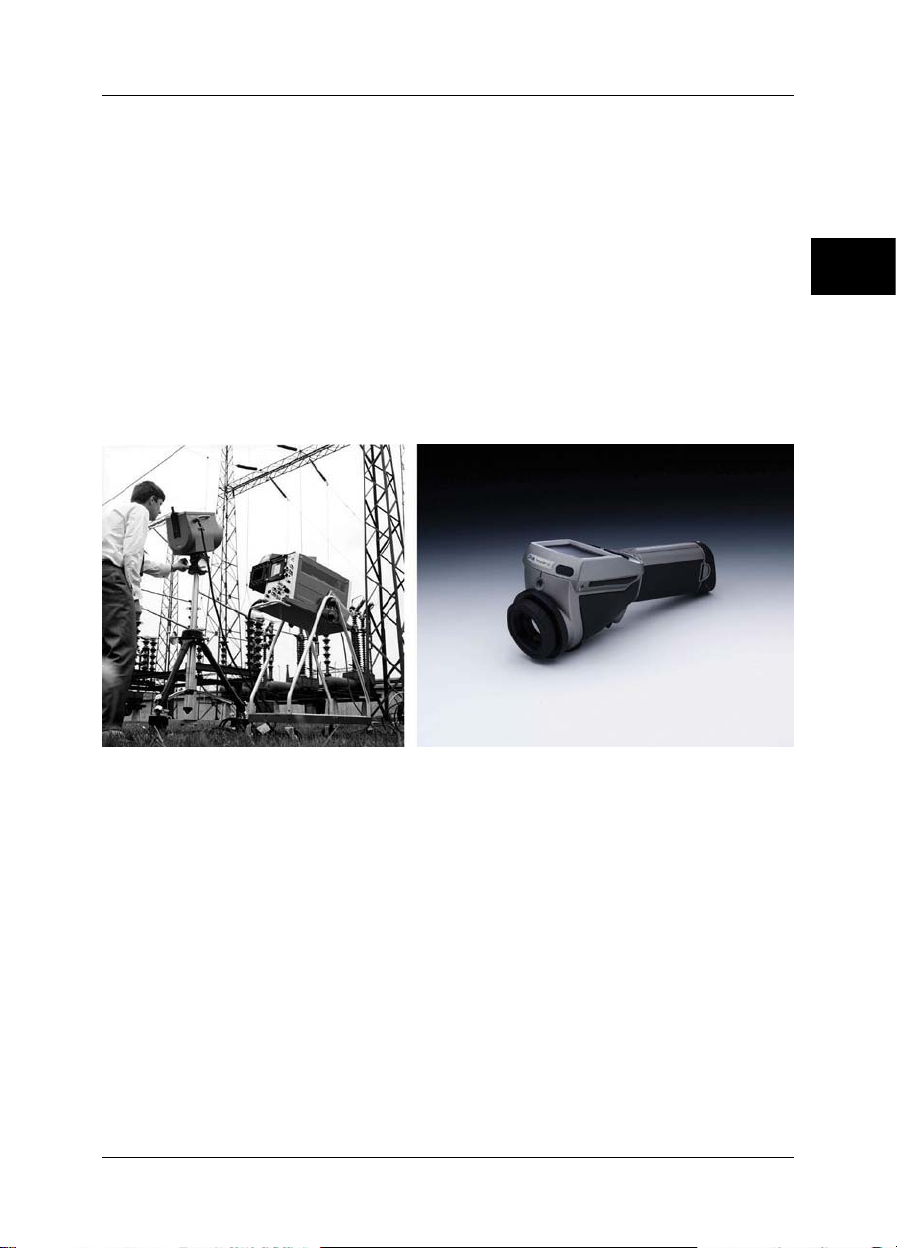

Figure 3.3 LEFT: FLIR Systems Thermovision® Model 661. The photo is taken on May 30th, 1969 at the

distribution plant near Beckomberga, in Stockholm, Sweden. The camera weighed approx. 25 kg (55 lb),

the oscilloscope 20 kg (44 lb), the tripod 15 kg (33 lb). The operator also needed a 220 VAC generator

set, and a 10 L (2.6 US gallon)jar with liquidnitrogen. To the left of the oscilloscope thePolaroid attachment

(6 kg/13 lb) can be seen. RIGHT: FLIR Systems ThermaCAM Model E2 from 2002 – weight: 0.7 kg (1.54

lb), including battery.

With this tradition of unparalleled technical excellence and innovative achievements,

FLIR Systems continues to develop new infrared products, educational venues and

applications expertise to meet the diverse demands of thermographers worldwide.

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 7

Page 18

3 – Welcome!

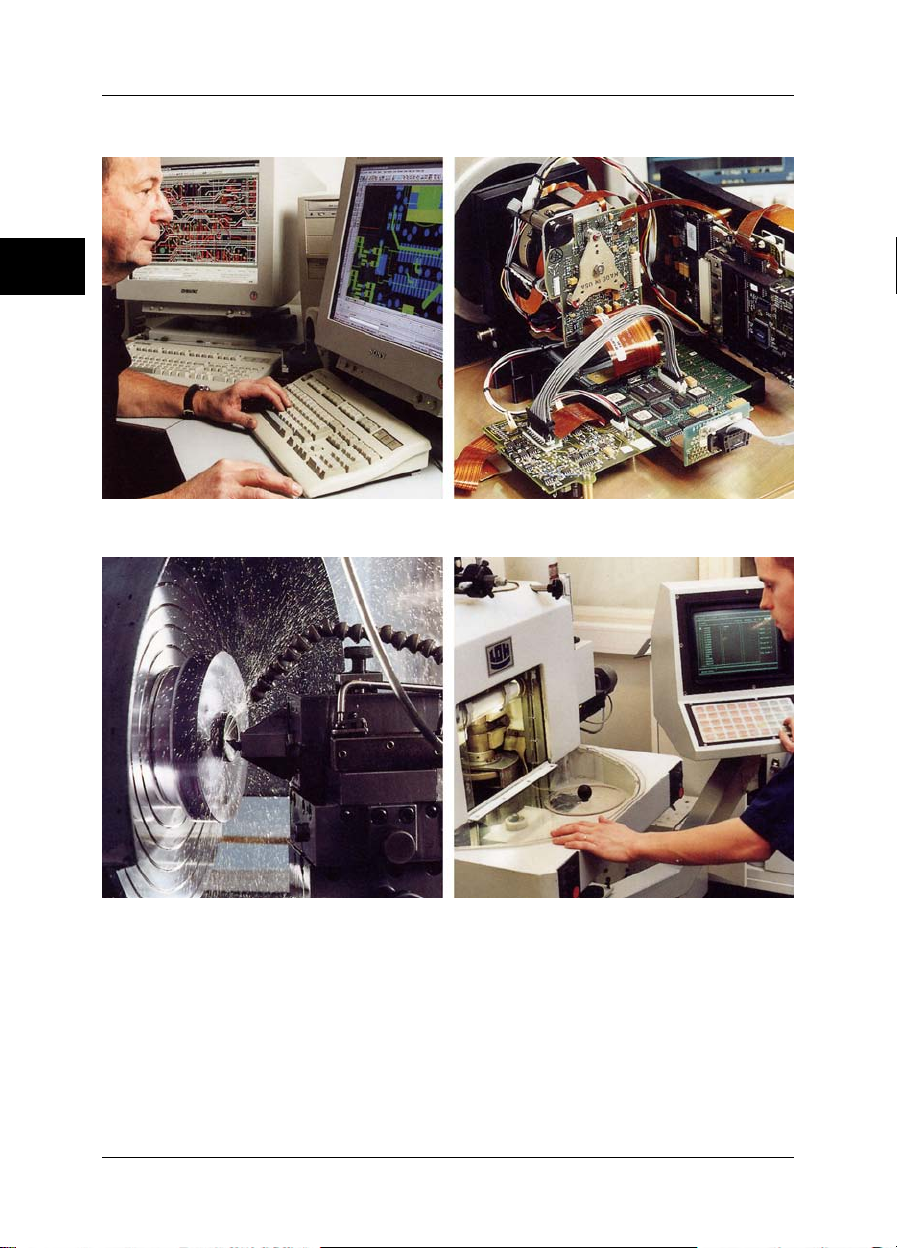

3.1.1 A few images from our facilities

10401303;a1

3

Figure 3.4 LEFT: Development of system electronics; RIGHT: Testing of an FPA detector

10401403;a1

Figure 3.5 LEFT: Diamond turning machine; RIGHT: Lens polishing

8 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 19

3 – Welcome!

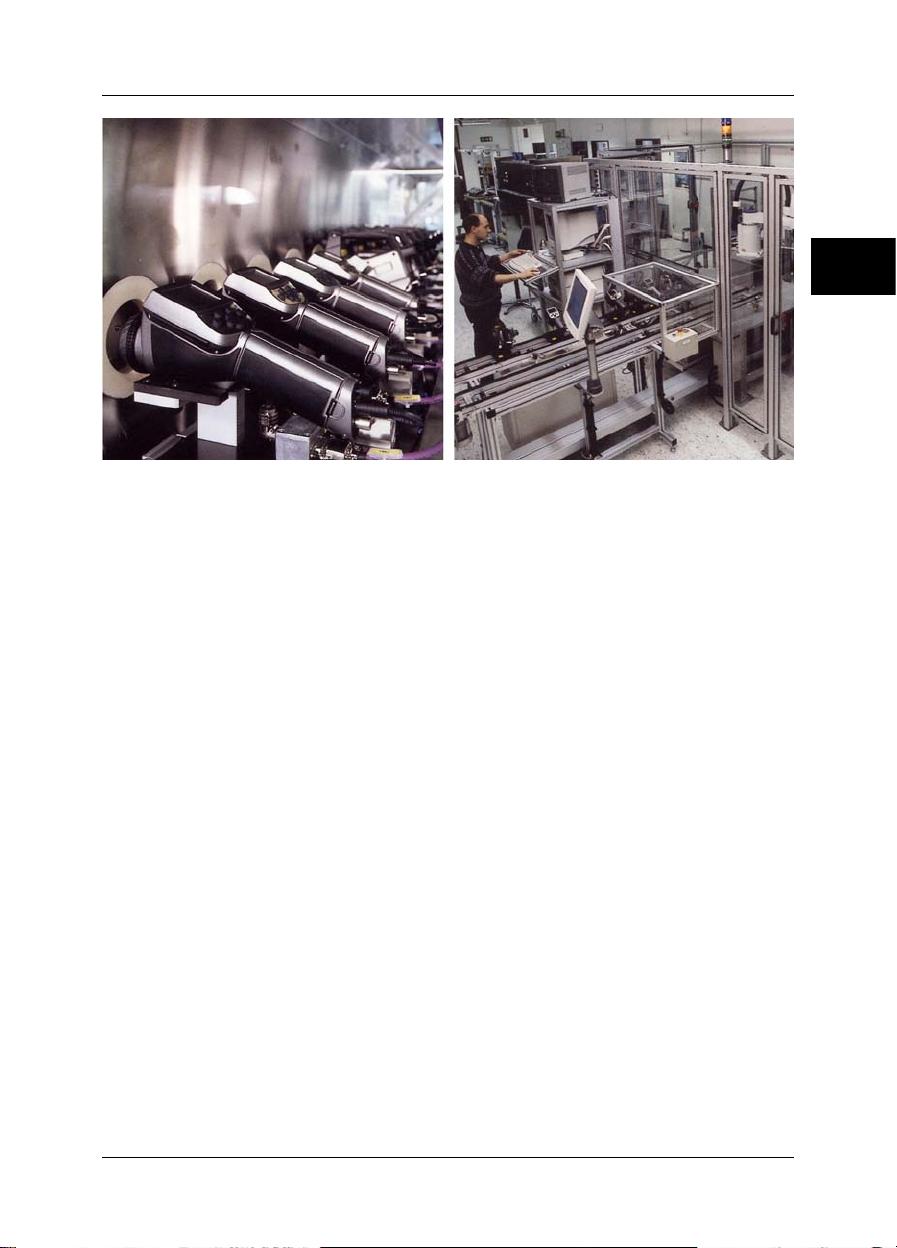

10401503;a1

Figure 3.6 LEFT: Testing of IR cameras in the climatic chamber; RIGHT: Robot for camera testing and

calibration

3

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 9

Page 20

3 – Welcome!

3.2 Comments & questions

FLIR Systems is committed to a policy of continuous development, and although we

have tested and verified the information in this manual to the best of our ability, you

may find that features and specifications have changed since the time of printing.

Please let us know about any errors you find, as well as your suggestions for future

editions, by sending an e-mail to:

3

documentation@flir.se

➲ Do not use this e-mail address for technical support questions. Technical support

is handled by FLIR Systems local sales offices.

10 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 21

4 Packing list

The ThermaCAM™ P65 HS and its accessories are delivered in a hard transport case

which typically contains the items below. On receipt of the transport case, inspect all

items andcheck them againstthe delivery note. Any damaged itemsmust be reported

to the local FLIR Systems representative immediately.

QtyPart numberDescription

11 195 3464" LCD/remote control

11 909 820Adapter for CompactFlash card

21 195 268Battery

11 195 267Battery charger

11 910 017CompactFlash card

11 909 775CVBS video cable

11 909 813FireWire cable 4/4

11 909 812FireWire cable 4/6

4

Headset withBluetooth® wireless technology

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 11

1 910 218

■

1 910 219

■

1 910 213

■

1One of the following part numbers:

11 195 317Lens cap for camera body

11558240Operator’s manual

11 909 528Power supply

1117 132Shoulder strap

1Configuration-dependentThermaCAM™ P65 HS

11 195 314USB cable

11 195 994Video lamp

Page 22

4 – Packing list

4

INTENTIONALLY LEFT BLANK

12 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 23

5 System overview

This system overview shows all accessories that are possible to order for a ThermaCAM™ P65 HS.

10570903;a3

5

Figure 5.1 System overview

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 13

Page 24

5 – System overview

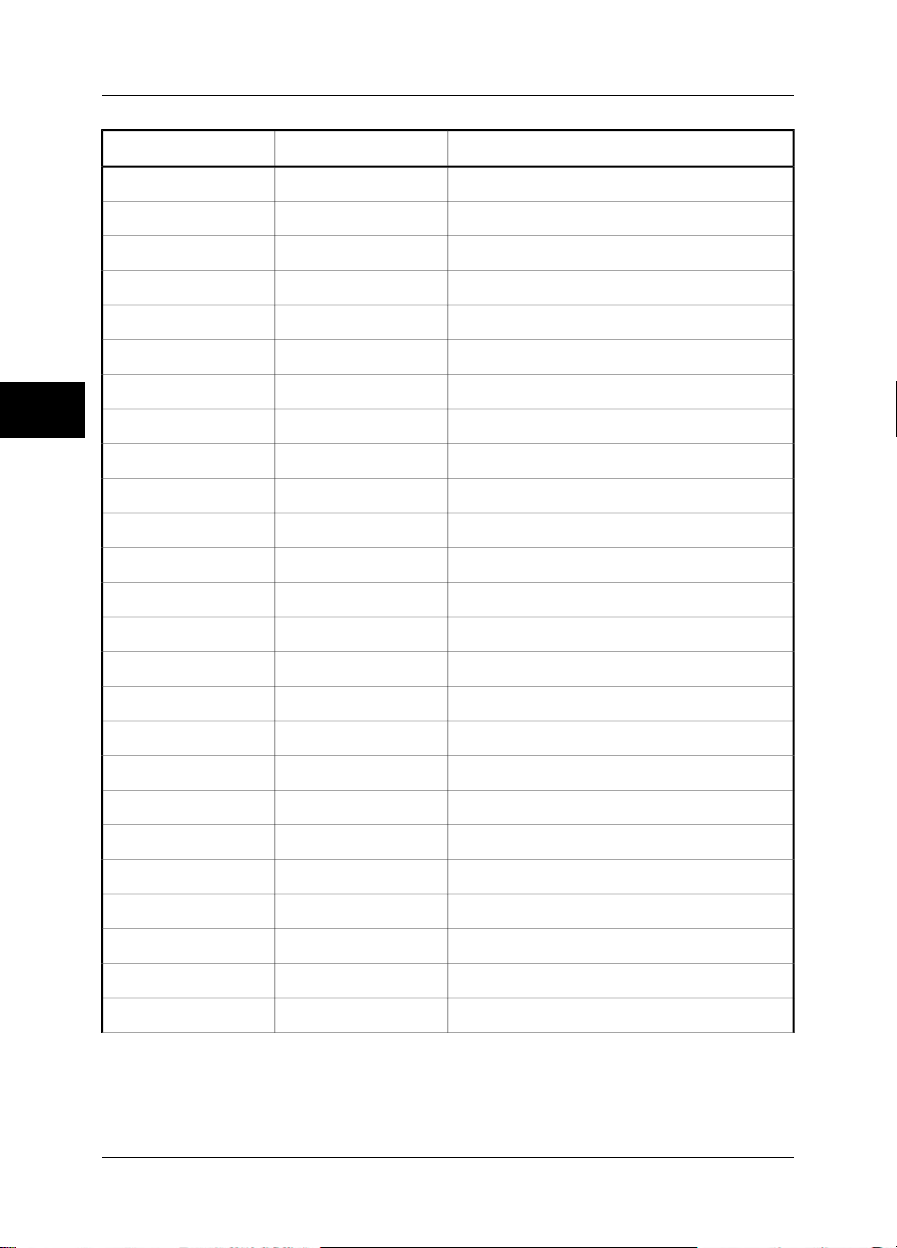

Figure 5.2 Explanations of callouts

5

Description of partPart No.Callout

Protective plastic window194 5601

Protective window1 194 9772

124 mm IR lens194 5793

72 mm IR lens194 1764

18 mm IR lens194 4015

9.0 mm IR lens194 7026

64/150 close-up IR lens194 5337

34/80 close-up IR lens1 194 9788

50 μm IR lens1 700 5009

Battery1 195 26810

2-bay battery charger1 195 26711

External power supply1 909 52812

Automotive (cigarette lighter) 12 VDC adapter1 195 14313

Shoulder strap117 13214

Adapter for CompactFlash™ card1 909 82015

CompactFlash™ card1 909 65316

Protective cap for RS-232/USB connector1 910 23317

■

USB cable1 195 31419

RS-232 cable1 195 31320

CVBS cable (composite video cable)1 909 77522

FireWire cable 4/41 909 81224

FireWire cable 4/61 909 81325

Remote control1 195 34626

Video lamp1 195 99427

IrDA infrared communication link28

14 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 25

5 – System overview

Description of partPart No.Callout

29

One of the following

part numbers:

1 910 218

■

1 910 219

■

1 910 213

■

Headset with Bluetooth® wireless technology

➲ Depending on your camera configuration, this

feature may be an extra option.

5

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 15

Page 26

5 – System overview

5

INTENTIONALLY LEFT BLANK

16 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 27

6 Connecting system components

6.1 Front connectors

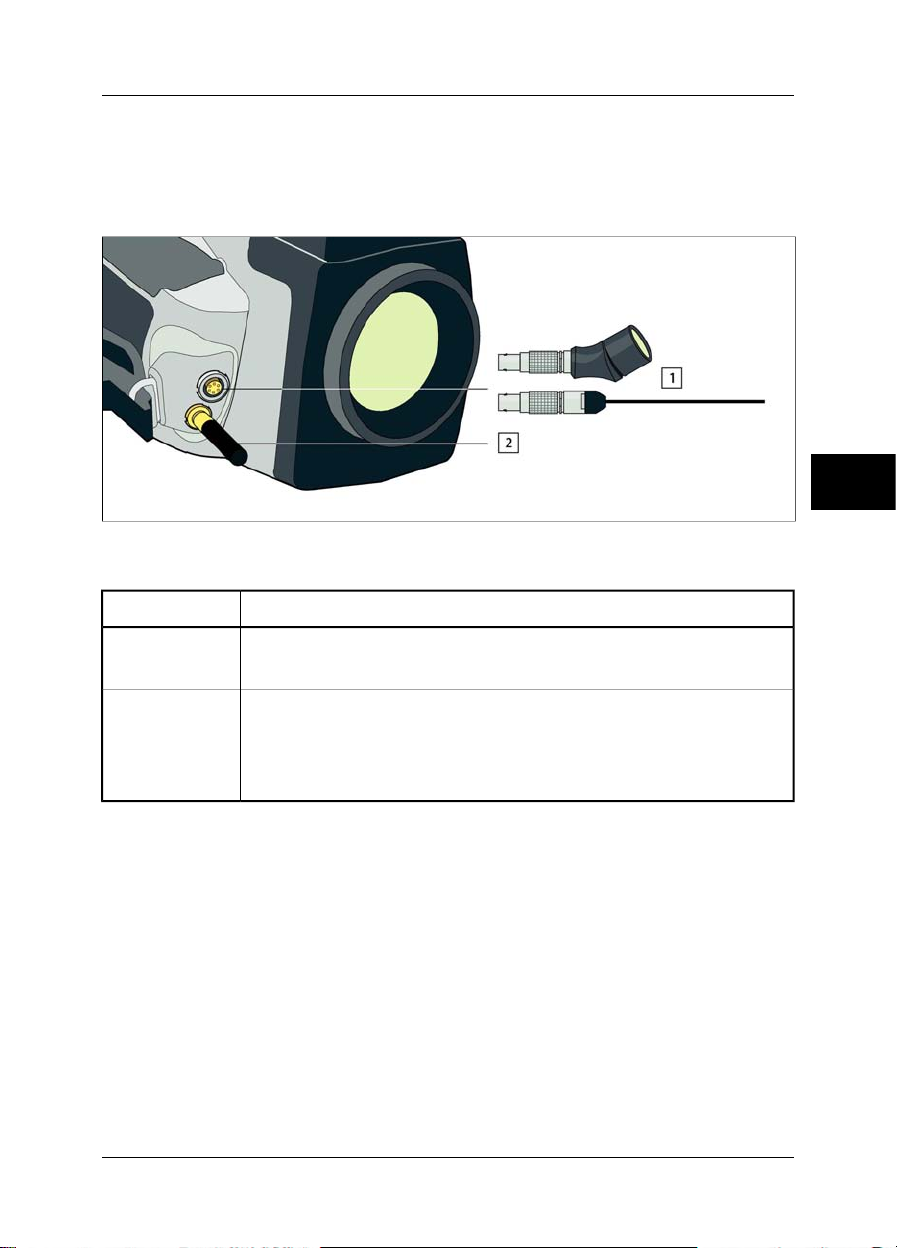

10569403;a2

Figure 6.1 How to connect system components: Front connectors

Figure 6.2 Explanations of callouts

ExplanationCallout

6

1

2

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 17

USB or RS-232 cable.

The connector on the camera is also used as a connector for the video lamp.

Bluetooth® antenna

For information about connecting a headset featuring Bluetooth® wireless tech-

nology, see section 10.2.5.6 – Bluetooth® on page 120.

➲ Depending on your camera configuration, this feature may be an extra option.

Page 28

6 – Connecting system components

6.2 Rear connectors

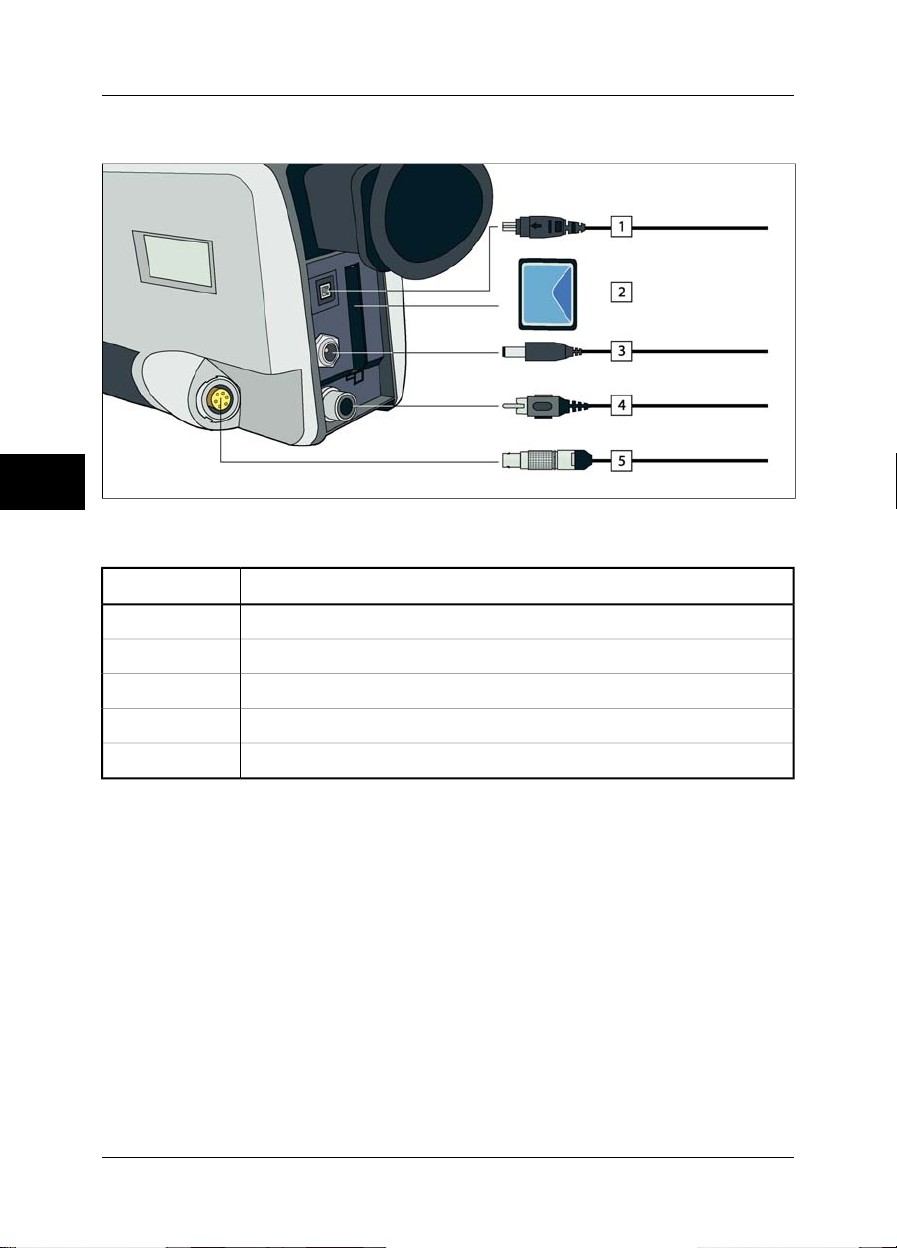

10438603;a2

6

Figure 6.3 How to connect system components: Rear connectors

Figure 6.4 Explanations of callouts

ExplanationCallout

FireWire cable1

CompactFlash card1

Power supply cable2

CVBS cable (i.e. composite video)3

Remote control cable4

18 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 29

6 – Connecting system components

6.3 Finding the IP address for cameras connected via FireWire: Method 1

ActionStep

On the camera, look for the serial number and write it down.1

2

The address for the camera is ircamXXXXX, where XXXXX are the five last figures

in the serial number.

6

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 19

Page 30

6 – Connecting system components

6.4 Finding the IP address for cameras connected via FireWire: Method 2

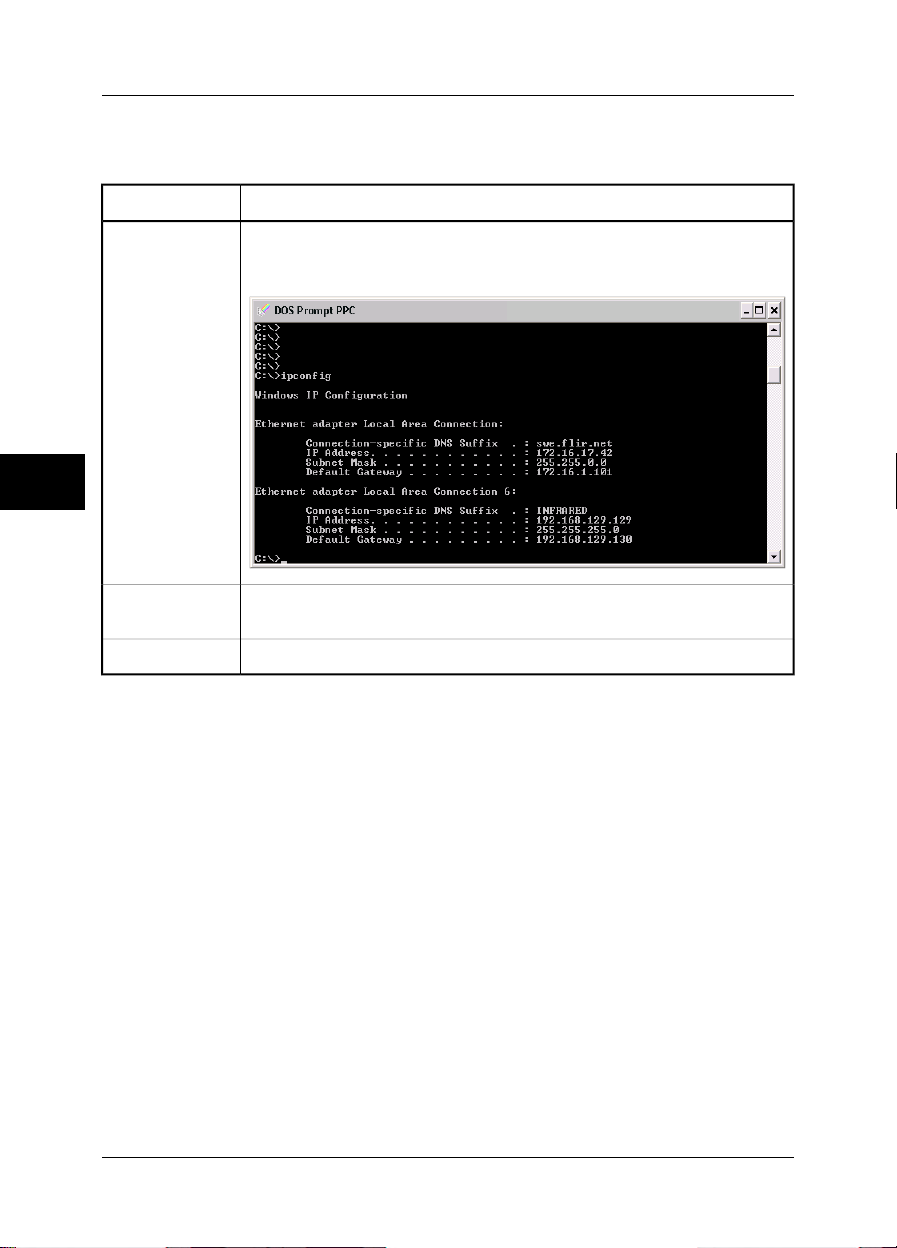

ActionStep

1

In the command window, type ipconfig.

This will typicallydisplay two networks – the camera network and the PC network:

10415703;a1

6

2

Look for the Default Gateway number for Connection specific DNS suffix: INFRARED and write it down.

The address for the camera is this number.3

20 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 31

7 Introduction to thermographic

inspections of electrical

installations

7.1 Important note

All camera functions and features that are described in this section may not be supported by your particular camera configuration.

Electrical regulations differ from country to country. For that reason, the electrical

procedures described in this section may not be the standard of procedure in your

particular country. Also, in manycountries carrying out electrical inspections requires

formal qualification. Always consult national or regional electrical regulations.

7.2 General information

7.2.1 Introduction

Today, thermography is a well-established technique for the inspection of electrical

installations. This was the first and still is the largest. the largest application of thermography. The infrared camera itself has gone through an explosive development

and we can say that today, the 8th generation of thermographic systems is available.

It all began in 1964, more than 40 years ago. The technique is now established

throughout the whole world. Industrialized countries as well as developing countries

have adopted this technique.

Thermography, in conjunction with vibration analysis, has over the latest decades

been the main method for fault diagnostics in the industry as a part of the preventive

maintenance program. The great advantage with these methods is that it is not only

possible to carry out the inspection on installations in operation; normal working

condition is in fact a prerequisite for a correct measurement result, so the ongoing

production processis not disturbed.Thermographic inspection of electrical installations

are used in three main areas:

■ Power generation

■ Power transmission

■ Power distribution, that is, industrial use of electrical energy.

The fact that these controls are carried out under normal operation conditions has

created a natural division between these groups. The power generation companies

measure during the periods of high load. These periods vary from country to country

7

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 21

Page 32

7 – Introduction to thermographic inspections of electrical installations

and for the climatic zones. The measurement periods may also differ depending on

the type of plant to be inspected, whether they are hydroelectric, nuclear, coal-based

or oil-based plants.

In the industry the inspections are—at least in Nordic countries with clear seasonal

differences—carried out during spring or autumn or before longer stops in the operation. Thus, repairs are made when the operation is stopped anyway. However, this

seems to be the rule less and less, which has led to inspections of the plants under

varying load and operating conditions.

7.2.2 General equipment data

The equipment to be inspected has a certain temperature behavior that should be

known to the thermographer beforethe inspection takesplace. In thecase of electrical

equipment, the physical principle of why faults show a different temperature pattern

because of increased resistance or increased electrical current is well known.

However, it is useful to remember that, in some cases, for example solenoids, ‘overheating’ is natural and does not correspond to a developing defect. In other cases,

like the connections in electrical motors, the overheating might depend on the fact

7

that the healthy part is taking the entire load and therefore becomes overheated. A

similar example is shown in section 7.5.7 – Overheating in one part as a result of a

fault in another on page 37.

Defective parts of electrical equipment can therefore both indicate overheating and

be cooler than the normal ‘healthy’ components. It is necessary to be aware of what

to expect by getting as much information as possible about the equipment before it

is inspected.

The general rule is, however, that a hot spot is caused by a probable defect. The

temperature and the load of that specific component at the moment of inspection will

give an indication of how serious the fault is and can become in other conditions.

Correct assessment in each specific case demands detailed information about the

thermal behavior of the components, that is, we need to know the maximum allowed

temperature of the materials involvedand the role the component plays in the system.

Cable insulations, for example, lose their insulation properties above a certain temperature, which increases the risk of fire.

In the case of breakers, where the temperature is too high, parts can melt and make

it impossible to open the breaker, thereby destroying its functionality.

22 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 33

7 – Introduction to thermographic inspections of electrical installations

The more the IR camera operator knows about the equipment that he or she is about

to inspect, the higher the quality of the inspection. But it is virtually impossible for an

IR thermographerto have detailedknowledge about all the different types of equipment

that can be controlled. It is therefore common practice that a person responsible for

the equipment is present during the inspection.

7.2.3 Inspection

The preparationof the inspection should include the choiceof the right type of report.

It isoften necessary touse complementary equipment such as ampere meters in order

to measure the current in the circuits where defects were found. An anemometer is

necessary if you want to measure the wind speed at inspectionof outdoor equipment.

Automatic functions help the IR operator to visualize an IR image of the components

with the right contrast to allow easy identification of a fault or a hot spot. It is almost

impossible to miss a hot spot on a scanned component. A measurement function will

also automatically display the hottest spot within an area in the image or the difference

between the maximum temperature in the chosen area and a reference, which can

be chosen by the operator, for example the ambient temperature.

10712703;a3

7

Figure 7.1 An infrared and a visual image of a power line isolator

When the fault is clearly identified and the IR thermographer has made sure that it is

not a reflection or a naturally occurring hot spot, the collection of the data starts, which

will allow the correct reporting of the fault. The emissivity, the identification of the

component, and the actual working conditions, together with the measured temperature, will be used in the report. In order to make it easy to identify the component a

visual photo of the defect is often taken.

7.2.4 Classification & reporting

Reporting has traditionally been the most time-consuming part of the IR survey. A

one-day inspection could result in one or two days’ work to report and classify the

found defects. This is still the case for many thermographers, who have chosen not

to use the advantages that computers and modern reporting software have brought

to IR condition monitoring.

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 23

Page 34

7 – Introduction to thermographic inspections of electrical installations

The classification of the defects gives a more detailed meaning that not only takes

into account the situation at the time of inspection (which is certainly of great importance), but also the possibility to normalize the over-temperature to standard load

and ambient temperature conditions.

An over-temperature of +30°C (+86°F) is certainly a significant fault. But if that overtemperature is valid for one component working at 100% load and for another at 50%

load, it is obvious that the latter will reach a much higher temperature should its load

increase from 50% to 100%. Such a standard can be chosen by the plant’s circumstances. Very often, however, temperatures are predicted for 100% load. A standard

makes it easier to compare the faults over time and thus to make a more complete

classification.

7.2.5 Priority

Based on the classification ofthe defects, themaintenance manager givesthe defects

a repair priority. Very often, the information gathered during the infrared survey is put

together withcomplementary information on the equipment collectedby other means

such as vibration monitoring, ultrasound or the preventive maintenance scheduled.

7

Even if the IR inspection is quickly becoming the most used method of collecting information about electrical components safely with the equipment under normal operating conditions, there are many other sources of information the maintenance or the

production manager has to consider.

The priority of repair should therefore not be a task for the IR camera operator in the

normal case. If a critical situation is detected during the inspection or during the

classification of the defects, the attention of the maintenance manager should of

course be drawn to it, but the responsibility for determining the urgency of the repair

should be his.

7.2.6 Repair

To repair the known defects is the most important function of preventive maintenance.

However, to assure production at the right time or at the right cost can also be important goals for a maintenance group. The information provided by the infrared survey

can be used to improve the repair efficiency as well as to reach the other goals with

a calculated risk.

To monitor the temperature of a known defect that can not be repaired immediately

for instance because spare parts are not available, can often pay for the cost of inspection a thousandfold and sometimes even for the IR camera. To decide not to

repair knowndefects to save on maintenance costsand avoid unnecessary downtime

is also another way of using the information from the IR survey in a productive way.

24 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 35

7 – Introduction to thermographic inspections of electrical installations

However, themost common resultof the identificationand classification of the detected

faults is a recommendation to repair immediately or as soon as it is practically possible.

It is important that the repair crew is aware of the physical principles for the identification of defects. If a defect shows a high temperature and is in a critical situation, it is

very common that the repair personnel expect to find a highly corroded component.

It should also come as no surprise to the repair crew that a connection, which is

usually healthy, can give the same high temperatures as a corroded one if it has come

loose. These misinterpretations are quite common and risk putting in doubt the reliability of the infrared survey.

7.2.7 Control

A repaired component should be controlled as soon as possible after the repair. It is

not efficient to wait for the next scheduled IR survey in order to combine a new inspection with the control of the repaired defects. The statistics on the effect of the repair

show that up to a third of the repaired defects still show overheating. That is the same

as saying that those defects present a potential risk of failure.

To wait until the next scheduled IR survey represents an unnecessary risk for the

plant.

Besides increasing the efficiency of the maintenance cycle (measured in terms of

lower risk for the plant) the immediate control of the repair work brings other advantages to the performance of the repair crew itself.

7

When a defect still shows overheating after the repair, the determination of the cause

of overheating improves the repair procedure, helps choose the best component

suppliers and detect design shortcomings on the electrical installation. The crew

rapidly sees the effect of the work and can learn quickly both from successful repairs

and from mistakes.

Another reason to provide the repair crew with an IR instrument is that many of the

defects detected during the IR survey are of low gravity. Instead of repairing them,

which consumes maintenance and production time, it can be decided to keep these

defects under control. Therefore the maintenance personnel should have access to

their own IR equipment.

It is common to note on the report form the type of fault observed during the repair

as well as the action taken. These observations make an important source of experience that can be used to reduce stock, choose the best suppliers or to train new

maintenance personnel.

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 25

Page 36

7 – Introduction to thermographic inspections of electrical installations

7.3 Measurement technique for thermographic inspection of electrical installations

7.3.1 How to correctly set the equipment

A thermal image may show high temperature variations:

10712803;a4

Figure 7.2 Temperature variations in a fusebox

In the images above, the fuse to the right has a maximum temperature of +61°C

(+142°F), whereas the one to the left is maximum +32°C (+90°F) and the one in the

middle somewhere in between. The three images are different inasmuch as the temperature scale enhances only one fuse in each image. However, it is the same image

and all the information about all three fuses is there. It is only a matter of setting the

7

temperature scale values.

7.3.2 Temperature measurement

Some cameras today can automatically find the highest temperature in the image.

The image below shows how it looks to the operator.

10712903;a3

Figure 7.3 An infrared image of a fusebox where the maximum temperature is displayed

The maximum temperature in the area is +62.2°C (+144.0°F). The spot meter shows

the exact location of the hot spot. The image can easily be stored in the camera

memory.

The correct temperature measurement depends, however, not only on the function

of the evaluation software or the camera. It may happen that the actual fault is, for

example, a connection, which is hidden from the camera in the position it happens

26 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 37

7 – Introduction to thermographic inspections of electrical installations

to be in for the moment. It might be so that you measure heat, which has been conducted oversome distance, whereasthe ‘real’ hot spot is hiddenfrom you. Anexample

is shown in the image below.

10717603;a3

Figure 7.4 A hidden hot spot inside a box

Try to choose different angles and make sure that the hot area is seen in its full size,

that is, that it is not disappearing behind something that might hide the hottest spot.

In this image, the hottest spot of what the camera can ‘see’, is +83°C (+181°F), where

the operating temperature on the cables below the box is +60°C (+140°F). However,

the real hot spot is most probably hidden inside the box, see the in yellow encircled

area. This fault is reported as a +23.0°C (+41.4°F) excess temperature, but the real

problem is probably essentially hotter.

7

Another reason for underestimating the temperature of an object is bad focusing. It

is very important that the hot spot found is in focus. See the example below.

10717403;a2

Figure 7.5 LEFT: A hot spot in focus; RIGHT: A hot spot out of focus

In the left image, the lamp is in focus. Its average temperature is +64°C (+147°F). In

the right image, the lamp is out of focus, which will result in only +51°C (+124°F) as

the maximum temperature.

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 27

Page 38

7 – Introduction to thermographic inspections of electrical installations

7.3.3 Comparative measurement

For thermographic inspections of electrical installations a special method is used,

which is based on comparison of different objects, so-called measurement with a

reference. This simply means that you compare the three phases with each other.

This method needs systematic scanning of the three phases in parallel in order to

assess whether a point differs from the normal temperature pattern.

A normal temperature pattern means that current carrying components have a given

operation temperature shown in a certain color (or gray tone) on the display, which

is usually identical for all three phases under symmetrical load. Minor differences in

the color might occur in the current path, for example, at the junction of two different

materials, at increasing or decreasing conductor areas or on circuit breakers where

the current path is encapsulated.

The image below shows three fuses, thetemperatures of which are very close to each

other. The inserted isotherm actually shows less than +2°C (+3.6°F) temperature

difference between the phases.

Different colors are usually the result if the phases are carrying an unsymmetrical

7

load. This difference in colors does not represent any overheating since this does not

occur locally but is spread along the whole phase.

10713203;a3

Figure 7.6 An isotherm in an infrared image of a fusebox

A ‘real’ hot spot, on the other hand, shows a rising temperature as you look closer

to the source of the heat. See the image below, where the profile (line) shows a

steadily increasing temperature up to about +93°C (+199°F) at the hot spot.

28 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 39

7 – Introduction to thermographic inspections of electrical installations

10713303;a4

Figure 7.7 A profile (line) in an infrared image and a graph displaying the increasing temperature

7.3.4 Normal operating temperature

Temperature measurement withthermography usually gives the absolute temperature

of the object. In order to correctly assess whether the component is too hot, it is

necessary to know its operating temperature, that is, its normal temperature if we

consider the load and the temperature of its environment.

As the direct measurement will give the absolute temperature—which must be considered as well (as most components have an upper limit to their absolute temperatures)—it is necessary to calculate the expected operatingtemperature given theload

and the ambient temperature. Consider the following definitions:

■ Operating temperature: the absolute temperature of the component. It depends

on the current load and the ambient temperature. It is always higher than the ambient temperature.

■ Excess temperature (overheating): the temperature difference between a properly

working component and a faulty one.

7

The excess temperature is found as the difference between the temperature of a

‘normal’ component and the temperature of its neighbor. It is important to compare

the same points on the different phases with each other.

As an example, see the following images taken from indoor equipment:

10713403;a4

Figure 7.8 An infrared image of indoor electrical equipment (1)

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 29

Page 40

7 – Introduction to thermographic inspections of electrical installations

10713503;a4

Figure 7.9 An infrared image of indoor electrical equipment (2)

The two left phases are considered as normal, whereas the right phase shows a very

clear excess temperature. Actually, the operating temperature of the left phase is

+68°C (+154°F), that is, quite a substantial temperature, whereas the faulty phase

to the right shows a temperature of +86°C (+187°F). This means an excess temperature of +18°C (+33°F), that is, a fault that has to be attended to quickly.

For practical reasons, the (normal, expected) operating temperature of a component

is taken as the temperature of the components in at least two out of three phases,

7

provided that you consider them to be working normally.. The ‘most normal’ case is

of course that all three phases have the same or at least almost the same temperature.

The operating temperature of outdoor components in substations or power lines is

usually only 1°C or 2°C above the air temperature (1.8°F or 3.6°F). In indoor substations, the operating temperatures vary a lot more.

This fact is clearly shown by the bottom image as well. Here the left phase is the one,

which shows an excess temperature. The operating temperature, taken from the two

‘cold’ phases, is +66°C (+151°F). The faulty phase shows a temperature of +127°C

(+261°F), which has to be attended to without delay.

7.3.5 Classification of faults

Once a faulty connection is detected, corrective measures may be necessary—or

may not be necessary forthe time being.In order torecommend the most appropriate

action the following criteria should be evaluated:

■ Load during the measurement

■ Even or varying load

■ Position of the faulty part in the electrical installation

■ Expected future load situation

■ Is the excess temperaturemeasured directly on the faulty spot or indirectly through

conducted heat caused by some fault inside the apparatus?

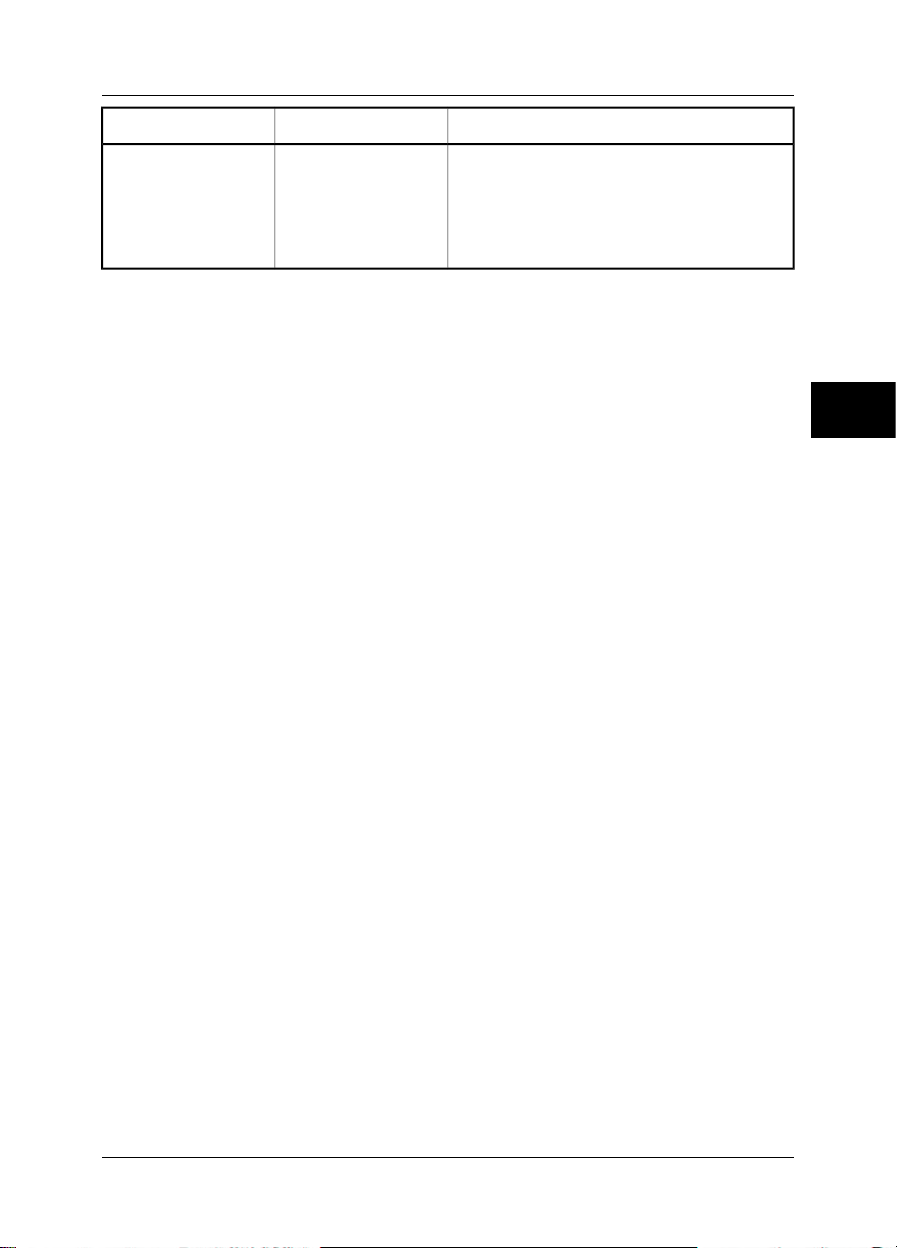

Excess temperatures measured directly on the faulty part are usually divided into

three categories relating to 100% of the maximum load.

30 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 41

7 – Introduction to thermographic inspections of electrical installations

< 5°C (9°F)I

5–30°C (9–54°F)II

>30°C (54°F)III

The start of the overheat condition. This must be carefully

monitored.

Developed overheating. It must

be repaired as soon as possible

(but think about the load situation before a decision is made).

Acute overheating. Must be repaired immediately (but think

about the load situation before

a decision is made).

7

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 31

Page 42

7 – Introduction to thermographic inspections of electrical installations

7.4 Reporting

Nowadays, thermographicinspections of electrical installations are probably, without

exception, documentedand reported by the use of a report program. Theseprograms,

which differ from one manufacturer to another, are usually directly adapted to the

cameras and will thus make reporting very quick and easy.

The program, which has been used for creating the report page shown below, is

called ThermaCAM™Reporter. It is adaptedto several types of infrared camerasfrom

FLIR Systems.

A professional report is often divided into two sections:

■ Front pages, with facts about the inspection, such as:

Who the client is, for example, customer’s company name and contact person

□

Location of the inspection: site address, city, and so on

□

Date of inspection

□

Date of report

□

Name of thermographer

□

7

Signature of thermographer

□

Summary or table of contents

□

■ Inspection pages containing IR images to documentand analyze thermalproperties

or anomalies.

Identification of the inspected object:

□

What is the object: designation, name, number, and so on

■

Photo

■

IR image. When collecting IR images there are some details to consider:

□

Optical focus

■

Thermal adjustment of the scene or the problem (level & span)

■

Composition: proper observation distance and viewing angle.

■

Comment

□

Is there an anomaly or not?

■

Is there a reflection or not?

■

Use a measurement tool—spot, area or isotherm—to quantify the problem.

■

Use the simplest tool possible; a profile graph is almost never needed in

electrical reports.

32 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 43

10713603;a3

7 – Introduction to thermographic inspections of electrical installations

7

Figure 7.10 A report example

Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006 33

Page 44

7 – Introduction to thermographic inspections of electrical installations

7.5 Different types of hot spots in electrical installations

7.5.1 Reflections

The thermographiccamera sees anyradiation that entersthe lens, notonly originating

from the object that you are looking at, but also radiation that comes from other

sources andhas been reflected by the target. Most of the time,electrical components

are like mirrors to the infrared radiation, even if it is not obvious to the eye. Bare

metal parts are particularly shiny, whereas painted, plastic or rubber insulated parts

are mostly not. In the image below, you can clearly see a reflection from the thermographer. This is of course not a hot spot on the object. A good way to find out if what

you see is a reflection or not, is for you to move. Look at the target from a different

angle and watch the ‘hot spot.’ If it moves when you do, it is a reflection.

Measuring temperature of mirror like details is not possible. The object in the images

below has painted areas which are well suited for temperature measurement. The

material is copper, which is a very good heat conductor. This means that temperature

variation over the surface is small.

10717503;a2

7

Figure 7.11 Reflections in an object

7.5.2 Solar heating

The surface of a component with a high emissivity, for example, a breaker, can on a

hot summer day be heated up to quite considerable temperatures by irradiation from

the sun. The image shows a circuit breaker, which has been heated by the sun.

34 Publ. No. 1558240 Rev. a156 – ENGLISH (EN) – March 1, 2006

Page 45

7 – Introduction to thermographic inspections of electrical installations

10713803;a3

Figure 7.12 An infrared image of a circuit breaker