Page 1

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

i

Tau SWIR ISC1202

User’s Guide

Document Number: 102-2009-45

Revision 102

Issue Date: October 2018

Page 2

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

ii

Table of Contents

1.0 Scope .............................................................................................................. vi

2.0 Resources ......................................................................................................... 7

FLIR Reference Documents.......................................................................................................... 7

3.0 Unpacking the Camera .................................................................................. 7

4.0 Standard Camera Kit ..................................................................................... 8

Electrical Interface ........................................................................................................................ 8

Main Connector .................................................................................................................................... 8

TEC Connector ................................................................................................................................... 13

TEC Power Through Accessory Boards ............................................................................................. 14

Mechanical Interface ................................................................................................................... 15

Optical Interface .......................................................................................................................... 16

5.0 Optional Accessories ....................................................................................16

VPC Module Accessory .............................................................................................................. 16

Installation ........................................................................................................................................... 18

Camera Link Module Accessory ................................................................................................. 19

Installation ........................................................................................................................................... 20

6.0 Connecting to the Camera ...........................................................................21

Physical Connection .................................................................................................................... 21

FLIR Camera Controller GUI ..................................................................................................... 22

FLIR Camera Controller Software Interface............................................................................... 24

Troubleshooting the FLIR Camera Controller GUI .................................................................... 27

7.0 Operation of the FLIR Camera Controller GUI .......................................29

Menu Bar .................................................................................................................................... 29

Calibration Tab ........................................................................................................................... 31

Optimization Tab ........................................................................................................................ 35

AGC Modes: ....................................................................................................................................... 35

Linear Parameters: .............................................................................................................................. 38

Automatic Parameters: ........................................................................................................................ 38

Enhancements: .................................................................................................................................... 39

Page 3

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

iii

AGC ROI: ........................................................................................................................................... 39

Window Editor .................................................................................................................................... 40

AGC ROI Coordinate Values ............................................................................................................. 40

Digital Zoom: ...................................................................................................................................... 40

Orientation: ......................................................................................................................................... 40

Polarity / Palette: ................................................................................................................................. 41

Auto-Exposure Enable: ....................................................................................................................... 42

Save Settings ....................................................................................................................................... 42

Factory Defaults .................................................................................................................................. 42

Reset Camera ...................................................................................................................................... 42

Utilities Tab ................................................................................................................................ 43

Camera Link Configuration ................................................................................................................ 43

Camera Updates .................................................................................................................................. 44

External Sync ...................................................................................................................................... 45

Test Pattern ......................................................................................................................................... 47

TEC Control ........................................................................................................................................ 47

Lens Control ........................................................................................................................................ 47

Save Settings ....................................................................................................................................... 47

Factory Defaults .................................................................................................................................. 48

Reset Camera ...................................................................................................................................... 48

Debug .......................................................................................................................................... 49

8.0 Appendix – Extraordinary Conditions .......................................................50

Disassmbly .................................................................................................................................. 50

Cleaning the VPA Window......................................................................................................... 50

External Conditions .................................................................................................................... 50

Page 4

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

iv

Table of Figures

FIGURE 1. TAU SWIR CAMERA –HIROSE CONNECTOR ................................................................................... 8

FIGURE 2. PINS ON TAU SWIR HIROSE CONNECTOR ................................................................ ....................... 9

FIGURE 3. DETAILED ILLUSTRATION OF TEC POWER CONNECTOR ......................................................... 13

FIGURE 4. TEC POWER CONNECTOR PIN ASSIGNMENTS ............................................................................. 13

FIGURE 5. TEC WIRES ............................................................................................................................................ 14

FIGURE 6. OPTIONAL ¼-20 MOUNT ACCESSORY ............................................................................................ 15

FIGURE 7. FRONT-FACE C-MOUNT ADAPTOR .................................................................................................. 16

FIGURE 8. TAU SWIR CAMERA WITH VPC MODULE ...................................................................................... 17

FIGURE 9. VPC MODULE ACCESSORY KIT ....................................................................................................... 18

FIGURE 11. CAMERA LINK MODULE (SHOWN INSTALLED ON A TAU SWIR CAMERA) ........................ 19

FIGURE 12. CAMERA LINK MODULE ACCESSORY KIT ................................................................................. 20

FIGURE 13. CAMERA LINK MODULE INSTALLATION ................................................................................... 20

FIGURE 14. BNC TO RCA ADAPTOR ................................................................................................................... 21

FIGURE 15. DEVICE MANAGER SHOWING PROPER DRIVER INSTALLATION .......................................... 23

FIGURE 16. SELECT CAMERA MANAGER ......................................................................................................... 24

FIGURE 17. FLIR CAMERA CONTROLLER GUI STATUS TAB – NOT CONNECTED ................................... 25

FIGURE 18. FLIR CAMERA CONTROLLER GUI CONNECTION WINDOW PART 1...................................... 26

FIGURE 19. FLIR CAMERA CONTROLLER GUI CONNECTION WINDOW PART 2...................................... 26

FIGURE 20. CAMERA TYPE SELECTION ............................................................................................................ 27

FIGURE 21. FLIR CAMERA CONTROLLER GUI STATUS TAB – CONNECTED ............................................ 27

FIGURE 22. FLIR CAMERA CONTROLLER ERROR MESSAGE ....................................................................... 27

FIGURE 23. FLIR CAMERA CONTROLLER GUI – MENU BAR ........................................................................ 29

FIGURE 24. HELP -- ABOUT CAMERA CONTROLLER ..................................................................................... 30

FIGURE 25. FLIR CAMERA CONTROLLER GUI – STATUS TAB ..................................................................... 31

FIGURE 26. FLIR CAMERA CONTROLLER GUI -- OPTIMIZATION TAB ....................................................... 35

FIGURE 27. LOOK-UP TABLE OPTIONS (AS SEEN WITH TEST PATTERN ENABLED) .............................. 41

FIGURE 28. FLIR CAMERA CONTROLLER GUI -- VIDEO TAB ................................................................ ....... 43

FIGURE 29. IMPERX FRAMELINK EXPRESS SOFTWARE – CAMERA PARAMETERS WINDOW ............. 44

FIGURE 30. INTEGRATION PRIORITY MODE SYNCHRONIZATION ............................................................. 46

FIGURE 31. READOUT PRIORITY MODE SYNCHRONIZATION ..................................................................... 47

FIGURE 32. FLIR CAMERA CONTROLLER – DEBUG TAB .............................................................................. 49

Page 5

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

v

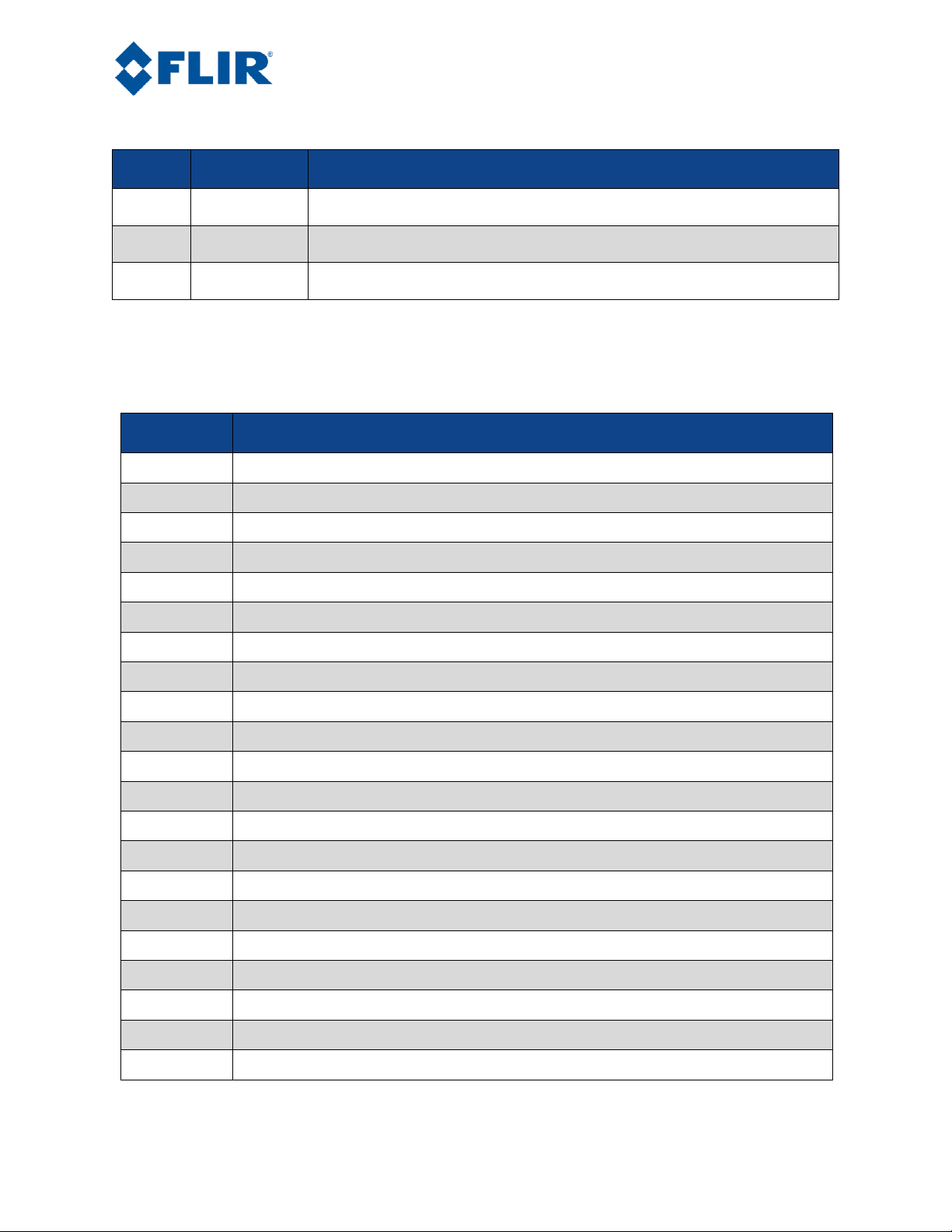

Revision History

Version

Date

Comments

100

December 2016

Initial release

101

February 2018

Added detail to descriptions

102

October 2018

Updated controls for TEC table

List of Abbreviations

Abbreviation/

Acronym

Components

ACE

Actinve Contrast Enhancement

AGC

Automatic Gain Control

CDS

Correlated Double Sampling

DDE

Digital Detail Enhancement

ESD

Electrostatic Damage

FFC

Flat Field Calibration (or Correction)

FOV

Field of View

FPA

Focal Plane Array

FPS

Frames Per Second

GUI

Graphical User Interface

I/O

Input / Output

ICD

Interface Control Drawing / Document

IDD

Interface Description Drawing / Document

InGaAs

Indium Galium Arsenide

ISC1202

Indigo Systems Corporation, February 2012

LACE

Local Area Contrast Enhancement

LUT

Look-Up Table

NTSC

National Television System Committee

NUC

Non Uniformity Correction

OSD

On Screen Display

PAL

Phase Alternating Line

Page 6

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

vi

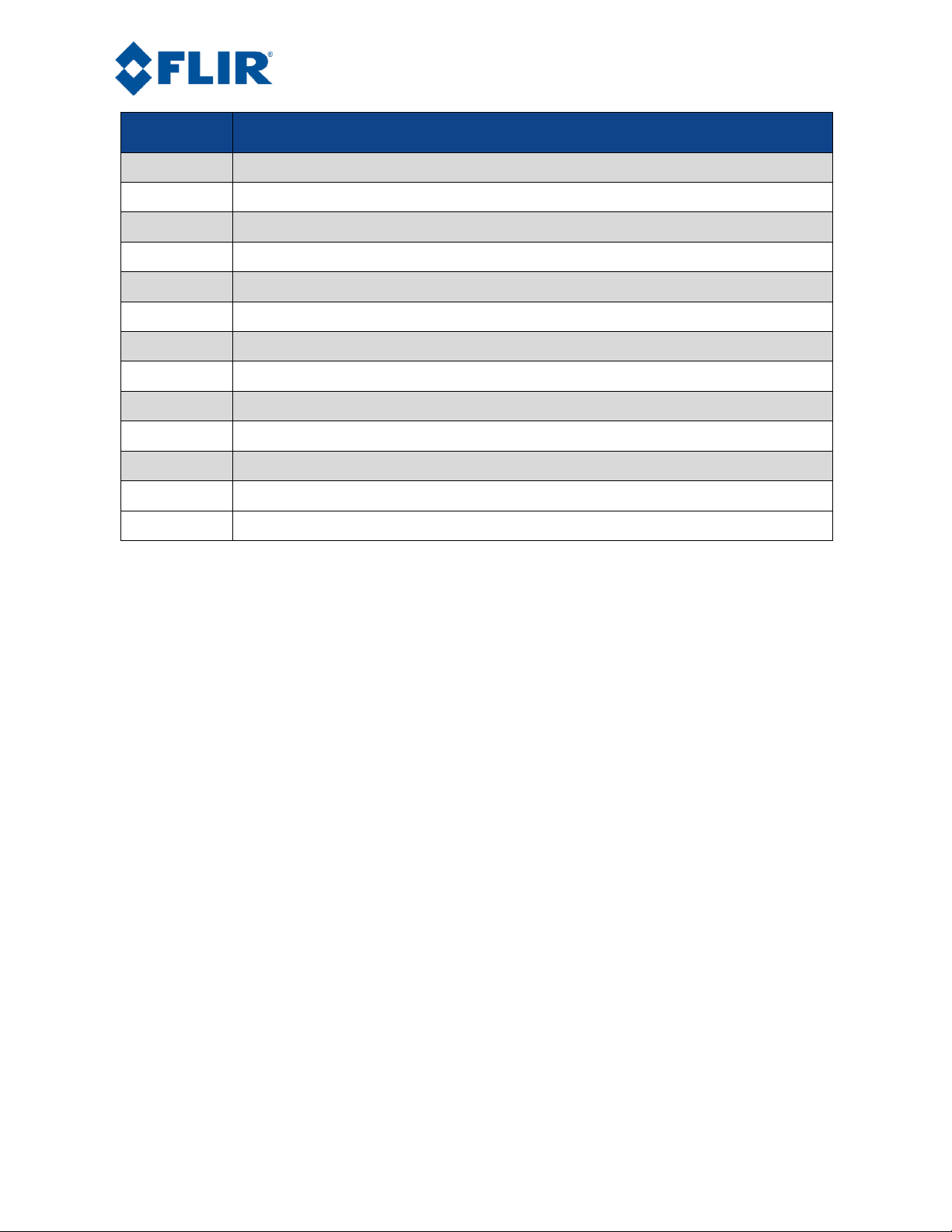

Abbreviation/

Acronym

Components

REACH

Registration, Evaluation, Authorisation and Restriction of Chemicals

RoHS

Reduction of Hazardous Substances

ROI

Region of Interest

ROIC

Read Out Integrated Circuit

SIC-200

Silicon Inspection XX

SWIR

Short Wave Infrared

SSO

Smart Scene Optimization

TBD

To Be Determined

TEC

Thermo Electric Cooler

URL

Uniform Resource Locator

USB

Universal Serial Bus

VPA

Vacuum Package Assembly

Page 7

Page 7

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

1.0 Scope

Tau ™ SWIR is a miniature, 38mm×38mm×47mm, short wave infrared (SWIR) imaging core from FLIR

Systems, built around FLIR’s ISC1202 InGaAs SWIR sensor. This sensor provides high sensitivity from

0.9 to 1.7μm, low dark current, temperature stabilization and on chip (in-pixel) correlated double sampling

(CDS) for noise reduction, CDS fold-over protection (prevents “black sun effect”), anti-blooming (low gain

only), snapshot integration, 640 × 512 resolution with a 15μm pixel pitch running at 60 frames per second.

FLIR’s proprietary image processing algorithms start with 14-bit digital imagery and result in high-quality,

analog video or 8-bit digital imagery in both low light conditions and full daylight. Frame rates may be

adjusted from a minimum of 1fps to a maximum of 60fps for a full frame image. A preset 2X window of

the central 320 × 256 pixels may be selected allowing for a frame rate of up to 120fps. An external sync

mode allows integration with other camera systems, SWIR illuminators or pulsed lasers, synchronizing the

integration period of the camera with the external system.

There are three sensor gain modes providing increasing sensitivity, Low, Mid or High. Low gain is

appropriate for well illuminated, wide dynamic range scenes while each step up in sensitivity allows

imaging under lower SWIR illumination levels with an accompanying decrease in the dynamic range that

can be imaged. Within each gain mode, the integration period may be adjusted from as little as 10μs to as

high as the frame period. Response of the 14-bit digital imagery increases linearly with increasing

integration period.

FLIR’s built in Auto-Exposure algorithm allows automatic, smooth transitions of integration period (tint)

based on scene content to maximize image quality and detail without user intervention.The camera includes

FLIR’s advanced Non-Uniformity Correction (NUC), in-camera nonresponsive pixel replacement and

Automatic Gain Control (AGC) algorithms. The Tau SWIR comes standard with a C-mount lens adapter

installed. This may be removed allowing for custom lens mounts.

This User’s Guide includes quick-start information for the Tau SWIR, as well as detailed descriptions of

functions and adjustments for the camera that can be performed using FLIR’s Tau SWIR Camera Controller

GUI.

2.0 Resources

FLIR Reference Documents

Document Number

Document Title

102-2009-42

Tau SWIR 1202 Software IDD

102-2009-40

Tau SWIR 1202 Product Specification

102-2009-44

Tau SWIR Mechanical IDD

3.0 Unpacking the Camera

Page 8

Page 8

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

When unpacking the camera, please heed customary electrostatic-discharge (ESD) sensitive device

precautions including static-safe work station and proper grounding. The camera is placed in a conductive

anti-static bag to protect from electrostatic-discharge damage and safely packaged to prevent damage during

shipping.

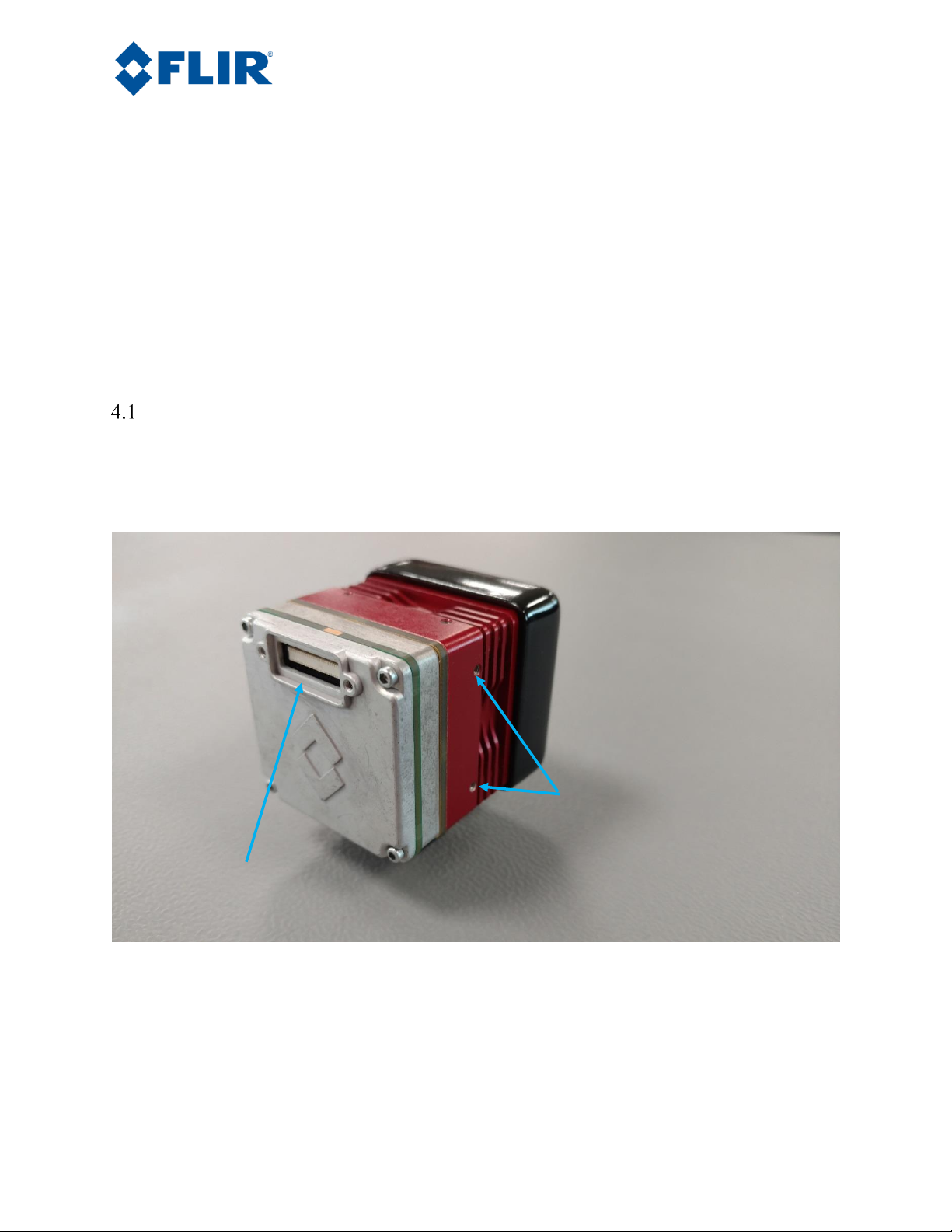

4.0 Standard Camera Kit

Components that come standard with the Tau SWIR camera are:

1. Camera body (includes standard Tau backshell, C-Mount Adapter installed)

2. 2-Wire, 12” lead for TEC power (shown in Figure 5)

3. Black Cap to cover C-Mount

Electrical Interface

Main Connector

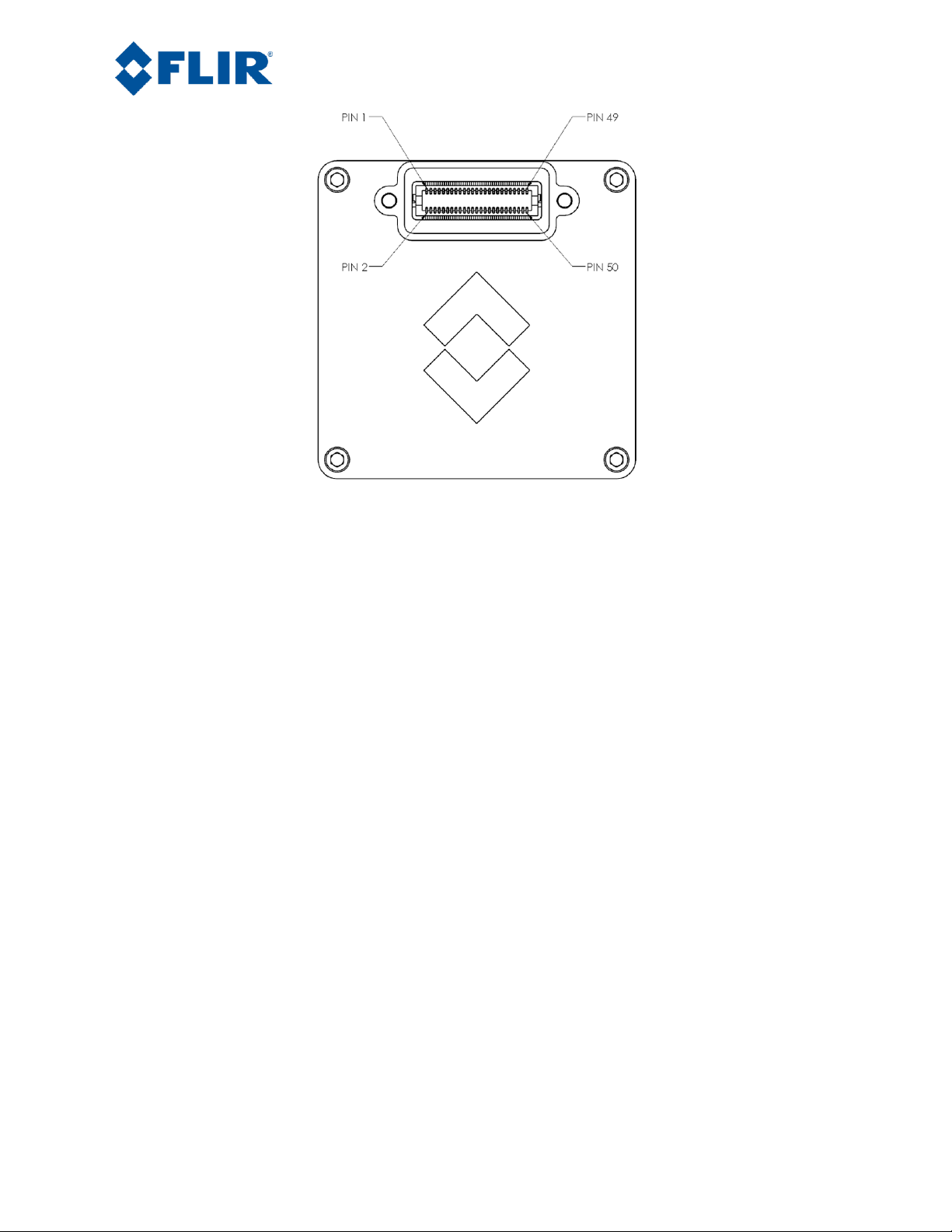

Communication, video, and camera power are all accommodated through the Hirose 50-pin connector

shown in Figure 1 and Figure 2. Pin designations are described in Table 1, Table 2, and Table 3.

Figure 1. Tau SWIR Camera –Hirose Connector

M2x0.4, 4mm deep mounting

holes, 24mm separation, 3 sides.

high-density 50-pin connector:

Hirose #DF12-50DS-0.5V(86)

Page 9

Page 9

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Figure 2. Pins on Tau SWIR Hirose Connector

Page 10

Page 10

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

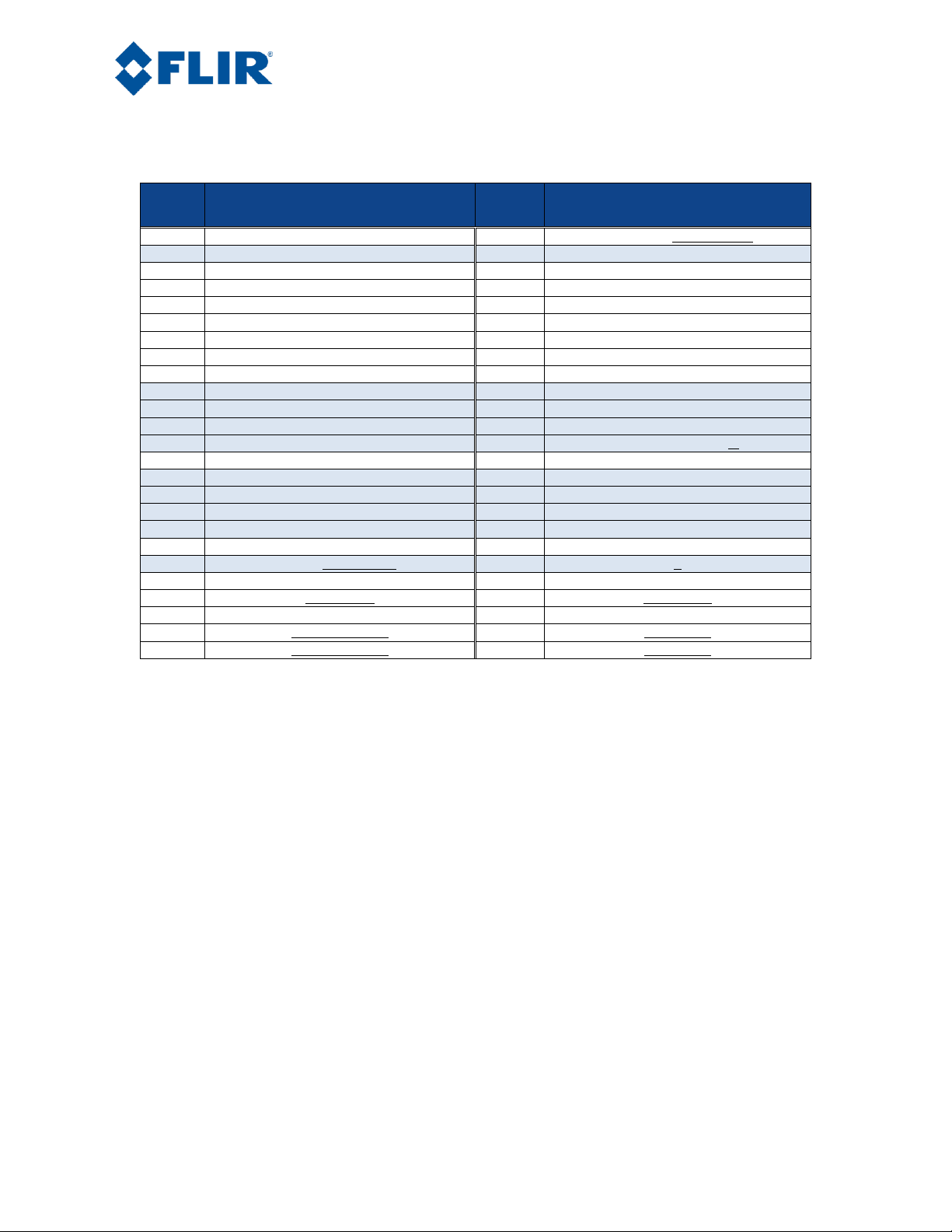

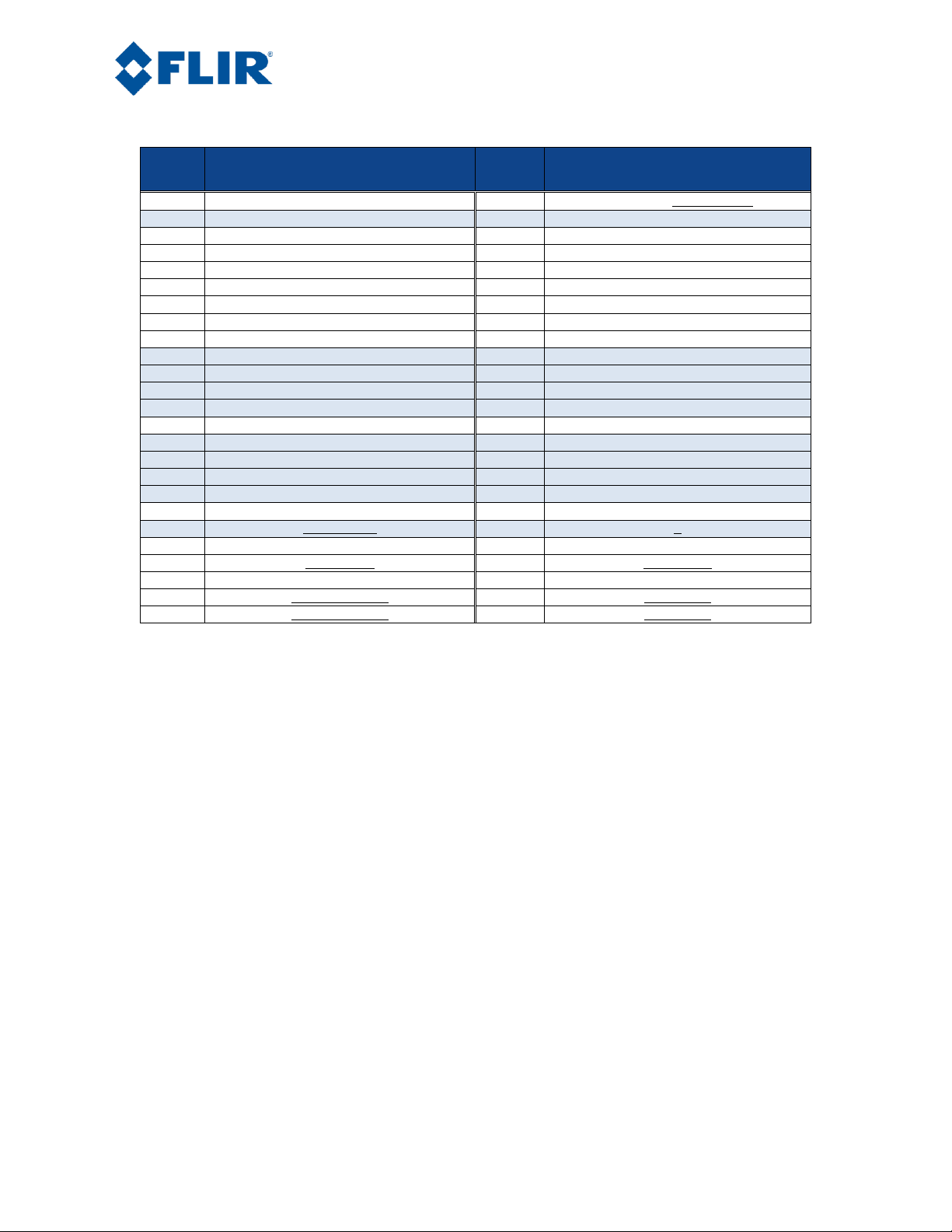

Table 1. Tau SWIR Pin-Out, Hirose Connector Mode (2) CMOS 14-bit (default)

Pin #

Signal Name

Pin #

Signal Name

1

COMM_TX (RS232_TX_OUT)

2

COMM_RX (RS232_RX_IN)

3

CMOS LINE_VALID_OUT

4

CMOS FRAME_VALID_OUT

5

DGND

6

DGND

7

CAMLINK_CLK [P]

8

CAMLINK_CLK [N]

9

CAMLINK_DATA [0P]

10

CAMLINK_DATA [0N]

11

CAMLINK_DATA [1P]

12

CAMLINK_DATA [1N]

13

CAMLINK_DATA [2P]

14

CAMLINK_DATA [2N]

15

CAMLINK_DATA [3P]

16

CAMLINK_DATA [3N]

17

DGND

18

DGND

19

DISCRETE IO REG [0]

20

CMOS DATA_OUT [13]

21

EXTERNAL_SYNC

22

CMOS DATA_OUT [12]

23

CMOS DATA_OUT [11]

24

CMOS DATA_OUT [10]

25

CMOS DATA_OUT [9]

26

CMOS DATA_OUT [8]

27

DGND

28

DGND

29

CMOS DATA_OUT [7]

30

CMOS DATA_OUT [6]

31

CMOS DATA_OUT [5]

32

CMOS DATA_OUT [4]

33

CMOS DATA_OUT [3]

34

CMOS DATA_OUT [2]

35

CMOS DATA_OUT [1]

36

CMOS DATA_OUT [0]

37

DGND

38

DGND

39

CMOS CLOCK_OUT

40 Z 41

DGND

42

DGND

43

VID_OUT_H

44

VID_OUT_L

45

DGND

46

n/c

47

MAIN_PWR_RTN

48

MAIN_PWR

49

MAIN_PWR_RTN

50

MAIN_PWR

Page 11

Page 11

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

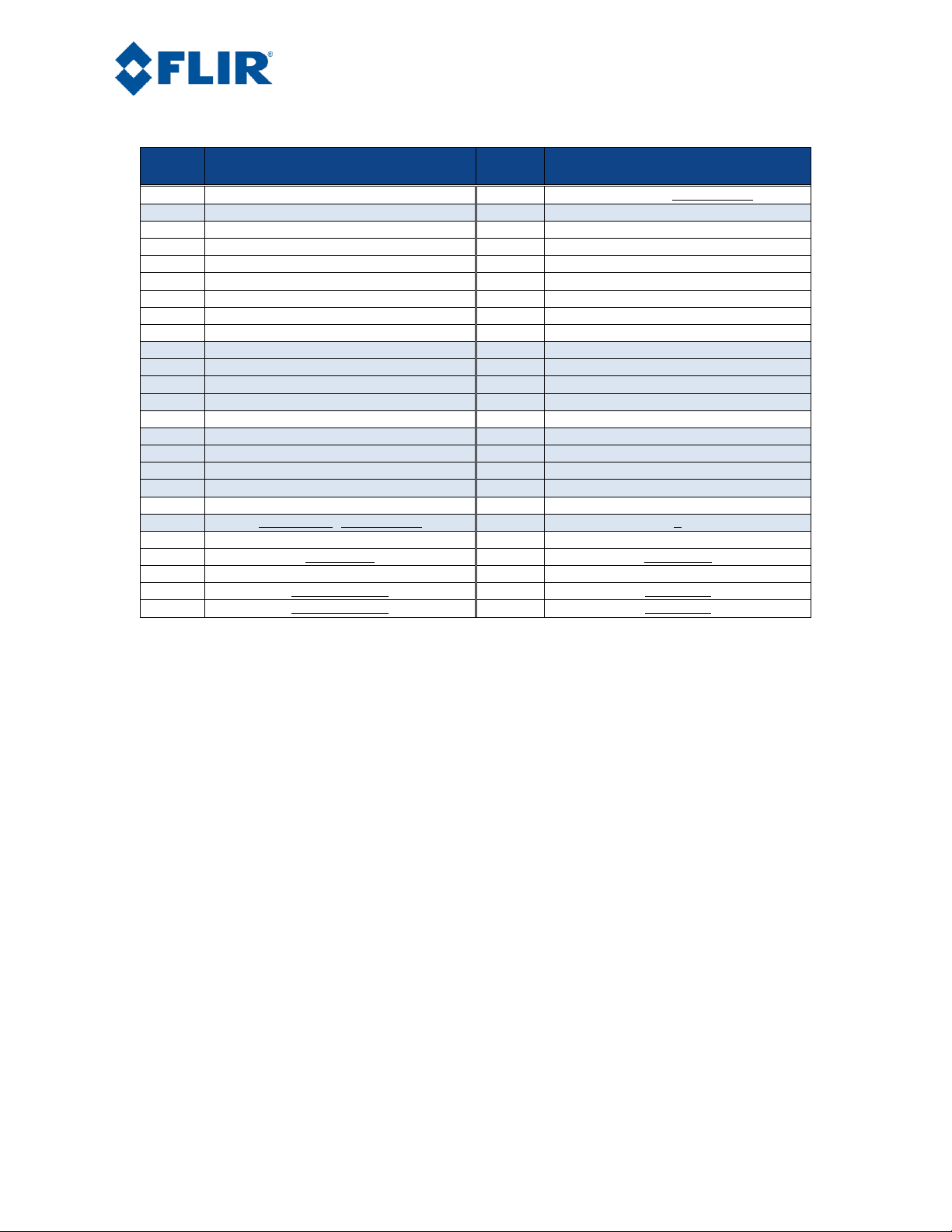

Table 2. Pinout Hirose 50-Pin Connector, Output Mode (3) CMOS 8-bit

Pin #

Signal Name

Pin #

Signal Name

1

COMM_TX (RS232_TX_OUT)

2

COMM_RX (RS232_RX_IN)

3

LINE_VALID_OUT

4

FRAME_VALID_OUT

5

DGND

6

DGND

7

CAMLINK_CLK [P]

8

CAMLINK_CLK [N]

9

CAMLINK_DATA [0P]

10

CAMLINK_DATA [0N]

11

CAMLINK_DATA [1P]

12

CAMLINK_DATA [1N]

13

CAMLINK_DATA [2P]

14

CAMLINK_DATA [2N]

15

CAMLINK_DATA [3P]

16

CAMLINK_DATA [3N]

17

DGND

18

DGND

19

DISCRETE IO REG [0]

20

DISCRETE IO REG [1]

21

EXTERNAL_SYNC

22

(XP 12) Z

23

DISCRETE IO REG [2]

24

DISCRETE IO REG [3]

25

DISCRETE IO REG [4]

26

DISCRETE IO REG [5]

27

DGND

28

DGND

29

CMOS DATA_OUT [7]

30

CMOS DATA_OUT [6]

31

CMOS DATA_OUT [5]

32

CMOS DATA_OUT [4]

33

CMOS DATA_OUT [3]

34

CMOS DATA_OUT [2]

35

CMOS DATA_OUT [1]

36

CMOS DATA_OUT [0]

37

DGND

38

DGND

39

CLOCK_OUT

40

Z

41

DGND

42

DGND

43

VID_OUT_H

44

VID_OUT_L

45

DGND

46

n/c

47

MAIN_PWR_RTN

48

MAIN_PWR

49

MAIN_PWR_RTN

50

MAIN_PWR

Page 12

Page 12

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Table 3. Pinout Hirose 50-pin Connector, Output Mode (1), BT.656

Pin #

Signal Name

Pin #

Signal Name

1

COMM_TX (RS232_TX_OUT)

2

COMM_RX (RS232_RX_IN)

3

DISCRETE IO REG [6]

4

DISCRETE IO REG [7]

5

DGND

6

DGND

7

CAMLINK_CLK [P]

8

CAMLINK_CLK [N]

9

CAMLINK_DATA [0P]

10

CAMLINK_DATA [0N]

11

CAMLINK_DATA [1P]

12

CAMLINK_DATA [1N]

13

CAMLINK_DATA [2P]

14

CAMLINK_DATA [2N]

15

CAMLINK_DATA [3P]

16

CAMLINK_DATA [3N]

17

DGND

18

DGND

19

DISCRETE IO REG [0]

20

DISCRETE IO REG [1]

21

EXTERNAL_SYNC

22

(XP 12) Z

23

DISCRETE IO REG [2]

24

DISCRETE IO REG [3]

25

DISCRETE IO REG [4]

26

DISCRETE IO REG [5]

27

DGND

28

DGND

29

BT656 DATA_OUT [7]

30

BT656 DATA_OUT [6]

31

BT656 DATA_OUT [5]

32

BT656 DATA_OUT [4]

33

BT656 DATA_OUT [3]

34

BT656 DATA_OUT [2]

35

BT656 DATA_OUT [1]

36

BT656 DATA_OUT [0]

37

DGND

38

DGND

39

CLOCK_OUT BT656 (27Mhz)

40

Z

41

DGND

42

DGND

43

VID_OUT_H

44

VID_OUT_L

45

DGND

46

n/c

47

MAIN_PWR_RTN

48

MAIN_PWR

49

MAIN_PWR_RTN

50

MAIN_PWR

Page 13

Page 13

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

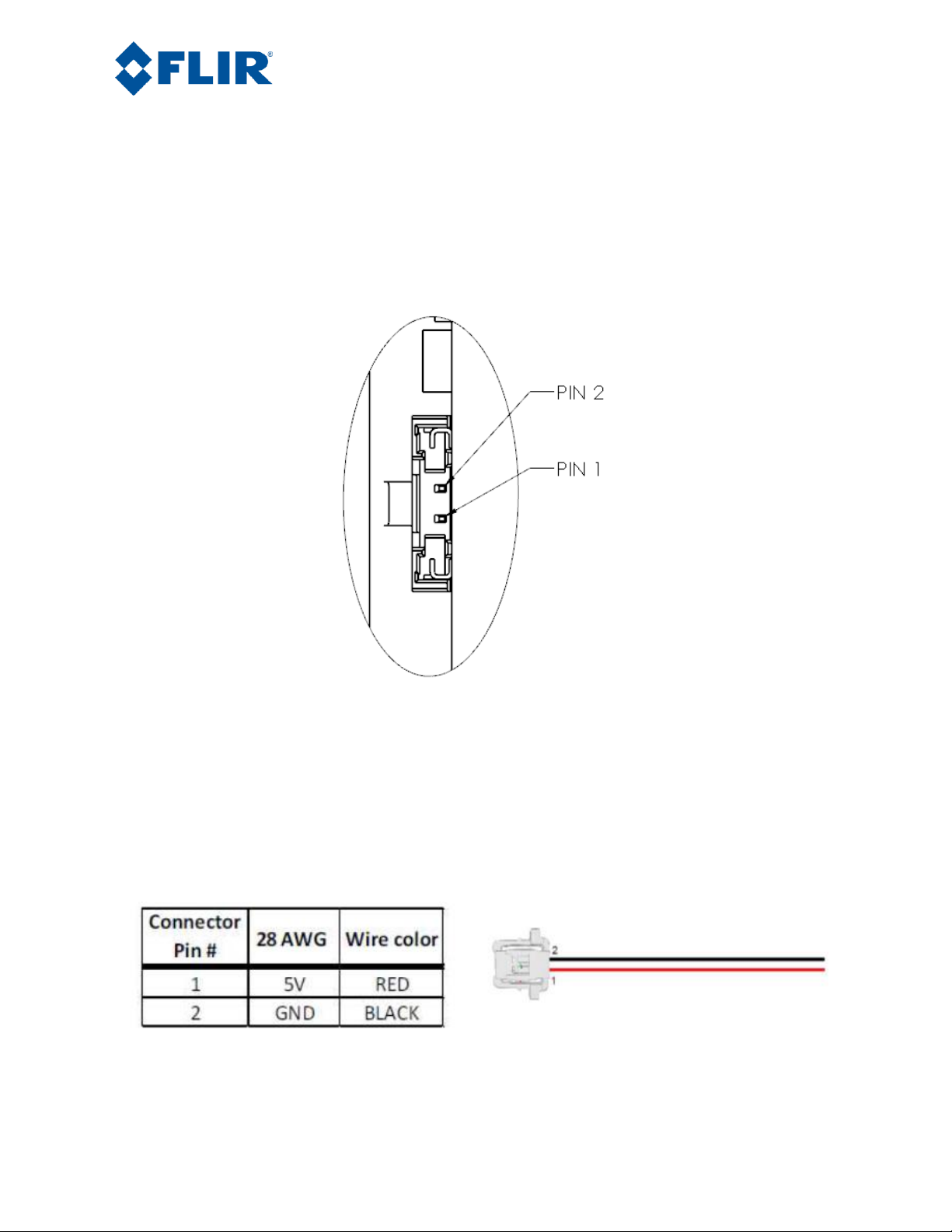

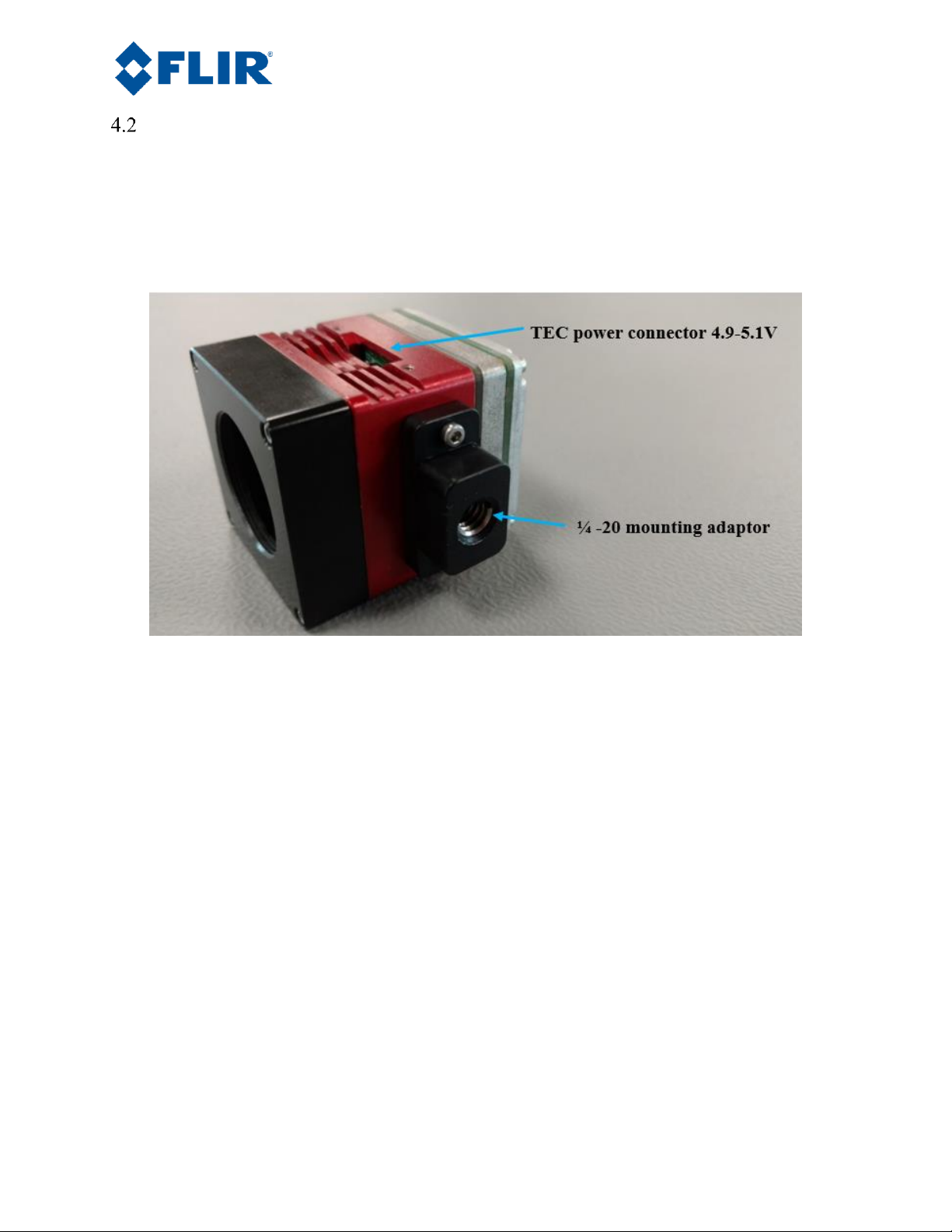

TEC Connector

On one side of the camera housing there is a Molex connector that provides power for the thermo-electric

cooler (TEC). The TEC requires 4.9-5.5VDC input. While actual power consumption will vary with the

ambient and mounting environment, peak power for this connection is limited to 2.5W. Commonly, this

connector requires 0.3W at room ambient temperatures with the camera mounted on a tripod.

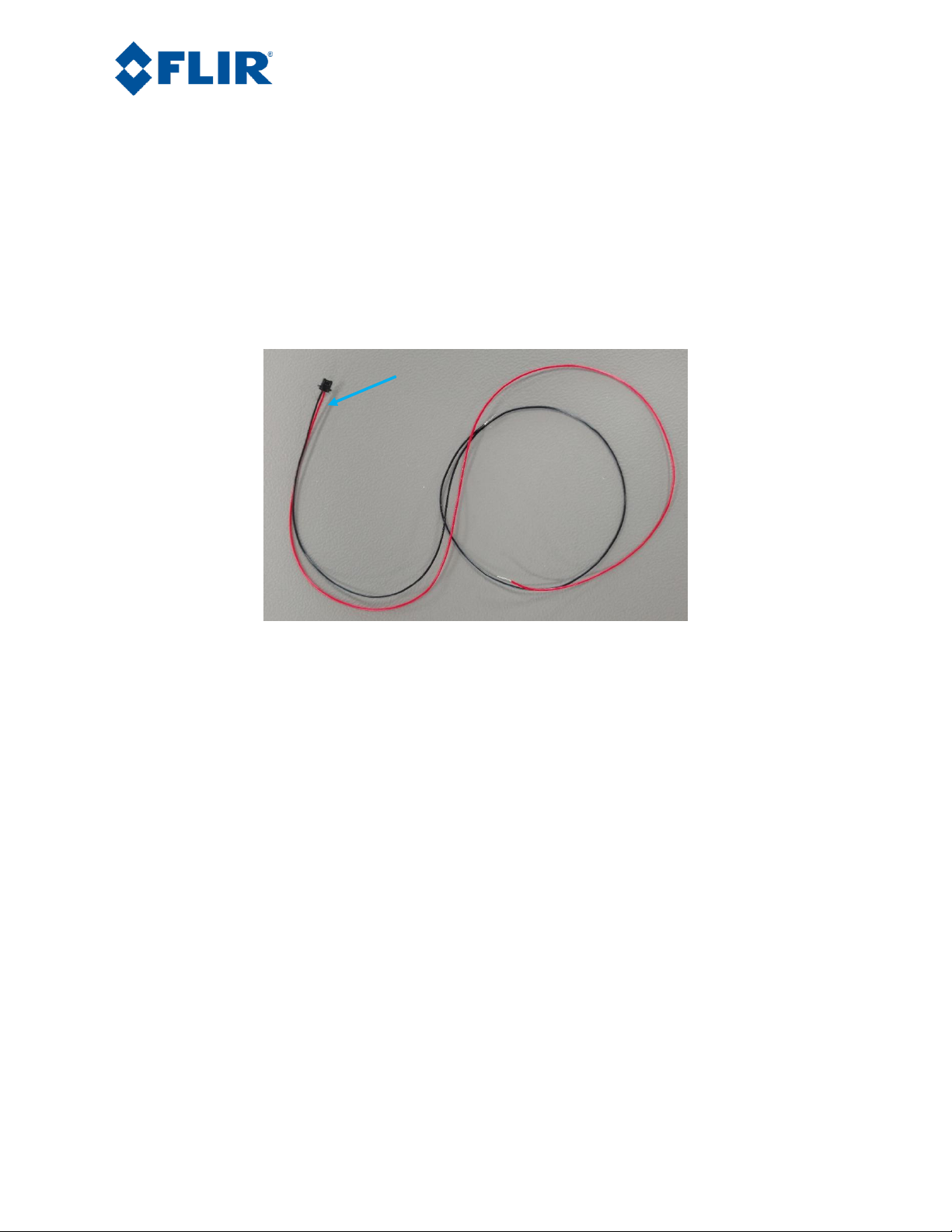

Included in the standard camera kit is a matching TEC power cable (FLIR PN 308-0268-00) terminated

at one end with a Molex Pico-Lock 2-pin connector. See Figure 5. This connector is keyed to prevent

connecting a reversed voltage to the TEC. The wires are black and red. The red is for a +5V supply and

the black is for the return or ground.

Figure 3. Detailed illustration of TEC power connector

Note: If, for any reason, the TEC power cable must be removed, the Molex Pico-Lock connector must be

pinched on both ends to disengage the locking mechanism. Once unlocked, gently pull out and slightly

forward (toward the front of the camera), ensuring the connector does not get hung up on the camera

body. Apply the minimum force necessary to remove the cable from the connector. Use caution as to not

pull the wires out of the connector body.

Figure 4. TEC Power Connector Pin Assignments

Page 14

Page 14

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

TEC Power Through Accessory Boards

When using either the VPC or Camera Link Adaptor accessory boards, power may be supplied to the

TEC Power connector via a cable from the accessory board. See Section 5.0 for a description of these

accessory boards. Once connected, a cover plate is installed over the cable and TEC power connector

port on the side of the camera. In this configuration both camera power and TEC power are supplied

through the USB connector on the accessory board. With either of these two accessory boards a USB

cable with a second power input is provided to handle higher than ½ amp current normally supplied

through USB from a computer.

Figure 5. TEC wires

TEC power connector

Page 15

Page 15

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Mechanical Interface

Mechanically mounting the camera can be accomplished by utilizing the M2.0 x 0.4 mounting holes

located on the top, bottom and left side of the camera. Each pair of holes are 4mm deep and have a 24mm

separation.

Alternatively, an optional ¼ x 20 mounting accessory (FLIR part number 261‐2071‐00) can be purchased

that utilizes one of the the three M2.0 x 0.4 hole pairs. See Figure 6.

Figure 6. Optional ¼-20 Mount Accessory

Page 16

Page 16

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

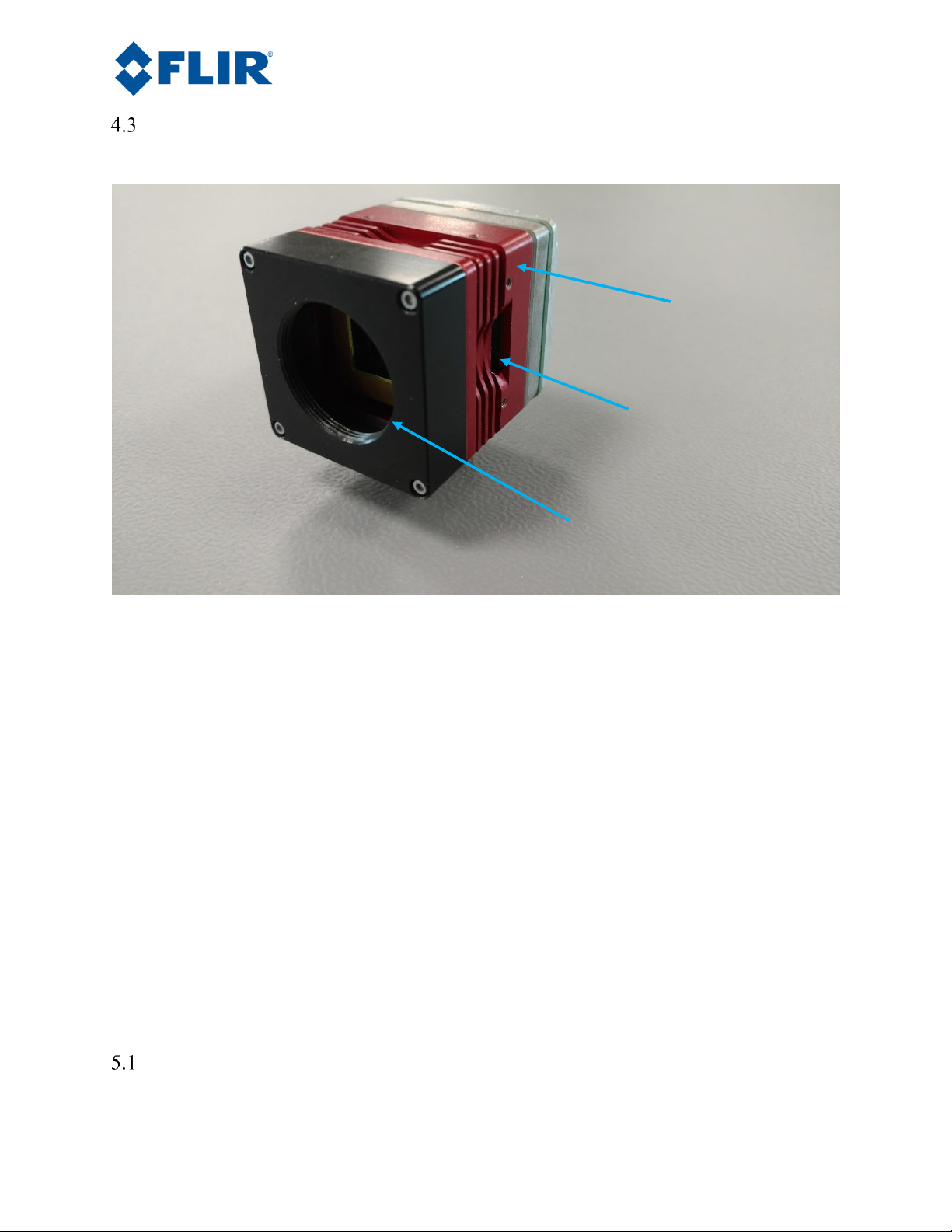

Optical Interface

The standard Tau SWIR camera kit comes with a C-mount optical adaptor, as shown in Figure 7.

Figure 7. Front-Face C-Mount Adaptor

If the C-mount interface is not needed, it can be removed by unscrewing the four M1.6 mounting screws

using an M1.5 allen head wrench. Further details on the optical interface can be found in the Mechanical

IDD document. Use extreme caution when working with the optics to prevent contamination of the VPA

window. If cleaning becomes necessary, see Section 8.2 for instructions.

5.0 Optional Accessories

The Tau SWIR Camera can be used with either the Tau SWIR VPC Module Accessory (FLIR PN 4210059-00) or the Tau SWIR Camera Link Module Accessory (FLIR PN 421-0058-00) for simple desktop

operation. These accessories provide an easy way to evaluate the camera core and access analog and, in

the case of the Camera Link Module, digital video during development. To help simplify mechanical

mounting of the Tau SWIR camera, it can be used with the ¼ 20 Mount accessory (261‐2071‐00).

When using either the VPC or Camera Link Adaptor accessory boards, power may be supplied to the

TEC power connector via a cable from the accessory board. A cover plate is installed (see Figure 8) over

the cable and TEC power connector port on the side of the camera. In this configuration both camera

power and TEC power are supplied through the USB connector on the accessory board.

VPC Module Accessory

C-Mount Adaptor

TEC Power Connector

Camera Body

Page 17

Page 17

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

The VPC module accessory kit includes a special USB-A (2-headed) to USB-mini B power and serial

communication cable, USB power supply, MCX-to-BNC analog video cable, TEC Power Cover Plate,

module mounting screws, and cover plate mounting screws. This module differs from the standard Tau

(uncooloed) camera VPC modle in that it has an additional VPC-to-TEC cable. Due to the fact that

standard USB ports on computers typically cannot supply enough current to run the TauSWIR camera

and TEC, both USB-A connectors on the USB cable must be plugged into a power source when this

VPC-to-TEC cable is connected to the camera.

Figure 8. Tau SWIR camera with VPC module

Analog video out

USB mini,

communication

and power

TEC power cover plate

Page 18

Page 18

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

VPC Installation

The VPC module plugs into the Hirose connector on the back of the Tau SWIR camera, as shown in

Figure 8. Use the two M1.6 x 0.35 x 8mm screws included in the kit to secure the module to the camera.

Plug the TEC cable into the TEC power connector on the side of the camera. Install the TEC power cover

plate using the supplied screws.

Figure 9. VPC Module Accessory Kit

Page 19

Page 19

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Camera Link Module Accessory

The Camera Link module is an expansion board for FLIR cameras that matches the functionality of the

VPC Module and adds the ability to access digital data via Camera Link connection. The Camera Link

module takes CMOS-type digital data from the camera and converts it to Camera Link. In order to use a

Camera Link module for acquisition of data, first enable the digital data output using the FLIR Camera

Controller GUI. The red/black wires connect to the TEC board. The black and green wires are connected

to the external synchronization signal in the camera. This accessory does not include a Camera Link

cable, frame grabber, or capture software.

Figure 10. Camera Link Module (shown installed on a Tau SWIR camera)

Page 20

Page 20

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Figure 11. Camera Link Module Accessory Kit

Camera Link Installation

The Camera Link Module plugs into the Hirose connector on the back of the Tau SWIR camera, as shown

in.Figure 10. Prior to installing the two M1.6 x 0.35 x 20mm screws, the two mini spacers must be

slipped in between the module and the back cover of the camera, as shown in Figure 12.

Figure 12. Camera Link Module Installation

Plug the TEC cable into the TEC power connector on the side of the camera, ensureing the locking

mechanism engages. Install the TEC power cover plate using the supplied screws. If, for any reason, the

TEC power connector must be removed, the Molex Pico-Lock connector must be pinched on both ends to

disengagy the locking mechanism. Once unlocked, gently pull out and slightly forward (toward the front

of the camera), ensuring the connector does not get hung up on the camera body. Apply the minimum

force necessary to remove the cable from the connector. Use caution as to not pull the wires out of the

connector body.

Page 21

Page 21

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

6.0 Connecting to the Camera

This section describes installation of necessary software, physical camera connections, and software

connection to the camera.

Physical Connection

This section describes physical connections to the camera and assumes that either the VPC or Camera Link

Accessory Module is being used with the camera. For connections not involving either of these FLIR

accessories, please see Section 4.1 for a description of the Hirose connector interface.

1. Plug the accessory (VPC or Camera Link) expansion board directly into the 50-pin Hirose

connector on the rear of the camera. Use the included hardware to secure the expansion board to

the camera. These will insert on either side of the 50-pin connector. The VPC module uses M1.6 ×

0.35 × 8 mm screws (see Section 5.1 on VPC installation) and the Camera Link module uses M1.6

× 0.35 × 8 mm screws. Using longer screws could damage the camera. The Camera Link module

also requires the installation of two M1.6 x 0.35 x 20mm screws. Make sure to install the two

spacers between the back cover of the camera and the Camera Link module (see section 5.2 on

Camera Link installation). An M1.5 allen head wrench will be required for tightening the screws.

2. Connect the analog video cable to the VPC or Camera Link Module. There is an MCX mini coaxial

connector on the back of each accessory. The opposite end of the cable has a standard BNC

connector. Connect this to the video input of an analog monitor. It may be necessary to use a BNC

Female to Phono Plug (RCA) adaptor (Figure 13) included in the accessory kit, which allows the

camera to be connected to a standard yellow RCA video input on a monitor. The Tau SWIR camera

core provides either NTSC or PAL compatible composite video output, selectable in the software

GUI or SDK.

Note: For best transmission of the analog video channel, a coaxial cable with 75 ohm

characteristic impedance, similar to what is included in the VPC and Camera Link module kits, is

required. The analog output is current mode and a 75 Ohm termination is required. This

termination is present in most display devices.

Figure 13. BNC to RCA Adaptor

3. Connect the USB-mini B cable to the VPC Module or the Camera Link Module and both USB-A

connectors to the computer. (If sound is enabled on the computer, a chime will sound and a

notification that the device has been connected will pop up). The Tau SWIR ISC1202 core inputvoltage range is 4.9V – 5.5V. Core power is < 3.0W.

Page 22

Page 22

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

4. If two USB ports are not available on the host computer, a separate 4.9V -5.5V input voltage may

be used to power the TEC. Section 4.1 describes the TEC power connection requirements.

5. Analog video (a Splash Screen) should appear within a few seconds after connecting the USB cable.

Verify analog video is displayed on the monitor to ensure the camera electronics are properly

powered. Some notebook computer USB ports provide just the minimum 500 mA (2.5W) and very

little headroom for turn-on current surge. The Tau SWIR camera may not function optimally under

this condition.

FLIR Camera Controller GUI

The FLIR Camera Controller GUI provides communication between a PC and a FLIR camera using either

the USB interface or some other means of serial communication through the camera’s connector. The Tau

SWIR version of the GUI is export controlled software that is used to configure and control the Tau SWIR

camera.

1. Computers with an older version of the FLIR Camera Controller GUI should first uninstall it using

the Windows Uninstall utility via the Windows Control Panel before proceeding with this

installation.

2. The box in which the camera is delivered will contain a CD or USB flash drive with a copy of the

install file for the Tau SWIR version of the FLIR Camera Controller GUI described in this manual.

Copy this file to a folder on the host computer.

3. Open the directory where the saved file is and double-click “CameraControllerSetup.msi”.

4. Walk through the installation steps.

5. When the primary installation is completed, a message will prompt the user to install Silicon

Laboratories drivers. This portion of the installation is necessary for using a USB connection to

the camera.

6. The program will install to All Programs→FLIR Systems→Camera Controller GUI

7. If a connection cannot be established with the camera, access the Device Manager of the host

computer to verify proper driver installation and verify the communications port. Connection

issues are most often caused by attempting to use either the wrong COM Port or the wrong

baud rate to connect to the camera.

a. Right-Click on “My Computer” and select “Manage”. This is typically either on the

desktop or available through the start menu.

b. Select “Device Manager” on the left Pane.

c. Expand the tree for “Ports (COM & LPT)”.

d. Note the COM Port number used for Silicon Labs. The following example shows COM3.

Page 23

Page 23

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Figure 14. Device Manager showing proper driver installation

Page 24

Page 24

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

FLIR Camera Controller Software Interface

This section describes simple communication with the camera using the FLIR Camera Controller GUI and

assumes that the camera is connected to the PC using a USB cable and either the VPC or Camera Link

Accessory Module.

1. Run the FLIR Camera Controller GUI by clicking on the start menu and accessing Start→All

Programs→FLIR Systems→Camera Controller GUI. The software may take up to 30 seconds to load

the first time. The first time the camera is connected, a window will pop up asking the user to

select the camera type. Select SWIR.

Figure 15. Select Camera Manager

2. When the GUI first opens, it will display “Not Connected” on the bottom left (see Figure 16). The

first step is to connect to the camera.

Page 25

Page 25

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Figure 16. FLIR Camera Controller GUI Status Tab – Not Connected

3. Connect to the camera by selecting Tools→ Connection

Page 26

Page 26

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Figure 17. FLIR Camera Controller GUI Connection Window Part 1

4. Select Serial (RS-232), select 921600 as the Baud Rate for fastest communication, and click Finish.

If there are more than one serial communication ports enabled on the computer, the button will

display Next.

Figure 18. FLIR Camera Controller GUI Connection Window Part 2

5. If required, select the Com port listed in the Device Manager and click Finish. The camera selection

can also be switched by selecting Select from the Camera pull-down menu at the top of the user

interface window.

Page 27

Page 27

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Figure 19. Camera Type Selection

6. The GUI will now automatically connect to the camera and refresh information in the software.

The software will automatically identify the camera type and display “Tau SWIR Camera

Controller” in the upper left of the Status screen. The status LED will turn green and it will display

“Connected” on the bottom left. It is also possible to retrieve the part number and serial number of

the camera from this screen.

Figure 20. FLIR Camera Controller GUI Status Tab – Connected

Note: The connection status, Camera status, Camera Part #, Serial # and FPA Size are displayed

at the bottom of all tabs.

Troubleshooting the FLIR Camera Controller GUI

If the FLIR Camera Controller GUI does not link with the camera, there will be a popup shown below

which indicates that the GUI has not been able to communicate with the camera.

Figure 21. FLIR Camera Controller Error Message

If this is the case, verify the following:

• The USB Cable is properly connected to both the computer and the Accessory Module so that there

is a green LED illuminated on the accessory.

• Verify the proper port was selected if it was not detected automatically. Select Advanced, then Next

in the Tools→Connection dialog box. Also, try disconnecting and then re-connecting the cable to

the PC. If the GUI was launched before the cable was connected, close the GUI, connect the cable,

and then re-launch the GUI.

• The Baud rate must be set in the Tools→Connection dialog box. The FLIR camera supports Baud

rates of 57600 and 921600. The FLIR camera automatically detects if the Baud Rate of the first

incoming message is either 57600 or 921600 and will communicate at that Baud Rate until reset.

Page 28

Page 28

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

• The Port may be occupied by another application. Shut down any other applications that may be

using the port. Also, multiple instances of the FLIR Camera Controller GUI Program can be

initiated using different ports. Be sure the camera that is intended in being controlled is actually

connected to the physical port that was verified in the Device Manager in Section 6.2, step 7.

• Verify that the camera is powered by checking that the camera is producing an image on an analog

monitor. The Tau SWIR camera takes approximately 5 seconds to start up, stabilize the temperature

of the focal plane array (FPA), and provide video. Until this time a splash screen will be displayed

on the monitor. Digital video will not be available until the FPA is stable.

• If the GUI says LWIR, Muon, or sUAS Camera Controller on the top, use the Camera pull-

down menu and choose Select to select SWIR. If this option is not present, the GUI will need to

be uninstall using the Windows Uninstall utility via the Windows Control Panel and delete the

Program Files directory (C:\Program Files (x86)\FLIR Systems\Camera Controller GUI). Go to the

FLIR website (http://www.flir.com/cores/display/?id=51880) to download the latest Tau Camera

Controller software.

• Ensure the host computer has all Important Windows Updates installed, including the latest .NET

Framework. .NET Framework can also be downloaded and installed from the Microsoft website

(http://www.microsoft.com/net/download). It is best to use the client profile from the web. Once

all updates are installed, reinstall the Camera Controller GUI and use Camera→Select to select

SWIR.

If serial communication cannot be initiated with the camera after verifying these items, refer to the

frequently asked questions (FAQ) at http://www.flir.com/cvs/cores/faqs/tau/all/. Additionally, a FLIR

Applications Engineer can be contacted at SBA-Cores@flir.com.

Page 29

Page 29

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

7.0 Operation of the FLIR Camera Controller GUI

This section describes operation of the FLIR Camera Controller GUI and explains adjustments that can be

made to the camera.

Menu Bar

The FLIR Camera Controller GUI has a classic menu bar where drop down menus are displayed.

Figure 22. FLIR Camera Controller GUI – Menu Bar

View: Select Log to display a log at the bottom of the GUI. This does not display all commands

sent to the camera, but rather displays connection information and possible error messages. This

Logger pane is displayed in some of the screen shots below. Click Refresh to refresh the GUI. This

can also be done with the F5 function key on a keyboard.

Camera: Select Connect to connect to a camera using the same communications parameters that

were used previously. If connection cannot be established, it will ask to retry or open the connection

wizard.

Select Disconnect to open the COM port that the GUI is occupying and disconnect from the camera.

This can be useful if using other software to communicate with the camera.

The Select submenu allows selection of different camera types. The type “LWIR-MWIR” can be

used for Tau SWIR, Quark, Tau 2, Tau, and Photon.

Tools: Select Clear Log to clear the log that can be displayed using the View menu.

Select Connection to open the connection wizard. This allows the ability to configure

communication settings such as COM Port and baud rate.

Select Settings to configure the GUI. It is possible to configure the GUI to automatically connect

at startup using the previous settings, allow multiple instances to be open at once, or change

communication timing parameters.

Help: Open the Camera Controller User Guide in the default pdf viewer. The latest version of this

document installs in the Program Files directory. Note: This selection is not enabled as of

the release date for this manual.

Select About Camera Controller to open a separate window with version information for the GUI

and the camera.

Page 30

Page 30

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

About: The GUI Framework is the version of the GUI. The Main App is the software version of

the camera. The version in the example is 123.21.16.126. The firmware is 16.14.0.23.

Click Details to view versions for each individual dll in the GUI.

Figure 23. Help -- About Camera Controller

Page 31

Page 31

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Calibration Tab

When the FLIR Camera Controller GUI successfully links to the camera, the window shown below will be

visible. At the bottom of the application window, there is the Camera and FPA status. The GUI provides

six tabs allowing for camera control as described below.

Figure 24. FLIR Camera Controller GUI – Status Tab

Configuration

Integration Time: The Integration Time text box is used to set the integration time in milliseconds.

The integration time is similar to the exposure time of a standard daylight camera and is the time

per frame during which charge is collected. The camera operates in “snapshot” mode, meaning

that charge is collected on the entire array of pixels at the same time. Integration times may be set

as low as 0.010ms, while the upper limit depends on the frame rate and is limited to about 0.032ms

less than the frame period, about 16 milliseconds in 60fps mode or 33ms in 30fps mode . Short

integration times should be used for viewing very bright objects, while long integration times are

used for low illuminiation conditions. If integration times that are too short or too long are used,

the image will appear non-uniform and will seem to be non responsive to the signal, so some

experimentation is required to determine the best integration time for the scene being imaged.

Using the Image Mean Intensity feature will assist in determining the best integration time. An

integration time resulting in good imagery for a typical application is when the camera is “looking”

at the scene of interest and the image mean intensity is between 3000 and 6000 counts.

Note: In order to manually select values for integration time, Auto-Exposure,

located on the Optimization tab, must be disabled.

Page 32

Page 32

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Frame Rate: The Frame Rate box is used to set the frame rate of the camera’s digital output. The

NTSC or PAL analog output will not be affected, except to output repeated frames for frame rates

less than 30fps or to skip frames for frame rates greater than 30fps..

Sensor Gain: Some FLIR SWIR cameras support multiple gain modes. Selecting between these modes

will adjust the intrascene range and control the sensitivity.

Corrections: The Corrections buttons turn on and off the NUC corrections for the camera. These states

are saved with the Save Settings command and so are global rather than applying separately to each NUC

table.

FFC: Flat field correction (FFC) is a process whereby offset terms are updated to improve image

quality. This is done by presenting a uniform brightness (a flat field) to every detector element.

While imaging the flat field, the camera updates correction coefficients, resulting in a more

uniform array output. During an FFC, the analog and buffered digital video is frozen for less than

500 ms, and resumes automatically thereafter.

Repeating the FFC operation often prevents the imagery from appearing “grainy”. This is

especially important when the camera temperature is fluctuating, such as immediately after turnon or when ambient temperature is drifting.

Bad Pixel: The Bad Pixel button turns on or off the bad pixel replacement function.

Gain: The Gain button turns on or off the application of the gain correction table.

Noise: The Noise button turns on and off a temporal noise filter which will reduce the temporal

noise of the camera by about a factor of two without otherwise affecting the image.

Bad Pixel Detection Limits: These are the parameters outside of which a pixel is considered “bad” during

the 2-point NUC process. The Min and Max Pixel Range parameters define the limits of the absolute value

in A/D counts within which each pixel must fall in order to be considered good. The Min and Max Gain

parameters are the limits of the gain correction factors by which the pixel values must be multiplied in order

to be equal to the array average value. These limits can be set for the NUC process, but not saved.

NUC Table Calibration: The NUC Table Calibration area is one of the most critical sections in generating

a good image. Some of the camera’s most important functions are performed here. First, the desired NUC

table to be calibrated should be selected using the Select NUC pulldown menu. Be sure to disable the autoexposure feature. Then the integration time should be set appropriately to the scene illuminaiton to be

imaged. The Image Mean Intensity (see below) is useful in doing this. Two uniform, flat white sources

are needed for the 2-point correction and it is best if they span a large part of the range of scene illumination

values to be imaged. Integrating sphere sources are ideal for this purpose, however a very near field

uniformly illuminated white paper may be used. The Image Orientation and Bad Pixel Detection Limits

also need to be set appropriately before the process is started. Now, push the Start button to initiate the 2point NUC process. Follow the prompts to place the bright and dark sources in front of the camera so they

fill the entire field of view. A message will appear when the process is complete. The Abort button will

Page 33

Page 33

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

be active during the NUC process and will allow the user to abort and possibly restart the 2pt NUC process.

When the NUC process is complete, check to see that the image is good and the number of bad pixels found

is not unreasonably high, then press the Save NUC button to save the NUC parameters. The NUC

parameters include a header with the selections relevant to that NUC (integration time, invert/revert, etc.),

a gain table with the gain values for each pixel, and an offset table with the offset values for each pixel. If

a pixel is found to be bad, a bit is set in the gain table for that pixel indicating its status and the value of the

average of the eight nearest good neighbors is substituted in the image. If it is not desired to save the NUC,

reselecting it from the pulldown menu will return to the NUC table values which were active before the

process was initiated.

Image Mean Intensity: Each time the “Get” button is pressed, the camera will calculate the

average intensity value of the entire array, in 14-bit A/D counts (0-16383). The range of values

may not span the entire A/D converter range, but will be about 500 to 15800 counts

Detection Results: These boxes show the bad pixels resulting from the last 2-point NUC

performed. The significance of the word “New” is that those boxes only report pixels which were

not already in the bad pixel map for that NUC. Note that if a good NUC has already been

performed, and unless the Clear All RAM Bad Pixels button has been pressed, they will usually be

0. Also, the gain bad pixel calculation is done first, and only those pixels which are not gain bad

pixels will be reported as bad range. The Array Total will always report the total bad pixels in the

bad pixel map, whether they come from the last NUC or were there before.

Clean Start

Clear All RAM Bad Pixels: This button is used before performing a 2-point NUC if a new bad

pixel table is desired. Note that a warning text will come up saying that the gain table will be

initialized during this process. Therefore a new 2-point correction will need to be performed

subsequently in order to generate a satisfactory image.

Restore Factory Bad Pixels: A bad pixel map will be generated at the factory during Acceptance

Testing that will include pixels which are not typically found by the standard 2-point NUC, such

as noisy or flickering pixels. This map should always be installed to give the best image. It will

need to be Restored if the Clear All RAM Bad Pixels function is used. The bad pixel map can

always be viewed by pressing the Retrieve BP Map button.

Important: If the image for that NUC table is to be Inverted or Reverted, first set the

Orientation to Normal (not Inverted or Reverted), then Restore the Factory Bad Pixels, then

reset the Orientation to the desired configuration for that NUC table.

Do FFC: This button will cause the camera to do a one-point (offset only) NUC correction. A uniform

flat white source should be placed in front of the camera before pressing this button. This function is useful

to achieve the most uniform correction possible, for example if the camera power has been cycled since the

last 2-point NUC has been performed.

Page 34

Page 34

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Bad Pixel Control: All defective pixels are identified by FLIR as part of the standard factory Acceptance

Test. However, it is possible that a camera in the field may have a pixel that needs replacing. Usually these

are flickering pixels, or pixels which have developed an offset, and may appear as white on a black

background.

Note: When eliminating pixels, it is important that the camera is not inverted and not reverted.

The bad pixel kill procedure involves taking a snapshot of a scene that clearly shows the bad pixel. Once

a snapshot is taken, the Retrieve Snapshot button will open a separate window that has pane on the right

that shows a reticle with a zoomed subframe. Use the mouse, then the arrow keys to fine tune the cursor

location until the offensive pixel is between the crosshairs. The zoom value of the subframe can be adjusted

using the slider bar. Use the Enter key to select the pixel and add it to the pixel kill list.

Bad pixels can also be manually added to the list by entering the row and column, and clicking Add.

Bad pixels can be removed from the Kill Pixel List by selecting them one by one and clicking Remove

Selected Pixels. Use Ctrl to select multiple pixels or Shift to select a group of pixels to be removed. There

is also a Remove All Pixels from the List button that will clear the list.

Once the list is populated, click Set Bad Pixels to add these pixels to the camera’s bad pixel map. This will

immediately affect the video output. Verify that the pixel is being replaced and click Save Bad Pixels to

save this change in the camera. If the pixels are not being replaced, reset the camera using the Setup Tab to

revert back to the previous state.

The bad pixel map currently in the camera can always be displayed by pressing the Retrieve BP Map

button.

FPA Temperature: The camera’s Focal Plane Array (FPA) temperature in Celsius is reported in this edit

box. The factory setting for this target FPA temperature is 20°C, as managed by the TE Cooler in the VPA.

If the camera cannot maintain this temperature due to extreme environmental temperatures or to insulating

mounting configurations then the camera will automatically step to the best TEC temperature that can be

maintained and will display the actual temperature of the FPA in this edit box.

Page 35

Page 35

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Optimization Tab

The Optimization tab, shown in Figure 25Error! Reference source not found. below, provides the ability

to control the Automatic Gain Control (AGC) features and the enhancement algorithms. Parameters for a

given mode are contextually made available depending on which mode is selected. If configuration options

are changed in the camera the Save Settings button should be used before resetting the camera. Factory

Defaults helps the customer return the camera to the options originally configured by the factory when

shipped.

Figure 25. FLIR Camera Controller GUI -- Optimization Tab

AGC Modes: There are four Histogram Equalization Modes included in the Tau SWIR camera. There are

also four Legacy Modes for customers wishing to stay with existing AGC modes from previous revisions

of FLIR cameras.

Histogram Equalization Modes: The Plateau Histogram Equalization algorithm seeks to maximize

the dynamic range available for the content of the scene. It does this using a transfer function that is based

on the number of pixels that are in each bin and allocating more 8-bit range for that bin. The Plateau value

is the pixels/bin limit when the transfer function is maximized. When this number is small, the Automatic

AGC will approach a linear algorithm that preserves a linear mapping between the 14-bit and 8-bit data.

The goal of the Automatic algorithm is to try and make each of the 255 bins have the same number of

pixels in it, which should give the best contrast for the given scene. When the plateau value is higher, the

algorithm is more able to redistribute the data to achieve this goal. This prevents wasted levels of grey on

regions that have no scene content and can visually be seen in the histograms by noticing that peaks are

much smoother and the data is spread much more evenly.

Page 36

Page 36

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Automatic (“Auto”): This is the most sophisticated algorithm and for most imaging situations, the

best all-around choice. This factory default along with the default parameter settings should be used

in general imaging situations. In Automatic, image contrast and brightness are optimized

automatically as the scene varies. This mode provides an AGC which is based on a plateau

histogram equalization algorithm. An excellent starting point for the understanding of histogram

equalization can be found in Wikipedia at http://en.wikipedia.org/wiki/Histogram_equalization.

The implementation in the Tau SWIR camera is much more sophisticated than the basic, providing

controls for the Linear Percent (low “bin” enhancement), Plateau Value (histogram high “bin”

clipping level), ITT Mean (gray scale mid-point), Max Gain (AGC gain), AGC filter (speed at

which the AGC reacts), and Tail Rejection (removes outermost values of the histogram) with

available ranges to the side of the configurable values. Adjusting these parameters beyond the

standard default settings can be used to optimize for specific scenes. Creating a generalized AGC

algorithm for any scene and all users is very difficult. Most specific scenes can be optimized to

provide the best image for that particular situation and that particular users needs. The default

settings are those that FLIR has chosen to work over a variety of scenes.

LACE: Local Area Contrast Enhancement performs histogram equalization separately over 20 tiled

regions of the image. This accentuates the contrast in each local area rather than the entire scene.

LACE can greatly enhance the visual quality of imagery where there is a lot of local contrast and

detail in a scene with a wide global dynamic range. Dynamic DDE, ACE threshold and ITT mean

are all applicable to LACE. This mode is defined for the full 640 × 512 window size.

Auto w/ Info Based: This mode can most easily be explained as a joining of the two AGC modes

Auto Mode and Information Based Mode. The result should lie somewhere in between those two

modes in terms of relative dynamic range distribution for various irradiance ranges.

Information Based: Tau SWIR includes Information-based algorithms which reserve more

shades of gray for areas with more information or scene content by assigning areas with less

information or scene content lesser gray shades. By assigning fewer gray shades to areas with less

information (e.g. sky, sea, roads) the fixed pattern noise is reduced in these areas and allows for

more detail to be given to the more interesting portions of the image. Both Information-based

algorithms undergo the plateau equalization process described in a previous paragraph, and

therefore all parameters described also apply.

The differences between the Information-based and Information-based Equalization algorithms are

noteworthy as both have advantages. The Information-based algorithm completely excludes pixels

from histogram equalization if they are below the information threshold (described later in this

section). This is advantageous in that noise is completely removed from areas of the image

determined by the algorithm to not contain information, but scenarios in which the user is

attempting to detect small temperature or emissivity variations are not ideal for this mode because

desired information may be lost depending on the threshold. The Information-based Equalization

algorithm includes every pixel independent of scene information in the histogram equalization

process, but simply weights each pixel based on the information threshold. This mode shows more

moderate improvements in scenes with large areas void of information, but the advantage over the

Information-based mode is that scene content will never be removed.

Page 37

Page 37

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Note: The default mode (“Auto”) along with the default parameter settings for the Automatic

AGC mode have been proven to offer the best image quality for generalized scene imaging. It

may be possible to tune the AGC to achieve a better image for a given scenario. However, be

aware that it is possible to make AGC adjustments that will configure the camera to produce no

8-bit image (all black or all white). If these settings have not been saved, simply reset the camera

to restor previously saved settings. Alternatively, restoring the factory defaults on the Optimization

or Utilities Tab will return the camera to its factory default state.

Legacy Modes:

Once Bright: In this mode, the brightness will be set once when the mode is selected. The

brightness (level) is calculated as the mean of the current scene when the Once Bright button is

selected. The scene is mapped to the analog video using a linear transfer function. Image contrast

can be adjusted by the Contrast slider. This is the only user adjustable parameter. Upon entry into

the once bright mode, the currently- stored value of contrast is applied (i.e. the power-on defaults

or the last saved values).

Auto-Bright: In this mode, the brightness (level) is calculated as the mean of the current scene just

as in Once Bright mode. The difference with Auto-Bright is that the values selected for the start

and end of the linear transfer function are automatically updated in real-time, not only at the start

of AGC mode selection. The Brightness Bias offsets the displayed image in intensity. Upon entry

into the auto bright mode, the currently-stored values of Contrast and Brightness Bias are applied

(i.e. The power-on defaults or the last saved values).

Manual: In this mode, image Contrast (gain) and Brightness (level) are entered completely

manually via the sliders. The scene is mapped using a linear transfer function. Upon entry into the

manual mode, currently-stored values of brightness and contrast are applied (i.e. the power-on

defaults or the last saved values). The brightness adjustment is ranges from 0 to 16383 and spans

the 14-bit data. The One-shot brightness adjustment button can be used to set the brightness in

Manual mode. This finds the mean of the 14-bit histogram and sets it as the value for the brightness.

This is the same method as used in Once-Bright and Auto-Bright.

Linear Histogram: Image contrast and brightness (gain and level) are optimized automatically

based on scene statistics using a linear transfer function. Controls for the ITT Mean (sets gray scale

midpoint) and Max Gain (AGC gain) are adjustable by entering the value in the Automatic

Parameters section. The Linear Histogram algorithm uses scene statistics to set a global gain and

offset (contrast and brightness) for the image. The Tail Rejection control determines what

percentage of the outermost values of the histogram to remove when performing the algorithm.

Upon entry into the linear histogram mode, the currently stored values are applied (i.e. The poweron defaults or the last saved values).

Note: In Manual mode and Once Bright mode, the brightness setting must be updated as the

camera scene changes. To avoid this issue, it is recommended to use Automatic, Linear Histogram,

or Auto Bright modes when possible. Also, AGC mode will only affect the digital data output if the

Page 38

Page 38

The information contained in this document pertains to a dual use product controlled for export by the Export Administration

Regulations (EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not required prior to

export or transfer to foreign persons or parties unless otherwise prohibited.

Digital Video output mode is set to 8-bit data. The 14-bit digital data bypasses the AGC sections

of digital processing.

Linear Parameters: Used for fine tuning the Auto Bright, Once Bright, and Manual modes, these settings

are contextually active depending on which Algorithm is selected. Each of their settings is described above.

Once Bright – Only the Contrast control is active.

Auto Bright – The Brightness Bias and Contrast controls are active.

Manual – The Brightness and Contrast controls are active.

Automatic Parameters: Used for fine tuning the Histogram Equalization Modes and Linear Histogram

modes, these settings are contextually active depending on which AGC algorithm is selected. Each of their

settings is described below as they pertain to the particular Algorithm.

Smart Scene Optimization (SSO): The Smart Scene Optimization value defines the percentage

of the histogram that will be allotted a linear mapping. Enabling this feature facilitates the

avoidance of irradiance level compression, which is specifically important for bi-modal scenes.

With SSO enabled, the difference in gray shades between two objects is more representative of

the difference in reflected energy). SSO helps to set how linear the HEQ and information based

AGC algorithms are allowed to be to provide the highest amount of perceived contrast in every

scene. SSO can range from 0% to 100%.

Plateau Value: When plateau value is set high, the algorithm approaches the behavior of classic

histogram equalization – gray shades are distributed proportionally to the cumulative histogram,

and more gray shades will be devoted to large areas of similar temperature in a given scene. On