Page 1

Tau CNV

User’s Manual

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual Page 1 of 49

Tau Color Night Vision Camera

Page 2

FLIR Advanced Imaging Systems, Inc.

FLIR Advanced Imaging Systems (AIS) produces a wide range of high performance cameras for applications that

demand high resolution, high data rates, wide dynamic range, high sensitivity (low light), low power and small form

factors (space claim) packaging. FLIR AIS satisfies the needs of our customers by applying the best camera sensor

technologies to our customers’ challenging applications, and coupling these sensor technologies with low noise and

precision analog design, proprietary thermal stabilization, and real-time image processing. FLIR AIS’ cameras are

designed and built in our ISO certified facility and each camera is 100% tested and inspected using the photon

transfer curve methods and best manufacturing practices to verify performance to technical specifications and to

ensure total product quality.

FLIR AIS designs, develops, and manufactures its high performance cameras at its facility in Colorado Springs,

Colorado, USA, and is part of FLIR Systems Inc., a world leader in the design, manufacture, and marketing of

sensor systems that enhance perception and awareness for a wide variety of users in the commercial, industrial, and

government markets, internationally as well as domestically.

Contact Information:

FLIR Systems, Inc.

FLIR Advanced Imaging Systems, Inc.

5061 North 30

Colorado Springs, CO 80919 USA

(719) 598-6006 phone

(719) 598-6556 fax

http://www.flir.com/cvs/cores

supportais@flir.com

th

Street, Suite 103

10-10032-01 2011 FLIR Advanced Imaging Systems ECO 594

Rev A1 Tau CNV Camera User’s Manual page 2 of 49

Page 3

Table of Contents

1 INTRODUCTION .................................................................................................................. 6

2 CAMERA POWER ................................................................................................................ 6

2.1 IMPORTANT SYSTEM GROUNDING REQUIREMENTS ........................................................................................ 6

2.2 IMPORTANT POWER-UP SEQUENCING REQUIREMENTS ................................................................................... 6

2.3 IMPORTANT CLEANING AND LENS INSTALLATION INFORMATION .................................................................. 6

3 CAMERA FEATURES AND FUNCTIONS ....................................................................... 7

3.1 HIGH DEFINITION, 1280 X 1024 IMAGER ........................................................................................................ 7

3.2 PROGRAMMABLE ELECTRONIC SHUTTER ....................................................................................................... 8

3.3 AUTOMATIC GAIN CONTROL .......................................................................................................................... 8

3.4 AUTOMATIC COLOR AND WHITE BALANCE .................................................................................................... 8

3.5 SELECTABLE NOISE SUPPRESSION .................................................................................................................. 8

3.6 INTEGRATED, MOTORIZED, IR CUT FILTER OPTION ....................................................................................... 9

3.7 TRIGGER MODES - FREE RUN, OR EXTERNAL TRIGGER .................................................................................. 9

3.8 FLAT FIELDING (NON-UNIFORMITY CORRECTION)....................................................................................... 10

3.9 DIGITAL AND ANALOG VIDEO OUTPUT OPTIONS ......................................................................................... 10

3.10 SMALL SPACE-CLAIM AND LOW POWER REQUIREMENTS ............................................................................ 10

3.11 EFFECTIVE DAY AND NIGHT COLOR THROUGH BUILT-IN FILTER SLIDER (OPTIONAL) ................................. 10

4 CAMERA SPECIFICATIONS ........................................................................................... 11

4.1 CAMERA SPECIFICATIONS ............................................................................................................................ 11

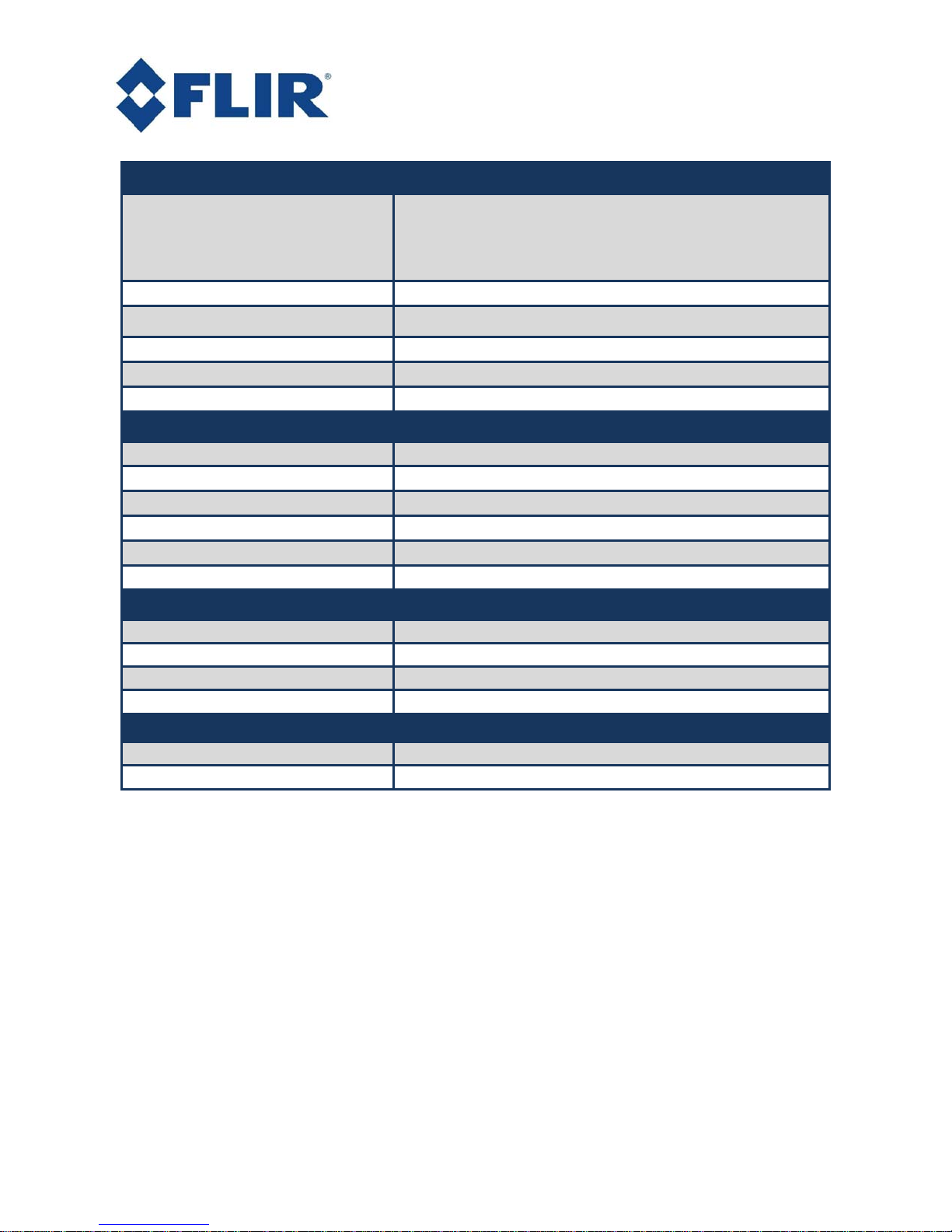

4.2 QUANTUM EFFICIENCY (QE) RESPONSE CURVES ......................................................................................... 13

5 THEORY OF OPERATION ............................................................................................... 14

5.1 CAMERA LAYOUT ......................................................................................................................................... 14

5.2 LENS MOUNT ASSEMBLY ............................................................................................................................. 14

5.3 TAU CNV CMOS SENSOR ........................................................................................................................... 16

5.4 SENSOR MOUNT AND HEAT SINK ................................................................................................................. 17

5.5 CAMERA ELECTRONICS ................................................................................................................................ 17

5.5.1 Sensor Bias and Interface .................................................................................................................... 17

5.5.2 Clock and Control Circuitry ................................................................................................................ 17

5.5.3 Power Conditioning and Distribution .................................................................................................. 17

5.5.4 Camera Interface .................................................................................................................................. 18

6 CAMERA INTERFACING ................................................................................................ 19

6.1 LVDS PARALLEL DATA COMMUNICATION .................................................................................................. 19

6.1.1 Power Connector ................................................................................................................................. 20

6.1.2 Parallel Data Connector ....................................................................................................................... 20

6.2 GROUP INTERFACE ....................................................................................................................................... 22

6.2.1 Group Interface Default Settings ......................................................................................................... 22

6.2.2 Power Connector ................................................................................................................................. 23

6.2.3 Camera Link ........................................................................................................................................ 23

6.2.4 Analog Video Output and Serial Interface (default configuration) ...................................................... 25

6.2.5 Trigger In/Out ...................................................................................................................................... 25

6.2.6 Trigger In Mode ................................................................................................................................... 26

6.2.7 Trigger Out Mode ................................................................................................................................ 26

6.2.8 Video IRIS (future) .............................................................................................................................. 26

7 MECHANICAL DETAIL ................................................................................................... 26

7.1 HOUSING & MATERIALS ............................................................................................................................... 26

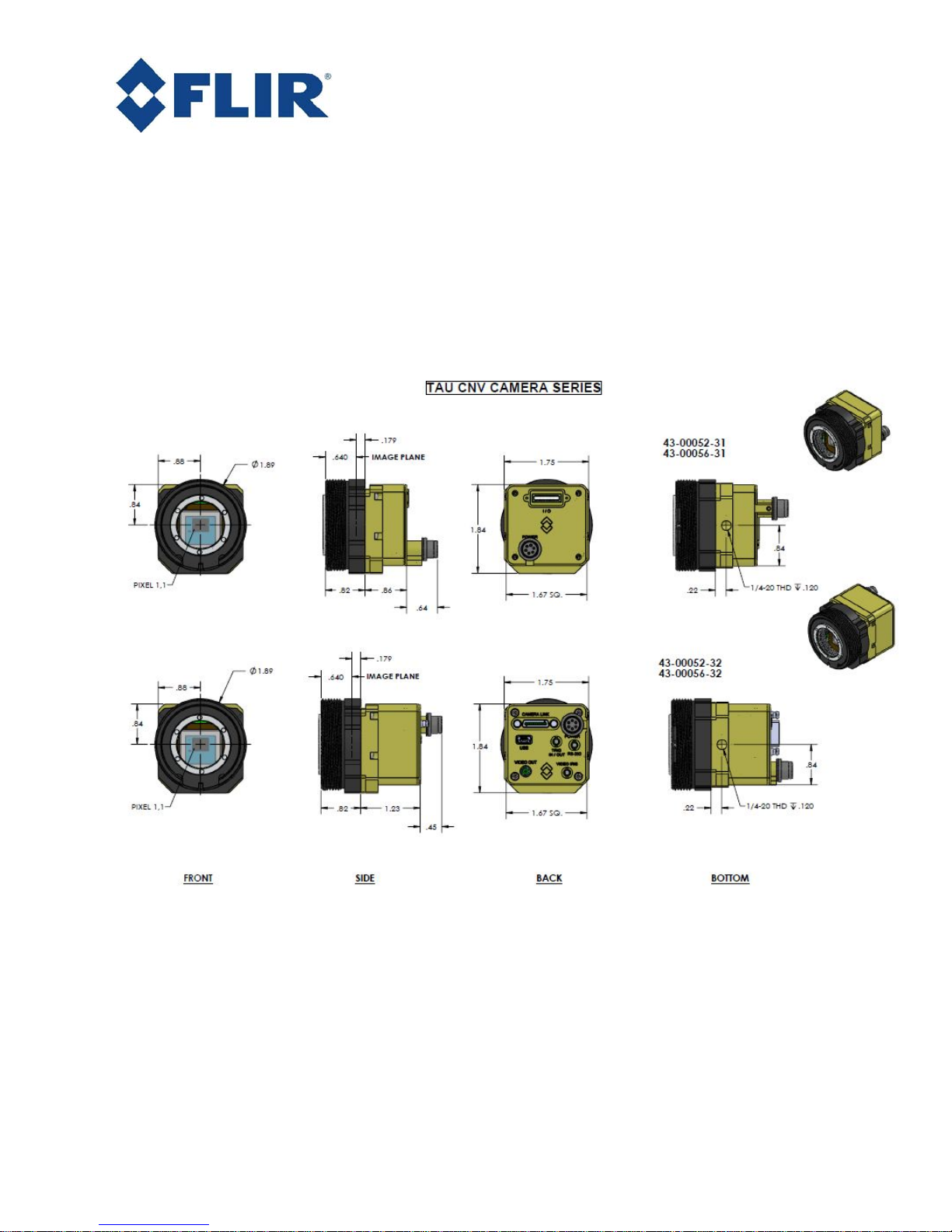

7.2 DIMENSIONS ................................................................................................................................................. 27

7.3 LENS MOUNTING AND BACK FOCUS ADJUSTMENT ...................................................................................... 27

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 3 of 49

Page 4

8 CAMERA MOUNTING & COOLING ............................................................................. 28

8.1 ¼ - 20 MOUNTING HOLE (TRIPOD) ............................................................................................................. 28

8.2 IMPORTANT MOUNTING REQUIREMENTS ...................................................................................................... 28

9 COMMAND AND CONTROL OF THE CAMERA ........................................................ 29

9.1 FLIR AIS’ CAMERA CONTROL UTILITY ....................................................................................................... 29

9.1.1 Installation ........................................................................................................................................... 29

9.1.2 Camera Connection Screen .................................................................................................................. 39

9.1.3 GUI Advanced User Mode ...................................................................................................................... 42

10 CAMERA CARE AND MAINTENANCE ..................................................................... 48

10.1 MAINTENANCE, RETURNS, AND REPAIR ....................................................................................................... 48

10.2 ELECTROSTATIC DISCHARGE (ESD) ............................................................................................................. 48

10.3 COVER GLASS DAMAGE ............................................................................................................................... 48

10.4 CLEANING THE CAMERA HOUSING ............................................................................................................... 49

11 REVISION CONTROL.................................................................................................... 49

List of Figures

Figure 1: Tau CNV Video Camera ............................................................................................................................... 7

Figure 2: QE Response Curves for Color Camera and Monochrome Cameras .......................................................... 13

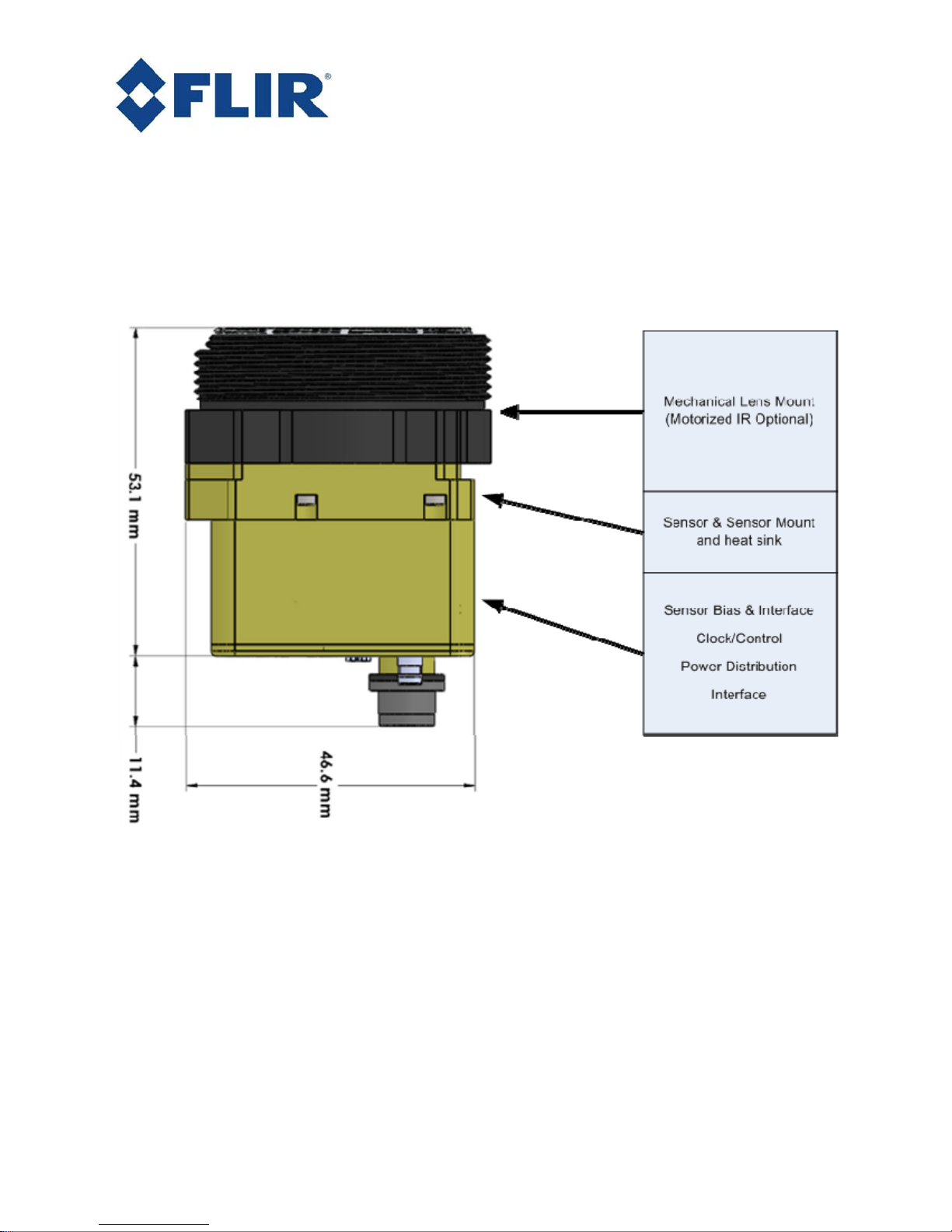

Figure 3: CNV Camera (not shown with optional motorized IR-cut Filter for color camera) .................................... 14

Figure 4: Tau CNV Camera with M42 Lens and C-Mount Adapter .......................................................................... 15

Figure 5: Tau CNV Camera with M42 Lens Mount, Integrated IR-Cut Filter Slider (color only), and C-Mount

Adapter ................................................................................................................................................................ 16

Figure 6: Camera Parallel Interface Back Plate Diagram. .......................................................................................... 19

Figure 7: Group Interface Back Panel View ............................................................................................................... 22

Figure 8: Camera Link SDR-26 diagram .................................................................................................................... 23

Figure 9: Dimensions .................................................................................................................................................. 27

List of Tables

Table 1: Tau CNV Camera Specifications

Table 2: Parallel Interface, Power Connector ............................................................................................................. 20

Table 3: Parallel Interface Connector Pinout .............................................................................................................. 20

Table 4: Group Interface Default Configuration ........................................................................................................ 22

Table 5: Parallel Interface, Power Connector ............................................................................................................. 23

Table 6: Camera Link SDR-26 Connector Pin Assignment ....................................................................................... 24

Table 7: USB Mini-B Interface .................................................................................................................................. 25

Table 8: TRIG IN/OUT Interface ................................................................................................................................ 25

1

............................................................................................................... 11

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 4 of 49

Page 5

Copyright and Trademark Notification

This document is subject to change without notice. FLIR Systems, Inc. is not responsible for the use, or

misuse, of the FLIR products that are associated with this document. After using this document, and the

associated referenced documents, you may need to contact FLIR support for additional assistance.

Reference to companies, technologies and trademarks does not imply that those referenced endorse or use

this product.

This document is copyrighted by FLIR Systems, Inc.

Camera Link is a registered trademark of the Automated Imaging Association.

Microsoft, Windows XP and Windows & are registered trademarks of Microsoft.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 5 of 49

Page 6

1 Introduction

Thank you for purchasing the FLIR AIS Tau CNV camera.

This user’s manual will give you an overview of the features and functions of your camera, and is part of

a document set:

User’s Manual to give you an overview of the camera’s features and functions;

Interface Control Document (ICD) for detailed interface and control information.

Your Tau CNV camera is backed by FLIR’s worldwide service and support team. If you do not find the

information that you need in one of these documents; please contact your sales representative and we will

get your questions answered quickly.

Important Notice:

representative for the latest version of this user’s manual.

This user manual is subject to change without notice. Please contact your FLIR

2 Camera Power

2.1 Important System Grounding Requirements

If you are using the Tau CNV camera with the FLIR 100-240VAC power supply (24-10038-01, 2420038-01, or 24-30038-01), ensure that a three wire single-phase (hot, neutral, earth-ground) connection

is used as supplied with your power supply. Also note that the TAU CNV camera chassis is isolated from

the earth-ground connection.

2.2 Important Power-Up Sequencing Requirements

The Tau CNV is designed against damage from hot-swapping; however, we recommend that you do not

hot-plug the camera to ensure proper operation. Make all connections to the camera before applying

power.

2.3 Important Cleaning and Lens Installation Information

Care is required when installing a lens to prevent dust from entering the lens mount opening. If dust is

introduced on the imager surface, on models without the automated Day/Night filter slider, you may clean

the surface of the imager using proper cleaning materials and good cleaning techniques for AR coated

glass. However, if your camera came with the automated Day/Night filter slider installed, the camera

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 6 of 49

Page 7

must be returned to the factory for cleaning since this operation requires disassembly and reassembly of

the camera. For this reason, it is recommended that all lens installations be performed under a flow hood

if available.

3 Camera Features and Functions

The FLIR AIS Tau CNV (see Figure 1) is an ultra-low light and small form factor video camera with user

programmable gain and on-chip electronic shuttering that provides large dynamic range and image

processing features that make it suitable for full sunlight to overcast starlight applications.

Color and Monochrome Low Light Imaging

High Definition, 1280 x 1024 Imager

Programmable Electronic Shutter

Automatic Exposure Control

Automatic Color and White Balance

Selectable Noise Filtering

Integrated, Motorized, IR Cut Filter Option

Free Run or External Trigger Modes

Flat Fielding (Non-Uniformity Correction)

Figure 1: Tau CNV Video Camera

Digital and Analog Video Output Options

Small Space-Claim and Low Power Requirements

3.1 High Definition, 1280 x 1024 Imager

The Tau CNV uses a CMOS imager with a 6.5μm2 pixel pitch, 5T active pixel type, 1280x1024 highdefinition (HD) resolution, and high dynamic range. These features, in addition to the low NEI of < 3E8

photons/cm

to larger and lower performance EMCCD and CCD sensor-based cameras.

The camera supports 960 lines per frame (default) or 720 lines per frame. The camera outputs 1280 pixels

per line, providing an overall frame resolution of 1280x960 or 1280x720.

2

-sec and typical read noise of less than 2 e- make this CMOS technology is a good alternative

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 7 of 49

Page 8

3.2 Programmable Electronic Shutter

The electronic shutter “exposure time” (also known as the “integration time”) is the amount of time the

sensor’s light sensitive pixels will collect charge when exposed to light, and is configurable via serial

command in increments of a “line time” (see ICD). Even though the camera output is 1280 pixels per line

by 960 lines per frame, internal camera functions require 993 lines to be clocked out of the sensor each

frame (Camera output includes a “line valid” signal to indicate which lines are the 960 valid image lines).

The time it takes to clock out a single line from a frame or “line time” is approximately 32.85us

(0.000032853333s). Therefore the minimum frame time for this camera is:

∗ 993 32.62

This corresponds to a maximum frame rate of slightly over 30fps.

Exposure time can be set anywhere from one line time (32.85us) to one line time less that the frame

period. At the maximum frame rate this corresponds to 992 * line time or 32.5ms.

The camera may be triggered internally (free running) or externally via the trigger-in pin of the trigger

in/out connector or via the Camera Link CC1 line

3.3 Automatic Gain Control

The automatic gain control (AGC) is used to automatically control the brightness and amount of detail in

the analog output image. The camera’s AGC will adjust the brightness and contrast to a level suitable for

viewing on an analog monitor by adjusting exposure (integration) time and histogram processing.

3.4 Automatic Color and White Balance

In the color version, automatic color and white balance are used for optimal image color production on

the analog video output. The camera sensor measures discrete green, red and blue color intensities

through the use of red, green, and blue filters in a Bayer mosaic pattern. The camera then uses a precision

algorithm to combine these three colors to produce optimal color representation of the image to match the

human visual system (HVS). Due to the wide variety of lighting, scene and other factors that influence

color, the image colors may not be accurately represented in all circumstances.

3.5 Selectable Noise Suppression

The Tau CNV supports noise suppression using image subtraction techniques. Noise suppression allows

frame-to-frame noise to be filtered out to improve image quality, especially for low-light imaging

applications. The amount of noise suppression is programmable (see Tau CNV ICD). Note: This use of

noise suppression can cause image-lag in dynamic scenes.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 8 of 49

Page 9

3.6 Integrated, Motorized, IR Cut Filter Option

The Tau CNV color camera can be purchased with an integrated, motorized, IR-cut filter option. The lens

mount assembly hosts a motorized two-glass position filter slider mechanism: (1) a BG38 IR-cut filter

for daytime operation to preserve accurate color representation, and (2) a clear glass filter that is used for

low-light imaging applications. A motorized assembly moves the appropriate glass filter into place as

instructed by a serial command.

3.7 Trigger Modes - Free Run, or External Trigger

The camera has two trigger modes: (1) Internal “free run”, and (2) external mode.

When the camera is triggered in Internal (free run) mode, images are continuously output at a frame rate

determined by trigger period. Trigger period resolution is in image line times which are approximately

32.85us (0.000032853333s). Valid trigger period settings are from 993 lines (approximately 30fps) to

29,425 lines (about 1fps). See the ICD for details on setting trigger period.

If attempts are made to set the trigger period to values greater than 29,425 lines, camera firmware

internally limits the actual setting to the 29,425 line maximum. If the trigger period register is set to

values less than 993 lines the camera will trigger erratically as some triggers will be missed.

In internal trigger mode, exposure or integration time is also configured in terms of line times. Minimum

exposure time can be set to 0 lines however the minimum useful exposure time is 1 line time or 32.85us.

The maximum exposure time is 1 line time less that the period setting. The period setting at max frame

rate (about 30fps) is 993 lines. This means the maximum integration time setting at this frame rate is 992

lines or 32.5ms. See the ICD for details on setting exposure.

In external mode, the rising edge of the trigger-in pulse starts a rolling reset of the sensor lines and the

falling edge of the trigger begins a rolling readout of the imager. Since the input trigger is asynchronous

to the internal camera timing and exposure and readout occur with line time resolution the actual time the

camera recognizes the input trigger rising and falling edges will have an uncertainty of one line time.

Note that this is a rolling shutter, and thus while the exposure time of each line will be consistent; the

exposure time of each line will not be simultaneous.

In external trigger mode the camera may be triggered at periodic rates of 30fps down to taking individual

snapshots. As in internal trigger mode the exposure time can be anywhere from 1 line to the trigger

period minus 1 line time. It should be noted however that practical max exposure time will be limited by

sensor dark current.

When in external trigger mode, care must be taken to ensure that falling edges of the trigger never occur

faster than the max frame rate of 30fps. Due to sensor operation details this can cause the sensor to get

into an invalid state that can take several seconds to recover from.

In external trigger mode, the external trigger pulses can be supplied via the trigger-in pin of the trigger

in/out connector or via the Camera Link CC1 line.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 9 of 49

Page 10

3.8 Flat Fielding (Non-Uniformity Correction)

Variations in the imager output, pixel-to-pixel within each color, are normalized to a common

response curve using an offset non-uniformity correction (NUC) performed at the factory. The

NUC correction is applied to both the digital and analog video outputs.

3.9 Digital and Analog Video Output Options

The Tau CNV provides both digital and analog video output. The digital output is a NUC corrected RGB

video output and is available using the Parallel or Camera Link interface. The analog video has NUC,

color, white balance and contrast corrections (as enabled) and is available in NTSC or PAL (future)

formats on the Group Interface and on the Parallel Interface.

3.10 Small Space-Claim and Low Power Requirements

The Tau CNV is designed for OEM applications that require small space claim and low power. The Tau

format provides a very compact camera by using high-density electronic circuitry and board-stacking

topology. Low power is achieved through the balance of performance, the use of low power circuitry and

high efficiency power management.

3.11 Effective Day and Night Color through built-in Filter Slider

(Optional)

Although the camera uses a precision algorithm for color production, an infrared cut (IR Cut) filter, such

as the BG38, should be used to obtain the best quality color. This is due to the physics of light energy.

Infrared (IR) light passes through the red, green, and blue filters of the Bayer pattern equally well

softening the colors by saturation. Through the use of a color daytime filter the colors are true throughout

the day time performance. Filter adjustment to night time operation and back is automatic. With the use

of the night time filter the near IR wavelengths are imaged, allowing enhanced nighttime viewing due to

higher sensitivity but sacrificing true color production. For more mechanical detail on the day/night filter

system see Figure 5. Use of an IR corrected lens is recommended to prevent apparent shifts in focus

when the night time filter is in use.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 10 of 49

Page 11

4 Camera Specifications

4.1 Camera Specifications

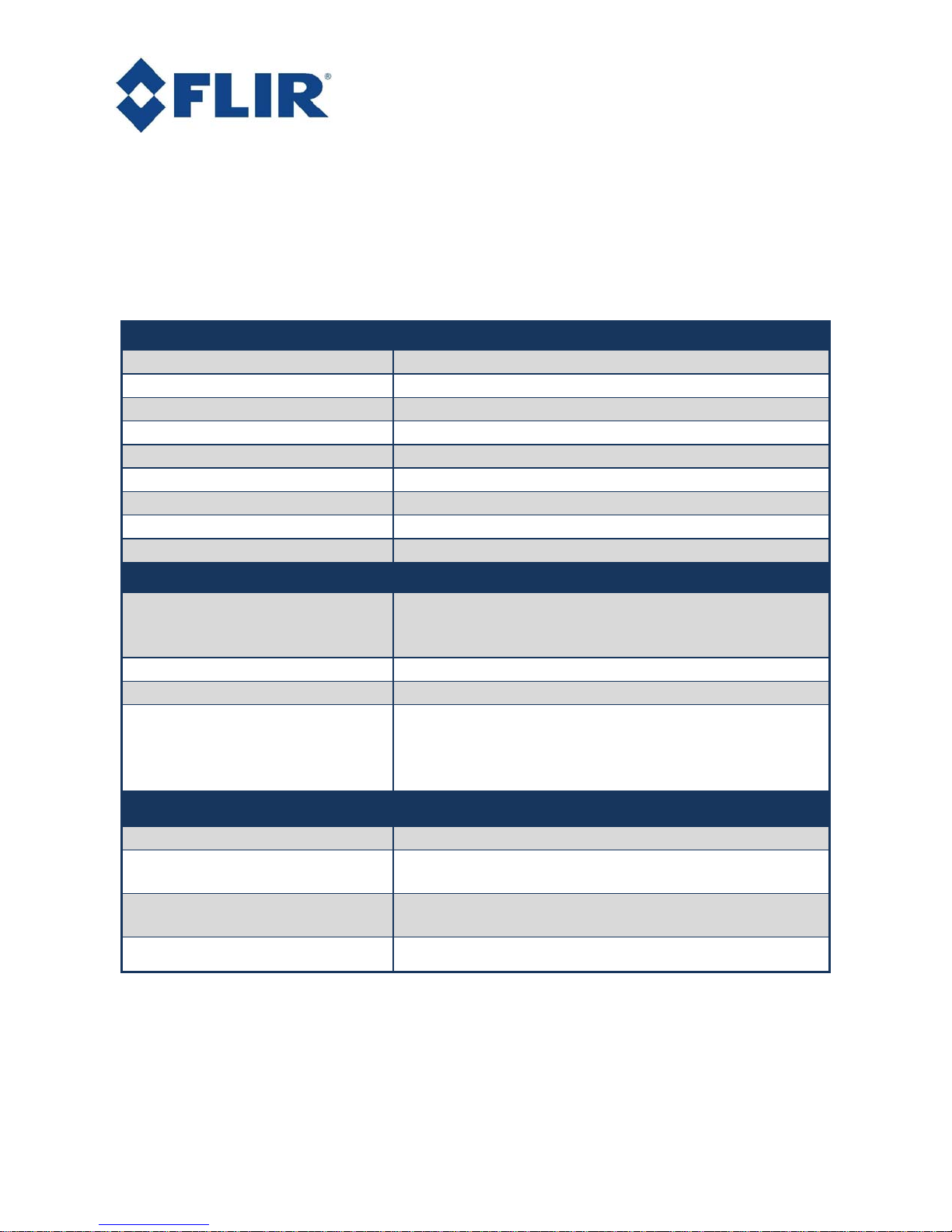

Table 1: Tau CNV Camera Specifications 1

Camera Specification

Image Sensing Color or Monochrome

Pixel Type 6.5um2 5T Active Pixels

Resolution 1280 x 960 and 1280x720 (HD 720p)

Dynamic Range 84 dB1

Shutter Mode Rolling Shutter

Read Noise 2 e- rms 1

Frame Rate 30 FPS @ HD Resolution

Quantum Efficiency >50% at 600nm

Image Lag < 0.1%

Input / Output Specification

14/16-bit Camera Link

Data Format

Trigger / Sync Connector Camera Link CC1 or LVTTL Level

Control & Communications Serial Commands

Communication Protocol

16-bit 3.3V LVCMOS Parallel

NTSC Video

3.3V LVCMOS Parallel

Camera Link

USB

RS-232 (future)

Trigger Specification

Definitions Serial Commands

Modes

External Trigger Source

Synchronization Sync Output Pulse (Trigger Input/Output Connector)

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 11 of 49

Free Run (Internal)*, External Trigger

*(with defined integration time)

Camera Link

Trigger Input/Output Connector

Page 12

Features Specification

Non-Uniformity Correction (NUC)

Image Correction

Gamma

Color Balance (color version only)

Gain

Gain Control Automatic (AGC) and Manual

AGC Region of Interest Selectable

White Balance Automatic and Manual (color version only)

Noise Filtering Multi-level, Selectable

IR Cut Filter Optional, Integrated Motorized Filter (color version only)

Mechanical Specification

Lens Mount M42 with C-mount or F-mount Adapter

Case Dimensions 48 x 49.4 x 64.5 mm

Case Material Aluminum, Alodine, Gold Finish

Lens Mount Material Aluminum, Anodized, Black Finish

Lens Mount Inserts Steel, Stainless

Weight < 175 grams

Environmental Specification

Temperature, Full Performance -20°C to +35°C

Temperature, Degraded Performance +35°C to +50°C

Temperature, Storage -40°C to +55°C

Humidity 95%, Non-Condensing

Power Requirements Specification

Input Voltage 12 VDC ± 5%

Power Consumption < 4W (typical)

Notes:

1. These are the specifications for camera performance at 20 °C. For camera performance

specifications over the operating temperature range, please contact your FLIR representative.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 12 of 49

Page 13

4.2 Quantum Efficiency (QE) Response Curves

Figure 2: QE Response Curves for Color Camera and Monochrome Cameras

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 13 of 49

Page 14

5 Theory of Operation

5.1 Camera Layout

Figure 3: CNV Camera (not shown with optional motorized IR-cut Filter for color camera)

5.2 Lens Mount Assembly

The lens mount assembly is a mechanical interface that positions and aligns a C-mount, F-mount, or M42

mount lens to the camera focal plane. The lens mount assembly is an M42 mechanical mount that is

properly aligned with the camera sensor mount via precision alignment pins. C-mount and F-mount

lenses interface to the M42 mechanical mount using their associated adapter mechanisms.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 14 of 49

Page 15

For customers that have their own optics and mechanical mounting housings, the CNV camera can be

used without the M42 lens mount assembly. In this case, the customer uses the sensor mounting plate

precision alignment pins to align the CNV camera focal plane with the customer’s optical assembly.

The M42 can be equipped with the optional motorized IR-cut filter for day and night imaging

applications. The IR-cut filter is an integrated BG38 glass filter for day time color imaging and optical

pass filter for low-light imaging applications. The filter is controlled manually using serial commands, or

under automatic control for detected low-light conditions. The default operation is manual control.

Figure 4: Tau CNV Camera with M42 Lens and C-Mount Adapter

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 15 of 49

Page 16

Figure 5: Tau CNV Camera with M42 Lens Mount, Integrated IR-Cut Filter Slider (color only), and C-

Mount Adapter

5.3 Tau CNV CMOS Sensor

The FLIR AIS Tau CNV is based on a high dynamic range Scientific CMOS (sCMOS) imager

technology. The sensor features a split readout scheme in which the top and bottom halves of the sensor

are read out independently. Each column within each half of the sensor is equipped with dual column

level amplifiers and dual analog-to-digital converters. This architecture was designed to minimize read

noise and maximize dynamic range simultaneously. The dual column level amplifier/ADC pairs have

independent gain settings, and the final image is reconstructed by combining pixel readings from both the

high gain and low gain readout channels to achieve a wide intra-scene dynamic range from such a small

pixel pitch. Micro-lenses are used to focus more of the incident light onto the exposed silicon and away

from the transistors where it can be gathered improving the quantum efficiency (QE) of the sensor.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 16 of 49

Page 17

Each pinned-photodiode pixel uses a 5-transistor (‘5T’ design), facilitating correlated double sampling

(CDS) and a lateral anti-blooming drain. Using this architecture, non-linearity is less than 1%.

5.4 Sensor Mount and Heat Sink

The sensor mount is used to align the lens assemblies to the camera focal plane using precision alignment

pins and to mount and heat-sink the camera to the customer’s assembly. The camera sensor is mounted to

the sensor mount plate. The sensor mount aligns the sensor to the precision alignment pins.

The sensor mount is also designed to be the mounting point for the camera to the customer’s assembly.

The sensor mount should be clamped into place with good thermal contact between the sensor mount

plate and the customer’s assembly. Care should be taken to maintain the case operating temperatures in

accordance with the camera specifications.

Heavy optical assemblies (focal length greater than 75mm) or other assemblies should not use the lens

mounting assembly without additional lens supports. The sensor mount also includes a tapped ¼-20

tripod adapter mounting hole, and the tripod adapter can be procured from FLIR.

See section 7 for the mechanical mounting information and section 8 for camera mounting & cooling

information.

5.5 Camera Electronics

The camera electronics includes four major subassemblies:

Sensor Bias and Interface

Clock and Control Circuitry

Power Conditioning and Distribution

Camera Interface

5.5.1 Sensor Bias and Interface

The sensor bias and interface circuits are used to provide the necessary bias controls to the camera sensor,

provide the necessary sensor timing signals, monitor sensor health and temperature, and to get the raw

sensor data from the sensor to the back-end electronics for image processing.

5.5.2 Clock and Control Circuitry

All camera control and image processing takes place in the clock and control circuitry. This circuitry

contains the FPGA that performs timing and control of the imaging sensor, image processing functions,

and memory for storing camera specific information and to support image processing.

5.5.3 Power Conditioning and Distribution

The power conditioning and distribution circuitry converts the single power input to a variety of internal

voltages to support image sensor biasing, logic biasing and external camera interface requirements. This

circuitry may also perform thermal electric cooler (TEC) control if your camera is equipped.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 17 of 49

Page 18

5.5.4 Camera Interface

The camera interface is used to provide external connections and formatting for camera control, video

output, and camera synchronization. The interface control document (ICD) covers both the pin-outs and

camera commands, and should be used as the reference document for interfacing to the camera.

The Tau CNV has two interface types: (1) The parallel interface; and (2) the group interface. The

parallel interface is a 3.3V Low Voltage CMOS (LVCMOS) interface connector that includes camera

control, digital video output, analog video output, and camera synchronization signals. The group

interface is a cluster of connectors including Camera Link interface for digital control and digital video,

USB control, analog video, trigger in/out, RS232 control (future), and video IRIS (future). See section

for a complete description of the camera interface.

6

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 18 of 49

Page 19

6 Camera Interfacing

The Tau CNV camera parameters are controlled and status monitored using serial communication via an

LVDS parallel, USB, or Camera Link connection. Digital video data and triggering are also available

over the LVDS parallel and Camera Link connection. Non-digital NTSC analog video is also available.

Two configurations are available. The LVDS parallel data communication interface and the group

interface which supports Camera Link data communication, analog output, trigger in/out, RS232 control

(future), and USB control.

For greater detail on the camera interface specifications, please see the Tau CNV interface control

document.

6.1 LVDS Parallel Data Communication

The basic camera configuration uses a 50-pin connector (Hirose DF12-50DS-0.5V (86)) for the parallel

data interface. A diagram of the back plate of the camera showing the various I/O connectors is shown

below:

Figure 6: Camera Parallel Interface Back Plate Diagram.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 19 of 49

Page 20

6.1.1 Power Connector

The input power connector is a Hirose HR30-6P-6S (71).

Table 2: Parallel Interface, Power Connector

Pin # Signal Type

1 Signal Ground

2 Signal Ground

3 No Connection

4 +12 VDC

5 +12 VDC

6 No Connection

6.1.2 Parallel Data Connector

The Tau CNV camera (with LVDS parallel configuration) can provide 14-bit or 16-bit CMOS data with

sync signals as well as analog video output simultaneously.

Table 3: Parallel Interface Connector Pin Out

Pin # Function I/0 Signal Type Description

1 RS232_TX Out 3.3V LVCMOS Serial to Controller

2 RS232_RX In 3.3V LVCMOS Serial to Camera

3 LVAL Out 3.3V LVCMOS Line Valid

4 FVAL Out 3.3V LVCMOS Frame Valid

5,6 Gnd - Ground

7 LVDS_RX0_P In LVDS Board Rev 0

8 LVDS_RX0_N In LVDS Board Rev 1

9 LVDS_Clk_P Out LVDS LVDS Clock +

10 LVDS_CLK_N Out LVDS Data 14

11 LVDS_Sync_P In LVDS Board Rev 2

12 LVDS_Sync_N Out LVDS LVDS Sync –

13 LVDS_Data0_P In LVDS CC1 Trigger Input

14 LVDS_Data0_N Out LVDS Data 15

15 LVDS_Data1_P Out LVDS LVDS Data 1 +

16 LVDS_Data1_N Out LVDS LVDS Data 1 17,18 Gnd - Ground

19 DISCRETE0 I/O 3.3V LVCMOS Programmable I/O

20 CMOS_Data13 Out 3.3V LVCMOS Data 13

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 20 of 49

Page 21

21 EXTERNAL_SYNC In 3.3V LVCMOS External Trigger Input

22 CMOS_DATA12 Out 3.3V LVCMOS Data 12

23 CMOS_DATA11 Out 3.3V LVCMOS Data 11

24 CMOS_DATA10 Out 3.3V LVCMOS Data 10

25 CMOS_DATA9 Out 3.3V LVCMOS Data 9

26 CMOS_DATA8 Out 3.3V LVCMOS Data 8

27,28 Gnd - Ground

29 CMOS/BT656_DATA7 Out 3.3V LVCMOS Data 7

30 CMOS/BT656_DATA6 Out 3.3V LVCMOS Data 6

31 CMOS/BT656_DATA5 Out 3.3V LVCMOS Data 5

32 CMOS/BT656_DATA4 Out 3.3V LVCMOS Data 4

33 CMOS/BT656_DATA3 Out 3.3V LVCMOS Data 3

34 CMOS/BT656_DATA2 Out 3.3V LVCMOS Data 2

35 CMOS/BT656_DATA1 Out 3.3V LVCMOS Data 1

36 CMOS/BT656_DATA0 Out 3.3V LVCMOS Data 0

37,38 Gnd Ground

39 CMOS/BT656_CLK Out 3.3V LVCMOS CMOS Clock

40 - - Unused

41,42 Gnd Ground

43 VIDEO_OUT Out

Analog 75Ohm

1Vpp

Analog Video

44,45 Gnd Ground

46 3V3 Out Power

3.3 Volt Supply for Adaptor

Boards

47,49 Gnd Ground

48,50 - - Unused

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 21 of 49

Page 22

6.2 Group Interface

The Tau CNV group interface supports: (1) Camera Link control and digital video output; (2) USB /

RS232 (future) camera control and analog video output; (3) trigger input/output; and (4) video IRIS

(future).

Figure 7: Group Interface Back Panel View

6.2.1 Group Interface Default Settings

The table below shows the group output default settings

Table 4: Group Interface Default Configuration

Function Default Condition

Trig IN/OUT Not Active

Trigger Mode Free Running

Video Output Active, NTSC Analog

Camera Link Enabled / Active

USB Enabled / Active

RS232 (future, do not use) Disabled (all modes)

VIDEO IRIS (future, do not

use)

Disabled (all modes)

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 22 of 49

Page 23

6.2.2 Power Connector

The input power connector is a Hirose HR30-6P- 6S (71).

Table 5: Parallel Interface, Power Connector

Pin # Signal Type

1 Signal Ground

2 Signal Ground

3 No Connection

4 +12 VDC

5 +12 VDC

6 No Connection

6.2.3 Camera Link

The Camera Link interface connector is labeled on the group interface back panel (see Figure 7: Group

Interface Back Panel View). The Camera Link connector is a 3M 12226-1150-00FR Shrunk Delta

Ribbon (SDR-26) female connector. The connector orientation is shown in figure 8 and the pin-out is

shown in table 6. Since most frame grabbers use an MDR-26 connector, the user may need a Camera

Link cable that includes a male SDR-26 connector on the camera end and an MDR-26 connector on the

frame grabber end.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 23 of 49

Figure 8: Camera Link SDR-26 diagram

Page 24

Table 6: Camera Link SDR-26 Connector Pin Assignment

Pin # Function I/0

1

Inner Shield Signal Ground

Signal

Type

Description

2 X0- Out LVDS Data 0 3 X1- Out LVDS Data 1 4 X2- Out LVDS Data 2 5 Xclk- Out LVDS Clock 6 X3- Out LVDS Data 3 7 SerTC+ In LVDS Serial Data to Camera +

8 SerTFG- Out LVDS Serial Data from Camera 9 CC1- In LVDS Camera Control 1 10,11,1

2

Unused

13,14 Inner Shield Signal Ground

15 X0+ Out LVDS Data 0 +

16 X1+ Out LVDS Data 1 +

17 X2+ Out LVDS Data 2 +

18 Xclk+ Out LVDS Clock +

19 X3+ Out LVDS Data 3 +

20 SerTC- In LVDS Serial Data to Camera 21 SerTFG+ Out LVDS Serial Data from Camera

22 CC1+ In LVDS Camera Control 1 +

23,24,2

5

Unused

26 Inner Shield Signal Ground

A complete description of the Camera Link standard can be purchased from the AIA organization at

http://www.machinevisiononline.org/store/category.cfm?category_id=76

. The FLIR AIS Tau CNV

camera provides a Frame Valid (FVAL) pulse which goes high during the reading out of the frame and

goes low after reading out the complete frame. The camera provides a Line Valid (LVAL) pulse which

goes high while each line of pixel data is read out and goes low once the line has been read out. The data

is converted inside the camera to 14 or 16 bit digital. The 14 or 16 bits of data per pixel are sent out over

the appropriate data lines according to the Camera Link base configuration standard. The default mode is

16 bits output. Most frame grabbers include a method to capture the full image in their frame store from

this data format. A list of frame grabbers that have been used with this camera can be obtained by

contacting supportais@flir.com

.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 24 of 49

Page 25

6.2.4 Analog Video Output and Serial Interface (default configuration)

The default video output is the analog output and is labeled as “Video Output” on the group interface

back panel (see Figure 7: Group Interface Back Panel View). The video output is NTSC and PAL

(future) and the connector is a Samtec MCX7-J-P-H-ST-TH1. When using the video output, camera

control and status uses the USB or RS232 (future) serial interface connector, labeled “USB” and “RS232”

on the group interface back panel.

The USB interface is the industry standard mini-USB with the connections as shown in Table 7

Note:

the camera is NOT powered through the USB connector.

Table 7: USB Mini-B Interface

Pin # Function

1 VCC

2 D3 D+

4 ID

5 GND

Description

+5VDC

Data Data +

A/B Distinction

Signal Ground

6.2.5 Trigger In/Out

The Trigger IO connector is a Hirose SR38-4R-3S(71) and is labeled “TRIG IN/OUT on the rear of the

camera.

Table 8: TRIG IN/OUT Interface

Pin # Function

1 TRIGGER IN

2 TRIGGER OUT

3 GND

Description

Logic Level

Logic Level

Signal Ground

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 25 of 49

Page 26

6.2.6 Trigger In Mode

The Tau CNV has two trigger modes, internal self-triggered “free-run” mode and external trigger mode.

External trigger mode is only through the parallel interface connector, Camera Link interface connector, and the

trig IN/OUT, as a Trig IN function, when using the USB/RS232 serial interfaces.

Free Run Mode – The camera operates at 30FPS based upon an internal, free-running clock.

External Trigger Mode – The camera can be synchronized with external events for capturing

image data. The integration begins when the external trigger goes high, and readout begins when

the external trigger goes low. The external trigger may be provided to the camera via the CC1

signal of the Camera Link interface or via the “Trigger In” pin of the TRIG IN/OUT connector on

the rear of the camera.

rate faster than the minimum frame period (approximately 33ms).

These trigger modes are fully described in the Tau CNV interface control document (ICD). Contact your

local sales or technical support for details.

NOTE: For proper operation, external trigger falling edges must never occur at a

6.2.7 Trigger Out Mode

The camera provides a trigger output signal on the “Trigger Out” pin of the TRIG IN/OUT connector on

the rear of the camera. This signal maintains a fixed timing relationship with the camera exposure and

can be used to tune external events to occur during the camera integration time.

6.2.8 Video IRIS (future)

The video IRIS connector is currently not enabled and reserved for future applications. Do not use this

connector.

7 Mechanical Detail

7.1 Housing & Materials

The Tau CNV camera housing encompasses front lens mount, sensor mount, and rear panel. This

housing performs the cooling and heat dissipation, mechanical mounting, and contains the rear panel

electrical markings and connections. The front lens mount material is anodized aluminum with a black

finish. The C-mount lens adapter is nickel plated aluminum. The F-mount adapter is black anodized

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 26 of 49

Page 27

aluminum. The case is Alodine treated aluminum with a gold finish and is electrically conductive to

reduce susceptibility to, and emission of EMI. The case back panel uses a laser etch process to mark all

connectors.

7.2 Dimensions

The Tau CNV is a small space-claim camera measuring only

48x49.4x64.5mm (without optics), which makes the camera perfect for

space limited OEM applications. See figure 9.

The C-mount adapter is fully adjustable for back focus to support a

wide variety of C-mount lenses.

The lens mount can be removed for customer specific optical packages;

use the dimensions provided in the Tau CNV sensor mounting plate.

Contact your local sales representative for this option.

Dimensions are given in millimeters.

7.3 Lens Mounting and Back Focus

Adjustment

The FLIR AIS Tau CNV camera has two options for lens mounting:

The M42/C-mount and the M42/F-mount. After mounting the lens into

the C-mount lens adapter, the camera must be back focus adjusted and

locked prior to use.

Figure 9: Dimensions

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 27 of 49

Page 28

8 Camera Mounting & Cooling

The Tau CNV operating temperature is specified as a case temperature range of -20°C to +50°C with

degraded performance in the +35°C to +50°C The Tau CNV sensor mount is used to both mount the

camera to the user’s assembly, and to conduct heat away from the camera electronics. The camera makes

automatic and continuous adjustment to compensate for changes in case temperature; however, to

maximize camera performance, the user should avoid rapid changes in the camera case temperature by

using a large thermal mass on which to mount the camera and with continuous controlled temperature air

flow over the camera.

8.1 ¼ - 20 Mounting Hole

The ¼ - 20 mounting hole is available for camera mounting but is not designed to be used with a standard

tripod mount. A standard tripod mount requires a deeper mounting hole than is available with the small

CNV camera size. Please note that these holes are electrically connected to chassis ground. The ¼-20

mounting hole is also a convenient heat sink attachment point. In addition, the other 3 sides of the sensor

mount are good surfaces for heat sinking purposes.

8.2 Important Mounting Requirements

For best performance from your TAU CNV camera the camera must be properly mounted to a heat

conducting surface. The camera will typically dissipate 4W and must be properly secured to a heat

conducting surface using the

structure containing the ¼-20 mounting hole

available ¼-20 mounting hole or customer provided custom clamp to the metal

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 28 of 49

Page 29

9 Command and Control of the Camera

Camera control can be accomplished either through the Camera Link interface or through the camera’s

USB interface using FLIR’s utility program “Universal Camera Controller”. Alternatively, by installing a

USB to COM port-bridge the user can pass serial commands or read camera status directly from a user’s

application program using the defined protocol and command set. To get more information about the

command structure and integrating it into your application contact FLIR tech support for a complete

Interface Control Document “ICD” (10-70044-01-A1) document.

9.1 FLIR AIS’ Camera Control Utility

FLIR AIS also provides a utility program which runs on a PC with Microsoft Windows XP® or Windows

7 operating system using a standard PC serial COM port, USB port or a Camera Link compatible frame

grabber which enables a serial COM port. With one of these connections cabled to the Tau CNV camera,

the camera controller GUI can be used to control operating modes and gather status. Most of the user

programmable functions that can be set and read by serial commands may also be set and read by using

the Universal Camera Controller.

9.1.1 Installation

On the installation media (CD or USB flash drive) are three files: one is the installer for Universal

Camera Controller, one is the USB serial bridge driver installer (required to communicate with the camera

using its USB connection), and one is the installer for Microsoft .Net Framework 4 (the runtime

environment in which UCC runs and is required). Install Microsoft .Net Framework first, followed by the

USB serial bridge driver (if needed), and then UCC.

Microsoft .Net Framework 4

To install .Net Framework, find the file, dotNetFx40_Full_x86_x64.exe, on the included USB flash drive

or CD. Double-click the file. If .Net Framework 4 is already installed, the following window (or one

similar) will appear.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 29 of 49

Page 30

In this case, click “Cancel” and proceed to the section on installing the USB serial bridge driver (or

directly to the section on installing UCC if you will not be communicating with the camera through its

USB connection).

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 30 of 49

Page 31

If .Net Framework 4 is not installed, the following window will appear:

Check “I have read and accept the license terms,” and click “Install.” The following window will appear

when installation is complete:

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 31 of 49

Page 32

Click “Finish.”

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 32 of 49

Page 33

USB Serial Bridge Driver

To install the USB serial bridge driver, find the file, CP210x_VCP_Win_XP_S2K3_Vista_7.exe, on the

included USB flash drive or CD. Double click the file. The following window will appear:

Click “Next.”

Select “I accept the terms of the license agreement,” and click “Next.”

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 33 of 49

Page 34

Click “Next.”

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 34 of 49

Click “Install.”

Page 35

Make sure “Launch the CP210x VCP Driver Installer” is checked, and click “Finish.” The following

window will appear:

Click “Install.” Wait until the following window appears:

Click “OK.”

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 35 of 49

Page 36

Universal Camera Controller

To install UCC, find the Universal Camera Controller Setup.msi file located on the included USB flash

drive or CD, double click it, and follow the prompts:

Click “Next”

Choose the location to install the program. In most cases you should be able to select the default location.

Click “Next.”.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 36 of 49

Page 37

Click “Install.”

The install should take a few moments. When complete, the following window will appear:

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 37 of 49

Page 38

The program installation is complete. Click “Finish” to exit setup. UCC is now installed and ready to

use. See below for details on operating the software.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 38 of 49

Page 39

9.1.2 Camera Connection Screen

Note: At all times make sure the camera is connected and powered on BEFORE starting the

Camera Controller GUI. This will make sure that the communication port is properly opened.

When Camera Controller GUI is first executed, the “Connections” screen will come up as shown below.

Select Camera > Connect> Connect to the camera. See the screenshot below:

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 39 of 49

Page 40

If successful, the “Connected” status will appear in the lower left of the GUI window along with the

camera status information as shown in the example screen shot below:

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 40 of 49

Page 41

Once connected, you can click on “Image” to access options on the “Image” screen. This screen allows

access to the basic controls of the camera as seen in the screenshot below.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 41 of 49

Page 42

9.1.3 GUI Advanced User Mode

The universal camera controller GUI offers an advanced mode intended for use by experienced

customers. To access the advanced user mode, press CTRL-SHIFT-M (hold CTRL and SHIFT while

pressing the M key). This will bring up a password dialog. We use a password as a layer of protection.

There are features in the advanced mode that can produce poor images if used improperly. Entering

advanced mode indicates the user understands and accepts this responsibility. The password is

“www.flir.com” (without quotes). Once the correct password has been entered, the initial connection

window will be slightly different as in the following screenshot.

Notice the new “Tools” menu option. Under “Tools” you have access to manual connection options.

Under the “Camera” menu option you also have a new option, “Camera Type”, see the following

screenshots for these:

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 42 of 49

Page 43

All of the available ports should show up in this screen. If a connection option isn’t available here, the

software is unable to see it and further troubleshooting may be required.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 43 of 49

Page 44

The software should automatically choose the proper camera type; however, if it does not, you can select

it manually here.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 44 of 49

Page 45

The other screens have also changed. The “Status” screen will appear as follows:

As you can see from the screenshot the “Tools” menu item is still there and there is a new window button

“Config”.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 45 of 49

Page 46

The next two screenshots indicate the changes in the window appearance for both the “Image” window

and the “Config” window:

Above is the “Image” window. Note the changes from the basic user interface mode. The available

functions are described here:

Nonlinear Contrast Enhancement – Selects between a linear image remapping algorithm and a

non-linear image remapping algorithm to remap the 16 bit data to an 8 bit analog output stream.

Contrast Stretch – Stretches the contrast to enhance the detail within the image.

Exposure – Selects automatic or manual exposure mode and allows the user to adjust the

exposure in manual mode by sliding the slide bar.

Noise Suppression – Enable or disable the automatic noise suppression algorithm and adjust the

level of noise filtering applied in manual mode.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 46 of 49

Page 47

Analog Video Gain – Enables or disables the main 16 bit to 8 bit analog remapping algorithm to

adjust the analog image.

Day/Night Filter – Moves the motorized day/night filter slider if your camera is so equipped.

Color Balance – Allows the user to select automatic color balance or to perform a manual color

balance.

Test Pattern – Displays the test pattern.

The “Configuration” window is completely new in the advanced mode and offers the following functions:

Flat Field Correction – Allows the user to perform a Non-Uniformity Correction (NUC) in the

field if conditions require it. Note that this NUC will only be valid while the camera is powered

on and will reset to default when the camera is power cycled.

Camera Link (Digital) Output – The user can select whether the output of the digital data is 14

or 16 bits and also whether the image processing is performed prior to data output.

Trigger Type – As previously mentioned, the camera can operate in two different trigger modes:

o Internal – The camera operates at up to 30FPS on an internally generated free running

clock.

o External – The camera is synced to a signal on the external trigger input.

Trigger Source – This option becomes available when an external trigger is selected. It chooses

which external trigger the camera will be using.

Number of Lines (Camera Link Only) – The user can select whether the output is 1280x960 or

1280x720. Note that this only affects the digital output.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 47 of 49

Page 48

Shutter Mode (Future – Not Implemented) – Allows the user to select between rolling and

global shutter.

10 Camera Care and Maintenance

10.1 Maintenance, Returns, and Repair

Your FLIR AIS camera should be handled with care as with any delicate high precision opto-electronic

instrument. The camera should not be exposed to liquid or shock environments. Temperature and

humidity should be kept within the operating and storage range specified. There are no user serviceable

parts on this camera.

If an issue cannot be resolved remotely, FLIR AIS will issue a Returned Materials Authorization (RMA)

for the camera. Please contact FLIR AIS support at supportais@flir.com

issues or to receive an RMA number and shipping information. If the camera is under warranty, the

camera will be repaired or replaced according to the terms of the warranty. If the camera is out of

warranty, the repair will be quoted on an individual basis.

for further information on field

10.2 Electrostatic Discharge (ESD)

Your FLIR AIS camera contains circuitry that can be damaged by electrostatic discharge. It is good

practice to carry the camera in a static free container or bag. When the camera is not plugged in, the user

should make sure that the working surface, and any tools used, are properly grounded.

10.3 Cover Glass Damage

The camera sensor has a protective cover glass over the sensor. If the lens mount is removed, this cover

glass is exposed at the front of the camera. It can easily become scratched, soiled or damaged. It is

especially difficult to remove oil from it, so avoid touching with fingers. It is best to keep the lens mount

on the camera to reduce the risk of physical damage.

If the cover glass does get dirty or dusty, use clean, dry compressed air to blow away any dust. If further

cleaning is required, use a lint-free, ESD safe soft cloth wipe such as a LENSX 90 (Item #:LN90.0406.24)

from Berkshire and optical cleaning fluid such as Coated Optics Cleaning Fluid (Cat No. 49120) from

Oriel. Proper techniques for cleaning AR coated glass should be used. See section 2.3 for important

cleaning information.

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 48 of 49

Page 49

10.4 Cleaning the Camera Housing

If the camera housing becomes dirty, a soft cloth with an isopropyl alcohol solution such as TechClean

AbsorbWipe (Model 2351-100) from TechSpray can be used.

11 Revision Control

Rev ECO # Date Initiator Revision Description

01 10-30-2011 D. Jenkins Pre-release draft

02 11-23-2011 D. Jenkins Preliminary

A1 594 1-4-2012 D. Jenkins First Release

10-10032-01 2011 FLIR Advanced Imaging Systems ECO: 594

Rev A1 Tau CNV Camera User’s Manual page 49 of 49

Loading...

Loading...