Page 1

Tau Camera

User’s Manual

®

FLIR Commercial Systems, Inc.

70 Castilian Drive

Goleta, CA 93117

Phone: 888.747.FLIR (888.747.3547)

International: +1.805.964.9797

www.flir.com

www.corebyindigo.com

Document Number: TAU-0035-00-10

Version: 150

Issue Date: June 2011

This document is controlled to FLIR Technology Level EAR 1. The information contained in this document is proprietary and/or restricted and pertains

to a dual use product controlled for export by the Export Administration Regulations (EAR). This document and data disclosed herein or herewith is

not to be reproduced, used, or disclosed in whole or in part to anyone without the written permission of FLIR Systems, Inc. Diversion contrary to US

law is prohibited. US Department of Commerce authorization is not required prior to export or transfer to foreign persons, parties, or uses otherwise

prohibited.

Page 2

Tau User’s Manual

© FLIR Commercial Systems, Inc., 2011. All rights reserved worldwide. No parts of this manual, in whole

or in part, may be copied, photocopied, translated, or transmitted to any electronic medium or machine

readable form without the prior written permission of FLIR Commercial Systems, Inc.

Names and marks appearing on the products herein are either registered trademarks or trademarks of

FLIR Commercial Systems, Inc. and/or its subsidiaries. All other trademarks, trade names, or company

names referenced herein are used for identification only and are the property of their respective owners.

Liberation fonts are copyright 2009 by RedHat and are used under authority of the GNU public license.

Information about these fonts and the GNU public license can be found at:

https://www.redhat.com/promo/fonts/.

This product is protected by patents, design patents, patents pending, or design patents pending.

If you have questions that are not covered in this manual, or need service, contact FLIR CVS Customer

Support at 805.964.9797 for additional information prior to returning a camera.

This documentation is subject to change without notice.

This equipment must be disposed of as electronic waste.

Contact your nearest FLIR Commercial Vision Systems, Inc. representative for instructions on

how to return the product to FLIR for proper disposal.

FCC Notice. This device is a subassembly designed for incorporation into other products in order to

provide an infrared camera function. It is not an end-product fit for consumer use. When incorporated

into a host device, the end-product will generate, use, and radiate radio frequency energy that may cause

radio interference. As such, the end-product incorporating this subassembly must be tested and

approved under the rules of the Federal Communications Commission (FCC) before the end-product may

be offered for sale or lease, advertised, imported, sold, or leased in the United States. The FCC

regulations are designed to provide reasonable protection against interference to radio

communications. See 47 C.F.R. §§ 2.803 and 15.1 et seq.

Industry Canada Notice. This device is a subassembly designed for incorporation into other products in

order to provide an infrared camera function. It is not an end-product fit for consumer use. When

incorporated into a host device, the end-product will generate, use, and radiate radio frequency energy

that may cause radio interference. As such, the end-product incorporating this subassembly must be

tested for compliance with the Interference-Causing Equipment Standard, Digital Apparatus, ICES-003, of

Industry Canada before the product incorporating this device may be: manufactured or offered for sale or

lease, imported, distributed, sold, or leased in Canada.

Avis d’Industrie Canada. Cet appareil est un sous-ensemble conçu pour être intégré à un autre produit

afin de fournir une fonction de caméra infrarouge. Ce n’est pas un produit final destiné aux

consommateurs. Une fois intégré à un dispositif hôte, le produit final va générer, utiliser et émettre de

l’énergie radiofréquence qui pourrait provoquer de l’interférence radio. En tant que tel, le produit final

intégrant ce sous-ensemble doit être testé pour en vérifier la conformité avec la Norme sur le matériel

brouilleur pour les appareils numériques (NMB-003) d’Industrie Canada avant que le produit intégrant ce

dispositif puisse être fabriqué, mis en vente ou en location, importé, distribué, vendu ou loué au Canada.

EU Notice. This device is a subassembly or component intended only for product evaluation, development

or incorporation into other products in order to provide an infrared camera function. It is not a finished

end-product fit for general consumer use. Persons handling this device must have appropriate electronics

training and observe good engineering practice standards. As such, this product does not fall within the

scope of the European Union (EU) directives regarding electromagnetic compatibility (EMC). Any endproduct intended for general consumer use that incorporates this device must be tested in accordance

and comply with all applicable EU EMC and other relevant directives.

-ii June 2011 TAU-0035-00-10, version 150

Page 3

Table of Contents

1 Introduction

1.1 Available Tau Configurations ................................................................. 1-2

1.2 Tau Specifications ............................................................................... 1-4

1.3 Unpacking Your Tau Camera ................................................................ 1-5

2 Optional Tau Camera Accessories

2.1 Tau VPC Module Accessory .................................................................. 2-1

2.2 Tau Camera Link Module ..................................................................... 2-2

2.3 Tau WFOV Locking Ring and Tool .......................................................... 2-3

2.4 Tripod Mount for Tau Camera .............................................................. 2-3

2.5 Photon Replicator Board ...................................................................... 2-3

2.6 Photon Replicator Kit .......................................................................... 2-4

2.7 Software Accessory Alternate Lens Calibration Software .......................... 2-4

2.8 Software Accessory SDK for Windows & Embedded ................................ 2-5

3 Basic Operation of the Tau and GUI

3.1 Operation of the Tau Camera using the USB Interface .............................. 3-1

3.2 Remote control of the Tau Camera ....................................................... 3-3

3.3 Installing the FLIR Camera Controller GUI ............................................... 3-4

3.4 Connecting the Tau to a PC via USB ...................................................... 3-7

3.5 Troubleshooting the FLIR Camera Controller GUI ................................... 3-10

3.6 Operation of the FLIR Camera Controller GUI ........................................ 3-11

3.7 Setup Tab ........................................................................................ 3-12

3.8 Analog Video Tab .............................................................................. 3-16

3.9 Digital Video Tab ............................................................................... 3-20

3.10 Image Capture Tab ......................................................................... 3-22

3.11 AGC Tab ....................................................................................... 3-23

3.12 ROI Tab ......................................................................................... 3-26

TAU-0035-00-10, version 150 iii

Page 4

Table of Contents Tau User’s Manual

3.13 Thermal Tab .................................................................................. 3-28

4 Tau Digital Data Channel

4.1 XP Bus Setting—BT.656 Digital Interface ............................................... 4-1

4.2 XP Bus Setting—CMOS Digital Interface ................................................. 4-3

4.3 Discrete I/O ...................................................................................... 4-5

4.4 Photon Camera Legacy LVDS Output ..................................................... 4-6

4.5 Legacy LVDS Digital Data Channels ....................................................... 4-8

5 Overview of the Electrical Interface

5.1 Input Power ....................................................................................... 5-1

5.2 Hirose 50-Pin Connector ..................................................................... 5-1

5.3 Analog Video Output ........................................................................... 5-3

5.4 Command and Control Channel ............................................................ 5-3

5.5 LVDS Digital Data Channel ................................................................... 5-3

5.6 Parallel Digital Data Channel ................................................................ 5-4

Appendix A Pin-out Definitions

A.1 I/O Module 333-0018-00 ................................................................... A-1

Appendix B Serial Communication Technical Details

B.1 Serial Communications Primary Interface ............................................... B-1

B.2 Serial Communications Protocol ........................................................... B-1

B.3 Status Byte ....................................................................................... B-2

B.4 Function Byte ..................................................................................... B-3

B.5 Example of the format of a serial message ........................................... B-11

B.6 Description of Serial Commands ......................................................... B-12

Appendix C Tau with Photon Accessories

C.1 Operation of the Tau camera using the Photon Accessory Kit .....................C-1

C.2 Remote control of the Tau camera .........................................................C-2

C.3 Connecting the serial communications interface using the development kit ...C-2

Appendix D Mechanical IDD Reference

Sheet 1 Tau Camera Mechanical Interface Control Document WFOV ............ D-3

Sheet 1 Tau Camera Core Interface Description Document 5mm - 19mm, .... D-4

Sheet 1 Tau Camera Core Interface Description Document 25mm ............... D-5

Sheet 1 Tau Camera Core Interface Description Document 35mm ............... D-6

Sheet 1 Tau Camera Core Interface Description Document 60mm ............... D-7

iv TAU-0035-00-10, version 150

Page 5

1 Introduction

The Tau camera is a long-wavelength (8 – 14 microns) uncooled microbolometer camera

designed for infrared imaging applications that demand absolute minimum size, weight, and

power consumption. It is available with multiple different lens focal length options, as well as

lens-less (not shown) and narrow-field-of-view (NFOV) options. The Tau Software Developer’s Kit

(SDK) enables camera control using one of several programming languages including VB6,

VB.net, C#, and C++ (MFC). The FLIR Camera Controller GUI is an example of an application

created using the SDK—See “Software Accessory SDK for Windows & Embedded” on page 2-

5.

5mm 13mm

(43° HFOV)

25mm

(18° HFOV)

9mm

(48° HFOV) (34° HFOV)

35mm

(13° HFOV)

100mm

(4.6° HFOV)

19mm

(24° HFOV)

60mm

(8° HFOV)

The camera provides “power-in, video-out” capability, which means that one need only apply input

voltage to receive analog video. For those applications requiring serial control, the Tau camera

includes a serial interface (RS-232) for transmitting camera commands and receiving status.

The Tau camera also provides 8-bit and 14-bit digital data options, including CMOS, BT.656,

and the Legacy Photon LVDS—See “Tau Digital Data Channel” on page 4-1.

TAU-0035-00-10, version 150 June 2011 1-1

Figure 1-1: Tau Cameras

Page 6

1—Introduction Tau User’s Manual

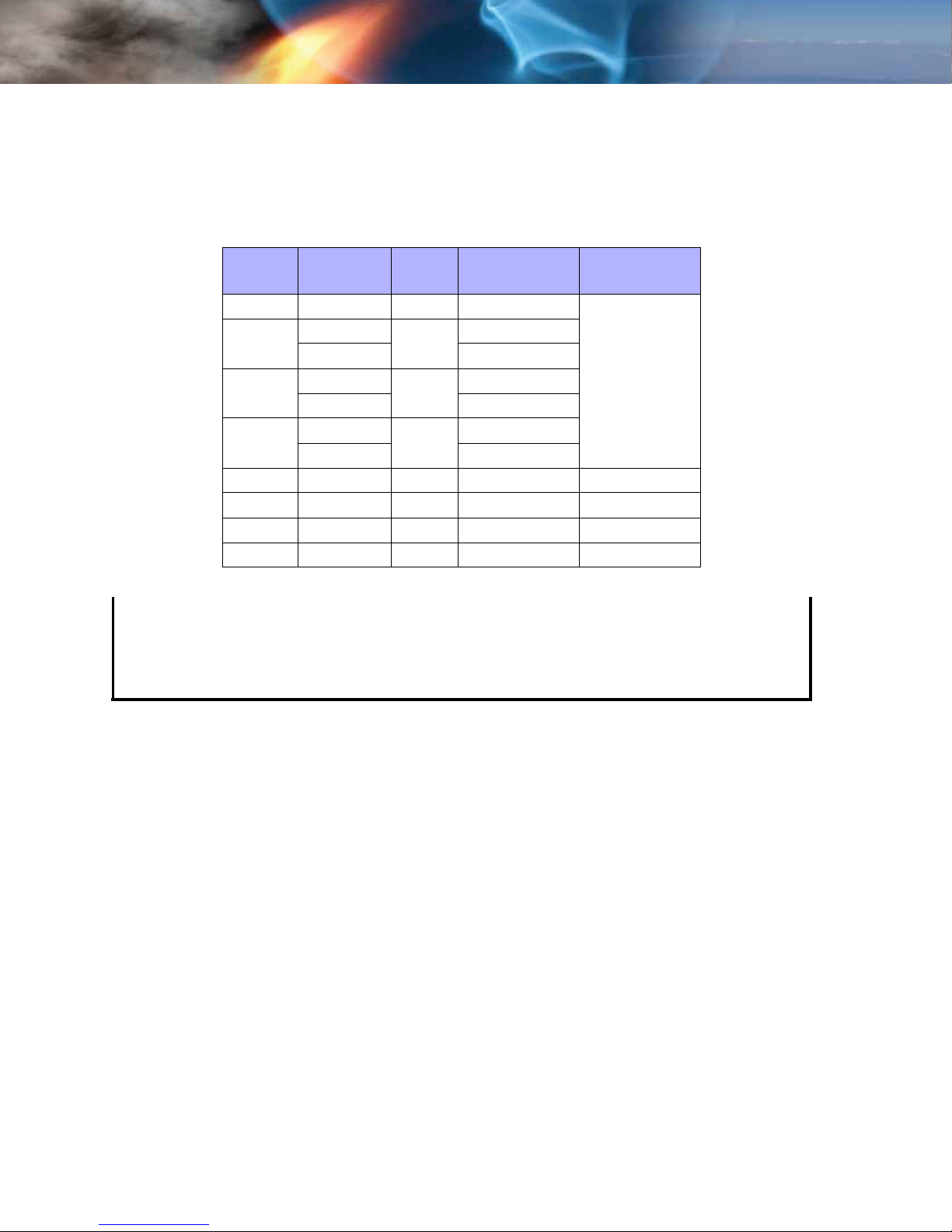

1.1 Available Tau Configurations

The Tau camera is available with different lenses providing different fields of view, the ‘Slow

Video’ or ‘9 Hz’ option for license-free exportability, and also a 160

reduced price.

× 120 resolution at a

Resolution f/# FOV (H × V)

5 mm 160 × 120 1.25 43° × 35°

9 mm

13 mm

19 mm

25 mm 320 × 240 1.4 18° × 14° 135 g

35 mm 320 × 240 1.4 13° × 10° 129 g

60 mm 320 × 240 1.1 7.6° × 5.7° 200 g

100 mm 320 × 240 1.6 4.6° × 3.7° 503 g

160 × 120

320 × 240 48° × 37°

160 × 120

320 × 240 34° × 26°

160 × 120

320 × 240 24° × 18°

1.25

1.25

1.25

25° × 20°

17° × 14°

12° × 10°

Weight with

lens

72 g

Note

The Tau camera lenses are sealed to IP67 (1 meter). The camera back is not sealed.

Boresight features are available on Tau WFOV cameras. See “Mechanical IDD Reference” on

page D-1.

Contact FLIR CVS Customer Support or your local FLIR sales representative for information

on available Tau camera configurations, part numbers, and ordering information.

1-2 June 2011 TAU-0035-00-10, version 150

Page 7

Tau User’s Manual 1—Introduction

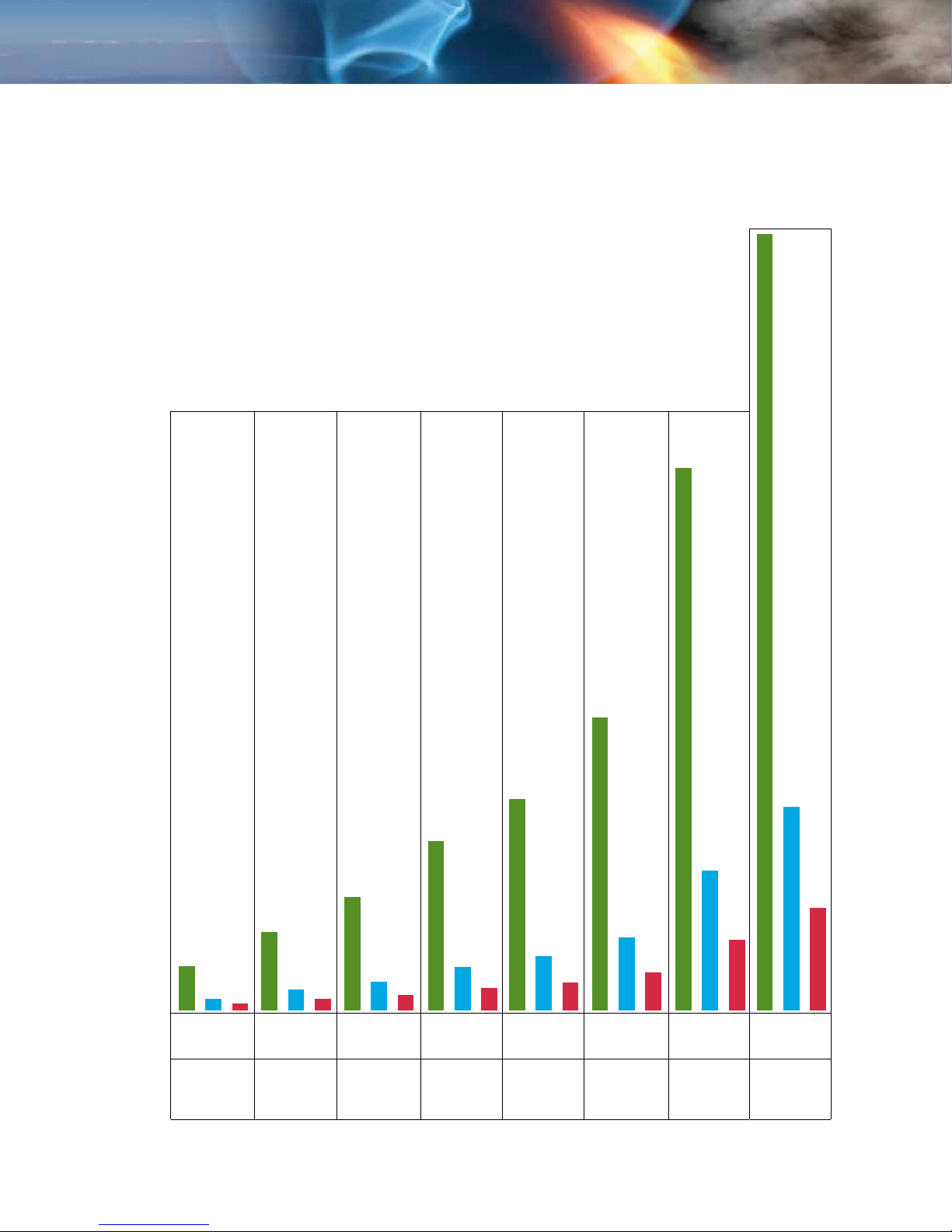

2075 meters—

Detection

115 meters—Detection

27 meters—Recognition

1320 meters—

Detection

780 meters—Detection

560 meters—Detection

540 meters—Recognition

450 meters—Detection

300 meters—Detection

205 meters—Detection

190 meters—Recognition

112 meters—Recognition

52 meters—Recognition

14 meters—Identification

26 meters—Identification

74 meters—Recognition

37 meters—Identification

56 meters—Identification

140 meters—Recognition

70 meters—Identification

97 meters—Identification

340 meters—Recognition

270 meters—Identification

172 meters—Identification

Table 1-1: Tau Camera Lens Range Performance (Standing Man—1.5m by 0.5m)

43°

5mm

HFOV

Lens

48°

9mm

HFOV

Lens

TAU-0035-00-10, version 150 June 2011 1-3

34°

13mm

HFOV

Lens

24°

19mm

HFOV

Lens

18°

25mm

HFOV

Lens

13°

35mm

HFOV

Lens

8°

60mm

HFOV

Lens

4.6°

100mm

HFOV

Lens

Page 8

1—Introduction Tau User’s Manual

1.2 Tau Specifications

• 320 (H) × 256 (V) or 160 (H) × 128 (V) uncooled microbolometer sensor array,

25 × 25 micron pixels

• Spectral band: 7.5 - 13.5μm

• NEdT Performance: < 50mK at f/1.0

• Input voltage range: 4.0 – 6.0 VDC

• Power Consumption: < 1.0 Watts (nominal at room temperature using 5V input)

• Time to image: < 3 seconds

• Operating Temperature Range: -40°C to +80°C

•Weight: ≤ 72 grams with either the 5mm, 9mm, 13mm, or 19mm lens option

1

2

Note

The Tau camera is an export controlled item. In order to increase the Camera’s

exportability, a ‘Slow Video’ version of Tau is available. The frame rate is reduced to

approximately 9 Hz. This change allows Tau to be exported without US export license to

most countries. Please contact FLIR for additional information.

• Analog video output:

NTSC (320 × 240) 30Hz (‘Slow Video’ rate (7.5Hz) is available for exportability)

or

PAL (320 × 256) 25Hz (‘Slow Video’ rate (8.3Hz) is available for exportability)

Note

The NTSC analog video format is default for cameras with analog video. The FLIR Camera

Controller GUI software (free download) allows you to select between NTSC or PAL video

output formats and save this configuration.

• Digital video output: 8- or 14-bit serial LVDS, CMOS, or BT 656

• Remote camera control RS-232 interface: FLIR Camera Controller GUI software

available for free download at http://www.corebyindigo.com/

• The VPC accessory used for USB connectivity requires that the driver is installed

before using. This driver is installed as part of the FLIR Camera Controller GUI

installation.

•2× and 4× Digital Zoom with electronic pan/tilt (analog video)

• Dynamic Digital Detail Enhancement (DDE)

The latest information concerning specifications, accessories, camera configurations, and

other information can be found in the Tau Thermal Imaging Camera Core Data Sheet at:

http://www.corebyindigo.com/

Tau /.

Tau

1. NEdT at the camera output measured with FLIR's proprietary noise reduction applied in the asshipped configuration. Typical performance is approximately 35mK with f/1.0 optics.

2. Some early WFOV Tau lens options (5mm, 9mm, 13mm, and 19mm) were shipped with a nickelplated magnesium lens flange which is not rated for salt/fog. All Tau cameras now ship with black

ecoated lens flanges with a secondary undercoating. This allows the Tau lens flange to survive hundreds of hours in a salt fog environment.

1-4 June 2011 TAU-0035-00-10, version 150

Page 9

Tau User’s Manual 1—Introduction

1.3 Unpacking Your Tau Camera

The Tau camera is typically delivered as a component part for incorporation into an original

equipment manufacturer’s (OEM) product; no documentation is included. Documentation and

utilities such as the latest version of this User’s Manual, the FLIR Camera Controller GUI, and

Mechanical Interface Description Documents are available for download from the

www.corebyindigo.com

Please unpack the camera heeding customary Electrostatic Sensitive Device (ESD) precautions

including static safe work station and proper grounding. The Tau camera is packaged in foam to

prevent damage during shipping. It is also placed in a conductive anti-static bag to protect from

electrostatic discharge damage.

website.

Caution!

Disassembling the camera can cause permanent damage and will void the warranty.

Operating the camera outside of the specified input voltage range or the specified operating

temperature range can cause permanent damage.

The camera back is not sealed. Avoid exposure to dust and moisture.

This camera contains electrostatic discharge sensitive electronics and should be handled

appropriately.

TAU-0035-00-10, version 150 June 2011 1-5

Page 10

1—Introduction Tau User’s Manual

1-6 June 2011 TAU-0035-00-10, version 150

Page 11

2 Optional Tau Camera Accessories

Accessories for your Tau camera can be purchased from the online FLIR Camera Accessory

Store located at www.flirshop.com

.

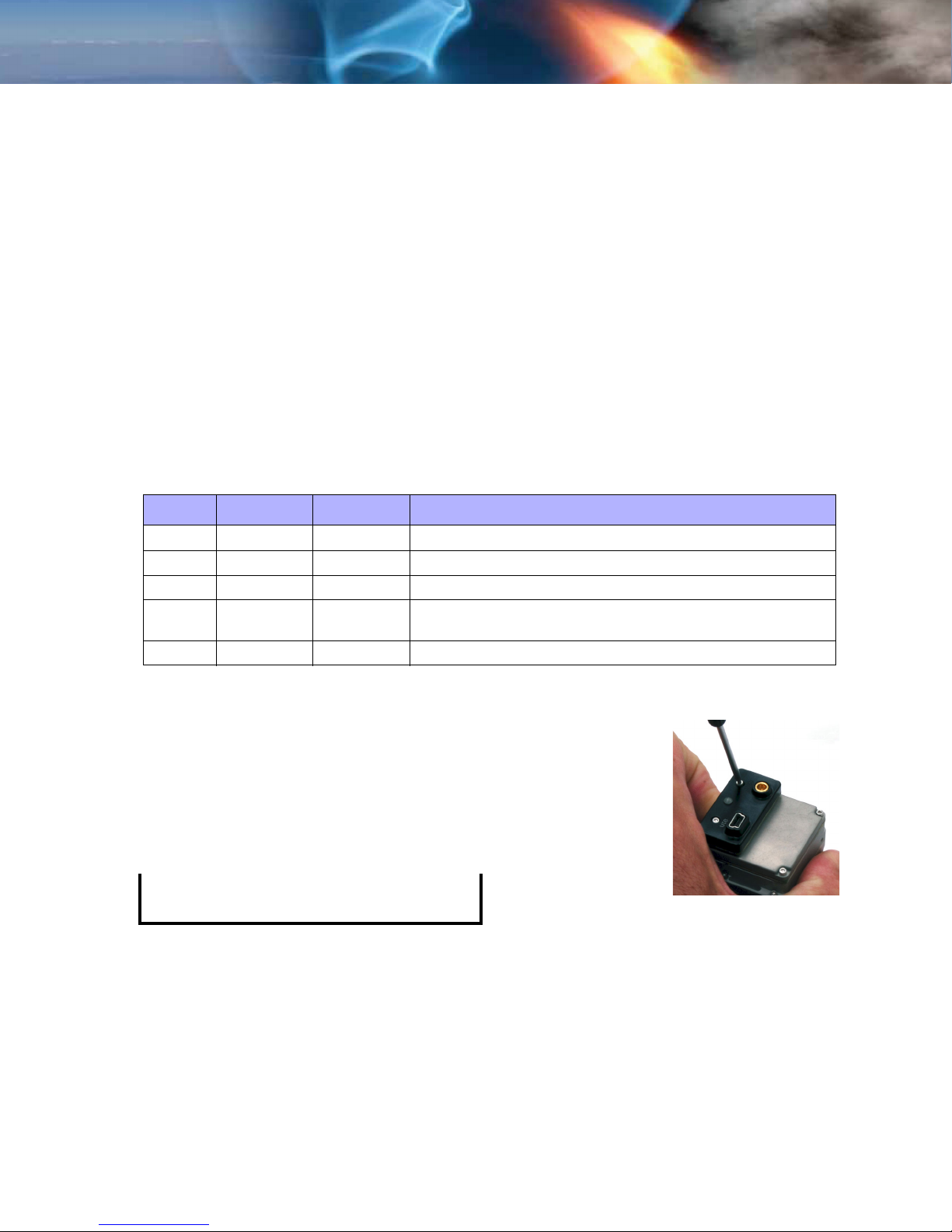

2.1 Tau VPC Module Accessory

The VPC (video, power, communications) module is an expansion board for the Tau camera that

provides a convenient way for customers to power and communicate with the camera via USB.

The VPC module also incorporates an MCX connector that outputs analog video. The VPC

module includes a USB-A to USB-mini B cable for power and communications, as well as an

MCX-to-BNC cable for analog video.

For instructions on installing the VPC Module refer to paragraph 3.1 “Operation of the Tau

Camera using the USB Interface” on page 3-1.

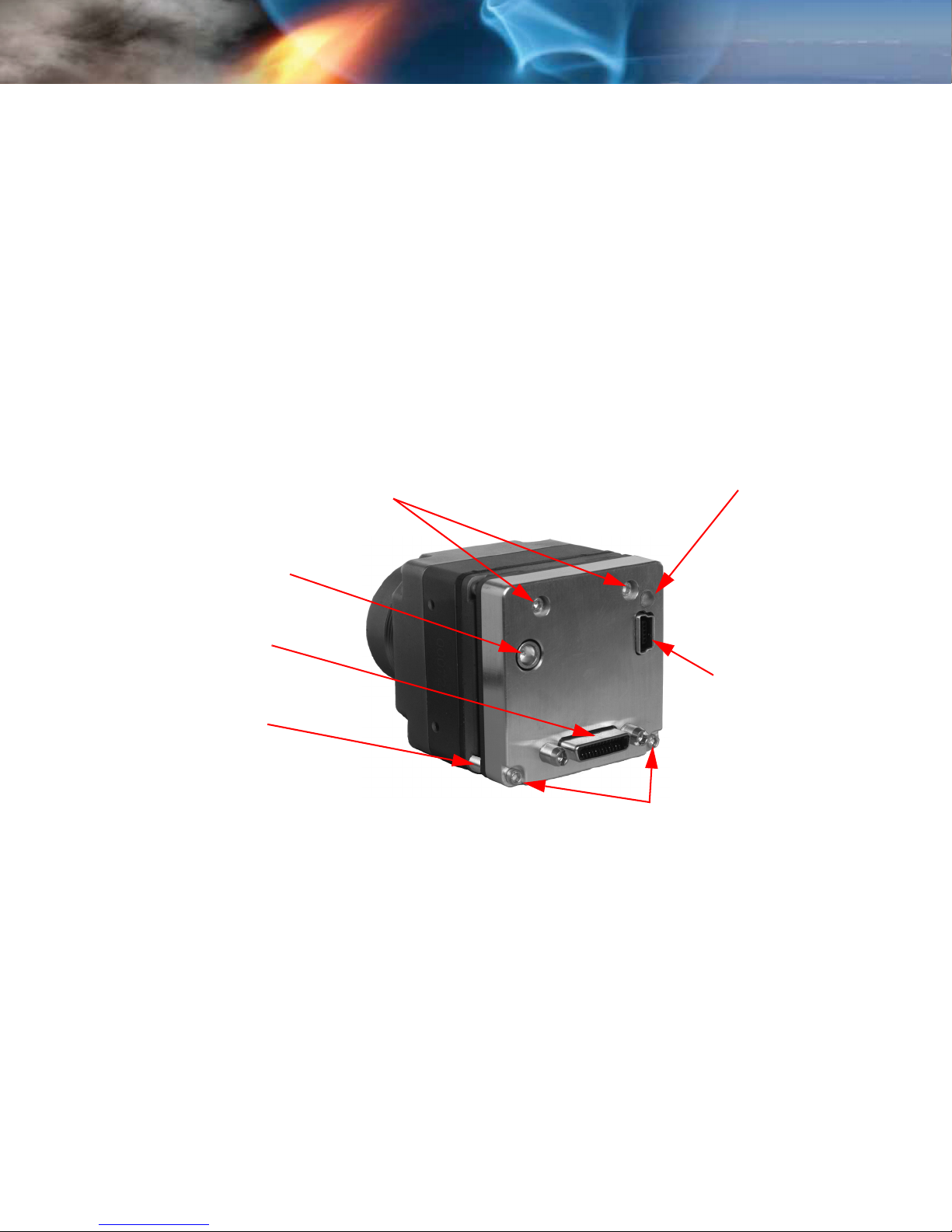

Mounting screws

M1.6 × 0.35 × 6 mm SHCS

Mini USB

Figure 2-1: Tau VPC Module Installed on a Tau camera

MCX coaxial

Power status light

The Tau camera is powered using the USB connector with a nominal draw of 180 mA at 5VDC

and a peak startup draw of 500 mA. The camera uses serial communication at either 57600

or 921600 Baud by creating a virtual COM Port on your computer for USB communications.

The Baud Rate is selected using auto-Baud and the camera will communicate at the first Baud

Rate in which it receives a valid command until it is powered off.

TAU-0035-00-10, version 150 June 2011 2-1

Page 12

2—Optional Tau Camera Accessories Tau User’s Manual

2.2 Tau Camera Link Module

The Camera Link module is an expansion board for the Tau camera that provides a convenient

way for customers to power and communicate with the camera via USB and access LVDS

digital video with a high-speed Camera Link channel. The Camera Link module also incorporates

an MCX connector that outputs analog video.

The Camera Link Module takes CMOS-type digital data from the Tau camera and converts it to

Camera Link. In order to use a Camera Link module for acquisition of data, you will need to first

enable the CMOS XP Bus Output using the FLIR Camera Controller GUI. See “Digital Video Tab”

on page 3-20. On this same page, you can select either 8-bit or 14-bit digital output. Once you

make these changes, it is a good idea to save settings to make them power cycle consistent.

See “Save Settings” on page 3-14.

The Camera Link module accessory comes with the spacers and mounting screws shown in

Figure 2-2. Note that Camera Link cable, frame grabber, or capture software are not included.

For instructions on installing the Camera Link Accessory refer to paragraph 3.1.2 “Installing

the Camera Link Module” on page 3-2.

Mounting screws

M1.6 × 0.35 × 8 mm SHCS

MCX coaxial

(analog video)

Mini Camera Link

(digital video)

Spacer

Ø3 mm × 3.1 mm

M1.6 × 0.35 × 16 mm SHCS

Figure 2-2: Tau Camera Link Module Installed on a Tau camera

Power status light

Mini USB

Mounting screws

The Tau camera is powered using the USB connector with a nominal draw of 230 mA at 5VDC

and a peak startup draw of 550 mA. The camera uses serial communication at either 57600

or 921600 Baud by creating a virtual COM Port on your computer for USB communications.

The Baud Rate is selected using auto-Baud and the camera will communicate at the first Baud

Rate in which it receives a valid command until it is powered off.

The digital data complies with Base Camera Link standards and should be compatible with any

brand Camera Link Frame Grabber and software. The FLIR Camera Controller allows for control

of the Tau camera, but does not support Camera Link frame capture and third-party software

must be used.

External sync is not possible with the Camera Link module.

2-2 June 2011 TAU-0035-00-10, version 150

Page 13

Tau User’s Manual 2—Optional Tau Camera Accessories

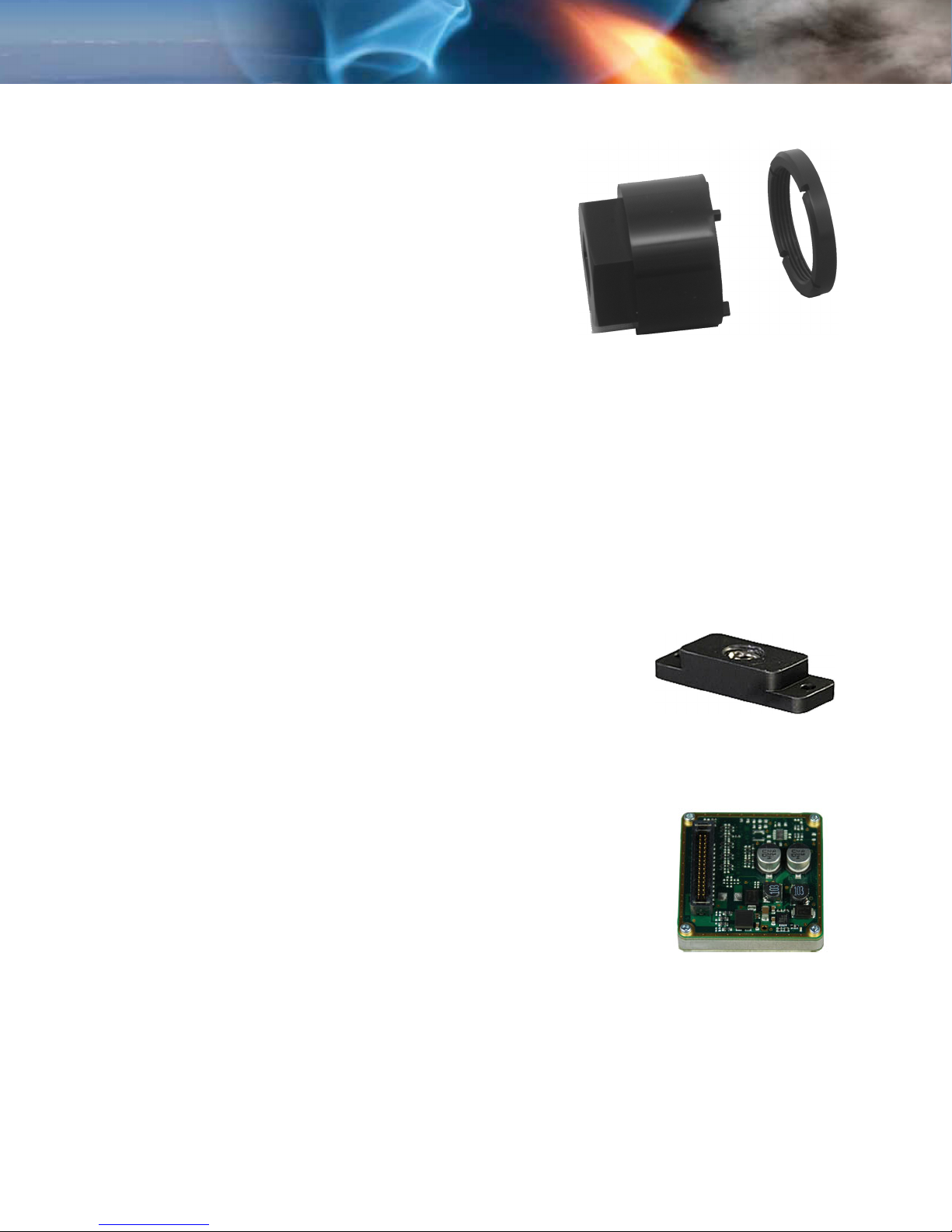

2.3 Tau WFOV Locking Ring and Tool

Tau Locking Ring Accessory,

421-0041-00

Lock Nut Tool,

421-0042-00

Type 2 - 025 O-ring

(not included)

The locking ring is designed to mount a Tau WFOV

camera into a bulkhead. The M29 x 1.0 thread on the

outside of the lens mount flange is placed through the

clearance hole in the bulkhead and the o-ring seals the

camera to the face.

The Type 2-025 O-ring is not for sale through FLIR. This is

a standard o-ring available from many suppliers.

The locking ring accessory is made of Delrin so as not to

scratch the Tau camera lens flange. Scratching the

external plating can compromise the coating and make

the Tau camera more susceptible to corrosion. The lock

nut tool will attach to a torque wrench for proper

tightening. Torque the locking ring to 4.0 in-lbs.

2.4 Tripod Mount for Tau Camera

Tripod mount,

261-2071-00

This accessory adapts two of the mounting points on the

Tau camera to a standard 1/4

plate. The tripod adapter mounts to the bottom of Tau

camera using two furnished socket head screws.

” x 20 tripod mounting

2.5 Photon Replicator Board

Photon Replicator Board,

421-0040-00

This expansion board adapts the Tau camera's native

50-pin Hirose connector to the 30-pin SAMTEC

connector used on FLIR's Photon cameras. The

replicator board makes the Tau camera electrically pincompatible to a Photon camera, including the provision

for operating the Tau camera over a similar input

voltage range as the Photon camera: 6.5-27 VDC.

A cast magnesium spacer and 4 socket-head machine

screws are included (not shown).

TAU-0035-00-10, version 150 June 2011 2-3

Page 14

2—Optional Tau Camera Accessories Tau User’s Manual

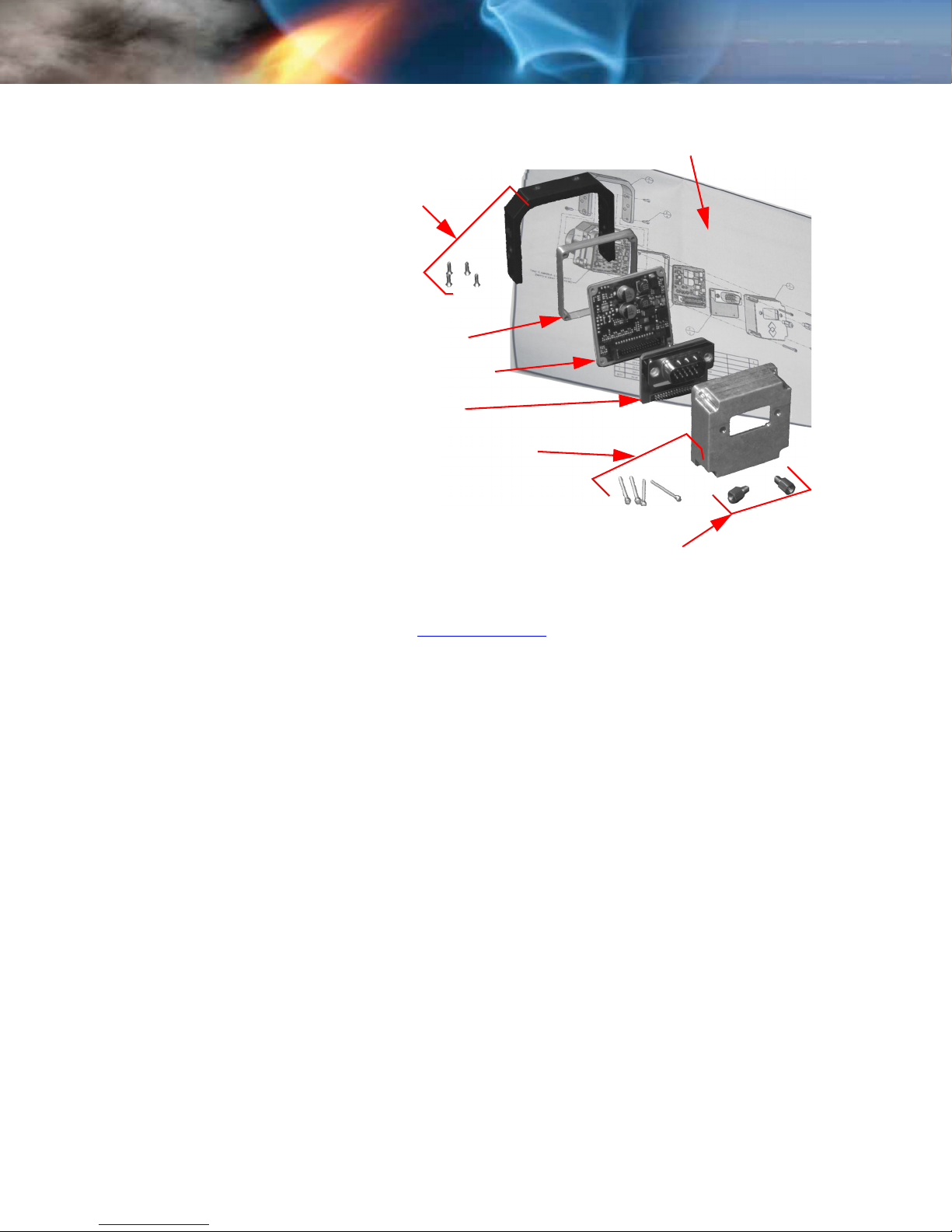

2.6 Photon Replicator Kit

The Photon Replicator kit,

421-0045-00)

Photon adapter

The Photon Replicator Kit

and M2 screws

includes a Photon Replicator

Board, as well as a wearsaver,

and rear cover, that emulates the

15-pin D-sub electrical interface

to Photon 320. A “horseshoe”

shaped bracket is also included

that, when attached to the Tau

Board spacer

camera, exactly mimics the

mounting scheme of the Photon

320 camera.

With this accessory kit, the user

will need a standard BNC cable

for analog video output and a

Replicator board

Adapter

board

Rear cover

and M1.6 screws

standard RS-232 serial COM

cable for advanced configuration

using the free downloadable FLIR

Camera Controller. The Photon

Replicator Board adapts the 50pin Tau connector to a 30-pin

Samtec connector that allows the

use of existing Photon cables and accessories. Purchase accessories for your camera from the

FLIR Camera Accessory Store located at www.flirshop.com

.

Assembly instructions

Connector

standoffs

2.7 Software Accessory Alternate Lens Calibration Software

110-0133-72

For customers that furnish their own optics for use with Tau cores, FLIR sells a Windows

application program called Alt Lens Cal. This software enables users to perform a

supplementary calibration of the camera with a lens. This field-calibration process requires the

use of at least one blackbody source (a uniform, controllable temperature reference) that has

an area greater than the diameter of the front of the lens.

The Alt Lens Cal software also requires a customer-furnished PC, which should be dedicated to

this task. The calibration routine calculates gain terms on a per-pixel basis with the customersupplied lens attached to the Tau core, and stores the customer-performed calibration in nonvolatile camera memory. The original factory calibration coefficients are first uploaded from the

camera and stored into a file on the PC, then the new calibration data is downloaded and

stored directly into the camera. Multiple calibration files can be stored on the host computer.

The original factory calibration file can be restored if necessary, and the customer can actually

build a library of lens calibration files for a Tau camera.

Alternately, customers can contact FLIR to purchase a Lens Calibration feature that works with

the FLIR Camera Controller GUI software.

2-4 June 2011 TAU-0035-00-10, version 150

Page 15

Tau User’s Manual 2—Optional Tau Camera Accessories

2.8 Software Accessory SDK for Windows & Embedded

110-0133-16

The Tau Software Developer’s Kit enables camera control using one of several programming

languages including VB6, VB.net, C#, and C++ (MFC). Code examples are included to help

illustrate how some of the camera control functions can be used. The FLIR Camera Controller

GUI is an example of an application created using the Tau SDK.

Refer to http://www.corebyindigo.com/

.

TAU-0035-00-10, version 150 June 2011 2-5

Page 16

2—Optional Tau Camera Accessories Tau User’s Manual

2-6 June 2011 TAU-0035-00-10, version 150

Page 17

3 Basic Operation of the Tau and GUI

3.1 Operation of the Tau Camera using the USB Interface

The Tau VPC Module and Camera Link Module are USB interfaces for the camera to provide

power and serial communication for more advanced camera command and control via the free

downloadable FLIR Camera Controller GUI. Both modules provide an analog video output, while

the Camera Link Module also provides a digital video output in the Camera Link format. Camera

Link command and control functions are not supported, only the camera link digital video output

is provided.

Connector Type: USB mini 5-pin

Power over USB VPC: nominal draw 180 mA at 5V

(peak load at startup 500 mA at 5V)

Power over USB Camera Link: nominal draw 230 mA at 5V

(peak load at startup 500 mA at 5V)

Serial communications baud rate: 57600 Baud or 921600 Baud

Hot swap protected

Windows Service for automatic detection supported through SDK

Table 3-1: Miniplug / Microplug

Pin Name Color Description

1VCC Red+5 V

2 D- White Data -

3D+GreenData +

4

5 GND Black Signal Ground

1. Pin 4 of mini-USB connector may be not connected, connected to GND, or used as attachment identification

at some portable devices.

1

ID

none

permits distinction of Micro-A- and Micro-B-Plug

Type A: connected to Ground, Type B: not connected

3.1.1 Installing the VPC Module

Step 1 Plug the VPC Module into the mating 50-pin

Hirose Connector on the back of the Tau camera.

Step 2 Install the two socket head cap screws to secure

the VPC Module.

Note

Use only M1.6 × 0.35 × 6 mm screws.

Longer screws will damage the camera.

TAU-0035-00-10, version 150 June 2011 3-1

Page 18

3—Basic Operation of the Tau and GUI Tau User’s Manual

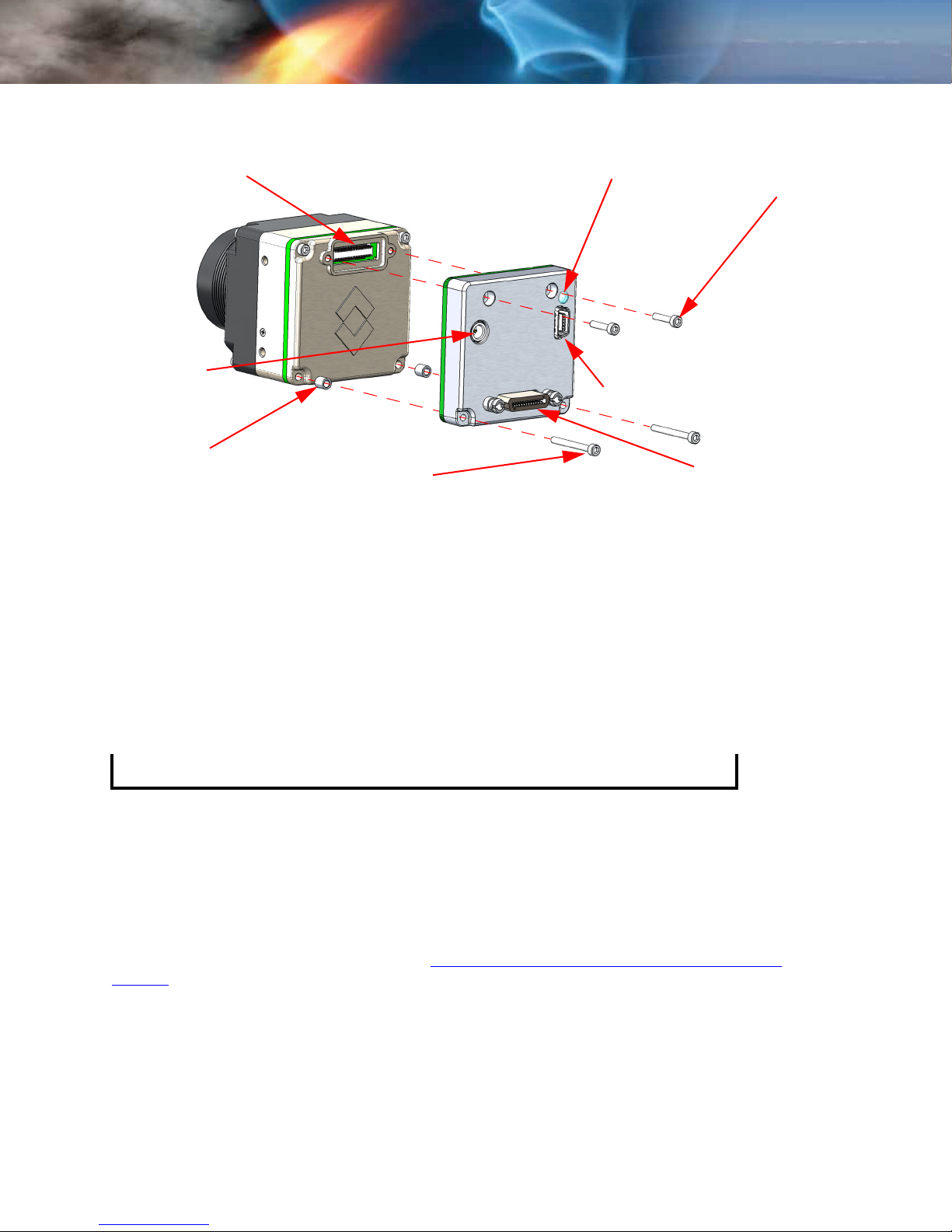

3.1.2 Installing the Camera Link Module

Hirose Connector

MCX coaxial

(analog video)

Spacer (2)

Ø3 mm × 3.1 mm

Power status light

Mini USB

Mounting screw (2)

M1.6 × 0.35 × 16 mm SHCS

Mounting screw (2)

M1.6 × 0.35 × 8 mm SHCS

Mini Camera Link

(digital video)

Step 1 Using a 1.5 mm socket driver, remove the two case screws at the bottom of the

camera (opposite connector).

Step 2 Insert the two M1.6 × 0.35 × 16 mm socket head cap screws through the corner

holes of the Camera Link module, install the spacers on the screws, and thread the

screws into the camera to replace the case screws removed earlier.

Step 3 Plug the module connector into the mating 50-pin Hirose Connector on the back of

the Tau camera.

Step 4 Install the two M1.6 × 0.35 × 8 mm socket head cap screws to secure the module at

the connector.

Note

Use only M1.6 × 0.35 × 8 mm screws. Longer screws will damage the camera.

Step 5 Finish tightening the two M1.6 × 0.35 × 16 mm socket head cap screws at the

corners of the case.

The digital data complies with the Base Camera Link standard and should be compatible with

any brand Camera Link Frame Grabber and software.

The FLIR Camera Controller allows you to control the Tau Camera, but does not support

Camera Link frame capture so that a third-party software must be used. FLIR has tested the

ImperX FrameLink Express frame grabber (http://imperx.com/frame-grabbers/framelink-

express).The ImperX frame grabber comes with FrameLink Express software that allows for

recording single or multiple images (BMP, JPG, TIF, and RAW) as well as standard AVI clips.

Configuration requires selecting 1 TAP, L->R for the tap reconstruction, selecting the

appropriate bit depth that you chose in the FLIR Camera Controller, and clicking “Learn” to

discover the number of digital pixels available.

3-2 June 2011 TAU-0035-00-10, version 150

Page 19

Tau User’s Manual 3—Basic Operation of the Tau and GUI

t

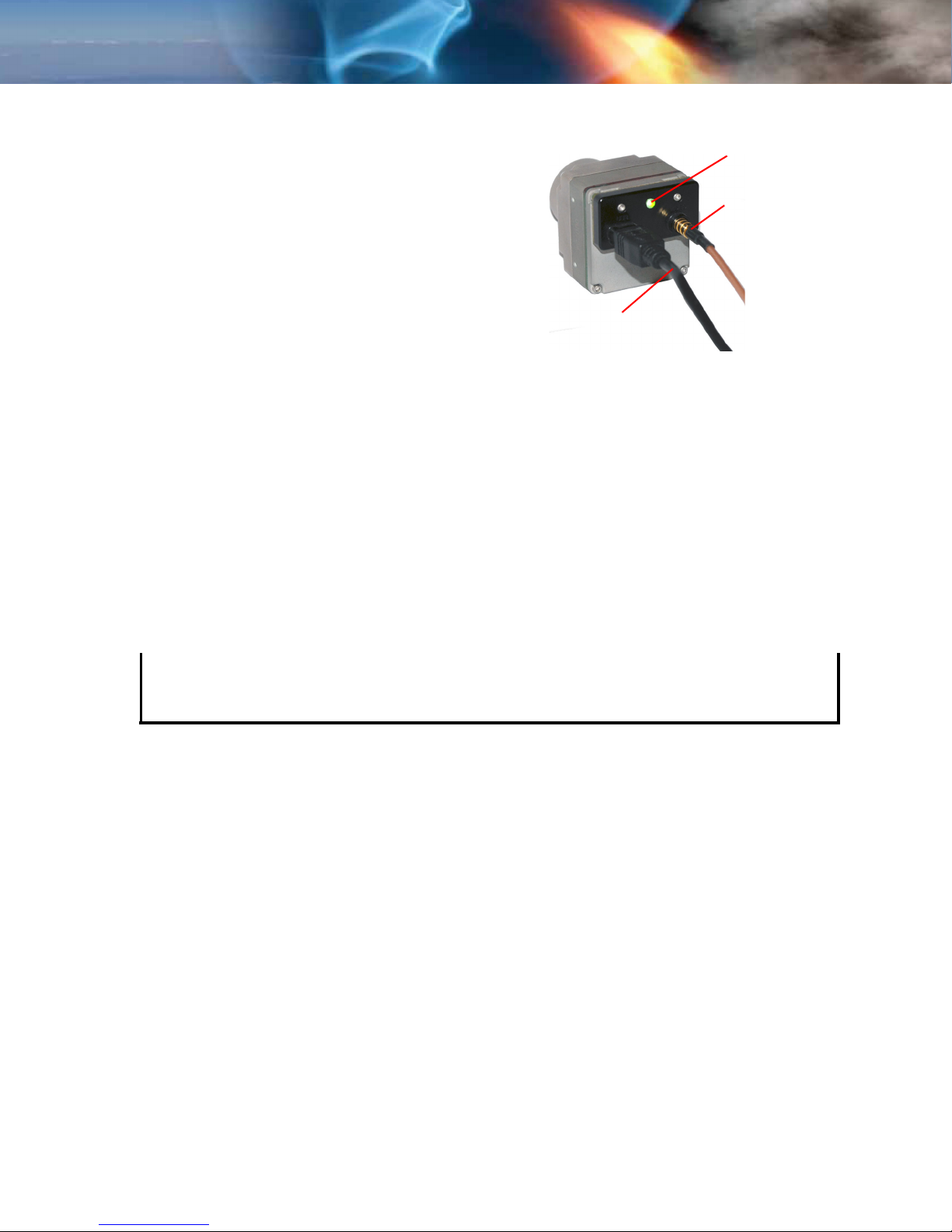

3.1.3 Connecting the Tau Camera for Analog Video

Plug the Video cable into the mating connector

on the back of the camera. Attach the other end

to a compatible video monitor’s composite video

input. If your monitor has an RCA input

connector, a BNC to RCA adapter can be used.

Plug the mini USB plug into the mating

connector on the back of the camera. Connect

the other end of the cable to a USB port on the

computer. At this point, you are only using the

power from the USB port.

USB cable

to computer

Power light

Analog video ou

3.2 Remote control of the Tau Camera

The Tau camera with the a Universal Serial Bus (USB) interface accommodates advanced

camera control through the FLIR Camera Controller GUI. A user can control the camera

through this interface using their own software and hardware by following the Serial

Communication Protocol and command structure defined in Appendix B. This requires

programming skills and a strong technical background. The user can also use the FLIR Camera

Controller GUI offered as a free download from FLIR using a Windows based PC with a

standard USB port. This software provides remote control of various camera features and

modes.

The FLIR Camera Controller GUI software is compatible with Windows XP with .Net Framework

version 2.0 or later. The GUI will prompt the user to update to the latest .Net Framework.

Note

We recommend that Windows Update is turned on, keeping the operating system current;

and that you use the latest version of the FLIR Camera Controller GUI

(available on our website).

If your embedded or specialty applications require custom control software, a Software

Developer’s Kit (SDK) is available. Those intending to generate their own custom software are

encouraged to read the remainder of this section regarding the FLIR Camera Controller GUI to

better understand the camera modes and parameters.

TAU-0035-00-10, version 150 June 2011 3-3

Page 20

3—Basic Operation of the Tau and GUI Tau User’s Manual

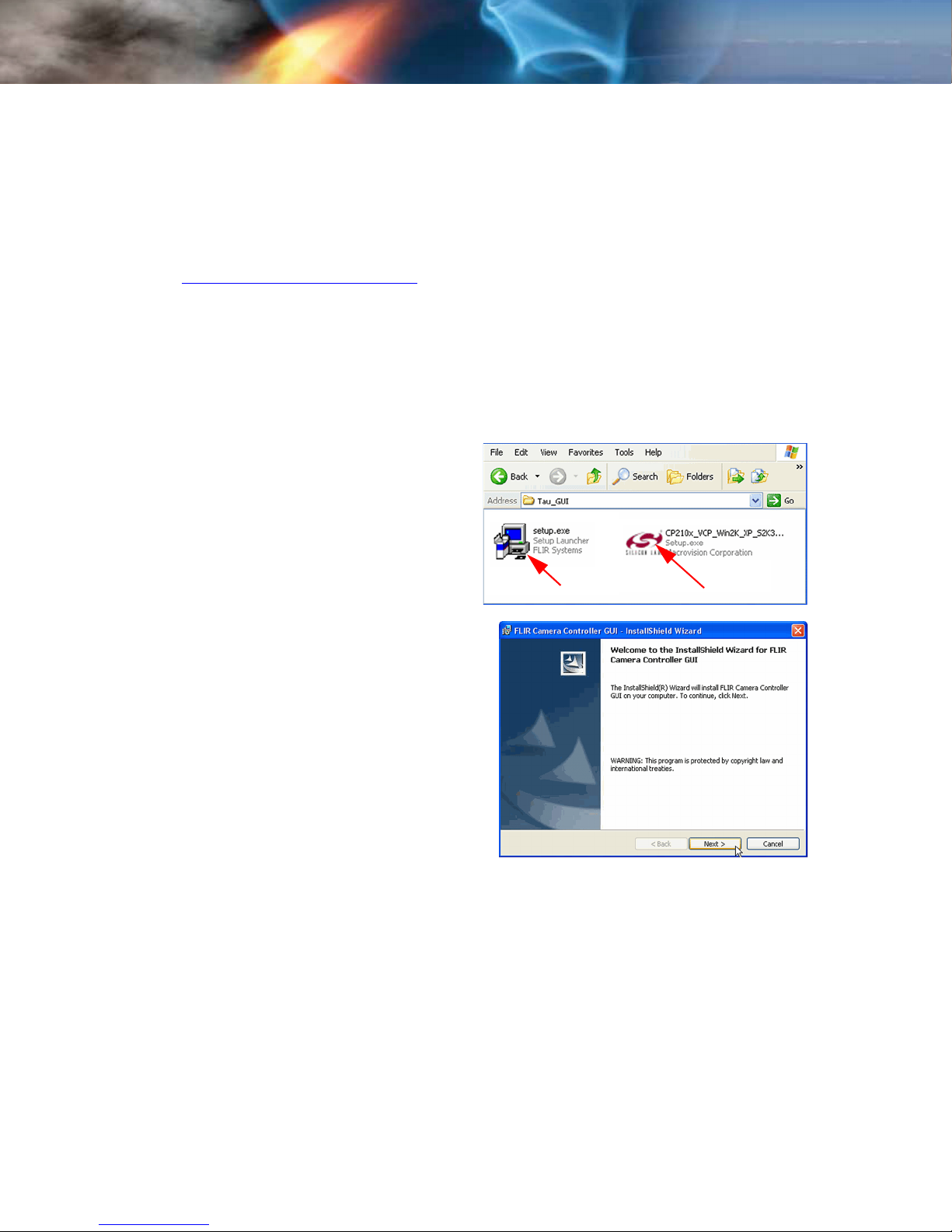

3.3 Installing the FLIR Camera Controller GUI

Step 1 If you have another version of the FLIR Camera Controller GUI loaded on your PC, you

should uninstall it using the Windows Uninstall utility via the Windows Control Panel

before proceeding with this installation. This is an important step as camera

malfunction is possible if you do not remove any older versions of Tau (or Omega/

Micron/A10) software.

Step 2 Using your favorite WWW browser, navigate to the following URL:

http://www.corebyindigo.com/

Step 3 Click the Download Tau GUI (Zip file) link.

Step 4 When the File Download prompt appears, choose Save. It is recommended that you

create a new empty directory such as “FLIR Camera Controller GUI Installable Files”

on your desktop, for download.

Step 5 Extract the Installable files using WinZip or other available software.

Step 6 Open the directory where you saved

the Installable files. Double-click the

setup.exe file to begin installation.

Tau.

Step 7 Click Next> at the Setup Welcome

screen.

When the installer finishes loading. Follow

the prompts.

Camera Controller GUI USB driver

3-4 June 2011 TAU-0035-00-10, version 150

Page 21

Tau User’s Manual 3—Basic Operation of the Tau and GUI

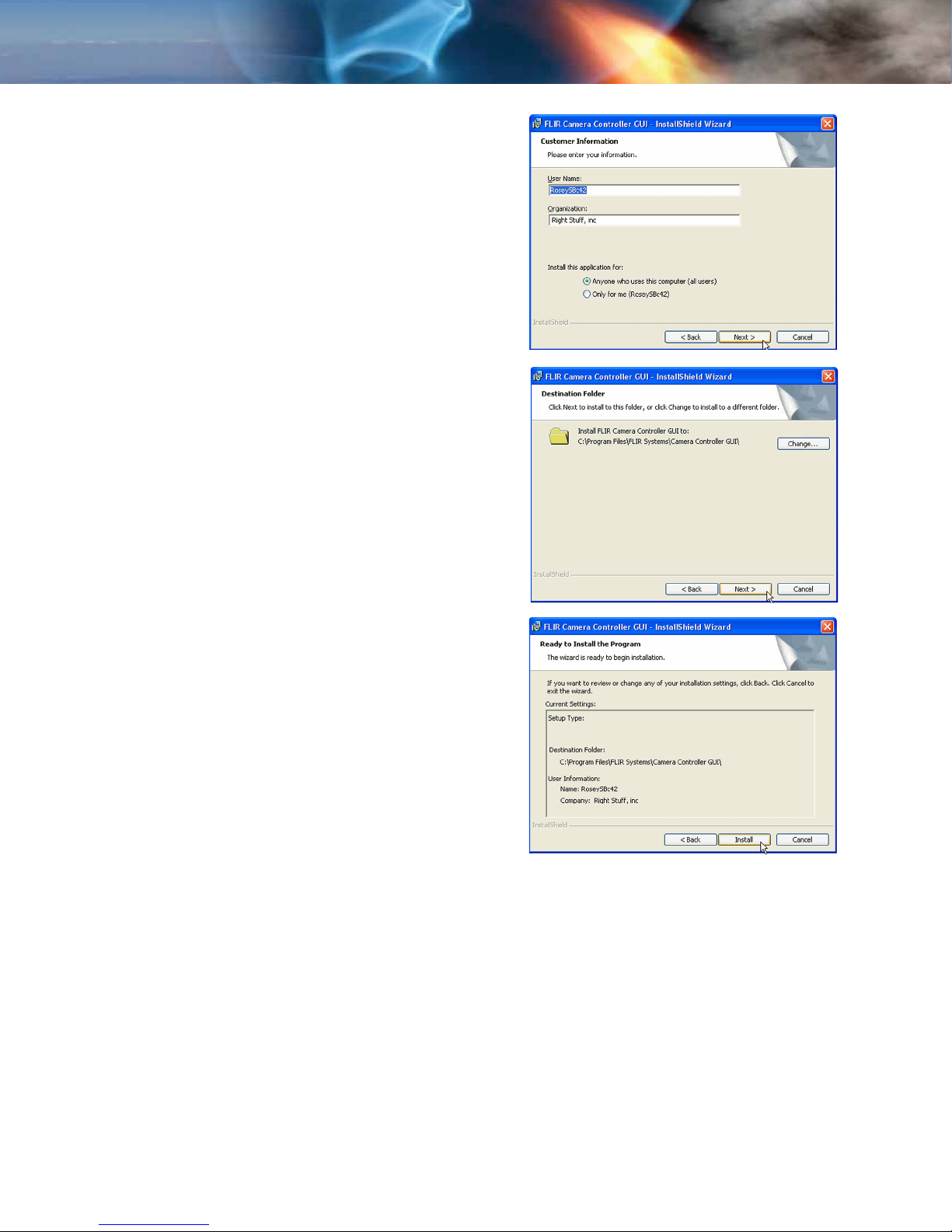

Step 8 Enter your User Name, Organization, and

select your access security.

Click Next>

Step 9 Select a Destination Folder if different

than the default.

Then, click Next>>.

Step 10 Review the settings you have entered for

this installation.

Then, click Install

TAU-0035-00-10, version 150 June 2011 3-5

Page 22

3—Basic Operation of the Tau and GUI Tau User’s Manual

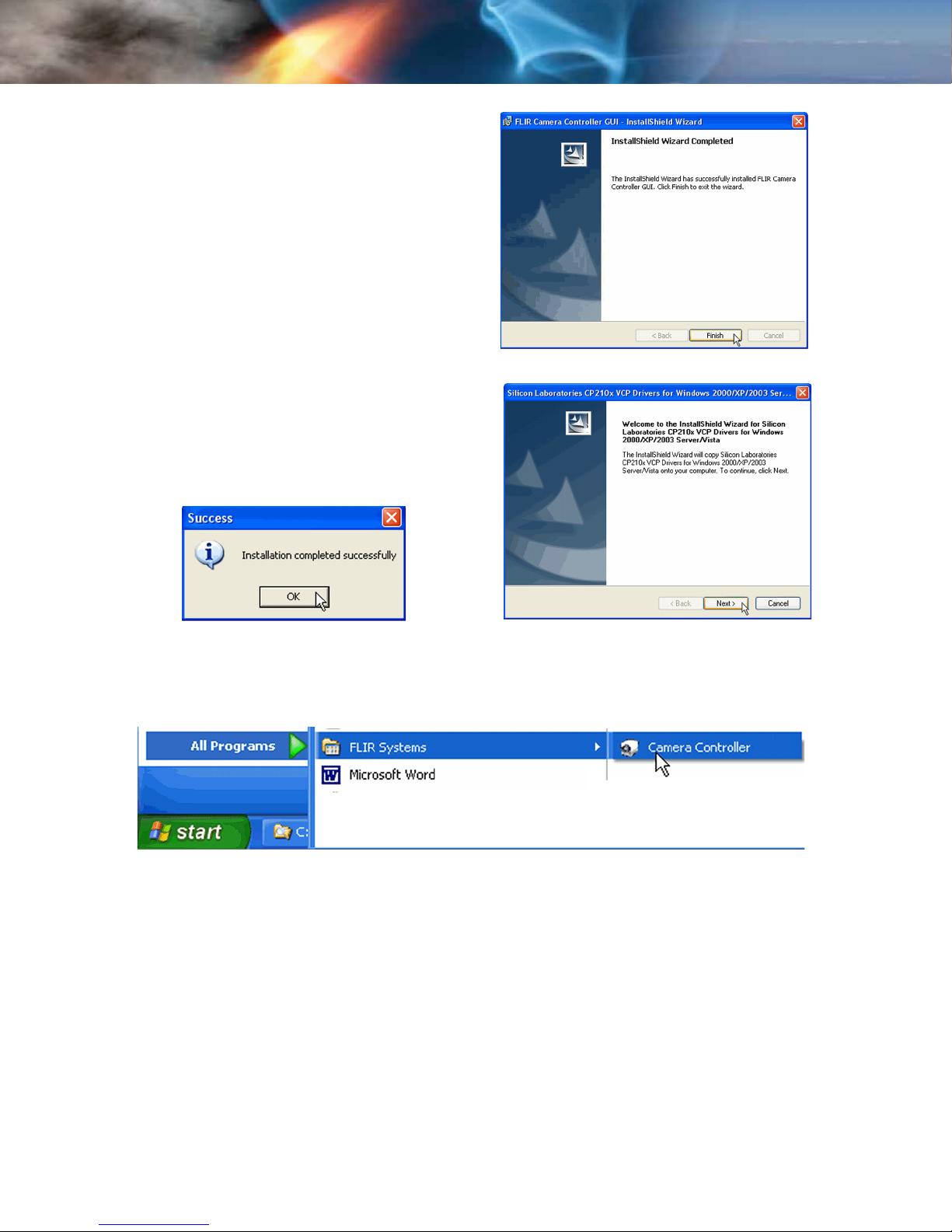

Step 11 Once installation is complete, click Finish.

Step 12 The CP210x_VCP...setup.exe USB driver

installer will start at this point.

Click Next> at the Setup Welcome

screen.

When the installer finishes loading. Follow

the prompts to finish the installation.

Step 13 Installation is complete. You can start the application or create a shortcut to the

application via the

Start→ All Programs→ FLIR Systems→ Camera Controller GUI path.

3-6 June 2011 TAU-0035-00-10, version 150

Page 23

Tau User’s Manual 3—Basic Operation of the Tau and GUI

3.4 Connecting the Tau to a PC via USB

The following steps assume that you have installed the FLIR Camera Controller GUI software

and the USB driver on your PC as described in the proceeding paragraphs 3.3.

Step 1 Follow the steps in paragraph 3.1.3 “Connecting the Tau Camera for Analog Video” on

page 3-3.

About two seconds after the USB cable from the camera is connected to your PC, you

should see video on your monitor. Verify that the camera is producing an image.

Step 2 Launch the FLIR Camera Controller GUI software by selecting Start→ Programs→ FLIR

Systems→ Camera Controller GUI.

Note

The FLIR Camera Controller GUI remembers the last COM port that successfully

communicated with a Tau camera and will use that port as the default when the application

starts. If the connected camera is no longer on that port, the port setting pop-up window will

appear asking for you to select the proper port setting.

TAU-0035-00-10, version 150 June 2011 3-7

Page 24

3—Basic Operation of the Tau and GUI Tau User’s Manual

When the FLIR Camera Controller GUI is started, the Status tab of the utility should

return data similar to the following.

Figure 3-1: FLIR Camera Controller GUI Status Tab

3-8 June 2011 TAU-0035-00-10, version 150

Page 25

Tau User’s Manual 3—Basic Operation of the Tau and GUI

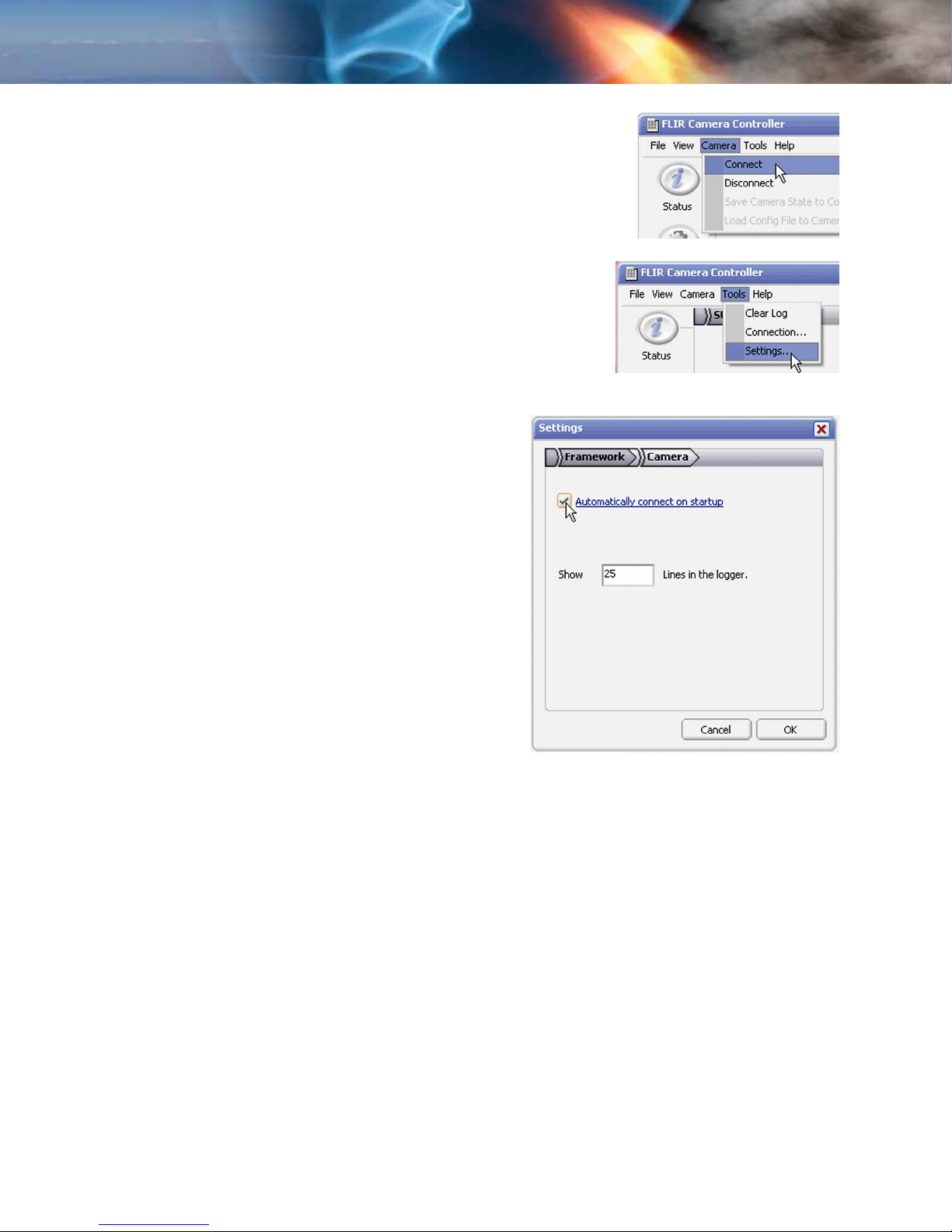

Step 3 Connect to your camera by selecting Connect from the

Camera menu.

Step 4 If you want the FLIR Camera Controller GUI

to automatically connect when it is started,

select Settings from the Tools menu, then

check the Automatically connect on

startup box in the Settings Framework tab.

Additional settings include camera

connection polling, status logging,

and FLIR Veneer style.

TAU-0035-00-10, version 150 June 2011 3-9

Page 26

3—Basic Operation of the Tau and GUI Tau User’s Manual

3.5 Troubleshooting the FLIR Camera Controller GUI

If the FLIR Camera Controller GUI does not link

with the camera, you may see the popup shown at

the right which indicates that the GUI has not

been able to communicate with the Tau camera.

Verify the items in the following checklist:

Is the camera properly cabled to the

host PC?:

Verify that you selected the proper port if it was

not detected automatically. Select Advanced, then

Next> in the Tools→ Connection... dialog box. Also,

try disconnecting and then re-connecting the cable

to the PC. If the GUI was launched before the

cable was connected, close the GUI, connect the

cable, then re-launch the GUI.

Is the Baud rate set correctly? Baud

rate must be set in the Tools→ Connection...

dialog box. The Tau camera supports Baud rates

of 57600 and 921600.

Is the port already in use by another

application?:

Shut down any other applications that may be

using the port. Also, multiple instances of the FLIR

Camera Controller GUI Program can be

instantiated using different ports so be sure the

camera you are interested in controlling is actually

connected to the physical port.

Is the Tau camera power on? Veri fy that

the camera is producing an image on a separate

monitor. On cameras with a shutter installed, at

camera power up, you can hear two sets of a

click-click sound, separated by about 5 seconds,

as the shutter performs its on-power-up

calibration.

If you cannot initiate serial communication with the camera after verifying these items, refer to

the frequently asked questions (FAQ) at http://www.corebyindigo.com/

or contact FLIR Customer Support at (805) 964-9797.

Tau

3-10 June 2011 TAU-0035-00-10, version 150

Page 27

Tau User’s Manual 3—Basic Operation of the Tau and GUI

3.6 Operation of the FLIR Camera Controller GUI

When the FLIR Camera Controller GUI successfully links to the camera, you will see the window

shown below. At the bottom of the application window, you should see Camera and FPA status.

The GUI provides five tabs allowing for camera control as described below.

Figure 3-2: FLIR Camera Controller GUI Status Tab

Camera Part #: indicates the specific camera configuration connected.

Camera Serial #: This is the serial number of the camera currently connected to the FLIR

Camera Controller GUI.

FPA Temperature: The camera’s Focal Plane Array (FPA) temperature.

The connection status, Camera status, Camera Part #, FPA Temp, and FPA Size are displayed

at the bottom of all tabs.

TAU-0035-00-10, version 150 June 2011 3-11

Page 28

3—Basic Operation of the Tau and GUI Tau User’s Manual

3.7 Setup Tab

The Setup tab, shown below, provides the ability to do the following:

Modify the Flat Field Correction (FFC)

Set the External Sync mode

Freeze the video via the Operating Mode section

Populate the Scratch Pad with text

Set the camera to generate a Test Pattern

Save the settings to the camera’s non volatile memory

Restore the Factory Defaults

Reset the Camera

Figure 3-3: FLIR Camera Controller GUI Setup Tab

3-12 June 2011 TAU-0035-00-10, version 150

Page 29

Tau User’s Manual 3—Basic Operation of the Tau and GUI

Flat-Field-Correction Mode: Tau cameras include

internal mechanisms for periodically improving image quality via

a process called flat-field correction (FFC). During FFC, a

shutter briefly blocks the detector array, presenting a uniform

temperature (a flat field) to every detector element. While

imaging the flat field, the camera updates correction

coefficients, resulting in a more uniform array output. The

analog video image is frozen during the entire process, which

takes less than a half second, and resumes automatically

thereafter. Repeating the FFC operation often prevents the

imagery from appearing “grainy”. This is especially important

when the camera temperature is fluctuating, such as

immediately after turn-on or when ambient temperature is

drifting. FFC can be controlled manually at any time using the

Do FFC command button.

Tau provides three FFC modes:

Auto: In the Automatic FFC mode, the camera performs FFC whenever its

temperature changes by a specified amount or at the end of a specified period of time

(whichever comes first). When this mode is selected, input windows are available in

the FLIR Camera Controller GUI for specifying the temperature change and the

number of frames that trigger automatic FFC. The temperature change is specified in

degrees, with valid values in the range 0 to 100 in 0.1 degree increments. The time

period is specified in analog video frames (33ms NTSC, 40ms PAL), with valid values

in the range 0 to 30,000 frames. A setting of 0 frames for the FFC Interval will allow

the Tau camera to only perform an FFC based on the values in Temp change. The

second set of Auto FCC parameters labeled Low Gain apply to Tau-P Cameras with

the auto gain switch enabled.

Note

FLIR recommends using the factory default values for the two automatic-FFC parameters if

possible. These values were selected to maintain a high degree of image quality over all

camera operating conditions.

Manual: In Manual FFC mode, the camera does not perform FFC automatically based

on specified values of temperature change or expired time. The FFC will be performed

once upon startup then again using the internal shutter when the “Do FFC” button is

clicked.

Note

Large camera temperature excursions cause the camera to perform the FFC operation (even

with Manual FFC mode selected), typically at temperature crossings near 0°C and 40 °C.

External: In External FFC mode a uniform source (blackbody) must be placed in front

of the camera. The image of this uniform source will be subtracted from all

subsequent images. This feature is useful if there are lens or lens mount nonuniformities that are not corrected by an internal FFC. The camera will not perform an

FFC process on startup if the saved state of the camera is External mode FFC.

Many customers have found that the palm of their hand or a table is an adequate

uniform source to perform an External FCC.

TAU-0035-00-10, version 150 June 2011 3-13

Page 30

3—Basic Operation of the Tau and GUI Tau User’s Manual

The Tau camera displays an on-screen

symbol called the Flat Field Imminent

Symbol prior to performing an automatic

FFC operation. As shown in Figure 3-4, it

is the square in the upper right of the

video output and is displayed nominally 2

seconds prior to the FFC operation. The

duration of the FFC Imminent Symbol

can be set using the FFC Warn Time

setting in the Analog Video tab. Setting

the Warn Time to less than 15 turns off

the warning (see paragraph 3.8).

Figure 3-4: Flat Field Imminent Symbol

External Sync Mode: The Tau

camera provides the ability to either accept or output a

frame synchronization signal on pin 21 of the 50-pin

Hirose connector or pin 26 of the Photon Replicator

board. This functionality can also be disabled. The designed

signal levels are 0V and 3.3V.

Disabled: The camera will turn off frame synchronization.

Slave: The camera will accept a frame synchronization signal on the interface

connector. The camera output will be frozen if the camera is in slave mode and no

external synchronization signal is received.

The focal plane array readout cycle starts when the external synchronization signal is

received and the camera will continue the output cycle until the frame is complete.

The frame sync signal embedded in the respective digital output should be used to

acquire digital data, not the external sync I/O.

Maximum external sync input rates are up to 29.980 Hz for NTSC and 27.25 Hz for

PAL. The ‘Slow Video’ versions of the Tau camera will have the same external sync

frame rates, but the image data output will be at 1/4 the rate (NTSC) or 1/3 the

rate (PAL).

Master: The camera will output a frame synchronization signal on the interface

connector when configured as a master. The output pulse width will be 100 ns at the

standard frame rates (27.970 Hz for NTSC; 25.000 for PAL).

Operating Mode: The Tau camera will freeze the

analog frame imaged when Frozen is selected. Live video

will cease and the frozen frame will persist. To return the

camera to live video, select Real-Time video mode.

Save Settings: After using the FLIR Camera Controller GUI to change

camera modes and settings to your desired values, use the Save Settings

button to store your current selections as new power-up defaults. The next

time the camera is powered, the Tau camera will remember these saved

settings. If you do not click Save Settings, the changes you make via the FLIR Camera

Controller GUI will be valid only for the current session. Cycling power to the camera will revert

to the previously saved settings.

3-14 June 2011 TAU-0035-00-10, version 150

Page 31

Tau User’s Manual 3—Basic Operation of the Tau and GUI

Factory Defaults: The Factory Defaults button restores the camera’s

settings to the initial values specified by the manufacturer.

If you want the factory default settings to become the power up defaults, first

click the Factory Defaults button, then click the Save Settings button.

Reset Camera: The Reset Camera button restarts the camera

software.

Test-Pattern: A Test-Pattern m o d e i s p r o v id e d to v e r if y

camera electronics. The Test-Pattern mode will not persist

over a power cycle.

Off: No test-pattern is provided in this mode.

This is the normal mode for viewing thermal

imagery.

Ramp: In this ramp mode, the test pattern shown

below and in the Color/LUT section that follows is

provided at the analog and digital data channels.

pix(0,0) = 0 pix(639,0)

pix(25,408) = 16383

pix(25,409) = 0

Figure 3-5: Ramp test pattern example for Top Portion of Tau Ramp Image

(Digital values shown apply to the optional 14-bit digital data stream.)

The above ramp pattern repeats 19 times in the complete 320 × 256 image.

Note

The ramp test pattern is intended primarily for verifying the output of the digital data channel.

The pattern will not necessarily look as shown above when displayed on an analog video

monitor, particularly if an Automatic Gain Control (AGC) mode other than Automatic is

selected. The above image is a horizontal slice of the full displayed image.

Gain Mode: The Tau camera has two gain ranges:

High gain mode is designed to maximize contrast for imaging applications.

Low gain mode has lower contrast but a higher dynamic range and is designed for

viewing hot targets.

Auto gain mode allows the Tau camera to switch between Low and High gain mode

based on the scene being viewed, Auto mode is controlled by the Gain Switch Values

in the Thermal tab. See “Thermal Tab” on page 3-28.

TAU-0035-00-10, version 150 June 2011 3-15

Page 32

3—Basic Operation of the Tau and GUI Tau User’s Manual

3.8 Analog Video Tab

The Analog Video tab on the FLIR Camera Controller GUI, shown below, provides the ability to

modify Tau camera modes:

Image Orientation Dynamic Digital Detail Enhancement (DDE)

Pan & Zoom Video On/Off

Polarity/LUT (Video Color) Video Standard NTSC/PAL

FFC Warn Time

1. Select Video

2. Select Analog Video

Figure 3-6: FLIR Camera Controller GUI Analog Video Tab

3-16 June 2011 TAU-0035-00-10, version 150

Page 33

Tau User’s Manual 3—Basic Operation of the Tau and GUI

Image-Orientation Mode: Two Image-Orientation mode selections are provided. Select

one or both to change the orientation of the video image.

Invert: The normal image is flipped vertically. The

pixel on the upper-left corner of the detector array

is displayed on the lower-left corner of the video

display in Invert mode. Invert is used when

mounting the camera upside-down. Invert applies

to analog, BT.656, CMOS, and LVDS video.

Revert: The normal image is flipped horizontally. The pixel on the upper-right corner of

the detector array is displayed on the upper-left corner of the video display in Revert

mode. Revert mode produces a mirror-image of Normal mode; use for applications

where the camera is imaged through a fold-mirror. Revert applies to analog and

BT.656 video only.

Note

Any time the image orientation mode is inverted, a flat-field correction automatically takes

place. Adjusting image orientation should be followed by a flat-field correction in all modes.

Pan & Zoom, Zoom: The Tau 320

camera has a built-in 2× and 4× digital zoom

Select to

enter offsets

capability. The Tau 160 camera has a built-in

2× digital zoom. The Zoom check boxes are

used to turn on/off the camera zoom. With

the Unzoom box checked, the Tau camera

Click to

center

displays the full sensor array image (NTSC:

320 × 240 pixels or PAL 320 × 256 pixels).

When the Zoom 2x box is checked, a smaller

central region of the sensor array is mapped

to the video output creating the zoom effect.

For NTSC and PAL video formats in 2× zoom

mode, 160 × 120 and 160 × 128 pixels,

respectively, are mapped to the analog video

Tilt

slider

Pan

slider

output. When the Zoom 4x box is checked,

80 × 60 (NTSC) and 80 × 64 (PAL) pixels,

respectively, are mapped to the analog video output. This reduced region of the array is called

the zoomed array region. The BT.656 video also has the zoom feature, but the CMOS and

LVDS do not.

Pan & Zoom, Pan: When in either zoomed mode, you can move the zoomed array region

within the full array area. This digitally simulates panning and tilting. Panning and tilting are

defined as moving the camera image in the horizontal and vertical axes, respectively.

The Pan/Tilt limits for 320 cameras are the same in both 2× and 4× mode.

The Pan/Tilt limits for 160 cameras are ±40/±30; or the same as the Fine range.

You can adjust the vertical and horizontal sliders to move the zoomed array region.

When the fine box is not checked the slider controls move the zoomed image from edge to

edge of the full sized array. Checking the fine box increases the sensitivity of the slide control so

that the zoomed array moves one half the total range but all step values are achievable. Simple

TAU-0035-00-10, version 150 June 2011 3-17

Page 34

3—Basic Operation of the Tau and GUI Tau User’s Manual

experimentation while viewing the displayed image will quickly give you familiarity with this

feature.

Note

The Spot Meter function always reports values from the center of the full array. Pan/Tilt

moves the image but not the location of the Spot Meter. If Pan/Tilt is being used, the Spot

Meter readings will not be correct.

Flat-Field Correction (FFC): The Tau

automatically performs flat-field corrections (see

paragraph “Flat-Field-Correction Mode:” on page 3-

13). A square is displayed on your video monitor as a

warning that the FFC is going to take place. Use this

function to set the number of analog video frames

(33ms NTSC, 40ms PAL) during which the warning will be displayed. The time period, specified

in frames, can range from 0 to 30,000 frames.

The factory setting of 60 frames equates to a two second warning. Setting the FFC Warning to

less than 15 frames turns off the warning. A setting of 0 frames for the FFC Warning will allow

the camera to only perform FFC based on the temperature change values if in Auto FFC mode.

Dynamic Digital Detail Enhancement (DDE) filter:

The DDE algorithm sets edge enhancement dynamically

proportional to the number of bins occupied in the

image histogram.

In a high dynamic range scene the gain will be higher

than in a low dynamic range scene. This allows faint

details to be visible in high dynamic range scenes

without increasing temporal and fixed pattern noise in

low dynamic range scenes.

The DDE filter operates independently from the AGC and will enhance edges without effecting

brightness or contrast. The valid range of Dynamic DDE setting is from 1 to 63 with 17 being

the neutral setting where the filter has no effect. Settings below 17 will smooth the image

reducing the appearance of sharp edges. Higher DDE settings will enhance all image nonuniformities resulting in a very detailed but grainy picture especially in high dynamic range

scenes. Typical factory settings are between 25 and 30. Settings from 18 to 39 are normal

imaging modes where the edge enhancement can be tuned for the scene. Use the slider to

adjust the setting, or select the text field and type in the desired setting.

Note

In 14-bit Raw mode, selecting the DDE mode will not affect the digital data output.

Video On/Off: This feature allows you to turn off

the analog video output which will result in some power

savings (approximately 55mW).

Video Standard: Choose the video standard for

your system.

3-18 June 2011 TAU-0035-00-10, version 150

Page 35

Tau User’s Manual 3—Basic Operation of the Tau and GUI

Polarity/LUT: The Tau camera detects and

images the temperatures in a given scene. Within the

camera, these temperatures are mapped (as

determined by the AGC algorithm selected) to a range

of 0 to 255 values. In a black and white display mode,

this range is converted to shades of grey with, for

example, 0 being totally black and 255 being totally

white. The 0 to 255 grayshades range sensed is

referenced to a Look-Up Table (LUT) permanently

stored in the camera to convert the scene to a video

image. Different LUTs are available to change the

appearance of the displayed image. The most common

selection is either White Hot (hotter objects appear

brighter than cooler objects in the video display) or

Black Hot (hotter objects appear darker than cooler objects). Since the difference between

these two modes simply reverses the choice of darker or lighter for temperature extremes, this

is sometimes referred to as Polarity. Other color LUTs are available as shown below.

Figure 3-7 shows each of the LUTs as displayed in Test Pattern Ramp Mode starting with the

upper left: White Hot, Black Hot, Fusion, Rainbow, Globow, Ironbow1, Ironbow2, Sepia, Color1,

Color2, Ice Fire and Rain. Select one of these LUTs from the pull-down menu to view your image

displayed using the LUT you choose.

Cold

Cold

White Hot

Cold

Globow

Cold

Color1

Hot

Hot

Hot

Hot

Cold

Black Hot Fusion Rainbow

Cold

Ironbow1 Ironbow2 Sepia

Cold

Color2 Ice Fire Rain

Figure 3-7: Look-Up Table Options

Cold

Hot

Cold

Hot

Cold

Hot

Hot

Hot

Hot

Cold

Hot

Cold

Hot

Cold

Hot

Simple experimentation with this feature while viewing the video image will give you familiarity.

Remember that you must click the Save Settings button on the Setup tab to save the LUT

settings as default at power-up.

Note

The setting of the Polarity/LUT mode will not affect the digital data output.

TAU-0035-00-10, version 150 June 2011 3-19

Page 36

3—Basic Operation of the Tau and GUI Tau User’s Manual

3.9 Digital Video Tab

Tau offers a LVDS interface digital output that can be configured in four modes. Changing these

modes will have no effect on the analog (NTSC or PAL) signal. In order to access the digital

output, you must use an advanced interface as described in Chapter 4, Tau Digital Data

Channel. See the Tau Electrical Interface Control Document (102-PS220-41) for information on

how to access digital video for LVDS, BT.656, and CMOS.

1. Select Video

2. Select Digital Video

Figure 3-8: FLIR Camera Controller GUI Digital VIdeo Tab

Camera Digital Output

Note

The Revert feature is not available in digital video.

Note

AGC mode will only affect the digital data output if Camera Digital Output mode is set to 8-bit

data.

Off: The digital data stream coming from the Tau camera is turned off.

3-20 June 2011 TAU-0035-00-10, version 150

Page 37

Tau User’s Manual 3—Basic Operation of the Tau and GUI

8-bit: Data from the 320 × 240 (NTSC) or 320 × 256 (PAL) video pixels is provided

after application of the current Automatic Gain Control (AGC) and Dynamic Detail

Enhancement (DDE). The 8-bit data is essentially a digital version of the same data

provided on the analog video channel.

14-bit Filtered: Data from 324 × 256 pixels is provided prior to video processing

modes in the 8-bit data described above. The 14-bit data is the filtered data to include

the Dynamic Detail Enhancement (DDE) and will appear gray when saving 16-bit TIFF

files. See “Tau Digital Data Channel” on page 4-1.

14-bit Raw: Data from 324 × 256 pixels is provided prior to all video processing and

does not include the Dynamic Detail Enhancement (DDE). The 14-bit data is the ‘raw’

data and will also appear gray when saving 16-bit TIFF files. See “Tau Digital Data

Channel” on page 4-1.

XP Mode Select

The Tau camera has 18 XP pins on the 50-pin Hirose connector. The XP mode uses a

number of these pins to output parallel digital image data.

BT656: The BT.656 parallel output is a common interface which will drive many LCD

displays. The data is digitally encoded NTSC/PAL video and will have AGC, DDE,

symbols, and color included.

CMOS: The CMOS interface is a parallel output that allows the user to access 8-bit

AGC corrected data or 14-bit data. The signal levels are 0 - 3.3 V CMOS logic and are

intended to drive boards mounted directly to the Tau camera. CMOS is not intended to

drive a cable. An XP-board reference design is available upon request.

TAU-0035-00-10, version 150 June 2011 3-21

Page 38

3—Basic Operation of the Tau and GUI Tau User’s Manual

3.10 Image Capture Tab

The Image Capture tab on the FLIR Camera Controller GUI, shown below, allows you to capture

two 8-bit AGC corrected images to camera memory for retrieval to a host computer. The

images will be 8-bit grayscale only, without symbols. (The camera actually captures and

stores14-bit images and the FLIR Camera Controller GUI displays them as 8-bit images with

linear AGC applied.)

1. Select Video 2. Image Capture

Figure 3-9: FLIR Camera Controller GUI Analog Video Tab

Save Currently Displayed Image...: Saves an 8-bit .bmp file as described above.

Take Snapshot: Take two snapshots sequentially. Snapshot memory must be erased

before taking new snapshots; snapshots will not overwrite memory.

Retrieve Snapshot: Snapshot # is retrieved and displayed one at a time.

Erase Snapshot: Snapshots will stay in the camera until erased. This button will erase

all the snapshots from the camera, allowing new snapshots to be taken.

3-22 June 2011 TAU-0035-00-10, version 150

Page 39

Tau User’s Manual 3—Basic Operation of the Tau and GUI

3.11 AGC Tab

The AGC tab, shown in Figure 3-10, controls the Automatic Gain Control (AGC) mode or

algorithm along with selectable parameters. Only one mode can operate at a time and is

selected by clicking one of the Algorithm buttons in the upper left portion of the window.

Parameters for a given mode are contextually made available depending on which mode is

selected. The Region of Interest (ROI) for the AGC mode is adjustable as well (see

paragraph 3.12).

1. Select AGC tab

2. Select AGC

Figure 3-10: FLIR Camera Controller GUI AGC Tab

Note

FLIR has invested heavily in designing high quality AGC algorithms. The default mode

(Automatic) along with the default parameter settings for the Automatic AGC mode have been

proven to offer the best image quality for generalized scene imaging. Also, be aware that you

can make AGC adjustments that will configure the Tau camera to produce no image (all black

or all white). Restoring the Factory Defaults on the Setup Tab will return the camera to its

factory default state and likely restore normal camera operation.

TAU-0035-00-10, version 150 June 2011 3-23

Page 40

3—Basic Operation of the Tau and GUI Tau User’s Manual

AGC Modes: The Tau provides five AGC algorithms for Image-Optimization:

Automatic: This is the most sophisticated algorithm

and for most imaging situations, the best all-around

choice. This factory default along with the default

parameter settings should be used in general imaging

situations. In Automatic, image contrast and

brightness are optimized automatically as the scene

varies. This mode provides an AGC which is based on

a histogram-equalization algorithm. Controls for the

ITT Mean (gray scale mid-point), Max Gain (AGC gain)

and Plateau Value are enabled.

The histogram equalization used in the automatic mode scales the 14-bit to 8-bit

transfer function based on the number of pixels in a bin. The more pixels in a bin, the

higher the gain. But the Plateau value is the pixels/bin limit when the transfer function

is maximized. Normally 250 is the plateau value for imaging cameras when more

contrast is desired.

This algorithm analyzes the scene content in real time and redistributes the dynamic

range of the scene. The goal of this redistribution is that every one of the 255 bins of

display dynamic range has an equal number of pixels in it. This method tends to give

better scene contrast under conditions where the scene statistics are bimodal (for

example, a hot object imaged in a cold background. It should be noted that the heat

range in a given scene is not divided evenly across the grey levels sent to be displayed.

Instead, the AGC algorithm analyzes the scene and distributes the dynamic range to

best preserve statistical scene content (populated regions of the histogram) and

display a redistributed scene representation.

Once Bright: In this mode, the brightness will be set once when the mode is selected.

The brightness (level) is calculated as the mean of the current scene when the Once

Bright button is selected. The scene is mapped to the analog video using a linear

transfer function. Image contrast can be adjusted by the Contrast slider. This is the

only user adjustable parameter. Upon entry into the once bright mode, the currentlystored value of contrast is applied (i.e. the power-on defaults or the last saved values).

Auto-Bright: In this mode, the brightness (level) is calculated as the mean of the

current scene just as in Once Bright mode. The difference with Auto-Bright is that

the values selected for the start and end of the linear transfer function are

automatically updated in real-time, not only at the start of AGC mode selection. The

Brightness Bias offsets the displayed image in intensity. Upon entry into the auto

bright mode, the currently-stored values of Contrast and Brightness Bias are applied

(i.e. the power-on defaults or the last saved values).

Manual: In this mode, image Contrast (gain) and Brightness (level) are entered

completely manually via the sliders. The scene is mapped using a linear transfer

function. Upon entry into the manual mode, currently-stored values of brightness and

contrast are applied (i.e. the power-on defaults or the last saved values).

3-24 June 2011 TAU-0035-00-10, version 150

Page 41

Tau User’s Manual 3—Basic Operation of the Tau and GUI

Linear Histogram: Image contrast and brightness (gain and level) optimized

automatically based upon scene statistics using a linear transfer function. Controls for

the ITT Mean (sets grey scale midpoint) and Max Gain (AGC gain) are adjustable by

entering the value in the Automatic Parameters section. The Linear Histogram

algorithm uses scene statistics to set a global gain and offset (contrast and

brightness) for the image. Upon entry into the linear histogram mode, the currentlystored values are applied (i.e. the power-on defaults or the last saved values).

Note

In Manual mode and Once Bright mode, the brightness setting must be updated as the

camera temperature changes. To avoid this issue, it is recommended to use Automatic or

Auto Bright right modes when possible. Also, AGC mode will only affect the digital data output

if the Digital Video output mode is set to 8-bit data. The 14-bit digital data bypasses the AGC

sections of digital processing.

Linear Parameters: Used for fine tuning the Auto Bright, Once

Bright, and Manual modes, these settings are contextually active

depending on which Algorithm is selected. Each of their settings is

described above.

Once Bright – Only the Contrast control is active.

Auto Bright – The Brightness Bias and Contrast controls

are active.

Manual – The Brightness and Contrast controls are active.

Automatic Parameters: Used for fine tuning the

Automatic and Linear Histogram modes, these settings are

contextually active depending on which AGC algorithm is

selected. Each of their settings is described above as they

pertain to the particular Algorithm.

Automatic – The Plateau Value, ITT Mean, and Max

Gain controls are active.

Manual – The ITT Mean and Max Gain controls are

active.

TAU-0035-00-10, version 150 June 2011 3-25

Page 42

3—Basic Operation of the Tau and GUI Tau User’s Manual

3.12 ROI Tab

The Tau camera allows the user to set a Region of Interest (ROI) or a rectangle of pixels on the

sensor array that the AGC algorithm will use for its calculations. The ROI can be set for either

the entire frame size (0,0 : 320,256) or some smaller portion as shown below. The ROI tab,

shown in Figure 3-11, provides both a Window Editor and text entry coordinates to control the

size and location of the Region of Interest (ROI).

1. Select AGC tab

2. Select ROI Window editor

Figure 3-11: FLIR Camera Controller GUI ROI Tab

3-26 June 2011 TAU-0035-00-10, version 150

Page 43

Tau User’s Manual 3—Basic Operation of the Tau and GUI

Window Editor: Use the mouse to drag the

green ROI rectangle to any location on the FPA. The

size of the ROI rectangle (in pixels) is displayed. To

change the size of the ROI rectangle, drag one of the

corner or side bubbles.

AGC ROI Coordinate Values: The settings use

an X-Y coordinate system with (0,0) being at the

center of the sensor array. The upper two numbers

marked (left,top) are the pixel coordinates of the upper

left corner of the ROI rectangle. The lower two

numbers marked (right,bottom) define the lower right

corner of the ROI rectangle. In the example at the

right, the ROI is specified as a ROI rectangle 66 × 65

pixels located 20 pixels to the left and 10 pixels down

from the center of the FPA.

The new AGC ROI size setting is not active until the Set

button is pressed.

The AGC ROI may be set independently for Unzoom,

Zoom 2×, and Zoom 4×. The AGC ROI may be set anywhere in the full array size, even outside

the zoom window. The Pan and Tilt function will attempt to move the Zoom AGC ROI to remain

centered on the zoom window. If the camera is being used in zoom mode, it is recommended

that the zoom AGC ROI be set to the same size as the zoom window.

TAU-0035-00-10, version 150 June 2011 3-27

Page 44

3—Basic Operation of the Tau and GUI Tau User’s Manual

3.13 Thermal Tab

The Tau cameras (except the Tau-D) have a rough thermal measurement capability. The Spot

Meter reports the temperature viewed by the four pixels in the center of the image. The

Isotherm mode enables special colorization of objects in the scene that are above a specified

threshold.

1. Select Thermal tab

2. Select Mode

Figure 3-12: FLIR Camera Controller GUI Thermal Tab

Spot Meter: The Spot Meter must be on before either the thermal Digital readout or

Thermometer can be displayed.

Select either Fahrenheit or Celsius to enable the Spot Meter.

Select Digital and/or Thermometer to display the symbols on the analog display.

Gain Switch Values are used to control the High Gain/Low Gain switch points. The

table switch is enabled using the Gain Mode switch on the Setup tab.

Note

The factory settings have hysteresis in the table switch settings. Changing these settings can

result in oscillatory behavior or the camera may get stuck in either high or low Gain Mode.

3-28 June 2011 TAU-0035-00-10, version 150

Page 45

4 Tau Digital Data Channel

The Tau camera provides three digital data channels. The BT.656 channel output is a digitally

encoded analog format which contains image, symbol, and color information. The CMOS

channel is a parallel image data output. The Legacy LVDS channel is common with the FLIR

Photon camera.

4.1 XP Bus Setting—BT.656 Digital Interface

The BT.656 parallel output is a common interface which will drive many LCD displays. The data

is digitally encoded NTSC/PAL video and will have AGC, DDE, symbols, and color included. The

signal levels are 0 - 3.3 V CMOS logic and are intended to drive boards mounted directly to the

Tau camera. Table 4-1 shows the connector pin definitions with BT.656 enabled. Also shown in

the table are the optional discrete input pins. Figure 4-1 details BT.656 format and timing.

Table 4-1: 50-pin Hirose connector interface with BT.656 output enabled

Pin # Signal Name Pin # Signal Name

1 RS232_TX 2 RS232_RX

3 DISCRETE6 4 DISCRETE7

5DGND 6 DGND

7 unused 8 unused

9 LVDS_CLK_P 10 LVDS_CLK_N

11 LVDS_SYNC_P 12 LVDS_SYNC_N

13 LVDS_DATA_P 14 LVDS_DATA_N

15 unused 16 unused

17 DGND 18 DGND

19 DISCRETE0 20 DISCRETE1

21 EXT_SYNC 22 unused

23 DISCRETE2 24 DISCRETE3

25 DISCRETE4 26 DISCRETE5

27 DGND 28 DGND

29 BT656_DATA7 30 BT656_DATA6

31 BT656_DATA5 32 BT656_DATA4

33 BT656_DATA3 34 BT656_DATA2

35 BT656_DATA1 36 BT656_DATA0

37 DGND 38 DGND

39 BT656_CLK 40 unused

41 DGND 42 DGND

43 VID_OUT_H 44 VID_OUT_L

45 DGND 46 3V3

47, 49 MAIN_PWR_RTN 48, 50 MAIN_PWR

TAU-0035-00-10, version 150 June 2011 4-1

Page 46

4—Tau Digital Data Channel Tau User’s Manual

H Control Sign al

Start of digital line Start of digital active line

FF0000XY8010801

0

8010FF0000XYC

C

Y

b

r

4 clocks 268 clocks 4 clocks

1716 clocks

D7 D6 D5 D4 D3 D2 D1 D0

1 1 1 1 1 1 1 1

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

1 F V H P3 P2 P1 P0

Blanking

(V = 1)

(V = 0)

Blanking

(V = 1)

(V = 0)

Fram e Line 1

Fram e Line 20

Fram e Line 21, Field1 Line 0

Fram e Line 263 , Field1 Li ne 242

Fram e Line 264

Fram e Line 282

Fram e Line 283 , Field2 Line 0

Fram e Line 525 , Field2 Li ne 242

LINE 4

Field 1

(F = 0)

Odd

LINE 266

Field 2

(F = 1)

Even

LINE 3

Preamble

Status Word

Field 1 Active

Field 2 Active

H=1

H=0

EAV

SAV

1716 clocks @ 27MHz = 63.55us/line

63.55us/line x 525 lines = 29.97 ms/frame

slexiP detisoCedoC VASgniknalBedoC VAE

C

Y

C

Y

b

Y

r

C

b

1440 clocks

F = 0 for field 1, F = 1 for field 2

V = 1 during vertical blanking

H = 0 at SAV, H = 1 at EAV

P3 - P0 = protection bits

P3 = V XOR H

P2 = F XOR H

P1 = F XOR V

P0 = F XOR V XOR H

Line

Number

4 - 20

21 - 263

264 - 265

266 - 282

283 - 525

F V

0

0

0

1

1

1

0

1

1

0

C

Y

Y

r

H

EAVVSAV

01111 - 3

01

01

01

01

01

C

Y

b

243 acti ve lines

243 acti ve lines

EAV Code

C

FF0000X

Y

r

20 blank lines

19 blank lines

Y

Cb, Y, Cr, Y

Any Clock Ena ble

Any Clock

50.625MHz * 8/15

27MHz

YCbCr

NOTES:

This FIFO is outside the

BT.656 Formatter

8

we re

PixelsPerLine

1111

rwcwwc

8

0 = 640

1 = 720

BT.656 Formatter

27MHz

Registers forced

8 8

'0' D

'1'

BT.656 Clock

The FI FO Wri te Clock can be any value as lon g as it is der ived from and locked to 50.626MHz.

The FIFO must store at least 1440 bytes and must be filled at a mini mum rate of 1 byte per

27MHz c lock period (faster is OK ).

A full line must be made available every 1,716 27MHz clock periods.

Sinc e the BT.6 56 Formatt er has no knowl edge of upstream video tim ing, no data shall be

writ ten into t he FIFO unt il the fir st active l ine (line 1 , field 1) of v ideo is available after reset.

Incoming vi deo must conform to the active/blank tim es specified i n the Timing section of this

document.

Figure 4-1: BT.656 Video Formatter Timing and Block Diagram

into IOBs

DQ

r

Q

D

f

C

r

C

f

27MHz

BT.656 Data

BT.656 Data

BT.656 Clock

4-2 June 2011 TAU-0035-00-10, version 150

Page 47

Tau User’s Manual 4—Tau Digital Data Channel

4.2 XP Bus Setting—CMOS Digital Interface

The CMOS interface is a parallel output that allows the user to access 8-bit AGC corrected data

or 14-bit data. The signal levels are 0 - 3.3 V CMOS logic and are intended to drive boards

mounted directly to the Tau camera. CMOS is not intended to drive a cable. An XP-board