Page 1

Computer Controlled

PAN-TILT UNIT

Model PTU-D300

USER’S MANUAL

Version 2.19

www.flir.com/mcs

Page 2

Pan-Tilt Unit (Model PTU-D300) User’s Manual, Version 2.19,

June 25, 2012

©1991,2006 by FLIR Commercial Systems, Inc., 890C Cowan

Road, Burlingame, California 94010, (650)692-3900, FAX:

(650)692-3930, www.flir.com/mcs.

All rights reserved. Protected under numerous U.S. Patents

including 5463432 and 5802412, and patents pending. No part of

this book may be reproduced, stored in a retrieval system, or

transcribed, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written

permission of FLIR Commercial Systems, Inc.

The information in this manual is subject to change without notice

and, except for the warranty, does not represent a commitment on

the part of FLIR Commercial Systems, Inc. FLIR Commercial

Systems, Inc. cannot be held liable for any mistakes in this manual

and reserves the right to make changes.

Page 3

1 INTRODUCTION .................................................................................................1

1.1 IMPORTANT SAFEGUARDS AND WARNINGS....................................2

1.2 Models .........................................................................................................2

2 QUICK START......................................................................................................3

2.1 Overview......................................................................................................3

2.2 Installation Components ..............................................................................3

2.3 Basic Setup Steps.........................................................................................4

3 INSTALLATION & INITIAL SETUP ................................................................5

3.1 Pan-Tilt Mounting........................................................................................5

3.2 Wiring and Connectors................................................................................5

3.3 Power Sources..............................................................................................6

3.4 RS-232 Interface and Host Settings.............................................................7

3.5 Initial Power-up and Test.............................................................................8

3.6 Basic Pan-Tilt Unit Commands...................................................................8

3.7 Mounting Your Payload...............................................................................8

3.7.1 Over-the-Top Bracket Mounting......................................................9

3.7.2 Side-Mount Bracket Mounting........................................................9

3.8 Payload Wiring Connections .....................................................................10

4 COMMAND REFERENCE................................................................................11

4.1 Binary Command Format ..........................................................................11

4.2 General ASCII Command Format.............................................................11

4.3 Positional Control Commands & Queries .................................................11

4.3.1 Position (absolute) .........................................................................11

4.3.2 Offset Position (relative offset)......................................................12

4.3.3 Resolution per Position..................................................................12

4.3.4 Limit Position Queries...................................................................13

4.3.5 Position Limit Enforcement...........................................................13

4.3.6 Immediate Position Execution Mode.............................................14

4.3.7 Slaved Position Execution Mode...................................................14

4.3.8 Await Position Command Completion ..........................................15

4.3.9 Halt Command...............................................................................15

4.3.10 Monitor (Autoscan) Command......................................................16

4.3.11 Position Presets..............................................................................16

4.4 Speed Control Commands & Queries........................................................17

4.4.1 Speed Control & Relevant Terms..................................................17

4.4.2 Speed (absolute).............................................................................17

4.4.3 Delta Speed (relative offset) ..........................................................18

4.4.4 Acceleration...................................................................................19

4.4.5 Base (Start-Up) Speed....................................................................19

4.4.6 Speed Bounds ................................................................................20

4.4.7 Speed Control Modes.....................................................................20

4.5 Unit Commands.........................................................................................21

Page 4

4.5.1 Reset Pan-Tilt Unit ........................................................................21

4.5.2 Default Save/Restore .....................................................................22

4.5.3 Echo Query/Enable/Disable...........................................................22

4.5.4 Feedback Verbose/Terse/Off..........................................................23

4.5.5 Controller Firmware Version Query ..............................................23

4.5.6 Outside Supply Voltage and Controller Temperature Query.........23

4.6 Power Control Commands & Queries .......................................................23

4.6.1 Stationary Power Mode..................................................................24

4.6.2 In-Motion Power Mode .................................................................24

4.7 Host Serial Port and Control......................................................................25

4.7.1 Configuring Host Serial Port Baud and Communications.............25

4.8 Step Modes.................................................................................................26

4.8.1 Configuring Step Mode..................................................................26

5 SPECIAL CONFIGURATIONS ........................................................................27

5.1 High-Speed Operation ...............................................................................27

5.2 High-Payload Operation ............................................................................27

5.3 Battery-Powered Operation .......................................................................27

6 PTU OPTIONS ....................................................................................................28

6.1 EIO Option: Expansion Serial Ports and Control......................................28

7 NETWORKING...................................................................................................28

7.1 Basic Networking Setup Steps...................................................................28

7.2 PTU Network Connections........................................................................29

7.3 PTU Network Software Commands ..........................................................29

7.3.1 Unit Network ID............................................................................29

7.3.2 Unit Select/Deselect.......................................................................30

A. SPECIFICATIONS..............................................................................................31

A.1 D300 Mechanical Dimensions...................................................................31

A.2 D300 Payload Bracket Dimensions...........................................................32

A.3 D300 Base Connector Wiring....................................................................33

A.4 D300 Payload Wiring PL01.......................................................................34

A.5 D300 Payload Wiring PL02.......................................................................35

A.6 D300 Payload Mounting............................................................................36

REGULATORY INFORMATION.....................................................................37

LIMITED WARRANTY .....................................................................................38

Page 5

PTU-D300 User’s Manual (v2.19) INTRODUCTION

1 INTRODUCTION

The PTU-D300 Pan-Tilt Unit from FLIR Commercial Systems, Inc. provides fast, accurate,

and durable positioning of cameras, antennas, lasers, and other large payloads. Some general

features:

• Simple to command from any RS-232 or RS-485 terminal or computer

• Payload capacity up to 35-70 lbs.

• Resolution of 0.02 degrees

• Precise control of position, speed & acceleration

• On-the-fly position and speed changes

• Self calibration upon reset

• Power consumption can be controlled from host

• ASCII command mode for simplicity, binary commands available for efficient program

control

• Constant current DMOS motor drives for increased performance and control

• DC power input from an unregulated source

• Flexible connectivity options.

Applications of the PTU-D300 include:

• Mid and Long-range Surveillance systems

• Automated detection and tracking

• Multi-sensor perimeter monitoring systems

• Thermal and IR cameras

• Marine/shipboard sensor systems

• Harbor and Port Security

• Border Security & Law Enforcement

• Highway & Transportation Monitoring

• Military special operations

• Satellite communications systems

• Microwave antenna systems (passive, active)

• Robotics & computer vision.

This User’s Manual provides information needed to set up and operate the PTU-D300 unit. The

next section provides a brief overview to allow you to get started as quickly as possible. More

detailed technical information is provided in the remaining sections.

page 1

Page 6

INTRODUCTION PTU-D300 User’s Manual (v2.19)

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

IMPORTANT SAFEGUARDS AND WARNINGS

1. Please read these instructions prior to use.

2. Please keep these instructions accessible.

3. Please heed all warnings.

4. Please follow all instructions.

5. Installation should be done only by qualified personnel and conform to all local codes.

CAUTION: These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing other than that contained

in the operating instructions unless you are qualified to do so.

6. Use only mounting methods and materials capable of supporting at least four times the combined weight of the D300 pan-tilt, mounted payloads, and cabling.

7. For outdoor use, use only corrosion resistant hardware to fasten the mount and payloads (e.g., stainless steel screws).

8. The unit should not be installed in environments that present conditions beyond the

environmental specification of the D300. Installation near heat sources such as radiators,

heat registers, stoves, or other apparatus (including amplifiers) can exceed the unit’s

temperature ratings.

9. Refer all servicing to qualified service personnel. If the unit is damaged, remove power immediately, and contact FLIR Commercial Systems, Inc.

10. A readily accessible power disconnect shall be incorporated into the installation wiring.

11. Only use replacement parts recommended by FLIR Commercial Systems, Inc.

1.2 Models

PTU-D300 Standard base config uration. Includes basic slip-ring, integral controller, stan-

dard convertible “L” bracket.

page 2

Page 7

PTU-D300 User’s Manual (v2.19) QUICK START

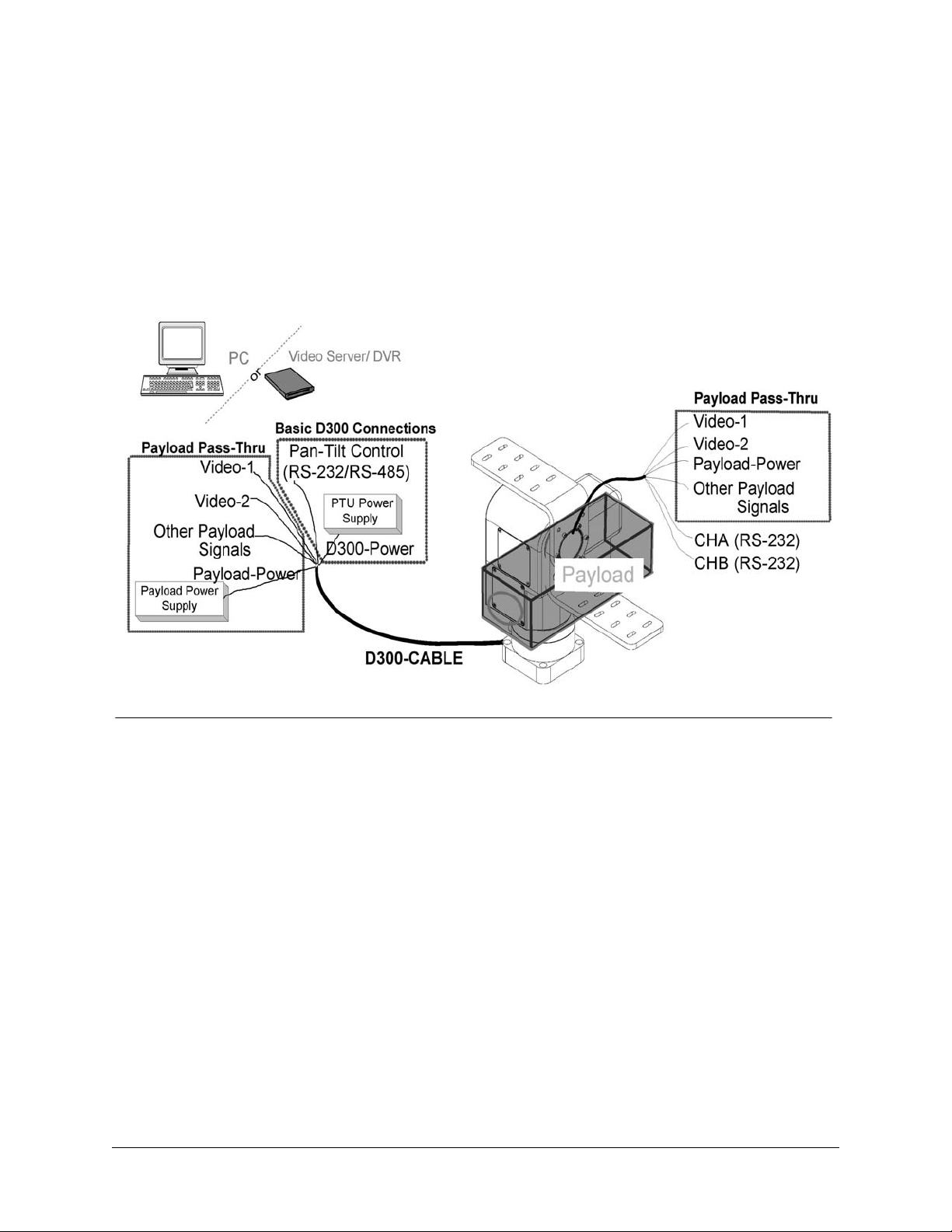

Figure 1: Pan-Tilt System Overview

2 QUICK START

2.1 Overview

Figure 1 shows a system overview. The PTU-D300 includes an integral controller and it

accepts control commands from any host computer over RS-232 or RS-485. The basic D300

connections are: D300-power from a DC power source, and Pan-Tilt Control via RS232/485.

In addition to pan-tilt control connections, “Payload Pass-Thru” internally routes payload

signals such as video, payload power, and other payload connections from a single stationary

connector in the PTU base to a single payload connector that moves with your payload.

The PTU-D300 can be controlled from any host computer using the built-in ASCII protocol

described in this manual. For high speed, hard real-time controls (such as tracking), a binary

protocol is supported via a C Programmers Interface (PTU-CPI). Drivers are also available in 3rd

party software packages such as LabView and digital video control systems.

2.2 Installation Components

Components supplied with this manual are:

• Pan-Tilt Unit

• Standard Payload Mounting Bracket

• Pan-Tilt Cable Harness - Optional

• AC/DC Power Supply - Optional

page 3

Page 8

QUICK START PTU-D300 User’s Manual (v2.19)

2.3 Basic Setup Steps

The following outlines the basic pan-tilt set-up and installation steps. Section 3 details each

of these steps.

1. Unpack the D300 pan-tilt. Mount the pan-tilt securely. See section 3.1 for details on mounting.

2. Establish wiring to the pan-tilt. Factory cable with breakouts for power and other connections makes this easy (model PTU-CAB-25BO). Or you can make your own cables that better suit your installation.

3. Connect an RS-232 or RS-485 cable between Pan-Tilt Control input and a host computer.

When using factory cable PTU-CAB-25BO, standard RS232 connection (DB9F) is

provided. HyperTerminal (built into Windows) is the most commonly used comm program.

Communications parameters are: 9600 baud, no parity, no handshaking. (see Section 3.4).

4. Provide DC power to the pan-tilt. When using factory cable PTU-CAB-25BO, easy plug-in

power is provided by AC/DC power supply model PTU-APS-30V. Or you can obtain your

own DC power source that better suits your installation. Always incorporate a readilyaccessible power disconnect into the installation wiring. Removing power by disconnecting

the power cable or cable harness is not recommended and can cause damage to the system.

5. Power up the pan-tilt. If power is working, the unit will go through a power-up calibration.

At power up, the pan-tilt defaults to providing splash text on your terminal that will identify

the unit configuration. Pan-tilt operation can then be tested by typing commands into your

terminal program.

6. Section 3.6 describes some basic pan-tilt commands to get you going. Section 4 provides a full description of all pan-tilt unit commands and queries.

7. You can now mount and wire your payload (e.g., camera) on the pan-tilt unit (see Section

3.8).

page 4

Page 9

PTU-D300 User’s Manual (v2.19) INSTALLATION & INITIAL SETUP

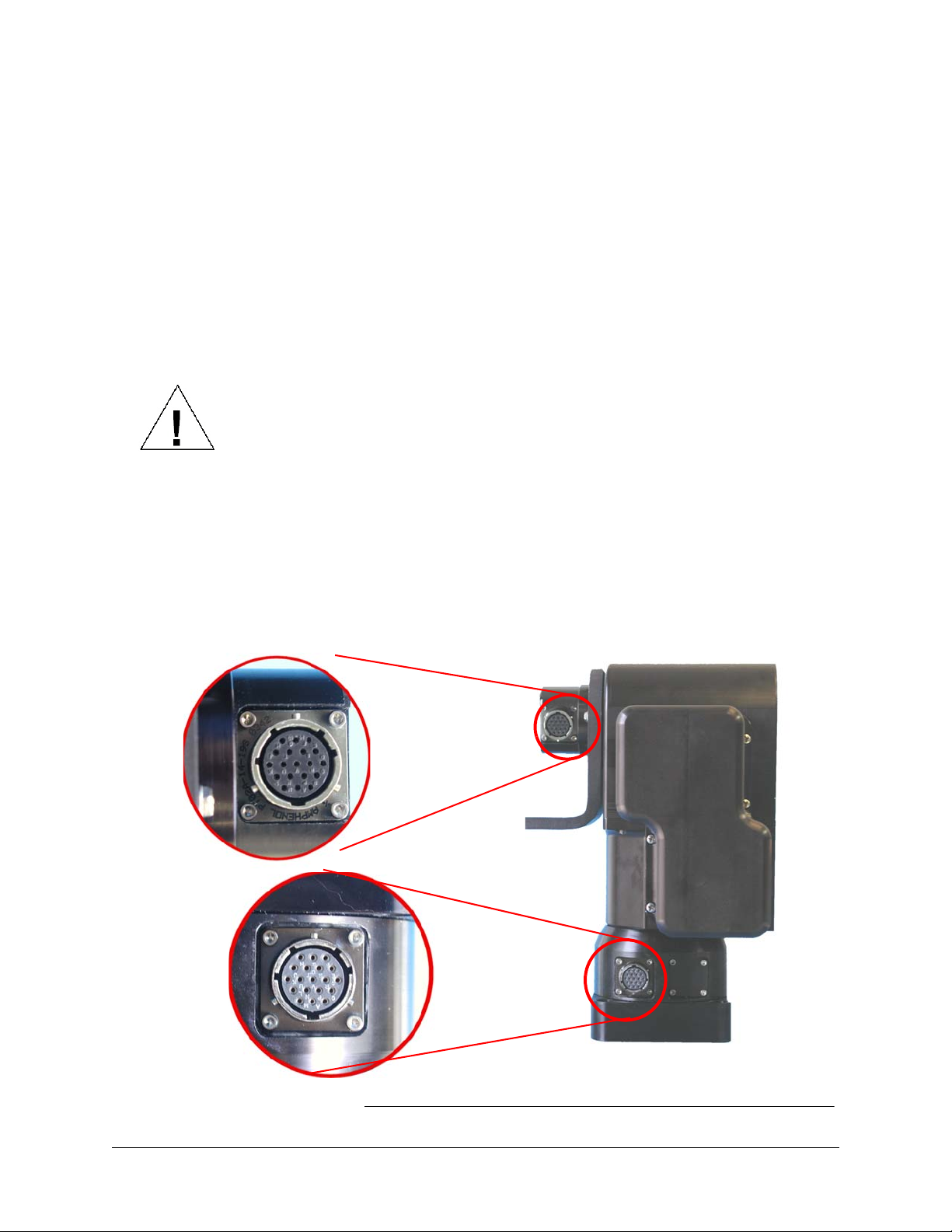

Figure 2: Wiring Overview

PAYLOAD

CONNECTOR

D300 BASE

CONNECTOR

3 INSTALLATION & INITIAL SETUP

This section describes the basic installation and setup steps required to get your pan-tilt

operational as quickly as possible.

3.1 Pan-Tilt Mounting

Appendix 1 shows the mounting pattern for the PTU-D300. The basic mounting pattern is

four #1/4-20 socket-head cap screws in a 3.375” (85.725mm) square pattern. All four mounting

screws should be used. The mount strength must be able to hold the weight of the unit plus the

payload plus any additional forces exerted on the system (e.g., wind, G forces). A good rule of

thumb: the mount must support at least four times the combined weight of the payload plus the

weight of the pan-tilt (e.g., a 25 lb. payload mounted to the D300 must support at least 205 lbs).

CAUTION: FAILURE TO SECURE THE PAN-TILT AND ITS PAYLOAD

TO A SUFFICIENTLY STRONG MOUNTING CAN RESULT IN

DAMAGE TO THE PA N-TILT, THE PAYLOAD, OR POSSIBLE INJURY

OR DEATH. YOU MUST ENSURE THE MOUNTING IS CAPABLE OF

HOLDING THE LOADS!

3.2 Wiring and Connectors

Figure 2 shows a back view of the D300. The D300 base connector is a MIL-C-26482

compatible receptacle (19 pins). Appendix A.3 shows the D300 base connector signals and

wiring. Basic control requires that you connect a DC power source to the D300-power input, and

a host computer connection (to HOST-232 or HOST-485) to communicate and control the D300.

page 5

Page 10

INSTALLATION & INITIAL SETUP PTU-D300 User’s Manual (v2.19)

The easiest way to wire into the D300 is to use the factory cable with breakouts for power

and other connections (model PTU-CAB-25BO), and to use the factory power supply (model

PTU-APS-30V). This allows you to plug in and run the D300 in minutes. Or you can use the

wiring diagram in Appendix A.3 to make your own cables that better suit your installation.

Connect an RS-232 or RS-485 cable between the D300 and a host computer. When using the

factory cable PTU-CAB-25BO, standard RS232 connection (DB9F) is provided. HyperTerminal

(built into Windows) is the most commonly used communications program. Communications

parameters are: 9600 baud, no parity, no handshaking. (see Section 3.4).

The D300 provides payload pass-thru signals that connect between pins in the base

connector to corresponding pins in the payload connector. Additional pins in the payload

connector provide other payload controls (auxiliary RS232 ports and TTL control). Figure 2

shows this payload connector which is also a MIL-C-26482 compatible receptacle (19 pins).

Appendix A.4 details the payload connector pin-out.

Appendix A.4 shows the payload connector wiring. Pins highlighted in red indicate payload

pass-thru signals connected to corresponding pins in the base connector.

When attaching payload signals to the system, care must be taken to adhere to all

specifications for the pass-thru signals, such as maximum voltage and current

levels.

3.3 Power Sources

The PTU-D300 requires a 12-30VDC (unregulated) power source capable of 2.25A peak.

Less peak current is required if you do not use the higher motor current controls available (see

Sections 4.6.1 and 4.6.2). To achieve the highest pan-tilt unit performance, use the highest motor

voltage within the allowable range. To achieve the quietest and smoothest pan-tilt operation, you

can use a lower motor voltage (e.g., 12VDC).

When wiring your own power source, failure to comply with wiring and power source

requirements described in this manual can result in decreased unit

performance or damage not covered under the limited warranty.

If you are providing your own DC power source, the power source must never supply

more than rated current, and if so, you must add a fuse in series with your DC power

source. For example, when connecting to a vehicle battery or lighter plug, you must fuse the

incoming DC source. Failure to properly fuse your input power source could cause overloading of

internal protection devices, pose a safety hazard, or void product warranties.

page 6

Page 11

PTU-D300 User’s Manual (v2.19) INSTALLATION & INITIAL SETUP

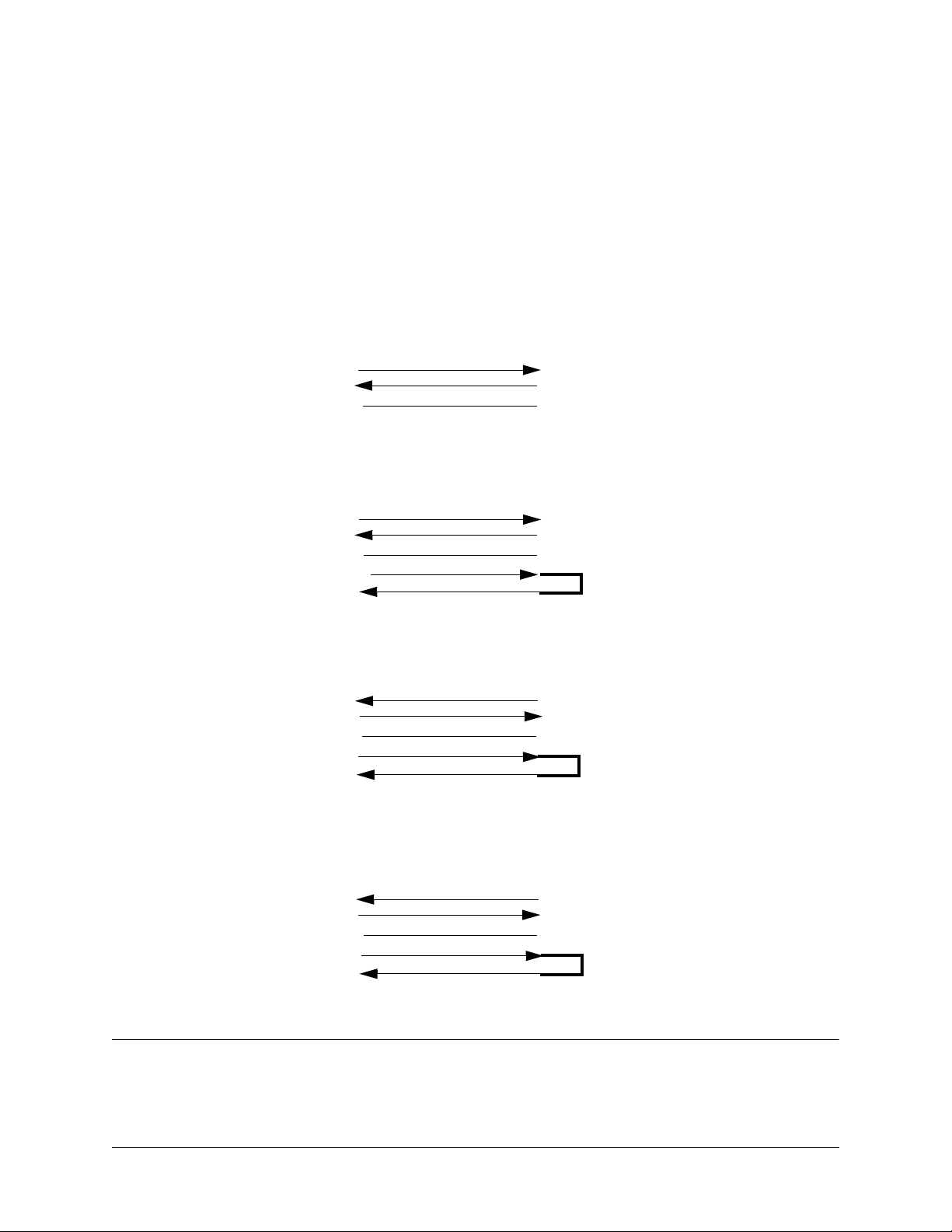

Figure 3: RS-232 Pan-Tilt Controller Connection to Common Hosts

RxD (pin 3)

TxD (pin 2)

GND (pin 5)

IBM PC

DB-25S

TxD (pin 2)

RxD (pin 3)

GND (pin 7)

PTU-CAB-25BO

(female DB-9)

TxD (pin 2)

GND (pin 5)

IBM PC

DB-9S

RxD (pin 2)

TxD (pin 3)

GND (pin 5)

(female DB-9)

TxD (pin 2)

RxD (pin 3)

GND (pin 5)

Apple Macintosh

8 Pin Mini-DIN

TxD (pin 3)

RxD (pin 5)

GND (pin 4)

RxD (pin 3)

Null modem may

be required.

DTR (pin 4)

DSR (pin 6)

DTR (pin 20)

DSR (pin 6)

(pin 4)

(pin 6)

(pin 4)

(pin 6)

DTR (pin 1)

(pin 4)

(pin 6)

DSR (pin 2)

PTU-CAB-25BO

(female DB-9)

PTU-CAB-25BO

RxD (pin 3)

TxD (pin 2)

GND (pin 5)

D300 Base Connector (19 pins)

MIL-C-26482 compatible receptacle

pin L

pin K

pin J

PTU-CAB-25BO

(female DB-9)

3.4 RS-232 Interface and Host Settings

An RS-232 terminal or host computer connects to the RS-232 Host Interface on the Pan-Tilt

Unit. The host terminal or computer should be set to 9600 baud, 1 start bit, 8 data bits, 1 stop bit,

and no parity. Hardware handshaking and XON/XOFF are not used.

The RS-232 connections to the Pan-Tilt are: TxD (pin 2), RxD (pin 3), and GND (pin 5).

Figure 3 shows cable configurations for some common computer hosts. Since TxD and RxD

assignments to pins 2 and 3 can vary on host computers, try using a null modem if your initial

connection does not work.

page 7

Page 12

INSTALLATION & INITIAL SETUP PTU-D300 User’s Manual (v2.19)

3.5 Initial Power-up and Test

If you have the power source and Host computer connected described in Sections 3.3 and 3.4,

you are ready to power-up and test its operation. Test and verify all cable connections and

connector wiring before power-up. We suggest that you do not mount your payload (e.g., camera)

until this initial installation is completed and tested.

1. Using HyperT erminal or a simil ar terminal program, configure the RS-232/485 serial port of the Host Computer to 9600 baud, 1 start bit, 8 data bits, 1 stop bit, and no parity. Hardware handshaking and XON/XOFF are not used.

2. You are now ready to power up the pan-tilt unit and test its operation. Apply power. Upon

power up, introduction text should appear on your screen, and the pan-tilt unit should go

through a reset cycle (pan and tilt axes will cycle through their full range of motion). This

reset is completed when an asterisk (‘*’) appears. If the unit did not reset properly, recheck

your power source and cabling. If the unit went through its reset procedure, but no text or

garbled text appears on your screen, then:

• Check that the host RS-232/RS-485 host port settings are correct (see Section 3.4)

• Check that the RS-232/RS-485 cable is correct for your host (see Section 3.4)

3. You are now connected to the pan-tilt. Enter the character ‘?’ for a complete listing of

commands. The next section describes some basic commands to help you get going, and a

full command description may be found in Section 4. We suggest that you exercise the unit

and become familiar with its operation and commands before mounting your payload (e.g.,

camera) as described in Section 3.8. Special attention should be paid to acceleration and

speed commands, and they should be set at levels appropriate to your payload weight and

size.

3.6 Basic Pan-Tilt Unit Commands

Below are some pan-tilt commands that will familiarize you with the pan-tilt unit and its

operation:

pp2500 *

tp-900 *

PS1900 *

pp0 *

This sets the pan axis to position 2500, the tilt axis to position -900, the pan speed to 2500

positions a second, and sets the pan position back home.

When operating the pan-tilt unit, the available command menu is printed when you enter the

‘?’ character. A detailed description of pan-tilt commands and queries may be found in Section 4.

3.7 Mounting Your Payload

The PTU-D300 sports a flexible payload bracket system that can be configured in a number

of ways to support a variety of payloads including cameras, lasers, antennas, and other equipment.

Because of the heavy payload weights and high potential speeds supported by the PTU-D300, it is

very important that all guidance and instructions regarding payload mounting be followed

carefully.

page 8

Page 13

PTU-D300 User’s Manual (v2.19) INSTALLATION & INITIAL SETUP

Figure 4: Payload Bracket Mounting

3.7.1 Over-the-Top Bracket Mounting

1. Ensure the pan-tilt has been through its calibration (at power up) so that the mounting hub is in a known home position.

2. Orient the bracket so the horizontal part of the bracket is topmost. When in the proper orientation, a peg in the bracket will locate into a hole in the D300 mounting hub.

3. Attach the bracket using 6pcs screws.

It is vital that thread lock is used for the bracket mounting screws. The thread

holes in the hub have thread lock applied to them. If the bracket is removed,

you should apply medium strength thread lock to the hub (e.g., Loctite 242).

4. Reset the pan-tilt and ensure that the bracket moves properly through its range of motion.

3.7.2 Side-Mount Bracket Mounting

1. Ensure the pan-tilt has been through its calibration (at power up) so that the mounting hub is in a known home position.

2. Orient the bracket so the horizontal part of the bracket is bottommost.

3. Attach the bracket using 6pcs screws.

It is vital that thread lock is used for the bracket mounting screws. The thread

holes in the hub have thread lock applied to them. If the bracket is removed,

you should apply medium strength thread lock to the hub (e.g., Loctite 242).

4. Reset the pan-tilt and ensure that the bracket moves properly through its range of motion.

page 9

Page 14

INSTALLATION & INITIAL SETUP PTU-D300 User’s Manual (v2.19)

Payloads should be mounted as close to the Pan-tilt housing as possible so as to position the

center of gravity as close to the pan-axis as possible.

In all cases, care must be taken to ensure that the payload will clear the Pan-tilt

housing and surrounding objects throughout the full range of motion of the unit.

Though the PTU-D300 unit is rated to a maximum load of 70 lbs, the distribution of the load

affects the actual load capable of being moved by the pan-tilt unit. The steps to determine whether

your load and its positioning (e.g., center of gravity) are within the maximum load capacity and

dynamics are:

• Mount your payload. Side-mount is preferred for heavier loads, as it keeps the payload

center of gravity closer to the tilt axis of rotation thereby minimizing torque requirements.

Ensure that the load is securely attached to the payload bracket.

• First move the pan axis through its range to test whether the pan-tilt can handle the load

(e.g., enter “dr pp2700 a pp-2700 a pp0 ”). A load that is too heavy or moved too

quickly will cause the unit to lose synchrony, and this will be accompanied by an audible

“rrrr” sound from the pan-tilt unit motors. See section 5.2 on page 27 for further information

on configuration of the Pan-Tilt for heavier payloads.

• If your load passed the pan axis load test, you can then test the tilt axis load handling

capability. The center of gravity for top mounted payloads is further from the tilt axis of

rotation, and this may require more torque to move the load. Move the tilt axis through its

range of motion to test whether the pan-tilt can handle the load (e.g., enter “DR TP-900 A

TP600 A TPp0 “). A load that is too heavy or moved too quickly will cause the unit to

lose synchrony, and this will be accompanied by an audible “rrrr” sound from the pan-tilt

unit motors.

• If your load fails the above pan or tilt axis load handling tests, check Section 5.2 for further

information. Significantly faster or lower power control can be obtained via commands to

the pan-tilt unit. The speed and acceleration of a mechanical system depends upon the

inertial properties of your load. The ability of the pan-tilt unit to successfully move your

load without losing synchrony depends upon the inertial load factors and their relationship

to power supply voltage, unit speed, acceleration, position, motor torque, etc. Section 5.2

discusses how to configure pan-tilt parameters to achieve more optimal pan-tilt unit

performance for your load. If you have questions about your payload mounting or load

handling, please contact Technical Support for further assistance.

• If your load passes the above pan and tilt axis load handling tests, you are ready to begin

controlling your load using the commands described in Section 4.

3.8 Payload Wiring Connections

The D300 provides payload pass-thru signals that connect between pins in the base

connector to corresponding pins in the payload connector. Additional pins in the payload

connector provide other payload controls (auxiliary RS232 ports and TTL control). Figure 2

shows this payload connector which is also a MIL-C-26482 compatible receptacle (19 pins).

Appendix A.4 details the payload connector pin-out. Your payload connects to the payload

connector via a male MIL-C-26482 compatible plug (e.g., PT06A14-19P).

Appendix A.4 shows the payload connector wiring. Pins highlighted in red indicate payload

pass-thru signals connected to corresponding pins in the base connector.

When attaching payload signals to the system, care must be taken to adhere to all

specifications for the pass-thru signals, such as maximum voltage and current

levels.

page 10

Page 15

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

4 COMMAND REFERENCE

This section describes the pan-tilt unit command set. Each command has a section that

provides a brief functional description, a format (syntax) description, examples, and related

topics. When controlling the pan-tilt unit from a terminal, a complete menu of pan-tilt commands

can be obtained by entering the character “?”.

4.1 Binary Command Format

A C Programmer’s Interface (model PTU-CPI) is available for higher bandwidth binary

communications between a host computer and the PTU controller.

4.2 General ASCII Command Format

When describing the format (syntax) of pan-tilt commands, the following conventions are

adopted:

• Commands issued to the pan-tilt unit (e.g., typed in by you) are shown in bold.

• Input characters may be in upper or lower case (we show them in upper case for

presentational consistency)

• A delimiter (<delim>) can be either a space (“ ”) or a carriage return (<CR>).

• A successfully executed command returns “*<CR>”. Successful query execution returns

“* <QueryResult><CR>”. Command execution failure returns

“! <ErrorMessage><CR>”. A pan axis limit hit asynchronously returns “!P” and a tilt

axis limit hit asynchronously returns “!T”.

4.3 Positional Control Commands & Queries

4.3.1 Position (absolute)

Description:

Specify or query the absolute pan or tilt axis position. Desired positions can

be changed on-the-fly without waiting for previous position commands to

complete.

Syntax

Query current absolute pan position: PP<delim>

Set desired absolute pan position: PP<position><delim>

Query current absolute tilt position: TP<delim>

Set desired absolute tilt position: TP<position><delim>

Example

The following sends the pan axis to the left, waits, then sends it to the right:

PP-2500 *

A *

PP * Current Pan position is -2500

PP2500 *

A *

PP * Current Pan position is 2500

page 11

Page 16

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

Related Topics

• Position (relative offset and desired position queries): See Section 4.3.2

• Position resolution (units): See Section 4.3.3

• Position limits: See Section 4.3.4

• Position execution modes: See Sections 4.3.6, 4.3.7 and 4.3.8

• Position limit enforcement modes: See Section 4.3.5

4.3.2 Offset Position (relative offset)

Description

Specify desired axis position as an offset from the current position, or Query

the current axis position. Desired offset positions can be changed on-the-fly

without waiting for previous position commands to complete.

Syntax

Query desired pan position: PO<delim>

Set desired offset pan position: PO<position><delim>

Query desired tilt position: TO<delim>

Set desired offset tilt position: TO<position><delim>

Example

The following sends the pan axis to position -500, then sends it 1500

positions to the left:

PP-500 *

A *

PO * Current Pan position is -500

PO1500 *

A *

PP * Current Pan position is 1000

Related Topics

• Position resolution (units): See Section 4.3.3

• Position limits: See Section 4.3.4

• Position execution modes: See Sections 4.3.6, 4.3.7 and 4.3.8

• Position limit enforcement modes: See Section 4.3.5

4.3.3 Resolution per Position

Description

Query returns the axis resolution per position moved (in seconds/arc).

Syntax

Query pan resolution: PR<delim>

Query tilt resolution: TR<delim>

Example

Resolution can be determined by:

PR * 92.5714 seconds arc per position

1 sec arc = 1/(60 min arc * 60 sec arc) = .0002778°. So 92.5714 seconds

arc equals (92.5714 sec arc * .002778°) = 0.025716335°. Thus, to pan 21.3°

left requires a relative move of (21.3°/0.025716°) 828 positions, yielding

the following command:

PO828 *

page 12

Page 17

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

Related Topics

• Factory options are available to achieve higher resolution or accuracy.

4.3.4 Limit Position Queries

Description

Queries return the axis position bounds determined upon unit reset.

Syntax

Query minimum pan position: PN<delim>

Query maximum pan position: PX<delim>

Query minimum tilt position: TN<delim>

Query maximum tilt position: TX<delim>

Example

R *

PN * Minimum Pan position is -3090

PX * Maximum Pan position is 3090

TN * Minimum Tilt position is -907

TX * Maximum Tilt position is 604

LE *

PP3200 ! Maximum allowable Pan position is 3090

Related Topics

• Position resolution (units): See Section 4.3.3

• Achieving larger axis bounds: See Section 4.3.5

4.3.5 Position Limit Enforcement

Description

Determines whether position commands beyond the detected pan axis limits

are allowable. The default is pan position limits are enabled (i.e., enforced).

When limits are enabled, commands outside of the limits return an error

message and are not executed. In enabled limit mode, limits are only reached

when the unit has lost synchrony and this error condition requires a unit reset

(see Section 4.5.1). When a limit is reached, a “!P” is printed to the host serial

port to indicate that the pan axis limit was hit.

When larger operational pan ranges are required, the limits may be

disabled. Positional pan commands outside the limits are not rejected when

limits are disabled.

Syntax

Query current pan position limit mode: L<delim>

Enable pan position limits: LE<delim>

Disable pan position limits: LD<delim>

Example

L * Limit bounds are ENABLED (soft limits enabled)

PX * Maximum Pan position is 3090

PP3200 ! Maximum allowable Pan position is 3090

LD *

PP3200 *

A *

PP * Current Pan position is 3200

page 13

Page 18

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

Related Topics

• Position commands: See Sections 4.3.1 and 4.3.2

4.3.6 Immediate Position Execution Mode

Description

Instructs pan-tilt unit to immediately execute positional commands. This is

the default mode.

Syntax

I<delim>

Example

For the below commands, the pan axis will immediately execute the pan

position command:

I *

PP1000 *

Related Topics

• Alternative slaved position execution mode: See Section 4.3.7

4.3.7 Slaved Position Execution Mode

Description

Instructs pan-tilt unit to execute positional commands only when an Await

Position Command Completion command is executed (see Section 4.3.8) or

when put into Immediate Execution Mode (see Section 4.3.6). This mode is

useful when coordinated pan and tilt axis movements are desired.

Syntax

S<delim>

Example

The following commands change the position execution mode, instruct the

axes which position to achieve, and an await command causes the position

commands to be executed simultaneously:

DR *

S *

PP1500 *

TP-900 *

PP * Current Pan position is 0

TP * Current Tilt position is 0

A *

PP * Current Pan position is 1500

TP * Current Tilt position is -900

Related Topics

• Alternative immediate position execution mode: See Section 4.3.6

page 14

Page 19

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

4.3.8 Await Position Command Completion

Description

Awaits the completion of the last issued pan and tilt axis position commands.

Used to coordinate axis motions.

Syntax

A<delim>

Example

The following commands instruct the pan axis to move to a position, then

move to another position:

I *

PP * Current Pan position is 0

PP2000 *

A *

PP * Current Pan position is 2000

PP0 *

A *

PP * Current Pan position is 0

In contrast, the following commands would begin to move to the first

position, and before that position is reached, the next position would be

moved towards (this is often called an on-the-fly position change):

I *

PP * Current Pan position is 0

PP2000 *

PP0 *

Related Topics

• This command can be used for both the Immediate Position Execution

Mode (see Section 4.3.6) and Slaved Position Execution Mode (see Section

4.3.7)

4.3.9 Halt Command

Description

Immediately decelerates and halts pan-tilt movement.

Syntax

Halt all pan-tilt movement: H<delim>

Halt pan axis movement: HP<delim>

Halt tilt axis movement: HT<delim>

Example

PP2500 *

A *

PP-2500

Then while the pan-tilt is moving, the host decides to stop immediately:

H *

Related Topics

• This command can be used for both the Immediate Position Execution

Mode (see Section 4.3.6) and Slaved Position Execution Mode (see Section

4.3.7)

page 15

Page 20

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

4.3.10 Monitor (Autoscan) Command

Description

Command defines and initiates repetitive monitoring (scanning) of the pantilt. Autoscanning is immediately terminated upon receipt of a character from

the host computer, and the pan-tilt is sent to its home position.

Syntax

Initiate monitor (autoscan) in pan axis only:

M<pan pos 1>,<pan pos 2><delim>

Initiate monitor (autoscan) in both pan and tilt axes:

M<pan pos 1>,<pan pos 2>,<tilt pos 1>,<tilt pos 2><delim>

Initiate last defined monitor (autoscan) command (the default at power up is

pan axis only autoscan between the pan limit positions):

M<delim>

Enable monitor (autoscan) at power up: ME<delim>

Disable monitor (autoscan) at power up: MD<delim>

Query monitor status at power up: MQ<delim>

Example

When executed at power up,

M *

the pan-tilt begins scanning between the minimum and maximum pan limit

positions.

<delim>

terminates the scanning and homes the pan-tilt. Other monitoring command

forms:

M-2500,100 *

M-2500,100,-800,600 *

M0,0,-300,300 *

Related Topics

• Limit Position Queries (see Section 4.3.4)

4.3.11 Position Presets

Description

Position preset functionality is provided for backward compatibility with

legacy CCTV applications. D300 pan-tilt controller firmware version v2-1211r2 and higher support position presets. The pan-tilt can be commanded to a

position using any of the standard motion control commands of the D300

PTU. The current pan and tilt position can be stored as a numbered “preset”.

The PTU can then be commanded to a previously stored preset using a new

“go to preset” command. Currently set motion parameters (acceleration, base

rate, etc.) apply during “go to preset” commands. Preset positions are

remembered when the controller is repowered.

Syntax

XS<index><delim> where <index> ? [0..32] “Set Preset”

XG<index><delim> where <index> ? [0..32] “Goto Preset”

XC<index><delim> where <index> ? [0..32] “Clear Preset”

Example

The following commands set the Pan/Tilt to position 500/400, store as preset

0, move the unit to position 600/800, and then goes back to previously stored

preset 0 position.

page 16

Page 21

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

UPPER SPEED LIMIT

BASE (start-up) SPEED

LOWER SPEED LIMIT

Figure 5: Axis Speed, Instantaneous Speeds, Trapezoidal Acceleration,

and On-The-Fly Speed and Position Changes

time

speeds

requiring

acceleration

instantaneous

speed

changes

PP500 *

TP400 *

XS0 *

PP600 *

TP800 *

XG0

4.4 Speed Control Commands & Queries

4.4.1 Speed Control & Relevant Terms

The Pan-Tilt Unit provides for precise control of axis speed and acceleration. This subsection

briefly describes how speed control is performed and it introduces relevant terms.

As shown in Figure 5, upper and lower speed limits determine the bounds on nonstationary

pan-tilt velocities. The base (start-up) speed specifies the velocity at which the pan-tilt axis can be

started from a full stop without losing synchrony (as described in Section 3.8), and it is more a

function of the motors rather than load characteristics. Due to base speed requirements and the

property that motors lose torque as speed increases, acceleration is required to achieve axis speeds

above the base rate. The pan-tilt controller uses trapezoidal acceleration and deceleration for

speeds above the base rate and less than the maximum allowed speed. Figure 5 shows two

acceleration cases. In the first, an axis accelerates up to a desired constant speed (slew rate), then

decelerates. The second case shows the case when the unit does not have sufficient time to

accelerate up to the desired slew speed before the need to decelerate to the desired position.

The pan-tilt controller provides for on-the-fly position and speed changes. If the direction is

changed on-the-fly, the controller manages all deceleration, direction reversal, and acceleration to

achieve the most recently specified target pan-tilt speed and acceleration rates.

Because speed, acceleration, and position are precisely controlled, you can accurately and

simply predict the position attained by the pan-tilt unit in time.

4.4.2 Speed (absolute)

Description

Specify or query desired axis speed. Desired speed is specified in positions/

second and it can be changed on-the-fly . The speed specifies the rate at which

the pan-tilt moves to achieve position movement commands.

Desired speed commands outside the speed bounds return an error and

are not executed.

page 17

Page 22

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

Syntax

Query desired pan speed: PS<delim>

Set desired pan speed: PS<positions/sec><delim>

Query desired tilt speed: TS<delim>

Set desired tilt speed: TS<positions/sec><delim>

Example

The following commands instruct the pan axis to move to the far left, then

slowly move right, and then on-the-fly it speeds up:

I *

PS1900 *

PP2600 *

A *

PS600 *

PP-2600 *

PS1900 *

Related Topics

• Position commands: See Section 4.3.1 - 4.3.2

• Position resolution (units): See Section 4.3.3

• Speed bounds: See Section 4.4.6

4.4.3 Delta Speed (relative offset)

Description

Specify desired axis speed as an offset from the current speed, or Query the

current axis speed. Desired delta (offset) speed is specified in positions/

second and it can be changed on-the-fly. A desired delta speed command that

results in a speed outside the legal speed bounds returns an error and it is not

executed.

Syntax

Query current pan speed: PD<delim>

Set desired delta (offset) pan speed: PD<positions/sec><delim>

Query current tilt speed: TD<delim>

Set desired delta (offset) tilt speed: TD<positions/sec><delim>

Example

The following commands instruct the pan axis to move to the far left, then

slowly move right, and then on-the-fly it decreases speed by -150 positions/

second, then queries the current speed:

I *

PS1900 *

PP2600 *

A *

PS600 *

PP-2600 *

PD-150 *

PD * Current Pan speed is 450 positions/sec

page 18

Related Topics

• Position commands: See Section 4.3.1 - 4.3.2

• Position resolution (units): See Section 4.3.3

Page 23

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

• Speed bounds: See Section 4.4.6

4.4.4 Acceleration

Description

Specify or query axis acceleration and deceleration for speeds above the base

speed. Acceleration is specified in positions/second2.

Syntax

Query desired pan acceleration: PA<delim>

Set desired pan acceleration: PA<positions/sec2><delim>

Query desired tilt acceleration: TA<delim>

Set desired tilt acceleration: TA<positions/sec2><delim>

Example

The following illustrate different rates of acceleration:

PA * Pan acceleration is 2000 positions/sec^2

PB * Current Pan base speed is 1000 positions/sec

PU * Maximum Pan speed is 2902 positions/sec

PP0 *

PS1900 *

PP2600 *

PA1500 *

PP0 *

Related Topics

• Position resolution (units): See Section 4.3.3

• Symmetric trapezoidal acceleration is used, so the rate of deceleration is

equivalent to the rate of acceleration

• Acceleration cannot be changed on-the-fly since it takes several seconds to

recompute the internal tables used to rapidly execute speed ramping.

4.4.5 Base (Start-Up) Speed

Description

Specify or query axis base (start-up) speed. Base speed is specified in

positions/second. Defaults to 57 positions/sec.

Syntax

Query desired pan base speed: PB<delim>

Set desired pan base speed: PB<positions/sec><delim>

Query desired tilt base speed: TB<delim>

Set desired tilt base speed: TB<positions/sec><delim>

Example

The following commands home the pan axis, moves it far left, changes the

base rate, then moves back to home:

I *

PP0 *

A *

PP2600 *

PB * Current Pan base speed is 1000 positions/sec

PB1000 *

PP0 *

page 19

Page 24

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

Related Topics

• Position resolution (units): See Section 4.3.3

• Acceleration: See Sections 4.4.1 and 4.4.4

• Speed bounds: See Section 4.4.6

• Changes in the base rate cannot be made on-the-fly since it takes several

seconds to recompute the internal tables used to rapidly execute speed

ramping.

4.4.6 Speed Bounds

Description

Set and query the upper and lower speed bounds for desired speed

commands.

Syntax

Query upper pan speed limit: PU<delim>

Set upper pan speed limit: PU<positions/sec><delim>

Query lower pan speed limit: PL<delim>

Set lower pan speed limit: PL<positions/sec><delim>

Query upper tilt speed limit: TU<delim>

Set upper tilt speed limit: TU<positions/sec><delim>

Query lower tilt speed limit: TL<delim>

Set lower tilt speed limit: TL<positions/sec><delim>

Example

PU * Maximum Pan speed is 1985 positions/sec

PS3300 ! Pan speed cannot exceed 1985 positions/sec

PS1985 *

PL * Minimum Pan speed is 31 positions/sec

PL20 ! Motor speed cannot be less than 31 pos/sec

PL40 *

Related Topics

• Position resolution (units): See Section 4.3.3

• Changes in the upper speed limit cannot be made on-the-fly since it takes

several seconds to recompute the internal tables used to rapidly execute

speed ramping.

4.4.7 Speed Control Modes

Description

By default, position control commands are independent from the speed

control commands. In this independent control mode, the commanded speed

is an unsigned magnitude that determines the speed at which independently

commanded positions are effected, and the execution of these speed

commands do not affect the commanded desired positions themselves. This

mode is appropriate for pure position control methods (when pan-tilt control

is effected solely by commanding pan-tilt position) and hybrid positionvelocity control methods (when pan-tilt positions and the rate at which they

are achieved are both controlled).

An alternative pan-tilt control method uses a pure velocity control mode

in which all pan-tilt control is effected by signed changes in command axis

page 20

Page 25

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

speed. In this mode, the speed command specifies a signed velocity in which

the sign determines the direction of axis movement, and the ordinal value

specifies the speed of movement in this direction. In this mode, if the

commanded speed is negative, the axis is automatically commanded to the

minimum axis position. Conversely, if the speed command is positive, the

axis is automatically commanded to the maximum axis position. A speed of

zero is applied by halting the axis motion. It is important to note that in pure

velocity control mode, a speed command for a given axis effectively overrides

currently executing position commands. As a result, the speed control mode

at power up is always set to independent control mode; the speed control

mode is not saved as defaults that are preserved when the unit is powered

back up.

These commands are available in PTU firmware versions 1.09.7 and

higher.

Syntax

Query the current speed control mode: C<delim>

Set to independent control mode (default): CI<delim>

Set to pure velocity control mode: CV<delim>

Example

Put into the default independent control mode, the pan-tilt will finish at

position -3000. Put in the pure velocity control mode, the pan-tilt will finish

on the opposite pan side. Note that the default restore (also executed upon

unit power up) restores the unit to independent control mode:

CI *

PP-3000 *

PS1000 *

A *

CV *

PP-3000 *

PS1000 *

DR *

PP-3000 *

PS1000 *

Related Topics

• Position commands: See Section 4.3.1-4.3.2

• Speed commands: See Section 4.4.2-4.4.3

4.5 Unit Commands

4.5.1 Reset Pan-Tilt Unit

Description

This command controls how, and when, the pan-tilt unit is calibrated. By

default, the pan-tilt unit is configured to reset both the pan and tilt axes

automatically upon power up and by issuing the reset command.

tilt power up, and to allow reset of an individual pan-tilt axis. The reset

calibration allows the pan-tilt unit to determine axis coordinates, hence a

pan-tilt axis should be reset prior to issuing any axis position commands. A

pan-tilt axis that has not been calibrated has a minimum and maximum axis

The reset mode commands are used to control the reset performed at pan-

page 21

Page 26

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

position of 0 (see Section 4.3.4), hence position commands in limit enabled

mode (see Section 4.3.5) will return an illegal position command feedback.

Syntax

Performs Reset calibration: R<delim>

Reset modes (saved in internal EEPROM for power up reset control):

Disable reset upon power up: RD<delim>

Reset tilt axis only: RT<delim>

Reset pan axis only: RP<delim>

Reset both pan and tilt axes upon power up: RE<delim>

Example

RT *

R *

RP *

R *

RD *

R *

RE *

R *

Related Topics

• A load beyond the handling capacity of the pan-tilt unit may cause the reset

to fail, so load handling capability should be tested as described in Section

3.7.

4.5.2 Default Save/Restore

Description

Allows current axis settings to be saved as defaults that are preserved when

the unit is powered back up. Also allows the factory defaults to be restored.

Syntax

Save current settings as defaults: DS<delim>

Restore stored defaults: DR<delim>

Restore factory defaults: DF<delim>

Related Topics

• Defaults are saved in EEPROM which have a lifetime limit on the number

of writes before memory failure. Though it is unlikely that these failure

limits will be reached, excessive saving of current defaults should be

avoided when possible.

4.5.3 Echo Query/Enable/Disable

Description

Sets of queries whether the pan-tilt controller echoes incoming commands

from the host.

Syntax

Query current echo mode: E<delim>

Enable host command echoing: EE<delim>

Disable host command echoing: ED<delim>

page 22

Page 27

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

Example

PP * 22

ED *

<pp entered again, but not echoed>* 22

4.5.4 Feedback Verbose/Terse/Off

Description

Command and query the ASCII feedback returned by PTU commands.

Syntax

Enable verbose ASCII feedback: FV<delim>

Enable terse ASCII feedback: FT<delim>

Query ASCII feedback mode: F<delim>

Example

FV *

PP * Current pan position is 0

FT *

PP * 0

F * ASCII terse mode

4.5.5 Controller Firmware Version Query

Description

Query specifies the version and copyrights for the pan-tilt controller

firmware.

Syntax

V<delim>

Example

V * Pan-Tilt Controller v2.12.1d1(C14/E), (C)2003 FLIR Commercial Systems, Inc., All

Rights Reserved

4.5.6 Outside Supply Voltage and Controller Temperature Query

Description

The pan-tilt controller includes sensors for the internal temperature and the

input voltage supplied to the pan-tilt. This query measures and prints the

controller temperature and input supply voltage.

Syntax

O<delim>

Example

O * Input 30 VDC @ 86 degF

4.6 Power Control Commands & Queries

A key advantage of the constant current motor control drivers used in the Pan-Tilt Controller

is that it allows the current consumed by the pan-tilt unit to be controlled via simple unit

commands. These capabilities are useful for battery powered operation (see Section 7), reducing

unit heat generation, and extending the rated life of the motor driver circuitry.

page 23

Page 28

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

4.6.1 Stationary Power Mode

Description

Set and query the current level applied to axis motors when not in-transit.

Syntax

Query pan hold power mode: PH<delim>

Regular pan hold power mode: PHR<delim>

Low pan hold power mode: PHL<delim>

Off pan hold power mode: PHO<delim>

Query tilt hold power mode: TH<delim>

Regular tilt hold power mode: THR<delim>

Low tilt hold power mode: THL<delim>

Off tilt hold power mode: THO<delim>

Example

PH * Pan in REGULAR hold power mode

PHL *

PH * Pan in LOW hold power mode

Related Topics

• Because holding torque for steppers is significantly greater than generated

dynamic torque, it is highly recommended that Low Hold Power Mode be

used when appropriate for your load. Regular hold power is intended to be

used for brief periods when very high holding torque may be required; this

requirement is rare. Regular hold power mode should be avoided or used

sparingly, as its use for long periods of time can lead to significant motor

and controller heating (depending on ambient temperature).

• When using Off Hold Power Mode, fully test that your load does not

backdrive the unit when stationary . Backdriving will cause the controller to

lose track of pan-tilt position, and this requires that the unit be reset (see

Section 4.5.1). Backdriving is more likely on the tilt axis which has higher

torque applied to it by the load.

4.6.2 In-Motion Power Mode

Description

Set and query the current level applied to axis motors when in-motion (intransit).

Syntax

Query pan move power mode: PM<delim>

High pan move power mode: PMH<delim>

Regular move hold power mode: PMR<delim>

Low pan move power mode: PML<delim>

Query tilt move power mode: TM<delim>

High tilt move power mode: TMH<delim>

Regular tilt move power mode: TMR<delim>

Low tilt move power mode: TML<delim>

page 24

Page 29

PTU-D300 User’s Manual (v2.19) COMMAND REFERENCE

Example

PM * Pan in REGULAR move power mode

PML *

PM * Pan in LOW move power mode

Related Topics

• It is not recommended that an axis be in transit more than 20% of the time

when in High Move Power Mode (i.e., a 20% duty cycle).

4.7 Host Serial Port and Control

As was described in Section 3, default host computer communications with the pan-tilt

controller is 9600 baud. Host computer communications can be via RS-232, or as described in

Section 7 it can be via the built-in RS-485.

Host serial port baud rates can be modified from the default. Also, a character delay may be

specified for applications that cannot consume pan-tilt output rapidly enough.

4.7.1 Configuring Host Serial Port Baud and Communications

Description

Command specifies the baud rate for the host serial port RS232/RS485

communications with the pan-tilt controller. Only baud rate can be modified.

The pan-tilt controller RS232/485 communications always use 1 start and

stop bit, 8 data bits and no handshaking. The command also allows a

transmission delay to be placed between bytes output by the pan-tilt

controller.

The host serial port command in this Section 4.7.1 is only available

when the controller is not networked (i.e., the unit ID is the default of 0).

When the controller is networked (i.e., unit ID is greater than 0), the host

serial port communications rate is automatically set to the default and it

cannot be modified by this command: the default is 9600 baud, 8 data bits, 1

start and stop bit, no parity, no handshaking, and no byte transmission delay.

This ensures that networked controllers will always communicate at the same

baud rate, and that higher data rates will not unduly burden pan-tilt controller

processors.

Syntax

Example

@(<baud>,<byte delay in msec>,<startup default>)<delim>

where:

<baud> may be 600, 1200, 2400, 4800, 9600, 19200 or 38400 bits/

sec

<byte delay in msec> is the time in milliseconds the pan-tilt controller

waits between transmitting output data. If no delay is desired, use a

parameter of 0, otherwise, the delay may vary from 10 ms to 1000 ms.

<startup default> If T, <baud> and <byte delay in msec> are

applied at power up; otherwise, the power up default is 9600 baud with

no byte transmission delay.

The following command sets the host serial port RS232/RS485 to a baud rate

of 38,400 bits/second (8 data bits per byte, no parity, no handshaking), no

delay in controller outbound byte transmission, and the power up baud rate is

the system default of 9600 baud.

@(38400,0,F) *

page 25

Page 30

COMMAND REFERENCE PTU-D300 User’s Manual (v2.19)

The following command sets the host serial port RS232/RS485 to a baud rate

of 19,200 bits/second (8 data bits per byte, no parity, no handshaking), a

30ms delay between bytes output from the pan-tilt controller, and the power

up baud rate overrides the default and is set at 19,200 baud.

@(19200,30,T) *

Related Topics

• To wire the host port serial RS232 communications: See Section 3.4

• To wire the host port serial RS485 communications: See Section 7.2

• To set the pan-tilt controller unit ID: See Section 7.3.1

4.8 Step Modes

4.8.1 Configuring Step Mode

Description

The default motion resolution of the D300 controller is half step mode.

Firmware versions 2.12.8 and higher added microstepping in quarter and

eighth steps. Microstepping provides much quieter operation and smoother

motion at slow speeds. In addition, the microstepping increases the effective

resolution of the pan-tilt unit.

Firmware versions 2.13.0 and higher added autostep electronic gearing.

The controller will automatically select the correct step mode based on the

pan-tilt’s current speed, a nd process all units as though the unit were in eighth

step mode while allowing the unit to move at the higher speeds of half step.

Syntax

W<axis><resolution> where

<axis> :== T | P

<resolution> :== F | H | Q | E | A

for Full, Half, Quarter, Eighth and Auto step

resolution.

Example

The following command puts the tilt axis into eighth step resolution and

recalibrates the tilt axis, which returns success (*).

WTE *

Known Issues

• Autostep mode is only supported in firmware versions v2.13.0 and higher.

This firmware supports querying the microstep mode with the

“W<axis><delimiter>” command.

• Microstepping decreases the pull-out torque of the motor.

page 26

Page 31

PTU-D300 User’s Manual (v2.19) SPECIAL CONFIGURATIONS

5 SPECIAL CONFIGURATIONS

5.1 High-Speed Operation

This section discusses how to improve high speed pan-tilt unit performance for your load.

The primary factors that affect high speed operation are:

• Load weight, weight distribution and dynamics

• Desired upper speed limit (see Section 4.4.6)

• Rate of acceleration (see Section 4.4.4)

• The base (start-up) speed (see Section 4.4.5)

• The voltage of the source power supply. Use of the highest available voltage in the range 930VDC significantly improves axis speed and acceleration performance.

• The in-motion power mode (see Section 4.6.2) and stationary power mode (see Section

4.6.1).

• Multi-axis dynamics. Simultaneously moving the tilt and pan axes affects the forces exerted

on the pan axis.

High speed operation tests should always begin on each axis in isolation. When the best

performance for each axis in isolation is understood, high speed operation of simultaneous pan-tilt

axis movements can be performed.

An example configuration string for high speed operations is:

PA9000 TA9000 DS

5.2 High-Payload Operation

This section discusses how to improve high payload weight operation of the pan-tilt. The

primary factors affecting payload capacity is the tilt axis, as it forms a mechanical lever which is

an efficient force multiplier. The primary means to increase payload capacity are:

• Configure the pan-tilt controller for increased motor current and torque. An example

configuration string to increase payload capacity is:

DF PA1000 TA1000 PB57 TB57 PMR TMR DS

If your move duty cycle is less than 20%, you can alternatively use the highest move current

settings and regular hold power settings of PMH TMH PHR THR .

• Move the payload center of gravity closer to the tilt axis

• Use a higher voltage power source in the range 9-30VDC

• Determine if the payload can be modified to lighten it.

5.3 Battery-Powered Operation

The Pan-Tilt Unit has been designed for battery powered operation. Battery powered

applications need to conserve power when possible. The pan-tilt unit has commands to control

pan-tilt motor power consumption while in transit and when stationary (see Sections 4.6.1 and

4.6.2). Careful testing can be used to determine the lowest power modes that assure your load can

be moved and held without losing synchrony (see Section 3.8).

page 27

Page 32

PTU OPTIONS PTU-D300 User’s Manual (v2.19)

6 PTU OPTIONS

6.1 EIO Option: Expansion Serial Ports and Control

For OEM applications, internal D300 wiring can be brought out on FFC (flat flex connectors)

to provide for additional control signals. For example, other serial devices attached or proximal to

the pan-tilt may require other RS232 serial ports. Please contact FLIR Commercial Systems, Inc.

for additional information on these custom configurations.

7 NETWORKING

The PTU lets you connect up to 127 PTUs to a single host computer port. Your host computer

can then address each PTU on the network as though the PTU were the only unit attached to the

host. In this way, it is simple to migrate existing code developed for a single PTU to a network of

PTUs controlled by a single host computer.

This section describes the basic installation and setup steps required to network your pan-tilt

units.

7.1 Basic Networking Setup Steps

The steps in networking your PTUs to your host computer are:

1. Sketch out the physical placement of your PTUs and host computer.

2. Assign a unique network ID number to each PTU.

3. Connect the PTUs and host computer to the PTU network.

4. T est the configuration by addressing each PTU by its unit ID and commanding and querying its attached pan-tilt unit.

page 28

Page 33

PTU-D300 User’s Manual (v2.19) NETWORKING

Figure 6: Making PTU Network Connections

HOST

COMPUTER

net/termin. network

PTU-NCONN

120 1% terminator

network net/termin.

PTU-NCONN

120 1% terminator

net/termin. network

PTU-NCONN

• • •

• • •

RS-485 Multi-Drop Network

(full duplex)

7.2 PTU Network Connections

Figure 6 illustrates how PTUs can be networked and connected to a host computer via its RS232 port. Each PTU has a built-in RS-232 to RS-485 converter, and the host computer can be

connected to the RS-485 controller network by simply connecting to the RS-232 connector on a

PTU. The PTUs are then connected together via an RS-485 multi-drop network (full duplex).

quality cable. Though a good quality telephone cord cable can be used, use of a twisted pair cable

is highly recommended. A twisted pair whose impedance is about 100 is typically used for

longer RS-485 runs. The twisted pair provides good noise immunity owing to the relative signals

used by the RS-485 standard.

this case, you may directly connect your host computer to the PTU network. For computers with

only RS-232, RS-485 connections may be simply made using an external RS-232 to RS-485

converter. FLIR Commercial Systems, Inc. has tested/qualified two converters: ATEN IC-485S

and Moxa A50 which both require a flipped RJ-12 connector (such as a standard phone cord). It is

important to note that the network should be terminated using 120 1% resistors to protect

against signal ringing on the network. Termination is achieved by placing the resistors between

the RS-485 Transmit+/Transmit- and Receive+/Receive- wires at each end of the multidrop

wiring network.

7.3 PTU Network Software Commands

configuration of your PTU controllers.

Several issues are important to note when you make your own data cables. First, use a good

For some applications, the host computer may directly provide RS-485 full-duplex I/O. In

This section describes the pan-tilt command set used to configure, set and query the network

7.3.1 Unit Network ID

Description

Specify or query the PTU controller network unit ID number. By default, the

PTU unit ID is set to zero which indicates the PTU controller is not

networked, and the PTU controller is in the default interactive

communications mode. When assigning a unit ID number to a controller, the

unit ID number should be unique, the controller should be the only PTU

controller attached to the host computer or terminal (otherwise other

page 29

Page 34

NETWORKING PTU-D300 User’s Manual (v2.19)

controllers may be set to the same unit ID number). A unit ID of zero may be

used to put a PTU controller back in interactive (non- networked) mode.

Syntax

Query current PTU network unit ID: U<delim>

Set PTU to interactive mode (non-networked): U0<delim>

Set PTU network unit ID: U<unit_ID><delim>

where 1 <unit_ID> 127

Example

The following queries a PTU unit ID, then sets and stores the unit ID

configuration so that upon power-up the new unit ID will be used.

U * Unit ID is 0

U1 *

U * Unit ID is 1

U1 *

DS *

Related Topics

• Unit Select/Deselect: See Section 7.3.2.

7.3.2 Unit Select/Deselect

Description

Command is used to select the PTU to be controlled. A PTU will execute

incoming host computer commands only when the preceding unit_ID

selected by the host is (a) equal to the PTU’s assign unit ID, or , (b) equal to 0.

A host computer can broadcast instructions to be executed by all PTUs using

unit_ID=0. Only one PTU can provide feedback to the host computer at a

time. A PTU provides feedback to the host computer only when the host

computer has selected its unit ID. A PTU buffers its outgoing data until the

host computer polls it -- the current PTU buffer size is about 100 bytes.

Syntax

Select a PTU for bi-directional data: _<unit_ID><delim>

Broadcast to all networked PTUs: _0<delim>

where 0 <unit_ID> 127

Example

_1

pp300 *

_0

pp300

_1

*

Related Topics

• Unit Network ID: See Section 7.3.1.

page 30

Page 35

PTU-D300 User’s Manual (v2.19) Appendix A.: SPECIFICATIONS

11.61

3.325

.375 THICK

2.950

1.850

9.80

9.85

TILT AXI S

PAN AXIS

PAYLOAD B RACKET IN

SIDE POSITION

PAYLOAD B RACKET IN

OVERHEAD POSITION

6.432.10

A

PAN AXIS

3.375

2X

2X 3.375

1/4-20

CLEARANCE HOLE

4X

.475

C-BORE

.625

.550

DETAIL A

CUT AWAY

SCALE 1 : 1

4X

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF DIRECTED PERCEPTION AN D IS TENDERED SUBJECT

TO THE CONDITIONS THAT THE INFORMATION (A) BE RETAINED IN CONFIDENCE, (B) NOT BE USED OR

INCORPORATED IN ANY PRODUCT EXCEPT UNDER WRITTEN AGREEMENT WITH DIRECTED PERCEPTION.

EMD/BC

08APR04

.X = ± -

.XX = ± 0.01

.XXX = ± 0.005

±1/2

EMD/BC

08APR04

D300 DIMENSIONAL DRAWING

1 2

D300_dimensional_drawing.PRT

D

2:3

1 OF 1

D300

11.1

D300_dimensional_drawing.SLDDRW

D300

1 OF 1

11.1

11

--

BG INITIAL RELEASE

02MAR05

4

3

2

E-M DESIGNS

1

C

B

A

8

B

7

6

5

C

D

8

7

6

5

43

2

C

1

D

DRAWING OR

DO NOT SCALE DRAWING

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

MATERIAL

DECIMALS

FINISH

ANGLES

QTY REQD

ITEM

NO.

PART NO.

MATERIAL/SPECIFICATION

SIZE SHEET DWG. NO.

SCALE

DATE

DRAWN

DATE

DATE

DESIGN

CHECK

TITLE

DESCRIPTION

PARTS LIST

REV

DWG. NO.

SHT

REV

REVISIONS

THIRD ANGLE PROJECTION

SOLIDWORKS.prt:

INCHES

SOLIDWORKS .drw:

BYZONE

REV

APPROVED

DESCRIPTION DATE

ADD PAYLOAD CONNECTOR HOUSING

28APR05

BG

--

11.1

A. SPECIFICATIONS

A.1 D300 Mechanical Dimensions

page 31

Page 36

PTU-D300 User’s Manual (v2.19) Appendix A.: SPECIFICATIONS

3.325

.375 THICK

3.250

2.631

4.131

5.631

7.131

8.000

.257

.736

2.250

C

L

C

L

C

L

C

L

C

L

A.2 D300 Payload Bracket Dimensions

page 32

Page 37

PTU-D300 User’s Manual (v2.19) Appendix A.: SPECIFICATIONS

A.3 D300 Base Connector Wiring

page 33

Page 38

PTU-D300 User’s Manual (v2.19) Appendix A.: SPECIFICATIONS

A.4 D300 Payload Wiring PL01

page 34

Page 39

PTU-D300 User’s Manual (v2.19) Appendix A.: SPECIFICATIONS

A.5 D300 Payload Wiring PL02

page 35

Page 40

PTU-D300 User’s Manual (v2.19) Appendix A.: SPECIFICATIONS

R6.90

PAN CLEARANCE

ALL AROUND

2.700 BC

B

#8-32 TAP FOR HELICOIL CHANGED TO #10-24

THIS DOCUMENT CONTAINS PROPRIETARY INF ORMATION OF DIRECTED PERCEPTIO N AND IS TENDERED SUBJECT

TO THE CONDITIONS THAT THE INFORMATION (A) BE RETAINED IN CONFIDENCE, (B) NOT BE USED OR

INCORPORATED IN ANY PRODUCT EXCE PT UNDER WRITTEN AGREEMENT WITH DIRE CTED PERCEPTION.

EMD/BG MAR05

.X = ± -

.XX = ± 0.01

.XXX = ± 0.005

±1/2

EMD/BC JAN04

JC

DRAWING

D300_payload_mounting_11_2.PRT

D

2:3

1 OF 1

D300

11.2

D300_payload_mounting_11_2.SLDDRW

D300

1 OF 1

11.2

11

--

BG

INITIAL RELEASE

02MAR05

4

3

2

E-M DESIGNS

1

C

B

A

8

B

7

6

5

C

D

8

7

6

5

4

3

2

C

1

D

DRAWING OR

DO NOT SCALE DRAWING

UNLESS OTHERWISE SPECIFIED

ALL DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

MATERIAL

DECIMALS

FINISH

ANGLES

QTY REQD

ITEM

NO.

PART NO.

MATERIAL/SPECIFICATION

SIZE SHEET DWG. NO.

SCALE

DATE

DRAWN

DATE

DATE

DESIGN

CHECK

TITLE

DESCRIPTION

PARTS LIST

REV

DWG. NO.

SHT

REV

REVISIONS

THIRD ANGLE PROJECTION

SOLIDWORKS.prt:

INCHES

SOLIDWORKS .drw:

BY

ZONE

REV

APPROVED

DESCRIPTION

DATE

ADD PAYLOAD CONNECTOR HOUSING

28APR05

BG

--

11.1

11.1

--

D300 PAYLOAD MOUNTING

28APR05

2.200

1.850

1.918

UNIT WITH NO

PAYLOAD BRACKET

DETAIL B

PAYLOAD MOUNTING

HOLE PATTERN

SCALE 2 : 1

6X 60°

6X #10-24 .285 HELICOIL insert

A.6 D300 Payload Mounting

page 36

Page 41

REGULATORY INFORMATION

Electromagnetic Interference (EMI) is any signal or emission, radiated in free space or conducted along power or signal leads that endangers the function of a radio navigation or other safety service or seriously degrades, obstructs, or

repeatedly interrupts a licensed radio communications service.

Class A

Class A equipment has been tested and found to comply with the limits for a C lass A digit al device, pu rsuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required to correct the interference

at his/her own expense.

Class B

Class B equipment has been tested and found to comply with the limi ts for a Class B digital device, pursuan t to Part