Page 1

Photon Block 2

User Guide

412-0035-00-10

Version 100

FLIR Systems

Indigo Operations

70 Castilian Dr.

Goleta, CA 93117-3027

805 964-9797 FAX 805 685-2711

www.indigosystems.com

Page 2

Photon User Guide 412-0035-00-10 Version 100

TABLE OF CONTENTS

1 INTRODUCTION................................................................................................................. 4

2 PHOTON SPECIFICATIONS ............................................................................................ 4

3 UNPACKING YOUR PHOTON CAMERA...................................................................... 5

4 OPTIONAL PHOTON ACCESSORIES............................................................................ 6

5 OVERVIEW OF THE PHOTON ELECTRICAL INTERFACE.................................... 6

INPUT POWER............................................................................................................................... 8

ANALOG VIDEO OUTPUT ............................................................................................................. 8

COMMAND AND CONTROL CHANNEL........................................................................................... 9

DIGITAL DATA CHANNEL ............................................................................................................ 9

EXTERNAL SYNCHRONIZATION.................................................................................................... 9

Voltage Outputs .................................................................................................................... 10

Input/Output Pins.................................................................................................................. 10

6 BASIC OPERATION OF THE PHOTON CAMERA.................................................... 11

7 REMOTE CONTROL OF THE PHOTON CAMERA .................................................. 12

INSTALLATION OF PHOTON CONTROL PANEL SOFTWARE .......................................................... 13

CONNECTING PHOTON TO A PC VIA THE I/O MODULE ............................................................... 13

TROUBLESHOOTING THE COMMAND & CONTROL LINK ............................................................. 13

OPERATION OF THE PHOTON CONTROL PANEL .......................................................................... 14

7.1.1 Control Panel Camera Tab................................................................................... 15

7.1.2 Control Panel Video Tab ...................................................................................... 19

7.1.3 Control Panel AGC Tab........................................................................................ 25

7.1.4 Control Panel About Tab...................................................................................... 28

8 PHOTON DIGITAL DATA CHANNEL.......................................................................... 29

SING THE DIGITAL DATA CHANNEL ........................................................................................ 29

U

9 PHOTON PHYSICAL INTERFACE ............................................................................... 30

DIMENSIONED DRAWINGS ......................................................................................................... 30

WEIGHT ..................................................................................................................................... 30

M

OUNTING................................................................................................................................. 31

APPENDIX A: PIN-OUT DEFINITIONS ............................................................................... 37

I/O MODULE .............................................................................................................................. 37

COPYRIGHT NOTICE © FLIR SYSTEMS CORPORATION 2006

2

Page 3

Photon User Guide 412-0035-00-10 Version 100

Cautions:

• Do not remove the camera cover. Disassembly of the camera (including removal of the

cover) can cause permanent damage and will void the warranty.

• Operating the camera outside of the specified input voltage range or the specified

operating temperature range can cause permanent damage.

• The camera is not sealed. Avoid exposure to dust and moisture and replace the lens cap

when not in use.

• Do not image extremely high intensity radiation sources, such as the sun, lasers, arc

welders, etc.

• The camera is a precision optical instrument and should not be exposed to excessive

shock and/or vibration. Refer to the Product Specification (ISC doc. 102-0005-09) for

detailed environmental requirements.

• This camera contains static-sensitive electronics and should be handled appropriately.

• If you have questions that are not covered in this manual, or need service, contact

Customer Support at (805) 964-9797 for additional information prior to returning a

camera.

3

Page 4

Photon User Guide 412-0035-00-10 Version 100

1 INTRODUCTION

The Photon is a long-wavelength (7.5 – 13.5 microns) uncooled microbolometer camera designed

for infrared imaging applications that demand absolute minimum size, weight, and power

consumption. It is available with five different lens options: 14.25 mm focal length (50° H field of

view or FOV), 19 mm focal length (36° HFOV), 30 mm (23° HFOV), 35 mm (20° HFOV) or 50

mm (14° HFOV). The camera provides “power-in, video-out” capability, which means that one

need only apply input voltage to receive analog video. For those applications demanding more

advanced control the Photon includes a serial interface (RS-232) for transmitting camera

commands and receiving status. Photon provides digital data interface via a parallel interface.

Figure 1: Photon 50 mm, 30 mm, 19 mm and 14.25 mm

2 PHOTON SPECIFICATIONS

• 324 (H) x 256 (V) uncooled microbolometer sensor array, 38 x 38 micron pixels

• Input power range: 5.0 – 24.0 VDC

• Power Consumption: 1.5 Watts (nominal at room temperature with 8V input)

• Operating Temperature Range: -40°C to +75°C external temp range

• Dimensions: see detailed drawings in Section 9

• Weight: approx 97 grams for camera core

• Analog video output: NTSC (PAL optional)

• Remote interface: RS-232 (Control Panel software included.)

• Included features:

o 2X Digital Zoom with electronic pan/tilt

o Digital Detail Enhancement

Note: These specifications are subject to change without notice. See the Electrical Interface

Control Document (ISC doc. 102-1238-41) for detailed interface descriptions.

4

Page 5

Photon User Guide 412-0035-00-10 Version 100

3 UNPACKING YOUR PHOTON CAMERA

The items shown in Figure 2 come standard in your Photon Camera package. If there is any

discrepancy between this list and the contents of your camera package, please contact FLIR

Systems Customer Support immediately at (805) 964-9797.

1. Photon camera

2. I/O Module

3. Interface cable

4. 110/220V AC/DC Converter with outlet plug

5. Wear Saver (may not be needed)

6. User’s Guide and Photon OEM GUI

6

4

5

1

2

3

Figure 2: Standard Photon Camera and OEM Package

5

Page 6

Photon User Guide 412-0035-00-10 Version 100

4 OPTIONAL PHOTON ACCESSORIES

• Digital data serial-to-parallel module (parallel data cable sold separate)

• Pleora IPort

• Battery Pack

Figure 3: Some of the Photon Accessories

5 OVERVIEW OF THE PHOTON ELECTRICAL INTERFACE

Depending on connector type, either a 15-pin HD D-Sub or a 30-pin SAMTEC, thru which

input/output signals are available on the back of the Photon camera.

The 15-pin high density or HD D-Sub connector pin definitions are shown in Table 2. The

signals on this connector include input power, analog video output, serial communication

channel for command and control and the digital data output.

Table 1: 15-Pin HD D-Sub (F) Connector Pin Definitions

Pin # Signal Name Signal Definition

1 VIDEO_HI Analog Video, positive output

2 SD_ FSYNC+ Digital Port 1 Sync, positive output

3 GND Ground

4 GND Ground

5 GND Ground

6 VIDEO_LO Analog Video, negative output see

7 SD_ CLK+ Digital Port 1 Clock, positive output

8 SD_ DATA+ Digital Port 1 Output Data, positive output

9 TX Primary Serial Communication transmit

10 PWR_IN Input voltage

11 SD_CLK- Digital Port 1 Clock, negative output

12 SD_FSYNC- Digital Port 1 Sync, negative output

13 SD_DATA- Digital Port 1 Output Data, negative output

14 RX Primary Serial Communication receive

15 PWR_IN Input voltage

Figure 4: 15-pin HD D-Sub (M) connector on camera

6

Page 7

Photon User Guide 412-0035-00-10 Version 100

The Photon camera provides all input/output signals via a single 30-pin SAMTEC TFML-11502-S-D-P connector (J1) with pin definitions as shown in Table 2 The signals on this connector

include input power, analog video output, serial communication channel for command and

control, external sync, voltage output, I/O pins and the digital data output.

Table 2: 30-pin Power Board to External I/O Connector Pin Definitions

Pin # Signal Name Signal Definition

1,2,5,6 GND Ground

3 3.15V_OUT 3.15V output

4 PWR_IN Input voltage

7 1.5V_OUT 1.5V output

8 LIN Do not connect

9 RX2 Spare Serial Communication receive

10 RX Primary Serial Communication receive

11 TX2 Spare Serial Communication transmit

12 TX Primary Serial Communication transmit

13 LVDS_VID2+ Digital Port 2 Output Data, positive output

14 SD_DATA- Digital Port 1 Output Data, negative output

15 LVDS_VID2- Digital Port 2 Output Data, negative output

16 SD_ DATA+ Digital Port 1 Output Data, positive output

17 LVDS_VID1+ Digital Port 2 Sync, positive output

18 SD_FSYNC- Digital Port 1 Sync, negative output

19 LVDS_VID1- Digital Port 2 Sync, negative output

20 SD_ FSYNC+ Digital Port 1 Sync, positive output

21 LVDS_VID0+ Digital Port 2 Clock, positive output

22 SD_CLK- Digital Port 1 Clock, negative output

23 LVDS_VID0- Digital Port 2 Clock, negative output

24 SD_ CLK+ Digital Port 1 Clock, positive output

25 TEMP2 Temp Sensor port 2

26 DIS0_EXT External Sync

27 DIS2_EXT Discrete Input Channel 2

28 VIDEO_LO Analog Video, negative output

29 DIS1_EXT Discrete Input, Channel 1

30 VIDEO_HI Analog Video, positive output

Note: The mating connector is SAMTEC SFML-115-T1-S-D-K

30

4

29

Figure 5: 30-pin SAMTEC (M) connector on camera

Note: See the Electrical Interface Control Document (ISC doc. 102-1238-41) for detailed interface

requirements. Pin-out definitions for the I/O Module are provided in Appendix A.

7

321

Page 8

Photon User Guide 412-0035-00-10 Version 100

Input Power

Included with the Photon camera is an AC/DC converter that generates 8VDC input power from

110 VAC or 220 VAC. If you prefer to provide your own power supply, please verify that the

input power at the camera connector meets the specifications shown in Table 3 when applied

across PWR_IN and GND pins.

CAUTION: Reversing polarity of input power will damage the camera’s internal power supply

and repair is not covered under the camera warranty.

Table 3: Input Power Requirements

Parameter

Minimum voltage 5.0 V Absolute minimum is 4.8V

Maximum voltage 24.0V Absolute maximum is 26 V

Nominal Load

Power

Peak Load Power

at start-up

Baseline

Value

< 2000 mW Typical power is 1500 mW

4000 mW Assuming no load between

Comment

HTR and HTR_RTN.

Analog Video Output

The video output of the Photon camera can be configured to either NTSC or PAL-compatible.*

In either case, the output is intended to drive a 75-ohm load. Use of coaxial cable with 75 ohm

characteristic impedance is strongly suggested. The analog video signal is across the

VIDEO_LO and VIDEO_HI pins. See Table 4 for a list of other relevant video parameters.

Table 4: Video parameters

Parameter NTSC PAL

Monochrome equivalent RS-170A CCIR

Frame rate 29.97 Hz 25 Hz

Active video lines 480 510

# displayed detector samples 320 (H) x 240 (V) 320 (H) x 255 (V)

Note: To use the Photon Isotherm option, the video monitor must be color capable. For display

of Photon video without Isotherm capability, a monitor complying with the monochromeequivalent standard shown in Table 4 can be used.

*

NTSC is the U.S. standard for color analog video. PAL is the European standard.

8

Page 9

Photon User Guide 412-0035-00-10 Version 100

Command and Control Channel

Remote control of the Photon camera is provided via a RS-232 serial interface consisting of

signals named RX, TX and GND using 3.3 volt signal levels. Section 7 provides information

regarding remote control using the Photon OEM GUI. The Electrical Interface Control

Document (ISC doc. 102-1238-41) describes the serial communications protocol for the Photon

camera.

Digital Data Channel

Photon provides a digital channel with real-time serialized digital video. The camera outputs

either 8-bit or 14-bit data using the SD_CLK±, SD_FSYNC± and SD_DATA± signals.

Conversion of the digital data to a parallel format for data acquisition requires a serial-to-parallel

converter accessory or an Ethernet Module which is also an accessory. Section 8 provides

information regarding the digital data interface. Also, the Electrical Interface Control Document

(ISC doc. 102-1238-41) describes the specific timing information.

External Synchronization

Photon camera provides the ability to either accept or output frame synchronization if needed.

1. Slave Mode: The camera will accept a frame synchronization signal on the interface

connector (DIS0_EXT) when configured as a slave via the serial communications port. The sync

signal starts the FPA frame timing sequence. The sync signal consists of a positive going, 3 volt

pulse as defined in Table 5. The frame sync signal should be sent only once per frame and the

camera core will not output digital data until a valid frame sync is received. The video output

(analog) of the camera core is enabled while in external sync mode, however, the video frame

rate depends upon the external frame sync rate (e.g. the analog video may not conform to timing

standards). The camera synchronization state must be set prior to power-up (e.g. after the mode

is changed and saved, the camera must be re-started).

Table 5: Frame Sync Input Requirements

Frequency

Range

0 to 30 Hz 135ns

Pulse width

(minimum)

2. Master Mode: The camera will output a frame synchronization signal on the interface

connector (DIS0_EXT) when configured as a master via the serial communications port. The

sync signal corresponds to the start of the FPA frame timing sequence. The sync signal shall

consist of a positive going, 3 volt pulse as defined in Error! Reference source not found. . The

frame sync signal shall occur only once per frame. This signal output is intended to drive one

Photon which is configured for slave mode operation.

9

Page 10

Photon User Guide 412-0035-00-10 Version 100

Table 6: Frame Sync Output Requirements

Frequency

Range

29.97 Hz (NTSC

mode)

25 Hz (PAL

mode)

Pulse width

(minimum)

200 ns

200ns

Voltage Outputs

The Photon camera provides two conditioned voltage outputs, 3.15V_OUT and 1.5V_OUT,

intended to power auxiliary electronics and accessories. The characteristics of these two outputs

are shown in Table 7.

Table 7: Output Power Requirements

Parameter 3.15V_OUT 1.5V_OUT

Voltage 3.16V + 0.11V 1.50V + 0.05mV

Max. Supply

Current

500 mA 700 mA

Input/Output Pins

The Photon camera allows for custom defined I/O pins that can be programmed at the factory for

selected applications. Contact FLIR Systems Customer Support at (805) 964-9797 for details.

10

Page 11

Photon User Guide 412-0035-00-10 Version 100

6 BASIC OPERATION OF THE PHOTON CAMERA

Note: If you are using the Ethernet Module or SIPO adapter additional instructions may also be

provided.

1. Remove the lens cap. (Remember to replace the lens cap when the camera is not in use

to prevent accidental scratching and dust contamination.)

2. If using the standard Interface Cable and I/O Module, plug one end of the Interface Cable

into the mating connector on the back of the camera, as shown in Figure 6 . (Either end

of the Interface Cable can be plugged into the camera.) Connect the other end of the

Interface Cable to the mating connector on the I/O Module labeled “CAMERA”.

3. Attach one end of a standard BNC cable to the video port labeled “VIDEO” on the I/O

Module. Attach the other end to a compatible video monitor.

4. Attach one end of a standard RS-232 serial port (9-pin) PC cable to the communications

port labeled “RS-232” on the I/O Module. Attach other end to the serial port on the PC.

5. Plug the AC/DC converter into an electrical outlet. Insert the circular plug at the other

end of the AC/DC converter into the power jack labeled “POWER” on the I/O Module.

The camera will take ~1 second to produce an image after application of power.

6. The camera will automatically perform a flat-field correction (FFC) at periodic intervals.

This operation, which improves image quality, takes less than 1/2 second to complete.

This feature can be disabled or controlled manually or with a time delay via the Photon

OEM GUI (See page 16 .)

7. If you intend to use the Photon OEM GUI for remote control of the camera, follow the

additional steps described in Section 7. Figure 6 shows the I/O Module and camera after

cabling power, analog video and RS-232 interface.

8. If you intend to use the digital data channel, follow the additional steps described in

Section 8.

11

Page 12

Photon User Guide 412-0035-00-10 Version 100

To video

monitor

To electrical outlet

(only required if using RS-232

To PC

interface.)

Figure 6: Photon after cabling

7 REMOTE CONTROL OF THE PHOTON CAMERA

The Photon provides advanced camera control through an RS-232 serial interface. This can be

accessed using a PC with the standard serial communications port and the I/O Module. Included

with your Photon is PC-based Control Panel software that communicates with the camera. This

software provides remote control of various camera features and modes as well as image capture

using a graphical user interface (GUI). The Photon OEM GUI software is compatible with

Windows 2000 / 2000 Professional, and Windows XP Professional. The PC must have a spare

serial communications port for the I/O Module the Control Panel software.

If your application demands for embedded or specialty applications that require custom control

software, a Software Developer’s Kit (SDK) and an Electronic Interface Control Document

(ICD) are available to support your development efforts. Those intending to generate their own

custom software are encouraged to read the remainder of this section regarding the Photon OEM

GUI to better understand the camera modes and parameters.

12

Page 13

Photon User Guide 412-0035-00-10 Version 100

Installation of Photon Control Panel Software

1. Insert the CD marked Photon OEM GUI into your CD-ROM drive. If the setup program

(setup.exe) does not execute automatically, then execute it by finding setup.exe in the

CD-ROM with Windows Explorer and double-clicking the icon. (Alternatively, you can

select “Run” from your Windows start menu, and then type “E:\ setup.exe”, replacing E:

with the appropriate drive-letter for your CD-ROM.)

2. The installation program will present instructions for installing the application to your

hard drive. By default, the setup wizard will install the application in the directory

C:\ProgramFiles\Indigo\Photon, and the filename is OEMGUI.exe.

Connecting Photon to a PC via the I/O Module

1. Follow the steps shown in Section 6 for basic operation of the Photon camera. After

verifying that the camera is producing an image, power down the camera.

2. Connect one end of a standard serial cable (not included) to the 9-pin female DB9

connector on the I/O module labeled “RS-232”.

3. Connect the other end of the standard serial cable to an unused serial port on your

computer. These ports are usually labeled “COM1”, “COM2”, etc.

4. Power on the camera. Assuming the Control Panel software is already installed on the

PC (see installation instructions above), execute the software.

5. The Control Panel software will attempt to automatically identify the COM port upon

which the camera is installed. If the Control Panel successfully links to the camera, skip

ahead to the section below titled “Operation of the Photon Control Panel”.

Troubleshooting the Command & Control Link

If the Control Panel software does not link with the camera, verify the items in the following

checklist:

1. Is the camera properly cabled to the host PC? Verify that you selected the proper port if

it was not detected automatically. Also, try un-connecting and then re-connecting either

the RS-232 serial cable to the PC .

2. Is the port already in use by another application? Shut down any other applications that

may be using the port. Also, multiple instances of the Photon Camera Control Program

can be instantiated using different ports.

3. Is the Photon camera power on? Verify that the camera is producing an image on a

separate monitor.

Contact Indigo Customer Support at (805) 964-9797 if you cannot initiate serial communication

with the camera after verifying these items.

13

Page 14

Photon User Guide 412-0035-00-10 Version 100

Operation of the Photon Control Panel

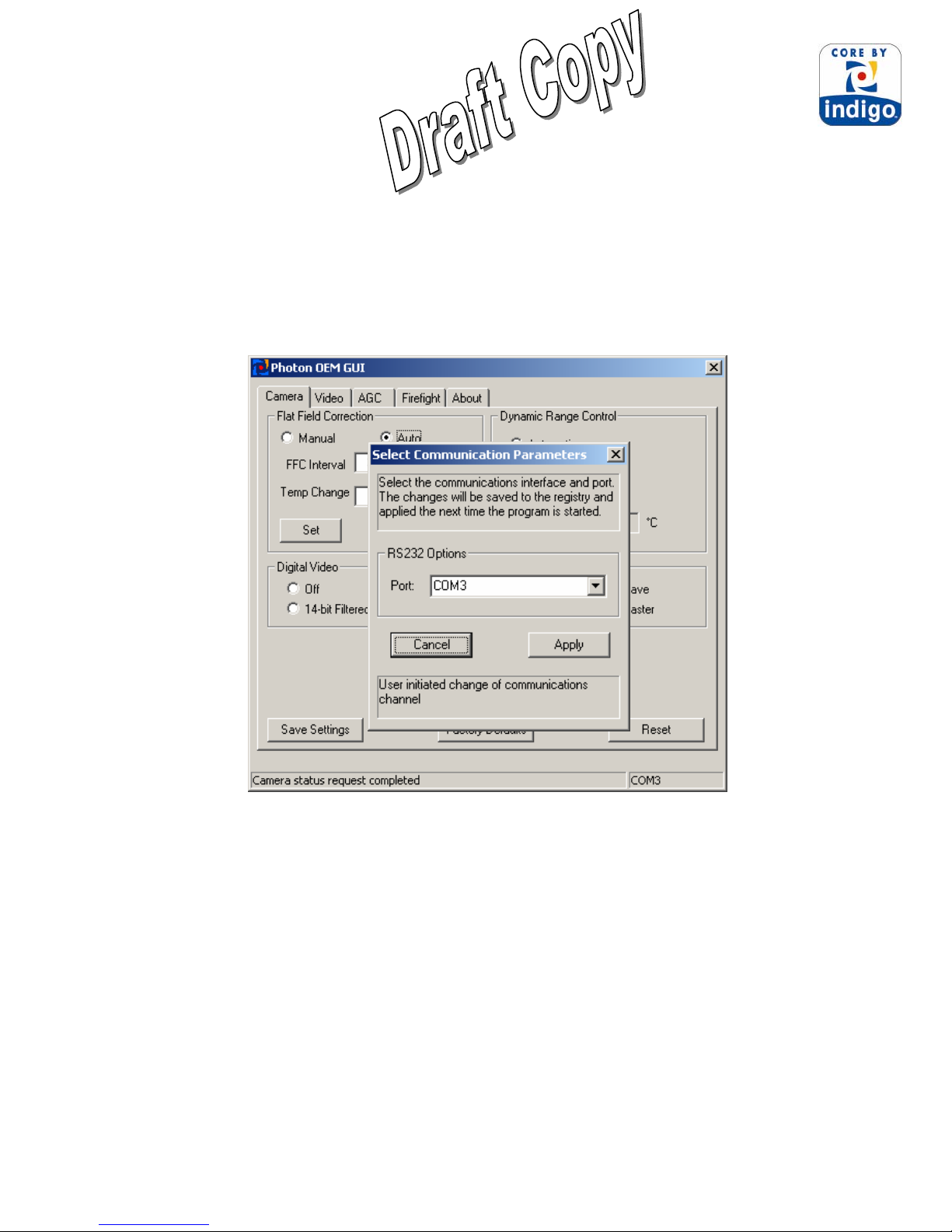

When the Control Panel successfully links to the camera, you may see the communications

window shown in Figure 7 then select the correct comm. Port and hit apply. The Control Panel

provides five tabs allowing for camera control as well as the ability to save/load configuration

settings and custom splash screens. It also provides a text message across the bottom showing

status information reported back from the camera after each command.

Figure 7: Photon Control Panel, Communication Tab

14

Page 15

Photon User Guide 412-0035-00-10 Version 100

7.1.1 Control Panel Camera Tab

The Camera Tab on the Control Panel, shown in Figure 8, provides the ability to modify the Flat

Field mode, the Digital Output mode as well as select the Dynamic Range and External Sync

modes.

Figure 8: Photon Control Panel, Camera Tab

Flat-Field-Correction Mode: Photon includes internal mechanisms for periodically

improving image quality via a process called “flat-field correction” (FFC). During FFC, a

small calibration flag rotates in front of the detector array, presenting a uniform temperature

(i.e. a “flat field”) to every detector element. While imaging the flat-field, the camera

updates correction coefficients, resulting in a more uniform array output. The video image is

frozen during the entire process, which takes approximately half a second, and it resumes

automatically thereafter. Repeating the FFC operation often prevents the imagery from

appearing “grainy”. This is especially important when camera temperature is fluctuating,

such as immediately after turn-on and/or when ambient temperature is drifting. FFC can be

commanded manually at any time using the FFC command in the Control Panel menu bar.

Photon provides two FFC modes for configuring automatic FFC conditions:

15

Page 16

Photon User Guide 412-0035-00-10 Version 100

1. Automatic. In the Automatic FFC mode, the camera performs FFC whenever its

temperature changes by a specified amount or at the end of a specified period of time

(whichever comes first). When this mode is selected, input windows are available on the

Control Panel for specifying the temperature change and the number of frames that

trigger automatic FFC. The temperature change is specified in degrees, with valid values

in the range 0 to 100 in 0.1 degree increments. The time period is specified in frames,

with valid values in the range 0 to 30,000 frames.

Note: It is recommended to use the factory default values for the two automatic-FFC

parameters if possible. These values were selected to maintain a high degree of image

quality over all camera operating conditions.

2. Manual

. In Manual FFC mode, the camera does not perform FFC automatically based on

specified values of temperature change or expired time.

Note: Even in manual FFC mode, Photon will perform automatic FFC when it changes

between low-temperature and high-temperature states. Furthermore, as the camera is

heated or cooled during operation, it will perform FFC automatically when its temperature

crosses through the different Non-Uniformity Correction tables.

On-Screen-Symbol: Photon uses on-screen symbols for displaying important camera status.

Specifically, the following indicator is provided:

a. FFC Imminent

: displayed nominally 2 seconds before automatic FFC.

Figure 9 shows the approximate size and location of this indicator on the display.

Figure 9: Approximate size and location of FFC-imminent indicator

Digital Output Modes: The Photon provides a digital data channel with four selectable

modes:

16

Page 17

Photon User Guide 412-0035-00-10 Version 100

1. Off. The digital data stream coming from the Photon camera is turned off.

2. 8-bit data. Data from the 320x240 (NTSC) or 320x255 video pixels (PAL) is provided

after application of the current AGC or Image-Optimization mode (refer to Section

7.1.2), isotherms, and on-screen symbols. The 8-bit data is essentially a digital version

of the same data provided on the analog video channel.

3. 14-bit data Filtered. Data from 324x256 pixels is provided prior to the video processing

modes in the 8-bit data described above. The 14-bit data is the *filtered* data to include

the Dynamic Detail Enhancement (DDE) and will appear gray when saving 16-bit TIFF

files.

4. 14-bit data Raw. Data from 324x256 pixels is provided prior to all video processing and

does not include the Dynamic Detail Enhancement. The 14-bit data is the *raw* data and

will also appear gray when saving 16-bit TIFF files.

Note: Only in the 8-bit mode will selecting AGC mode affect the digital data output.

Dynamic-Range Control Mode: Photon provides a low-temperature (high-sensitivity) state

intended for imaging scenes that are nominally less than 150 oC (302 oF) as well as a hightemperature (low-sensitivity) state intended for imaging up to 500 oC (932 oF). Three

Dynamic-Range-Control modes are provided for selecting the gain-state:

1. Automatic. In the optional Automatic mode, the camera automatically selects the

optimum state, low-temperature or high-temperature, based on scene content.

2. Low-Sensitivity. The camera operates exclusively in the high scene temperature (lowsensitivity) state.

3. High-Sensitivity. The camera operates exclusively in the low scene temperature (highsensitivity) state.

The current NUC table shows the active Non-Uniformity Correction table the camera is

using. The NUC table will automatically be selected when in Automatic mode.

Note: If your camera does not include the optional automatic dynamic-range-control feature,

you will not have the option of selecting this mode via the Control Panel. You will have the

ability to manually select Low Temp. or High Temp. modes.

FPA Temperature. The FPA Camera Temperature updates the automatically with a

measurement of camera FPA temperature. This temperature is measured on the camera’s

FPA or Focal Plane Array.

External Sync Mode: The Photon camera provides the ability to either accept or output

frame synchronization if needed. This functionality can also be disabled.

17

Page 18

Photon User Guide 412-0035-00-10 Version 100

1. Disabled Mode: The camera will turn off frame synchronization.

2. Slave Mode: The camera will accept a frame synchronization signal on the interface

connector.

3. Master Mode: The camera will output a frame synchronization signal on the interface

connector when configured as a master.

Note: See the Electrical Interface Control Document (ISC doc. 102-1238-41) for detailed

External Sync requirements.

Save Settings. After using the Control Panel to change all camera modes and settings to

desired values, use the Save Settings command to store your current selections as power-up

defaults. The next time the camera is powered, it will revert to the settings saved as defaults.

Factory Defaults. The Factory Defaults command restores the camera’s modes and settings

to the initial values originally specified by the manufacturer, replacing the customized

selections stored used in the Save Settings command.

Reset. The Reset command causes the camera to revert to its power-up default settings just

as if input power was toggled.

18

Page 19

Photon User Guide 412-0035-00-10 Version 100

7.1.2 Control Panel Video Tab

The Video Tab on the Control Panel, shown in Figure 10, provides the ability to modify six

different Photon modes: Image Orientation mode, Pan & Zoom, Polarity/LUT, Dynamic Detail

Enhancement, Video Standard mode and Test-Pattern mode.

Figure 10: Photon Control Panel, Video Tab

Image-Orientation Mode: Four Image-Orientation modes are provided:

1. Normal. The pixel on the upper-right corner of the detector array is displayed on the

upper-left corner of the video display in Normal mode.

2. Invert

. The pixel on the upper-left corner of the detector array is displayed on the upper-

left corner of the video display in Revert mode.

3. Revert. The pixel on the upper-left corner of the detector array is displayed on the upperleft corner of the video display in Revert mode.

4. Both

. The Invert and Revert display have been applied to the displayed data.

Notes: Revert mode (i.e. horizontal image flip) produces a mirror-image of Normal mode. It

is intended for applications in which the camera is imaged through a fold-mirror. Invert (i.e.

vertical image flip) can be accomplished by mounting the camera upside-down.

19

Page 20

Photon User Guide 412-0035-00-10 Version 100

Pan & Zoom: The Pan & Zoom also called PAN_AND_TILT command controls the camera

when the image is zoomed. It does not have any effect when the image is not zoomed. The

center of the screen is considered as coordinate (0,0). A positive number is needed to pan

right and negative number to pan left. A pan value of 1 pans to the right by one column and a

pan value of -1 pans to the left by one column from the center of the image. A positive

number is needed to tilt downwards and a negative number to tilt upwards. A tilt value of 1

tilts downwards by one row and a tilt value of -1 tilts upwards by one row from the center of

the image. When the image is being panned or tilted the ROI moves along with these

coordinates. The limits for the zoom ROI have been set to one and a half times the number of

rows and columns in the video. This is to enable a user to pan and tilt the zoomed portion of

the image without any change in the AGC if the image being looked at does not change. This

also means that the AGC of the image is also determined by portions of the image that is not

being currently viewed. An example of this is as shown in the Figure 11.

When the image is panned right to the maximum limit as shown in Figure 12, the number of

pixels in the ROI remains constant and the AGC of the image will not change.

Figure 11: ROI format

20

Page 21

Photon User Guide 412-0035-00-10 Version 100

ROI

VIDEO

Figure 12: Maximum ROI

If the ROI is set to the size of the visible portion of the zoomed image as shown in Figure 13 and

the image is tilted to the maximum limits as shown in Figure 14, pixels will not be dropped from

the ROI but the AGC will change as the ROI changes with the pan and tilt coordinates. The AGC

is determined only by the visible portion of the image.

Figure 13: ROI centered in video

If the ROI is set to larger than the visible portion of the zoomed image and smaller than one and

a half times the number of columns and rows as shown in Figure 15 and if the image is tilted to

the maximum limit, pixels are dropped from the ROI as shown in the Figure 16.

Figure 14: ROI at maximum tilt

21

Page 22

Photon User Guide 412-0035-00-10 Version 100

Figure 15: ROI larger than Zoomed video

Figure 16: ROI clipped

Note: Selecting the Pan & Zoom mode will not affect the digital data output.

Polarity/LUT: Imagery can be displayed in a variety of LUTs or Look Up Tables. The most

common selection is either white-hot (hotter objects brighter than cooler objects) or blackhot polarity (hotter objects darker than cooler objects). Table 8 shows each of the LUTs in a

ramp pattern starting with the upper left: White Hot, Black Hot, Fusion, Rainbow, Globow,

Ironbow1, Ironbow2, Sepia, Color1, Color2, Ice Fire and Rain. Select from the pull-down

menu and save settings once desired palette is selected.

Table 8: Photon LUTs

Note: Selecting Polarity/LUT mode will not affect the digital data output.

22

Page 23

Photon User Guide 412-0035-00-10 Version 100

Dynamic Detail Enhancement or DDE filter: This option applies a Bi-Lateral filter to

enhance image. The commands to control the DDE settings are Filter Gain to control the

gain, Filter Control to control the DDE filter threshold and Spatial Control to control the

spatial threshold of the DDE filter.

1. Filter Gain. The image remains unchanged when the value of the Filter Gain is 0 and 16.

The image becomes unfocussed/unsharpened when the value is between 1 and 15. The

image becomes more sharpened when the value is above 16. The Filter Gain can be set

between 0 and 250.

2. Filter Control

. Increasing the Filter Control, also called the threshold, will make the

edges sharper. For threshold values between 0 and about 50 the effect on the image is

lesser and has a greater effect above approximately 50. The Filter Control can be set

between 0 and 250.

3. Spatial Control

. Increasing the spatial threshold value will make the image look

smoother. The Spatial Control can be set between 0 and 255.

Note: In 14-bit Raw mode, selecting the DDE mode will not affect the digital data output.

Video Mode: Three Video modes are provided for configuring the camera output:

1. Real-Time. In this mode, the camera provides streaming thermal imagery in real-time.

2. Freeze-Frame. The camera freezes the image at the moment this mode is selected,

providing the same frame continuously.

3. Disabled. Infrared imagery is replaced by a uniform gray output in this mode.

Video Standard: Two Video modes are provided for configuring the camera video output:

1. NTSC

2. PAL

. The RS-170A or NTSC is a standard video format used in the United States.

. The CCIR or PAL is a standard video format used commonly in Europe.

23

Page 24

Photon User Guide 412-0035-00-10 Version 100

Test-Pattern Mode: A Test-Pattern mode is provided to verify camera electronics.

1. Off

. No test-pattern is provided in this mode. This is the normal mode for viewing

thermal imagery.

2. Ramp

. In this ramp mode, the test pattern shown in Figure 17 is provided at the analog

and digital data channels.

pix(0,0) = 0

pix(323,0) = 323

pix(183,50) = 16383

pix(184,50) = 0

Figure 17: Ramp test pattern

(Digital values shown apply to the optional 14-bit digital data stream.)

Note: The ramp test pattern is intended primarily for verifying the output of the digital data

channel. The pattern will not necessarily look as shown in Figure 17 when displayed on an

analog video monitor, particularly if an AGC mode other than Automatic is selected.

24

Page 25

Photon User Guide 412-0035-00-10 Version 100

7.1.3 Control Panel AGC Tab

The AGC Tab on the Control Panel, shown in Figure 18, provides the ability to modify three

different camera modes: AGC or Automatic Gain Control mode, AGC Parameters, Linear

Parameters and Region Of Interest or ROI.

Figure 18: Photon Control Panel, AGC Tab

AGC Mode: The Photon provides five AGC or Image-Optimization modes:

1. Automatic

. In Automatic mode, image contrast and brightness are optimized

automatically as the scene varies. This mode provides an Automatic Gain Control

(AGC) which is based on a histogram-equalization (HEQ) algorithm. The AGC

Parameters below allow for the Plateau, grey scale mid-point (ITT Mean) and Max Gain

terms of the Automatic to be manipulated based at the user’s need. The input windows

for specifying contrast, brightness, and brightness bias are grayed out on the Control

Panel when Automatic is enabled since they are not used in this mode.

25

Page 26

Photon User Guide 412-0035-00-10 Version 100

2. Auto-Bright. In Auto-Bright mode, image brightness is optimized automatically as the

scene varies but contrast is manually specified. Generally, Automatic AGC produces a

better image than Auto-Bright, but in some cases, specifying contrast manually can

improve the display of a specific feature in a scene. When Auto-Bright mode is selected,

input windows for specifying contrast and brightness-bias values are available on the

Control Panel. To specify a value, type it directly into the appropriate input window or

use the up/down arrow keys. Valid contrast values range from 0 to 255, with a smaller

value producing less contrast and a larger value producing more. The brightness bias

value ranges from –16383 to +16383. When brightness bias is 0, the camera applies the

value of brightness determined to be optimal for the current scene conditions.

Increasingly negative values cause a darker image than optimal whereas increasingly

positive values cause a brighter image.

3. Once Bright

. In Once Bright mode, image brightness and contrast are both specified

manually, which can occasionally improve the display of specific features in a scene,

particularly those that are significantly hotter or colder than the average scene

temperature. Upon entry into the Once Bright mode, Photon automatically optimizes the

value of brightness just as in Auto-Bright mode. However, the brightness value is not

continuously updated as the scene varies or as camera temperature changes. Valid

brightness values range from 0 to 16383, with a smaller value producing a darker image

and a larger value producing a brighter imager. Brightness bias is not used in this mode.

4. Manual

. Image brightness and contrast are both manually specified in Manual mode.

Unlike the Once Bright mode described above, the brightness value is not automatically

optimized upon entry into the Manual mode. Instead the last specified values for both

brightness and contrast are applied. (The power-on defaults are applied if brightness

and/or contrast have not already been specified using the Control Panel.) Brightness bias

is not used in this mode.

5. Linear Histogram. Image contrast and brightness (gain and level) are optimized

automatically based upon scene statistics using a linear transfer function. Controls for the

gray scale mid-point (ITT mean) and maximum gain (AGC gain) are adjustable using the

serial commands. The region of interest (ROI) for the histogram is adjustable using a

serial command. The corner locations (upper right and lower left) with respect to the

center of the image shall be used to determine the ROI location. Upon entry into the

linear histogram mode, the currently-stored values are applied (i.e. the power-on defaults

or the last saved values).

6. Logarithmic

. Image contrast and brightness (gain and level) optimized automatically

based upon scene statistics using a logarithmic transfer function. Controls for the gray

scale mid-point (ITT mean) and maximum gain (AGC gain) shall be adjustable using the

serial commands. The region of interest (ROI) for the histogram shall be adjustable using

a serial command. The corner locations (upper right and lower left) with respect to the

center of the image shall be used to determine the ROI location. Upon entry into the

linear histogram mode, the currently-stored values are applied (i.e. the power-on defaults

or the last saved values)

26

Page 27

Photon User Guide 412-0035-00-10 Version 100

Note: In Manual mode and Once Bright mode, the brightness setting must be updated as the

camera temperature changes. To avoid this issue, it is recommended to use Automatic or AutoBright modes when possible. Also, only in the 8-bit mode will selecting AGC mode affect the

digital data output.

Linear Parameters: The Linear Parameters are used for fine tuning the Auto Bright, Once

Bright and Manual modes. Each of their settings is described accordingly in detail above.

AGC Parameters: The AGC Parameters are used tuning the Automatic, Linear Histogram and

Logarithmic modes. Each of their setting is described accordingly in detail above.

Region Of Interest: The Photon camera allows the user to select the Region Of Interest that

which the AGC will use for it’s calculations. This Region Of Interest or ROI can be set for

either the entire frame size or some other portion as shown below in Figure 19. The settings are

similar to an X-Y coordinate system with 0,0 in the middle. Refer to the section for Pan & Zoom

on Page 4 for detail information on how these features work together.

Figure 19: Photon ROI defined

27

Page 28

Photon User Guide 412-0035-00-10 Version 100

7.1.4 Control Panel About Tab

The About Tab on the Control Panel, shown in Figure 20, provides information on the Photon

camera along with the ability to load splash screen and camera configuration.

Figure 20: Photon Control Panel, About Tab

Load Splash Screen. The Load Splash Screen option allows users to load a custom splash

screen to the Photon camera for use during startup. The file must be of size 324x256 (approx

83 KB) and a BMP format.

Camera Configuration. The Camera Configuration allows users to load a standard

configuration file (power on defaults) as well as load field upgrades.

Comm. Test. The Comm. Test command is a diagnostic feature for verifying the

communication link between the Control Panel and the Photon camera. Use this command if

you suspect that the camera and Control Panel are not communicating properly. The

message box in the lower left corner of the Control Panel will state “Communication test

completed” if the interface is working properly. If the message box reports “Camera

Timeout”, the link between the camera and Control Panel has been disrupted. Verify that the

camera is still powered and that the serial cable to the PC has not been disconnected. If you

cannot re-establish the Control Panel link, call FLIR Customer Support at (805) 964-9797 for

assistance.

28

Page 29

Photon User Guide 412-0035-00-10 Version 100

8 PHOTON DIGITAL DATA CHANNEL

Photon provides a digital data channel that provides thermal imagery in digital format. This

channel can be used in conjunction with commercially-available digital frame grabbers, digital

displays, or custom receive electronics. Again, for Photon users with embedded or specialty

applications that require custom control software, a Software Developer’s Kit (SDK) and an

Interface Control Document (ICD) are available to support your development efforts.

The digital data channel can be configured to output 14-bit data after application of calibration

terms. This mode is most useful for external signal-processing and/or analysis of the camera

output. The digital channel can also be configured to provide 8-bit data after application of

video processing algorithms (e.g. “automatic”, white-hot/black-hot polarity, image orientation,

DDE filtered, and on-screen symbols). The 8-bit data is essentially a digital version of the video

stream provided on the analog video channel and is therefore more appropriate than the 14-bit

data for interfacing to a digital display.

The digital data channel employs serial low-voltage differential signaling (LVDS). The channel

consists of three signal lines – a clock, a composite sync (frame sync and line sync), and serial

data. A serial-in-parallel-out (SIPO) module is available from FLIR Systems for converting the

serial data to 14-bit parallel LVDS output (plus frame sync, line sync, and pixel clock). The

parallel data can be captured using a frame-grabber board installed in a PC. Two commercial

frame grabbers are currently supported: Bitflow Road Runner PCI 12 and National Instruments

PCI-1422. Cabling and software configuration files for either frame grabber are available from

Indigo Systems.

Indigo also offers an optional digital data converters such as the Ethernet Module. The Ethernet

Module connects the Photon digital output directly to a LAN using standard CAT-5 LAN cable.

Using either the Ethernet Module allows for digital output and camera control via the Photon

SDK software directly to a PC.

For users intending to interface directly to the camera’s serial digital data channel, detailed

timing and format information is provided in the ICD (ISC doc. 102.1238.41). Information on

the timing and data format of the parallel output is also provided in separate ICD specific to the

SIPO module (ISC doc. 333.0008.19). Please contact FLIR Systems Customer Support to

request either of these documents.

Using the Digital Data Channel

Note: The following instructions assume that you have purchased the optional serial-to-parallelout (SIPO) accessory module with parallel data cable. If you are using the Ethernet module,

29

Page 30

Photon User Guide 412-0035-00-10 Version 100

follow the instructions with the device. If you are using custom cabling and/or interface

electronics, contact FLIR Systems Customer Support at (805) 964-9797 if you need additional

assistance.

1. Follow the steps shown in Section 6 for basic operation of the Photon camera. After

verifying that the camera is operating properly, disconnect power from the Interface

Module.

2. Connect the SIPO accessory module directly to the three-row DB15 connector on the

Interface Module labeled “DIGITAL DATA”. (No cabling is required.)

3. Connect the parallel data cable to the mating connector on the SIPO module. Connect

the other end to the frame-grabber board installed in your PC.

Note: The parallel data cable is specific to a particular frame grabber. In other words, a

parallel data cable intended to mate to a Bitflow frame grabber will not mate with a

National Instruments frame grabber or vice versa.

4. Follow instructions included with the frame grabber for selecting the camera

configuration file included with the SIPO module.

5. Reapply power to the Interface Module. This will power-up both the Photon camera and

the SIPO module, and digital data will begin streaming.

6. If desired, change the digital data mode using the Control Panel software (see Section

7.1.1).

9 PHOTON PHYSICAL INTERFACE

Dimensioned Drawings

A dimensional drawing for each lens configuration is shown in Table 9 . The Table 9 also shows

a list of corresponding ICDs or Interface Control Documents of the Photon camera in the 14.25

mm, 19 mm, 30 mm, 35 mm and 50 mm lens configurations, respectively.

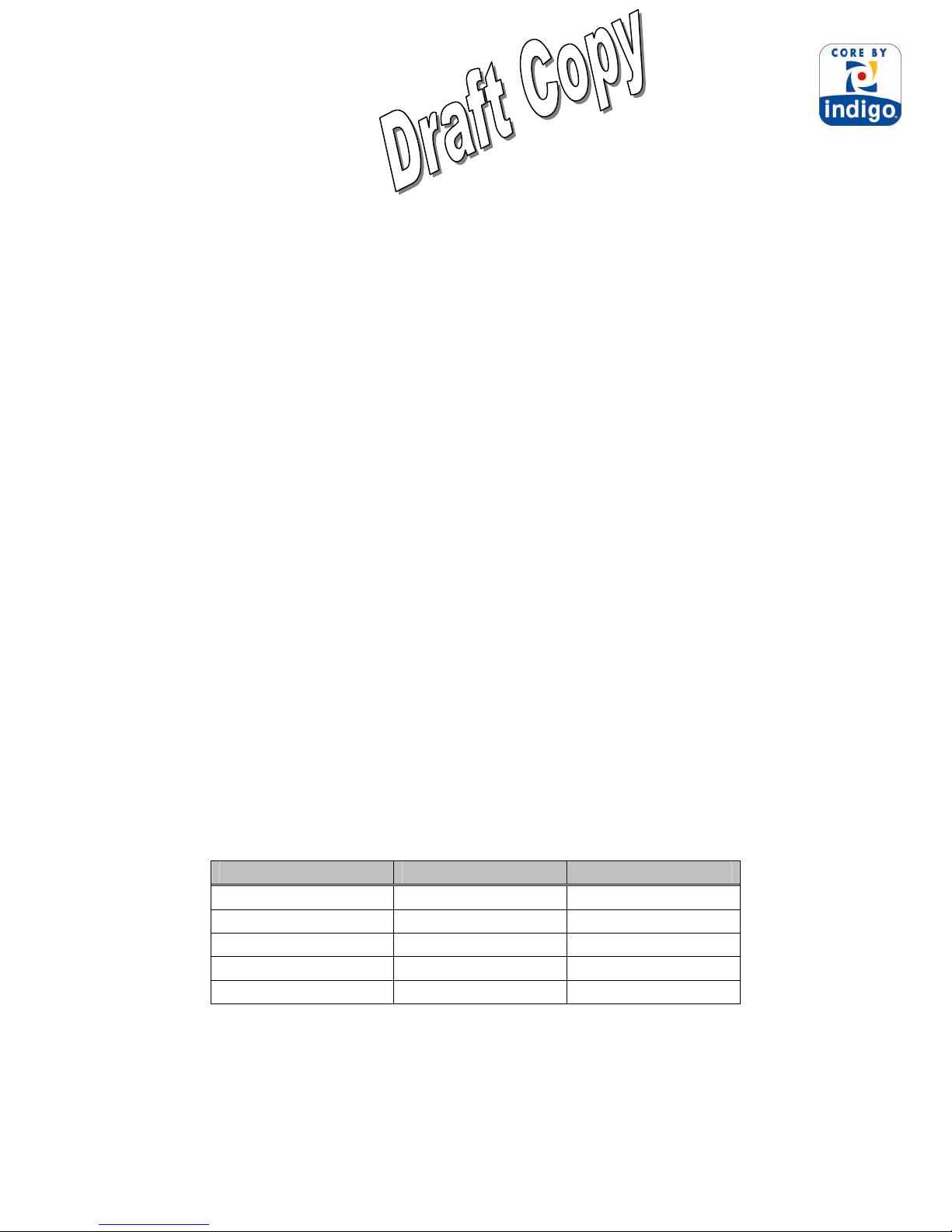

Table 9: Photon Lens Configurations

Figure Number Nominal focal length ICD

Figure 21 14.25 mm 102-1239-78

Figure 22 19 mm

Figure 23 30 mm

Figure 24 35 mm

Figure 25 50 mm

102-1239-77

102-1239-78

102-1239-80

102-1239-83

Weight

Below in Table 10 are the combined weight of the Photon Camera core and the lens.

30

Page 31

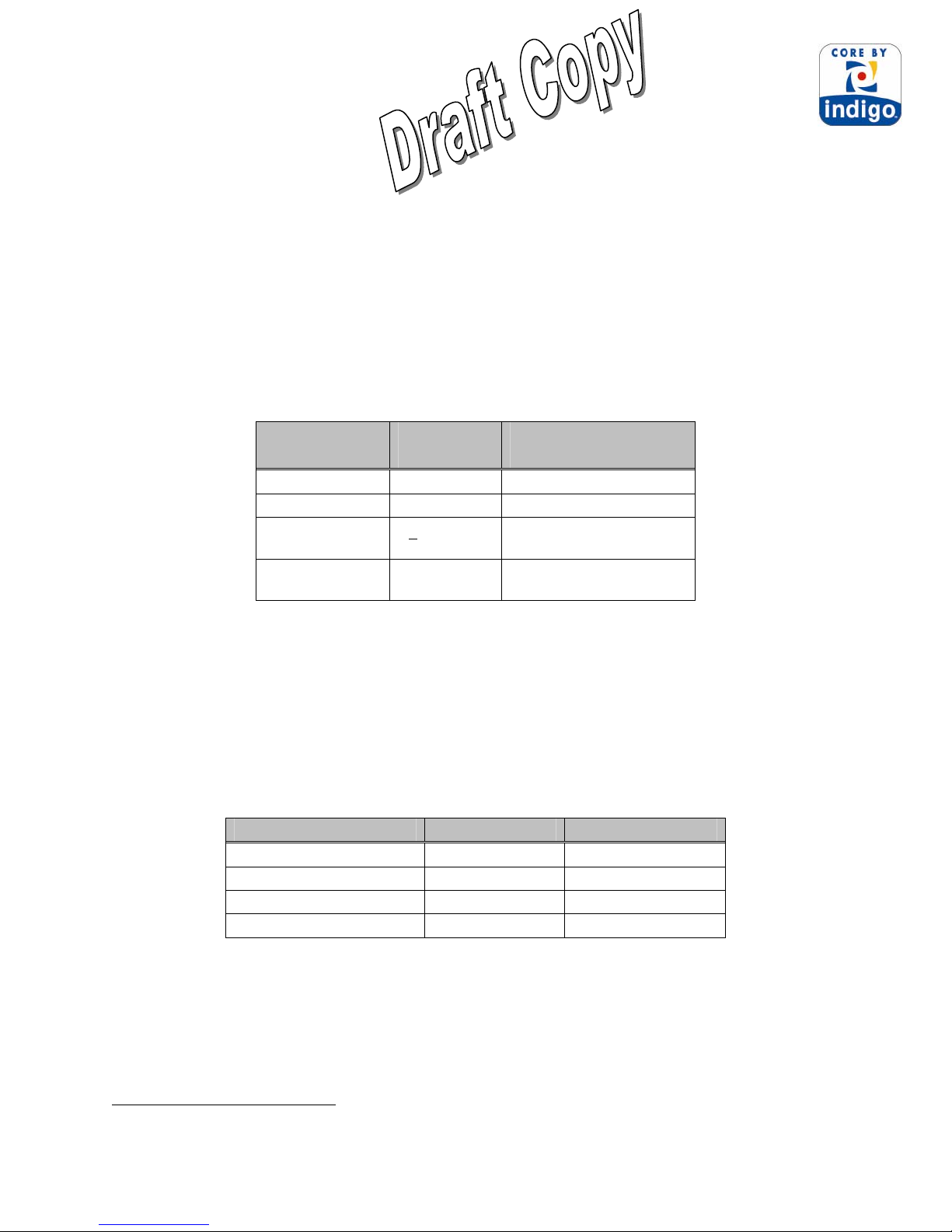

Photon User Guide 412-0035-00-10 Version 100

Table 10: Photon Camera Core and Lens Combined Weight

Photon camera focal

length

14.25 mm

19 mm

30 mm

35 mm

50 mm

Weight

Mounting

There is a single threaded mounting hole on the bottom surface of the camera. For precision

alignment, there is also a hole on the bottom surface that allows an anti-clocking pin to be

installed in the mounting platform.

31

Page 32

Photon User Guide 412-0035-00-10 Version 100

32

Figure 21: Photon 14-mm lens configuration

Page 33

Photon User Guide 412-0035-00-10 Version 100

33

Figure 22: Photon 19-mm lens configuration

Page 34

Photon User Guide 412-0035-00-10 Version 100

34

Figure 23: Photon 30-mm lens configuration

Page 35

Photon User Guide 412-0035-00-10 Version 100

35

Figure 24: Photon 35-mm lens configuration

Page 36

Photon User Guide 412-0035-00-10 Version 100

36

Figure 25: Photon 50-mm lens configuration

Page 37

Photon User Guide 412-0035-00-10 Version 100

APPENDIX A: PIN-OUT DEFINITIONS

I/O Module

Camera Connector: Same as camera connector. See Table 1for valid mates.

Power Connector

Video Connector

Serial Connector

Digital Data Connector

: Mates to Switchcraft S760 Miniature Power Plug.

: Mates to 75Ω BNC twist-on plug.

: Mates to DB9 Male.

: Mates to Three-Row DB15 Female.

Table A1: I/O Module Power Connector Pin-Out

Pin # Signal Name Signal Definition

Pin PWR input power

Sleeve PWR_RTN input power return

Table A2: I/O Module Video Connector Pin-Out

Pin # Signal Name Signal Definition

Pin VIDEO analog video output

Sleeve VIDEO_RTN analog video return

Table A3: I/O Module Serial Connector Pin-Out

Pin # Signal Name Signal Definition

2 RX_232 RS232 Receive channel

3 TX_232 RS232 Transmit channel

5 DGND Digital Ground

1,4, 6-9 NC Spare (do not connect)

37

Page 38

Photon User Guide 412-0035-00-10 Version 100

Table A4: I/O Module Digital Data Connector Pin-Out

Pin # Signal Name Signal Definition

1 DATA_SYNC+ Digital data sync (LVDS high)

2 DATA_OUT+ Digital data output channel (LVDS high)

4 DATA_CLK+ Digital output channel clock (LVDS high)

6 DATA_SYNC- Digital data sync (LVDS low)

7 DATA_OUT- Digital data output channel (LVDS low)

9 DATA_CLK- Digital output channel clock (LVDS low)

10 DGND Digital ground

11 PWR input power (connected to power connector pin)

12 PWR_RTN input power return (connected to power connector

sleeve)

13 NC Spare (do not connect)

3,5,8,14,15 NC Spare (do not connect)

38

Loading...

Loading...