Page 1

User’s manual

FLIR Exx series

T559597Publ. No.

a500Revision

English (EN)Language

December 10, 2010Issue date

Page 2

Page 3

User’s manual

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 4

Legal disclaimer

All products manufactured by FLIR Systemsarewarranted against defectivematerialsandworkmanship for aperiodof one(1)year from the

delivery date of the original purchase, provided such products have been under normal storage, use and service, and in accordance with

FLIR Systems instruction.

Products which are not manufactured by FLIR Systems but included in systems delivered by FLIR Systems to the original purchaser, carry

the warranty, if any, of the particular supplier only. FLIR Systems has no responsibility whatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It is not applicable to any product which has been subjected to

misuse, neglect, accident or abnormal conditions of operation. Expendable parts are excluded from the warranty.

In the case of adefect inaproduct coveredbythis warrantytheproduct must notbe furtherusedin order toprevent additional damage.The

purchaser shall promptly report any defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, at its option, repair or replace any such defective product free of charge if, upon inspection, it proves to be defective in

material or workmanship and provided that it is returned to FLIR Systems within the said one-year period.

FLIR Systems has no other obligation or liability for defects than those set forth above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims the implied warranties of merchantability and fitness for a

particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidentalor consequential loss or damage, whether basedon contract, tort

or any other legal theory.

This warranty shall be governed by Swedish law.

Any dispute, controversy or claim arising out of or in connection with this warranty, shall be finally settled by arbitration in accordance with

the Rules of the Arbitration Institute of the Stockholm Chamber of Commerce. The place of arbitration shall be Stockholm. The language to

be used in the arbitral proceedings shall be English.

U.S. Government Regulations

The products described in the user documentation may require government authorization for export/re-export, or transfer. Contact FLIR

■

Systems for details.

Depending on license andexportprocedures,lensesmaybe permanently fixedtocamerasshippedtocustomersoutsideUnited States.

■

Interchangeable lenses fall under U.S. Department of State jurisdiction.

Copyright

© 2010, FLIRSystems. All rights reservedworldwide. No parts ofthesoftware including source codemaybe reproduced, transmitted, transcribed

or translated into any language or computer language in any form or by any means, electronic, magnetic, optical, manual or otherwise,

without the prior written permission of FLIR Systems.

This documentation must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic medium or

machine readable form without prior consent, in writing, from FLIR Systems.

Names and marks appearing on the products herein are eitherregistered trademarksor trademarksof FLIR Systems and/or its subsidiaries.

All othertrademarks,trade names or companynames referenced herein areusedfor identification only andarethe property of theirrespective

owners.

Quality assurance

The Quality Management System under which these products are developed and manufactured has been certified in accordance with the

ISO 9001 standard.

FLIR Systems is committed to a policy of continuous development; therefore we reserve the right to make changes and improvements on

any of the products described in this manual without prior notice.

Patents

One or several of the following patents or design patents apply to the products and/or features described in this manual:

0002258-2; 000279476-0001; 000439161; 000499579-0001; 000653423; 000726344; 000859020; 000889290; 001106306-0001; 0101577-5;

0102150-0; 0200629-4; 0300911-5; 0302837-0; 1144833; 1182246; 1182620; 1188086; 1263438; 1285345; 1287138; 1299699; 1325808;

1336775; 1365299; 1678485; 1732314; 200530018812.0; 200830143636.7; 2106017; 235308; 3006596; 3006597; 466540; 483782; 484155;

518836; 60004227.8;60122153.2;602004011681.5-08; 6707044; 68657; 7034300;7110035;7154093; 7157705; 7237946; 7312822;7332716;

7336823; 7544944; 75530; 7667198; 7809258; 7826736; D540838; D549758; D579475; D584755; D599,392; DI6702302-9; DI6703574-4;

DI6803572-1; DI6803853-4; DM/057692; DM/061609; ZL00809178.1; ZL01823221.3; ZL01823226.4; ZL02331553.9; ZL02331554.7;

ZL200480034894.0; ZL200530120994.2; ZL200630130114.4; ZL200730151141.4; ZL200730339504.7; ZL200830128581.2.

EULA Terms

You have acquired a device (“INFRARED CAMERA”) that includes software licensed by FLIR Systems AB from Microsoft Licensing, GP

■

or its affiliates (“MS”). Those installed software products of MS origin, as well as associated media, printed materials, and “online” or

electronic documentation(“SOFTWARE”)are protected by internationalintellectualproperty laws and treaties.TheSOFTWARE is licensed,

not sold. All rights reserved.

iv Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 5

IF YOU DO NOTAGREE TO THISENDUSER LICENSE AGREEMENT(“EULA”), DONOT USE THEDEVICEOR COPY THE SOFTWARE.

■

INSTEAD, PROMPTLY CONTACT FLIR Systems AB FOR INSTRUCTIONS ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND.

ANY USE OF THE SOFTWARE, INCLUDING BUT NOT LIMITED TO USE ON THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT

TO THIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

GRANT OF SOFTWARE LICENSE. This EULA grants you the following license:

■

You may use the SOFTWARE only on the DEVICE.

■

NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. FLIR Systems AB HAS INDEPENDENTLY DETERMINED

■

HOW TOUSE THE SOFTWAREIN THE DEVICE,AND MS HASRELIED UPON FLIRSystems AB TOCONDUCT SUFFICIENT TESTING

TO DETERMINE THAT THE SOFTWARE IS SUITABLE FOR SUCH USE.

NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided “AS IS” and with all faults. THE ENTIRE RISK AS TO SAT-

■

ISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU. ALSO,

THERE ISNO WARRANTY AGAINSTINTERFERENCE WITH YOURENJOYMENT OF THESOFTWAREOR AGAINST INFRINGEMENT.

IF YOU HAVE RECEIVED ANY WARRANTIES REGARDING THE DEVICE OR THE SOFTWARE, THOSE WARRANTIES DO NOT

ORIGINATE FROM, AND ARE NOT BINDING ON, MS.

No Liability for Certain Damages. EXCEPT AS PROHIBITED BY LAW, MS SHALL HAVE NO LIABILITY FOR ANY INDIRECT,

■

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL APPLY EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE.

IN NO EVENT SHALL MS BE LIABLE FOR ANY AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

Limitations on Reverse Engineering, Decompilation, and Disassembly. Youmay not reverse engineer, decompile,or disassemble

■

the SOFTWARE, exceptand only to the extentthat such activity isexpresslypermitted by applicable lawnotwithstandingthis limitation.

SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS. Youmaypermanentlytransferrights under this EULA only aspart

■

of a permanent sale or transfer of the Device, and only if the recipient agrees to this EULA. If the SOFTWARE is an upgrade, any

transfer must also include all prior versions of the SOFTWARE.

EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is subject to U.S. export jurisdiction. You agree to comply with all

■

applicable international andnationallawsthatapplytotheSOFTWARE, includingthe U.S. Export Administration Regulations,aswell

as end-user, end-use and destination restrictions issued by U.S. and other governments. For additional information see

http://www.microsoft.com/exporting/.

TAT The Astonishing Tribe powers the user interface of this FLIR product. TAT Cascades (UI Framework) is

recognized for its graphics capabilities, time-to-market savings, resource efficiency and platform independence,

providing a more dynamic, faster and richer user experience.

TAT - The Astonishing Tribe™, the TAT logo, TAT Cascades™, TAT Motion Lab™, TAT Kastor™, the Design ♥

Technology tagline and the TAT product logos are either registered trademarks or trademarks of TAT - The

Astonishing Tribe AB in Sweden and/or other countries.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 6

vi Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 7

Table of contents

11 Warnings & Cautions .....................................................................................................................

32 Notice to user ..................................................................................................................................

43 Customer help ................................................................................................................................

54 Documentation updates .................................................................................................................

65 Important note about this manual .................................................................................................

76 Parts lists .........................................................................................................................................

76.1 Scope of delivery ..................................................................................................................

86.2 List of accessories and services ...........................................................................................

97 Quick Start Guide ...........................................................................................................................

108 Camera parts ...................................................................................................................................

108.1 View from the right ................................................................................................................

118.2 View from the left ..................................................................................................................

128.3 Keypad ..................................................................................................................................

148.4 View from the bottom ...........................................................................................................

158.5 Battery condition LED indicator ............................................................................................

168.6 Power LED indicator .............................................................................................................

178.7 Laser pointer .........................................................................................................................

199 Screen elements .............................................................................................................................

2010 Navigating the menu system .........................................................................................................

2111 Connecting external devices and storage media .......................................................................

2312 Pairing Bluetooth devices ..............................................................................................................

2413 Handling the camera ......................................................................................................................

2413.1 Turning on the camera .........................................................................................................

2413.2 Turning off the camera ..........................................................................................................

2513.3 Adjusting the infrared camera focus manually ....................................................................

2613.4 Operating the laser pointer ...................................................................................................

2714 Working with images ......................................................................................................................

2714.1 Previewing an image ............................................................................................................

2814.2 Saving an image ...................................................................................................................

2914.3 Opening an image ................................................................................................................

3014.4 Adjusting an image ...............................................................................................................

3314.5 Changing the palette ............................................................................................................

3414.6 Deleting an image .................................................................................................................

3514.7 Deleting all images ...............................................................................................................

3614.8 Creating a PDF report in the camera ...................................................................................

3715 Working with measurement tools .................................................................................................

3715.1 Laying out a measurement tool ............................................................................................

3815.2 Moving or resizing a measurement tool ...............................................................................

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 vii

Page 8

3915.3 Creating and setting up a difference calculation .................................................................

4015.4 Changing object parameters ................................................................................................

4216 Fetching data from external Extech meters .................................................................................

4416.1 Typical moisture measurement and documentation procedure ..........................................

4517 Working with alarms .......................................................................................................................

4517.1 Building alarms .....................................................................................................................

4618 Annotating images ..........................................................................................................................

4718.1 Taking a digital photo ...........................................................................................................

4818.2 Creating a text annotation ....................................................................................................

4919 Changing settings ..........................................................................................................................

5020 Cleaning the camera ......................................................................................................................

5020.1 Camera housing, cables, and other items ...........................................................................

5120.2 Infrared lens ..........................................................................................................................

5220.3 Infrared detector ...................................................................................................................

5321 Technical data .................................................................................................................................

5421.1 Additional data ......................................................................................................................

5522 Dimensional drawings ...................................................................................................................

5522.1 Camera dimensions, front view (1) ......................................................................................

5622.2 Camera dimensions, front view (2) ......................................................................................

5722.3 Camera dimensions, side view (1) .......................................................................................

5822.4 Camera dimensions, side view (2) .......................................................................................

5922.5 Camera dimensions, side view (3) .......................................................................................

6022.6 Infrared lens (30 mm/15°) .....................................................................................................

6122.7 Infrared lens (10 mm/45°) .....................................................................................................

6222.8 Battery (1) .............................................................................................................................

6322.9 Battery (2) .............................................................................................................................

6422.10 Battery (3) .............................................................................................................................

6522.11 Battery charger (1) ................................................................................................................

6622.12 Battery charger (2) ................................................................................................................

6722.13 Battery charger (3) ................................................................................................................

6822.14 Battery charger (4) ................................................................................................................

6923 Application examples .....................................................................................................................

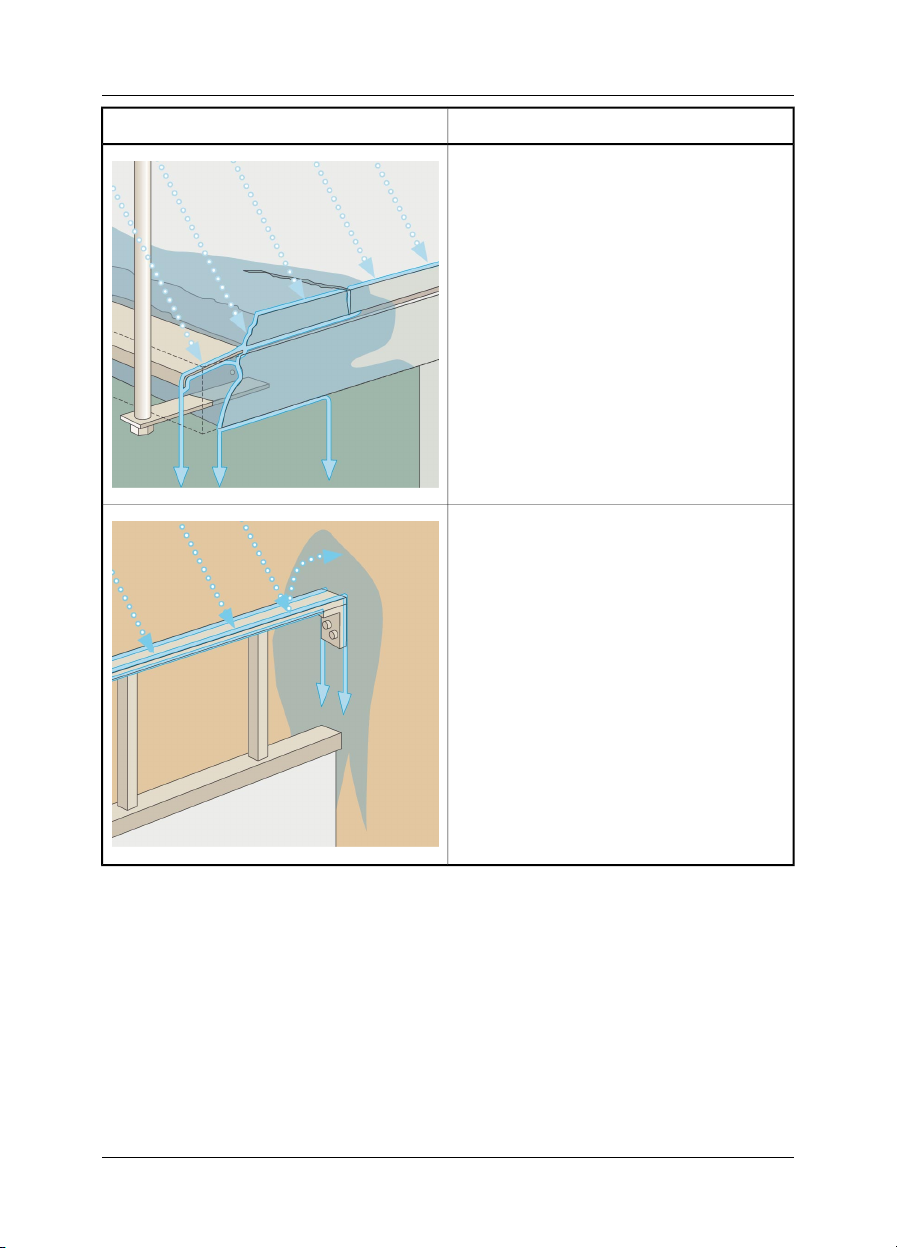

6923.1 Moisture & water damage ....................................................................................................

7023.2 Faulty contact in socket ........................................................................................................

7123.3 Oxidized socket ....................................................................................................................

7223.4 Insulation deficiencies ..........................................................................................................

7323.5 Draft ......................................................................................................................................

7424 Introduction to building thermography ........................................................................................

7424.1 Disclaimer .............................................................................................................................

7424.1.1 Copyright notice ...................................................................................................

7424.1.2 Training & certification ..........................................................................................

7424.1.3 National or regional building codes .....................................................................

7424.2 Important note ......................................................................................................................

7524.3 Typical field investigations ....................................................................................................

7524.3.1 Guidelines .............................................................................................................

7524.3.1.1 General guidelines ............................................................................

viii Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 9

24.3.1.2 Guidelines for moisture detection, mold detection & detection of

water damages ..................................................................................

24.4.8 Excerpt from Technical Note ‘Assessing thermal bridging and insulation

continuity’ (UK example) ......................................................................................

75

7624.3.1.3 Guidelines for detection of air infiltration & insulation deficiencies ...

7724.3.2 About moisture detection .....................................................................................

7724.3.3 Moisture detection (1): Low-slope commercial roofs ..........................................

7724.3.3.1 General information ...........................................................................

7824.3.3.2 Safety precautions ............................................................................

7924.3.3.3 Commented building structures .......................................................

8024.3.3.4 Commented infrared images ............................................................

8224.3.4 Moisture detection (2): Commercial & residential façades ..................................

8224.3.4.1 General information ...........................................................................

8224.3.4.2 Commented building structures .......................................................

8424.3.4.3 Commented infrared images ............................................................

8424.3.5 Moisture detection (3): Decks & balconies ..........................................................

8424.3.5.1 General information ...........................................................................

8524.3.5.2 Commented building structures .......................................................

8724.3.5.3 Commented infrared images ............................................................

8724.3.6 Moisture detection (4): Plumbing breaks & leaks ................................................

8724.3.6.1 General information ...........................................................................

8824.3.6.2 Commented infrared images ............................................................

9024.3.7 Air infiltration .........................................................................................................

9024.3.7.1 General information ...........................................................................

9024.3.7.2 Commented building structures .......................................................

9224.3.7.3 Commented infrared images ............................................................

9324.3.8 Insulation deficiencies ..........................................................................................

9324.3.8.1 General information ...........................................................................

9324.3.8.2 Commented building structures .......................................................

9524.3.8.3 Commented infrared images ............................................................

9724.4 Theory of building science ...................................................................................................

9724.4.1 General information ..............................................................................................

9824.4.2 The effects of testing and checking .....................................................................

9924.4.3 Sources of disruption in thermography ................................................................

10124.4.4 Surface temperature and air leaks .......................................................................

10124.4.4.1 Pressure conditions in a building .....................................................

10724.4.5 Measuring conditions & measuring season .........................................................

10724.4.6 Interpretation of infrared images ..........................................................................

10924.4.7 Humidity & dew point ...........................................................................................

10924.4.7.1 Relative & absolute humidity ............................................................

10924.4.7.2 Definition of dew point ......................................................................

109

10924.4.8.1 Credits ...............................................................................................

11024.4.8.2 Introduction .......................................................................................

11024.4.8.3 Background information ...................................................................

11124.4.8.4 Quantitative appraisal of thermal anomalies ....................................

11424.4.8.5 Conditions and equipment ...............................................................

11524.4.8.6 Survey and analysis ..........................................................................

11624.4.8.7 Reporting ...........................................................................................

11825 Introduction to thermographic inspections of electrical installations ......................................

11825.1 Important note ......................................................................................................................

11825.2 General information ..............................................................................................................

11825.2.1 Introduction ...........................................................................................................

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 ix

Page 10

11925.2.2 General equipment data .......................................................................................

12025.2.3 Inspection .............................................................................................................

12025.2.4 Classification & reporting ......................................................................................

12125.2.5 Priority ...................................................................................................................

12125.2.6 Repair ....................................................................................................................

12225.2.7 Control ..................................................................................................................

12325.3 Measurement technique for thermographic inspection of electrical installations ...............

12325.3.1 How to correctly set the equipment .....................................................................

12325.3.2 Temperature measurement ...................................................................................

12525.3.3 Comparative measurement ..................................................................................

12625.3.4 Normal operating temperature .............................................................................

12725.3.5 Classification of faults ...........................................................................................

12925.4 Reporting ..............................................................................................................................

13125.5 Different types of hot spots in electrical installations ...........................................................

13125.5.1 Reflections ............................................................................................................

13125.5.2 Solar heating .........................................................................................................

13225.5.3 Inductive heating ...................................................................................................

13225.5.4 Load variations ......................................................................................................

13325.5.5 Varying cooling conditions ...................................................................................

13425.5.6 Resistance variations ............................................................................................

13425.5.7 Overheating in one part as a result of a fault in another ......................................

13625.6 Disturbance factors at thermographic inspection of electrical installations ........................

13625.6.1 Wind ......................................................................................................................

13625.6.2 Rain and snow ......................................................................................................

13725.6.3 Distance to object .................................................................................................

13825.6.4 Object size ............................................................................................................

14025.7 Practical advice for the thermographer ................................................................................

14025.7.1 From cold to hot ...................................................................................................

14025.7.2 Rain showers ........................................................................................................

14025.7.3 Emissivity ..............................................................................................................

14125.7.4 Reflected apparent temperature ...........................................................................

14125.7.5 Object too far away ...............................................................................................

14226 About FLIR Systems .......................................................................................................................

14326.1 More than just an infrared camera .......................................................................................

14426.2 Sharing our knowledge ........................................................................................................

14426.3 Supporting our customers ...................................................................................................

14426.4 A few images from our facilities ...........................................................................................

14627 Glossary ...........................................................................................................................................

15028 Thermographic measurement techniques ...................................................................................

15028.1 Introduction ..........................................................................................................................

15028.2 Emissivity ..............................................................................................................................

15128.2.1 Finding the emissivity of a sample .......................................................................

15128.2.1.1 Step 1: Determining reflected apparent temperature .......................

15328.2.1.2 Step 2: Determining the emissivity ...................................................

15428.3 Reflected apparent temperature ..........................................................................................

15428.4 Distance ................................................................................................................................

15428.5 Relative humidity ..................................................................................................................

15428.6 Other parameters ..................................................................................................................

15529 History of infrared technology ......................................................................................................

x Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 11

15930 Theory of thermography ................................................................................................................

15930.1 Introduction ...........................................................................................................................

15930.2 The electromagnetic spectrum ............................................................................................

16030.3 Blackbody radiation ..............................................................................................................

16130.3.1 Planck’s law ..........................................................................................................

16230.3.2 Wien’s displacement law ......................................................................................

16430.3.3 Stefan-Boltzmann's law .........................................................................................

16530.3.4 Non-blackbody emitters .......................................................................................

16730.4 Infrared semi-transparent materials .....................................................................................

16931 The measurement formula .............................................................................................................

17532 Emissivity tables .............................................................................................................................

17532.1 References ............................................................................................................................

17532.2 Important note about the emissivity tables ..........................................................................

17632.3 Tables ....................................................................................................................................

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 xi

Page 12

xii Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 13

1 Warnings & Cautions

This equipment generates, uses, and can radiate radio frequency energy and if

WARNING

■

not installed and used in accordance with the instruction manual, may cause interference to radio communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designedto providereasonable protection againstsuch interference when operated in a commercial environment. Operation of this equipment

in a residential area is likely to cause interference in which case the user at his

own expense will be required to take whatever measures may be required to

correct the interference.

(Applies only to cameras with laser pointer:) Do not look directly into the laser

■

beam. The laser beam can cause eye irritation.

Applies only to cameras with battery:

■

Do not disassemble or do a modification to the battery. The battery contains

■

safety and protection devices which, if they become damaged, can cause the

battery to become hot, or cause an explosion or an ignition.

If there is a leak from the battery and the fluid gets into your eyes, do not rub

■

your eyes.Flush well withwater and immediatelyget medical care. Thebattery

fluid can cause injury to your eyes if you do not do this.

Do not continue to charge the battery if it does not become charged in the

■

specified charging time. If you continue to charge the battery, it can become

hot and cause an explosion or ignition.

Only use the correct equipment to discharge the battery. If you do not use the

■

correct equipment, you can decrease the performance or the life cycle of the

battery. If you do not use the correct equipment, an incorrect flow of current

to the battery can occur. This can cause the battery to become hot, or cause

an explosion and injury to persons.

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and

■

warning labelson containersbeforeyou usea liquid: theliquids can bedangerous.

Do not point theinfrared camera (withor without the lens cover)at intensive energy

CAUTION

■

sources, for example devices that emit laser radiation, or the sun. This can have

an unwanted effect on the accuracy of the camera. It can also cause damage to

the detector in the camera.

Do not use the camera in a temperature higher than +50°C (+122°F), unless

■

specified otherwise in the user documentation. High temperatures can cause

damage to the camera.

(Applies only to cameras with laser pointer:) Protect the laser pointer with the

■

protective cap when you do not operate the laser pointer.

Applies only to cameras with battery:

■

Do not attach the batteries directly to a car’s cigarette lighter socket, unless a

■

specific adapter for connecting the batteries to a cigarette lighter socket is

provided by FLIR Systems.

Do not connect the positive terminal and the negative terminal of the battery

■

to each other with a metal object (such as wire).

Do not get water or salt water on the battery, or permit the battery to get wet.

■

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 1

Page 14

1 – Warnings & Cautions

■

■

■

■

■

■

Do not make holes in the battery with objects. Do not hit the battery with a

■

hammer. Do not step on the battery, or apply strong impacts or shocks to it.

Do not put thebatteries inor near a fire, orinto direct sunlight. When thebattery

■

becomes hot, the built-in safety equipment becomes energized and can stop

the battery charging process. If the battery becomes hot, damage can occur

to the safety equipment and this can cause more heat, damage or ignition of

the battery.

Do not put the battery on a fire or increase the temperature of the battery with

■

heat.

Do not put the battery on or near fires, stoves, or other high-temperature loca-

■

tions.

Do not solder directly onto the battery.

■

Do not use the battery if, when you use, charge, or store the battery, there is

■

an unusual smell fromthe battery,the battery feelshot, changes color, changes

shape, or is in an unusual condition. Contact your sales office if one or more

of these problems occurs.

Only use a specified battery charger when you charge the battery.

■

The temperature range through which you can charge the battery is ±0°C to

■

+45°C (+32°F to +113°F), unless specified otherwise in the user documentation. If you charge the battery at temperatures out of this range, it can cause

the battery to become hot or to break. It can also decrease the performance

or the life cycle of the battery.

The temperature range through which you can dischargethe battery is −15°C

■

to +50°C (+5°F to +122°F), unless specified otherwise in the user documentation. Use of the battery out of this temperature range can decrease the performance or the life cycle of the battery.

When the battery is worn, apply insulation to the terminals with adhesive tape

■

or similar materials before you discard it.

Remove any water or moisture on the battery before you install it.

■

Do not apply solvents or similar liquids to the camera, the cables, or other items.

This can cause damage.

Be careful when you cleanthe infraredlens. The lens has a delicate anti-reflective

coating.

Do not clean the infrared lens too vigorously. This can damage the anti-reflective

coating.

In furnace and other high-temperature applications,you mustmount aheatshield

on the camera. Using the camera in furnace and other high-temperature applications without a heatshield can cause damage to the camera.

(Applies only to cameras with an automatic shutter that can be disabled.) Do not

disable the automatic shutter in the camera for a prolonged time period (typically

max. 30 minutes). Disabling the shutter for a longer time period may harm, or irreparably damage, the detector.

The encapsulationratingis valid onlywhen all openings onthe camera are sealed

with their designated covers, hatches, or caps. This includes, but is not limited

to, compartments for data storage, batteries, and connectors.

2 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 15

2 Notice to user

Typographical

conventions

User-to-user

forums

Calibration

Accuracy

Disposal of

electronic waste

This manual uses the following typographical conventions:

Semibold is used for menu names, menu commands and labels, and buttons in

■

dialog boxes.

Italic is used for important information.

■

Monospace is used for code samples.

■

UPPER CASE is used for names on keys and buttons.

■

Exchange ideas,problems, and infraredsolutions with fellowthermographers around

the world in our user-to-user forums. To go to the forums, visit:

http://www.infraredtraining.com/community/boards/

(This notice only applies to cameras with measurement capabilities.)

We recommend that you send in the camera for calibration once a year. Contact

your local sales office for instructions on where to send the camera.

(This notice only applies to cameras with measurement capabilities.)

For very accurate results, we recommend that you wait 5 minutes after you have

started the camera before measuring a temperature.

For cameras where the detector is cooled by a mechanical cooler, this time period

excludes the time it takes to cool down the detector.

10742803;a1

As with most electronic products, this equipment must be disposed of in an environmentally friendlyway, and in accordancewith existingregulationsfor electronicwaste.

Please contact your FLIR Systems representative for more details.

Training

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 3

To read about infrared training, visit:

http://www.infraredtraining.com

■

http://www.irtraining.com

■

http://www.irtraining.eu

■

Page 16

3 Customer help

General

Submitting a

question

Downloads

For customer help, visit:

http://support.flir.com

To submit a question to the customer help team, you must be a registered user. It

only takes a fewminutes to registeronline. If you only wantto search the knowledgebase for existing questions and answers, you do not need to be a registered user.

When you want to submit a question, makesure thatyou have the following information to hand:

The camera model

■

The camera serial number

■

The communication protocol, or method, between the camera and your PC (for

■

example, HDMI, Ethernet, USB™, or FireWire™)

Operating system on your PC

■

Microsoft®Office version

■

Full name, publication number, and revision number of the manual

■

On the customer help site you can also download the following:

Firmware updates for your infrared camera

■

Program updates for your PC software

■

User documentation

■

Application stories

■

Technical publications

■

4 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 17

4 Documentation updates

General

Our manuals are updated several times per year, and we also issue product-critical

notifications of changes on a regular basis.

To access the latest manuals and notifications, go to the Download tab at:

http://support.flir.com

It only takes a few minutes to register online. In the download area you will also find

the latest releases of manuals for our other products, as well as manuals for our

historical and obsolete products.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 5

Page 18

5 Important note about this manual

General

NOTE

FLIR Systems issues generic manuals that cover several cameras within a model

line.

This means that this manual may contain descriptions and explanations that do not

apply to your particular camera model.

FLIR Systemsreserves therightto discontinuemodels,software, parts oraccessories,

and other items, or to change specifications and/or functionality at any time without

prior notice.

6 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 19

6 Parts lists

6.1 Scope of delivery

Infrared camera with lens

Contents

■

Hard transport case

■

Battery (2*)

■

Bluetooth headset*

■

Calibration certificate

■

FLIR Tools PC software CD-ROM

■

Handstrap

■

Lens cap

■

Memory card

■

Power supply, including multi-plugs

■

Printed Getting Started Guide

■

Printed Important Information Guide

■

USB cable

■

User documentation CD-ROM

■

Video cable

■

Warranty extension card or Registration card

■

* Dependent on the camera model/customer configuration.

NOTE

FLIR Systems reserves the right to discontinue models, parts or accessories, and

other items, or to change specifications at any time without prior notice.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 7

Page 20

6 – Parts lists

6.2 List of accessories and services

General

Accessories

This section contains a list of accessories and services that you can purchase for

your camera.

1196497 Cigarette lighter adapter kit, 12 VDC, 1.2 m/3.9 ft.

■

1196960 IR lens f = 10 mm, 45° including case

■

1196961 IR lens f = 30 mm, 15° including case

■

1910423 USB cable Std A to Mini-B

■

1910582 Video cable

■

ITC-ADV-3011 ITC Advanced Building—attendance 1 person

■

ITC-ADV-3019 ITC Advanced Building—group of 10 persons

■

ITC-ADV-3021 ITC Advanced General Thermography Course—attendance, 1

■

person

ITC-ADV-3029ITCAdvanced General Thermography Course—groupof10 persons

■

ITC-CER-5101 ITC Level 1 Thermography Course—attendance, 1 person

■

ITC-CER-5109 ITC Level 1 Thermography Course—group of 10 persons

■

ITC-CER-5201 ITC Level 2 Thermography Course—attendance, 1 person

■

ITC-CER-5209 ITC Level 2 Thermography Course—group of 10 persons

■

T197453 FLIR ResearchIR 1.2

■

T197453L10 FLIR ResearchIR 1.2, 10 user licenses

■

T197453L5 FLIR ResearchIR 1.2, 5 user licenses

■

T197454 FLIR QuickPlot 1.2

■

T197454L10 FLIR QuickPlot 1.2, 10 user licenses

■

T197454L5 FLIR QuickPlot 1.2, 5 user licenses

■

T197717 FLIR Reporter 8.5 SP2, Professional

■

T197717L10 FLIR Reporter 8.5 SP2, Professional, 10 user licenses

■

T197717L5 FLIR Reporter 8.5 SP2, Professional, 5 user licenses

■

T197771 Bluetooth headset

■

T197778 FLIR BuildIR 2.1

■

T197778L10 FLIR BuildIR 2.1, 10 user licenses

■

T197778L5 FLIR BuildIR 2.1, 5 user licenses

■

T910737 Memory card micro-SD with adapters

■

T910972 EX845: Clamp meter + IR therm TRMS 1000A AC/DC

■

T910973 MO297: Moisture meter, pinless with memory

■

NOTE

FLIR Systems reserves the right to discontinue models, parts or accessories, and

other items, or to change specifications at any time without prior notice.

8 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 21

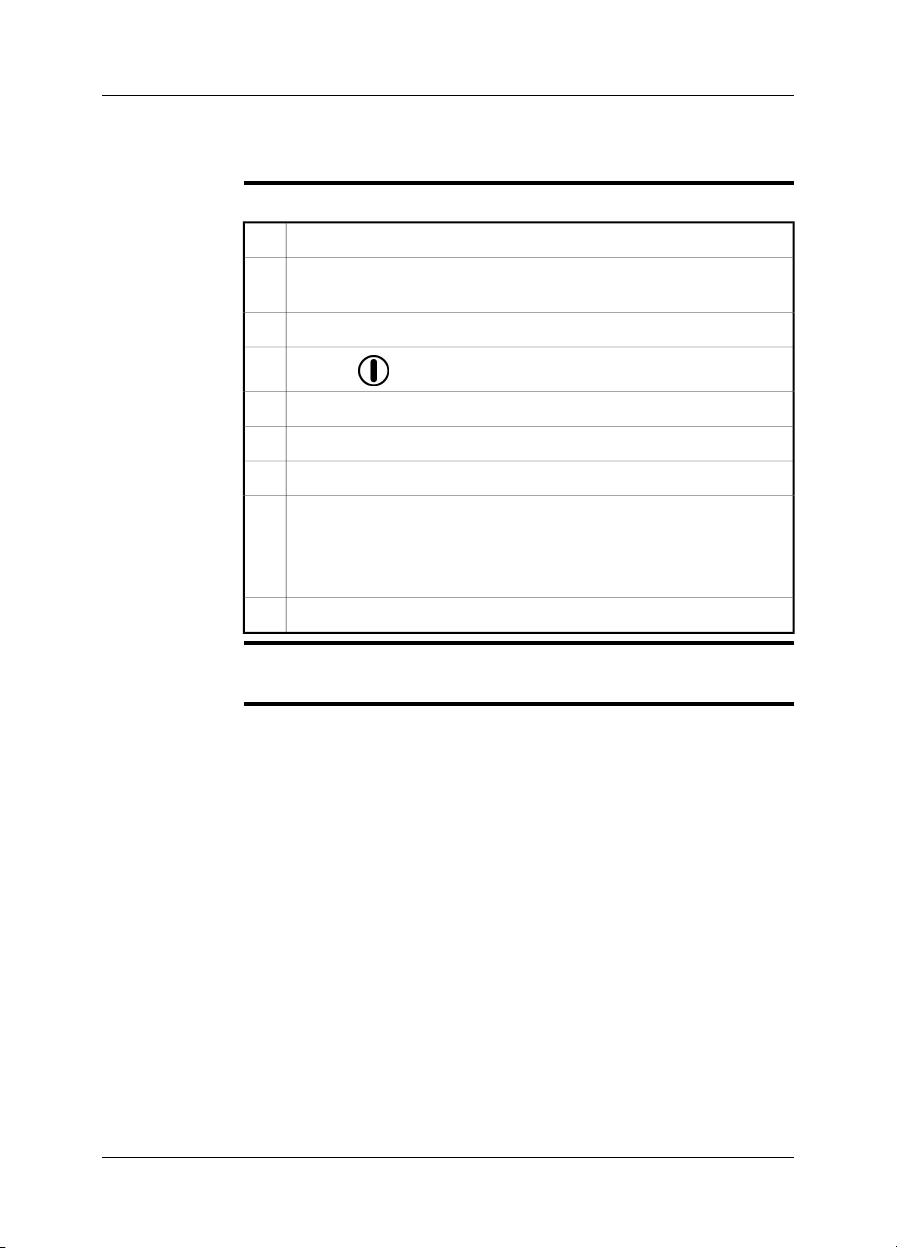

7 Quick Start Guide

Procedure

NOTE

Follow this procedure to get started right away:

Put a battery into the battery compartment.1

Charge the battery for 4 hours before starting the camera for the first time,

2

or until the green battery condition LED glows continuously.

Insert a memory card into a card slot.3

4

Push the button to turn on the camera.

Aim the camera towards the object of interest.5

Focus the camera by rotating the focus ring.6

Pull and hold the trigger for more than 1 second to save an image directly.7

Move the image to a computer by doing one of the following:

8

Remove the memory card and insert it in a card reader connected to a

■

computer.

Connect a computer to the camera using a USB mini-B cable.

■

Move theimage from the cardorcamera, using adrag-and-dropoperation.9

You can also move the images to the computer using FLIR Tools, which comes with

your camera.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 9

Page 22

8 Camera parts

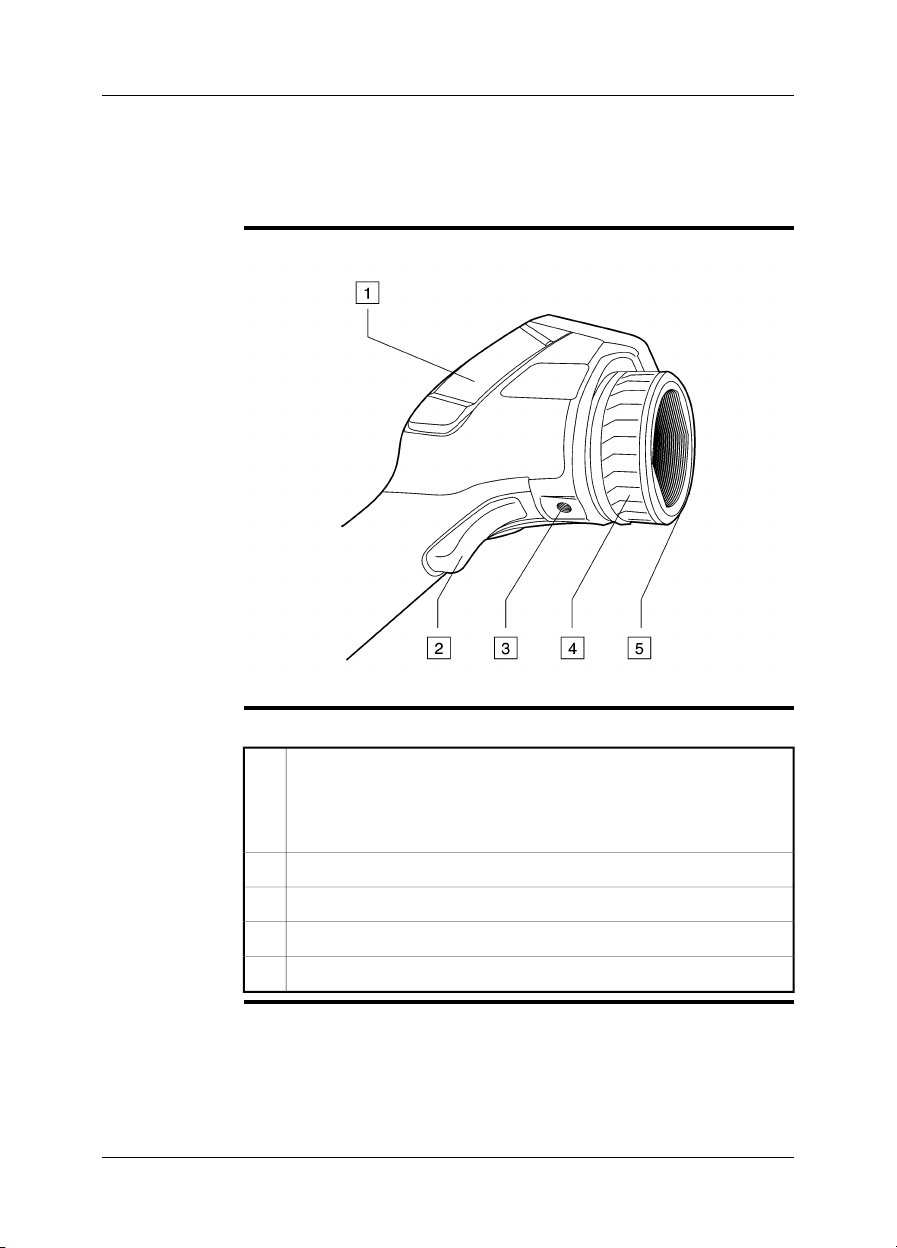

8.1 View from the right

Figure

Explanation

T638786;a1

This table explains the figure above:

Cover for the right-hand connectors compartment:

1

USB-A

■

USB mini-B

■

Power

■

Trigger to preview/save images2

Tripod mount. Requires an adapter (extra accessory)3

Focus ring4

Infrared lens5

10 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 23

8.2 View from the left

8 – Camera parts

Figure

Explanation

T638790;a1

This table explains the figure above:

Laser pointer1

Lamp for the digital camera2

Digital camera3

Cover for connectors and storage media:

4

Memory card

■

Video out

■

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 11

Page 24

8 – Camera parts

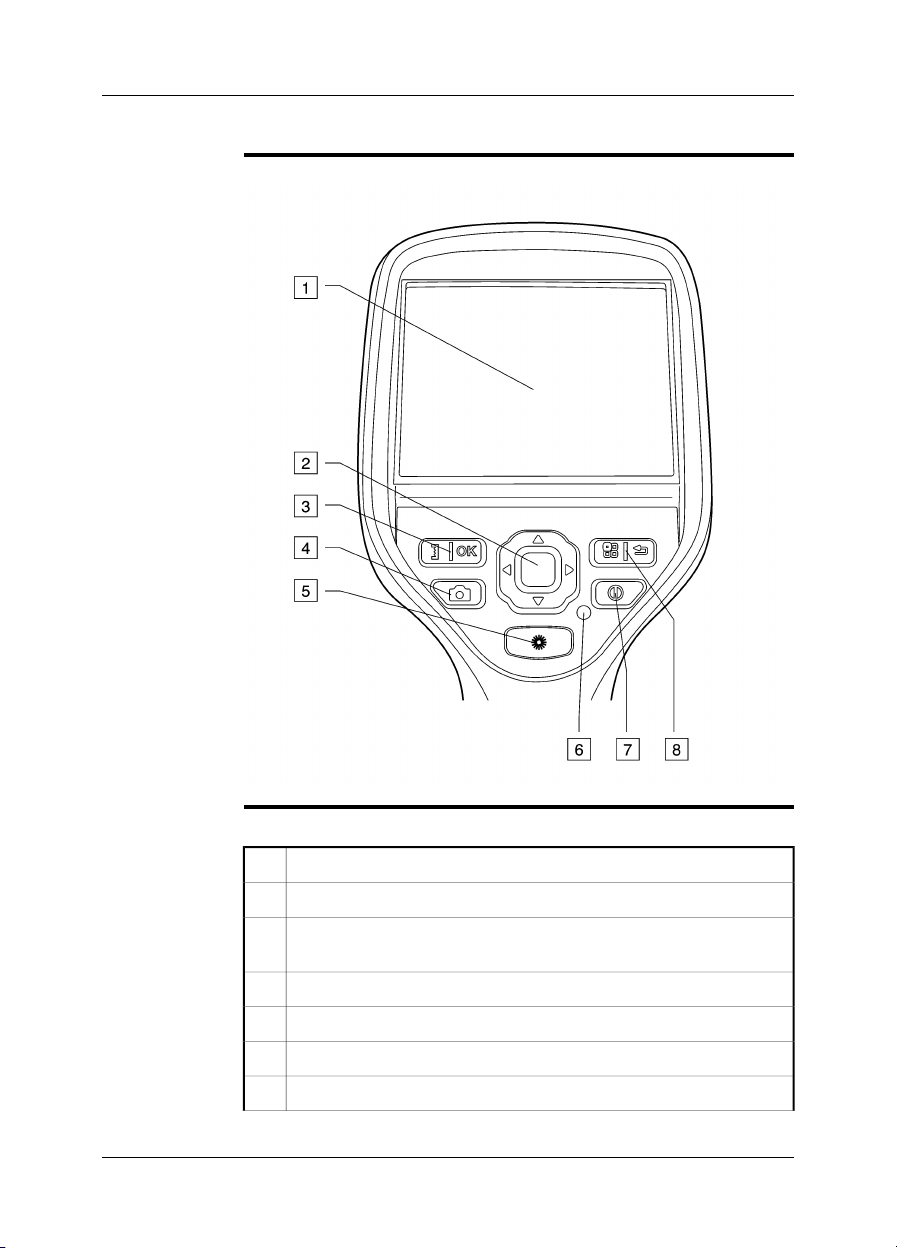

8.3 Keypad

Figure

T638787;a1

Explanation

This explains the figure above:

Touch-screen LCD1

Navigation pad2

Button to confirm choice

3

■

Button to go between automatic and manual adjustment modes

■

Image archive4

Button to operate the laser pointer5

Power indicator6

On/off button7

12 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 25

Button to display the menu system

8

■

Back button

■

8 – Camera parts

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 13

Page 26

8 – Camera parts

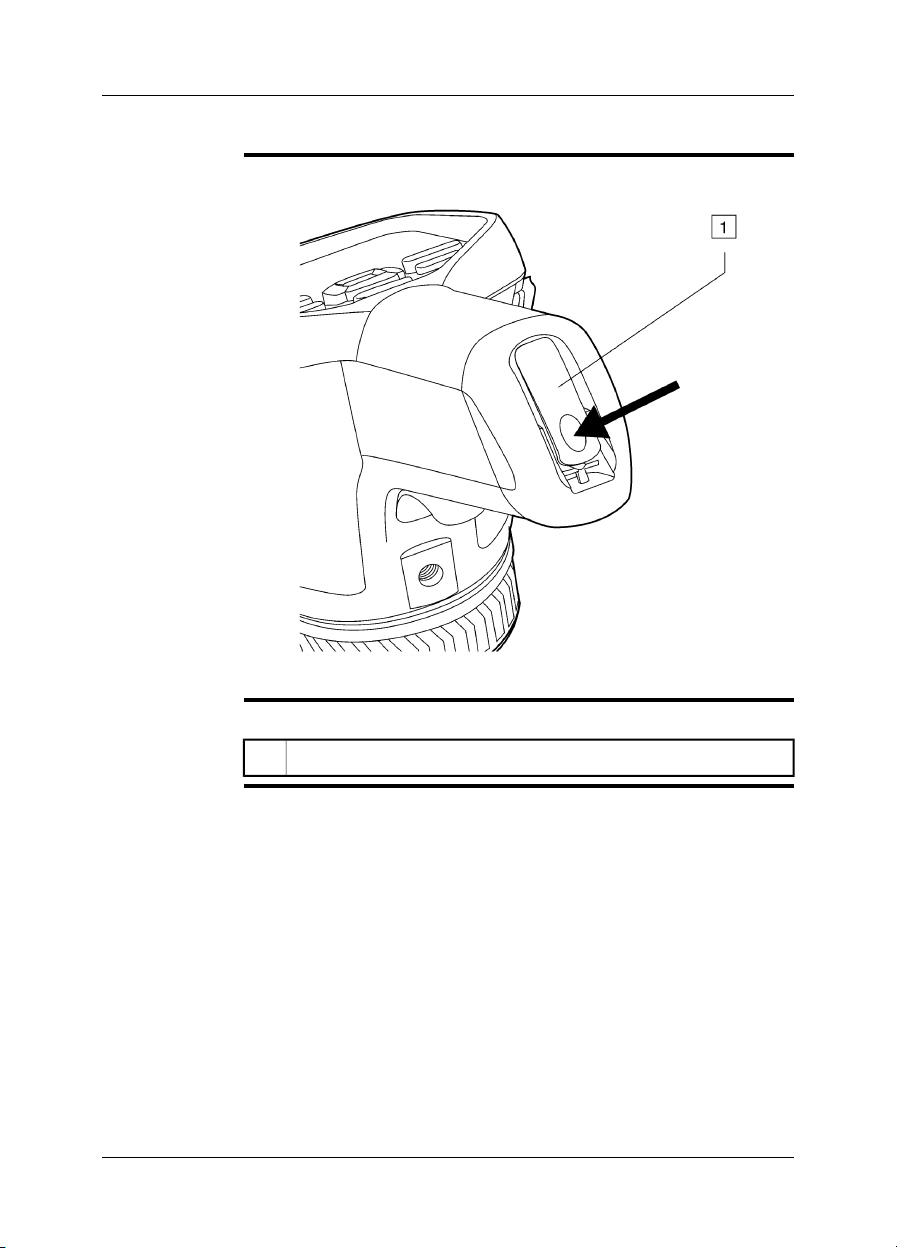

8.4 View from the bottom

Figure

Explanation

T638785;a3

This table explains the figure above:

Latch to open the cover for the battery compartment. Push to open1

14 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 27

8.5 Battery condition LED indicator

8 – Camera parts

Figure

Explanation

T638791;a1

This table explains the battery condition LED indicator:

ExplanationType of signal

The battery is being charged.The green LED flashes two times per

second.

The battery is fully charged.The green LED glows continuously.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 15

Page 28

8 – Camera parts

8.6 Power LED indicator

Figure

T638781;a1

Explanation

This table explains the power LED indicator:

ExplanationType of signal

The camera is off.The LED is off.

The camera is on.The LED is blue.

16 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 29

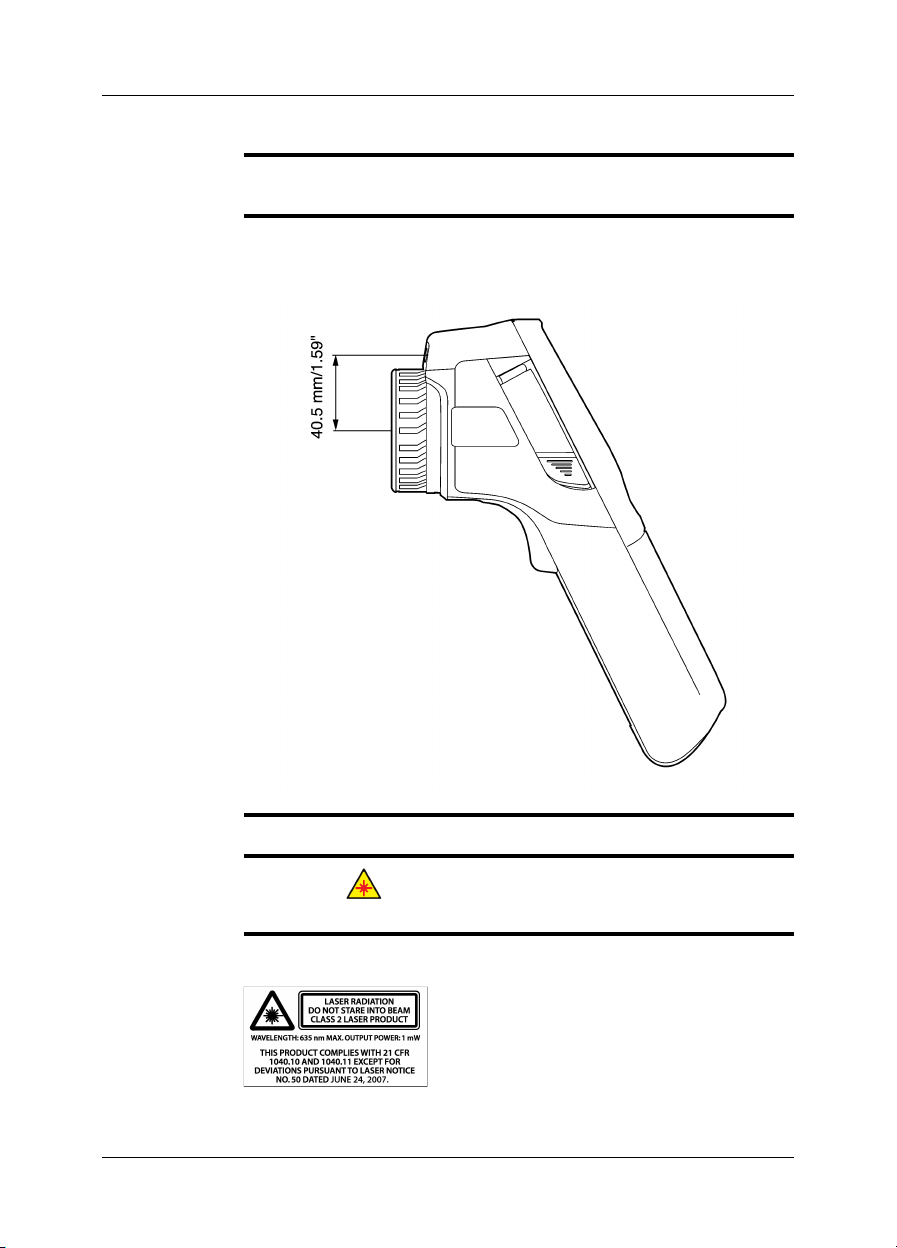

8.7 Laser pointer

8 – Camera parts

General

Figure

The camera has a laser pointer. When the laser pointer is on, you can see a laser

dot above the target.

This figure showsthe difference in position between the laser pointer and the optical

center of the infrared lens:

T638771;a1

WARNING

Do not look directly into the laser beam. The laser beam can cause eye irritation.

NOTE

The symbol is displayed on the screen when the laser pointer is on.

■

The laser pointer may not be enabled in all markets.

■

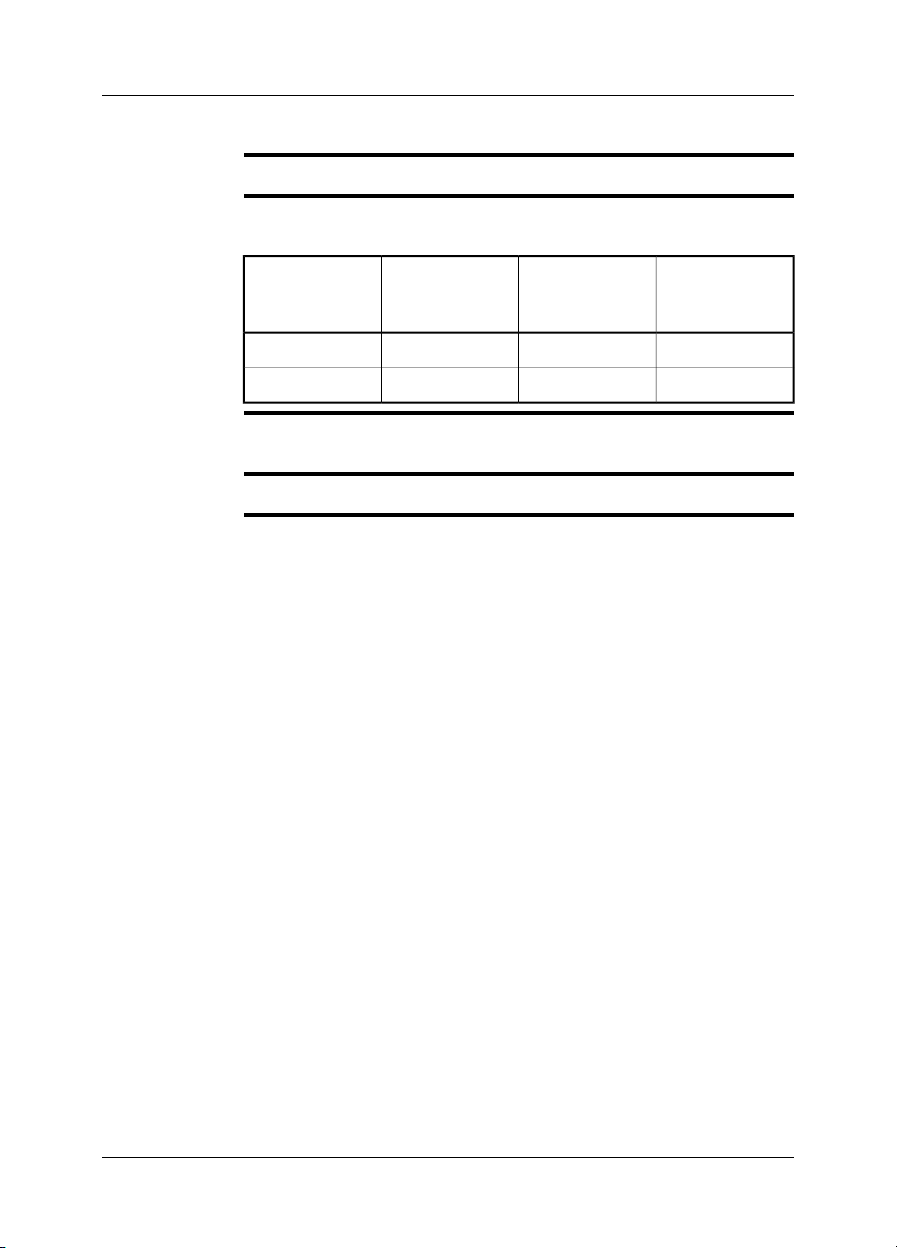

Laser warning

label

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 17

A laser warning label with the following information is attached to the camera:

10743603;a2

Page 30

8 – Camera parts

Laser rules and

regulations

Wavelength: 635 nm. Maximum output power: 1 mW.

This product complies with 21 CFR 1040.10 and 1040.11 except for deviations pur-

suant to Laser Notice No. 50, dated June 24, 2007.

18 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 31

9 Screen elements

Figure

Explanation

T638713;a2

This table gives an explanation to the figure above:

Measurement result table1

Measurement tools (e.g., area and spotmeter)2

Status and mode icons3

Tooltip for the currently selected menu item4

Temperature scale5

Setup6

Video clips recording7

Camera mode/live image mode8

Object parameters9

Measurement tools10

Color palettes11

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 19

Page 32

10 Navigating the menu system

Figure

Explanation

T638777;a1 T638780;a1

The figure above shows the two ways to navigate the menu system in the camera:

Using the index finger to navigate the menu system (left).

■

Using the navigation pad to navigate the menu system (right).

■

20 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 33

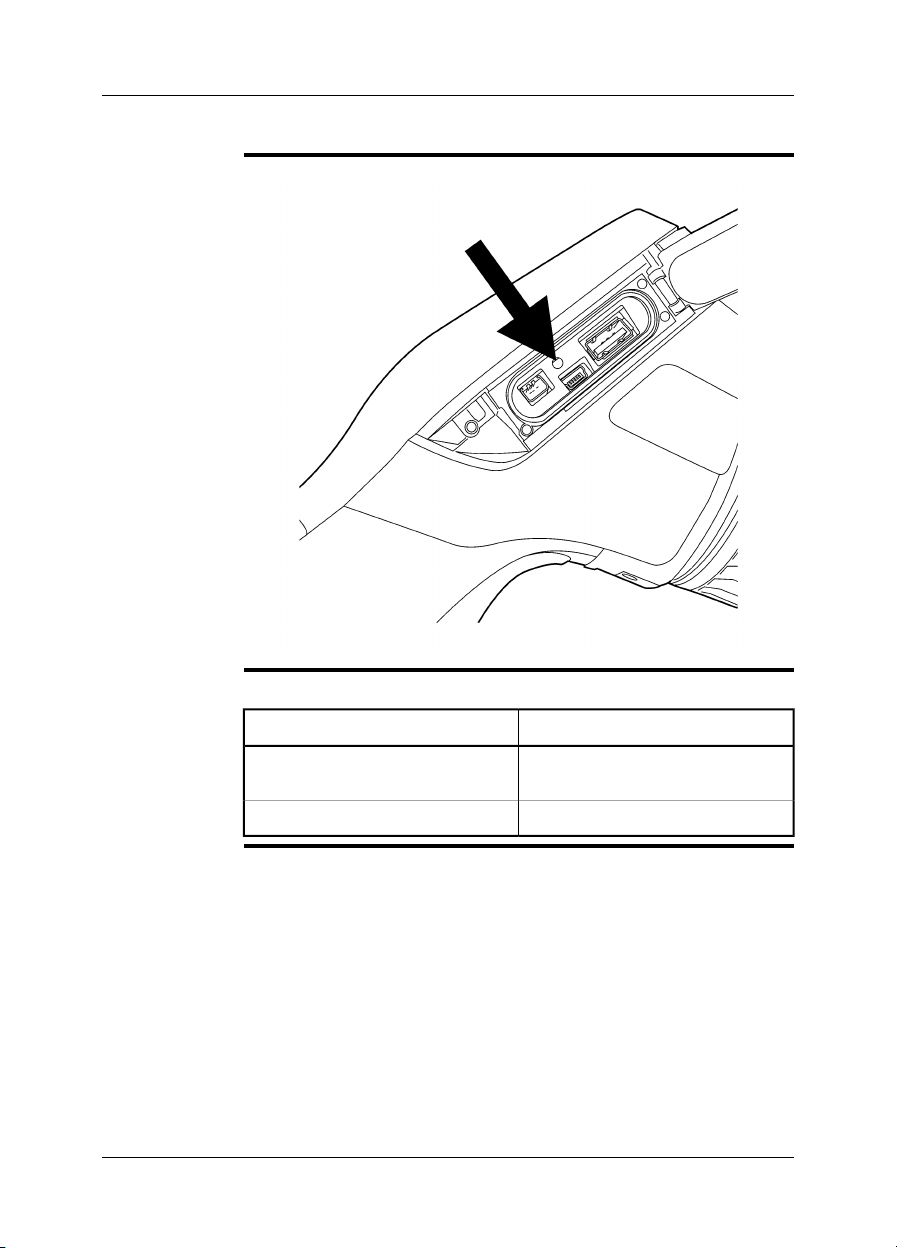

11 Connecting external devices and

storage media

Figure

T638789;a4

Explanation

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 21

This table explains the figure above:

Indicator showing that the memory card is busy. Note: Do not remove the

1

memory card when this indicator glows

Memory card2

Headset cable3

Page 34

11 – Connecting external devices and storage media

Figure

T638788;a1

Explanation

This table explains the figure above:

Power cable1

USB mini-B cable2

USB-A cable3

22 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 35

12 Pairing Bluetooth devices

General

Procedure

NOTE

Before youcan use a Bluetoothdevicewith the camera,youneed to pairthedevices.

Follow this procedure:

1

Go to (Setup) .

Go to the Connectivity tab.2

Activate Bluetooth.3

Select Add Bluetooth device.4

Select Scan for Bluetooth device and wait until a list of available devices

5

is displayed.

When a Bluetooth deviceis found, selectthe device toadd it. Nowthe device

6

is ready to be used.

You can add several devices.

■

You can remove an added device by selecting it and then selecting Remove.

■

After adding a MeterLink device, such as the Extech MO297 or EX845, the result

■

from the meter will be visible in the measurement result table.

After adding a Bluetooth-enabledheadset,it isready to beused in camerapreview

■

mode.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 23

Page 36

13 Handling the camera

13.1 Turning on the camera

Procedure

To turn on the camera, push and release the button.

13.2 Turning off the camera

Procedure

To turn on the camera, push and hold the button for more than 0.2 second.

24 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 37

13 – Handling the camera

13.3 Adjusting the infrared camera focus manually

Do not touch thelens surface whenyou adjust theinfrared camera focusmanually.

NOTE

■

If this happens, clean the lens according to the instructions in section 20.2 – Infrared lens on page 51.

The focus ring can be rotated infinitely, but only a certain amount of rotation is

■

needed when focusing.

Figure

T638779;a1

Procedure

Do one of the following:

For far focus, rotatethe focusring counter-clockwise (lookingat the touch-screen

■

LCD side).

For near focus, rotate the focus ring clockwise (looking at the touch-screen LCD

■

side).

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 25

Page 38

13 – Handling the camera

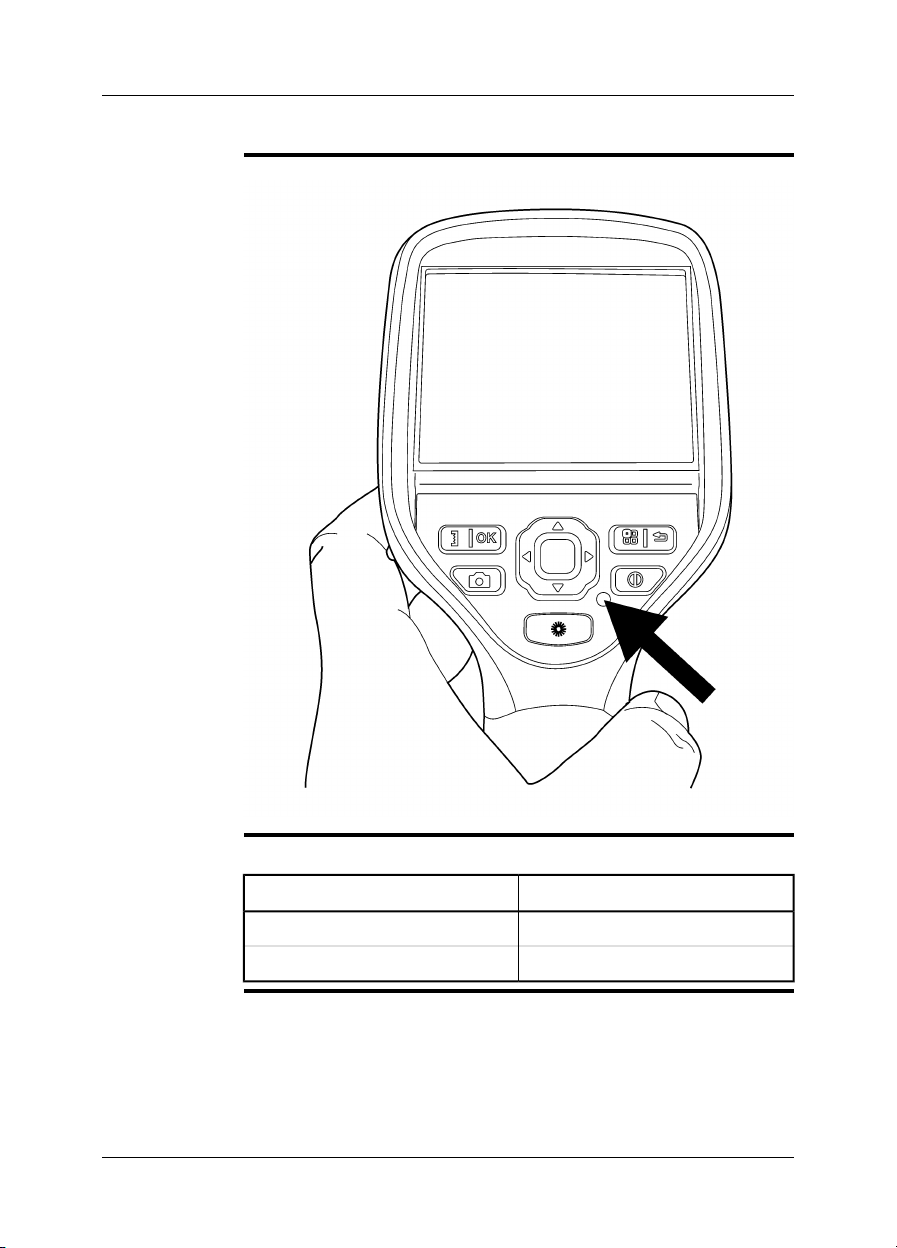

13.4 Operating the laser pointer

Figure

Procedure

T638778;a1

Follow this procedure to operate the laser pointer:

To turn on the laser pointer, push and hold the laser button.1

To turn off the laser pointer, release the laser button.2

26 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 39

14 Working with images

14.1 Previewing an image

General

Procedure

You can preview an infrared image or digital photo before you save it to a memory

card. Thisenables you tosee if the imageor photo containsthe information you want

before you save it.

In preview mode, you can also manipulate the image before you save it, and add

annotations.

To preview an image, briefly pull and release the trigger.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 27

Page 40

14 – Working with images

14.2 Saving an image

General

Image capacity

Naming

convention

Procedure

You can save an image directly, without previewing the image first.

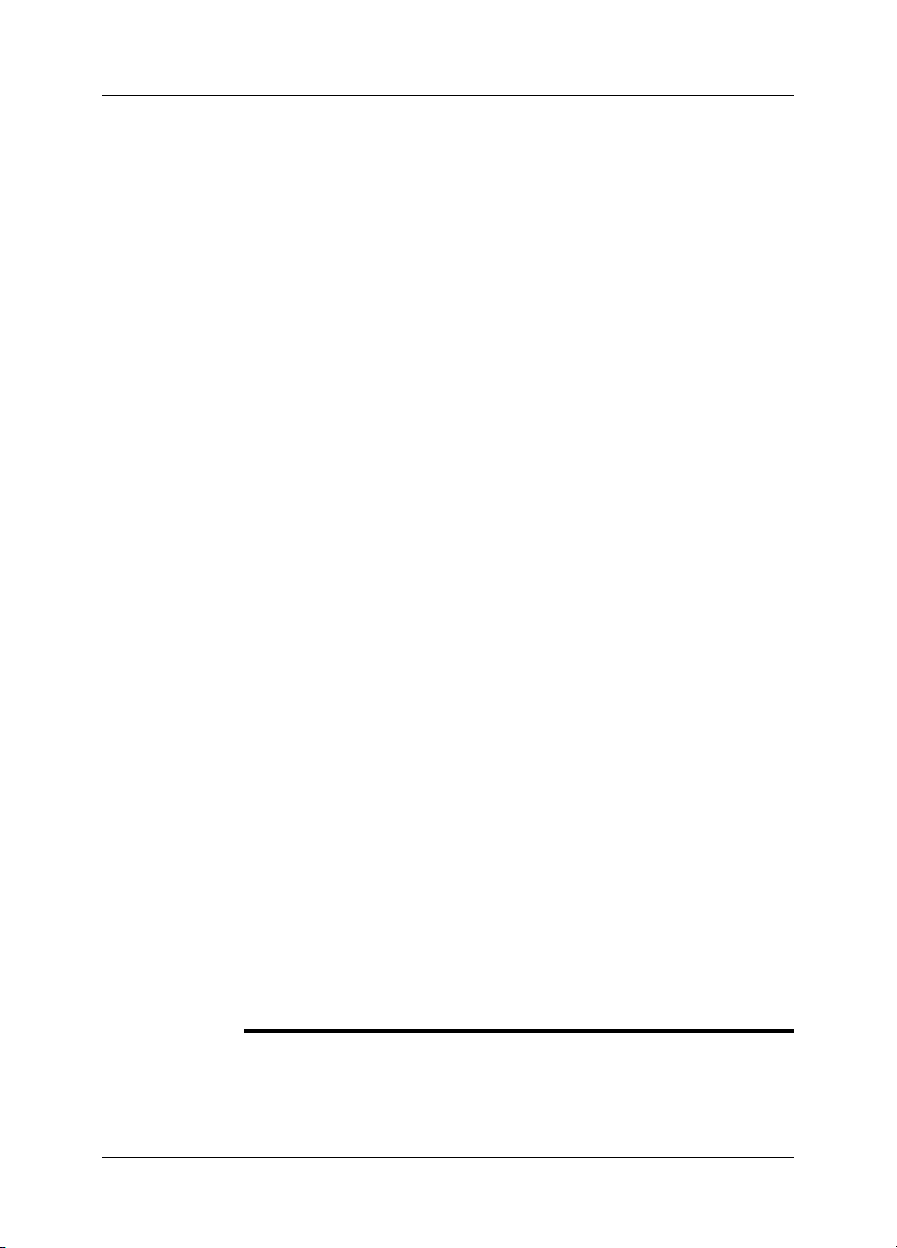

This table gives information on the approximate number of infrared (IR) and digital

camera (DC) images that can be saved on memory cards:

IR + DCIR onlyCard size

The naming convention for images is IR_xxxx.jpg, where xxxx is a unique counter.

To save an image directly, pull and hold down the trigger for more than 1 second.

IR + DC + 30

seconds voice

annotation

60085055001 GB

1200170011 0002 GB

28 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 41

14.3 Opening an image

14 – Working with images

General

Procedure

When yousave an image,the image isstored on amemory card. Todisplay the image

again, open it from the memory card.

Follow this procedure to open an image:

1

Push .

Push the navigation pad up/down or left/right to select the image you want

2

to view.

3

Push . This will display the image at full size.

(Optional step)

4

Push again to go to edit mode.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 29

Page 42

14 – Working with images

14.4 Adjusting an image

General

Example 1

An image can be adjusted automatically or manually. You use the button

to switch between these two modes. Note that this only works in live mode and not

in preview/archive mode.

This figure shows two infrared images of cable connection points. In the left image

a correct analysis of the left cable is difficult to do if you only auto-adjust the image.

You can analyze the left cable in more detail if you

change the temperature scale level

■

change the temperature scale span.

■

The image on the left ihas been auto-adjusted. In the right image the maximum and

minimum temperaturelevels have beenchangedto temperaturelevelsnear the object.

On the temperature scale to the rightof each imageyou can seehow thetemperature

levels were changed.

10577503;a2

30 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 43

14 – Working with images

Example 2

This figure shows two infrared images of an isolator in a power line.

In the image onthe left the cold skyand the power line structurehave been recorded

at a minimum temperature of –26.0°C (–14.8°F).In theright image the maximum and

minimum temperature levels have been changed to temperature levels near the isolator. This makes it easier to analyze the temperature variations in the isolator.

10742503;a3

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 31

Page 44

14 – Working with images

Changing

temperature scale

level

Changing

temperature scale

span

Follow this procedure to change the temperature scale level:

1

Push .

2

Use the navigation pad to select (Manual).

To change the scale level, push the navigation pad up/down.3

Follow this procedure to change the temperature scale span:

1

Push .

2

Use the navigation pad to select (Manual).

To change the scale span, push the navigation pad left/right.3

32 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 45

14.5 Changing the palette

14 – Working with images

General

Procedure

You can change the color palette that the camera uses to display different temperatures. A different palette can make it easier to analyze an image.

Follow this procedure to change the palette:

1

Push to display the menu system.

2

Use the navigation pad to go to .

3

Push to display a submenu.

Use the navigation pad to select a different palette.4

5

Push .

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 33

Page 46

14 – Working with images

14.6 Deleting an image

General

Procedure

You can delete one or more images in a folder.

Follow this procedure to delete an image:

1

Push .

Push the navigation pad up/down or left/right to select the image you want

2

to delete.

3

Push to display the menu system.

4

Use the navigation pad to select .

5

Push and confirm that you want to delete the image.

34 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 47

14.7 Deleting all images

14 – Working with images

General

Procedure

You can delete all images in a folder.

Follow this procedure to delete all images:

1

Push .

2

Push to display the menu system.

3

Use the navigation pad to select .

Select Delete all.

4

Push and confirm that you want to delete the images.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 35

Page 48

14 – Working with images

14.8 Creating a PDF report in the camera

General

Procedure

You can create a PDF report in the camera. You can then move the PDF report to a

computer, using a USB memory stick, or via Bluetooth, and send the report to a

customer.

Follow this procedure to create a PDF report in the camera:

1

Push .

2

Use the navigation pad to select .

3

Push to open a submenu.

On the submenu, select Create report.

4

A PDF report is now being created and will be displayed on the screen.

You can zoom into the report by using the controls in the top right corner

of the screen.

36 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 49

15 Working with measurement tools

15.1 Laying out a measurement tool

General

Procedure

To measure a temperature, you use one or several measurement tools, such as a

spotmeter, a box, etc.

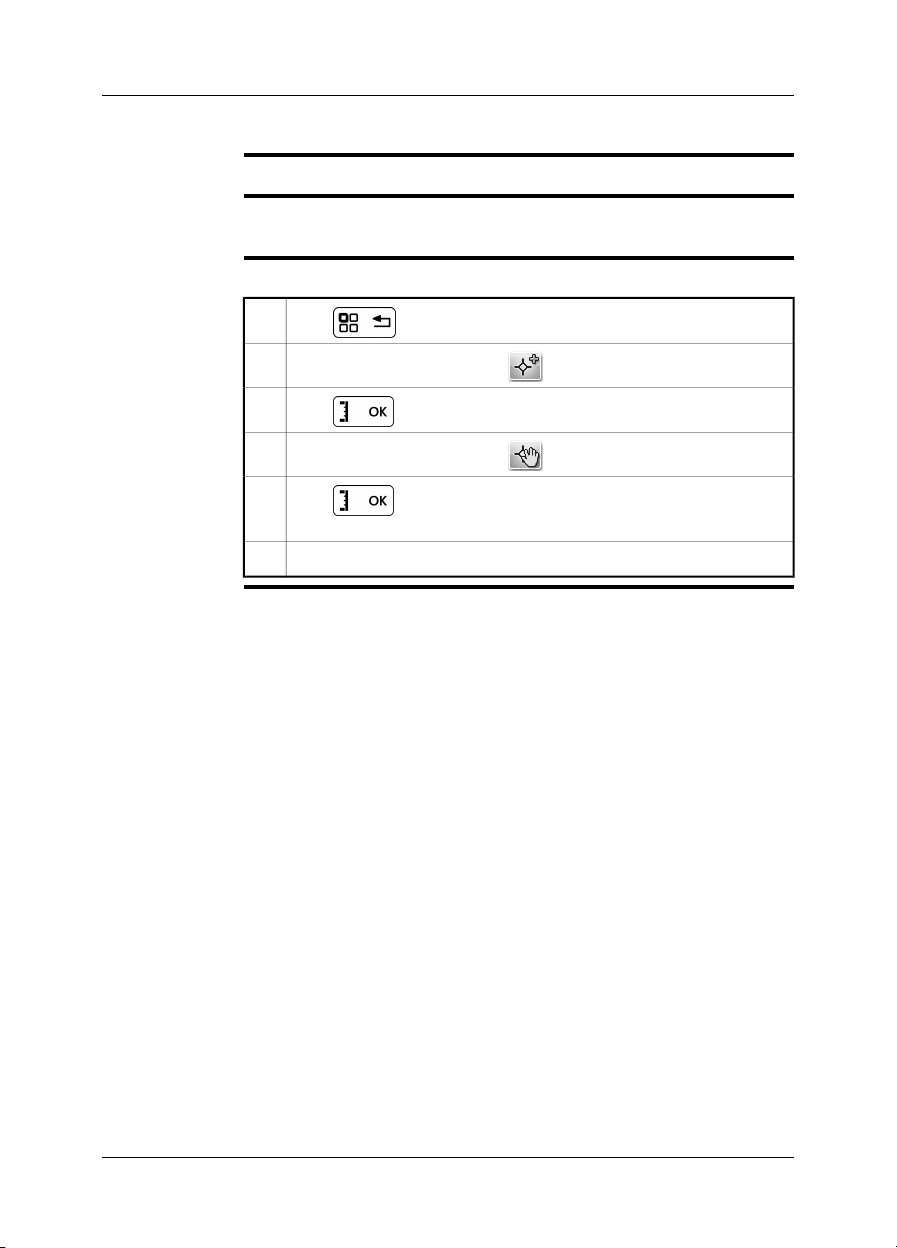

Follow this procedure to lay out a measurement tool:

1

Push to display the menu system.

2

Use the navigation pad to go to .

3

Push to display a submenu.

Use the navigation pad to go to a measurement tool.4

5

Push . This will display the measurement tool on the screen.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 37

Page 50

15 – Working with measurement tools

15.2 Moving or resizing a measurement tool

General

NOTE

Procedure

You can move and resize a measurement tool.

This procedure assumes that you have previously laid out a measurement tool on

the screen.

Follow this procedure to move or resize a measurement tool:

1

Push to display the menu system.

2

Use the navigation pad to go to (Tools).

3

Push to display a submenu.

4

Use the navigation pad to go to (Adjust tools).

5

Push and select the measurement tool that you want to move or

resize.

Use the navigation pad to move or resize the measurement tool.6

38 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 51

15 – Working with measurement tools

15.3 Creating and setting up a difference calculation

General

NOTE

Procedure

A difference calculation gives the difference between the values of two known measurement results.

This procedure assumesthat you have previously laid out at least two measurement

tools on the screen.

Follow this procedure to create and set up a difference calculation:

1

Push to display the menu system.

2

Use the navigation pad to go to (Tools).

3

Push to display a submenu.

4

Use the navigation pad to select (Add difference).

5

Push . This will display a dialog box where you can select the

measurement tools that you want to use in the difference calculation.

6

Push . The result of the difference calculation is now displayed in

the result table.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 39

Page 52

15 – Working with measurement tools

15.4 Changing object parameters

General

Types of

parameters

Recommended

values

For accurate measurements, you must set the object parameters.

The camera can use these object parameters:

Emissivity, i.e., how much radiation an object emits, compared with the radiation

■

of a theoretical reference object of the same temperature (called a “blackbody”).

The opposite of emissivity is reflectivity. The emissivity determines how much of

the radiation originates from the object as opposed to being reflected by it.

Reflected apparent temperature, which is used when compensating for the radi-

■

ation from the surroundings reflected by the objectinto thecamera. This property

of the object is called reflectivity.

Object distance, i.e., the distance between the camera and the object of interest.

■

Atmospheric temperature, i.e., the temperature of the air between the camera

■

and the object of interest.

Relative humidity, i.e., the relative humidity of the air between the camera and

■

the object of interest.

External IR window compensation, i.e., the temperature ofany protective windows,

■

etc., that are setup betweenthe camera and the objectof interest.If no protective

window or protective shield is used, this value is irrelevant and should be left inactive.

If you are unsure about the values, the following are recommended:

Atmospheric temperature +20°C (+69°F)

0.95Emissivity

1.0 m (3.3 ft.)Object distance

+20°C (+69°F)Reflected apparent temperature

50%Relative humidity

40 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 53

15 – Working with measurement tools

Procedure

NOTE

Related topics

Follow this procedure to change the object parameters:

1

Push to display the menu system.

2

Use the navigation pad to go to .

3

Push to display a dialog box.

Use the navigation pad to select and change an object parameter.4

5

Push . This will close the dialog box.

Of the parameters above, emissivity and reflected apparent temperature are the two

most important to set correctly in the camera.

For in-depth information about parameters, and how to correctly set the emissivity

and reflected apparent temperature, see section 28 – Thermographic measurement

techniques on page 150.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 41

Page 54

16 Fetching data from external

Extech meters

General

Figure

Supported Extech

meters

You can fetch data from an external Extech meter and merge this data into the result

table in the infrared image.

T638370;a1

Extech Moisture Meter MO297

■

Extech Clamp Meter EX845

■

Technical support

for Extech meters

NOTE

Procedure

support@extech.com

This support is for Extech meters only. For technical support for infrared cameras,

go to http://support.flir.com.

This procedure assumes that you have paired the Bluetooth devices.

■

For more information about products from Extech Instruments, go to

■

http://www.extech.com/instruments/.

Follow this procedure:

Turn on the camera.1

Turn on the Extech meter.2

42 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 55

16 – Fetching data from external Extech meters

On the meter, enable Bluetooth mode. Refer to the user documentation for

3

the meter for information on how to do this.

On the meter, choose the quantity that you want to use (voltage, current,

4

resistance, etc.). Refer to the user documentation forthe meter for information on how to do this.

Results from the meterwill now automaticallybe displayed inthe resulttable

in the top left corner of the infrared camera screen.

Do one of the following:

5

To preview an image, push the Preview/Save button. At this stage, you

■

can add additional values. To do so, take a new measurement with the

meter and select Add on the infrared camera screen.

To save an image without previewing, push and hold down the Pre-

■

view/Save button.

To add a value to a recalled image, turn on the meter after you have re-

■

called the image, then select Add on the infrared camera screen. A

maximum of eight values can be added, but note that some values are

broken into two lines.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 43

Page 56

16 – Fetching data from external Extech meters

16.1 Typical moisture measurement and documentation procedure

General

Procedure

The followingprocedure can form the basisfor other proceduresusing Extech meters

and infrared cameras.

Follow this procedure:

Use the infrared camera to identify any potential damp areas behind walls

1

and ceilings.

Use the moisture meter to measure the moisture levels at various suspect

2

locations that may have been found.

When a spot of particular interest is located, store the moisture reading in

3

the moisture meter’s memory and identify the measurement spot with a

handprint or other thermal identifying marker.

Recall the reading from the meter memory. The moisture meter will now

4

continuously transmit this reading to the infrared camera.

Use the camera to take a thermal image of the area with the identifying

5

marker. The stored data from the moisture meter will also be saved on the

image.

44 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 57

17 Working with alarms

17.1 Building alarms

General

About the

Humidity alarm

About the

Insulation alarm

Alarm signals

Procedure

The camera features alarmtypes that arespecific to the building trade.You canmake

the camera trigger the following types of alarms:

Humidity alarm: Triggers when a measurement tool detects a surface where the

■

relative humidity exceeds a preset value.

Insulation alarm: Triggers when there is an insulation deficiency in a wall.

■

To detect areas where the relative humidity is less than 100% you can use the Humidity alarm, where you can set the relative humidity above which the alarm will

trigger.

The Insulation alarm can detect areas where there may be an insulation deficiency

in the building. It will trigger when the insulation level falls below a preset value of

the energy leakage through the wall.

Different building codes recommend different values, but typical values for the insulation level are 0.6–0.8 for new buildings. Refer to your national building code for

recommendations.

When an alarm is triggered, an isotherm will be displayed.

Follow this procedure to set up an alarm:

1

Push to display the menu system.

2

Use the navigation pad to go to .

3

Push to display a submenu.

4

Use the navigation pad to go to .

5

Push . This will display a submenu.

In the submenu, select Humidity or Insulation. This will display a dialog

6

box where you can set the necessary parameters.

7

Push .

The alarm is now set, and an isotherm will be displayed when the alarm is

triggered.

NOTE

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 45

For this alarm to be meaningful, the parameters must be set with some care.

Page 58

18 Annotating images

General

This section describes how to save additional information to an infrared image by

using annotations.

The reason for using annotations is to make reporting and post-processing more

efficient by providing essential information about the image, such as conditions,

photos, information about where an image is taken, and so on.

You can set the camera to automatically add an annotation to your images.

46 Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010

Page 59

18.1 Taking a digital photo

18 – Annotating images

General

NOTE

Procedure

When you save an infrared image you can also take a digital photo of the object of

interest. This digital photo will automatically be grouped together with the infrared

image, which will simplify post-processing and reporting.

This procedure assumes that you have not set the camera to automatically add a

digital photo.

Follow this procedure to take a digital photo:

To preview an infrared image, briefly pull and release the trigger.1

Use the navigation pad to select Add photo.2

3

Push to display a submenu.

Use the navigation pad to select Add digital camera photo.4

Push to take the digital photo.

The digital photo will now be added to the IR image to what is called an

“infrared inspection group,” and will be grouped together in the image

archive, and also when moving files from the camera to reporting software

on the computer.

Publ. No. T559597 Rev. a500 – ENGLISH (EN) – December 10, 2010 47

Page 60

18 – Annotating images

18.2 Creating a text annotation

General

NOTE

Procedure

A text annotation is grouped with an image file. Using this feature, you can annotate

images. This text can be revised later.

This feature is very efficient when saving information on an image when you are inspecting a large number of similar objects. The idea behind using text annotations

is to avoid filling out forms or inspection protocols manually.

This procedure assumes that you have not set the camera to automatically add a

text annotation.

Follow this procedure to create a text annotation:

To preview an image, pull the trigger.1

2

Use the navigation pad to select .

3

Push to display a submenu.

Use the navigation pad to select Text annotation.4

Push to display a dialog box.

In this dialog box you can do one of the following:

Use an existing text annotation template.

■

Create a new field.

■

The text annotation will now be added to the IR image to what is called an