Page 1

Installation Manual

FLIR A3XX series

FLIR A6XX series

T559498Publ. No.

a461Revision

English (EN)Language

August 19, 2010Issue date

Page 2

Page 3

Installation Manual

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 4

Legal disclaimer

All products manufactured by FLIR Systemsarewarranted against defectivematerialsandworkmanship for aperiodof one(1)year from the

delivery date of the original purchase, provided such products have been under normal storage, use and service, and in accordance with

FLIR Systems instruction.

Products which are not manufactured by FLIR Systems but included in systems delivered by FLIR Systems to the original purchaser, carry

the warranty, if any, of the particular supplier only. FLIR Systems has no responsibility whatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It is not applicable to any product which has been subjected to

misuse, neglect, accident or abnormal conditions of operation. Expendable parts are excluded from the warranty.

In the case of adefect inaproduct coveredbythis warrantytheproduct must notbe furtherusedin order toprevent additional damage.The

purchaser shall promptly report any defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, at its option, repair or replace any such defective product free of charge if, upon inspection, it proves to be defective in

material or workmanship and provided that it is returned to FLIR Systems within the said one-year period.

FLIR Systems has no other obligation or liability for defects than those set forth above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims the implied warranties of merchantability and fitness for a

particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidentalor consequential loss or damage, whether basedon contract, tort

or any other legal theory.

This warranty shall be governed by Swedish law.

Any dispute, controversy or claim arising out of or in connection with this warranty, shall be finally settled by arbitration in accordance with

the Rules of the Arbitration Institute of the Stockholm Chamber of Commerce. The place of arbitration shall be Stockholm. The language to

be used in the arbitral proceedings shall be English.

Copyright

© 2010, FLIRSystems. All rights reservedworldwide. No parts ofthesoftware including source codemaybe reproduced, transmitted, transcribed

or translated into any language or computer language in any form or by any means, electronic, magnetic, optical, manual or otherwise,

without the prior written permission of FLIR Systems.

This documentation must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic medium or

machine readable form without prior consent, in writing, from FLIR Systems.

Names and marks appearing on the products herein are eitherregistered trademarksor trademarksof FLIR Systems and/or its subsidiaries.

All othertrademarks,trade names or companynames referenced herein areusedfor identification only andarethe property of theirrespective

owners.

Quality assurance

The Quality Management System under which these products are developed and manufactured has been certified in accordance with the

ISO 9001 standard.

FLIR Systems is committed to a policy of continuous development; therefore we reserve the right to make changes and improvements on

any of the products described in this manual without prior notice.

iv Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 5

Table of contents

11 Warnings & Cautions .....................................................................................................................

32 Notice to user ..................................................................................................................................

53 Customer help ................................................................................................................................

64 Documentation updates .................................................................................................................

75 Important note about this manual .................................................................................................

86 Overview of camera models ..........................................................................................................

86.1 FLIR A300 .............................................................................................................................

96.2 FLIR A310 .............................................................................................................................

106.3 FLIR A315 .............................................................................................................................

116.4 FLIR A320 Tempscreen ........................................................................................................

126.5 FLIR A615 .............................................................................................................................

137 Packing list ......................................................................................................................................

148 Installation .......................................................................................................................................

148.1 General information ..............................................................................................................

158.2 System requirements ...........................................................................................................

168.3 Installation .............................................................................................................................

179 Mechanical installation ..................................................................................................................

179.1 Installation of fixed cameras .................................................................................................

189.2 Mounting and removing lenses (FLIR A3XX series) ............................................................

189.2.1 Mounting an additional infrared lens ....................................................................

199.2.2 Removing an additional infrared lens ...................................................................

209.3 Mounting and removing lenses (FLIR A6XX series) ............................................................

209.3.1 Removing an infrared lens ....................................................................................

219.3.2 Mounting an infrared lens .....................................................................................

2210 Connectors, controls, and indicators ...........................................................................................

2611 Example system overviews ...........................................................................................................

2912 Temperature screening ..................................................................................................................

3113 Cleaning the camera ......................................................................................................................

3113.1 Camera housing, cables, and other items ...........................................................................

3213.2 Infrared lens ..........................................................................................................................

3313.3 Infrared detector ...................................................................................................................

3414 Technical data .................................................................................................................................

3515 Pin configurations ..........................................................................................................................

3716 Mechanical drawings .....................................................................................................................

3716.1 FLIR A3XX series ..................................................................................................................

3716.1.1 Camera dimensions (front) ...................................................................................

3816.1.2 Camera dimensions (side) ...................................................................................

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 v

Page 6

3916.1.3 Camera dimensions (bottom) ...............................................................................

4016.1.4 Camera dimensions (with 10 mm/45° lens) .........................................................

4116.1.5 Camera dimensions (with 30 mm/15° lens) .........................................................

4216.1.6 Infrared lens (10 mm/45°) .....................................................................................

4316.1.7 Infrared lens (30 mm/15°) .....................................................................................

4416.2 FLIR A6XX series ..................................................................................................................

4416.2.1 Camera dimensions (front view, without lens) .....................................................

4516.2.2 Camera dimensions (side view, without lens) ......................................................

4616.2.3 Camera dimensions (side view, with 24.5 mm/25° lens) ......................................

4716.2.4 Specification of mounting interfaces, #1 .............................................................

4816.2.5 Specification of mounting interfaces, #2 .............................................................

4916.2.6 Camera dimensions (rear view) ............................................................................

5016.2.7 Infrared lens (24.5 mm/25°) ..................................................................................

5117 About FLIR Systems .......................................................................................................................

5217.1 More than just an infrared camera .......................................................................................

5217.2 Sharing our knowledge ........................................................................................................

5217.3 Supporting our customers ...................................................................................................

5317.4 A few images from our facilities ...........................................................................................

5518 Glossary ...........................................................................................................................................

5919 Thermographic measurement techniques ...................................................................................

5919.1 Introduction ..........................................................................................................................

5919.2 Emissivity ..............................................................................................................................

6019.2.1 Finding the emissivity of a sample .......................................................................

6019.2.1.1 Step 1: Determining reflected apparent temperature .......................

6219.2.1.2 Step 2: Determining the emissivity ...................................................

6319.3 Reflected apparent temperature ..........................................................................................

6319.4 Distance ................................................................................................................................

6319.5 Relative humidity ..................................................................................................................

6319.6 Other parameters ..................................................................................................................

6420 History of infrared technology ......................................................................................................

6821 Theory of thermography ................................................................................................................

6821.1 Introduction ...........................................................................................................................

6821.2 The electromagnetic spectrum ............................................................................................

6921.3 Blackbody radiation ..............................................................................................................

7021.3.1 Planck’s law ..........................................................................................................

7121.3.2 Wien’s displacement law ......................................................................................

7321.3.3 Stefan-Boltzmann's law .........................................................................................

7421.3.4 Non-blackbody emitters .......................................................................................

7621.4 Infrared semi-transparent materials .....................................................................................

7822 The measurement formula .............................................................................................................

8423 Emissivity tables .............................................................................................................................

8423.1 References ............................................................................................................................

8423.2 Important note about the emissivity tables ..........................................................................

8523.3 Tables ....................................................................................................................................

vi Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 7

1 Warnings & Cautions

This equipment generates, uses, and can radiate radio frequency energy and if

WARNING

■

not installed and used in accordance with the instruction manual, may cause interference to radio communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designedto providereasonable protection againstsuch interference when operated in a commercial environment. Operation of this equipment

in a residential area is likely to cause interference in which case the user at his

own expense will be required to take whatever measures may be required to

correct the interference.

(Applies only to cameras with laser pointer:) Do not look directly into the laser

■

beam. The laser beam can cause eye irritation.

Applies only to cameras with battery:

■

Do not disassemble or do a modification to the battery. The battery contains

■

safety and protection devices which, if they become damaged, can cause the

battery to become hot, or cause an explosion or an ignition.

If there is a leak from the battery and the fluid gets into your eyes, do not rub

■

your eyes.Flush well withwater and immediatelyget medical care. Thebattery

fluid can cause injury to your eyes if you do not do this.

Do not continue to charge the battery if it does not become charged in the

■

specified charging time. If you continue to charge the battery, it can become

hot and cause an explosion or ignition.

Only use the correct equipment to discharge the battery. If you do not use the

■

correct equipment, you can decrease the performance or the life cycle of the

battery. If you do not use the correct equipment, an incorrect flow of current

to the battery can occur. This can cause the battery to become hot, or cause

an explosion and injury to persons.

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and

■

warning labelson containersbeforeyou usea liquid: theliquids can bedangerous.

Do not point theinfrared camera (withor without the lens cover)at intensive energy

CAUTION

■

sources, for example devices that emit laser radiation, or the sun. This can have

an unwanted effect on the accuracy of the camera. It can also cause damage to

the detector in the camera.

Do not use the camera in a temperature higher than +50°C (+122°F), unless

■

specified otherwise in the user documentation. High temperatures can cause

damage to the camera.

(Applies only to cameras with laser pointer:) Protect the laser pointer with the

■

protective cap when you do not operate the laser pointer.

Applies only to cameras with battery:

■

Do not attach the batteries directly to a car’s cigarette lighter socket, unless a

■

specific adapter for connecting the batteries to a cigarette lighter socket is

provided by FLIR Systems.

Do not connect the positive terminal and the negative terminal of the battery

■

to each other with a metal object (such as wire).

Do not get water or salt water on the battery, or permit the battery to get wet.

■

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 1

Page 8

1 – Warnings & Cautions

■

■

■

■

■

Do not make holes in the battery with objects. Do not hit the battery with a

■

hammer. Do not step on the battery, or apply strong impacts or shocks to it.

Do not put thebatteries inor near a fire, orinto direct sunlight. When thebattery

■

becomes hot, the built-in safety equipment becomes energized and can stop

the battery charging process. If the battery becomes hot, damage can occur

to the safety equipment and this can cause more heat, damage or ignition of

the battery.

Do not put the battery on a fire or increase the temperature of the battery with

■

heat.

Do not put the battery on or near fires, stoves, or other high-temperature loca-

■

tions.

Do not solder directly onto the battery.

■

Do not use the battery if, when you use, charge, or store the battery, there is

■

an unusual smell fromthe battery,the battery feelshot, changes color, changes

shape, or is in an unusual condition. Contact your sales office if one or more

of these problems occurs.

Only use a specified battery charger when you charge the battery.

■

The temperature range through which you can charge the battery is ±0°C to

■

+45°C (+32°F to +113°F), unless specified otherwise in the user documentation. If you charge the battery at temperatures out of this range, it can cause

the battery to become hot or to break. It can also decrease the performance

or the life cycle of the battery.

The temperature range through which you can dischargethe battery is −15°C

■

to +50°C (+5°F to +122°F), unless specified otherwise in the user documentation. Use of the battery out of this temperature range can decrease the performance or the life cycle of the battery.

When the battery is worn, apply insulation to the terminals with adhesive tape

■

or similar materials before you discard it.

Remove any water or moisture on the battery before you install it.

■

Do not apply solvents or similar liquids to the camera, the cables, or other items.

This can cause damage.

Be careful when you cleanthe infraredlens. The lens has a delicate anti-reflective

coating.

Do not clean the infrared lens too vigorously. This can damage the anti-reflective

coating.

In furnace and other high-temperature applications,you mustmount aheatshield

on the camera. Using the camera in furnace and other high-temperature applications without a heatshield can cause damage to the camera.

(Applies only to cameras with an automatic shutter that can be disabled.) Do not

disable the automatic shutter in the camera for a prolonged time period (typically

max. 30 minutes). Disabling the shutter for a longer time period may harm, or irreparably damage, the detector.

2 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 9

2 Notice to user

Typographical

conventions

User-to-user

forums

Calibration

Accuracy

Disposal of

electronic waste

This manual uses the following typographical conventions:

Semibold is used for menu names, menu commands and labels, and buttons in

■

dialog boxes.

Italic is used for important information.

■

Monospace is used for code samples.

■

UPPER CASE is used for names on keys and buttons.

■

Exchange ideas,problems, and infraredsolutions with fellowthermographers around

the world in our user-to-user forums. To go to the forums, visit:

http://www.infraredtraining.com/community/boards/

(This notice only applies to cameras with measurement capabilities.)

We recommend that you send in the camera for calibration once a year. Contact

your local sales office for instructions on where to send the camera.

(This notice only applies to cameras with measurement capabilities.)

For very accurate results, we recommend that you wait 5 minutes after you have

started the camera before measuring a temperature.

For cameras where the detector is cooled by a mechanical cooler, this time period

excludes the time it takes to cool down the detector.

10742803;a1

As with most electronic products, this equipment must be disposed of in an environmentally friendlyway, and in accordancewith existingregulationsfor electronicwaste.

Please contact your FLIR Systems representative for more details.

Training

Additional license

information

To read about infrared training, visit:

http://www.infraredtraining.com

■

http://www.irtraining.com

■

http://www.irtraining.eu

■

This license permits the user to install and use the software on any compatible

computer, provided the software is used on a maximum of two (2) computers at the

same time (for example, one laptop computer for on-site data acquisition, and one

desktop computer for analysis in the office).

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 3

Page 10

2 – Notice to user

One (1) back-up copy of the software may also be made for archive purposes.

4 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 11

3 Customer help

General

Submitting a

question

Downloads

For customer help, visit:

http://support.flir.com

To submit a question to the customer help team, you must be a registered user. It

only takes a fewminutes to registeronline. If you only wantto search the knowledgebase for existing questions and answers, you do not need to be a registered user.

When you want to submit a question, makesure thatyou have the following information to hand:

The camera model

■

The camera serial number

■

The communication protocol, or method, between the camera and your PC (for

■

example, HDMI, Ethernet, USB™, or FireWire™)

Operating system on your PC

■

Microsoft®Office version

■

Full name, publication number, and revision number of the manual

■

On the customer help site you can also download the following:

Firmware updates for your infrared camera

■

Program updates for your PC software

■

User documentation

■

Application stories

■

Technical publications

■

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 5

Page 12

4 Documentation updates

General

Our manuals are updated several times per year, and we also issue product-critical

notifications of changes on a regular basis.

To access the latest manuals and notifications, go to the Download tab at:

http://support.flir.com

It only takes a few minutes to register online. In the download area you will also find

the latest releases of manuals for our other products, as well as manuals for our

historical and obsolete products.

6 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 13

5 Important note about this manual

General

NOTE

FLIR Systems issues generic manuals that cover several cameras within a model

line.

This means that this manual may contain descriptions and explanations that do not

apply to your particular camera model.

FLIR Systemsreserves therightto discontinuemodels,software, parts oraccessories,

and other items, or to change specifications and/or functionality at any time without

prior notice.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 7

Page 14

6 Overview of camera models

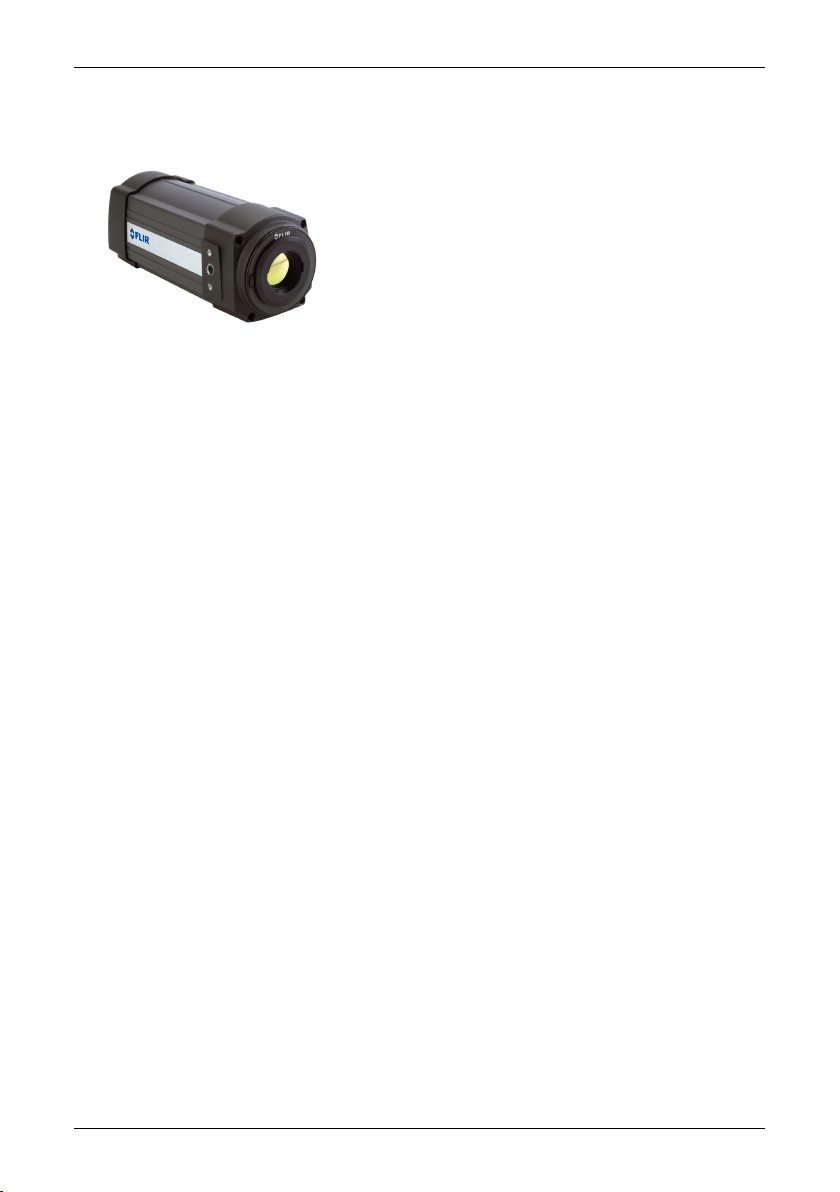

6.1 FLIR A300

T638517;a1

The FLIR A300 camera offers an affordable and accurate temperature measurement

solution for anyone who needs to solve problems that do not call forthe highest speed

or reaction and who uses a PC. Due to to its composite video output, it is also an

excellent choice for thermal image automation applications, where you can utilize its

unique properties such as looking through steam.

Key features:

■ MPEG-4 streaming

■ PoE (Power over Ethernet)

■ Built-in web server

■ General purpose I/O

■ 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.)

■ Synchronization through SNTP

■ Composite video output

■ Multi-camera utility software: IP Config Utility and IR Monitor included

■ Open and well-described TCP/IP protocol for control and set-up

■ 16-bit 320 × 240 images @ 3 Hz, radiometric

■ Lenses: 25° included, 15° and 45° optional

Typical applications:

■ Fire prevention, critical vessel monitoring, and power utility asset management

■ Volume-oriented industrial control (multi-camera installation is possible)

8 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 15

6 – Overview of camera models

6.2 FLIR A310

T638517;a1

The FLIR A310 camera offers an affordable and accurate temperature measurement

solution for anyone who needs to solve problems that need built in “smartness” such

as analysis, alarm functionality and autonomous communication using standard

protocols. The FLIR A310 camera also has all the necessary features and functions

to build distributed single- or multi-camera solutions utilizing standard Ethernet

hardware and software protocols.

The FLIR A310 camera also has built in support to connect to industrial control

equipment such as PLCs, and allows for sharing of analysis and alarm results and

simple control using the Ethernet/IP and Modbus TCP field bus protocol.

Key features:

■ Support forEthernetIP fieldbus protocol (analyse, alarm, and simple camera control)

■ Support for Modbus TCP field bus protocol (analyse, alarm, and simple camera

control)

■ Built-in extensive analysis functionality

■ Extensive alarm functionality, as a function of analysis and more

■ On schedule: file sending (FTP) or email (SMTP) of analysis results or images

■ On alarms: file sending (FTP) or email (SMTP) of analysis results or images

■ MPEG-4 streaming

■ PoE (Power over Ethernet)

■ Built-in web server

■ General purpose I/O

■ 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.)

■ Synchronization through SNTP

■ Composite video output

■ Multi-camera utility software: IP Config Utility and IR Monitor included

■ Open and well-described TCP/IP protocol for control and set-up

■ 16-bit 320 ×240 images @ 7–8 Hz, radiometric

■ Lenses: 25° included, 15° and 45° optional

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 9

Page 16

6 – Overview of camera models

Typical applications:

■ Safety with temperature alarms (multi-camera applications), fire prevention, critical

vessel monitoring, and power utility asset management

■ Volume-oriented industrial control (multi-camera installation is possible)

6.3 FLIR A315

T638517;a1

The FLIR A315 camera has features and functions that make it the natural choice for

anyone who uses PC software to solve problems and for whom 320 × 240 pixel resolution is sufficient. Among its main features are GigE Vision™ and GenICam™ compliance, which makes it plug-and-play when used with software packages such as

IMAQ Vision and Halcon.

Key features:

■ Affordable

■ GigE compliant

■ GenICam compliant

■ Trigg/synchronization/GPIO

■ 16-bit 320 × 240 images @ 60 Hz, signal, temperature linear, and radiometric

■ Compliant withany softwarethat supports GenICam, includingNational Instruments

IMAQ Vision and Stemmers Common Vision Blox

■ Lenses: 25° included, 15° and 45° optional

Typical applications:

■ High-end infrared machine vision that needs temperature measurement

■ Slag detection

■ Food processing

■ Electronics testing

■ Power resistor testing

■ Automotive

10 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 17

6 – Overview of camera models

6.4 FLIR A320 Tempscreen

T638517;a1

The FLIR A320 Tempscreen is a camera preconfigured to work well in applications

where you want to find temperature deviations in a population of people, utilizing

difference temperature alarms with a dynamically updated reference temperature.

In addition, the FLIR A320 Tempscreen camera offers an affordable and accurate

temperature measurement solution for anyone who needs to solve problems that

need built in “smartness” such as analysis, alarm functionality and autonomous

communication using standard protocols. The FLIR A320 Tempscreen camera also

has all the necessary features and functions to build distributed single- or multicamera solutions utilizing standard Ethernet hardware and software protocols.

Key features:

■ Screening: difference temperature alarm with a dynamic updated reference tem-

perature (visualized by the isotherm)

■ Built-in extensive analysis functionality

■ Extensive alarm functionality, as a function of analysis and more

■ On schedule: file sending (FTP) or email (SMTP) of analysis results or images

■ On alarms: file sending (FTP) or email (SMTP) of analysis results or images

■ MPEG-4 streaming

■ PoE (Power over Ethernet)

■ Built-in web server

■ General purpose I/O

■ 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.)

■ Synchronization through SNTP

■ Composite video output

■ Multi-camera utility software: IP Config Utility and IR Monitor included

■ Open and well-described TCP/IP protocol for control and set-up

■ 16-bit 320 × 240 images semi-real time, signal and temperature linear

■ Lenses: 25° included, 15° and 45° optional

Typical applications:

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 11

Page 18

6 – Overview of camera models

■ Safety with temperature alarms (multi-camera applications), fire prevention, critical

vessel monitoring, and power utility asset management

■ Volume-oriented industrial control (multi-camera installation is possible)

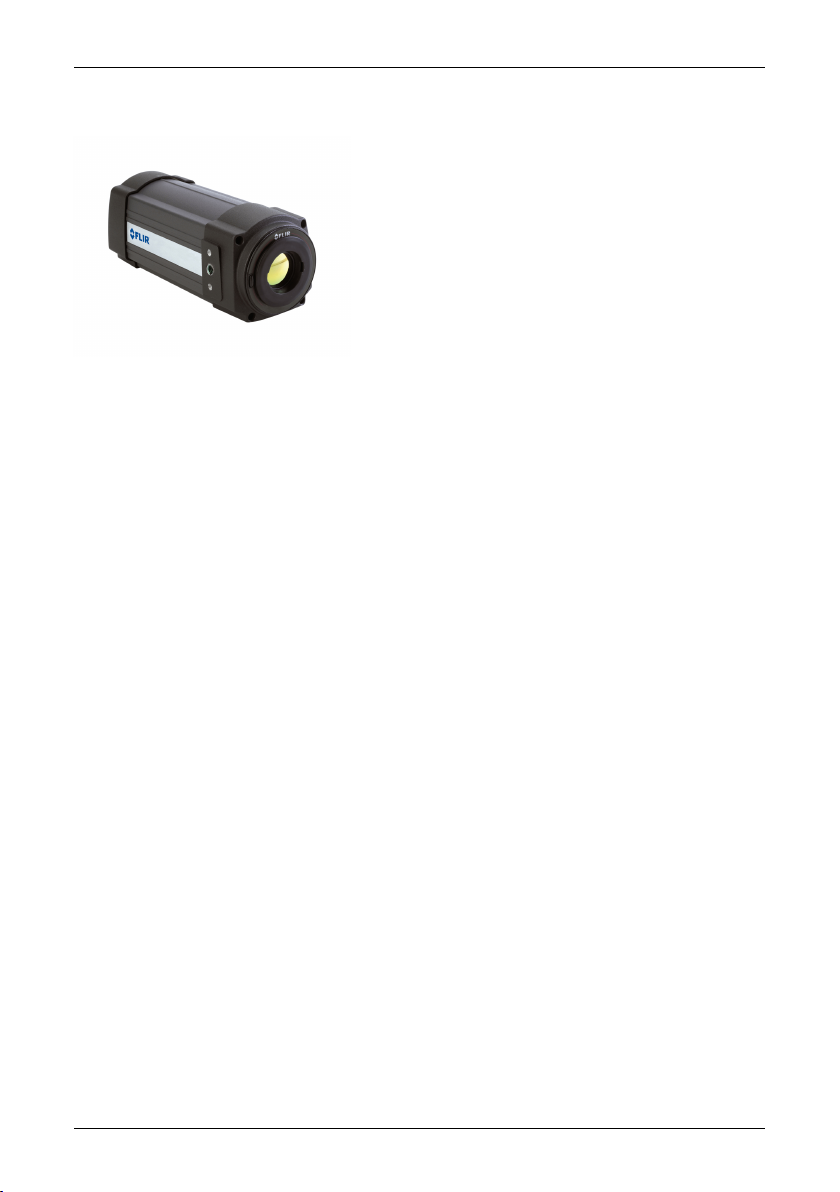

6.5 FLIR A615

T638519;a1

The FLIR A615 camera has features and functions that make it the natural choice for

anyone whouses PCsoftware tosolve problemsand needs640 ×480 pixel resolution.

Among its main features are GigE Vision™and GenICam™compliance, which makes

it plug-and-playwhen used with software packages such as IMAQ Visionand Halcon.

Key features:

■ Affordable

■ GigE compliant

■ GenICam compliant

■ Trigg/synchronization/GPIO

■ 16-bit 640 × 480 images @ 50 Hz, signal, temperature linear, and radiometric

■ Windowing mode: 640 × 240 @ 100 Hz or 640 × 120 @ 200 Hz

■ Compliant withany softwarethat supports GenICam, includingNational Instruments

IMAQ Vision and Stemmers Common Vision Blox

■ Open and well described TCP/IP protocol for control and set-up

■ Lenses: 25° included, 15° and 45° optional

Typical applications:

■ High-end infrared machine vision that needs temperature measurement

■ Slag detection

■ Food processing

■ Electronics testing

■ Power resistor testing

■ Automotive

12 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 19

7 Packing list

General

Contents

NOTE

The numberofpartsand accessories included depends onthecameramodel and/or

customer configuration.

Hard transport case or cardboard box

■

Infrared camera with lens

■

ThermoVision™ System Tools & Utilities CD-ROM

■

Application CD-ROM

■

Calibration certificate

■

Ethernet™ cable

■

Mains cable

■

Power cable, pig-tailed

■

Power supply

■

Printed Getting Started Guide

■

Printed Important Information Guide

■

User documentation CD-ROM

■

Warranty extension card or Registration card

■

six-pole screw terminal (mounted on camera)

■

Hard transport case or cardboard box

■

USB cable

■

FLIR Systems reserves the right to discontinue models, parts or accessories, and

other items, or to change specifications at any time without prior notice.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 13

Page 20

8 Installation

8.1 General information

Explanation

Default installation

paths

NOTE

The following programs are included on the ThermoVision™ System Tools & Utilities

application CD:

FLIR IP Config: A set-up and configuration program to detect and find FLIR au-

■

tomation andscience cameras ona networkand automatically assign or manually

set IP addresses.

FLIR IR Monitor: A program to control FLIR automation and science cameras on

■

a network. You typically use FLIR IR Monitor to change camera settings, lay out

measurement tools on the screen, set up alarms, etc.

FLIR IRCamera Player: APC-based remotecontrol and videoplayerfor IR cameras

■

from FLIR Systems.

A link to aweb installationof FLIR AXXXControl & Image Interfaces: Aninstallation

■

that includes Interface Control Documents (ICDs), user documentation and Ccode examples. We recommend that you read through the documentation.

C:\Program Files\FLIR Systems\FLIR IP Config

■

C:\Program Files\FLIR Systems\FLIR IR Monitor

■

C:\Program Files\FLIR Systems\FLIR IR Camera Player

■

C:\Program Files\FLIR Systems\AXXX Control & Image Interfaces

■

Functionality in the PC programs is dependent on the camera model.

14 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 21

8.2 System requirements

Microsoft®Windows®XP Professional, with Service Pack 2 (SP2)

Operating system

Hardware

■

Microsoft®Windows®Vista Ultimate 32-bit

■

Microsoft®Windows®7, 32- and 64-bit

■

Personal computer with a 2 GHz 32-bit or 64-bit processor

■

1 GB of RAM, or greater

■

20 GB of hard disk space

■

Super VGA (1024 × 768) or higher-resolution monitor

■

Support for DirectX 9 graphics with:

■

WDDM driver

■

128 MB of graphics memory (minimum)

■

Pixel Shader 2.0 (in hardware)

■

32 bits per pixel

■

DVD-ROM drive

■

Audio output

■

Keyboard and Microsoft®mouse, or a compatible pointing device

■

8 – Installation

Software

SEE

Microsoft®Internet Explorer 6 or later

For specific information about system requirements for the operating systems mentioned above, please visit: http://www.microsoft.com/windows/.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 15

Page 22

8 – Installation

8.3 Installation

General

NOTE

Procedure

Last-minute changes and other important information can be found in the read-me

file on the CD-ROM. We recommend that you read this file before you install the

programs.

If you experience problemsduring theinstallation, please visit our CustomerHelp

■

by pointing your browser to http://support.flir.com.

You must be an Adminstrator or a user with Administrative Rights to install the

■

programs.

A complete installation consists of several subinstallations, some of which are

■

from third-party vendors. Do not abort these subinstallations, as they are needed

for the complete installation.

A complete installation can take up to 10 minutes to complete.

■

Follow this procedure:

Close down all applications.1

Insert the ThermoVision™ System Tools & Utilities CD-ROM into the CD-

2

ROM drive on the computer. The installation should start automatically.

Should the installation notstart automatically,start Windows®Explorer and

double-click SETUP.HTM on the CD-ROM.

Click one of the following:

3

Install FLIR IP Config.

■

Install FLIR IR Monitor.

■

Install FLIR Camera Player.

■

Install AXXX Control & Image Interfaces.

■

Follow the on-screen instructions.4

16 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 23

9 Mechanical installation

9.1 Installation of fixed cameras

Mounting

interfaces

Notes on

permanent

mounting

Vibrations

Further

information

The camera unit has been designed to allow it to be mounted in any position. The

housing hasthree mounting interfaces–bottom, left, andright – eachwith the following threaded holes.

FLIR A3XX cameras:

2 × M4 metric threaded holes

■

1 × UNC ¼-20 standard tripod mount.

■

FLIR A6XX cameras:

2 × M4 metric threaded holes

■

1 × UNC ¼-20 standard tripod mount.

■

If the camera unit is to be permanently mounted at the application site, certain steps

are required.

The camera unit might need to be enclosed in a protective housing and, depending

on the ambient conditions (e.g. temperature), the housing may need to be cooled

or heated by means of water or air.

In very dusty conditions the installationmight also need to have a stream of pressurized air directed at the lens, in order to prevent dust build-up.

When mounting the camera unit in harsh industrial environments, every precaution

should be taken when securing the unit.

If the environment exposesthe unit tosevere vibrations, theremay be aneed to secure

the mounting screws by means of Loctite™ or another industrial brand of threadlocking liquid, as well as to dampen the vibrations by mounting the camera unit on

a specially designed base.

For further information regarding mounting recommendations and environmental

enclosures, contact FLIR Systems.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 17

Page 24

9 – Mechanical installation

9.2 Mounting and removing lenses (FLIR A3XX series)

9.2.1 Mounting an additional infrared lens

NOTE

Procedure

Do nottouchthe lens surfacewhenyou mount an infraredlens. If this happens,clean

the lens according to the instructions in section 13.2 – Infrared lens on page 32.

Follow this procedure to mount an additional infrared lens:

Push the lens release button to unlock the lens ring. The lens ring is made

1

of plastic and holds the plastic lens cap.

Rotate the lens ring 30° counter-clockwise (looking at the front of the lens).2

Carefully pull out the lens ring from the bayonet ring.3

Correctly position the lens in front of the bayonet ring.4

Carefully push the lens into position.5

Rotate the lens 30° clockwise (looking at the front of the lens).6

18 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 25

9.2.2 Removing an additional infrared lens

Do not touch the lens surface when you remove an infrared lens. If this happens,

NOTE

■

clean the lens according to the instructions in section 13.2 – Infrared lens on

page 32.

When you have removed the lens, put the lens caps on the lens immediately, to

■

protect it from dust and fingerprints.

9 – Mechanical installation

Procedure

Follow this procedure to remove an additional infrared lens:

Push the lens release button to unlock the lens.1

Rotate the lens counter-clockwise 30° (looking at the front of the lens).2

Carefully pull out the lens from the bayonet ring.3

Correctly position the lens ring in front of the bayonet ring.4

Carefully push the lens ring into position.5

Rotate the lens ring 30° clockwise (looking at the front of the lens).6

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 19

Page 26

9 – Mechanical installation

9.3 Mounting and removing lenses (FLIR A6XX series)

9.3.1 Removing an infrared lens

Do not touch the lens surface when you remove an infrared lens. If this happens,

NOTE

■

clean the lens according to the instructions in section 13.2 – Infrared lens on

page 32.

When you have removed the lens, put the lens caps on the lens immediately, to

■

protect it from dust and fingerprints.

Procedure

Follow this procedure to remove an infrared lens:

Rotate the lens counter-clockwise 30° (looking at the front of the lens).1

Carefully pull out the lens from the bayonet ring.2

20 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 27

9.3.2 Mounting an infrared lens

9 – Mechanical installation

NOTE

Procedure

Do nottouchthe lens surfacewhenyou mount an infraredlens. If this happens,clean

the lens according to the instructions in section 13.2 – Infrared lens on page 32.

Follow this procedure to mount an infrared lens:

Correctly position the lens in front of the bayonet ring.1

Carefully push the lens into position.2

Rotate the lens 30° clockwise (looking at the front of the lens) until a click

3

is heard.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 21

Page 28

10 Connectors, controls, and

indicators

FLIR A3XX series

Explanation

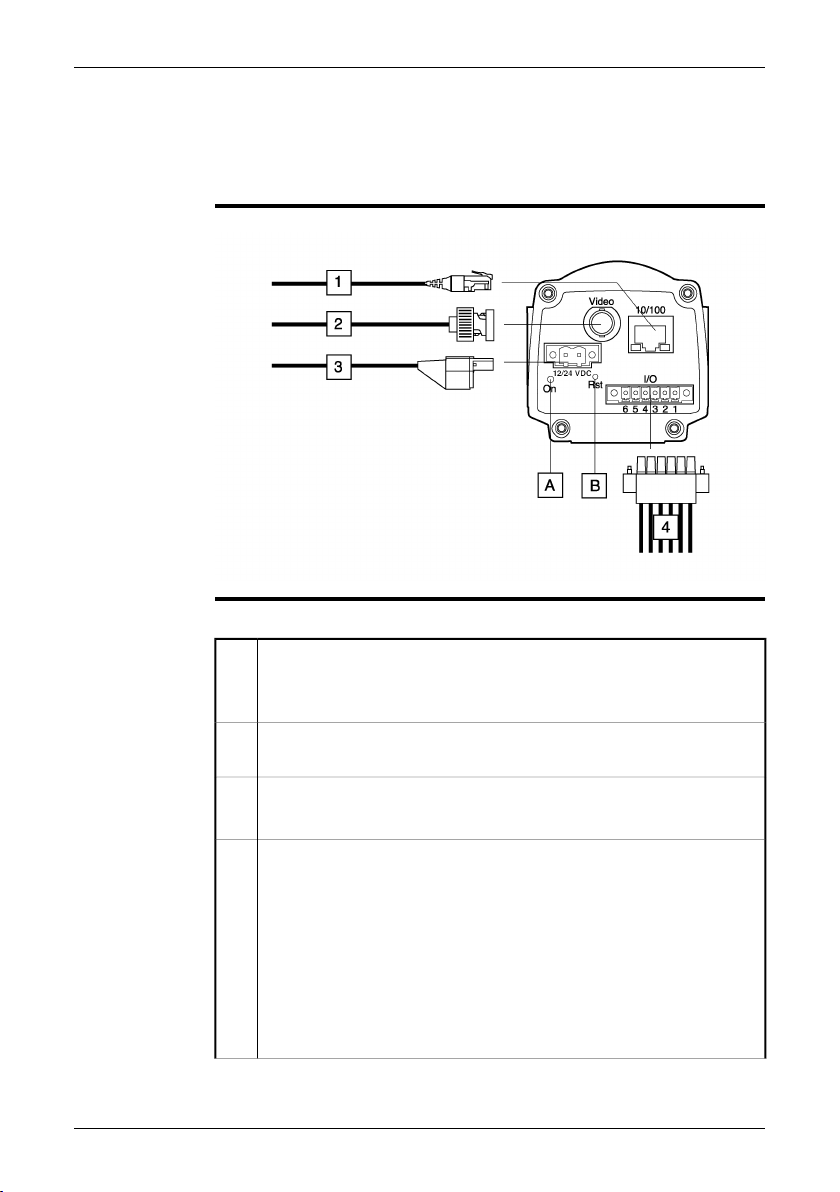

10769803;a2

This table explains the figure above:

Network cablewith an RJ45connector for Ethernet™connectivity and PoE™

1

(dependent on the camera model)

Note: Only CAT-6 Ethernet™ cables should be used with this camera.

Video cable with a BNC connector for CVBS (composite video) output

2

(subject to camera model)

Power cable for 12–24 VDC power in

3

Note: The power connector on the camera is polarity protected.

Digital I/O ports, opto-isolated (six-pole screw terminal)

4

Pin configuration:

1 IN 1

2 IN 2

3 OUT 1

4 OUT 2

5 I/O +

6 I/O –

For a schematic overview of the digital I/O ports, see page 35.

22 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 29

Power indicator

A

Note: The LEDs indicate the following:

ange.

10 – Connectors, controls, and indicators

ExplanationType of signal

The camera is starting up.The LED glows continuously or-

NOTE

The LED glows continuously red.

An error has been detected. Contact service.

The camera has started.The LED glows continuously

green.

The LED flashes 10 times per second.

Hardware reset button (for a factory default reset)

B

An error has been detected. Contact service.

Use an unbent paper clip or a similartool to press the reset button through

the small hole on the back of the camera for 5 seconds, then release the

button.

Cables for digital I/O ports should be 100 m/328 ft. maximum.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 23

Page 30

10 – Connectors, controls, and indicators

FLIR A6XX series

Explanation

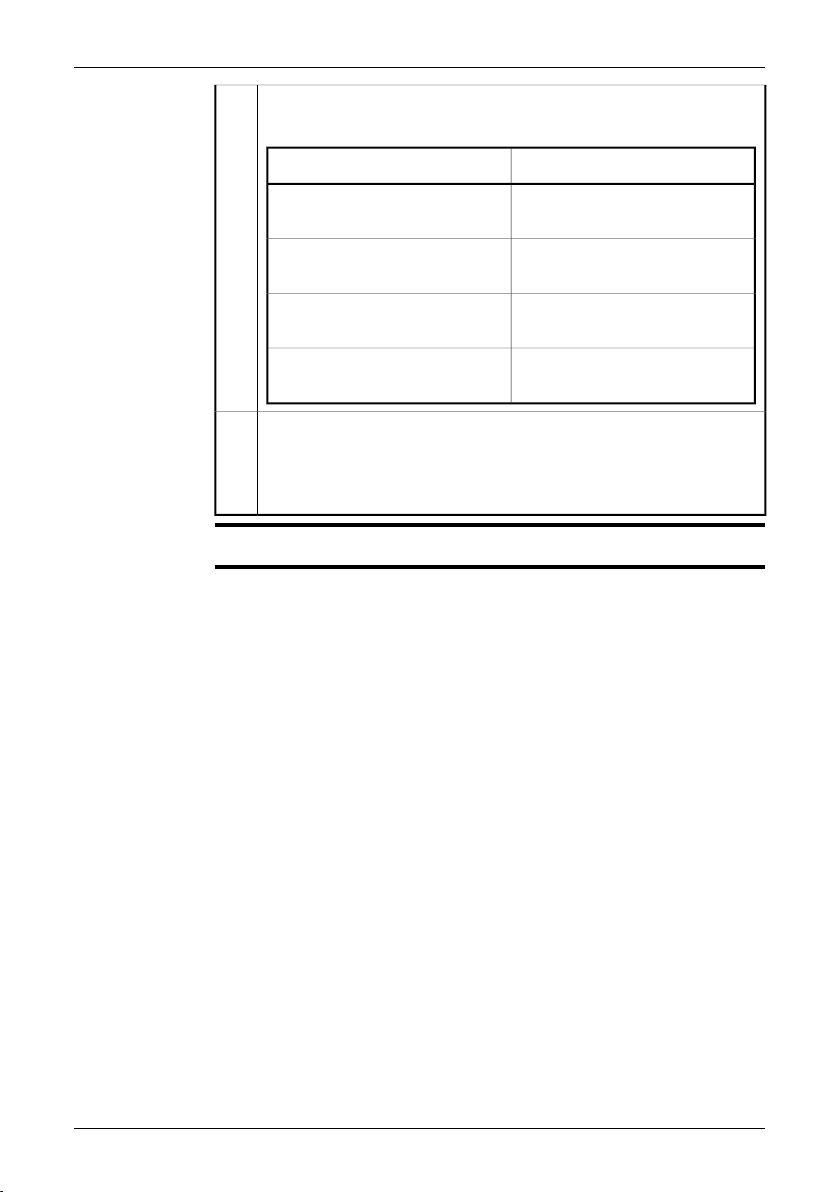

T638542;a1

This table explains the figure above:

Network cablewith an RJ45connector for Ethernet™connectivity and PoE™

1

(dependent on the camera model)

Note: Only CAT-6 Ethernet™ cables should be used with this camera.

Power cable for 12–24 VDC power in

2

Note: The power connector on the camera is polarity protected.

USB cable with a USB mini-B connector for control and image transfer.3

Digital I/O ports, opto-isolated (six-pole screw terminal)

4

Pin configuration:

1 IN 1

2 IN 2

3 OUT 1

4 OUT 2

5 I/O +

6 I/O –

For a schematic overview of the digital I/O ports, see page 35.

Hardware reset button (for a factory default reset)

A

Use an unbent paper clip or a similartool to press the reset button through

the small hole on the back of the camera for 5 seconds, then release the

button.

24 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 31

Power indicator

B

Note: The LEDs indicate the following:

ange.

10 – Connectors, controls, and indicators

ExplanationType of signal

The camera is starting up.The LED glows continuously or-

NOTE

The LED glows continuously red.

An error has been detected. Contact service.

The camera has started.The LED glows continuously

green.

The LED flashes 10 times per second.

An error has been detected. Contact service.

Cables for digital I/O ports should be 100 m/328 ft. maximum.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 25

Page 32

11 Example system overviews

Figure

10777403;a3

Explanation

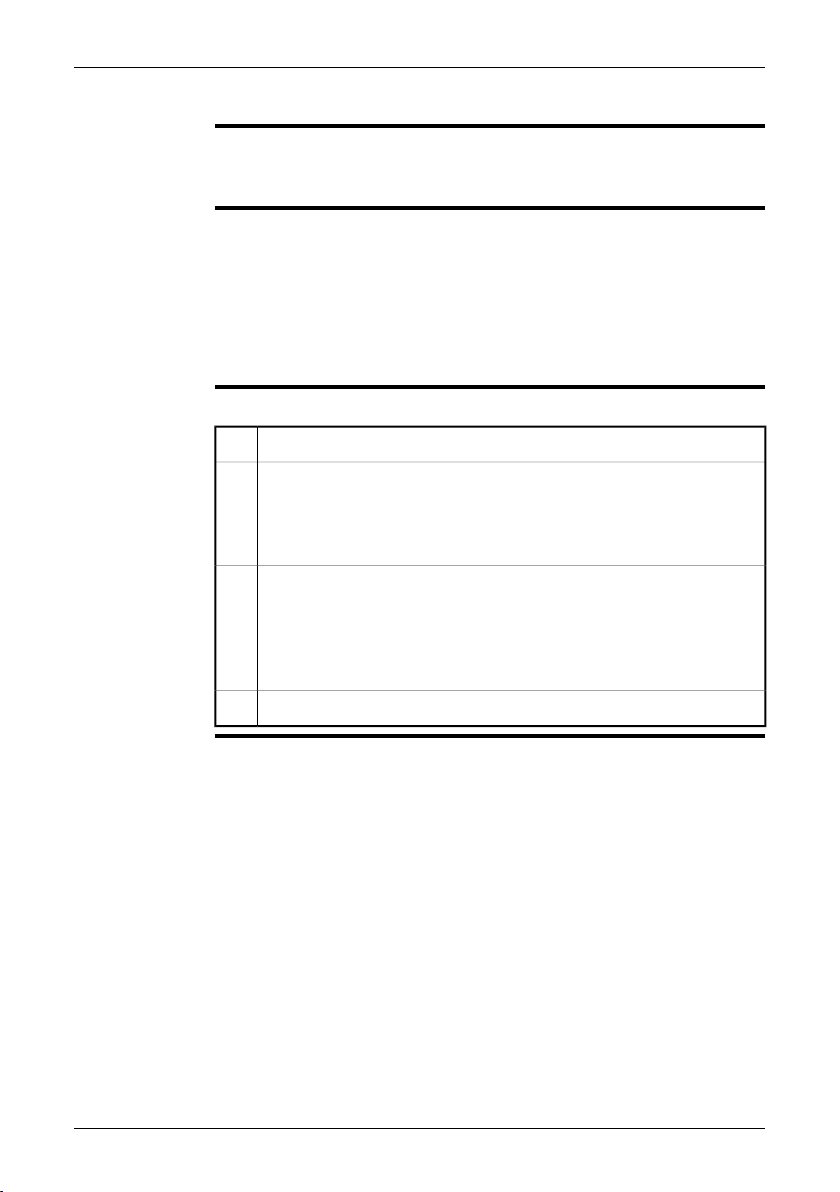

This table explains the figure:

Computer1

CAT-6 Ethernet™ cable with RJ45 connectors2

Industrial Ethernet™ switches with fiber optic ports3

Fiber optic cable4

FLIR A3XX/A6XX cameras5

Industrial process to be monitored, e.g., items on a conveyor belt6

26 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 33

11 – Example system overviews

Figure

10777503;a3

Explanation

This table explains the figure:

Computer1

CAT-6 Ethernet™ cable with RJ45 connectors2

Industrial Ethernet™ switch3

FLIR A3XX/A6XX cameras4

Industrial process to be monitored, e.g., a gasifier5

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 27

Page 34

11 – Example system overviews

Figure

10777603;a4

Explanation

This table explains the figure:

Computer1

CAT-6 Ethernet™ cable with RJ45 connectors2

Industrial Ethernet™ switches with fiber optic ports3

Fiber optic cable4

Wireless access points5

CAT-6 Ethernet™ cablewith RJ45 connectors—poweringthe camera using

6

PoE (Power over Ethernet™, dependent on the camera model)

Industrial Ethernet™ switch7

FLIR A3XX/A6XX cameras8

28 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 35

12 Temperature screening

Applicability

Description of the

function

NOTE

Procedure

This section applies to the following camera models:

FLIR A320 (30 Hz) Temp screen

■

FLIR A320 (9 Hz) Temp screen

■

The screening function in allows you to screen a large number of persons for facial

temperatures that lie above a set reference temperature.

When an elevated temperature is detected, the camera will trigger a visible and/or

audible alarm.

You can change thetemperature 2°C/3.6°F (describedbelow) using theScreening

■

tab in FLIR IR Monitor (included on the ThermoVision™ System Tools & Utilities

1.5.1 HF2 (1.5.1.16)). HF2 can be downloaded from http://support.flir.com.

The camerashould run for at least 30 minutes beforecarrying out measurements.

■

The distance to the face should be adapted so that the face covers more than

■

75% of the image width.

Follow this procedure:

Connect the camera to a video monitor.1

Connect the camera to power.2

Connect the IN 1 port to +10–30 VDC, using cables and an NO (normally

3

open) electrical switch.

Now aim the camera at a face (at the inner corner of the eye) having a

4

supposedly normal temperature. Close the switch for a period of less than

2 seconds to acquire a temperature sample. Repeat this procedure on at

least 10 faces with supposedly normal temperatures. You have now set the

reference temperature. If you want to reset or restart the reference temperature, close the switch for a period of more than 2 seconds. See the

schematic drawing on the next page for setup details.

You can now begin the screening. Aim the camera at the faces of the per-

5

sons whose facial temperatures you want to screen (at the inner corner of

the eye). If a person’s facial temperature ismore than 2°C/3.6°F above the

set reference temperature, an alarm will be triggered.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 29

Page 36

+ 10 - 30 volts

Ground

focus near

focus far

both = autofocus

Acquire sample

Reset/restart reference temperature

Autofocus

Screening of elevated facial temperatures using

FLIR A320

12 – Temperature screening

T638569;a1

30 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 37

13 Cleaning the camera

13.1 Camera housing, cables, and other items

Liquids

Equipment

Procedure

CAUTION

Use one of these liquids:

Warm water

■

A weak detergent solution

■

A soft cloth

Follow this procedure:

Soak the cloth in the liquid.1

Twist the cloth to remove excess liquid.2

Clean the part with the cloth.3

Do not apply solvents or similar liquids to the camera, the cables, or other items.

This can cause damage.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 31

Page 38

13 – Cleaning the camera

13.2 Infrared lens

Liquids

Equipment

Procedure

WARNING

CAUTION

Use one of these liquids:

96% ethyl alcohol (C2H5OH).

■

DEE (= ‘ether’ = diethylether, C4H10O).

■

50% acetone (= dimethylketone, (CH3)2CO)) + 50% ethyl alcohol (by volume).

■

This liquid prevents drying marks on the lens.

Cotton wool

Follow this procedure:

Soak the cotton wool in the liquid.1

Twist the cotton wool to remove excess liquid.2

Clean the lens one time only and discard the cotton wool.3

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and

warning labels on containers before you use a liquid: the liquids can be dangerous.

Be careful when you cleanthe infraredlens. The lens has a delicate anti-reflective

■

coating.

Do not clean the infrared lens too vigorously. This can damage the anti-reflective

■

coating.

32 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 39

13.3 Infrared detector

13 – Cleaning the camera

General

NOTE

CAUTION

Procedure

Even small amounts of dust on the infrared detector can result in major blemishes

in the image. To remove any dust from the detector, follow the procedure below.

This section only appliesto cameras whereremoving the lensexposes the infrared

■

detector.

In somecases thedustcannot be removedby following thisprocedure: the infrared

■

detector mustbe cleanedmechanically. Thismechanical cleaning mustbe carried

out by an authorized service partner.

In Step2 below,do not usepressurized air frompneumatic air circuits ina workshop,

etc., as this air usually contains oil mist to lubricate pneumatic tools.

Follow this procedure:

Remove the lens from the camera.1

Use pressurized air from a compressed air canister to blow off the dust.2

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 33

Page 40

14 Technical data

For technical data, refer to the datasheets on the User Documentation CD-ROM that

comes with the camera.

Datasheets are also available at http://support.flir.com.

34 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 41

15 Pin configurations

Pin configuration

for I/O connector

ConfigurationPin

1 IN 1

IN 22

OUT 13

OUT 24

I/O +5

I/O –6

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 35

Page 42

15 – Pin configurations

Schematic

overview of the

digital I/O ports

10771603;a1

36 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 43

16 Mechanical drawings

16.1 FLIR A3XX series

16.1.1 Camera dimensions (front)

Figure

10770303;a1

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 37

Page 44

16 – Mechanical drawings

16.1.2 Camera dimensions (side)

Figure

NOTE

10770403;a1

The BNC connector on the rear panel is dependent on the camera model.

38 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 45

16.1.3 Camera dimensions (bottom)

16 – Mechanical drawings

Figure

NOTE

10770503;a1

The BNC connector on the rear panel is dependent on the camera model.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 39

Page 46

16 – Mechanical drawings

16.1.4 Camera dimensions (with 10 mm/45° lens)

Figure

NOTE

10770603;a1

The BNC connector on the rear panel is dependent on the camera model.

40 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 47

16.1.5 Camera dimensions (with 30 mm/15° lens)

16 – Mechanical drawings

Figure

NOTE

10770703;a1

The BNC connector on rthe ear panel is dependent on the camera model.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 41

Page 48

16 – Mechanical drawings

16.1.6 Infrared lens (10 mm/45°)

Figure

10762403;a1

42 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 49

16.1.7 Infrared lens (30 mm/15°)

16 – Mechanical drawings

Figure

10762503;a1

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 43

Page 50

16 – Mechanical drawings

16.2 FLIR A6XX series

16.2.1 Camera dimensions (front view, without lens)

Figure

T638548;a1

44 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 51

16.2.2 Camera dimensions (side view, without lens)

16 – Mechanical drawings

Figure

T638546;a1

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 45

Page 52

16 – Mechanical drawings

16.2.3 Camera dimensions (side view, with 24.5 mm/25° lens)

Figure

T638545;a1

46 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 53

16.2.4 Specification of mounting interfaces, #1

16 – Mechanical drawings

Figure

T638550;a1

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 47

Page 54

16 – Mechanical drawings

16.2.5 Specification of mounting interfaces, #2

Figure

T638544;a1

48 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 55

16.2.6 Camera dimensions (rear view)

16 – Mechanical drawings

Figure

T638547;a1

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 49

Page 56

16 – Mechanical drawings

16.2.7 Infrared lens (24.5 mm/25°)

Figure

T638549;a1

50 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 57

17 About FLIR Systems

FLIR Systemswas establishedin 1978to pioneerthe developmentof high-performance

infrared imaging systems, and is the world leader in the design, manufacture, and

marketing of thermal imaging systems for a wide variety of commercial, industrial,

and government applications. Today, FLIR Systems embraces five major companies

with outstanding achievements in infrared technology since 1958—the Swedish

AGEMA Infrared Systems (formerly AGA Infrared Systems), the three United States

companies Indigo Systems, FSI, and Inframetrics, and the French company Cedip.

In November 2007, Extech Instruments was acquired by FLIR Systems.

10722703;a2

Figure 17.1 LEFT: Thermovision® Model 661 from 1969. The camera weighed approximately 25 kg

(55 lb.), the oscilloscope20 kg (44 lb.), and the tripod 15 kg (33 lb.). The operatoralso needed a 220 VAC

generator set, and a 10 L (2.6 US gallon) jar with liquid nitrogen.To the left of the oscilloscope thePolaroid

attachment (6 kg/13 lb.) can be seen. RIGHT: FLIR i7 from 2009. Weight: 0.34 kg (0.75 lb.), including the

battery.

The companyhas soldmore than100,000 infraredcameras worldwidefor applications

such as predictive maintenance, R & D, non-destructive testing, process control and

automation, and machine vision, among many others.

FLIR Systems has three manufacturing plants in the United States (Portland, OR,

Boston, MA, Santa Barbara, CA) and one in Sweden (Stockholm). Since 2007 there

is alsoa manufacturingplant in Tallinn, Estonia. Direct sales officesin Belgium,Brazil,

China, France, Germany, Great Britain, Hong Kong, Italy, Japan, Korea, Sweden, and

the USA—togetherwith a worldwide network of agents and distributors—support our

international customer base.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 51

Page 58

17 – About FLIR Systems

FLIR Systems is at the forefront of innovation in the infrared camera industry. We anticipate marketdemand by constantly improving our existing cameras and developing

new ones.The companyhas set milestones in product design and development such

as the introduction of the first battery-operated portable camera for industrial inspections, and the first uncooled infrared camera, to mention just two innovations.

FLIR Systems manufactures all vital mechanical and electronic components of the

camera systemsitself. From detector design and manufacturing, to lenses and system

electronics, to final testing and calibration, all production steps are carried out and

supervised by our own engineers. The in-depth expertise of these infrared specialists

ensures the accuracy and reliability of all vital components that are assembled into

your infrared camera.

17.1 More than just an infrared camera

At FLIR Systems we recognize that our job is to go beyond just producing the best

infrared camera systems. We are committed to enabling all users of our infrared

camera systems to work more productively by providing them with the most powerful

camera–software combination.Especially tailoredsoftware forpredictive maintenance,

R & D, and process monitoring is developed in-house. Most software is available in

a wide variety of languages.

We support all our infrared cameras with a wide variety of accessories to adapt your

equipment to the most demanding infrared applications.

17.2 Sharing our knowledge

Although our cameras are designed to be very user-friendly, there is a lot more to

thermography than just knowing how to handle a camera. Therefore, FLIR Systems

has founded the Infrared Training Center (ITC), a separate business unit, that provides

certified training courses. Attending one of the ITC courses will give you a truly handson learning experience.

The staff of the ITC are also there to provide you with any application support you

may need in putting infrared theory into practice.

17.3 Supporting our customers

FLIR Systems operates a worldwide service network to keep your camera running at

all times. If you discover a problem with your camera, local service centers have all

the equipment and expertise to solve it within the shortest possible time. Therefore,

there is no need to send your camera to the other side of the world or to talk to

someone who does not speak your language.

52 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 59

17 – About FLIR Systems

17.4 A few images from our facilities

10401303;a1

Figure 17.2 LEFT: Development of system electronics; RIGHT: Testing of an FPA detector

10401403;a1

Figure 17.3 LEFT: Diamond turning machine; RIGHT: Lens polishing

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 53

Page 60

17 – About FLIR Systems

10401503;a1

Figure 17.4 LEFT: Testing of infrared cameras in the climatic chamber; RIGHT: Robot used for camera

testing and calibration

54 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 61

18 Glossary

ExplanationTerm or expression

absorption (absorption factor)

atmosphere

autoadjust

autopalette

blackbody

blackbody radiator

calculated atmospherictransmission

cavity radiator

color temperature

continuous adjust

The amount of radiation absorbed by an object relative to the

received radiation. A number between 0 and 1.

The gasesbetween the objectbeing measured andthe camera,

normally air.

A function making a camera perform an internal image correction.

The IR image isshown with anuneven spread ofcolors, displaying cold objects as well as hot ones at the same time.

Totally non-reflective object. All its radiation is due to its own

temperature.

An IR radiating equipment with blackbody properties used to

calibrate IR cameras.

A transmissionvalue computed fromthe temperature, therelative

humidity of air and the distance to the object.

A bottle shaped radiator with an absorbing inside, viewed

through the bottleneck.

The temperature for which the color of a blackbody matches a

specific color.

The process that makes heat diffuse into a material.conduction

A function that adjusts the image. The function works all the

time, continuouslyadjusting brightness andcontrast according

to the image content.

convection

emissivity (emissivity factor)

emittance

environment

estimated atmospheric transmission

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 55

Convection is a heat transfer mode where a fluid is brought into

motion, either by gravity or another force, thereby transferring

heat from one place to another.

An isotherm with two color bands, instead of one.dual isotherm

The amount of radiation coming from an object, compared to

that of a blackbody. A number between 0 and 1.

Amount of energy emitted from an object per unit of time and

area (W/m2)

Objects and gases that emit radiation towards the object being

measured.

A transmissionvalue, supplied bya user, replacing a calculated

one

Page 62

18 – Glossary

ExplanationTerm or expression

external optics

FOV

graybody

IFOV

image correction(internal or external)

isotherm

isothermal cavity

Laser LocatIR

Extra lenses, filters, heat shields etc. that can be put between

the camera and the object being measured.

A material transparent onlyto some ofthe infrared wavelengths.filter

Field of view: The horizontal angle that can be viewed through

an IR lens.

Focal plane array: A type of IR detector.FPA

An object that emits a fixed fraction of the amount of energy of

a blackbody for each wavelength.

Instantaneous field of view: A measureof the geometrical resolution of an IR camera.

A way of compensatingfor sensitivity differencesin various parts

of live images and also of stabilizing the camera.

Non-visible radiation,having a wavelengthfrom about2–13 μm.infrared

infraredIR

A function highlighting those parts of an image that fall above,

below or between one or more temperature intervals.

A bottle-shaped radiator with a uniform temperature viewed

through the bottleneck.

An electrically powered light source on the camera that emits

laser radiation in a thin, concentrated beam to point at certain

parts of the object in front of the camera.

laser pointer

level

manual adjust

NETD

object parameters

object signal

An electrically powered light source on the camera that emits

laser radiation in a thin, concentrated beam to point at certain

parts of the object in front of the camera.

The center value of the temperature scale, usually expressed

as a signal value.

A wayto adjust theimageby manually changingcertainparameters.

Noise equivalenttemperature difference. Ameasureof theimage

noise level of an IR camera.

Undesired small disturbance in the infrared imagenoise

A set of values describing the circumstances under which the

measurement ofan object was made, andthe object itself(such

as emissivity, reflected apparent temperature, distance etc.)

A non-calibrated value related to the amount of radiation received by the camera from the object.

56 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 63

18 – Glossary

ExplanationTerm or expression

The set of colors used to display an IR image.palette

Stands for picture element. One single spot in an image.pixel

radiance

radiation

range

reference temperature

reflection

relative humidity

saturation color

span

Amount of energy emitted from an object per unit of time, area

and angle (W/m2/sr)

Amount of energy emitted from an object per unit of time (W)radiant power

The process by which electromagnetic energy, isemitted byan

object or a gas.

A piece of IR radiating equipment.radiator

The current overall temperature measurement limitation of an

IR camera. Cameras can have several ranges. Expressed as

two blackbody temperatures that limit the current calibration.

A temperature which the ordinary measured values can be

compared with.

The amount of radiation reflected by an object relative to the

received radiation. A number between 0 and 1.

Relative humidity represents theratio between thecurrent water

vapour mass in the airand the maximum it may contain in saturation conditions.

The areas that contain temperatures outside the present level/span settings are colored with the saturation colors. The saturation colors contain an ‘overflow’ color and an ‘underflow’

color. There is also a thirdred saturation colorthat marks everything saturated by the detectorindicating that the range should

probably be changed.

The interval of the temperature scale, usually expressed as a

signal value.

spectral (radiant) emittance

Amount of energy emitted from an object per unit of time, area

and wavelength (W/m2/μm)

temperature difference,or difference

of temperature.

temperature range

A valuewhich is theresult of a subtraction between twotemperature values.

The current overall temperature measurement limitation of an

IR camera. Cameras can have several ranges. Expressed as

two blackbody temperatures that limit the current calibration.

temperature scale

The way in whichan IR imagecurrently is displayed.Expressed

as two temperature values limiting the colors.

infrared imagethermogram

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 57

Page 64

18 – Glossary

ExplanationTerm or expression

transmission (ortransmittance) factor

transparent isotherm

visual

Gases and materials can be more orless transparent. Transmission is the amount of IR radiation passing through them. A

number between 0 and 1.

An isothermshowing a linearspread of colors,instead of covering the highlighted parts of the image.

Refers to the video mode of a IR camera, as opposed to the

normal, thermographicmode. When a camera isin video mode

it captures ordinary video images, while thermographic images

are captured when the camera is in IR mode.

58 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 65

19 Thermographic measurement

techniques

19.1 Introduction

An infraredcamera measuresand imagesthe emitted infrared radiation from an object.

The fact that radiation is a function of object surface temperature makes it possible

for the camera to calculate and display this temperature.

However, the radiation measured by the camera does not only depend on the temperature of the object but is also a function of the emissivity. Radiation also originates

from the surroundings and is reflected in the object. The radiation from the object

and the reflected radiation will also be influenced by the absorptionof the atmosphere.

To measure temperature accurately, it is therefore necessary to compensate for the

effects of a number of different radiation sources. This is done on-line automatically

by the camera. The following object parameters must, however, be supplied for the

camera:

■ The emissivity of the object

■ The reflected apparent temperature

■ The distance between the object and the camera

■ The relative humidity

■ Temperature of the atmosphere

19.2 Emissivity

The most important object parameter to set correctly is the emissivity which, in short,

is a measure of how much radiation is emitted from the object, compared to that from

a perfect blackbody of the same temperature.

Normally, object materials and surface treatments exhibit emissivity ranging from

approximately 0.1 to 0.95. A highly polished (mirror) surface falls below 0.1, while an

oxidized or painted surface has a higher emissivity. Oil-based paint, regardless of

color in the visible spectrum, has an emissivity over 0.9 in the infrared. Human skin

exhibits an emissivity 0.97 to 0.98.

Non-oxidized metals represent an extreme case of perfect opacity and highreflexivity,

which does not vary greatly with wavelength. Consequently, the emissivity of metals

is low– onlyincreasing with temperature. For non-metals, emissivity tendsto behigh,

and decreases with temperature.

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 59

Page 66

19 – Thermographic measurement techniques

19.2.1 Finding the emissivity of a sample

19.2.1.1 Step 1: Determining reflected apparent temperature

Use one of the following two methods to determine reflected apparent temperature:

19.2.1.1.1 Method 1: Direct method

Look for possible reflection sources, considering that the incident angle = reflection angle (a

1

= b).

10588903;a1

Figure 19.1 1 = Reflection source

If the reflection source is a spot source, modify the source by obstructing it using a piece if

2

cardboard.

10589103;a2

Figure 19.2 1 = Reflection source

60 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 67

19 – Thermographic measurement techniques

Measure the radiation intensity (= apparent temperature) from the reflecting source using the

3

following settings:

Emissivity: 1.0

■

D

: 0

■

obj

You can measure the radiation intensity using one of the following two methods:

10589003;a2

Figure 19.3 1 = Reflection source

Note: Using a thermocouple to measure reflected apparent temperature is not recom-

mended for two important reasons:

■ A thermocouple does not measure radiation intensity

■ A thermocouple requires a very good thermal contact to the surface, usually by

gluing and covering the sensor by a thermal isolator.

19.2.1.1.2 Method 2: Reflector method

Crumble up a large piece of aluminum foil.1

Uncrumble the aluminum foil and attach it to a piece of cardboard of the same size.2

Put the piece of cardboard in front of the object you want to measure. Make sure that the side

3

with aluminum foil points to the camera.

Set the emissivity to 1.0.4

Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010 61

Page 68

19 – Thermographic measurement techniques

Measure the apparent temperature of the aluminum foil and write it down.

5

10727003;a2

Figure 19.4 Measuring the apparent temperature of the aluminum foil

19.2.1.2 Step 2: Determining the emissivity

Select a place to put the sample.1

Determine and set reflected apparent temperature according to the previous procedure.2

Put a piece of electrical tape with known high emissivity on the sample.3

Heat the sample at least 20 K above room temperature. Heating must be reasonably even.4

Focus and auto-adjust the camera, and freeze the image.5

Adjust Level and Span for best image brightness and contrast.6

Set emissivity to that of the tape (usually 0.97).7

Measure the temperature of the tape using one of the following measurement functions:

8

Isotherm (helps you to determine both the temperature and how evenly you have heated

■

the sample)

Spot (simpler)

■

Box Avg (good for surfaces with varying emissivity).

■

Write down the temperature.9

Move your measurement function to the sample surface.10

Change the emissivity setting until you read the same temperature as your previous measure-

11

ment.

Write down the emissivity.12

Note:

62 Publ. No. T559498 Rev. a461 – ENGLISH (EN) – August 19, 2010

Page 69

19 – Thermographic measurement techniques

■ Avoid forced convection

■ Look for a thermally stable surrounding that will not generate spot reflections

■ Use high quality tape that you know is not transparent, and has a high emissivity

you are certain of

■ This method assumes that the temperature of your tape and the sample surface

are the same. If they are not, your emissivity measurement will be wrong.

19.3 Reflected apparent temperature

This parameter is used to compensate for the radiation reflected in the object. If the

emissivity is low and the object temperature relatively far from that of the reflected it

will be important to set and compensate for the reflected apparent temperature correctly.

19.4 Distance

The distance is the distance between the object and the front lens of the camera.This

parameter is used to compensate for the following two facts:

■ That radiation from the target is absorbed by the athmosphere between the object

and the camera.

■ That radiation from the atmosphere itself is detected by the camera.

19.5 Relative humidity

The camera can also compensate for the fact that the transmittance is also dependent

on the relative humidity of the atmosphere. To do this set the relative humidity to the

correct value. For short distances and normal humidity the relative humidity can normally be left at a default value of 50%.

19.6 Other parameters

In addition, some cameras and analysis programs from FLIR Systems allow you to

compensate for the following parameters:

■ Atmospheric temperature – i.e. the temperature of the atmosphere between the

camera and the target

■ External optics temperature – i.e. the temperature of any external lensesor windows

used in front of the camera

■ External optics transmittance – i.e. the transmission of any external lenses or win-