Page 1

A6700sc/A6750sc

User’s Manual

This document is controlled to FLIR Technology Level 2. The information contained in this document

pertains to a dual use product controlled for export by the Export Administration Regulations

(EAR). Diversion contrary to US law is prohibited. US Department of Commerce authorization is not

required prior to export or transfer to foreign persons or parties unless otherwise prohibited.

Document Number: 29249-000

Version: 5

Issue Date: February 2, 2015

Page 2

FLIR Systems, Inc.

9 Townsend West,

Nashua, NH 03063

Support: 1-800-GO-INFR A (800-464-6372)

http://flir.custhelp.com

A6700sc/A6750sc User’s Manual

Service: 1-866-FLIR-911

www.flir.com

©2015 FLIR Systems, Inc.

2

Page 3

Table of Contents

1 REVISION HISTORY ...................................................................................................................................... 6

2 INTRODUCTION ............................................................................................................................................. 7

2.1 Camera System Components .......................................................................................... 7

2.2 System Overview............................................................................................................. 7

2.3 Key features of the A6700sc/A6750sc cameras .............................................................. 8

3 WARNINGS AND CAUTIONS ...................................................................................................................... 10

4 INSTALLATION ............................................................................................................................................ 11

4.1 Basic Connections ......................................................................................................... 11

4.1.1 Power ......................................................................................................................................... 12

4.1.2 Analog Video .............................................................................................................................. 12

4.1.3 GigE Digital Vi deo ...................................................................................................................... 12

5 CAMERA CONTROLLER ............................................................................................................................. 13

5.1 ResearchIR Mini Controller ............................................................................................ 13

5.1.1 Single Preset Mode .................................................................................................................... 13

5.1.2 Superframing Mode [A675xsc only] ........................................................................................... 13

5.2 Menu Bar ....................................................................................................................... 14

5.2.1 Tools Menu ................................................................................................................................. 14

Advanced Time Controls .................................................................................................................................... 14

5.2.2 Help Menu .................................................................................................................................. 15

5.2.3 Status Page ................................................................................................................................ 15

5.2.4 Setup Page ................................................................................................................................. 16

5.2.4.1 Setup Tab ................................................................................................................................... 16

5.2.4.2 Sync Tab [A6750sc only] ............................................................................................................ 17

5.2.4.2.1 Sync Mode .......................................................................................................................................... 17

5.2.4.2.2 Sync Source ........................................................................................................................................ 20

5.2.4.2.3 Sync Options ....................................................................................................................................... 21

5.2.4.2.4 Sync Out ............................................................................................................................................. 22

5.2.5 Correction Page .......................................................................................................................... 22

NUC Information ................................................................................................................................................. 24

Manage NUCs .................................................................................................................................................... 24

Load NUC Options .............................................................................................................................................. 24

Performing a NUC .............................................................................................................................................. 25

What is a Non-Uniformity Correction (NUC)? ..................................................................................................... 27

5.2.5.1.1 One-Point Correction Process............................................................................................................. 28

5.2.5.1.2 Two-Point Correction Process............................................................................................................. 28

A6700sc/A6750sc User’s Manual

3

Page 4

5.2.5.1.3 Offset Update ...................................................................................................................................... 29

5.2.5.1.4 Bad Pixel Correction ........................................................................................................................... 29

5.2.6 Video Page ................................................................................................................................. 31

6 INTERFACES ................................................................................................................................................ 34

6.1 Mechanical (dimensions in inches) ................................................................................ 34

6.1.1 Status Lights ............................................................................................................................... 36

6.1.2 Power Interface .......................................................................................................................... 36

6.1.3 Other Interfaces .......................................................................................................................... 37

6.1.3.1 Gigabit Ethernet .......................................................................................................................... 37

6.1.3.2 Sync In ........................................................................................................................................ 37

6.1.3.3 Video .......................................................................................................................................... 37

6.1.3.4 AUX Connector [A6750sc only] .................................................................................................. 37

7 SPECIFICATIONS ........................................................................................................................................ 39

7.1 Interface ........................................................................................................................ 39

7.2 Windowing Capacity ...................................................................................................... 39

7.3 Acquisition Modes and Features .................................................................................... 39

7.4 Analog Video ................................................................................................................. 40

7.5 Performance Characteristics ......................................................................................... 40

7.6 Non Uniformity Correction ............................................................................................. 41

7.7 Detector/FPA ................................................................................................................. 41

7.8 General Characteristics ................................................................................................. 42

8 MAINTENANCE ............................................................................................................................................ 43

8.1 Camera and Lens Cleaning ........................................................................................... 43

8.1.1 Camera Body, Cables and Accessories ..................................................................................... 43

8.1.2 Lenses ........................................................................................................................................ 43

9 INFRARED PRIMER ..................................................................................................................................... 45

9.1 History of Infrared .......................................................................................................... 45

9.2 Theory of Thermography ............................................................................................... 48

9.2.1 Introduction ................................................................................................................................. 48

9.2.2 The Electromagnetic Spectrum .................................................................................................. 48

9.2.3 Blackbody Radiation ................................................................................................................... 48

Planck’s Law ....................................................................................................................................................... 49

Wien’s Displacement Law ................................................................................................................................... 50

Stefan-Boltzmann's Law ..................................................................................................................................... 51

Non-Blackbody Emitters ..................................................................................................................................... 52

9.2.4 Infrared Semi-Transparent Materials .......................................................................................... 54

9.3 The Measurement Formula ........................................................................................... 55

9.4 Emissivity tables ............................................................................................................ 58

A6700sc/A6750sc User’s Manual

4

Page 5

A6700sc/A6750sc User’s Manual

5

Page 6

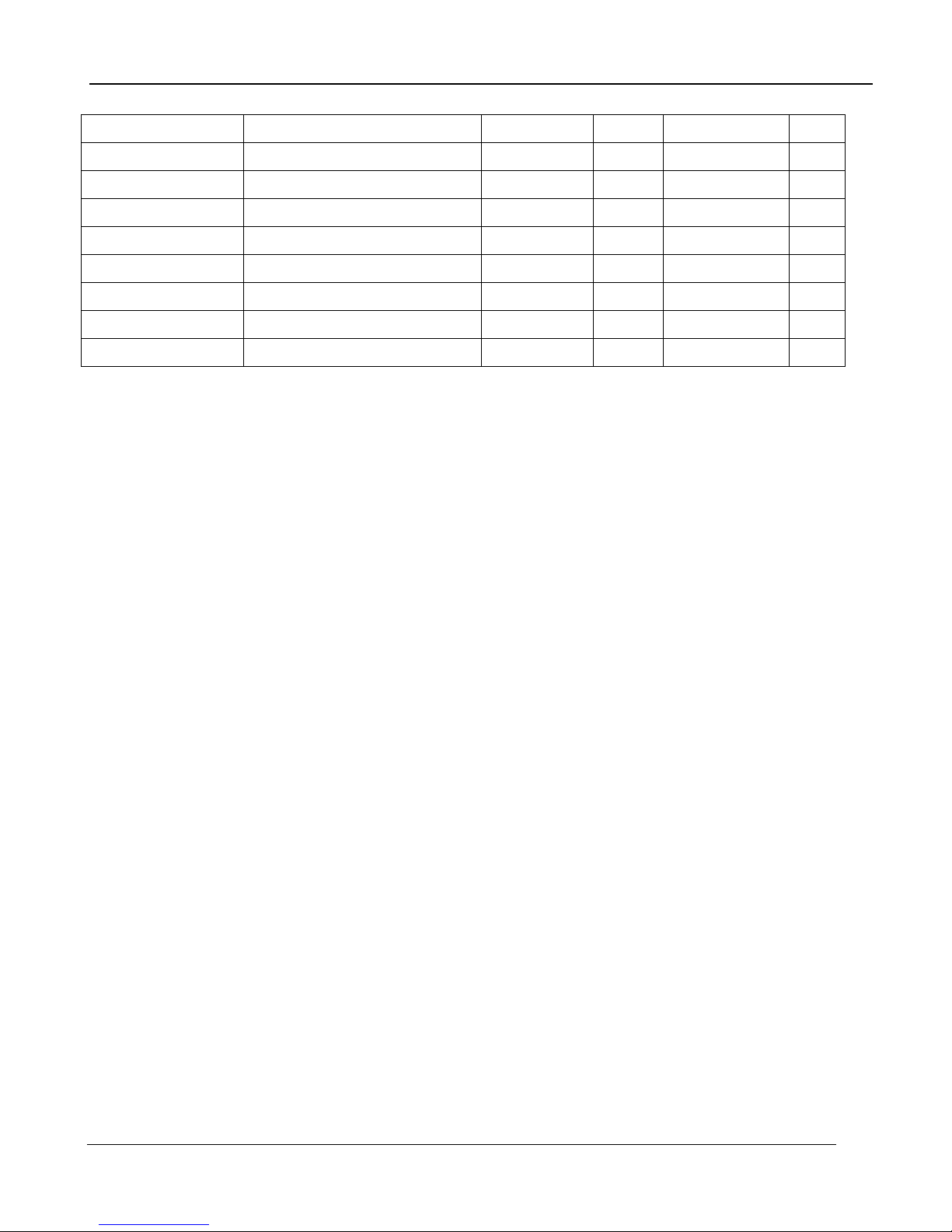

1 Revision History

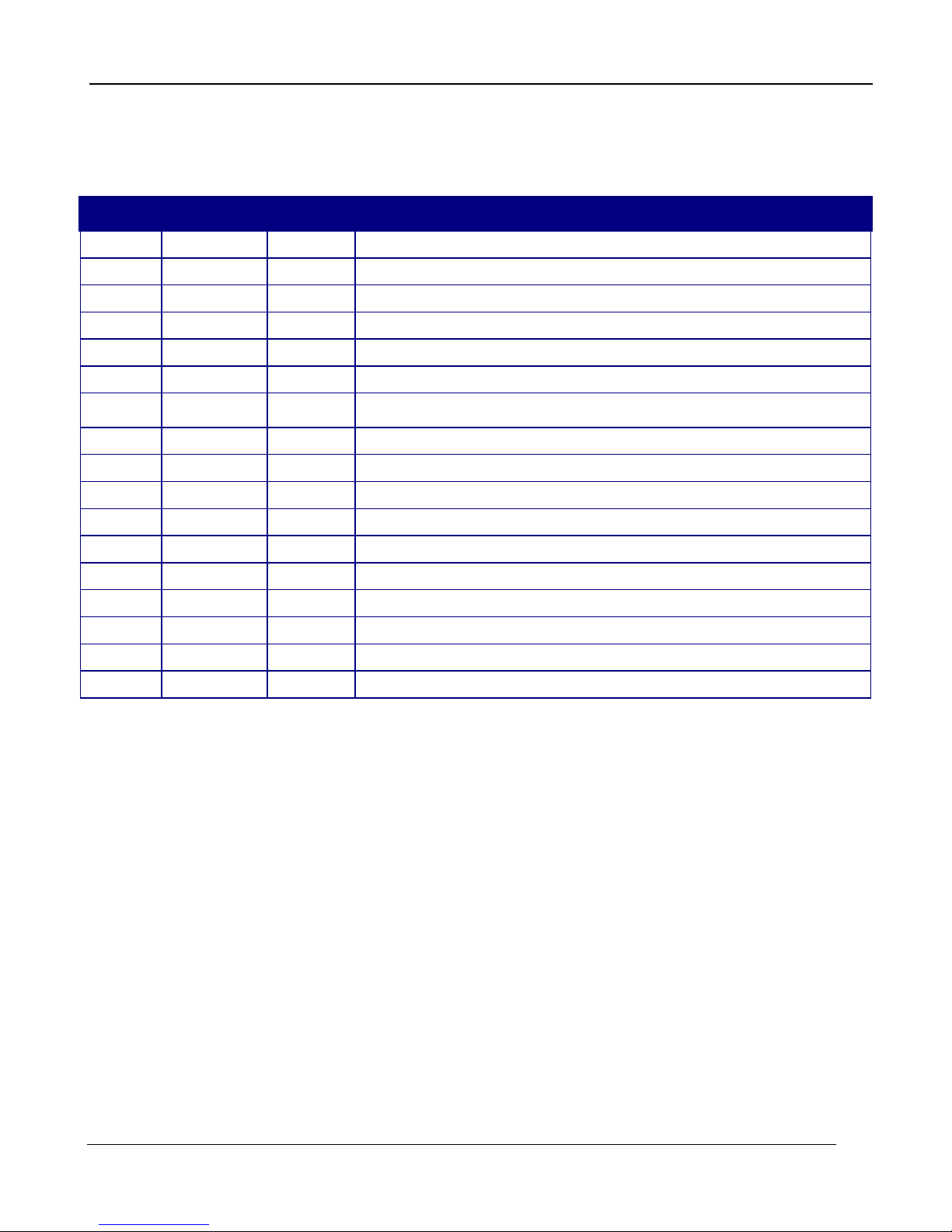

Version

Date

Initials

Changes

2

08/27/13

RM

Added 2D drawings, corrections

1 08/26/13 RM Initial Release

3 11/21/13 RM Corrections to specifications section

4 11/05/14 RM Removed ITAR control statement.

5 02/02/15 RM Added A6750sc GigE

1 – Revision History

A6700sc/A6750sc User’s Manual

6

Page 7

2 – Introduction

2 Introduction

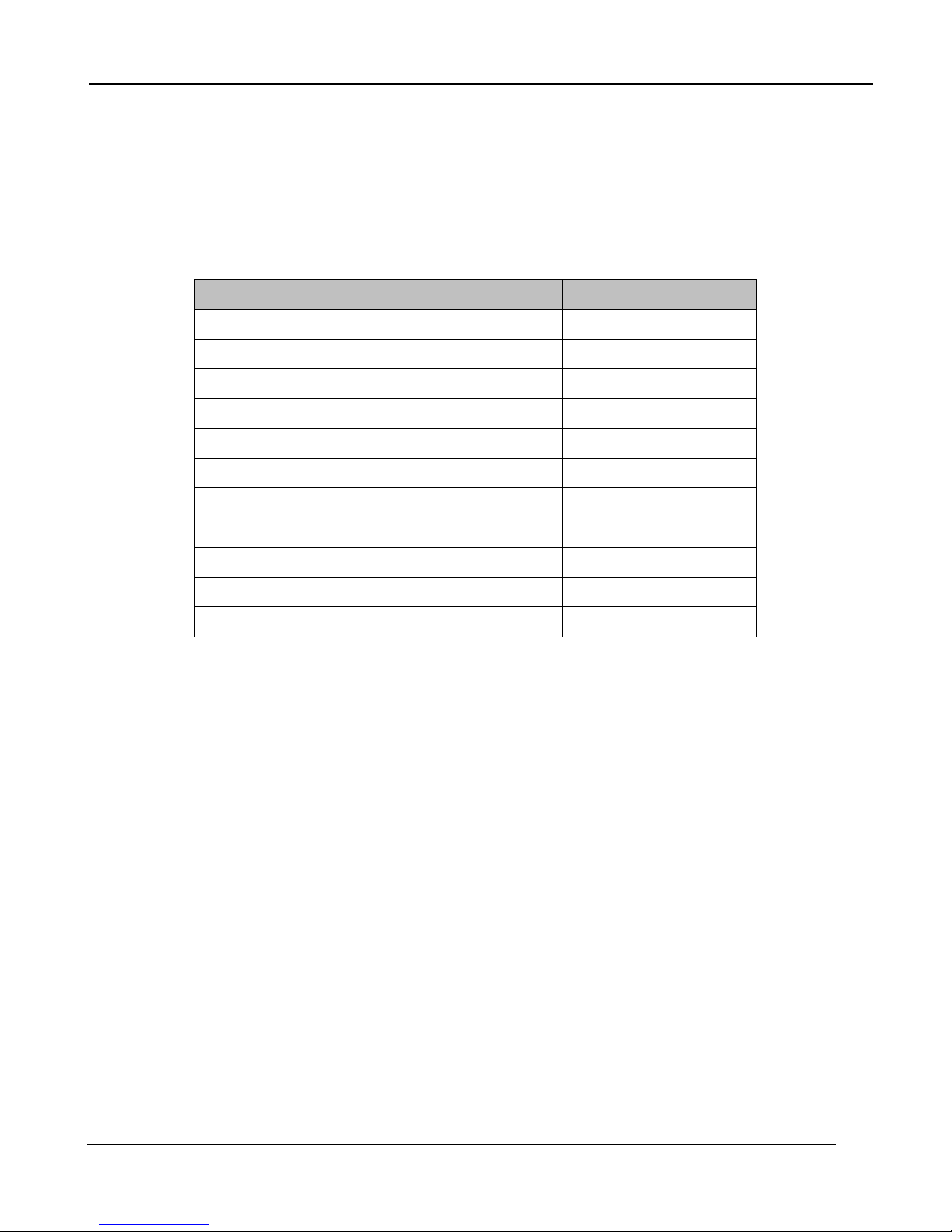

2.1 Camera System Components

The A6700sc infrared camera and its accessories are delivered in a box which typically contains the

items below. There may also be additional items that you have ordered such as lenses, software,

CDs, etc.

Description FLIR Part Number

A67xxsc Camera 29350-2xx

Power supply, 24V, 4A 24123-000

AC line cord 24124-000

Gigabit Ethernet Cat-6 cable, 2m length 23700-000

Bayonet mount plug 23901-000

BNC cable 26393-000

ResearchIR Max download/activation card T199013

AUX connector breakout cable [A6750sc only] 29402-500

Laboratory calibration plate 261-0005-00

Water-resistant transit case 24043-000

Documentation CD 24048-050

2.2 System Overview

The A6700sc infrared camera system has been developed by FLIR Advanced Thermal Solutions

(ATS) to meet the needs of the commercial R&D user. The camera makes use of FLIR’s advanced

ISC0403 4-channel readout integrated circuit (ROIC), mated to an Indium Antimonide (InSb) detector

to cover the midwave infrared band. The A6700sc camera utilizes a large format, 640 x 512 array

with 15μm pixel pitch.

The A6700sc is a stand-alone imaging camera that interfaces to host PC using Gigabit Ethernet. An

SDK is available, which makes it possible for t he system designer to write their own camera cont roller

and acquire image data with their own custom application.

A6700sc/A6750sc User’s Manual

7

Page 8

2.3 Key features of the A6700sc/A6750sc cameras

Fully GEV/GenICam compliant

The image stream protocol is GigE Vision 2.0 compliant and the camera is fully controllable

by GenICam.

Improved Linearity to Zero Well-Fill

Typical direct injection ROIC designs exhibit a non-linear response when the signal drops

below 10% of well-fill. The ISC0403 ROIC provides a linear response even at very low signal

levels. This results in an increased linear dynamic range, much better NUC performance at

low signal levels and makes it easier to perform a user calibration of the camera.

14-Bit Digital Image Data

The A6700sc camera system is built around high performance 14-bit A/D converters,

preserving the full dynamic range of the FPA.

Windowing Capability

Higher frame rates are available by windowing down at the Focal Plane Array (FPA) level.

The A6700sc has three available window sizes with a max frame rate of 480Hz. The

A6750sc has flexible window sizes with frame rates up to 4kHz.

2 – Introduction

Presets

Up to four presets and their associated parameters such as integration time, frame rate,

window size and window location, are available for instant selection with a single command.

Superframing [A6750sc only]

Up to four presets can be cycled continuously. This can be used in conjunction with the

Dynamic Range Extension (DRX) algorithm to provide a single movie with increased dynamic

range.

Independently Adjustable Frame Rates

Frame rate is user selectable from 0.0015 Hz up to the maximum allowed for the select ed

window size.

External Sync

The A6700sc camera provides a SYNC input that can be used to control the camera frame

rate using an external LVCMOS input (can handle 5.5V Max) .

External Trigger [A6750sc only]

An external trigger input can be used to signal ResearchIR to start rec ording or to precisely

start the image stream relative to an external event.

Multiple Video Outputs

The A6700sc camera features multiple independent and simultaneous video:

▫ Digital – Gigabit Ethernet

▫ Analog – Composite video (NTSC or PAL)

Analog Video Color Palettes

The A6700sc camera supports a selection of standard and user-defined color palettes f or th e

analog video output.

A6700sc/A6750sc User’s Manual

8

Page 9

2 – Introduction

Digital Detail Enhancement (DDE)

DDE is an analog video AGC mode that provides a significant improvement to scene detail

and contrast.

On-Camera NUCs with Auto Update

NUCs can be stored in camera memory and can be applied independently to the digital and

analog video outputs. The camera can be configured to automatically update the NUC using

the internal flag based on a change of an internal temperature sensor and/or a timer.

Standard Lens Interface

The A6700sc camera uses th e same bayonet-mount as other SCx000 series cameras.

However, even though the mount is the same, due to differences in the opto-mechanical

layout, lenses for the SC6000/4000 are not an optimal solution for the A6700sc. The SC6000

lenses will provide fairly good imagery but some vignetting in the corners may be visible. For

best performance the user should use lenses designed for the A6700sc. Lenses for the

SC8000 will not work on the A6700sc.

A6700sc/A6750sc User’s Manual

9

Page 10

3 – Warnings and Cautions

3 Warnings and Cautions

For best results and user safety, the following warnings and precautions should be followed when

handling and operating the camera.

Warnings and Cautions:

Do not open the camera body for any reason. Disassembly of the camera (including

removal of the cover) can cause permanent damage and will void the warranty.

Great care should be exercised with your camera optics. Refer to Chapter 7 for lens

cleaning.

Operating the camera outside of the specified input voltage range or the specified

operating temperature range can cause permanent damage.

The camera is not completely sealed. Avoid exposure to dust and moisture and replace

the lens cap when not in use.

Do not image extremely high intensity radiation sources, such as the sun, lasers, arc

welders, etc.

The camera is a precision optical instrument and should not be exposed to excessive

shock and/or vibration. Refer to the Chapter 6 for detailed environmental requirements.

The camera contains static-sensitive electronics and should be handled appropriately.

A6700sc/A6750sc User’s Manual

10

Page 11

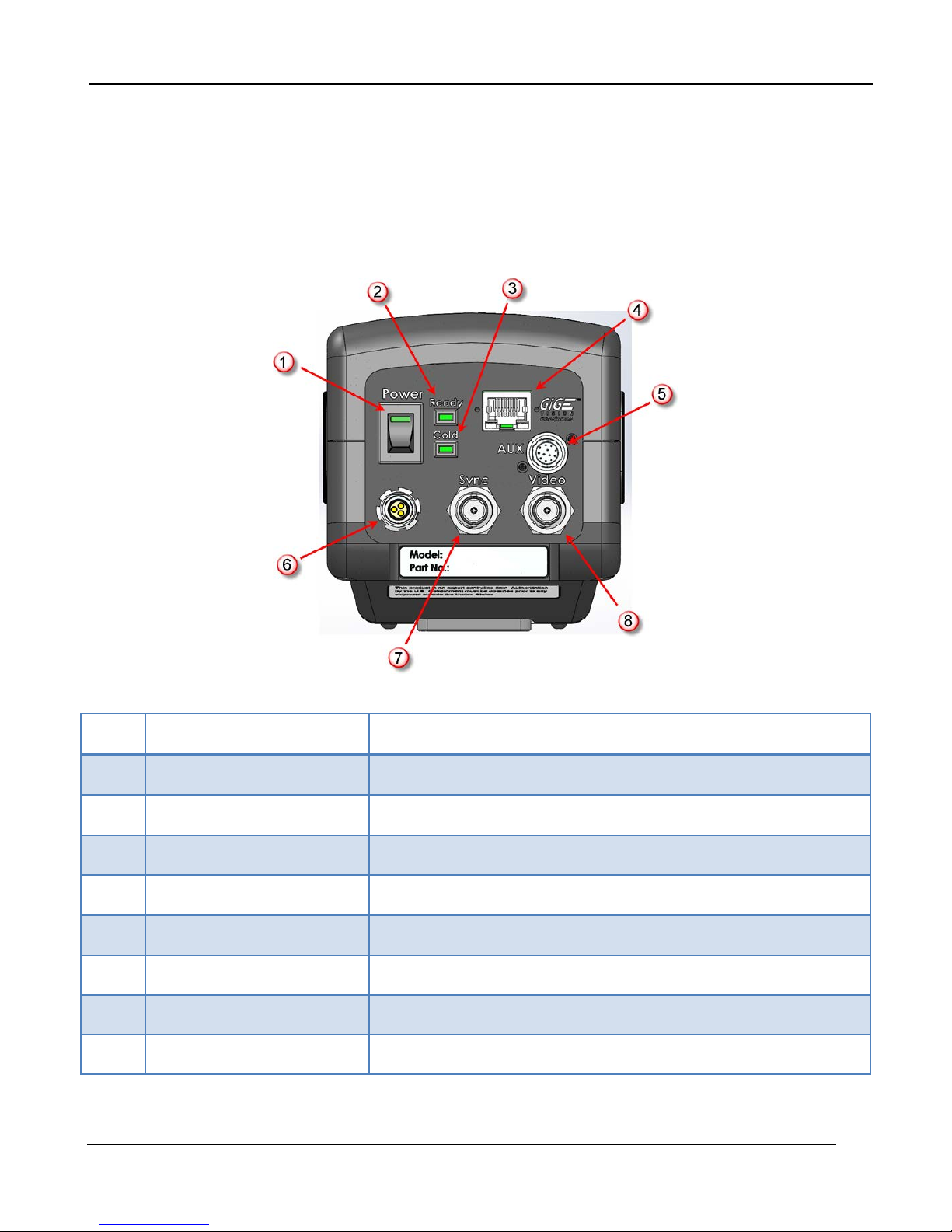

4 Installation

4.1 Basic Connections

All connections to the A6700sc are located on the Back Panel.

4 – Installation

Item Name Description

1

2

3

4

5

6

7

8

Power Switch LED will light when power is ON

Ready Light LED will turn on when camera is booted

Cold LED LED will light when FPA temp is <80K

Gigabit Ethernet (RJ45) Connect to a PC for digital IR image data

AUX Connector A675xsc only. (See Section 6.1.3.4 for details)

DC Power Input 24VDC

Sync Input External Frame Sync

Video Out NTSC or PAL, selectable in camera controller

A6700sc/A6750sc User’s Manual

11

Page 12

4 – Installation

4.1.1 Power

Plug in the AC power supply to a standard 120V outlet. Connect the DC power cable between the

power supply and the power connector located on the rear panel of the A6700sc camera. Turn on

the imaging head by pressing the power button on the rear panel. The green power LED will

illuminate to indicate that the unit is ON.

4.1.2 Analog Video

The camera will automatically boot up into the last saved state. The boot process takes about 30

seconds. To see the Composite video on a monitor, connect the provided BNC cable from the VIDEO

port to your monitor. If you are powering up the camera for the first time, the camera should produce

a 640x480 image with Non-Unifority Correction (NUC), ba d pixel replacement enabled.

4.1.3 GigE Digital Video

If you have a PC data system running ResearchIR (or your own custom application based on the BHP

SDK) you can view the 14-bit digital video over Gigabit Ethernet.

The A6700sc has a Gigabit Ethernet interface that is GigE Vision (GEV) and GenICam compliant Use

a regular CAT5e or CAT6 Ethernet patch cable. If a crossover cable is used, the camera interface will

automatically detect and configure itself to work with this kind of cable.

A6700sc/A6750sc User’s Manual

12

Page 13

5 –Camera Controller

5 Camera Controller

5.1 ResearchIR Mini Controller

The Camera Controller (also called the Graphical User Interface or GUI) can be accessed from within

the ResearchIR software. Once you are connected to the camera, a mini controller will be visible in

the left pane. This controller will have basic controls for the most commonly used settings, like

integration time, frame rate, preset selection, and window size. Choosing the Camera>>Control menu

option will display the full camera controller. The rest of this chapter will describe the full camera

controller features in detail.

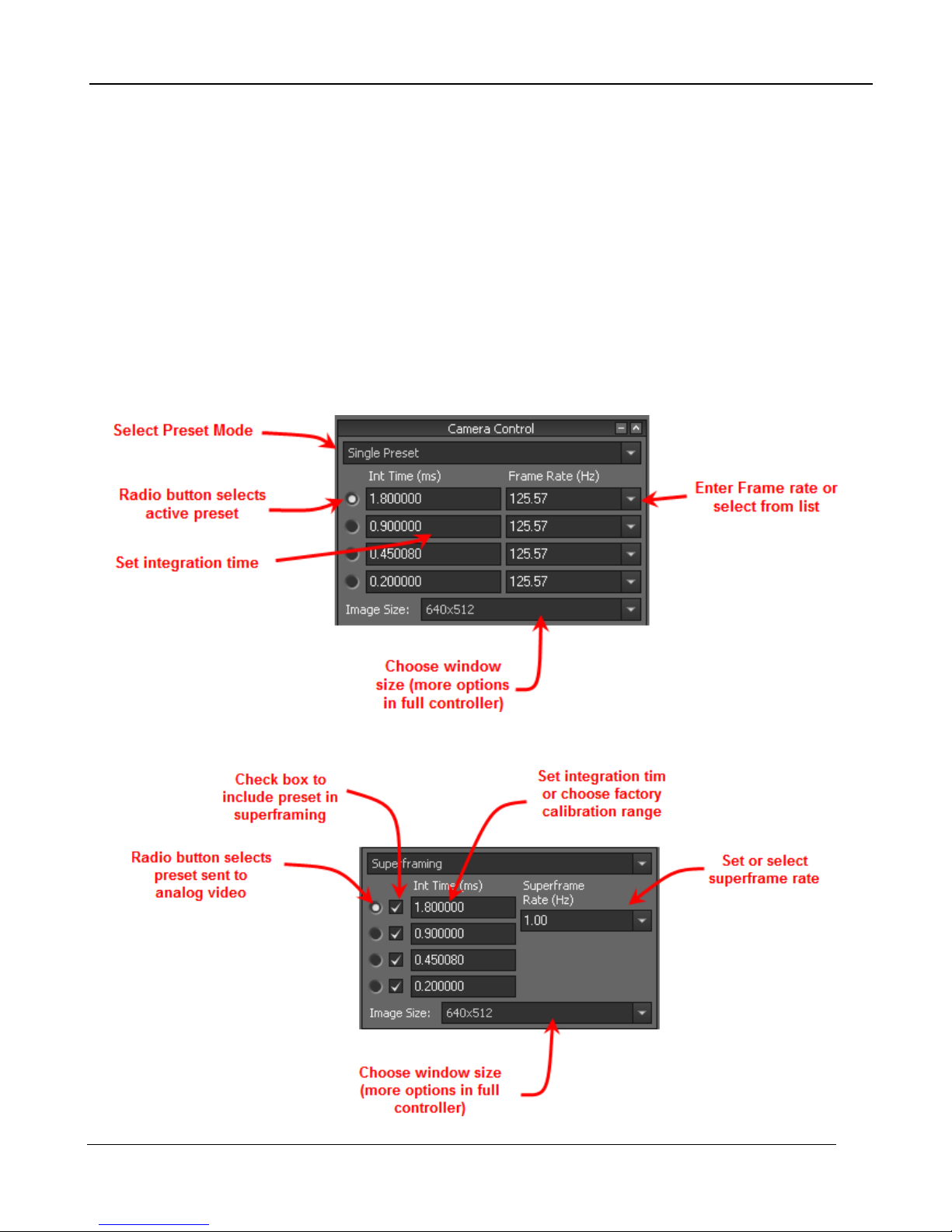

5.1.1 Single Preset Mode

5.1.2 Superframing Mode [A675xsc only]

A6700sc/A6750sc User’s Manual

13

Page 14

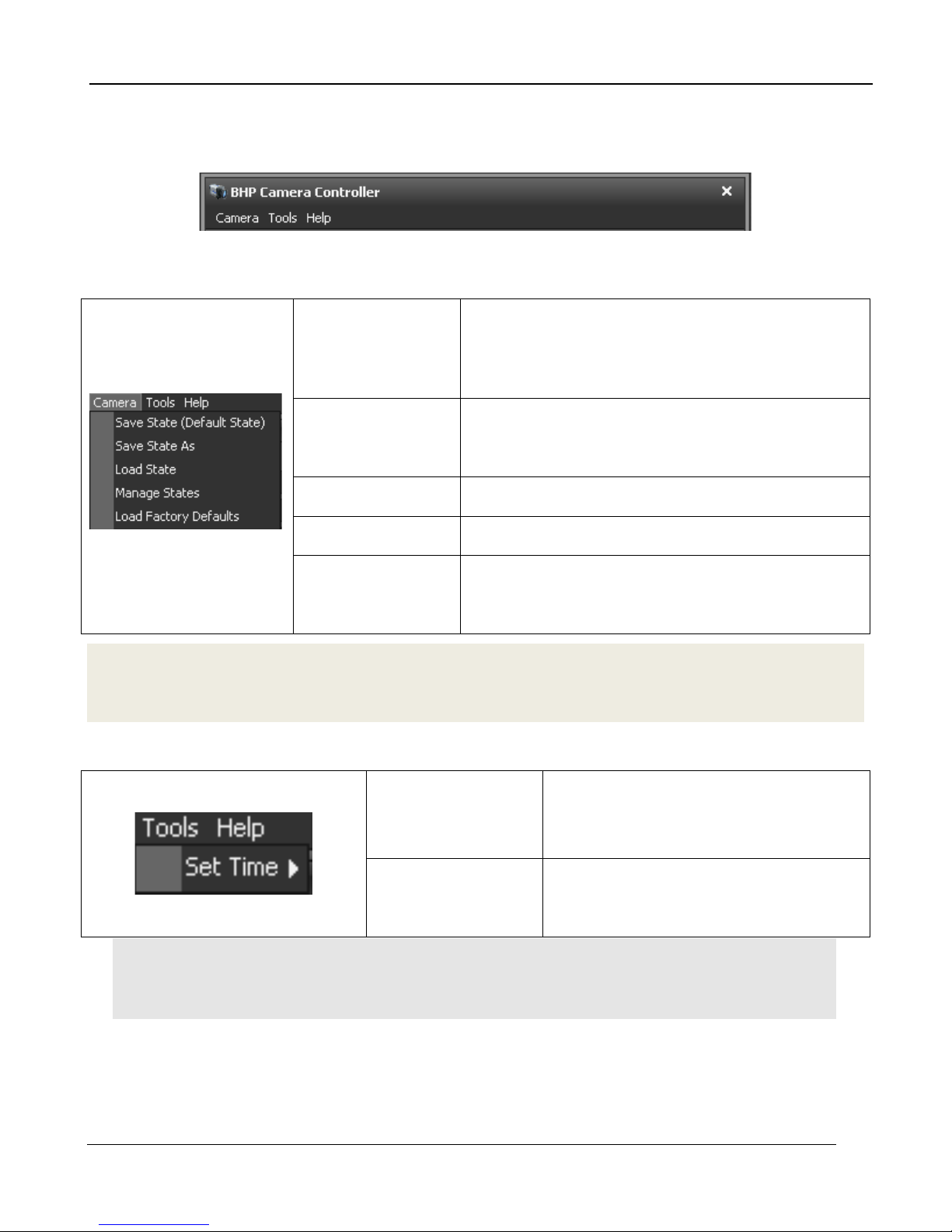

5.2 Menu Bar

The menu bar is the same for both Basic and Advanced User Modes .

Saves the camera state to the current (name). This

Save State (name)

Save State As

Load State Load a state from flash memory.

Manage States Rename or delete states from camera memory.

state will be reloaded at power up. Stored in flash

memory.

Saves the current camera state to a name chosen

by the user. State names other than (name) my be

loaded manually. Stored in flash memory

5 –Camera Controller

Load Factory

Defaults

Loads factory defaults for all camera Settings and

NUCs. The factory defaults cannot be modified by

the user.

NOTE: Camera states contain information about all configurable camera parameters. They do not

contain the NUC data, but contain the filenames of the currently loaded NUCs. These NUCs will be

reloaded with the state, however, if the NUCs are changed, deleted, or renamed, the state may not be

able to load the NUCs.

5.2.1 Tools Menu

Set Camera Time to

PC Time

NOTE: The A6700sc has two internal clocks: a Real Time Clock (RTC) and a timestamp clock. The RTC is a low

resolution clock used to keep system time. The RTC has a battery backup and will retain time while the camera is

off. The timestamp clock is a high resolution clock (1us). This clock does not have a battery backup but at power

up the timestamp clock is initialized to the current RTC time and will free-wheel until the camera is power cycled.

Advanced…

Sets the camera RTC clock to the time

from the PC clock.

Allows user to manually set the IRIG and

RTC clocks in the camera. See Section

4.2.2.1

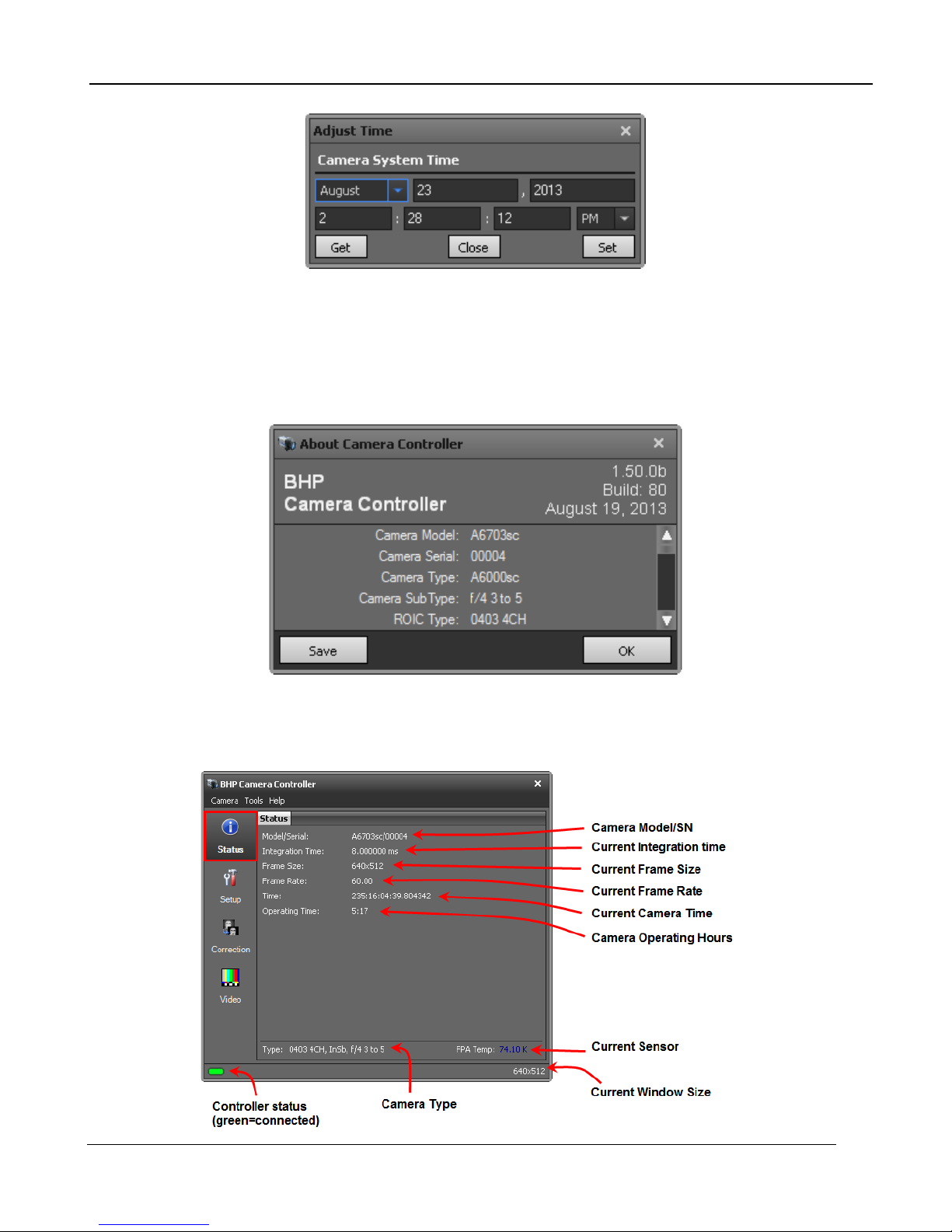

Advanced Time Controls

This dialog is accessed using the Tools>>Set Time>>Advanced menu options. This allows the user

to directly set the cameras system time. The Get button will pull time from the PC clock. The Set

button will set the camera RTC clock using the manually entered time.

A6700sc/A6750sc User’s Manual

14

Page 15

5 –Camera Controller

Figure 4-1 Advanced Time Controls

5.2.2 Help Menu

The “About” menu item shows a dialog indicating the current controller version number. If the

controller is connected to a camera a list will be displayed that shows all versions of software and

firmware in the camera. The “Save” button allows the user to create a text file with this version

information.

5.2.3 Status Page

The Status Page gives general information about the camera state including camera type, camera

time, integration time, frame size, and frame rate.

A6700sc/A6750sc User’s Manual

15

Page 16

5 –Camera Controller

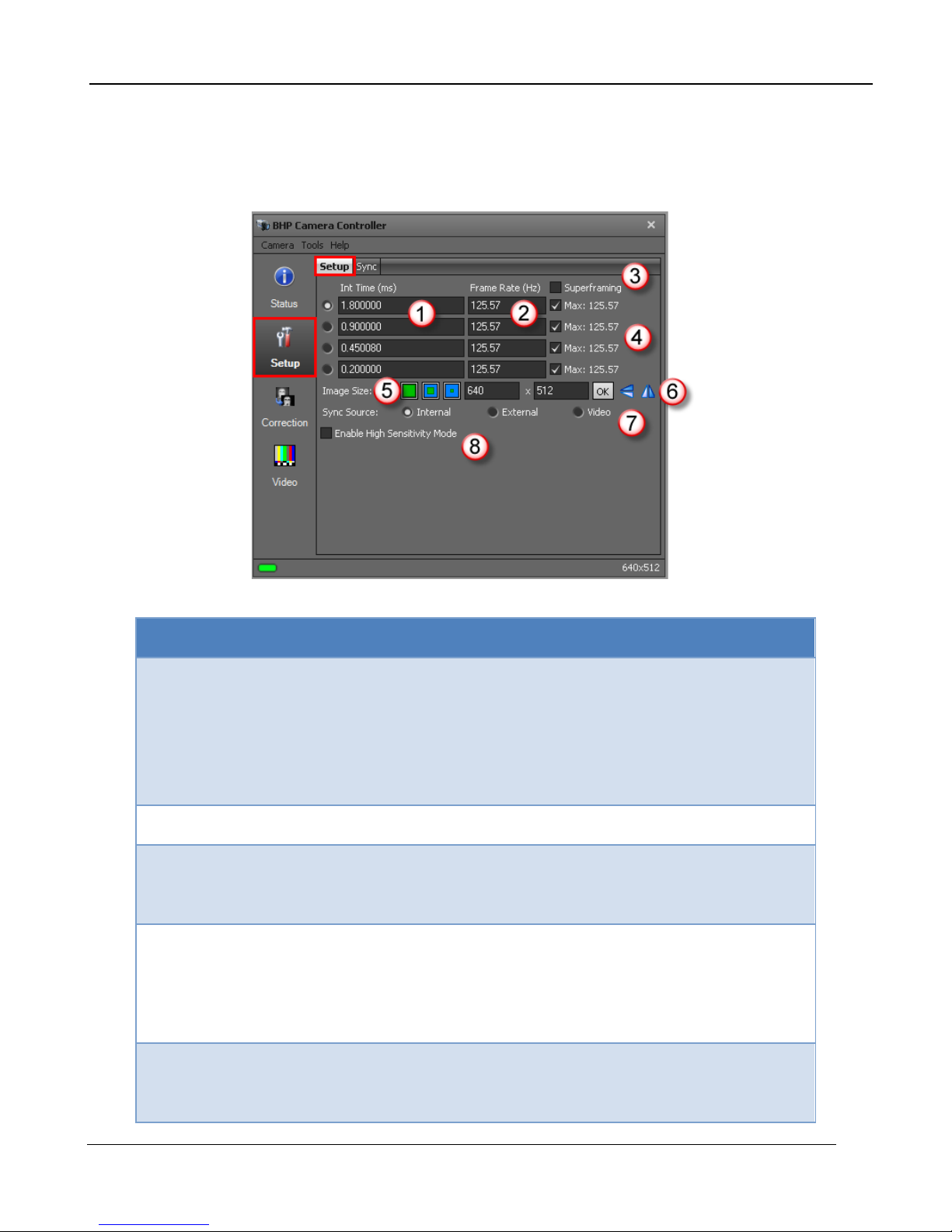

5.2.4 Setup Page

The Setup page allows the user to set integration time, frame rate, frame size, and Sync source.

5.2.4.1 Setup Tab

Item Name Description

1

Integration Time No factory calibration: Enter desired integration

time in milliseconds.

With factory calibration: The box will have a

dropdown list with the available ranges. To

manually enter integration time scroll to bottom of

list and select “no factory calibration”.

2

3

Frame Rate Enter the desired frame rate in Hz.

Superframing

[A6750sc only]. When this is enabled the user

can then select the presets to include and set the

burst rate.

4

Max Frame Rate This indicates the max possible frame rate based

on the current window size and integration time.

Checking the box will automatically keep the

camera at max frame rate as these parameters

change.

5

Image size A6700sc: This control will be simply a dropdown

A6700sc/A6750sc User’s Manual

list with the three window size options available

(Full, ½, ¼).

16

Page 17

Item Name Description

A6750sc: There are buttons to select Full, ½, ¼

windows as well as boxes to enter other sizes.

Click “OK” to set a size. The box will turn red if the

size is not valid.

5 –Camera Controller

6

Image Flipping

The icons control horizontal and vertical

image flipping. With these controls, the flipping is

done in the camera so both the digital and analog

video are affected.

7

Sync Source Select internal, external, or video.

Internal: The frame sync is generated internally to

run at the frequency set by the user

External: The frame sync is generated externally

through the Sync In connect on the camer a rear

chassis.

Video: The FPA frame sync is generated from the

internal video encoder , locking the digital and

analog clocks together

8

High Sensitivity Mode

(HSM)

HSM is a FLIR-patented algorithm first introduced

in the Gas FindIR cameras that allows the user to

see small temperature changes in the scene.

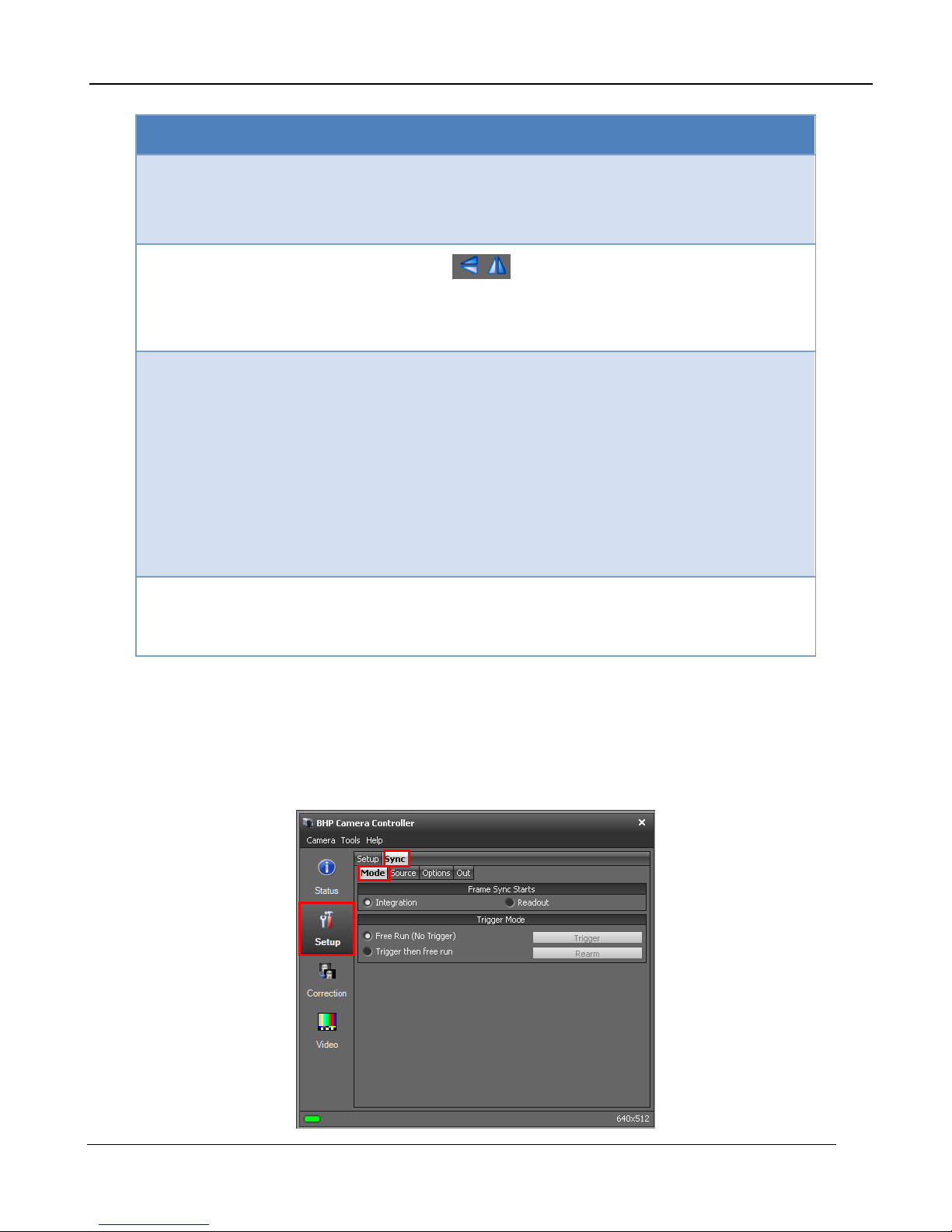

5.2.4.2 Sync Tab [A6750sc only]

The sync tab allows the user to control function for Syncs, and triggers. All of these sync features

apply only to the A6750sc.

5.2.4.2.1 Sync Mode

A6700sc/A6750sc User’s Manual

17

Page 18

5 –Camera Controller

Preset 0

Data

Frame Sync

Preset 1

Data

Preset 2

Data

Preset 3

Data

Frame Sync Frame Sync Frame Sync

Preset 3

Integration

Preset 2

Integration

Preset 1

Integration

Preset 0

Integration

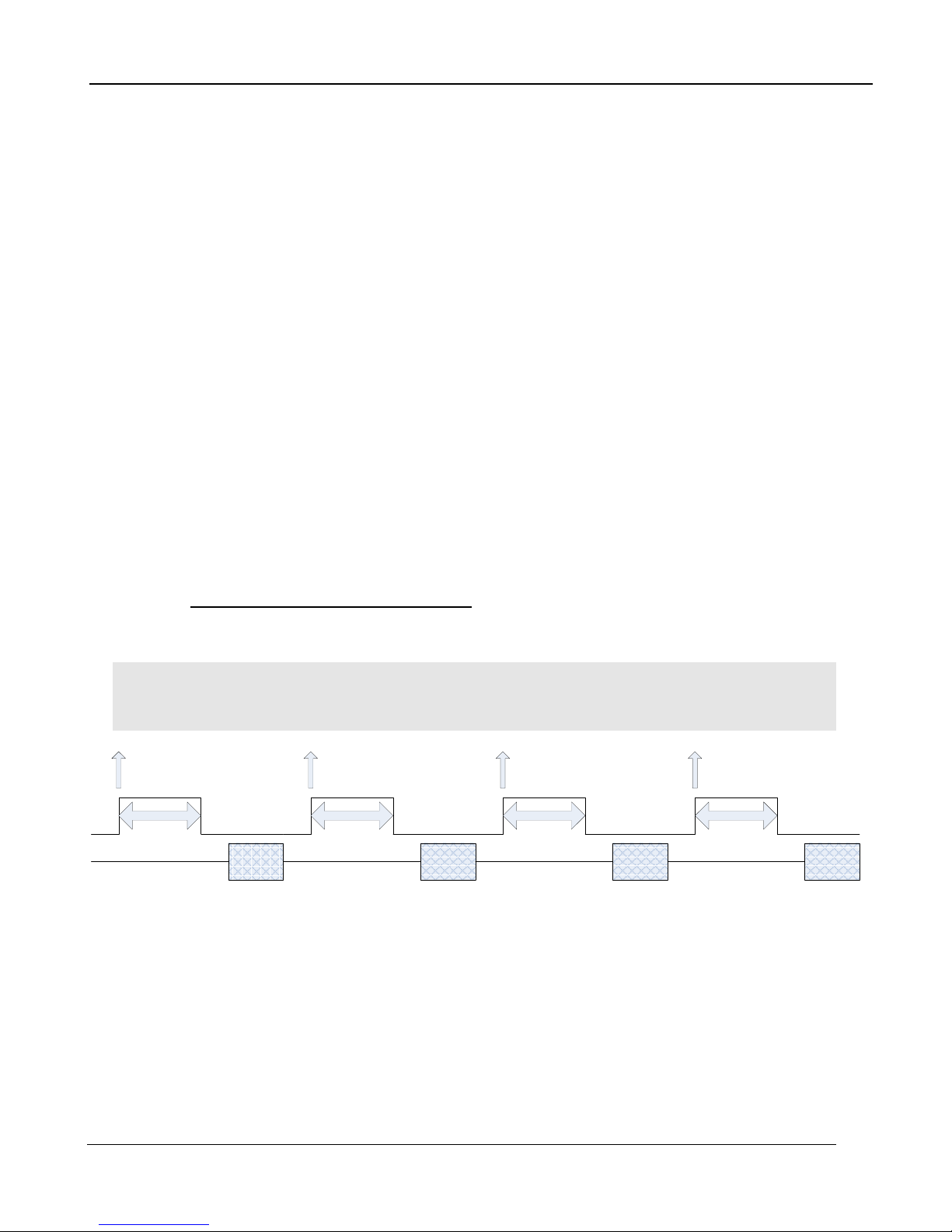

5.2.4.2.1.1 Frame Sync Starts

The A6750sc makes use of frame syncs and triggers to control the generation of image data. Frame

syncs control the start of individual frames whereas triggers start sequences of frames.

The generation of a frame consists of two phases: integration and data readout. Depending on the

timing between these two events, you can have two basic integration modes: Integrate Then Read

(ITR), and Integrate While Read (IWR). In ITR, integration and data readout occur sequentially. The

complete frame time is the combined total of the integration time plus readout time. In IWR, the

integration phase of the current frame occurs during the readout phase of the previous fra me. In

other words, ITR and IWR terms refer to whether or not the camera will overlap the data readout and

integration periods. In ITR, the data is not overlapped which means lower frame rates but provides a

less noisy image. IWR can achieve much faster frame rates with a slight increase in noise. The

A6750sc does not require the user to explicitly choose whether to operate in ITR or IWR modes. The

camera will automatically select the integration mode based on the integration time, frame rate, and

frame sync mode.

The A6750sc supports two Frame Sync Modes: Frame Sync Starts Integration (FSSI), and Frame

Sync Starts Readout (FSSR). FSSI and FSSR determine which phase of the frame generation

process (integration or data readout) is synchronized to the frame sync. FSSI starts the integration

period when a frame sync occurs (i.e. “take a picture now”). The camera automatically calculates

when to start data readout. FSSR starts the data readout (for the previous frame) when a frame sync

occurs (i.e. “give me data now”). The camera automatically calculates when to start integration for the

current frame. In FSSI mode, the camera could be in either ITR or IWR mode. In FSSR mode, the

camera is always in IWR mode.

5.2.4.2.1.1.1 Frame Sync Starts Integration (FSSI)

Upon frame sync, the camera immediately integrates followed by data read out. Based on integration

time, frame size, and frame rate, the camera will automatically choose ITR or IWR mode.

NOTE: When using an external frame sync and superframing, the external frame sy nc should be set

to comply with ITR frame rate limits. If the exte rnal syn c rate is to o fast, the camera w ill ignore syncs

that come before the camera is ready

Figure 4-2: Frame Sync Starts Integration, ITR

A6700sc/A6750sc User’s Manual

18

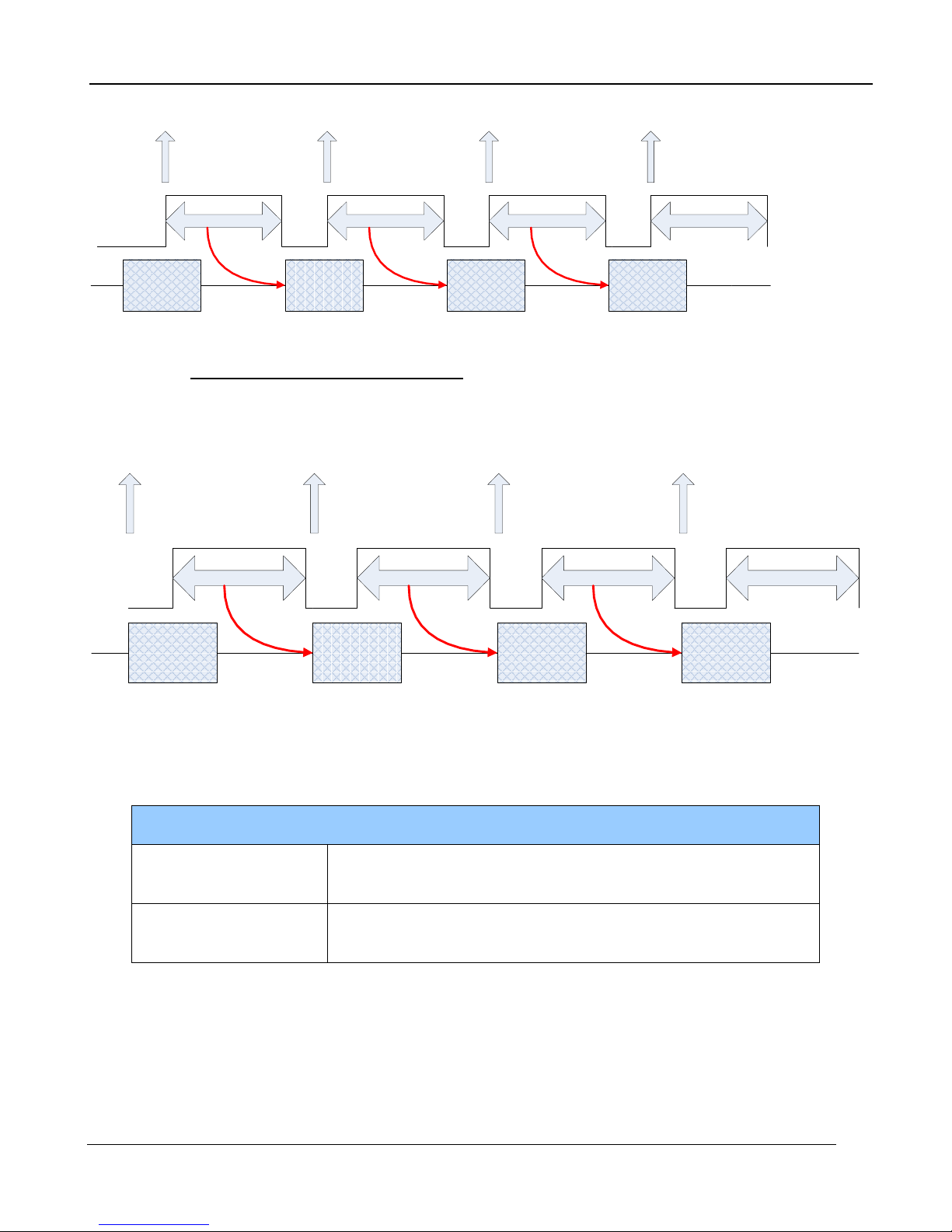

Page 19

5 –Camera Controller

Frame

1 Data

Frame 1 Integration

Frame 2 Integration

Frame Sync

Frame Sync

Frame 2 Data

Frame 3 Integration

Frame Sync

Frame 3 Data

Frame 4 Integration

Frame Sync

Frame 1

Data

Frame 1 Integration

Frame 2 Integration

Frame Sync

Frame Sync

Frame 2 Data

Frame 3 Integration

Frame Sync

Frame 3 Data

Frame 4 Integration

Frame Sync

Figure 4-3: Frame Sync Starts Integration, IWR

5.2.4.2.1.1.2 Frame Sync Starts Readout (FSSR)

Upon frame sync, the camera immediately transmits the data from the previous frame. The

integration period is then placed to meet ROIC requirements. This mode always operates in IWR

mode. This mode can be used with either internal or external frame sync at full frame rates.

Figure 4-4: Frame Sync Starts Readout

5.2.4.2.1.2 Trigger Mode

When the camera is placed in a triggered mode, the image stream will stop until the trigger is

received.

Trigger Modes

Free Run (No Trigger)

Trigger then free run

In free run the camera cycles through frames/sequences

continuously.

Upon receiving a trigger (external or software) the camera will

start to generate sequences continuously.

A6700sc/A6750sc User’s Manual

19

Page 20

5 –Camera Controller

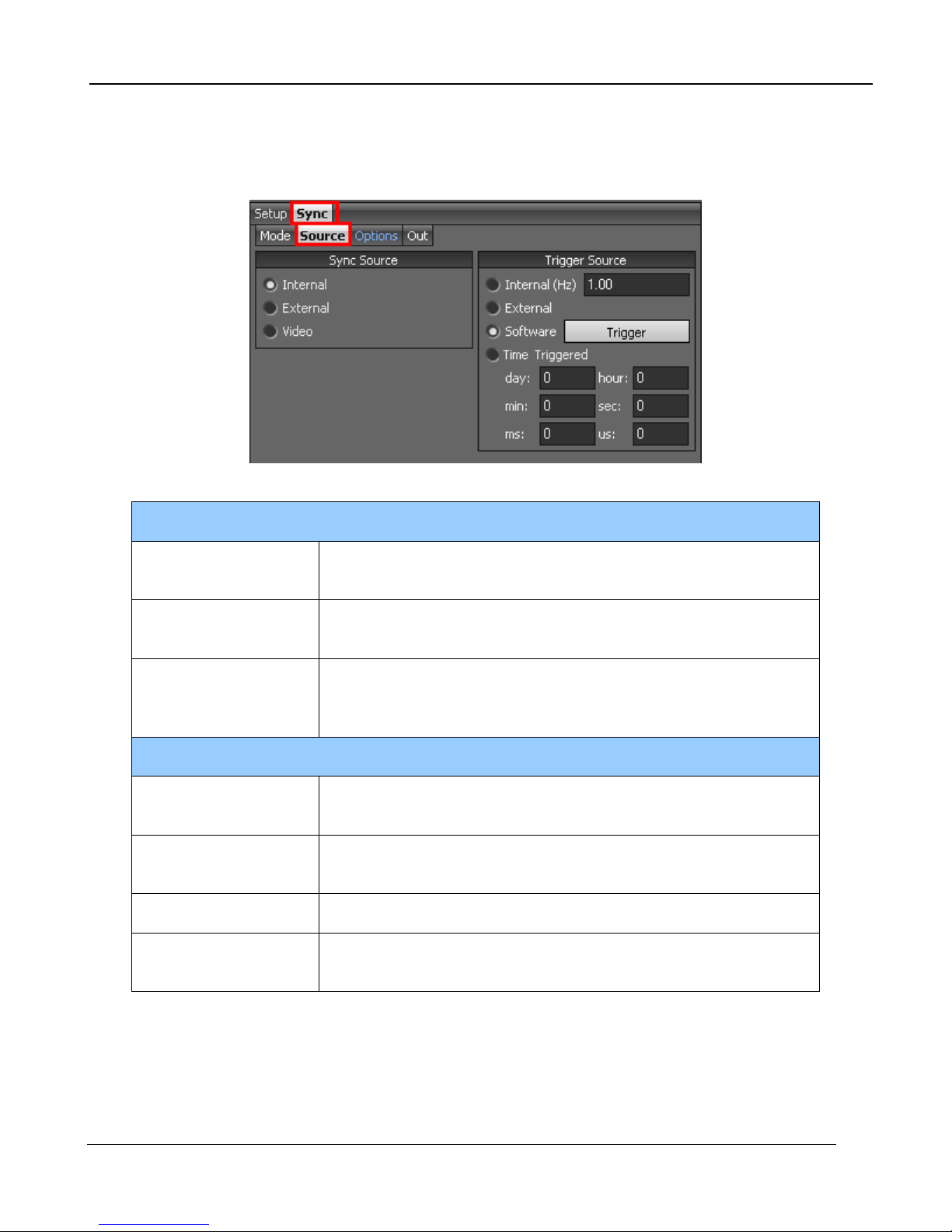

5.2.4.2.2 Sync Source

The Source options page allows the user to select the source for Syncs and Triggers.

Sync Sources

Internal

External

The frame sync is generated internally to run at the frequency

set by the user

The frame sync is generated externally through the Sync In

connect on the camera rear chassis.

The frame sync is generated from a external video source

Video

connected to the Gen Lock In connector on the camera rear

chassis.

Trigger Sources

Internal

External

The tri gger is gener ated internally to run at the frequency set by

the user (Hz).

The trigger is generated externally through the Trigger In

connector on the camera rear chassis. (3.3V LVCMOS)

Software The trigger is generated via a software button (Trigger button)

Time Triggered

Camera generates an internal trigger when the internal

timestamp clock reaches a specified time.

A6700sc/A6750sc User’s Manual

20

Page 21

5 –Camera Controller

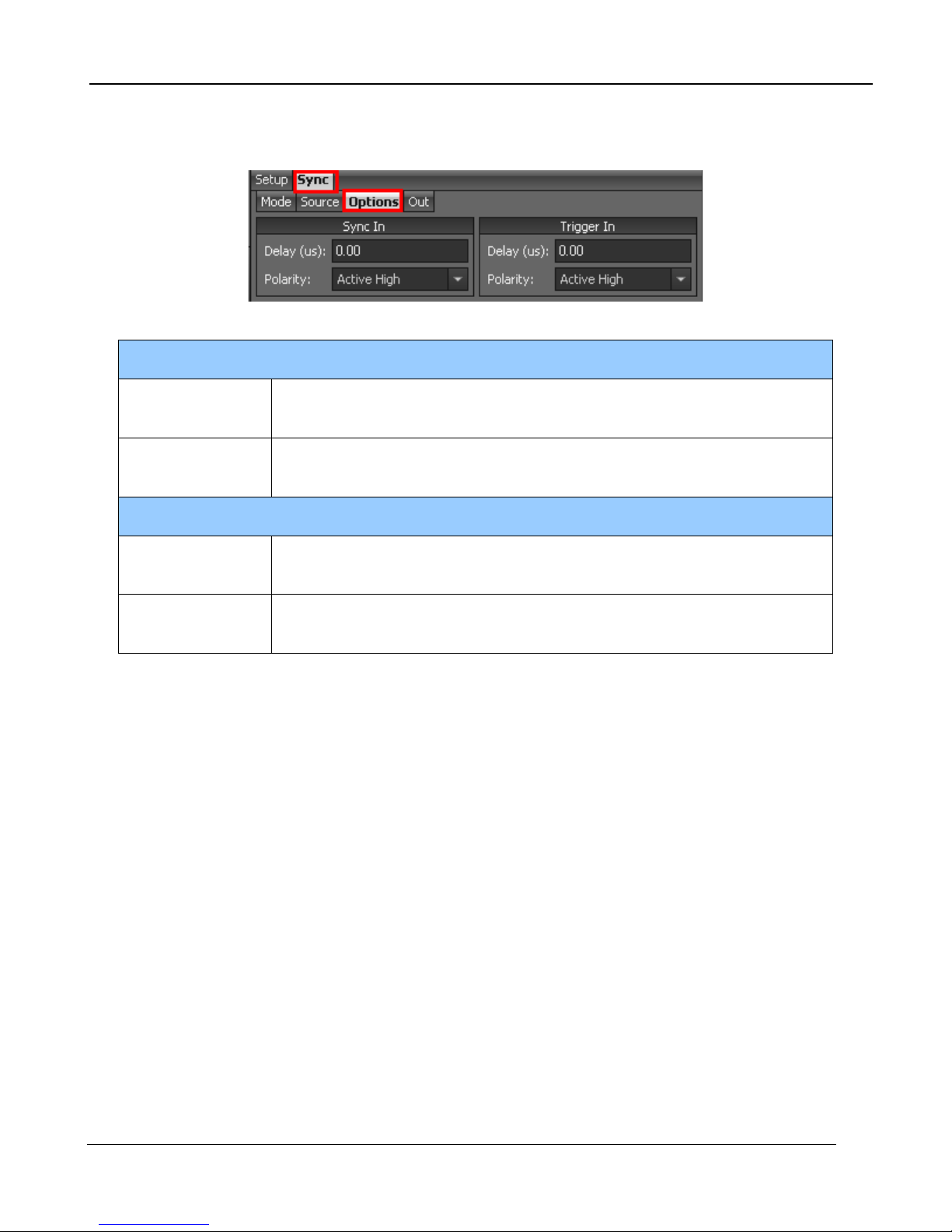

5.2.4.2.3 Sync Options

The Sync Options page allows the user to set delays and polarities for the Sync and Trigger In.

Sync In

Delay

Polarity

Delay

Polarity

Allows for the user to set a delay (µsec) for the external sync. See

timing diagrams below.

The sync is edge triggered. Allows for the camera to use the rising or

falling edge.

Allows for the user to set a delay (µsec) for the external trigger. See

timing diagrams below.

Trigger is edge triggered. Allows for the camera to use the rising or

falling edge.

Trigger In

A6700sc/A6750sc User’s Manual

21

Page 22

5 –Camera Controller

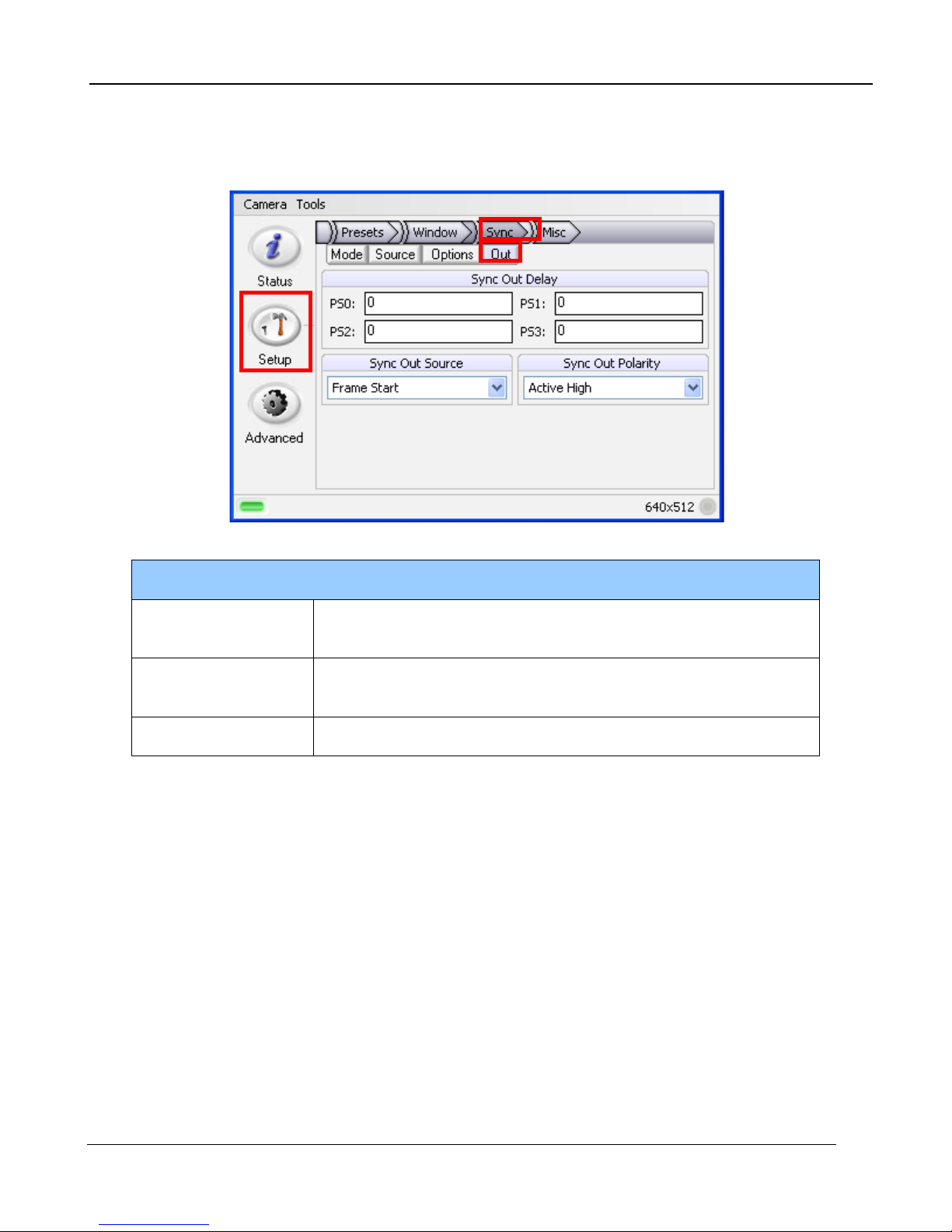

5.2.4.2.4 Sync Out

The Sync Out options allow the user to set a delay for the sync out pulse as well as the sync delay

reference and polarity. The Sync Out signal always has a jitter of ±1 clock (160nsec).

Sync Out Options

Sync Out Delay Allows for the user to set a delay for the sync out on a preset

basis.

Sync Out Source Allows for the sync out to be referenced to the star t of frame or

start of integration.

Sync Out Polarity Allows for the sync out to be active high or low.

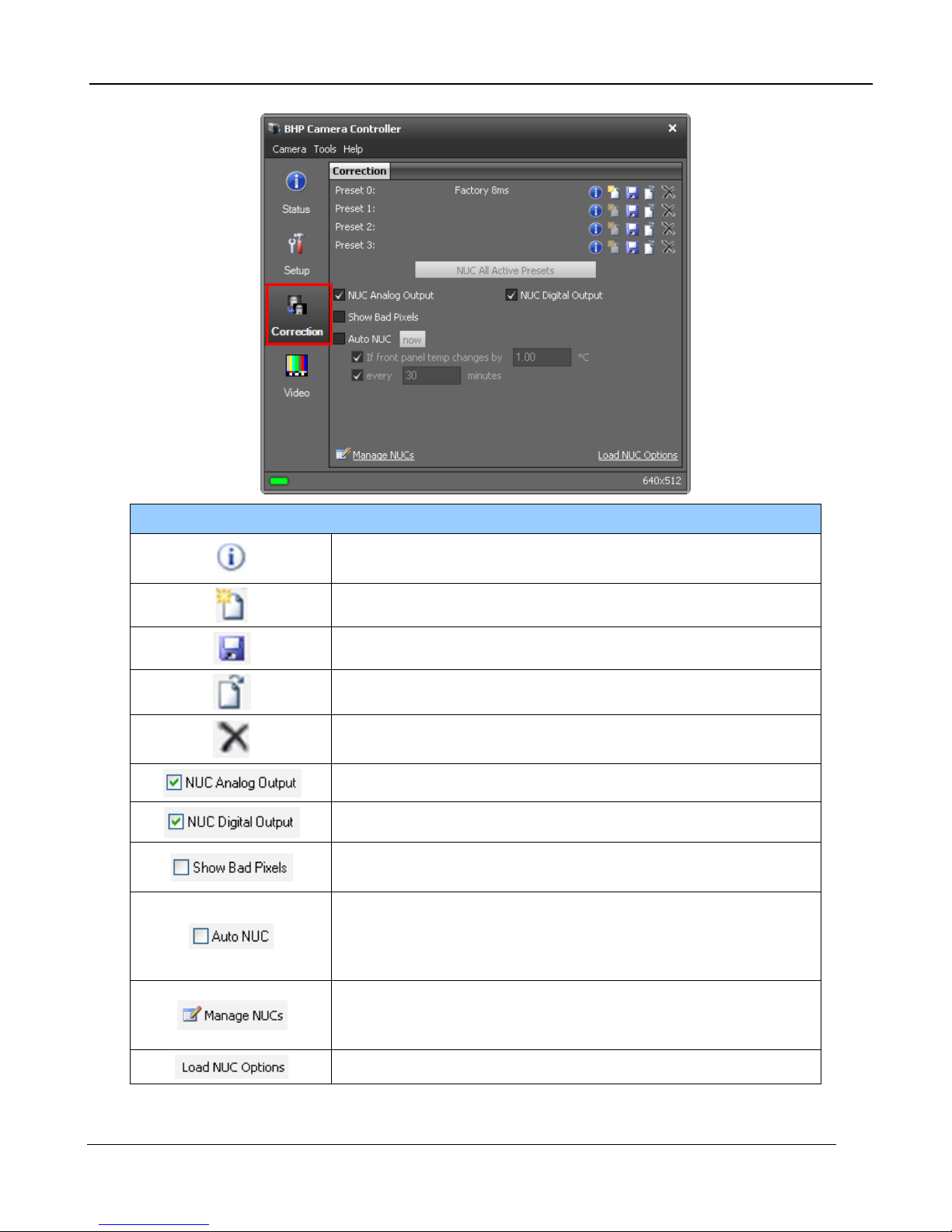

5.2.5 Correction Page

The Correction Tab contains all the controls needed to manage the on-camera NUCs. On-camera

NUCs are stored in two types of memory:

RAM memory. This type of memory is used to store NUCs that will be applied to live image data.

There is enough RAM memory for one NUC to be loaded for each Preset. This memory is volatile

and is lost when then camera is turned off. If a NUC was loaded into RAM, the camera will reload that

NUC from flash automatically when the camera is turned on if a Save State was performed.

Flash Memory. This type of memory is used as nonvolatile NUC storage. There is about 2GB of

flash memory available for storing NUCs. This is enough space to store hundreds of full frame NUCs.

A6700sc/A6750sc User’s Manual

22

Page 23

5 –Camera Controller

flag and perform a NUC Offset Update when selected criteria

Displays a list of NUCs stored in flash memory. User can

NUC Controls

NUC Info. Displays camera parameters and statistics related

to the selected NUC

Perform NUC. Starts the NUC Wizar d.

Updates the current NUC to flash memory

Load a NUC from flash to RAM memory.

Unload NUC from RAM mem ory. No on-camera NUC will be

applied to the data.

Apply NUC to Analog video data

Apply NUC to Digital output (Gig E, CameraLink)

Displays all pixels marked as “bad” as white dots on both the

analog and digital outputs.

When enabled, the camera will automatically drop the internal

are met. The NUC update can be triggered on demand, by a

change in the internal temperature sensor or by a ti mer

delete NUCs from flash memory as well as upload/download

NUCs (.NPK files) from the host PC.

Displays options for loading NUCs.

A6700sc/A6750sc User’s Manual

23

Page 24

5 –Camera Controller

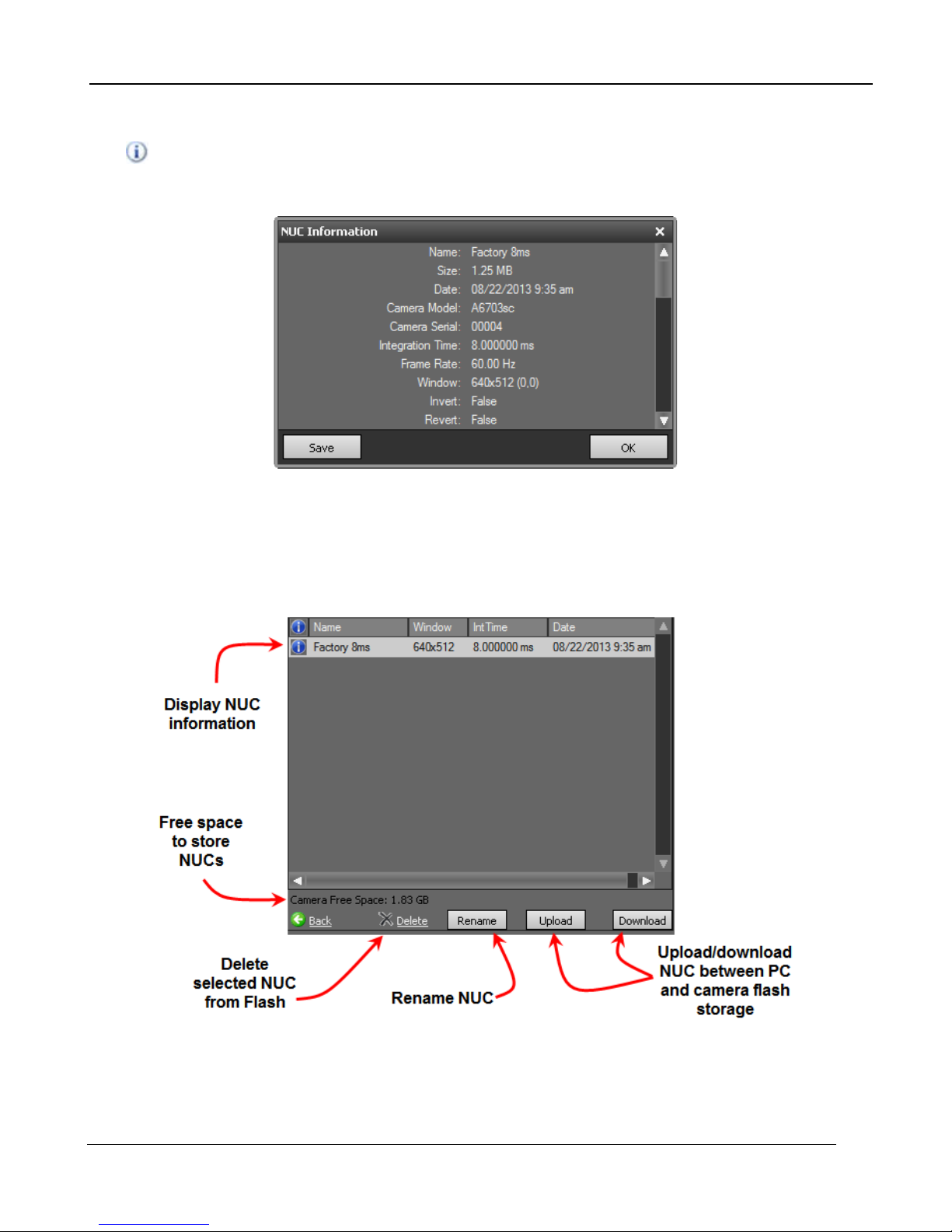

NUC Information

The button displays a list of camera parameters that are saved as part of the NUC as well as bad

pixel statistics. Note that there is a scroll bar that can be used to see the whole list. The Save button

allows the user to dump this list to a text file.

Manage NUCs

This dialog box allows the user to manage NUCs stored in non-volatile flash memory. Changes here

will persists through a camera power cycle. For example, if you rename a NUC here and do not

update the NUC loaded into RAM and the camera state, the camera will not be able to reload the

NUC after a power cycle.

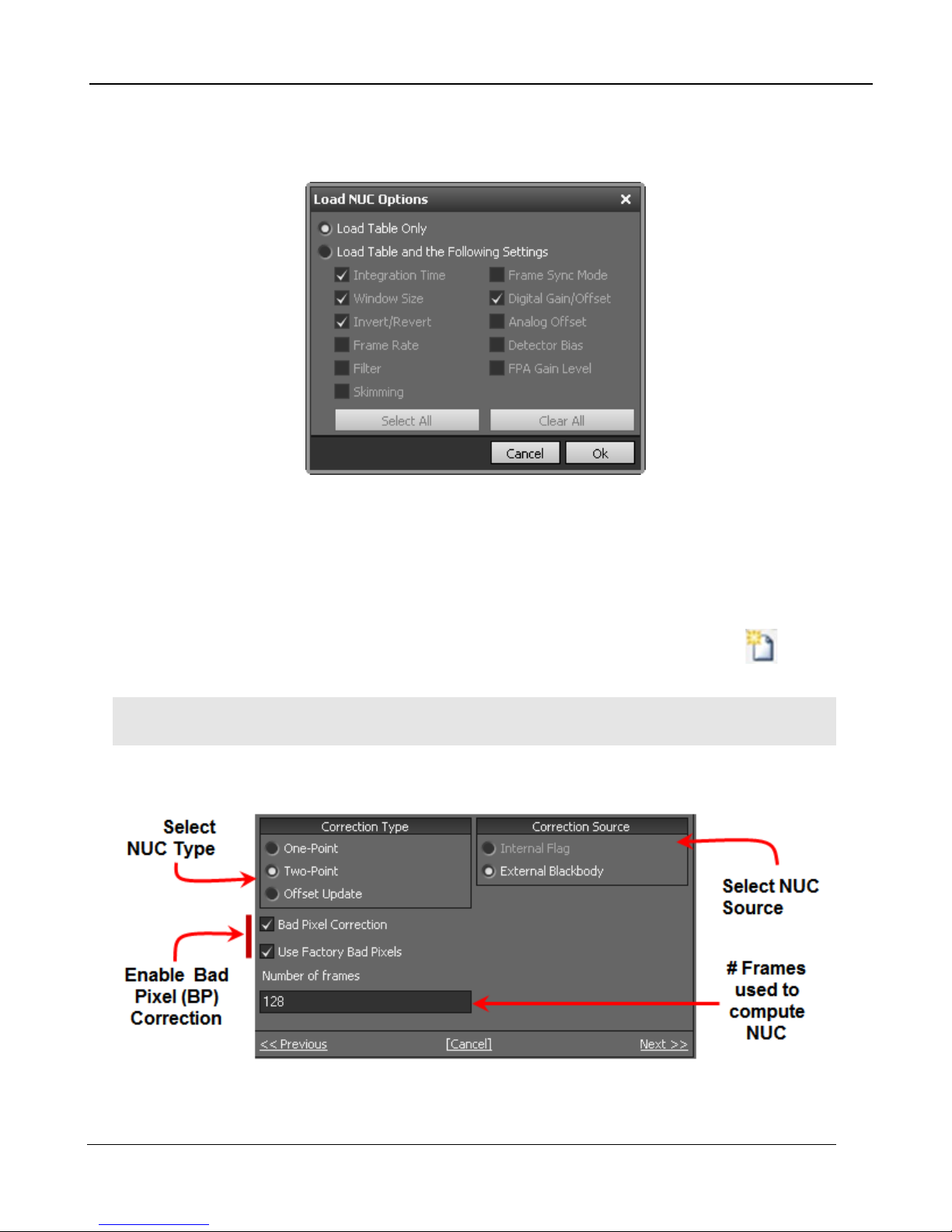

Load NUC Options

Typically, all of the camera configuration parameters are derived from the current Camera State.

When the camera is powered up, it loads the last saved camera state. The names of the NUCs are

stored as part of the state. Normally the NUC is performed with the settings that are eventually going

A6700sc/A6750sc User’s Manual

24

Page 25

5 –Camera Controller

to be part of the state. If a NUC is loaded that has a setting that differs from the camera state, the

state will override the NUC. If the user wants the NUC setting to override the state then “Load NUC

Options” can be set.

The default setting is to “Load Table Only”, in which case only the NUC coefficients are used from a

NUC file. When the user selects “Load Table and the Following Settings”, the user can select which

parameters from the NUC will override the current state. The option will not affect NUCs that are

currently loaded into RAM, only those NUCs that are subsequently loaded from Flash memory.

Unless a new state is saved, these override settings will not be remembered after a power cycle.

Performing a NUC

To build a NUC table using the camera electronics, select the Perform Correction icon to start

the NUC Wizard for the desired preset.

NOTE: Due to differences in camera electronics and FP A timi ngs i t is i mpo rtant to p erform the NUC

with the camera operatin g modes confi gured as it w ill be used w hen imaging.

After selecting the Perform Correction a second window comes up to allow the user to select

correction parameters. When all selections have been made, click Next>> to continue.

A6700sc/A6750sc User’s Manual

25

Page 26

One Point

5 –Camera Controller

Correction (NUC) Types

Sets the gain terms to “1” and computes the offset terms.

Uses a single NUC source. Does not compute a BP

correction.

Two Point

Sets both the gain and offset terms. Uses two NUC

sources. Computes a bad pixel correction.

Retains the current NUC gain terms and updates the offset

Offset Update

terms. Uses a single NUC source. Retains the current bad

pixel (BP) correction.

Correction Sources

Use the internal flag as the NUC source. Because the flag

Internal Flag

is not temperature controlled, it can only be used for 1-point

and Offset Update NUC functions

Use an external blackbody as the NUC source. Program

External Blackbody

will prompt the user to place each source in front of the

camera. NUC source needs to fill the entire field of view.

Set the number of to average when computing NUC

Number of frames

coefficients. 16 frames is the default and works well for

most scenarios. The value can be to be 2, 4, 8, 16, 32, 64,

or 128.

After configuring the correction parameters and selecting Next>> the next window allows the user to

set up the parameters used for the Bad Pixel Detection. Once the parameters are set, select Next>>

to continue.

A6700sc/A6750sc User’s Manual

26

Page 27

5 –Camera Controller

The next window allows the user to name the NUC. Simply type in the name for the table in the text

box or select a previously saved file to replace it. Select Next>> to continue.

The next two screens will collect data from the NUC sources. If using the internal flag you will only

see a few status messages. If using external blackbodies you will be prompted. After each step, click

Next>> to continue.

The last screen gives a report of the bad pixels found. The dialog shows how many pixels failed in

each category. If the result is satisfactory, click Accept to save the NUC. The NUC table will be

stored to flash memory and loaded into RAM memory for that preset. If the NUC is poor and you want

to abort, click[Discard].

NOTE: It is possible for a bad pixel to fail more than one category , so the total bad pixels may be less

than the sum of each category. “Fac tory” bad pixels are those that were deter mined to be bad during

camera production testing.

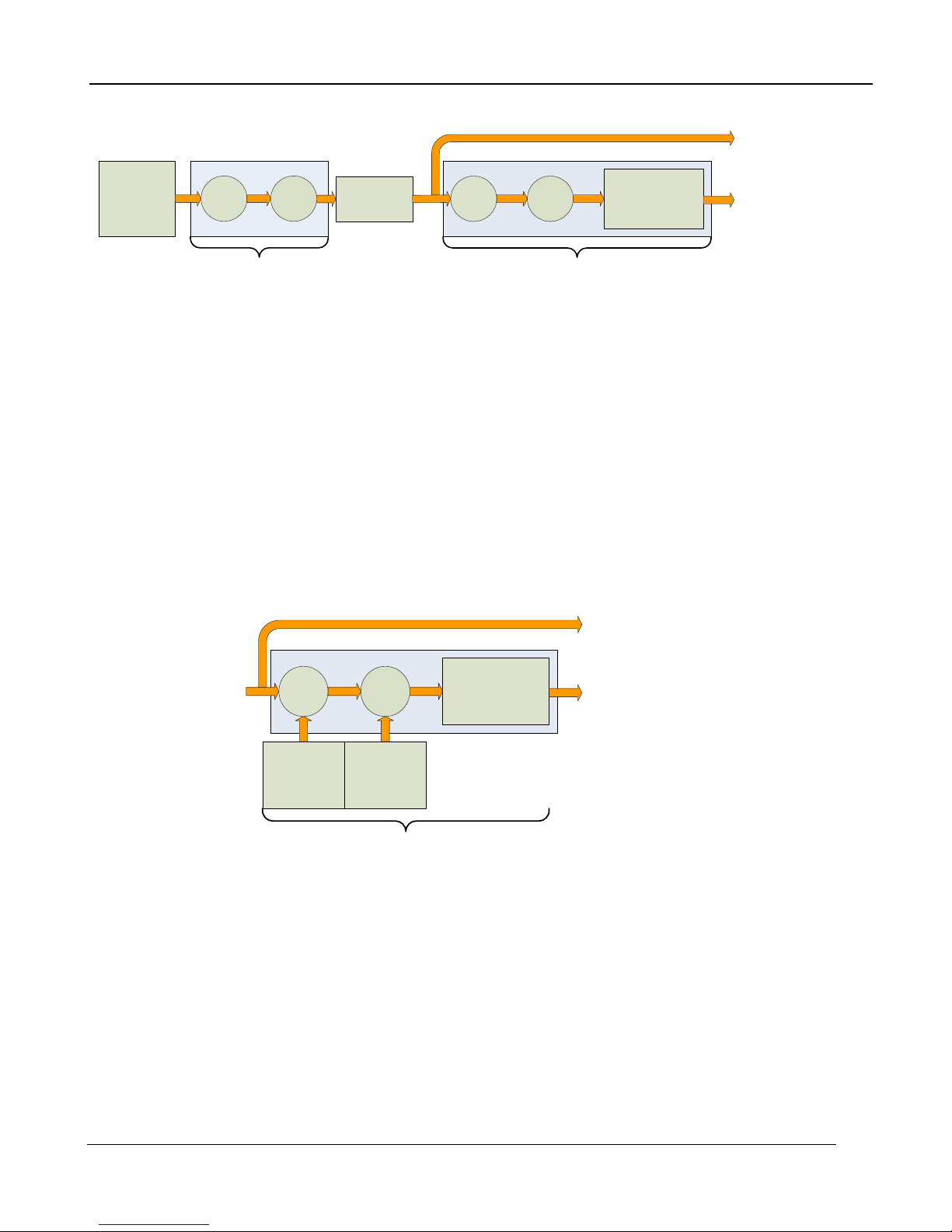

What is a Non-Uniformity Correction (NUC)?

Non-Uniformity Correction (NUC) refers the process by which the camera electronics correct for the

differences in the pixel-to-pixel response for each individual pixel in the detector array. The camera

can create (or allow for the user to load) a Non-Uniformity Correction (NUC) table which consists of a

unique gain and offset coefficient and a bad pixel indicator for each pixel. The table is then applied in

the digital processing pipeline as shown in Figure 4-12. The result is corrected data where each pixel

responds consistently across the detector input range creating a uniform image.

A6700sc/A6750sc User’s Manual

27

Page 28

5 –Camera Controller

Detector

14

-bit A/D

x +

NUC Table

Bad Pixel

Replacement

Algorithm

Corrected Data

Uncorrected Data

x

+

Analog

Gain/Offset

x

+

NUC Table

Bad Pixel

Replacement

Algorithm

Corrected Data

Uncorrected Data

“

1”

Offset

Coefficients

Figure 4-12: Digital Process Showing NUC Table Application

To create the NUC table, the camera images either one or two uniform temperature sources. The

source can be an external source provided by the user or the camera’s internal NUC flag which is

basically a shutter the camera places in front of the detector. If the source is external it should be

uniform and large enough to overfill the cameras field-of-view (FOV). By analyzing the pixel data from

these constant sources, the non-uniformity of the pixels can be determined and corrected. There are

three types of processes which are used to create the NUC table; One-Point, Two-Point, and Offset

Update.

5.2.5.1.1 One-Point Correction Process

A One-Point Correction Process requires one uniform source, which is typically in the middle of the

usable range. The One-Point Correction replaces all gain coefficients in the NUC table with a value of

one (“1”) as seen in Figure 4-13. The offset coefficients are computed uniquely for each pixel.

5.2.5.1.2 Two-Point Correction Process

The Two-Point Correction Process builds a NUC table that contains an individually computed gain

and offset coefficient for each pixel as seen in Figure 4-14. Two uniform sources are required for this

correction. One source at the low end and a second source at the upper end of the usable detector

input range. Because of the use of two images at either end of the input range, the Two-Point

Correction yields better correction results verses the One-Point process. A 2-point correct will also

work better over a wider range of scene temperatures than a 1-point correction.

A6700sc/A6750sc User’s Manual

Figure 4-13: One-Point Correction

28

Page 29

5 –Camera Controller

x

+

NUC Table

Bad Pixel

Replacement

Algorithm

Corrected Data

Uncorrected Data

Gain

Coefficients

Offset

Coefficients

x

+

NUC Table

Bad Pixel

Replacement

Algorithm

Corrected Data

Uncorrected Data

Bad Pixel

Indicator

Figure 4-14: Two-Point Correction

5.2.5.1.3 Offset Update

Often times during the normal operation of a camera the electronics and/or optics will heat up or cool

down which changes the uniformity of the camera image. This change requires a new NUC.

However, this change is mainly in the offset response of the image while the gain component stays

constant. An Offset Update simply computes a new offset coefficient using the existing gain

coefficient and corrects the image non-uniformity. Offsets Update are typically performed when a

Two-Point NUC table is being used.

An Offset Update requires only one uniform source, usually set at a temperature on the lower edge of

the operational range.

5.2.5.1.4 Bad Pixel Correction

Within the NUC table there is an indication as to whether or not a pixel has been determined to be

bad as seen in Figure 4-15. There are two methods the A6700sc uses to determine bad pixels.

First, the NUC table gain coefficients are compared to a user defined acceptance boundary,

Responsivity Limit Low/High (%). The responsivity of a pixel can be thought of as the gain of that

pixel. The gain coefficient in the NUC Table is a computed value that attempts to correct the

individual pixel gain, or responsivity, to a normalized value across the array. Since the responsivity

A6700sc/A6750sc User’s Manual

Figure 4-15: Bad Pixel Correction

29

Page 30

5 –Camera Controller

value directly relates to the gain coefficient in the NUC table, the A6700sc can scan the NUC table

gain coefficients and use them to determine if a pixel’s responsivity exceeds the limits as set by the

user.

The second method of determining bad pixels is to search for twinklers. Twinklers are pixels that

have responsivity values within normal tolerances, but still exhibit large swings for small input

changes. These pixels are on the “verge” of being bad and often appear to be noisy. To find these

types of pixels the camera collects N number of frames and records the maximum and minimum

values across that sample set for each pixel. If the delta between max and min exceeds the Twinkler

max pixel value delta then the pixel is determined to be bad.

Since the responsivity test requires a gain coefficient, it is useless on NUC tables determine by the

One-Point Correction because those tables have a value of one (“1”) as the gain coefficients. The

Twinkler test can be done on either correction process.

The A6700sc uses two algorithms for bad pixel replacement: 2-point Gradient, and Nearest Neighbor.

The 2-point gradient algorithm is the default bad pixel correction method. With this algorithm, the two

pairs of pixels above and below and to the left and right of the bad pixel are evaluated. The algorithm

compares the differences between the pixels and chooses the pair with smallest gradient (difference).

It then averages the two adjacent pixels and uses that value for the replacement value. This

algorithm is better at handling bad pixels near a high contrast edge and is the default method. If the

algorithm encounters a situation is cannot solve (for example, an edge or corner) it will fall back on the

nearest neighbor algorithm.

Nearest neighbor uses a simple replacement using an adjacent pixel. The adjacent pixel is picked

using the pattern depicted below. When a bad pixel is near an edge, those search positions are

skipped.

A6700sc/A6750sc User’s Manual

30

Page 31

5 –Camera Controller

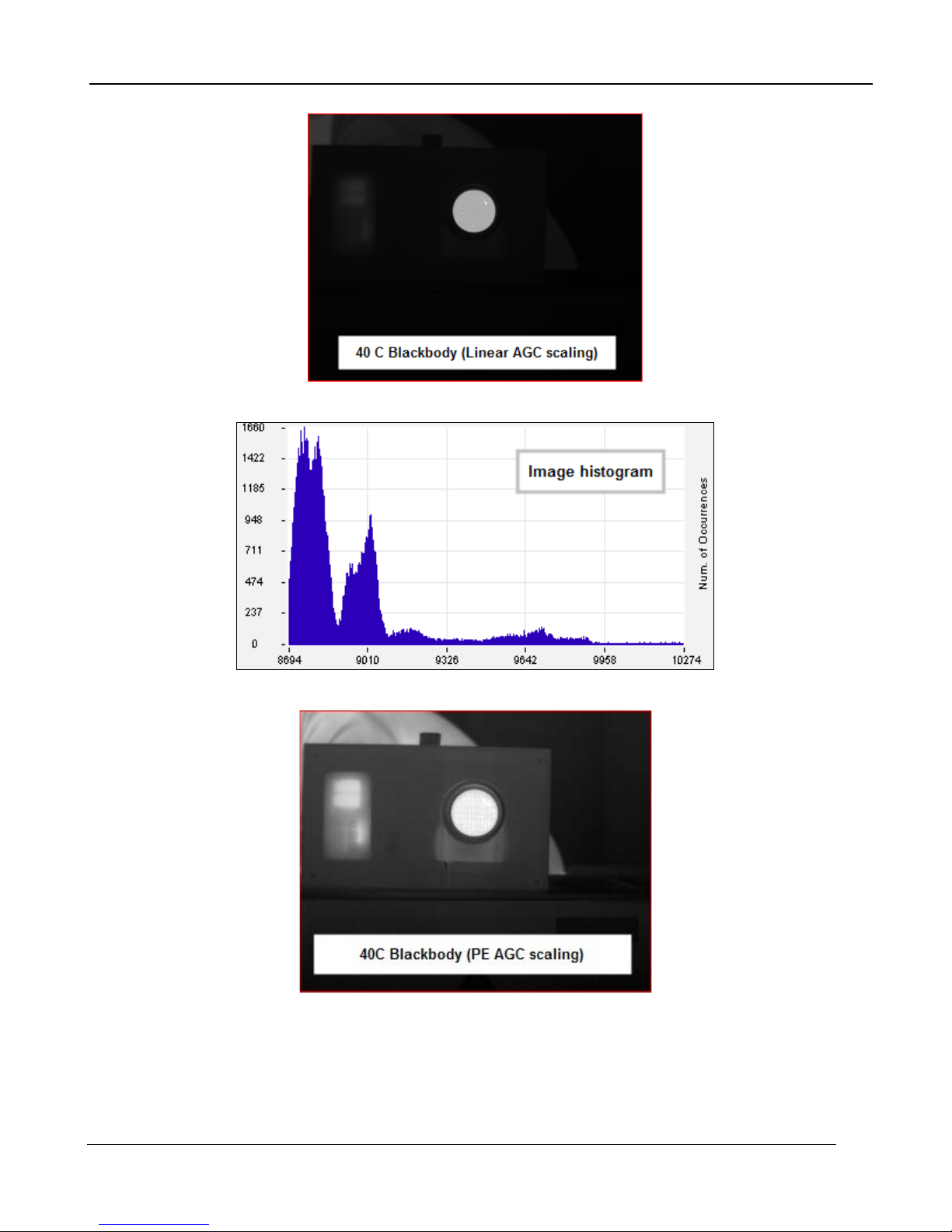

5.2.6 Video Page

The A6700sc camera has a 14-bit digital output. However, the analog output is only 8-bit. An

Automatic Gain Control (AGC) algorithm is used to map the 14-bit digital to the 8-bit analog data. The

Video Tab provides controls related to optimizing the Analog video output. These controls affect

only the analog video. Figure 4-16 shows a flow chart of the analog video process and how the

parameters of this screen are used.

Analog Video Setup Options

NTSC: 640x480, 30Hz interlaced, color based on Palette selection,

(Note: top and bottom 16 lines are truncated when full images are

displayed. The Analog window can be adjusted +/- 16 rows using the

Format

Overlay Enables the analog video overlay.

Filter Rate Rate at which AGC is com puted (1 to 20 Hz)

Dampening

Setup>>Window Tab)

PAL: 640x480, 25Hz interlaced, color based on Palette selection

Note: When camera frame size is smaller than video frame size, black

borders are added to maintain standard video output sizes

Rate at which AGC is allowed to change. This will keep the AGC from

responding rapidly to fast tridents changes. Specified as a fraction from

0 to 1. This fraction is used as a weighting factor for the current AGC vs.

the newly computed AGC.

A6700sc/A6750sc User’s Manual

31

Page 32

AGC Mode

Corrected Data

Uncorrected Data

Mux

Plateau

Scalar

Linear

Scalar

GUI: Plateau P

GUI: Bounds

Mux

GUI

: AGC Mode

Video

Encoder

GUI: Format

GUI: Position

GUI: Brightness

GUI: Contrast

Overlay

GUI: Overlay

GUI: NUC’d

Analog Video

Pallete

Scalar

GUI: Palette

5 –Camera Controller

Analog Video Setup Options

Plateau: Uses a plateau equalization (PE) algorithm to scale the image

data for video display

DDE: Digital Detail Enhancement.

Manual Linear: Scales the im age data to a windowed s ec tion of data range

as set by the user

Auto Linear: Same as Manual Linear except camera analyzes image and

sets limits at ~1% and 98% of the histogram.

Plateau P

Bounds

DDE Sharpness

Scaling factor for the Plateau Equalization function

Note: Plateau P is only visible when AGC Mode>> Plat eau is select ed

Sets the lower and upper data range to be scaled to on the video data.

Note: Bounds is only visible when AGC Mode>>Manual Linear is selected

Only visible when AGC is set to DDE. Selects the amount of enhancement

processing.

Palette Allows user to select the color scheme to use on the analog video channel.

Allows user to set brightness and contrast on the video encoder. As shown

Brightness and

Contrast

in Figure 4-16, this occurs after the digital data has been scaled and

converted to analog. These controls don’t tend to have as much effect as

the controls that are applied to the digital side (before the video encoder).

The Manual Linear algorithm evenly distributes the grayscale values over the digital values. This

works fairly well if the image dynamic range is fairly evenly distributed but in general does not produce

high contrast imagery, but it also does not saturate or clip the hot and cold regions either. The

Plateau Equalization algorithm (also called PE) is a nonlinear AGC algorithm that uses the image

histogram to optimally map the 256 gray scales. This algorithm works well for most scenes but it

works best when the scene has a “bi-modal” distribution (two clumps). It usually the most popular

because algorithm because it produces high contrast (but more saturated) video. The following

pictures illustrate the differences in AGC algorithms. (The data was captured from the digital output

but the effect is similar for the analog side.)

A6700sc/A6750sc User’s Manual

Figure 4-5: Analog Video Flow

32

Page 33

5 –Camera Controller

One final note about the PE algorithm. It is very aggressive. It can pull detail out of very low contrast

imagery. It can also pull out some very low-level NUC and FPA artifacts and noise if the contrast is

low enough. This does not necessarily mean there is a problem with the camera, or NUC.

A6700sc/A6750sc User’s Manual

33

Page 34

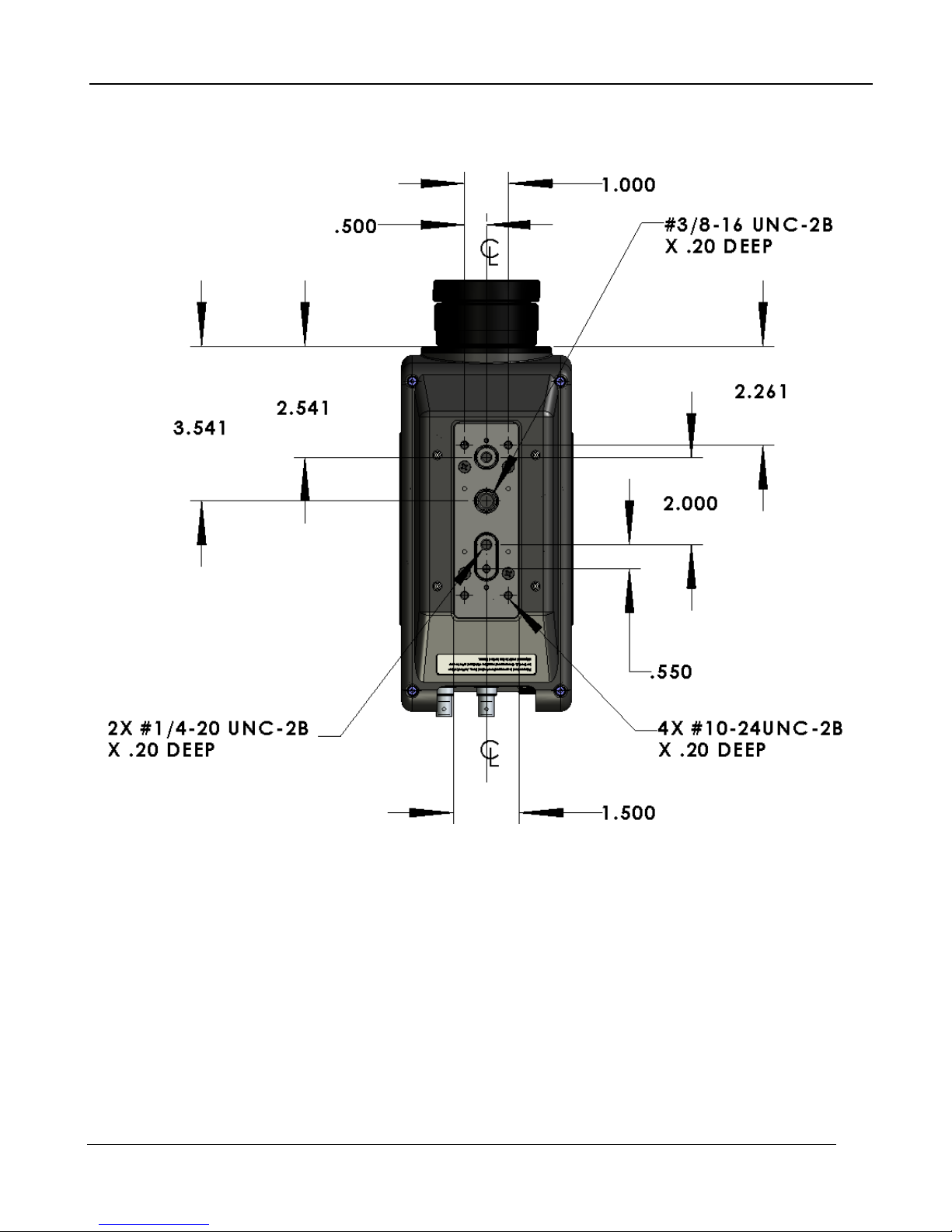

6 Interfaces

6.1 Mechanical (dimensions in inches)

6 – Interfaces

Figure 6-1: Front view of A6700sc

Figure 6-2: Side view of A6700sc with 50mm lens

A6700sc/A6750sc User’s Manual

34

Page 35

6 – Interfaces

A6700sc/A6750sc User’s Manual

Figure 6-1: Bottom view of A6700sc

35

Page 36

6 – Interfaces

6.1.1 Status Light s

The A6700sc provides a set of status indicators on the back panel to give the user some visual

feedback on the camera operating state.

POWER (on power switch): Indicates that the camera is ON.

READY: Camera electronics have completed boot up. Camera is

ready to accept commands.

COLD: Indicates that the FPA has reached operating tem perature

(<80K).

6.1.2 Power Interface

24V DC nominal, external AC-DC power converter is provided with the A6700sc camera system as a

standard accessory. Power supply specifications are:

Input voltage range: 100-250VAC 50/60Hz

Current draw: 24 VDC at up to 4.0 amps input to the camera

Converter dimensions: 6.25 inches x 3.5 inches x 2.75 inch (L x W x H)

Converter weight: approximately 1 lb

The power input pinouts are shown in Figure 6-4.

Figure 6-4: A6700sc Power Input Pinouts

When using your own DC power supply, you should take note of the following information:

Output voltage: 24 VDC

Current draw: 1.4 amps nominal steady state, 2.6 amps peak (during cooldown)

A6700sc power dissipation is <50 Watts steady state at nominal ambient temperature.

Mating Connector: Fisher Connectors, S103A052-130+E31 103.1/5.7 +B. (FLIR PN 26399-000).

The power cable should be 20AWG (stranded 10/30), 3 conductor, no shield, max diameter of 0.223

inches. (Example: Alphawire PN 882003)

A6700sc/A6750sc User’s Manual

36

Page 37

6 – Interfaces

6.1.3 Other Interfaces

6.1.3.1 Gigabit Ethernet

Gigabit Ethernet (GigE) is a common interface found in most PC’s. The GigE interface can be used

for image acquisition and/or camera control. The GigE interface is GigE Vision compliant (for the

image stream, but does not support Genicam for camera control).

6.1.3.2 Sync In

The Sync In can be selected, by the user, to operate as an external clock It is a rising edge LV-CMOS

signal (5.5V max). The minimum width is 160nS.

6.1.3.3 Video

Composite video out (BNC connector). User selectable to be NTSC standard (640x480, 30Hz

interlaced) or PAL standard (640x512, 25Hz interlaced). Video supports user selectable color

palettes.

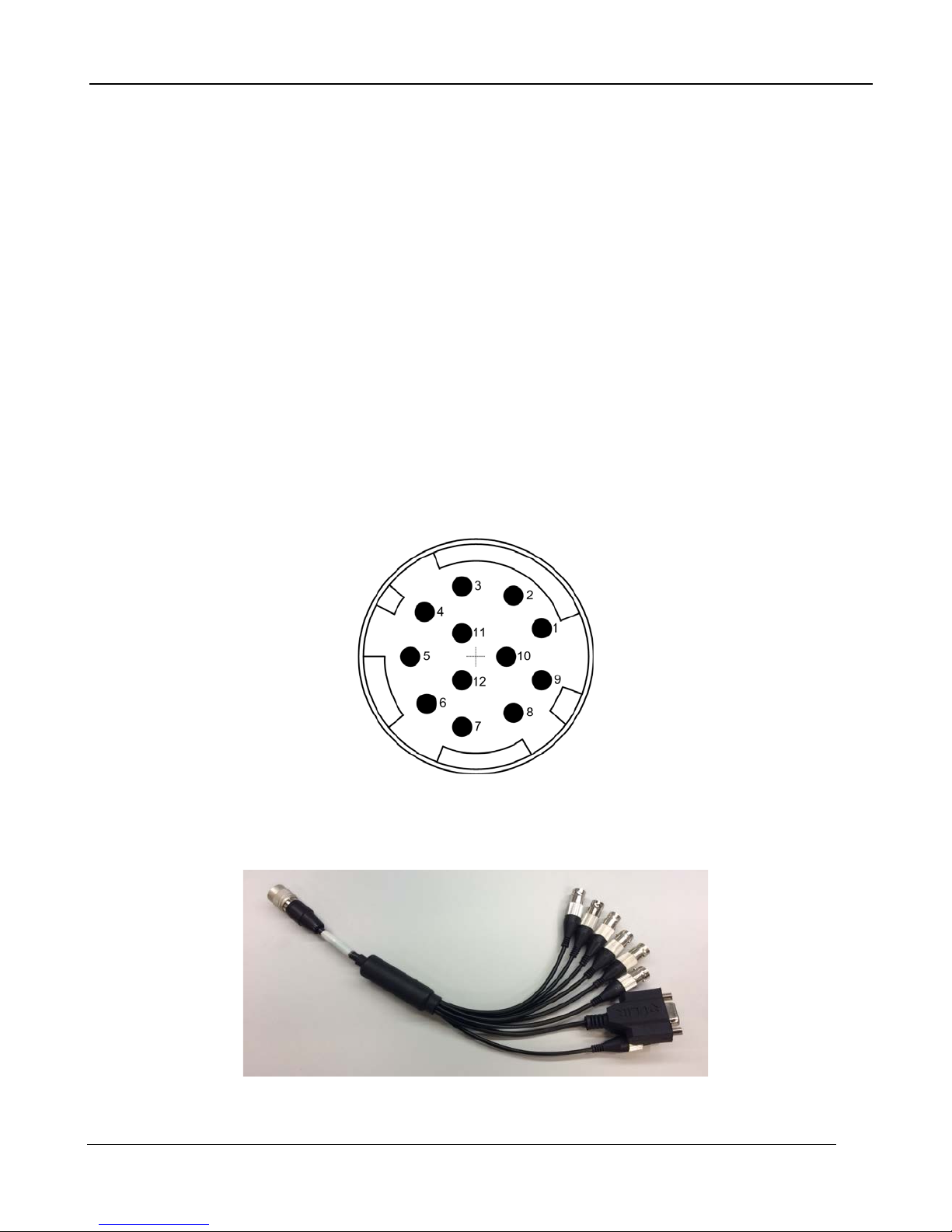

6.1.3.4 AUX Connector [A6750sc only]

The AUX connector provides access to additional signals. The diagram below shows a closeup view

of the rear panel connector.

A breakout cable is provided with all A6750sc cameras.

A6700sc/A6750sc User’s Manual

37

Page 38

6 – Interfaces

The provided breakout cable has numerical markings on the BNC overmolding that are described in

the table below.

Pin Name Breakout

Type Description

Connector

1

NC

2

NC

3

RECORD

START

4

SYNC OUT BNC 4 OUTPUT 160ns wide pulse at start of integration

5

GROUND

6

GPIO IN BNC 6 INPUT Sets bits in image header. Updated at ~1Hz rate.

7

Reserved BNC 7

8

TRIGGER BNC 8 INPUT External trigger. Can be used by ResearchIR to start

BNC 3 INPUT Sets bit in image header. Can be used by

ResearchIR to start recording.

recording.

9

Reserved BNC 9

10

SYNC IN BNC 10 INPUT Duplicate of rear panel input. Do not use both at the

same time.

11

RS-232 TX DB9 Male OUTPUT For camera control

12

RS-232 RX DB9 Male INPUT For camera control

Inputs are all LV-CMOS. High>2V, Low<0.2V. Max is 5.5V

If you wish to make your own breakout cable, there are three variants of the Hirose mating connector

that will work: HR10A-10P-12S(73), HR10-10P-12S(73) or HR10A-10P-12SC(73).

A6700sc/A6750sc User’s Manual

38

Page 39

7.1 Interface

7 – Specifications

7 Specifications

AC Power

Control

Analog Video Out

Frame Sync In

Digital Video Out

Optical Interface

Thermal Interface

Mechanical Interface

7.2 Windowing Capacity

Window Sizes

90-230VAC, 50-60 Hz (using FLIR 24123-000 power supply)

Genicam over Gigabit Ethernet (10/100/1000)

Selectable

• NTSC/PAL selectable, BNC, 75Ω, 1V pk-pk

LVCMOS singled ended, BNC, selectable polarity, >160ns pulse

width

14-bit Gigabit Ethernet (GigE Vision 2.0)

Bayonet

Semi-sealed enclosure with integral forced air heat exchanger

2 (two) ¼-20 tripod screws; 1 (one) 3/8-16 professional tripod

screw; 4 (four) 10-24 mount holes

640x512, 320x256, 160x120, [flexible for A6750sc]

Windowing Step Size

Window Offset Step Size

16 columns, 4 rows (A6750sc)

No offset, FPA centered

7.3 Acquisition Modes and Features

Frame Rate :

Max at Full Window

Max w/ Windowing

Max @ Min Window

Minimum

Resolution

Pixel Rate (burst)

Integration Width

Maximum

60 Hz for A6700, 125Hz for A6750sc

240 Hz @ ½ window, 480 Hz @ ¼ window (A6700sc)

406 Hz @ ½ window, 1063 Hz @ ¼ window (A6750sc)

4175 Hz @ 16x4 (A6750sc)

1.45mHz

160nS

50 MHz

98% selected frame time (1/frame rate)

A6700sc/A6750sc User’s Manual

39

Page 40

7 – Specifications

Minimum

480 nS

Resolution

Preset Sequencing

Digital Video Output

7.4 Analog Video

Video Output

Data Output

AGC

160 nS

• N/A

Selectable:

• Raw digital video (14-bits)

• Gain and offset (NUC) corrected (14-bits)

• NUC with bad pixel replaced (14-bits)

• NTSC or PAL composite

Selectable

• Raw, uncorrected

• Corrected

Selectable

• DDE

• Plateau based equalization

• Linear equalization

User controlled damping factor

AGC Filter

User controlled update rate

Overlay

Available on analog output

Selectable

Palettes

• Grayscale

• Various color palettes

Auto-selected

Zoom (Analog video)

• x1 for 640x512

• x2 for 320x256 and 160x120 window sizes

Brightness and Contrast

(analog video)

User controlled to increase or decrease

7.5 Performance Characteristics

Power Consumption

FLIR PWR Supply @ 120V

Continuous Cool Down: 50 VA

AC

Continuous Normal: 41 VA

A6700sc/A6750sc User’s Manual

40

Page 41

7 – Specifications

Power Consumption

Camera DC Power @ 24V

Cool-down Ti me

Sensitivity (w/o optics)

NEΔT

1) NE∆T is at 50% nominal bucket fill, 298K background, + 5oC signal

Continuous Cool Down: 24 Watts

DC

Continuous Normal: 21.25 Watts

≈7 minutes to reach operating temperature

1

18 mK typ .

7.6 Non Uniformity Correcti on

One Point (offset value with unity gain)

NUC Types

NUC Source

Bad Pixel Replacement

Two Point (offset and gain values) non-volatile

Two Point w/Bad Pixel Detection/Replacement

Update Offset (recalculates offset using current gain)

Internal: Ambient flag (for 1-pt and offset update only)

External: Any user supplied source which covers entire FOV

Two-Point Gradient and neares t neighbor (autoselected)

Number of NUC’s

NUC Time

NUC Performance

7.7 Detector/FPA

Spectral Response

Detector Type

f/#

Integration Mode

Format (HxV)

Operability

Charge Handling

Capacity

Detector Pitch

1

4 active NUC’s in preset selectable form

>100 NUCs in on-board flash

< 15 seconds

0.1%

3-5um (1-5um for broadband models)

InSb

f/2.5 or f/4

Snapshot

640 x 512

>99.8%, 99.95% typical

7.2 x106 e-

15 microns

Detector Cooling

A6700sc/A6750sc User’s Manual

Rotary Cryo Cooler

41

Page 42

7.8 General Characteristics

7 – Specifications

Size

Length

Width

Height

Weight

Temperature

Operating

Storage

Shock

Vibration

Humidity

Altitude

Operating Orientation

8.5 inches

4.0 inches

4.3 inches

(not including lens or lens cover)

5 lbs (not including lens or lens cover)

-40C to +50C

-55C to +80C

40 g’s, 11 msec half sine pulse

4.3 g's RMS random vibration, all three axes

<95% relative humidity, non-condensing

0 to 10,000 feet operational, 0 to 70,000 feet non-operational

No restriction in orientation

A6700sc/A6750sc User’s Manual

42

Page 43

8 – Maintenance

8 Maintenance

8.1 Camera and Lens Cleaning

8.1.1 Camera Body, Cables and Accessories

The camera body, cables and accessories may be cleaned by wiping with a soft cloth. To remove

stains, wipe with a soft cloth moistened with a mild detergent solution and wrung dry, then wipe with a

dry soft cloth.

Do not use benzene, thinner, or any other chemical product on the camera, the cables or the

accessories, as this may cause deterioration.

8.1.2 Lenses

It is recommends that all optics be handled with care and the need for cleaning is eliminated or at

least reduced. If however,cleaning is deemed necessary, the methods herein are accepted industry

standards and should yield good results.

Before you BEGIN,

Identify the type of optic to be cleaned.

▫ Is it hard or soft material?

▫ Is it coated & with what?

How is it contaminated?

▫ Particulate or film or both.

Set a standard of cleanliness.

▫ What is clean enough?

▫ Establish & document a standard.

Know your solvent.

▫ Read the MSDS

▫ See recommended solvents

Assemble your supplies:

▫ Latex gloves

▫ Clean, well-lit work area

▫ Inspection light

▫ Lens tissue or cloth

▫ Dust bulb or filtered air

▫ Proper solvent

▫ Solvent dispenser

The Drag Wipe Method:

Set-up a clean area to work from with an anti-roll barrier around the edge to prevent anything from

leaving the table.

Use a clean, lint free cloth or lens tissue.

Wear latex gloves - clean them with alcohol or detergent before handling optic.

A6700sc/A6750sc User’s Manual

43

Page 44

8 – Maintenance

NEVER touch the face of the optic.

Cover the optic and store in a dry - dust free area immediately after cleaning.

1. Blow or brush loose particles from surface. Don’t let them contaminate your work area. Use

air from a can or a filtered source.

2. Apply solvent directly to your cloth. Use slow, even, light pressure working from edge to edge

across the optic.

Recommended Solvents

Material Solvent

Fused Silica 1,2,3,4 Zinc Selenide 1,2,4

BK-7 1,2,3,4 Zinc Sulfide 1,2,4

Optical Crown Glass 1,2,3,4 Sapphire 1,2,3,4

Zerodur 1,2,3,4

Calcium Fluoride 1,2,4 Coated Optics

Magnesium Fluoride 1,2,4 Dielectric coating 1,2,3,4

Sodium Chloride Nitrogen Interference filters 3

Potassium Chloride Nitrogen Soft metallic coating Air only

Potassium Bromide Nitrogen Hard/Protected metallic 1,2,3,4

Thallium Bromoiodide Nitrogen

1] Water free Acetone

2] Ethanol

3] Methanol

4] Isopropanol

A6700sc/A6750sc User’s Manual

44

Page 45

9 – Infrared Primer

9 Infrared Primer

9.1 History of Infrared

Less than 200 years ago the existence of the infrared portion of the electromagnetic spectrum wasn't

even suspected. The original significance of the infrared spectrum, or simply ‘the infrared’ as it is often

called, as a form of heat radiation is perhaps less obvious today than it was at the time of its discovery

by Herschel in 1800.

Figure 8-1: Sir William Herschel (1738–1822)

The discovery was made accidentally during the search for a new optical material. Sir William

Herschel – Royal Astronom er to King George III of England, and already famous for his discovery of

the planet Uranus – was searching for an optical filter material to reduce the brightness of the sun’s

image in telescopes during solar observations. While testing different samples of colored glass which

gave similar reductions in brightness he was intrigued to find that some of the samples passed very

little of t he sun’s heat, while others passed so much heat that he risked eye damage aft er only a few

seconds’ observation.

Herschel was soon convinced of the necessity of setting up a systematic experiment, with the

objective of finding a single material that would give the desired reduction in brig htness as well as the

maximum reduction in heat. He began the experiment by actually repeating Newton’s prism

experiment, but looking for the heating effect rather than the visual distribution of intensity in the

spectrum. He first blackened the bulb of a sensitive mercury-in-glass thermometer with ink, and with

this as his radiation detector he proceeded to test the heating effect of the various colors of the

spectrum formed on the top of a table by passing sunlight t hrough a g lass prism. Other thermometers,

placed outside the sun’s rays, served as controls.

As the blackened thermometer was moved slowly along the colors of the spectrum, the temperature

readings showed a steady increase from the violet end to the red end. This was not entirely

unexpected, since the Italian researcher, Landriani, in a similar experiment in 1777 had observed

much the same effect. It was Herschel, however, who was the f irst to recognize that there must be a

point where the heating effect reaches a maximum, and those measurements confined to the visible

portion of the spectrum failed to locate this point.

A6700sc/A6750sc User’s Manual

45

Page 46

9 – Infrared Primer

Figure 8-2: Marsilio Landriani (1746–1815)

Moving the thermometer into the dark region beyond the red end of the spectrum, Her s c h el c onfirmed

that the heating continued to increase. The maximum point, when he found it, lay well beyond the red

end – in what is known today as the ‘infrared wavelengths’.

When Herschel revealed his discovery, he referred to this new portion of the electromagnetic

spectrum as the ‘thermometrical spectrum’. The radiation itself he sometimes referred to as ‘dark

heat’, or simply ‘the invisible rays’. Ironically, and contrary to popular opinion, it wasn't Herschel who

originated the term ‘infrared’. The word only began to appear in print around 75 years later, and it is

still unclear who should receive credit as the originator.

Herschel’s use of glass in the prism of his original experiment led to some early controversies with his

contemporaries about the actual existence of the infrared wavelengths. Different investigators, in

attempting to confirm his work, used various types of glass indiscriminately, having different

transparencies in the infrared. Through his later experiments, Herschel was aware of the limited

transparency of glass to the newly-discovered thermal radiation, and he was forced to conclude that

optics for the infrared would probably be doomed to the use of reflective elements exclusively (i.e.

plane and curved mirrors). Fortunately, this proved to be true only until 1830, when the Italian

investigator, Melloni, made his great disc overy that naturally occurring rock salt (NaCl) – whic h was

available in large enough natural crystals to be made into lenses and prisms – is remarkably

transparent to the infrared. The result was that rock salt became the principal infrared optical material,

and remained so for the next hundred years, until the art of synthetic crystal growing was mastered in

the 1930’s.

Figure 8-3: Macedonio Melloni (1798–1854)

Thermometers, as radiation detectors, remained unchallenged until 1829, the year Nobili invented the

thermocouple. (Herschel’s own thermometer could be read to 0.2 °C (0.036 °F), and later models

were able to be read to 0.05 °C (0.09 °F)). Then a breakthrough occurred; Melloni connected a

number of thermocouples in series to form the first thermopile. The new device was at least 40 times

as sensitive as the best thermometer of the day for detecting heat radiation – capable of detecting the

heat from a person standing three meters away.

The first so-called ‘heat-picture’ became possible in 1840, the result of work by Sir John Herschel, son

of the discoverer of the infrared and a famous astronomer in his own right. Based upon the differential

evaporation of a thin film of oil when exposed to a heat pattern focused upon it, the thermal image

could be seen by reflected light where the interference effects of the oil film made the image visible to

the eye. Sir John also m anaged to obtain a primitive record of the thermal image on paper, which he

called a ‘thermograph’.

A6700sc/A6750sc User’s Manual

46

Page 47

9 – Infrared Primer

Figure 8-4: Samuel P. Langley (1834–1906)

The improvement of infrared-detector sensitivity progressed slowly. Another major breakthrough,

made by Langley in 1880, was the invention of the bolometer. This consisted of a thin blackened strip

of platinum connected in one arm of a Wheatstone bridge circuit upon which the infrared radiation was

focused and to which a sensitive galvanometer responded. This instrument is said to have been able

to detect the heat from a cow at a distance of 400 meters.

An English scientist, Sir James Dewar, first introduced the use of liquefied gases as cooling agents

(such as liquid nitrogen with a temperature of -196 °C (-320. 8 °F)) in low temperature research. In

1892 he invented a unique vacuum insulating container in which it is possible to store liquefied gases

for entire days. The common ‘thermos bottle’, used for storing hot and c old drinks, is based upon his

invention.

Between the years 1900 and 1920, the inventors of the world ‘discovered’ the infrared. Many patents

were issued for devices to detect personnel, artillery, aircraft, ships – and even icebergs. The first

operating systems, in the modern sense, began to be developed during the 1914–18 war, when both

sides had research programs devoted to the military exploitation of the infrared. These programs

included experimental systems for enemy intrusion/detection, remote temperature sensing, secure

communications, and ‘flying torpedo’ guidance. An infrared search system tested during this period

was able to detect an approaching airplane at a distance of 1.5 km (0.94 miles), or a person more

than 300 meters (984 ft.) away.

The most sensitive systems up to this time were all based upon variations of the bolometer idea, but

the period between the two wars saw the development of two revolutionary new infrared detectors:

the image converter and the photon detector. At first, the image converter received the greatest

attention by the military, because it enabled an observer for the first time in history to literally ‘see in

the dark’. However, the sensitivity of the image converter was limited to the near infrared

wavelengths, and the most inter esting military targets (i.e. enemy soldiers) had to be illuminated by

infrared search beams. Since this involved the risk of giving away the observer’s position to a

similarly-equipped enemy observer, it is underst andable that military interest in the imag e converter

eventually faded.

The tactical military disadvantages of so-called 'active’ (i.e. search beam-equipped) thermal imaging

systems provided impetus following the 1939–45 war for extensive secret military infrared-research

programs into the possibilities of developing ‘passive’ (no search beam) systems around the

extremely sensitive photon detector. During this period, military secrecy regulations completely

prevented disclosure of the status of infrare d -imaging technology. This secrecy only began to be lifted

in the middle of the 1950’s, and from that time adequate thermal-imaging devices finally began to be

available to civilian science and industry.

A6700sc/A6750sc User’s Manual

47

Page 48

9 – Infrared Primer

9.2 Theory of Thermography

9.2.1 Introduction

The subjects of infrared radiation and the related technique of thermography are still new to many

who will use an infrared camera. In this section the theory behind thermography will be given.

9.2.2 The Electromagnetic Spectrum

The electromagnetic spectrum is divided arbitrarily into a number of wavelength regions, called bands,

distinguished by the methods used to produce and detect the radiation. There is no fundamental

difference between radiation in the different bands of the electromagnetic spectrum. They are all

governed by the same laws and the only differences are those due to differences in wavelength.

Figure 8-5 The Electromagnetic Spectrum

1: X-ray; 2: UV; 3: Visible; 4: IR; 5: Microwaves; 6: Radiowaves.

Thermography makes use of the infrared spectral band. At the short -wavelength end the boundary

lies at the limit of visual perception, in the deep red. At the longwavelength end it merges with the

microwave radio wavelengths, in the millimeter range.

The infrared band is often further subdivided into four smaller bands, the boundaries of which are also

arbitrarily chosen. They include: the near infrared (0.75–3 μm), the middle infrared (3–6 μm), t he far

infrared (6–15 μm) and the extreme infrared (15–100 μm). Although the wavelengths are given in μm

(micrometers), other units are often still used to measure wavelength in this spectral region, e.g.

nanometer (nm) and Ångström (Å). The relationships between the different wavelength

measurements is:

9.2.3 Blackbod y Radiation

A blackbody is defined as an object which absorbs all radiation that impinges on it at any wavelength.

The apparent misnomer black relating to an object emitting radiation is explained by Kirchhoff’s Law

A6700sc/A6750sc User’s Manual

48

Page 49

9 – Infrared Primer

(after Gustav Robert Kirchhoff, 1824–1887), which states that a body capable of absorbing all

radiation at any wavelength is equally capable in the emission of radiation.

Figure 8-6: Gustav Robert Kirchhoff (1824–1887)

The construction of a blackbody source is, in principle, very simple. The radiation characteristics of an

aperture in an isotherm cavity made of an opaque absorbing material represents almost exactly the

properties of a blackbody. A practical application of the principle to the construction of a perfect

absorber of radiation consists of a box that is light tight except for an aperture in one of the sides. Any

radiation which then enters the hole is scattered and absorbed by repeated reflections so only an

infinitesimal fraction can possibly escape. The blackness which is obtained at the aperture is nearly

equal to a blackbody and almost perfect for all wavelengths.

By providing such an isothermal cavity with a suitable heater it becomes what is termed a cavity

radiator. An isothermal cavity heated to a uniform temperature generates blackbody radiation, the

characteristics of which are determined solely by the temperature of the cavity. Such cavity radiators

are commonly used as sources of radiation in temperature reference standards in the laboratory for

calibrating thermographic instruments, such as a FLIR Systems camera for example.

If the temperature of blackbody radiation increases to more than 525 °C (977 °F), the source begins to

be visible so that it appears to the eye no longer black. This is the incipient red heat temperature of

the radiator, which then becomes orange or yellow as the temperature increases further. In fact, the

definition of the so-called color temperature of an object is the temperature to which a blackbody

would have to be heated to have the same appearance. Now consider three expressions that

describe the radiation emitted from a blackbody.

Planck’s Law

Figure 8-7: Max Planck (1858–1947)

Max Planck (1858–1947) was able to describe the spectral distribution of the radiation from a

blackbody by means of the following formula:

A6700sc/A6750sc User’s Manual

49

Page 50

9 – Infrared Primer

Where:

Wλb = Blackbody spectral radiant emittance at wavelength λ.

c = Velocity of light = 3 × 108 m/s

h = Planck’s constant = 6.6 × 10-34 Joule sec.

k = Boltzmann’s constant = 1.4 × 10-23 Joule/K.

T = Absolute temperature (K) of a blackbody.

λ = Wavelength (μm).

Note

The factor 10-6 is used since spectral emittance in the curves is expressed in Watt/m2 m. If the

factor is excluded, the dim ension w ill be Watt/m2μm.

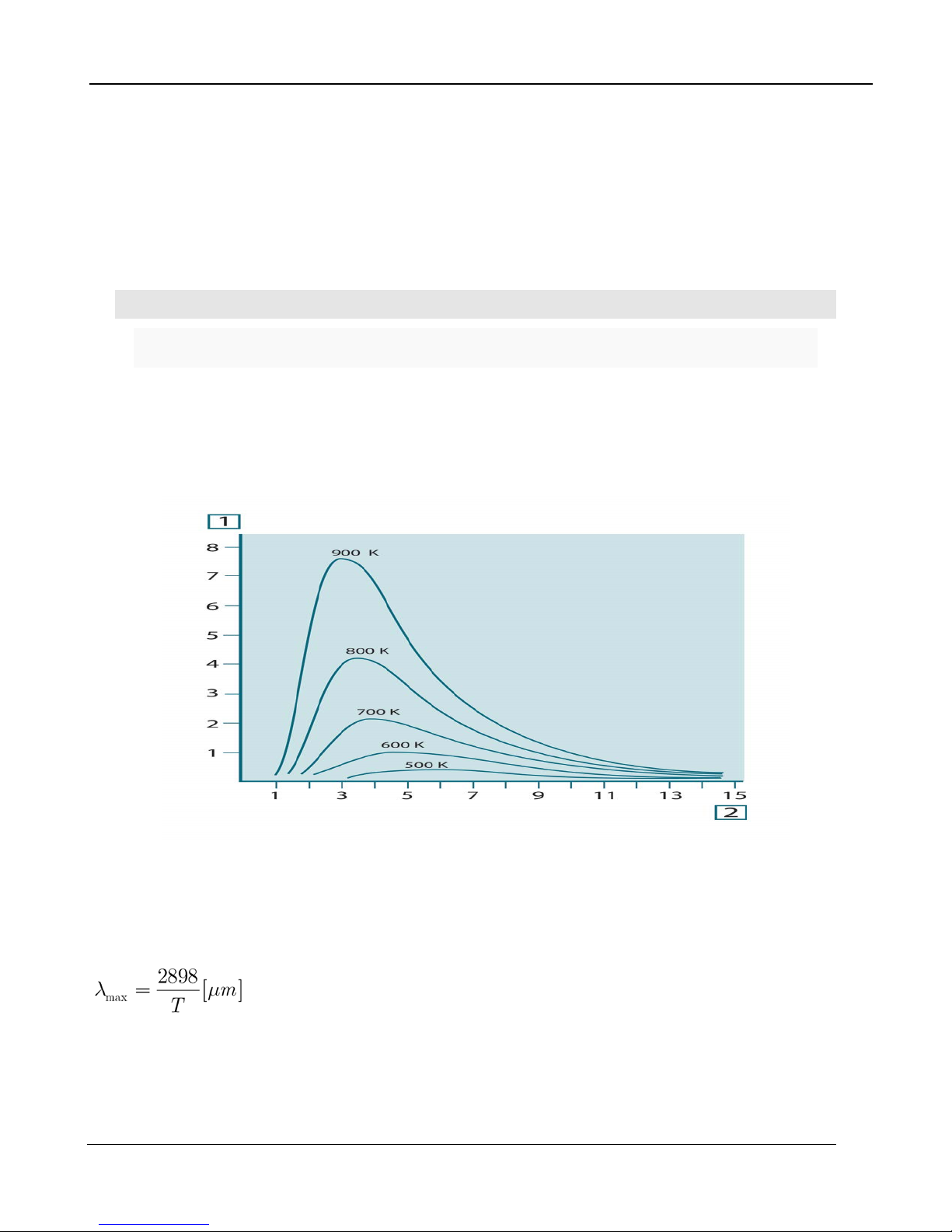

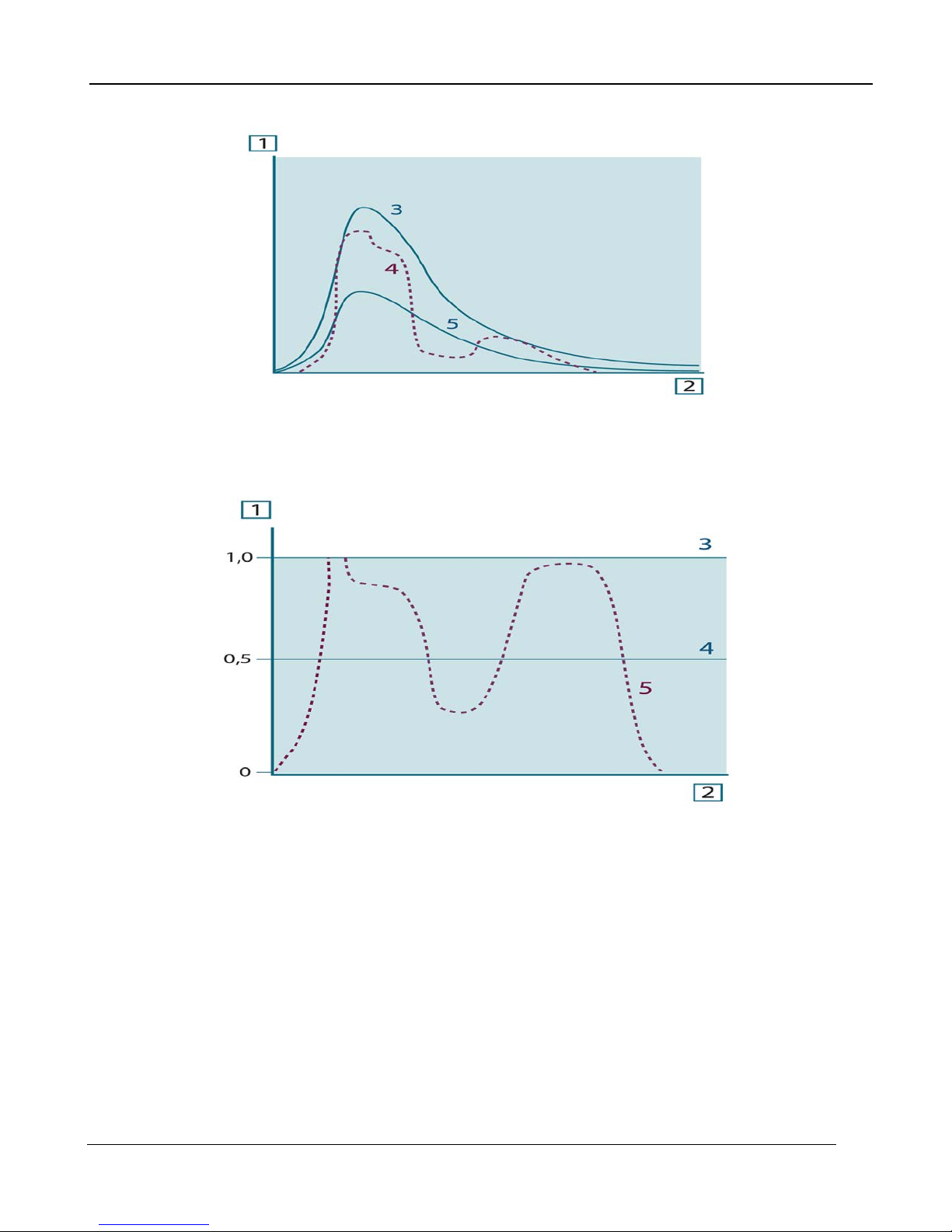

Planck’s formula, when plotted graphically for various temperatures, produces a family of curves.

Following any particular Planck curve, the spectral emittance is zero at λ = 0, then increases r apidly to

a maximum at a wavelength λmax and after passing it approaches zero again at very long

wavelengths. The higher the temperature, the shorter the wavelength at which maximum occurs.

Figure 8-8: Blackbody spectral radiant emittance according to Planck’s law, plotted for various

absolute temperatures. 1: Spectral radiant emittance (W/cm2 × 103(μm)); 2: Wavelength (μm)

Wien’s Displacement Law

By differentiating Planck’s formula with respect to λ, and finding the maximum, we have:

This is Wien’s formula (after Wilhelm Wien, 1864–1928), which expresses mathematically the

common observation that colors vary from red to orange or yellow as the temperature of a thermal