Page 1

User’s manual

FLIR A3xx pt series

Page 2

Page 3

User’s manual

FLIR A3xx pt series

#T559795; r.21371/22369; en-US

iii

Page 4

Page 5

Table of contents

1 Legal disclaimer ....... ....... ....... .......................... ....... ....... .....................1

1.1 Legal disclaimer ......................................................................... 1

1.2 Usage statistics .......................................................................... 1

1.3 Changes to registry .....................................................................1

1.4 U.S. Government Regulations........................................................1

1.5 Copyright ..................................................................................1

1.6 Quality assurance .......................................................................1

1.7 Patents.....................................................................................1

1.8 EULA Terms ..............................................................................1

2 Safety information .... ....... ....... ....... ................... ....... ....... ....... ..............2

3 Notice to user .. ....... ....... .......................... ....... ....... ................... ....... ... 4

3.1 User-to-user forums ....................................................................4

3.2 Calibration.................................................................................4

3.3 Accuracy ..................................................................................4

3.4 Disposal of electronic waste .......................................................... 4

3.5 Training ....................................................................................4

3.6 Documentation updates ............................................................... 4

3.7 Important note about this manual.................................................... 4

4 Customer help ................................. ....... ....... .......................... ....... ....5

4.1 General ....................................................................................5

4.2 Submitting a question .................................................................. 6

4.3 Downloads ................................................................................6

5 Introduction....................... ....... ....... ....... ................... ....... ....... ....... ....7

5.1 FLIR A3xx pt series .....................................................................7

6 List of accessories and services ........... ........................................ ....... .8

7 Installation ....... ....... ................... ....... ....... ....... ................................. 10

7.1 Installation overview .................................................................. 10

7.2 Installation components.............................................................. 10

7.3 Location considerations ............................................................. 10

7.4 Camera mounting ..................................................................... 11

7.5 Prior to cutting/drilling holes ........................................................ 12

7.6 Back cover .............................................................................. 13

7.7 Removing the back cover ........................................................... 14

7.8 Connecting power..................................................................... 14

7.9 Video connections .................................................................... 15

7.10 Ethernet connection .................................................................. 15

7.11 Serial communications overview .................................................. 15

7.12 Serial connections .................................................................... 15

7.13 Setting configuration dip switches................................................. 15

8 Verifying camera operation..................................... ............................ 18

8.1 Power and analog video ............................................................. 18

8.2 IP communications.................................................................... 18

8.3 FLIR A3xx pt series camera configuration ...................................... 19

8.4 Setting DNS name servers.......................................................... 21

9 Technical data ... ....... ................... ....... ....... ....... ................................. 24

9.1 Online field-of-view calculator ...................................................... 24

9.2 Note about technical data ........................................................... 24

9.3 FLIR A310pt 15° (9 Hz) NTSC ..................................................... 25

9.4 FLIR A310pt 15° (9 Hz) PAL........................................................ 29

#T559795; r.21371/22369; en-US

v

Page 6

Table of contents

9.5 FLIR A310pt 15° NTSC .............................................................. 33

9.6 FLIR A310pt 15° PAL................................................................. 37

9.7 FLIR A310pt 25° (9 Hz) NTSC ..................................................... 41

9.8 FLIR A310pt 25° (9 Hz) PAL........................................................ 45

9.9 FLIR A310pt 25° NTSC .............................................................. 49

9.10 FLIR A310pt 25° PAL................................................................. 53

9.11 FLIR A310pt 45° (9 Hz) NTSC ..................................................... 57

9.12 FLIR A310pt 45° (9 Hz) PAL........................................................ 61

9.13 FLIR A310pt 45° NTSC .............................................................. 65

9.14 FLIR A310pt 45° PAL................................................................. 69

9.15 FLIR A310pt 6° (9 Hz) NTSC....................................................... 73

9.16 FLIR A310pt 6° (9 Hz) PAL.......................................................... 77

9.17 FLIR A310pt 6° NTSC................................................................ 81

9.18 FLIR A310pt 6° PAL .................................................................. 85

9.19 FLIR A310pt 90° (9 Hz) NTSC ..................................................... 89

9.20 FLIR A310pt 90° (9 Hz) PAL........................................................ 93

9.21 FLIR A310pt 90° NTSC .............................................................. 97

9.22 FLIR A310pt 90° PAL............................................................... 101

10 Mechanical drawings ................................................. ....... ....... ........ 105

11 Pin configurations and schematics ....... ....... ...................................... 114

11.1 Pin configuration for camera I/O connector ................................... 114

11.2 Schematic overview of the camera unit digital I/O ports ................... 114

11.3 Schematic overview of the A3xx pt board ..................................... 115

12 Certificate of conformity. ........................................ .......................... 116

13 Cleaning the camera ........................ ........................................ ........ 117

13.1 Camera housing, cables, and other items..................................... 117

13.1.1 Liquids....................................................................... 117

13.1.2 Equipment.................................................................. 117

13.1.3 Procedure .................................................................. 117

13.2 Infrared lens .......................................................................... 117

13.2.1 Liquids....................................................................... 117

13.2.2 Equipment.................................................................. 117

13.2.3 Procedure .................................................................. 117

14 About FLIR Systems ....... ....... .......................... ....... ....... ....... ........... 118

14.1 More than just an infrared camera .............................................. 119

14.2 Sharing our knowledge ............................................................ 119

14.3 Supporting our customers......................................................... 120

14.4 A few images from our facilities .................................................. 120

15 Glossary .......... ....... ....... ....... ................... ....... ....... ....... ................. 121

16 Thermographic measurement techniques ......... ................................. 124

16.1 Introduction .......................................................................... 124

16.2 Emissivity.............................................................................. 124

16.2.1 Finding the emissivity of a sample.................................... 124

16.3 Reflected apparent temperature ................................................. 128

16.4 Distance ............................................................................... 128

16.5 Relative humidity .................................................................... 128

16.6 Other parameters.................................................................... 128

#T559795; r.21371/22369; en-US

vi

Page 7

Table of contents

17 History of infrared technology... ........................................ ................ 129

18 Theory of thermography................. ....... ....... .......................... ....... ... 132

18.1 Introduction ........................................................................... 132

18.2 The electromagnetic spectrum................................................... 132

18.3 Blackbody radiation................................................................. 132

18.3.1 Planck’s law ................................................................ 133

18.3.2 Wien’s displacement law................................................ 134

18.3.3 Stefan-Boltzmann's law ................................................. 136

18.3.4 Non-blackbody emitters ................................................. 136

18.4 Infrared semi-transparent materials............................................. 138

19 The measurement formula........................... ..................................... 140

20 Emissivity tables .. ....... ....... ................... ....... ....... ....... ................... .. 144

20.1 References............................................................................ 144

20.2 Tables .................................................................................. 144

#T559795; r.21371/22369; en-US

vii

Page 8

Page 9

1

Legal disclaimer

1.1 Legal disclaimer

All products manufactured by FLIR Systems are warranted against defective

materials and workmanship for a period of one (1) year from the delivery date

of the original purchase, provided such products have been under normal storage, use and service, and in accordance with FLIR Systems instruction.

Uncooled handheld infrared cameras manufactured by FLIR Systems are warranted against defective materials and workmanship for a period of two (2)

years from the deliverydate of the original purchase, provided such products

have been under normal storage, use and service, and in accordance with

FLIR Systems instruction, and provided that the camera has been registered

within 60 days of original purchase.

Detectors for uncooled handheld infrared cameras manufactured by FLIR Systems are warranted against defective materials and workmanship for a period

of ten (10) years from the delivery date of the original purchase,provided such

products have been under normal storage, use and service, and in accordance

with FLIR Systems instruction, and provided that the camera has been registered within 60 days of original purchase.

Products which are not manufactured by FLIR Systems but included in systems delivered by FLIR Systems to the original purchaser, carry the warranty, if

any, of the particular supplieronly. FLIR Systems has no responsibility whatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It

is not applicable to any product which has been subjected to misuse, neglect,

accident or abnormal conditions of operation. Expendable parts are excluded

from the warranty.

In the case of a defect in a product covered by this warranty the product must

not be further used in order to prevent additional damage. The purchaser shall

promptly report any defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, atits option, repair or replace any such defective product

free of charge if, upon inspection, it proves to be defective in material or workmanship and provided that it is returned to FLIR Systems within the said oneyear period.

FLIR Systems has no other obligation or liability for defects than those set forth

above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims

the implied warranties of merchantability and fitnessfor a particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidental or

consequential loss or damage, whether based on contract, tort or any other legal theory.

This warranty shall be governed by Swedish law.

Any dispute, controversy or claim arising out of or in connection with this war-

ranty, shall be finally settled by arbitration in accordance with the Rules of the

Arbitration Institute of the Stockholm Chamber of Commerce. The place of arbitration shall be Stockholm. The language to be usedin the arbitral proceedings shall be English.

1.2 Usage statistics

FLIR Systems reserves the right to gather anonymous usage statistics to help

maintain and improve the quality of our software and services.

1.3 Changes to registry

The registry entry HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet

\Control\Lsa\LmCompatibilityLevel will be automatically changed to level 2 if

the FLIR Camera Monitor service detects a FLIR camera connected to the

computer with a USB cable. The modification will only be executedif the camera device implements aremote network service that supports network logons.

1.4 U.S. Government Regulations

This product may be subject to U.S. Export Regulations. Please send any inquiries to exportquestions@flir.com.

1.5 Copyright

© 2014, FLIR Systems, Inc. All rights reserved worldwide. No parts of the software including source code may be reproduced, transmitted, transcribed or

translated into any language or computer language in any form or by any

means, electronic, magnetic, optical, manual or otherwise, without the prior

written permission of FLIR Systems.

The documentation must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic medium or machine readable form without priorconsent, in writing, from FLIRSystems.

Names and marks appearing on the products herein are either registered

trademarks or trademarks of FLIR Systems and/or its subsidiaries. All other

trademarks, trade names or company names referenced herein are used for

identification only and arethe property of their respective owners.

1.6 Quality assurance

The Quality Management System under which these products are developed

and manufactured has been certified in accordance with the ISO 9001

standard.

FLIR Systems is committed to a policy of continuous development; therefore

we reserve the right to make changes and improvements on any of the products without prior notice.

1.7 Patents

One or several of the following patents and/or design patents may apply to the

products and/or features. Additional pending patents and/or pending design

patents may also apply.

000279476-0001; 000439161; 000499579-0001; 000653423; 000726344;

000859020; 001106306-0001; 001707738; 001707746; 001707787;

001776519; 001954074; 002021543; 002058180; 002249953; 002531178;

0600574-8; 1144833; 1182246; 1182620; 1285345; 1299699; 1325808;

1336775; 1391114; 1402918; 1404291; 1411581; 1415075; 1421497;

1458284; 1678485; 1732314; 2106017; 2107799; 2381417; 3006596;

3006597; 466540; 483782; 484155; 4889913; 5177595; 60122153.2;

602004011681.5-08; 6707044; 68657; 7034300; 7110035; 7154093;

7157705; 7237946; 7312822; 7332716; 7336823; 7544944; 7667198;

7809258 B2; 7826736; 8,153,971; 8018649 B2; 8212210 B2; 8289372;

8354639 B2; 8384783; 8520970; 8565547; 8595689; 8599262; 8654239;

8680468; 8803093; D540838; D549758; D579475; D584755; D599,392;

D615,113; D664,580; D664,581; D665,004; D665,440; D677298; D710,424

S; DI6702302-9; DI6903617-9; DI7002221-6; DI7002891-5; DI7002892-3;

DI7005799-0; DM/057692; DM/061609; EP 2115696 B1; EP2315433; SE

0700240-5; US 8340414 B2; ZL 201330267619.5; ZL01823221.3;

ZL01823226.4; ZL02331553.9; ZL02331554.7; ZL200480034894.0;

ZL200530120994.2; ZL200610088759.5; ZL200630130114.4;

ZL200730151141.4; ZL200730339504.7; ZL200820105768.8;

ZL200830128581.2; ZL200880105236.4; ZL200880105769.2;

ZL200930190061.9; ZL201030176127.1; ZL201030176130.3;

ZL201030176157.2; ZL201030595931.3; ZL201130442354.9;

ZL201230471744.3; ZL201230620731.8.

1.8 EULA Terms

• Youhave acquired a device (“INFRARED CAMERA”) that includes software licensed by FLIR Systems AB from Microsoft Licensing, GP or its affiliates (“MS”). Those installed software products of MS origin, as well as

associated media, printed materials, and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual property

laws and treaties. The SOFTWARE is licensed, not sold. All rights

reserved.

• IF YOU DO NOTAGREE TOTHIS END USER LICENSE AGREEMENT

(“EULA”), DO NOT USE THEDEVICE OR COPY THE SOFTWARE. INSTEAD, PROMPTLYCONTACT FLIR Systems AB FOR INSTRUCTIONS

ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND. ANY USE

OF THE SOFTWARE, INCLUDING BUT NOT LIMITED TO USE ON

THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT TOTHIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

• GRANT OF SOFTWARE LICENSE. This EULA grants you the following

license:

• Youmay use the SOFTWAREonly on the DEVICE.

• NOT FAULT TOLERANT. THE SOFTWARE IS NOTFAULT TOLER-

ANT.FLIR Systems AB HAS INDEPENDENTLY DETERMINED

HOW TO USE THE SOFTWARE IN THE DEVICE, AND MS HAS

RELIED UPON FLIR Systems AB TO CONDUCT SUFFICIENT

TESTING TO DETERMINE THAT THE SOFTWARE IS SUITABLE

FOR SUCH USE.

• NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is

provided “AS IS” and with all faults. THE ENTIRE RISK AS TO SATISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU.

ALSO, THERE IS NO WARRANTY AGAINST INTERFERENCE

WITH YOUR ENJOYMENT OF THE SOFTWARE OR AGAINSTINFRINGEMENT.IF YOU HAVE RECEIVED ANY WARRANTIES RE-

GARDING THE DEVICE OR THE SOFTWARE, THOSE

WARRANTIES DO NOT ORIGINATE FROM, AND ARE NOT

BINDING ON, MS.

• No Liability for Certain Damages. EXCEPTAS PROHIBITED BY

LAW,MS SHALL HAVE NO LIABILITY FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING

FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL APPLY

EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE. IN

NO EVENT SHALL MS BE LIABLE FOR ANY AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

• Limitations on Reverse Engineering, Decompilation, and Dis-

assembly. You may not reverse engineer, decompile, or disassem-

ble the SOFTWARE, except and only to the extent that such activity

is expressly permitted by applicable law notwithstanding this

limitation.

• SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS.

Youmay permanently transfer rights under this EULA only as part of

a permanent sale or transfer of the Device, and only if the recipient

agrees to this EULA. If the SOFTWARE is an upgrade, any transfer

must also include all prior versions of the SOFTWARE.

• EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is

subject to U.S. export jurisdiction. You agree to comply with all applicable international and national laws that apply to the SOFTWARE,

including the U.S. Export Administration Regulations, as well as

end-user, end-use and destination restrictions issued by U.S. and

other governments. For additional information see http://www.microsoft.com/exporting/.

#T559795; r.21371/22369; en-US

1

Page 10

2

Safety information

DANGER

Applicability: FLIR A3xx pt & G300 pt.

Do not install the unit in lightning weather. A lightning strike can hit the unit and cause injury or death.

DANGER

Applicability: FLIR A3xx pt & G300 pt.

Be careful when you install or do an inspection of the unit at high heights. The unit can move suddenly

and this can cause you to fall. This can cause injury or death.

DANGER

Applicability: FLIR A3xx pt & G300 pt.

Make sure that you use the industry standard safety procedures when you install or do an inspection of

the unit at high heights. If you do not use the industry standard safety procedures, this can cause you to

fall. This can cause injury or death.

WARNING

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and warning labels on containers before you use a liquid. The liquids can be dangerous. Injury to persons can occur.

WARNING

Applicability: FLIR A3xx pt & G300 pt.

Be careful when you lift the unit when it is not energized. This can cause the parts of the unit to move

freely and cause injury.

WARNING

Applicability: FLIR A3xx pt & G300 pt.

Do not go near the unit when it is energized. The unit can move suddenly and cause injury.

WARNING

Applicability: FLIR A3xx pt & G300 pt.

Do not go near the unit during the startup. The unit can move suddenly and cause injury.

WARNING

Applicability: FLIR A3xx pt & G300 pt.

A minimum of two persons are necessary to lift the unit. The unit can cause injury when the center of

gravity moves.

WARNING

Applicability: FLIR A3xx pt & G300 pt.

Make sure that you install the unit safely. If you do not install it safely, the unit can fall down and cause

injury.

WARNING

Applicability: FLIR A3xx pt & G300 pt.

If the IR or the TV window breaks, do not touch the broken pieces. The pieces can cause injury.

#T559795; r.21371/22369; en-US

2

Page 11

2

Safety information

WARNING

Applicability: FLIR A3xx pt & G300 pt.

Be careful when you touch the unit. Some parts can be sharp and cause injury.

CAUTION

Do not point the infrared camera (with or without the lens cover) at strong energy sources, for example,

devices that cause laser radiation, or the sun. This can have an unwanted effect on the accuracy of the

camera. It can also cause damage to the detector in the camera.

CAUTION

Do not use the camera in temperatures more than +50°C (+122°F), unless other information is specified

in the user documentation or technical data. High temperatures can cause damage to the camera.

CAUTION

Do not apply solvents or equivalent liquids to the camera, the cables, or other items. Damage to the battery and injury to persons can occur.

CAUTION

Be careful when you clean the infrared lens. The lens has an anti-reflective coating which is easily damaged. Damage to the infrared lens can occur.

CAUTION

Do not use too much force to clean the infrared lens. This can cause damage to the anti-reflective

coating.

CAUTION

Applicability: Cameras with an automatic shutter that can be disabled.

Do not disable the automatic shutter in the camera for a long time period (a maximum of 30 minutes is

typical). If you disable the shutter for a longer time period, damage to the detector can occur.

NOTE

The encapsulation rating is only applicable when all the openings on the camera are sealed with their correct covers, hatches, or caps. This includes the compartments for data storage, batteries, and

connectors.

CAUTION

Applicability: Cameras where you can remove the lens and expose the infrared detector.

Do not use the pressurized air from the pneumatic air systems in a workshop when you remove dust from

the detector. The air contains oil mist to lubricate the pneumatic tools and the pressure is too high. Damage to the detector can occur.

#T559795; r.21371/22369; en-US

3

Page 12

3

Notice to user

3.1 User-to-user forums

Exchange ideas, problems, and infrared solutions with fellow thermographers around the

world in our user-to-user forums. To go to the forums, visit:

http://www.infraredtraining.com/community/boards/

3.2 Calibration

We recommend that you send in the camera for calibration once a year. Contact your local

sales office for instructions on where to send the camera.

3.3 Accuracy

For very accurate results, we recommend that you wait 5 minutes after you have started

the camera before measuring a temperature.

3.4 Disposal of electronic waste

As with most electronic products, this equipment must be disposed of in an environmentally friendly way, and in accordance with existing regulations for electronic waste.

Please contact your FLIR Systems representative for more details.

3.5 Training

To read about infrared training, visit:

• http://www.infraredtraining.com

• http://www.irtraining.com

• http://www.irtraining.eu

3.6 Documentation updates

Our manuals are updated several times per year, and we also issue product-critical notifications of changes on a regular basis.

To access the latest manuals and notifications, go to the Download tab at:

http://support.flir.com

It only takes a few minutes to register online. In the download area you will also find the lat-

est releases of manuals for our other products, as well as manuals for our historical and

obsolete products.

3.7 Important note about this manual

FLIR Systems issues generic manuals that cover several cameras within a model line.

This means that this manual may contain descriptions and explanations that do not apply

to your particular camera model.

#T559795; r.21371/22369; en-US

4

Page 13

4

Customer help

4.1 General

For customer help, visit:

http://support.flir.com

#T559795; r.21371/22369; en-US

5

Page 14

4

Customer help

4.2 Submitting a question

To submit a question to the customer help team, you must be a registered user. It only

takes a few minutes to register online. If you only want to search the knowledgebase for

existing questions and answers, you do not need to be a registered user.

When you want to submit a question, make sure that you have the following information to

hand:

• The camera model

• The camera serial number

• The communication protocol, or method, between the camera and your device (for example, HDMI, Ethernet, USB, or FireWire)

• Device type (PC/Mac/iPhone/iPad/Android device, etc.)

• Version of any programs from FLIR Systems

• Full name, publication number, and revision number of the manual

4.3 Downloads

On the customer help site you can also download the following:

• Firmware updates for your infrared camera.

• Program updates for your PC/Mac software.

• Freeware and evaluation versions of PC/Mac software.

• User documentation for current, obsolete, and historical products.

• Mechanical drawings (in *.dxf and *.pdf format).

• Cad data models (in *.stp format).

• Application stories.

• Technical datasheets.

• Product catalogs.

#T559795; r.21371/22369; en-US

6

Page 15

5

Introduction

5.1 FLIR A3xx pt series

Figure 5.1 FLIR A3xx pt series camera

The FLIR A3xx pt series camera offers an affordable solution for anyone who needs to

solve problems that require built-in “smartness” such as analysis and alarm functionality.

The FLIR A3xx pt series camera has all the necessary features and functions to build distributed single- or multi-camera solutions to monitor large areas, such as in coal pile monitoring and substation monitoring utilizing standard Ethernet hardware and software

protocols.

The FLIR A3xx pt series camera precision pan/tilt mechanism gives operators accurate

pointing control while providing fully programmable scan patterns, radar slew-to-cue, and

slew-to-alarm functionality.

Multi-sensor configurations also include a day/night 36× zoom color CCD camera on the

same pan/tilt package.

Key features:

• Built-in extensive analysis functionality.

• Extensive alarm functionality, as a function of analysis and more.

• H.264, MPEG-4, and MJPEG streaming.

• Built-in web server.

• 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.).

• Composite video output.

• Precision pan/tilt mechanism.

• Daylight camera.

• IP66

• IP control (the FLIR A3xx pt series camera can be integrated in any existing TCP/IP network and controlled over a PC).

• Serial control interface (use Pelco D or Bosch commands over RS-232, RS-422, or RS485 to a remotely control the FLIR A3xx pt series camera).

• Multi-camera software (FLIR Sensors Manager allows users to manage and control a

FLIR A3xx pt series camera in a TCP/IP network).

#T559795; r.21371/22369; en-US

7

Page 16

6

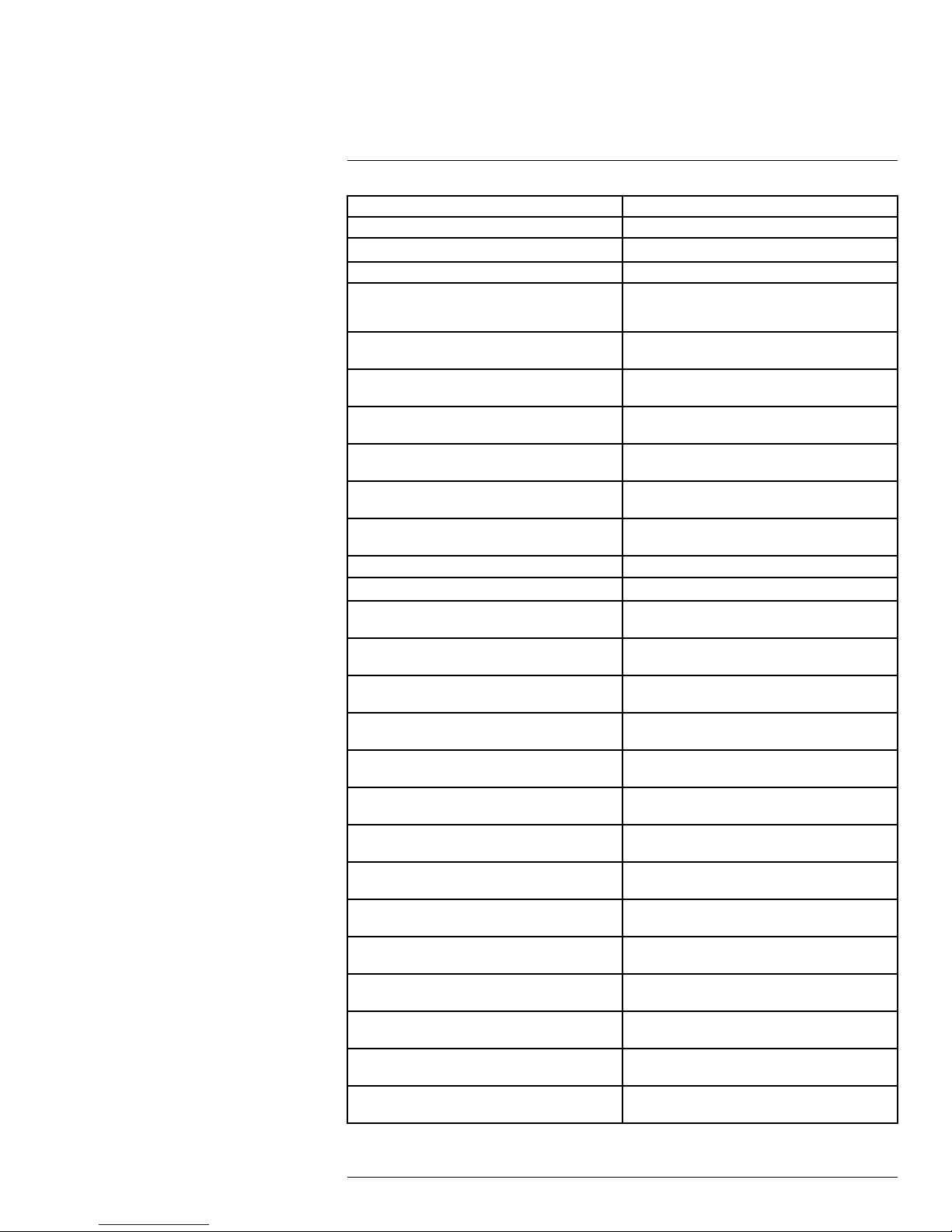

List of accessories and services

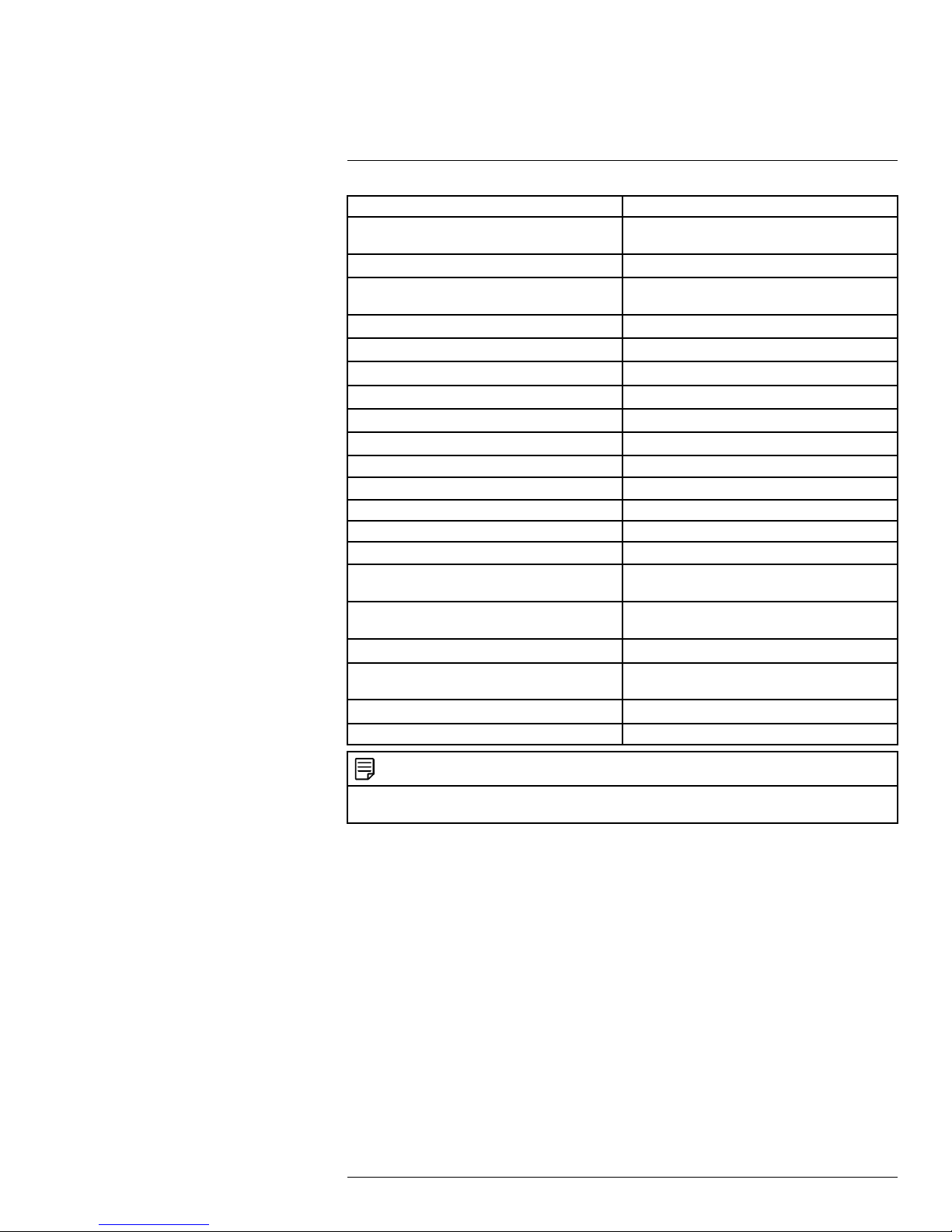

Part number Product name

4119468

4130235

324-0010-00

T197000 High temp. option +1200°C/+2192°F for FLIR T/

ITC-ADV-3021 ITC Advanced General Thermography Course - at-

ITC-ADV-3029 ITC Advanced General Thermography Course-

ITC-ADV-3061 ITC Advanced Thermal applications course - at-

ITC-ADV-3069 ITC Advanced Thermal applications course - group

ITC-AUT-3101 ITC Automated safety systems training - attend-

ITC-AUT-3109 ITC Automated safety systems training - group of

ITC-CON-1001 ITC conference fee

ITC-EXP-1041 ITC Customized workshop - per person (per day)

ITC-EXP-1021 ITC In-house training - additional attendance 1

ITC-EXP-1029 ITC In-house training - group up to 10 pers. (per

ITC-EXP-1050 ITC Infrared application and system consultancy

ITC-CER-5105 ITC Level 1 Thermography Course - additional stu-

ITC-CER-5101 ITC Level 1 Thermography Course - attendance, 1

ITC-CER-5109 ITC Level 1 Thermography Course – group of 10

ITC-CER-5205 ITC Level 2 Thermography Course - additional stu-

ITC-CER-5201 ITC Level 2 Thermography Course - attendance, 1

ITC-CER-5209 ITC Level 2 Thermography Course – group of 10

ITC-EXP-2036 ITC R&D basics for industry users - group up to 6

ITC-EXP-2025 ITC Short course Fever Screening - additional stu-

ITC-EXP-2021 ITC Short course Fever Screening - attendance 1

ITC-EXP-2029 ITC Short course Fever Screening - inclusive 10

ITC-EXP-1019 ITC Short course Introduction to thermography - in-

ADAPTER PLATE - PT-SERIES

FLIR Sensors Manager, pro

Hard case - PT-SERIES

B2xx to T/B4xx and A3xx, A3xxf, A3xxpt, A3xxsc

series

tendance, 1 pers.

group of 10 pers.

tendance 1 pers. (3 days)

up to 10 pers. (3 days)

ance 1 pers (3 days)

up to 10 pers (3 days)

pers. (per day)

day)

(per day)

dent to on site class, 1 pers

pers.

pers.

dent to on site class, 1 pers

pers.

pers.

pers. (2 days)

dent to on site class (2 days)

pers. (2 days)

pers. (2 days)

clusive 10 pers. (1 day)

#T559795; r.21371/22369; en-US

8

Page 17

6

List of accessories and services

Part number Product name

ITC-EXP-1011 ITC Short course Introduction to thermography -at-

ITC-SOW-0001 ITC Software course - attendance 1 pers. (per day)

ITC-SOW-0009 ITC Software course - group up to 10 pers. (per

ITC-EXP-1001 ITC Training 1 day - attendance 1 pers.

ITC-EXP-1009 ITC Training 1 day - group up to 10 pers.

ITC-EXP-2001 ITC Training 2 days - attendance 1 pers.

ITC-EXP-2009 ITC Training 2 days - group up to 10 pers.

ITC-EXP-3001 ITC Training 3 days - attendance 1 pers.

ITC-EXP-3009 ITC Training 3 days - group up to 10 pers.

ITC-TFT-0100 ITC travel time for instructor

223-0017-00

500-0461-00

500-0509-00

4124857

ITC-TOL-1003 Travel and lodging expenses instructor (Center

ITC-TOL-1001 Travel and lodging expenses instructor (Europe,

ITC-TOL-1005 Travel and lodging expenses instructor (other)

ITC-TOL-1002 Travel and lodging expenses instructor (Russia/

ITC-TOL-1004 Travel and lodging expenses instructor (various)

500-0460-00

tendance 1 pers. (1 day)

day)

JOYSTICK ASSY, NEXUS CONSOLE

PEDESTAL MOUNT ASSY- PT-SERIES

POLE ADAPTER - PT-SERIES

POWER SUPPLY ASSY, 24VAC - PT-series

and South Africa)

Balcans, Turkey, Cyprus)

GUS, Middle East, North Africa)

WALL MOUNT ASSY- PT-SERIES

NOTE

FLIR Systems reserves the right to discontinue models, parts or accessories, and other items, or to

change specifications at any time without prior notice.

#T559795; r.21371/22369; en-US

9

Page 18

7

Installation

7.1 Installation overview

Figure 7.1 FLIR A3xx pt series camera

The FLIR A3xx pt series camera is a multi-sensor camera system on a pan/tilt platform.

Combinations of an infrared thermal imaging camera and a visible-light video camera are

intended for outdoor installations.

The FLIR A3xx pt series camera is intended to be mounted on a medium-duty fixed pedestal mount or wall mount commonly used in the CCTV industry. Cables will exit from the

back of the camera housing. The mount must support up to 45 lb. (20 kg).

The FLIR A3xx pt series camera is both an analog and an IP camera. The video from the

camera can be viewed over a traditional analog video network or it can be viewed by

streaming it over an IP network using MPEG-4, M-JPEG, and H.264 encoding. Analog video will require a connection to a video monitor or an analog matrix/switch. The IP video will

require a connection to an Ethernet network switch, and a computer with the appropriate

software for viewing the video stream.

The camera can be controlled through either serial or IP communication.

The camera operates on 24 VAC (21–30 VAC; 24 VAC: 215 VA max. with heater) or 24

VDC (21–30 VDC; 24 VDC: 195 W max. with heater).

In order to access the electrical connections and install the cables, it is necessary to tem-

porarily remove the back cover of the camera housing.

7.2 Installation components

In addition to the items included in the cardboard box, the installer will need to supply the

following items:

• Electrical wire, for system power.

• Camera grounding strap.

• Coaxial RG59U video cables (BNC connector at the camera end) for analog video.

• Shielded Category 6 Ethernet cable for control and streaming video over an IP network;

and also for software upgrades.

• Optional serial cable for serial communication.

• Miscellaneous electrical hardware, connectors, and tools.

7.3 Location considerations

The camera will require connections for power, communications (IP Ethernet and/or RS232/RS-422), and video (two video connections may be required for analog video

installations).

NOTE

Install all cameras with an easily accessible Ethernet connection, to support future software upgrades.

Ensure that cable lengths do not exceed the referenced standard specifications, and also adhere to all lo-

cal and Industry standards, codes, and best practises.

#T559795; r.21371/22369; en-US

10

Page 19

7

Installation

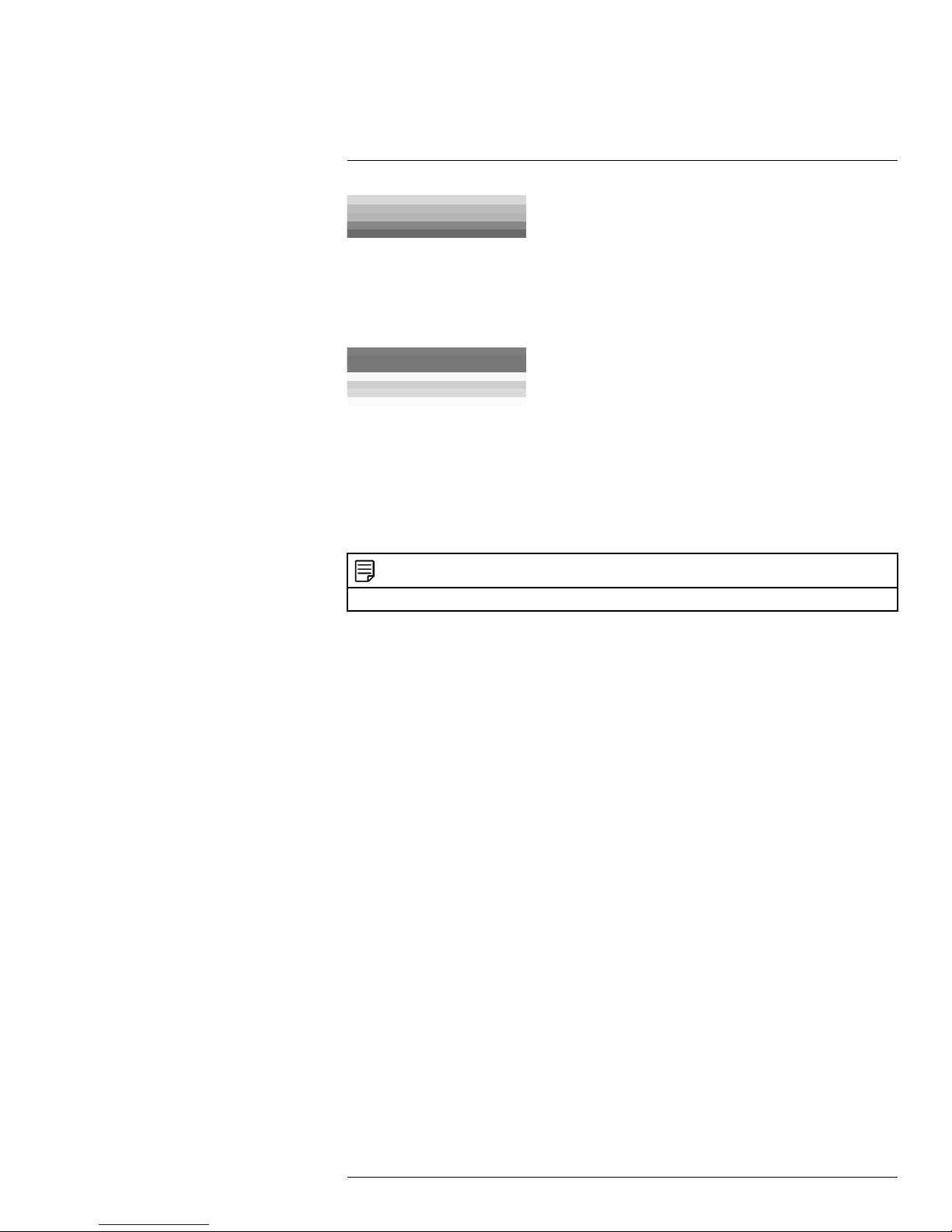

Figure 7.2 FLIR A3xx pt series camera exclusion zone. Height 480 mm (18.9″), diameter 740 mm (29.1″).

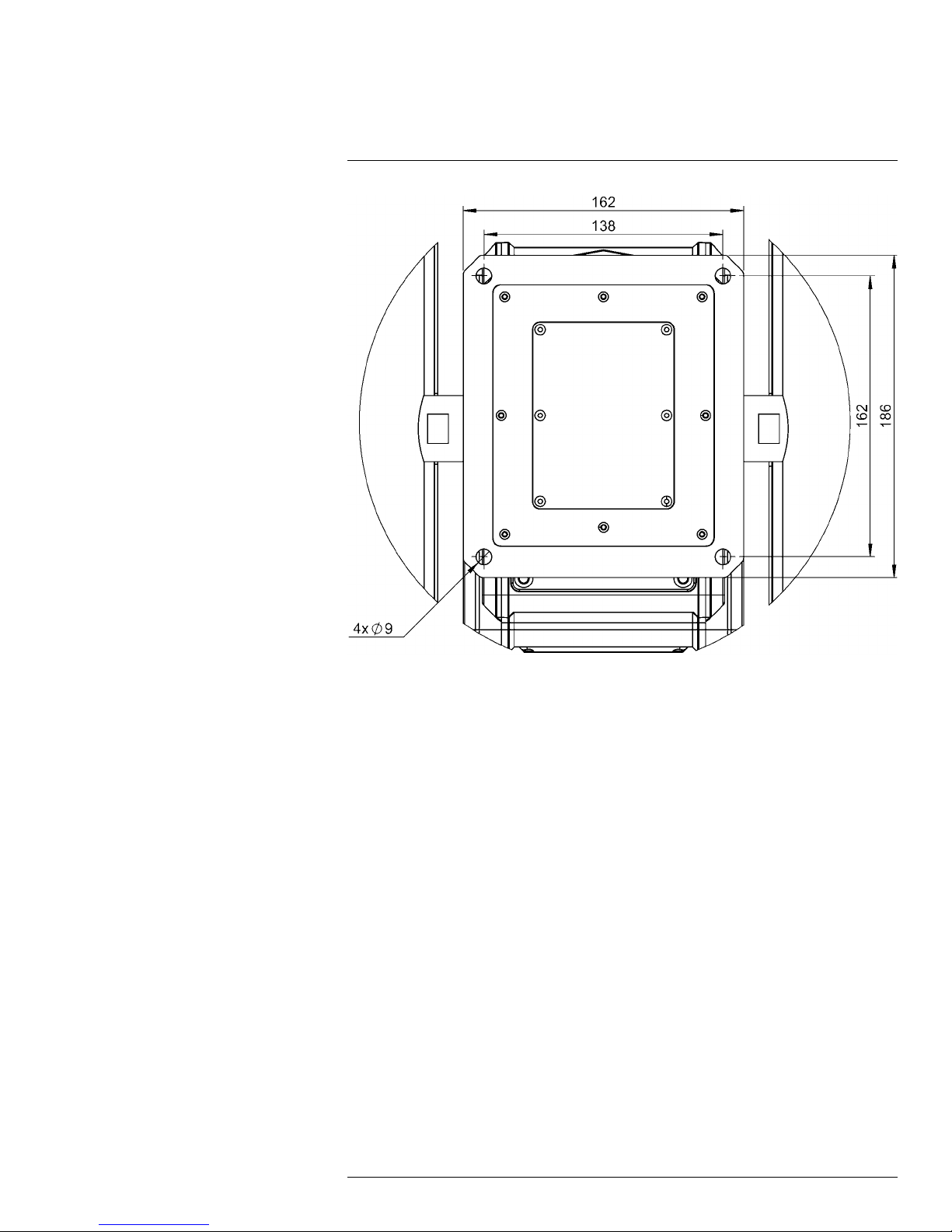

7.4 Camera mounting

FLIR A3xx pt series cameras must be mounted upright on top of the mounting surface,

with the base below the camera. The unit should not be hung upside down.

The FLIR A3xx pt series camera can be secured to the mount with four 5/16″ or M8 bolts,

as shown below.

NOTE

Use washers to protect the painting.

Once the mounting location has been selected, verify that both sides of the mounting surface are accessible.

#T559795; r.21371/22369; en-US

11

Page 20

7

Installation

Figure 7.3 FLIR A3xx pt series camera mounting (mm)

Connect and operate the camera as a bench test at ground level prior to mounting the

camera in its final location.

Use a thread-locking compound such as Loctite 242 or an equivalent with all metal-to-metal threaded connections.

Using the template supplied with the camera as a guide, mark the location of the holes for

mounting the camera. If the template is printed, ensure that it is printed to scale so that the

dimensions are correct.

Once the holes are drilled in the mounting surface, install four (4) 5/16″ or M8 bolts

through the base of the camera.

7.5 Prior to cutting/drilling holes

When selecting a mounting location for the FLIR A3xx pt series camera, consider cable

lengths and cable routing. Ensure that the cables are long enough given the proposed

mounting locations and cable routing requirements.

Use cables that have sufficient dimensions to ensure safety (for power cables) and adequate signal strength (for video and communications).

#T559795; r.21371/22369; en-US

12

Page 21

7

Installation

7.6 Back cover

Figure 7.4 Back cover of a FLIR A3xx pt series camera.

1. Shipping plug.

2. Breather valve.

3. Shipping plug.

4. Ground lug, for connection to earth.

5. Mounting screw (×6).

The FLIR A3xx pt series camera comes with two ¾″ NPT cable glands, each with a threehole gland seal insert. Cables can be between 0.23″ and 0.29″ OD. Up to six cables may

be installed. Plugs are required for the insert hole(s) not being used.

Figure 7.5 ¾″ NPTcable gland.

If non-standard cable diameters are used, you may need to locate or fabricate the appropriate insert to fit the desired cable. FLIR Systems does not provide cable gland inserts

other than what is supplied with the system.

Insert the cables through the cable glands on the enclosure before terminating and connecting them. (In general, the terminated connectors will not fit through the cable gland.) If

a terminated cable is required, make a single clean cut in the gland seal to install the cable

into the gland seal.

Proper installation of cable sealing glands and use of appropriate elastomer inserts is critical to long-term reliability. Cables enter the camera mount enclosure through liquid-tight

compression glands. Be sure to insert the cables through the cable glands on the enclosure before terminating and connecting them (the connectors will not fit through the cable

gland). Leave the gland nuts loosened until all cable installation has been completed. Inspect and install gland fittings in the back cover with suitable leak sealant, and tighten to

ensure water-tight fittings. PTFE tape or pipe sealant (e.g., DuPont RectorSeal T) is suitable for this purpose.

#T559795; r.21371/22369; en-US

13

Page 22

7

Installation

7.7 Removing the back cover

Use a cross-head screwdriver to loosen the four captive screws and remove the cover, exposing the connections at the back of the camera. There is a grounding wire connected

between the case and the back cover.

Figure 7.6 Rear view of a FLIR A3xx pt series camera, after the back cover has been released.

1. IP network.

2. Not used.

3. Serial connection for local control.

4. Analog infrared video.

5. Analog video (monitoring output only).

6. Analog visual video.

7. Camera power.

8. Heater power.

NOTE

• Be careful that gaskets are not pinched when mounting the back cover.

• Do not wipe off the grease from the gaskets when mounting the back cover. The grease is critical to

the tightness of the housing.

7.8 Connecting power

Power requirements:

24 VAC (21–30 VAC; 24 VAC: 215 VA max. with heater) or 24 VDC (21–30 VDC; 24 VDC:

195 W max. with heater).

The camera itself does not have an on/off switch. Generally, the FLIR A3xx pt series cam-

era will be connected to a circuit breaker, and the circuit breaker will be used to connect or

interrupt the power supply to the camera. If power is supplied to it, the camera will be in

one of two modes: Booting Up or Powered On.

The power cable supplied by the installer must use wires that are of a sufficient gauge size

(16 AWG is recommended) for the supply voltage and length of the cable run, to ensure

adequate current-carrying capacity. Always follow local building codes.

Ensure the camera is properly grounded. Typical to good grounding practices, the camera

chassis ground should be provided using the lowest resistance path possible. FLIR Systems requires using a grounding strap anchored to the grounding lug on the back plate of

the camera housing and connected to the nearest earth-grounding point.

#T559795; r.21371/22369; en-US

14

Page 23

7

Installation

NOTE

The terminal blocks for power connections will accept a maximum 16 AWG wire size.

7.9 Video connections

The analog video connections on the back of the camera are BNC connectors.

The video cable used should be rated as RG59U or better to ensure a quality video signal.

7.10 Ethernet connection

The cable gland seal is designed for use with shielded Category 6 Ethernet cable.

7.11 Serial communications overview

The installer must first decide if the serial communications settings will be configured via

hardware (DIP switch settings) or software. If the camera has an Ethernet connection, then

generally it will be easier (and more convenient in the long run) to make configuration settings via software. Then, configuration changes can be made over the network without

physically accessing the camera. Also, the settings can be saved to a file, and backed up

or restored as needed.

If the camera is configured via hardware, then configuration changes in the future may require accessing the camera on a tower or pole, dismounting it, removing the back, and so

on. If the camera does not have an Ethernet connection, the DIP switches must be used to

set the serial communication options.

NOTE

• The serial communications parameters for the FLIR A3xx pt series camera are set or modified either

via hardware DIP switch settings or via software, through a web browser interface. A single DIP switch

(SW102-9, software override) determines whether the configuration comes from the hardware DIP

switches or the software settings.

• The DIP switches are only used to control serial communications parameters. Other settings, related

to IP camera functions and so on, must be modified via software (using a web browser).

7.12 Serial connections

For serial communications, it is necessary to set the parameters such as the signalling

standard (RS-232 or RS-422), baud rate, number of stop bits, parity, and so on. It is also

necessary to select the communication protocol used (either Pelco D or Bosch) and the

camera address.

The camera supports RS-422 and RS-232 serial communications using common protocols (Pelco D, Bosch).

NOTE

The terminal blocks for serial connections will accept a maximum 20 AWG wire size.

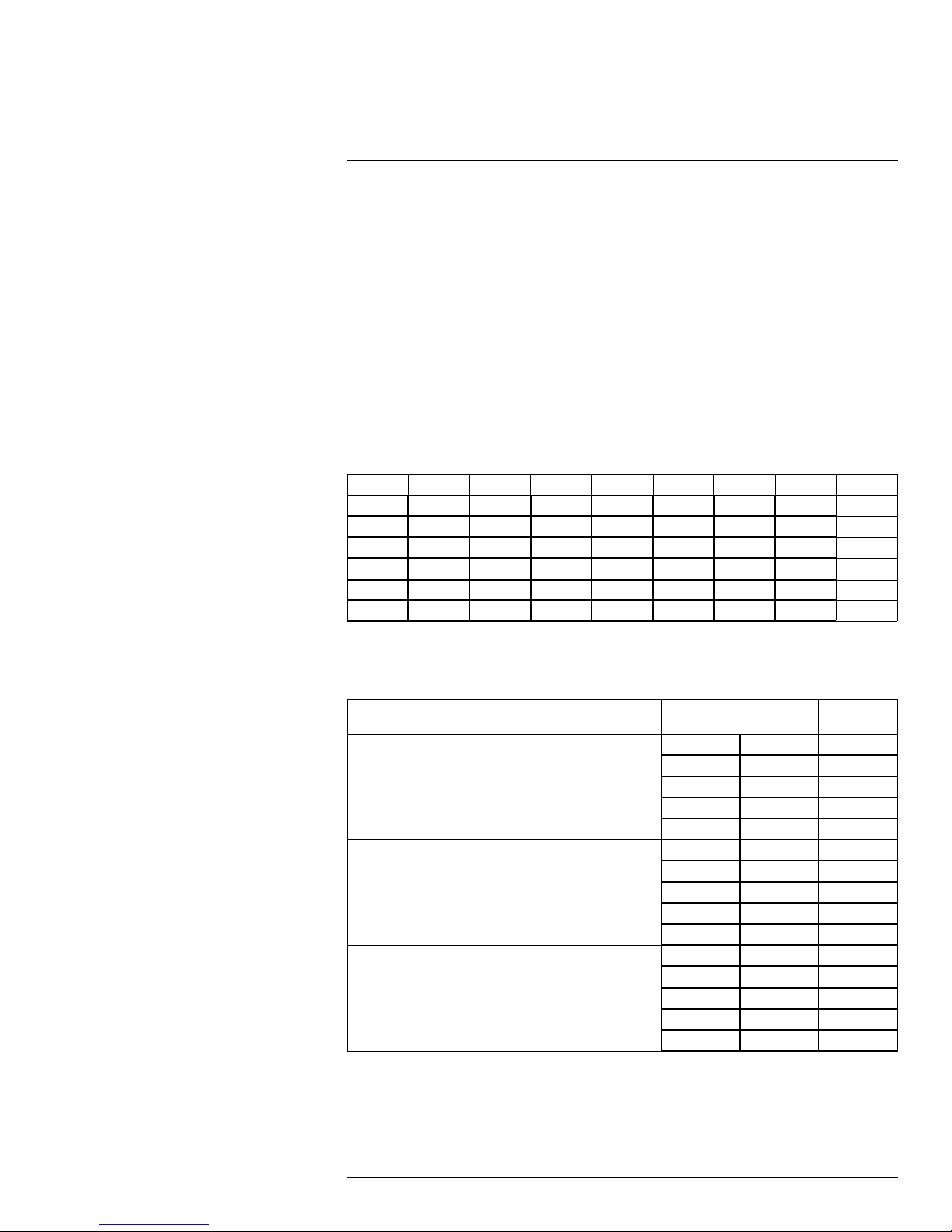

7.13 Setting configuration dip switches

The figure below shows the locations of dip switches SW102 and SW103

#T559795; r.21371/22369; en-US

15

Page 24

7

Installation

Figure 7.7 Dip switch locations in the FLIR A3xx pt series camera.

Pelco Address: This is the address of the system when configured as a Pelco device. The

available range of values is from decimal 0 to 255.

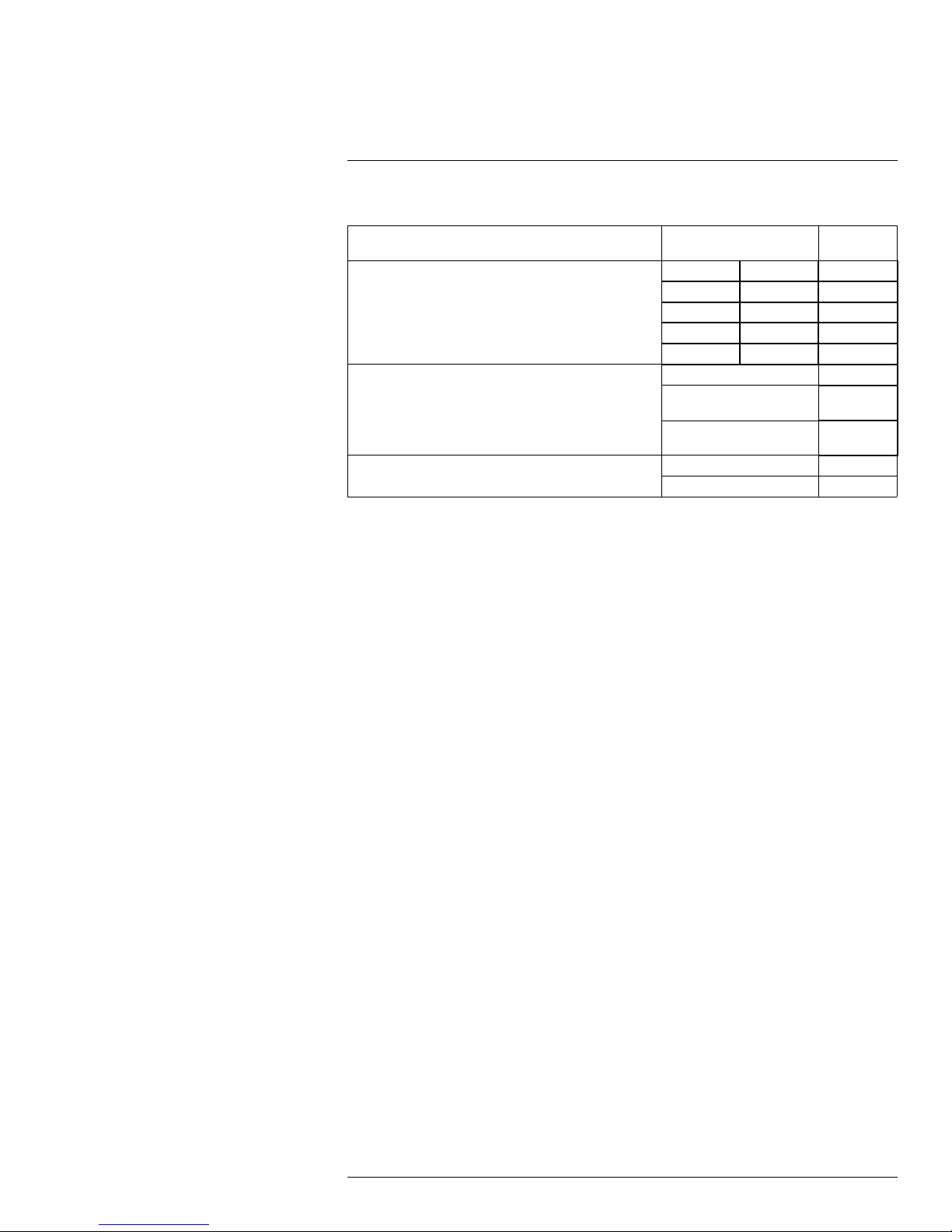

Table 7.1 Dip switch address/ID settings—SW102

ID Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 Bit 8

0

1

2

3

... ... ... ... ... ... ... ... ...

255

OFF OFF OFF OFF OFF OFF OFF OFF

ON OFF OFF OFF OFF OFF OFF OFF

OFF ON OFF OFF OFF OFF OFF OFF

ON ON OFF OFF OFF OFF OFF OFF

ON ON ON ON ON ON ON ON

Other serial communication parameters: The tables below defines the switch locations, bit

numbering, and on/off settings.

Table 7.2 Dip switch address/ID settings—SW103

Baud rate: This is the baud rate of the system user serial

port. The available values are 2400, 4800, 9600, 19200

kbaud.

Camera control protocol: This is the communication protocol selected for the system when operating over the serial port. The available protocols are Pelco-D and Bosch.

Serial communication protocol: This determines the

electrical interface selected for the user serial port. The

available settings are RS-422 and RS-232.

Settings Descrip-

Bit 1 Bit 2

OFF OFF

ON OFF

OFF ON

ON ON

Bit 3 Bit 4

OFF OFF Pelco-D

ON OFF N/A

OFF ON

ON ON N/A

Bit 5 Bit 6

OFF OFF N/A

ON OFF RS-422

OFF ON RS-232

ON ON N/A

tion

2400

4800

9600

19200

Bosch

#T559795; r.21371/22369; en-US

16

Page 25

7

Installation

Table 7.2 Dip switch address/ID settings—SW103 (continued)

Settings Descrip-

Not used. Bit 7 Bit 8

X X

X X

X X

X X

Software override DIP switch: This setting determines

whether the system will use software settings for configuration or if the dip switch settings will override the software

settings. The default is Off.

Not used. Bit 10

Bit 9

OFF Software

ON Hardware

X

tion

select

select

#T559795; r.21371/22369; en-US

17

Page 26

8

Verifying camera operation

Prior to installing the camera, use a bench test to verify camera operation and to configure

the camera for the local network. The camera provides analog video, and can be controlled through either serial or IP communications providing streaming video over an IP

network.

8.1 Power and analog video

Follow this procedure:

1. Connect the power, video, and serial cables to the camera.

2. Connect the video cable from the camera to a display/monitor, and connect the power

cable to a power supply. The camera operates on 24 VAC (21–30 VAC; 24 VAC: 215

VA max. with heater) or 24 VDC (21–30 VDC; 24 VDC: 195 W max. with heater). Verify

that video is displayed on the monitor.

3. Connect the serial cable from the camera to a serial device such as a keyboard, and

confirm that the camera is responding to serial commands. Before using serial communications, it may be necessary to configure the serial device interface to operate with

the camera. When the camera is turned on, the video temporarily displays system information including the serial number, IP address, Pelco address, Baud rate, and setting of the serial control DIP switch: SW (software control—the default) or HW

(hardware).

• S/N: 1234567

• IP Addr: 192.168.250.116

• PelcoD (Addr:1): 9600 SW

8.2 IP communications

As shipped from the factory, the FLIR A3xx pt series camera has an IP address of

192.168.250.116 with a netmask of 255.255.255.0.

Follow this procedure:

1. Configure a laptop or PC with another IP address from this network (i.e., 192.168.250.

xxx).

2. Connect the camera and the laptop to the same Ethernet switch (or back-to-back with

an Ethernet crossover cable). In some cases, a straight Ethernet cable can be used

because many PCs have auto detect Ethernet interfaces.

#T559795; r.21371/22369; en-US

18

Page 27

8

Verifying camera operation

3. Open a web browser, enter http://192.168.250.116 in the address bar, and press Enter.

If the following screen appears, then you have established IP communications with the

camera.

NOTE

The credentials are the following:

• User name: admin

• Password: fliradmin

8.3 FLIR A3xx pt series camera configuration

Follow this procedure:

1. Open a web browser, enter http://192.168.250.116 in the address bar, and press Enter.

This displays the following screen.

2. Log in using user name: admin and password: fliradmin.

#T559795; r.21371/22369; en-US

19

Page 28

8

Verifying camera operation

3. Under Server, click LAN Settings. This displays the following screen.

4. Under LAN Settings, you can change the following parameters:

• Host name.

• Host name mode.

• IP Address.

• IP Address mode.

• Netmask.

• Gateway.

• MTU.

5. Under Services, click Date and Time. This displays the following screen.

#T559795; r.21371/22369; en-US

20

Page 29

8

Verifying camera operation

6. Under Date and Time, you can change the following parameters:

• Date and Time Settings: NTP (to use a time server) or Custom (to enter a custom

time).

NOTE

If you select NTP, also select Time Zone below. You must also set name servers. See section 8.4

Setting DNS name servers, page 21 for more information.

• Custom Date & Time.

• Time zone.

• Time Server Mode.

• Time Server Address.

8.4 Setting DNS name servers

Follow this procedure:

1. Open a web browser, enter http://192.168.250.116 in the address bar, and press Enter.

This displays the following screen.

2. Log in using user name: admin and password: fliradmin.

#T559795; r.21371/22369; en-US

21

Page 30

8

Verifying camera operation

3. On the top menu bar, click Maintenance. This displays the following screen.

4. Scroll down to DNS servers.

5. Enter at least one name server.

6. Click Save. This displays a screen where you need to accept the name server change.

Click Accept.

#T559795; r.21371/22369; en-US

22

Page 31

8

Verifying camera operation

7. Click Restart Network. This displays a screen where you need to accept typing in the

new URL to reconnect. Click Accept.

#T559795; r.21371/22369; en-US

23

Page 32

9

Technical data

9.1 Online field-of-view calculator

Please visit http://support.flir.com and click the FLIR A3xx pt camera for field-of-view tables for all lens–camera combinations in this camera series.

9.2 Note about technical data

FLIR Systems reserves the right to change specifications at any time without prior notice.

Please check http://support.flir.com for latest changes.

#T559795; r.21371/22369; en-US

24

Page 33

Technical data9

9.3 FLIR A310pt 15° (9 Hz) NTSC

P/N: 60902-1102

Rev.: 22369

General description

The FLIR A310pt Pan & Tilt is an affordable solution for anyone who needs to solve problems that require

built in “smartness” such as analysis and alarm functionality. The FLIR A310pt Pan & Tilt has all the necessary features and functions to build distributed single- or multi-camera solutions to cover large areas to

monitor such as in coal pile monitoring and sub-station monitoring using standard Ethernet hardware and

software protocols.

The FLIR A310pt precision pan/tilt mechanism gives operators accurate pointing control while providing

fully programmable scan patterns, radar slew-to-cue, and slew-to-alarm functionality.

Multi-sensor configurations also include a day/night 36× zoom color CCD camera on the same pan/tilt

package.

Key features:

• Built-in extensive analysis functionality.

• Extensive alarm functionality, as a function of analysis and more.

• H.264, MPEG-4, and MJPEG streaming.

• Built-in web server.

• 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.).

• Composite video output.

• Precise pan/tilt mechanism.

• Daylight camera.

• IP66 rated.

• IP control: FLIR PTseries cameras can be integrated into any existing TCP/IP network and controlled

using a personal computer.

• Serial control interface, use Pelco D or Bosch commands over RS-232, RS-422, or RS-485 to remotely control the FLIR A310 pt.

• Multi-camera software: FLIR Sensors Manager allows users to manage and control a FLIR PT series

camera in a TCP/IP network.

Imaging and optical data

IR resolution 320 × 240 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Minimum focus distance 1.2 m (3.93 ft.)

Focal length 30.38 mm (1.2 in.)

Spatial resolution (IFOV)

Lens identification Automatic

F-number 1.3

Image frequency 9 Hz

Focus Automatic or manual (built in motor)

Zoom 1–8× continuous, digital, interpolating zooming on

Detector data

Detector type Focal Plane Array (FPA), uncooled microbolometer

Spectral range

Detector pitch 25 µm

Detector time constant Typical 12 ms

15° × 11.25°

0.82 mrad

images

7.5–13 µm

#T559795; r.21371/22369; en-US

25

Page 34

Technical data9

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading

Measurement analysis

Spotmeter

Area 10 boxes with max./min./average/position

Isotherm 1 with above/below/interval

Atmospheric transmission correction Automatic, based on inputs for distance, atmos-

Optics transmission correction Automatic, based on signals from internal sensors

Emissivity correction Variable from 0.01 to 1.0

Reflected apparent temperature correction Automatic, based on input of reflected temperature

External optics/windows correction Automatic, based on input of optics/window trans-

Measurement corrections

• –20 to +120°C (–4 to +248°F)

• 0 to +350°C (+32 to +662°F)

10

pheric temperature and relative humidity

mission and temperature

Global and individual object parameters

Alarm

Alarm functions 6 automatic alarms on any selected measurement

Set-up

Color palettes Color palettes (BW, BW inv, Iron, Rain)

Set-up commands Date/time, Temperature°C/°F

Imaging and optical data (visual camera)

Field of view (FOV) 57.8° (H) to 1.7° (H)

Focal length 3.4 mm (wide) to 122.4 mm (tele)

F-number 1.6 to 4.5

Focus Automatic or manual (built in motor)

Optical Zoom 36× continuous

Electronic Zoom 12× continuous, digital, interpolating

Detector data (visual camera)

Focal Plane Array (FPA) 1/4” Exview HAD CCD

Effective pixels

Technical specification (pan & tilt)

Azimuth Range Az velocity 360° continuous, 0.1 to 60°/sec max

Elevation Range

Programmable presets 128

Automatic heaters

function, camera temperature

380.000

El velocity ± 45°, 0.1 to 30°/sec. max

Clears window from ice. Switched on at +4°C (39°

F). Switched off at +15°C (59°F).

#T559795; r.21371/22369; en-US

26

Page 35

Technical data9

Ethernet

Ethernet Control, result and image

Ethernet, type 100 Mbps

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

Ethernet, communication

Ethernet, video streaming Two independent channels for each camera

- MPEG-4, H.264, or M-JPEG

Ethernet, protocols Ethernet/IP, Modbus TCP, TCP, UDP, SNTP, RTSP,

Composite video

Video out

Video, standard

RTP, HTTP, ICMP, IGMP, ftp, SMTP, SMB (CIFS),

DHCP, MDNS (Bonjour), uPnP

Composite video output, NTSC compatible

CVBS (SMPTE 170M NTSC)

Power system

Power 24 VAC (21-30 VAC; 24 VAC: 215 VA max. with

Environmental data

Operating temperature range –25°C to +50°C (-13°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

EMC

Encapsulation

Bump

Vibration

Physical data

Weight 17.9 kg (39.5 lb.)

Size (L × W × H) 460 × 467 × 326 mm (18.1 × 18.4 × 12.8 in.)

Base mounting

Housing material Aluminum

Shipping information

Packaging, type

List of contents

Packaging, weight

heater) or 24 VDC (21-30 VDC; 24 VDC: 195 W

max. with heater).

to +40°C (+77°F to +104°F)

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

IP 66 (IEC 60529)

5 g, 11 ms (IEC 60068-2-27)

2 g (IEC 60068-2-6)

Cardboard box

• Pan & tilt with infrared camera including lens

and visual camera

• FLIR Sensors Manager download card

• Lens cap

• Printed documentation

• Small accessories kit

• User documentation CD-ROM

#T559795; r.21371/22369; en-US

27

Page 36

Technical data9

Shipping information

Packaging, size 671 × 564 × 464 mm (26.4 × 22.2 × 18.3 in.)

EAN-13 7332558008867

UPC-12

Country of origin Sweden

845188009403

Supplies & accessories:

• T197000; High temp. option +1200°C/+2192°F for FLIR T/B2xx to T/B4xx and A3xx,

A3xxf, A3xxpt, A3xxsc series

• 4119468; ADAPTER PLATE - PT-SERIES

• 223-0017-00; JOYSTICK ASSY, NEXUS CONSOLE

• 500-0461-00; PEDESTAL MOUNT ASSY- PT-SERIES

• 500-0509-00; POLE ADAPTER - PT-SERIES

• 4124857; POWER SUPPLY ASSY, 24VAC - PT-series

• 500-0460-00; WALL MOUNTASSY- PT-SERIES

• 324-0010-00; Hard case - PT-SERIES

• 4130235; FLIR Sensors Manager, pro

#T559795; r.21371/22369; en-US

28

Page 37

Technical data9

9.4 FLIR A310pt 15° (9 Hz) PAL

P/N: 60901-1102

Rev.: 22369

General description

The FLIR A310pt Pan & Tilt is an affordable solution for anyone who needs to solve problems that require

built in “smartness” such as analysis and alarm functionality. The FLIR A310pt Pan & Tilt has all the necessary features and functions to build distributed single- or multi-camera solutions to cover large areas to

monitor such as in coal pile monitoring and sub-station monitoring using standard Ethernet hardware and

software protocols.

The FLIR A310pt precision pan/tilt mechanism gives operators accurate pointing control while providing

fully programmable scan patterns, radar slew-to-cue, and slew-to-alarm functionality.

Multi-sensor configurations also include a day/night 36× zoom color CCD camera on the same pan/tilt

package.

Key features:

• Built-in extensive analysis functionality.

• Extensive alarm functionality, as a function of analysis and more.

• H.264, MPEG-4, and MJPEG streaming.

• Built-in web server.

• 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.).

• Composite video output.

• Precise pan/tilt mechanism.

• Daylight camera.

• IP66 rated.

• IP control: FLIR PTseries cameras can be integrated into any existing TCP/IP network and controlled

using a personal computer.

• Serial control interface, use Pelco D or Bosch commands over RS-232, RS-422, or RS-485 to remotely control the FLIR A310 pt.

• Multi-camera software: FLIR Sensors Manager allows users to manage and control a FLIR PT series

camera in a TCP/IP network.

Imaging and optical data

IR resolution 320 × 240 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Minimum focus distance 1.2 m (3.93 ft.)

Focal length 30.38 mm (1.2 in.)

Spatial resolution (IFOV)

Lens identification Automatic

F-number 1.3

Image frequency 9 Hz

Focus Automatic or manual (built in motor)

Zoom 1–8× continuous, digital, interpolating zooming on

Detector data

Detector type Focal Plane Array (FPA), uncooled microbolometer

Spectral range

Detector pitch 25 µm

Detector time constant Typical 12 ms

15° × 11.25°

0.82 mrad

images

7.5–13 µm

#T559795; r.21371/22369; en-US

29

Page 38

Technical data9

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading

Measurement analysis

Spotmeter

Area 10 boxes with max./min./average/position

Isotherm 1 with above/below/interval

Atmospheric transmission correction Automatic, based on inputs for distance, atmos-

Optics transmission correction Automatic, based on signals from internal sensors

Emissivity correction Variable from 0.01 to 1.0

Reflected apparent temperature correction Automatic, based on input of reflected temperature

External optics/windows correction Automatic, based on input of optics/window trans-

Measurement corrections

• –20 to +120°C (–4 to +248°F)

• 0 to +350°C (+32 to +662°F)

10

pheric temperature and relative humidity

mission and temperature

Global and individual object parameters

Alarm

Alarm functions 6 automatic alarms on any selected measurement

Set-up

Color palettes Color palettes (BW, BW inv, Iron, Rain)

Set-up commands Date/time, Temperature°C/°F

Imaging and optical data (visual camera)

Field of view (FOV) 57.8° (H) to 1.7° (H)

Focal length 3.4 mm (wide) to 122.4 mm (tele)

F-number 1.6 to 4.5

Focus Automatic or manual (built in motor)

Optical Zoom 36× continuous

Electronic Zoom 12× continuous, digital, interpolating

Detector data (visual camera)

Focal Plane Array (FPA) 1/4” Exview HAD CCD

Effective pixels

Technical specification (pan & tilt)

Azimuth Range Az velocity 360° continuous, 0.1 to 60°/sec max

Elevation Range

Programmable presets 128

Automatic heaters

function, camera temperature

380.000

El velocity ± 45°, 0.1 to 30°/sec. max

Clears window from ice. Switched on at +4°C (39°

F). Switched off at +15°C (59°F).

#T559795; r.21371/22369; en-US

30

Page 39

Technical data9

Ethernet

Ethernet Control, result and image

Ethernet, type 100 Mbps

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

Ethernet, communication

Ethernet, video streaming Two independent channels for each camera

- MPEG-4, H.264, or M-JPEG

Ethernet, protocols Ethernet/IP, Modbus TCP, TCP, UDP, SNTP, RTSP,

Composite video

Video out

Video, standard

RTP, HTTP, ICMP, IGMP, ftp, SMTP, SMB (CIFS),

DHCP, MDNS (Bonjour), uPnP

Composite video output, PAL compatible

CVBS (ITU-R-BT.470 PAL)

Power system

Power 24 VAC (21-30 VAC; 24 VAC: 215 VA max. with

Environmental data

Operating temperature range –25°C to +50°C (-13°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

EMC

Encapsulation

Bump

Vibration

Physical data

Weight 17.9 kg (39.5 lb.)

Size (L × W × H) 460 × 467 × 326 mm (18.1 × 18.4 × 12.8 in.)

Base mounting

Housing material Aluminum

Shipping information

Packaging, type

List of contents

Packaging, weight

heater) or 24 VDC (21-30 VDC; 24 VDC: 195 W

max. with heater).

to +40°C (+77°F to +104°F)

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

IP 66 (IEC 60529)

5 g, 11 ms (IEC 60068-2-27)

2 g (IEC 60068-2-6)

Cardboard box

• Pan & tilt with infrared camera including lens

and visual camera

• FLIR Sensors Manager download card

• Lens cap

• Printed documentation

• Small accessories kit

• User documentation CD-ROM

#T559795; r.21371/22369; en-US

31

Page 40

Technical data9

Shipping information

Packaging, size 671 × 564 × 464 mm (26.4 × 22.2 × 18.3 in.)

EAN-13 7332558008874

UPC-12

Country of origin Sweden

845188009410

Supplies & accessories:

• T197000; High temp. option +1200°C/+2192°F for FLIR T/B2xx to T/B4xx and A3xx,

A3xxf, A3xxpt, A3xxsc series

• 4119468; ADAPTER PLATE - PT-SERIES

• 223-0017-00; JOYSTICK ASSY, NEXUS CONSOLE

• 500-0461-00; PEDESTAL MOUNT ASSY- PT-SERIES

• 500-0509-00; POLE ADAPTER - PT-SERIES

• 4124857; POWER SUPPLY ASSY, 24VAC - PT-series

• 500-0460-00; WALL MOUNTASSY- PT-SERIES

• 324-0010-00; Hard case - PT-SERIES

• 4130235; FLIR Sensors Manager, pro

#T559795; r.21371/22369; en-US

32

Page 41

Technical data9

9.5 FLIR A310pt 15° NTSC

P/N: 61002-1102

Rev.: 22369

General description

The FLIR A310pt Pan & Tilt is an affordable solution for anyone who needs to solve problems that require

built in “smartness” such as analysis and alarm functionality. The FLIR A310pt Pan & Tilt has all the necessary features and functions to build distributed single- or multi-camera solutions to cover large areas to

monitor such as in coal pile monitoring and sub-station monitoring using standard Ethernet hardware and

software protocols.

The FLIR A310pt precision pan/tilt mechanism gives operators accurate pointing control while providing

fully programmable scan patterns, radar slew-to-cue, and slew-to-alarm functionality.

Multi-sensor configurations also include a day/night 36× zoom color CCD camera on the same pan/tilt

package.

Key features:

• Built-in extensive analysis functionality.

• Extensive alarm functionality, as a function of analysis and more.

• H.264, MPEG-4, and MJPEG streaming.

• Built-in web server.

• 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.).

• Composite video output.

• Precise pan/tilt mechanism.

• Daylight camera.

• IP66 rated.

• IP control: FLIR PTseries cameras can be integrated into any existing TCP/IP network and controlled

using a personal computer.

• Serial control interface, use Pelco D or Bosch commands over RS-232, RS-422, or RS-485 to remotely control the FLIR A310 pt.

• Multi-camera software: FLIR Sensors Manager allows users to manage and control a FLIR PT series

camera in a TCP/IP network.

Imaging and optical data

IR resolution 320 × 240 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Minimum focus distance 1.2 m (3.93 ft.)

Focal length 30.38 mm (1.2 in.)

Spatial resolution (IFOV)

Lens identification Automatic

F-number 1.3

Image frequency 30 Hz

Focus Automatic or manual (built in motor)

Zoom 1–8× continuous, digital, interpolating zooming on

Detector data

Detector type Focal Plane Array (FPA), uncooled microbolometer

Spectral range

Detector pitch 25 µm

Detector time constant Typical 12 ms

15° × 11.25°

0.82 mrad

images

7.5–13 µm

#T559795; r.21371/22369; en-US

33

Page 42

Technical data9

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading

Measurement analysis

Spotmeter

Area 10 boxes with max./min./average/position

Isotherm 1 with above/below/interval

Atmospheric transmission correction Automatic, based on inputs for distance, atmos-

Optics transmission correction Automatic, based on signals from internal sensors

Emissivity correction Variable from 0.01 to 1.0

Reflected apparent temperature correction Automatic, based on input of reflected temperature

External optics/windows correction Automatic, based on input of optics/window trans-

Measurement corrections

• –20 to +120°C (–4 to +248°F)

• 0 to +350°C (+32 to +662°F)

10

pheric temperature and relative humidity

mission and temperature

Global and individual object parameters

Alarm

Alarm functions 6 automatic alarms on any selected measurement

Set-up

Color palettes Color palettes (BW, BW inv, Iron, Rain)

Set-up commands Date/time, Temperature°C/°F

Imaging and optical data (visual camera)

Field of view (FOV) 57.8° (H) to 1.7° (H)

Focal length 3.4 mm (wide) to 122.4 mm (tele)

F-number 1.6 to 4.5

Focus Automatic or manual (built in motor)

Optical Zoom 36× continuous

Electronic Zoom 12× continuous, digital, interpolating

Detector data (visual camera)

Focal Plane Array (FPA) 1/4” Exview HAD CCD

Effective pixels

Technical specification (pan & tilt)

Azimuth Range Az velocity 360° continuous, 0.1 to 60°/sec max

Elevation Range

Programmable presets 128

Automatic heaters

function, camera temperature

380.000

El velocity ± 45°, 0.1 to 30°/sec. max

Clears window from ice. Switched on at +4°C (39°

F). Switched off at +15°C (59°F).

#T559795; r.21371/22369; en-US

34

Page 43

Technical data9

Ethernet

Ethernet Control, result and image

Ethernet, type 100 Mbps

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

Ethernet, communication

Ethernet, video streaming Two independent channels for each camera

- MPEG-4, H.264, or M-JPEG

Ethernet, protocols Ethernet/IP, Modbus TCP, TCP, UDP, SNTP, RTSP,

Composite video

Video out

Video, standard

RTP, HTTP, ICMP, IGMP, ftp, SMTP, SMB (CIFS),

DHCP, MDNS (Bonjour), uPnP

Composite video output, NTSC compatible

CVBS (SMPTE 170M NTSC)

Power system

Power 24 VAC (21-30 VAC; 24 VAC: 215 VA max. with

Environmental data

Operating temperature range –25°C to +50°C (-13°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

EMC

Encapsulation

Bump

Vibration

Physical data

Weight 17.9 kg (39.5 lb.)

Size (L × W × H) 460 × 467 × 326 mm (18.1 × 18.4 × 12.8 in.)

Base mounting

Housing material Aluminum

Shipping information

Packaging, type

List of contents

Packaging, weight

heater) or 24 VDC (21-30 VDC; 24 VDC: 195 W

max. with heater).

to +40°C (+77°F to +104°F)

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

IP 66 (IEC 60529)

5 g, 11 ms (IEC 60068-2-27)

2 g (IEC 60068-2-6)

Cardboard box

• Pan & tilt with infrared camera including lens

and visual camera

• FLIR Sensors Manager download card

• Lens cap

• Printed documentation

• Small accessories kit

• User documentation CD-ROM

#T559795; r.21371/22369; en-US

35

Page 44

Technical data9

Shipping information

Packaging, size 671 × 564 × 464 mm (26.4 × 22.2 × 18.3 in.)

EAN-13 7332558004784

UPC-12

Country of origin Sweden

845188004729

Supplies & accessories:

• T197000; High temp. option +1200°C/+2192°F for FLIR T/B2xx to T/B4xx and A3xx,

A3xxf, A3xxpt, A3xxsc series

• 4119468; ADAPTER PLATE - PT-SERIES

• 223-0017-00; JOYSTICK ASSY, NEXUS CONSOLE

• 500-0461-00; PEDESTAL MOUNT ASSY- PT-SERIES

• 500-0509-00; POLE ADAPTER - PT-SERIES

• 4124857; POWER SUPPLY ASSY, 24VAC - PT-series

• 500-0460-00; WALL MOUNTASSY- PT-SERIES

• 324-0010-00; Hard case - PT-SERIES

• 4130235; FLIR Sensors Manager, pro

#T559795; r.21371/22369; en-US

36

Page 45

Technical data9

9.6 FLIR A310pt 15° PAL

P/N: 61001-1102

Rev.: 22369

General description

The FLIR A310pt Pan & Tilt is an affordable solution for anyone who needs to solve problems that require

built in “smartness” such as analysis and alarm functionality. The FLIR A310pt Pan & Tilt has all the necessary features and functions to build distributed single- or multi-camera solutions to cover large areas to

monitor such as in coal pile monitoring and sub-station monitoring using standard Ethernet hardware and

software protocols.

The FLIR A310pt precision pan/tilt mechanism gives operators accurate pointing control while providing

fully programmable scan patterns, radar slew-to-cue, and slew-to-alarm functionality.

Multi-sensor configurations also include a day/night 36× zoom color CCD camera on the same pan/tilt

package.

Key features:

• Built-in extensive analysis functionality.

• Extensive alarm functionality, as a function of analysis and more.

• H.264, MPEG-4, and MJPEG streaming.

• Built-in web server.

• 100 Mbps Ethernet (100 m cable, wireless, fiber, etc.).

• Composite video output.

• Precise pan/tilt mechanism.

• Daylight camera.

• IP66 rated.

• IP control: FLIR PTseries cameras can be integrated into any existing TCP/IP network and controlled

using a personal computer.

• Serial control interface, use Pelco D or Bosch commands over RS-232, RS-422, or RS-485 to remotely control the FLIR A310 pt.

• Multi-camera software: FLIR Sensors Manager allows users to manage and control a FLIR PT series

camera in a TCP/IP network.

Imaging and optical data

IR resolution 320 × 240 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Minimum focus distance 1.2 m (3.93 ft.)

Focal length 30.38 mm (1.2 in.)

Spatial resolution (IFOV)

Lens identification Automatic

F-number 1.3

Image frequency 30 Hz

Focus Automatic or manual (built in motor)

Zoom 1–8× continuous, digital, interpolating zooming on

Detector data

Detector type Focal Plane Array (FPA), uncooled microbolometer

Spectral range

Detector pitch 25 µm

Detector time constant Typical 12 ms

15° × 11.25°

0.82 mrad

images

7.5–13 µm

#T559795; r.21371/22369; en-US

37

Page 46

Technical data9

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading

Measurement analysis

Spotmeter

Area 10 boxes with max./min./average/position

Isotherm 1 with above/below/interval

Atmospheric transmission correction Automatic, based on inputs for distance, atmos-

Optics transmission correction Automatic, based on signals from internal sensors

Emissivity correction Variable from 0.01 to 1.0

Reflected apparent temperature correction Automatic, based on input of reflected temperature

External optics/windows correction Automatic, based on input of optics/window trans-

Measurement corrections

• –20 to +120°C (–4 to +248°F)

• 0 to +350°C (+32 to +662°F)

10

pheric temperature and relative humidity

mission and temperature

Global and individual object parameters

Alarm

Alarm functions 6 automatic alarms on any selected measurement

Set-up

Color palettes Color palettes (BW, BW inv, Iron, Rain)

Set-up commands Date/time, Temperature°C/°F

Imaging and optical data (visual camera)

Field of view (FOV) 57.8° (H) to 1.7° (H)

Focal length 3.4 mm (wide) to 122.4 mm (tele)

F-number 1.6 to 4.5

Focus Automatic or manual (built in motor)

Optical Zoom 36× continuous

Electronic Zoom 12× continuous, digital, interpolating

Detector data (visual camera)

Focal Plane Array (FPA) 1/4” Exview HAD CCD

Effective pixels

Technical specification (pan & tilt)

Azimuth Range Az velocity 360° continuous, 0.1 to 60°/sec max

Elevation Range

Programmable presets 128

Automatic heaters

function, camera temperature

380.000

El velocity ± 45°, 0.1 to 30°/sec. max

Clears window from ice. Switched on at +4°C (39°

F). Switched off at +15°C (59°F).

#T559795; r.21371/22369; en-US

38

Page 47

Technical data9

Ethernet