Page 1

User’s manual

FLIR Ax5 series

Page 2

Page 3

User’s manual

FLIR Ax5 series

#T559770; r.18834/22369; en-US

iii

Page 4

Page 5

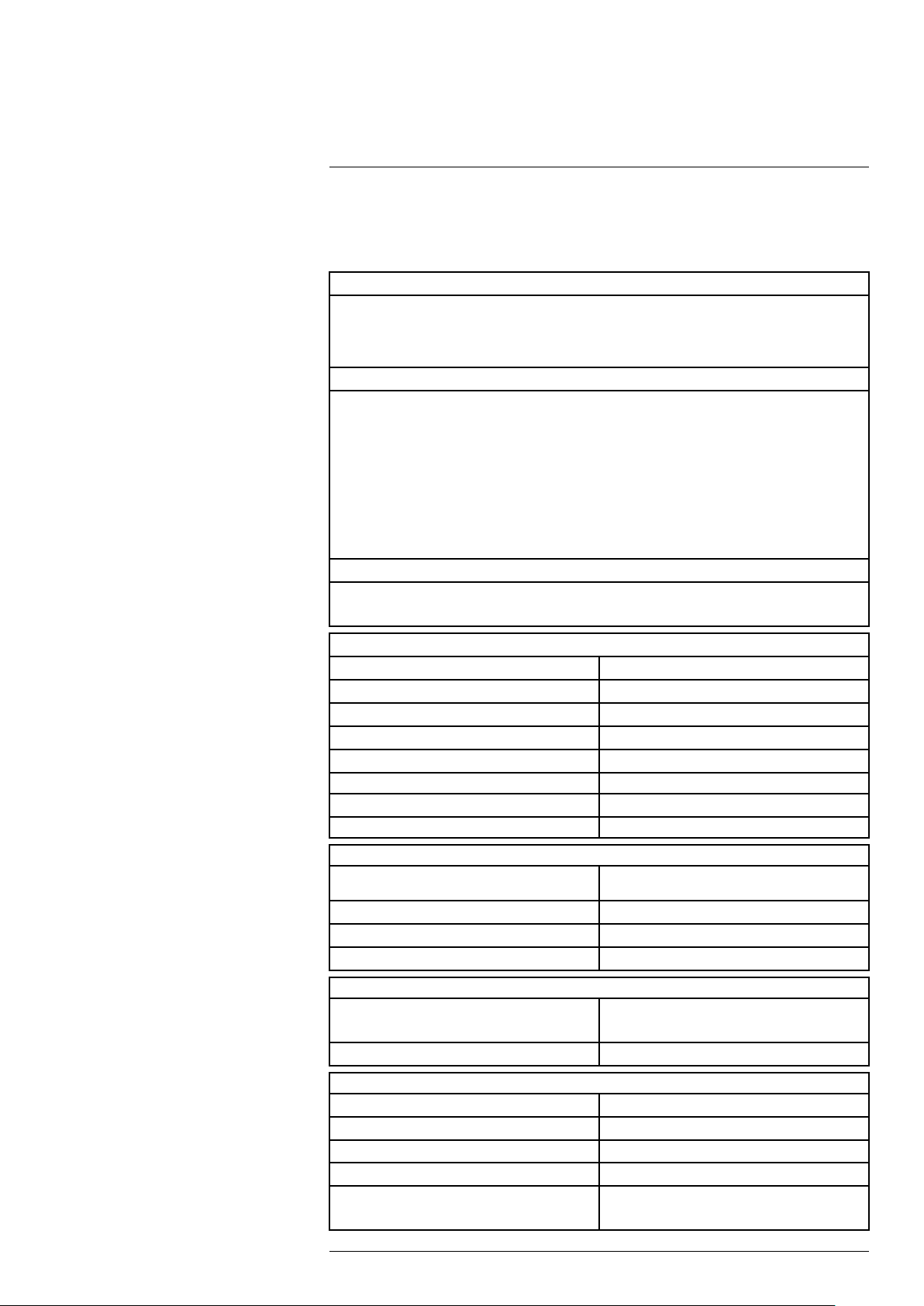

Table of contents

1 Legal disclaimer ............................................... ....... ....... ................... 1

1.1 Legal disclaimer .......................................................................1

1.2 Usage statistics ........................................................................ 1

1.3 Changes to registry ................................................................... 1

1.4 U.S. Government Regulations......................................................1

1.5 Copyright ................................................................................1

1.6 Quality assurance .....................................................................2

1.7 Patents...................................................................................2

1.8 EULA Terms ............................................................................2

2 Safety information .... ........................................ ....... ....... ....... ............ 4

3 Notice to user .... ................... ....... ....... ....... ................................. ......5

3.1 User-to-user forums .................................................................. 5

3.2 Calibration...............................................................................5

3.3 Accuracy ................................................................................ 5

3.4 Disposal of electronic waste ........................................................5

3.5 Training ..................................................................................5

3.6 Documentation updates ............................................................. 5

3.7 Important note about this manual..................................................5

4 Customer help ....... ....... ................... ....... ....... ....... ............................6

4.1 General ..................................................................................6

4.2 Submitting a question ................................................................ 6

4.3 Downloads ..............................................................................7

5 Introduction....................... ........................................ .......................8

6 List of accessories and services ...... ....... ....... ................... ....... ....... ....9

7 Mechanical installation ... ....... ....... ....... ........................................ .... 11

8 Focusing the camera . ....... ....... ................... ....... ....... ....... ................ 12

8.1 Focusing cameras with 5, 9, 13, and 19 mm lenses ........................ 12

8.1.1 Necessary tools ........................................................... 12

8.1.2 Procedure .................................................................. 12

8.2 Focusing cameras with 25 mm lenses ......................................... 13

8.2.1 Necessary tools ........................................................... 13

8.2.2 Procedure .................................................................. 13

9 Downloads ........ ....... ....... ....... ................... ....... ....... ....... ................ 14

10 About I/O, synchronization, and measurement ................. ....... ....... ..... 15

10.1 FLIR Ax5 General Purpose I/O................................................... 15

10.2 FLIR Ax5 synchronization ......................................................... 15

10.3 FLIR Ax5 measurement............................................................ 16

11 Technical data . ....... ................... ....... ....... ....... ................................. 19

11.1 Online field-of-view calculator .................................................... 19

11.2 Note about technical data ......................................................... 19

11.3 FLIR A15 f=19 mm .................................................................. 20

11.4 FLIR A15 f=19 mm (7.5 Hz)....................................................... 23

11.5 FLIR A15 f=9 mm.................................................................... 26

11.6 FLIR A15 f=9 mm (7.5 Hz) ........................................................ 29

11.7 FLIR A15 f=9 mm with SC kit ..................................................... 32

11.8 FLIR A15 f=9 mm with SC kit (7.5 Hz).......................................... 35

11.9 FLIR A35 f=19 mm .................................................................. 38

11.10 FLIR A35 f=9 mm.................................................................... 41

11.11 FLIR A35 f=9 mm with SC kit ..................................................... 44

11.12 FLIR A5 f=5 mm ..................................................................... 47

11.13 FLIR A5 f=5 mm (7.5 Hz) .......................................................... 50

11.14 FLIR A5 f=5 mm with SC kit....................................................... 53

11.15 FLIR A5 f=5 mm with SC kit (7.5 Hz) ........................................... 56

11.16 FLIR A5 f=9 mm ..................................................................... 59

#T559770; r.18834/22369; en-US

v

Page 6

Table of contents

11.17 FLIR A5 f=9 mm (7.5 Hz) .......................................................... 62

11.18 FLIR A65 f=13 mm .................................................................. 65

11.19 FLIR A65 f=13 mm (7.5 Hz)....................................................... 68

11.20 FLIR A65 f=13 mm with SC kit (7.5 Hz) ........................................ 71

11.21 FLIR A65 f=25 mm .................................................................. 74

11.22 FLIR A65 f=25 mm (7.5 Hz)....................................................... 77

12 Mechanical drawings .. ........................................ ............................. 80

13 Pin configurations and schematics..................... ....... ....... ................. 87

13.1 M12 connector pin configuration ................................................ 87

13.2 Pig-tail end of cable................................................................. 87

13.3 SYNC input/output schematics .................................................. 88

13.4 GP input/output schematics ...................................................... 88

14 Declaration of conformity .................................... ............................. 89

15 Cleaning the camera ..... ................... ....... ....... ....... ................... ....... . 90

15.1 Camera housing, cables, and other items..................................... 90

15.1.1 Liquids....................................................................... 90

15.1.2 Equipment.................................................................. 90

15.1.3 Procedure .................................................................. 90

15.2 Infrared lens .......................................................................... 90

15.2.1 Liquids....................................................................... 90

15.2.2 Equipment.................................................................. 90

15.2.3 Procedure .................................................................. 90

16 About FLIR Systems ....... ....... ....... ........................................ ........... 91

16.1 More than just an infrared camera .............................................. 92

16.2 Sharing our knowledge ............................................................ 92

16.3 Supporting our customers......................................................... 92

16.4 A few images from our facilities.................................................. 93

17 Glossary ............................... ........................................ ....... .......... 94

18 Thermographic measurement techniques ......... ....... ....... ....... ............ 97

18.1 Introduction .......................................................................... 97

18.2 Emissivity.............................................................................. 97

18.2.1 Finding the emissivity of a sample.................................... 97

18.3 Reflected apparent temperature ............................................... 100

18.4 Distance ............................................................................. 100

18.5 Relative humidity .................................................................. 100

18.6 Other parameters.................................................................. 100

19 History of infrared technology... ....... ....... ....... ................... ....... ....... 102

20 Theory of thermography................................................................. 105

20.1 Introduction ......................................................................... 105

20.2 The electromagnetic spectrum................................................. 105

20.3 Blackbody radiation............................................................... 105

20.3.1 Planck’s law .............................................................. 106

20.3.2 Wien’s displacement law.............................................. 107

20.3.3 Stefan-Boltzmann's law ............................................... 108

20.3.4 Non-blackbody emitters ............................................... 109

20.4 Infrared semi-transparent materials........................................... 111

21 The measurement formula. ....... ................... ....... ....... ....... .............. 112

22 Emissivity tables ................................... ....... ................................. 116

22.1 References.......................................................................... 116

22.2 Tables ................................................................................ 116

#T559770; r.18834/22369; en-US

vi

Page 7

1

Legal disclaimer

1.1 Legal disclaimer

All products manufactured by FLIR Systems are warranted against defective materials

and workmanship for a period of one (1) year from the delivery date of the original purchase, provided such products have been under normal storage, use and service, and in

accordance with FLIR Systems instruction.

Products which are not manufactured by FLIR Systems but included in systems delivered by FLIR Systems to the original purchaser, carry the warranty, if any, of the particular supplier only. FLIR Systems has no responsibility whatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It is not applicable to any product which has been subjected to misuse, neglect, accident or abnormal

conditions of operation. Expendable parts are excluded from the warranty.

In the case of a defect in a product covered by this warranty the product must not be further used in order to prevent additional damage. The purchaser shall promptly report any

defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, at its option, repair or replace any such defective product free of

charge if, upon inspection, it proves to be defective in material or workmanship and provided that it is returned to FLIR Systems within the said one-year period.

FLIR Systems has no other obligation or liability for defects than those set forth above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims the im-

plied warranties of merchantability and fitness for a particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidental or consequen-

tial loss or damage, whether based on contract, tort or any other legal theory.

This warranty shall be governed by Swedish law.

Any dispute, controversy or claim arising out of or in connection with this warranty, shall

be finally settled by arbitration in accordance with the Rules of the Arbitration Institute of

the Stockholm Chamber of Commerce. The place of arbitration shall be Stockholm. The

language to be used in the arbitral proceedings shall be English.

1.2 Usage statistics

FLIR Systems reserves the right to gather anonymous usage statistics to help maintain

and improve the quality of our software and services.

1.3 Changes to registry

The registry entry HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet\Control\Lsa

\LmCompatibilityLevel will be automatically changed to level 2 if the FLIR Camera Monitor service detects a FLIR camera connected to the computer with a USB cable. The

modification will only be executed if the camera device implements a remote network

service that supports network logons.

1.4 U.S. Government Regulations

This product may be subject to U.S. Export Regulations. Please send any inquiries to exportquestions@flir.com.

1.5 Copyright

© 2014, FLIR Systems, Inc. All rights reserved worldwide. No parts of the software including source code may be reproduced, transmitted, transcribed or translated into any

language or computer language in any form or by any means, electronic, magnetic, optical, manual or otherwise, without the prior written permission of FLIR Systems.

The documentation must not, in whole or part, be copied, photocopied, reproduced,

translated or transmitted to any electronic medium or machine readable form without prior consent, in writing, from FLIR Systems.

#T559770; r.18834/22369; en-US

1

Page 8

Legal disclaimer1

Names and marks appearing on the products herein are either registered trademarks or

trademarks of FLIR Systems and/or its subsidiaries. All other trademarks, trade names

or company names referenced herein are used for identification only and are the property of their respective owners.

1.6 Quality assurance

The Quality Management System under which these products are developed and manufactured has been certified in accordance with the ISO 9001 standard.

FLIR Systems is committed to a policy of continuous development; therefore we reserve

the right to make changes and improvements on any of the products without prior notice.

1.7 Patents

One or several of the following patents and/or design patents may apply to the products

and/or features. Additional pending patents and/or pending design patents may also

apply.

000279476-0001; 000439161; 000499579-0001; 000653423; 000726344; 000859020;

001106306-0001; 001707738; 001707746; 001707787; 001776519; 001954074;

002021543; 002058180; 002249953; 002531178; 0600574-8; 1144833; 1182246;

1182620; 1285345; 1299699; 1325808; 1336775; 1391114; 1402918; 1404291;

1411581; 1415075; 1421497; 1458284; 1678485; 1732314; 2106017; 2107799;

2381417; 3006596; 3006597; 466540; 483782; 484155; 4889913; 5177595;

60122153.2; 602004011681.5-08; 6707044; 68657; 7034300; 7110035; 7154093;

7157705; 7237946; 7312822; 7332716; 7336823; 7544944; 7667198; 7809258 B2;

7826736; 8,153,971; 8018649 B2; 8212210 B2; 8289372; 8354639 B2; 8384783;

8520970; 8565547; 8595689; 8599262; 8654239; 8680468; 8803093; D540838;

D549758; D579475; D584755; D599,392; D615,113; D664,580; D664,581; D665,004;

D665,440; D677298; D710,424 S; DI6702302-9; DI6903617-9; DI7002221-6;

DI7002891-5; DI7002892-3; DI7005799-0; DM/057692; DM/061609; EP 2115696 B1;

EP2315433; SE 0700240-5; US 8340414 B2; ZL 201330267619.5; ZL01823221.3;

ZL01823226.4; ZL02331553.9; ZL02331554.7; ZL200480034894.0;

ZL200530120994.2; ZL200610088759.5; ZL200630130114.4; ZL200730151141.4;

ZL200730339504.7; ZL200820105768.8; ZL200830128581.2; ZL200880105236.4;

ZL200880105769.2; ZL200930190061.9; ZL201030176127.1; ZL201030176130.3;

ZL201030176157.2; ZL201030595931.3; ZL201130442354.9; ZL201230471744.3;

ZL201230620731.8.

1.8 EULATerms

• You have acquired a device (“INFRARED CAMERA”) that includes software licensed

by FLIR Systems AB from Microsoft Licensing, GP or its affiliates (“MS”). Those installed software products of MS origin, as well as associated media, printed materials,

and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual property laws and treaties. The SOFTWARE is licensed, not sold. All

rights reserved.

• IF YOU DO NOTAGREE TO THIS END USER LICENSE AGREEMENT (“EULA”), DO

NOT USE THE DEVICE OR COPY THE SOFTWARE. INSTEAD, PROMPTLY CONTACT FLIR Systems AB FOR INSTRUCTIONS ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND. ANY USE OF THE SOFTWARE, INCLUDING BUT NOT

LIMITED TO USE ON THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT TO

THIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

• GRANT OF SOFTWARE LICENSE. This EULA grants you the following license:

• You may use the SOFTWARE only on the DEVICE.

• NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. FLIR Sys-

tems AB HAS INDEPENDENTLY DETERMINED HOW TO USE THE SOFTWARE

IN THE DEVICE, AND MS HAS RELIED UPON FLIR Systems AB TO CONDUCT

SUFFICIENT TESTING TO DETERMINE THAT THE SOFTWARE IS SUITABLE

FOR SUCH USE.

#T559770; r.18834/22369; en-US

2

Page 9

Legal disclaimer1

• NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided “AS IS”

and with all faults. THE ENTIRE RISK AS TO SATISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE)

IS WITH YOU. ALSO, THERE IS NO WARRANTYAGAINST INTERFERENCE

WITH YOUR ENJOYMENT OF THE SOFTWARE OR AGAINST INFRINGEMENT.

IF YOU HAVE RECEIVED ANY WARRANTIES REGARDING THE DEVICE OR

THE SOFTWARE, THOSE WARRANTIES DO NOT ORIGINATE FROM, AND

ARE NOT BINDING ON, MS.

• No Liability for Certain Damages. EXCEPT AS PROHIBITED BY LAW, MS SHALL

HAVE NO LIABILITY FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING FROM OR IN CONNECTION WITH THE USE

OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL APPLY

EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE. IN NO EVENT

SHALL MS BE LIABLE FOR ANY AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

• Limitations on Reverse Engineering, Decompilation, and Disassembly. You

may not reverse engineer, decompile, or disassemble the SOFTWARE, except and

only to the extent that such activity is expressly permitted by applicable law notwithstanding this limitation.

• SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS. You may per-

manently transfer rights under this EULA only as part of a permanent sale or transfer of the Device, and only if the recipient agrees to this EULA. If the SOFTWARE

is an upgrade, any transfer must also include all prior versions of the SOFTWARE.

• EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is subject to U.S.

export jurisdiction. You agree to comply with all applicable international and national laws that apply to the SOFTWARE, including the U.S. Export Administration

Regulations, as well as end-user, end-use and destination restrictions issued by U.

S. and other governments. For additional information see http://www.microsoft.

com/exporting/.

#T559770; r.18834/22369; en-US

3

Page 10

2

Safety information

WARNING

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and warning labels on containers before you use a liquid. The liquids can be dangerous. Injury to persons can occur.

WARNING

Applicability: FLIR Ax5.

Do not use screws that are too long. If you use screws that are too long, damage to the camera will occur. The maximum depth of the M3 holes is 4 mm (0.15 in.).

CAUTION

Do not point the infrared camera (with or without the lens cover) at strong energy sources, for example,

devices that cause laser radiation, or the sun. This can have an unwanted effect on the accuracy of the

camera. It can also cause damage to the detector in the camera.

CAUTION

Do not use the camera in temperatures more than +50°C (+122°F), unless other information is specified

in the user documentation or technical data. High temperatures can cause damage to the camera.

CAUTION

Do not apply solvents or equivalent liquids to the camera, the cables, or other items. Damage to the battery and injury to persons can occur.

CAUTION

Be careful when you clean the infrared lens. The lens has an anti-reflective coating which is easily damaged. Damage to the infrared lens can occur.

CAUTION

Do not use too much force to clean the infrared lens. This can cause damage to the anti-reflective

coating.

CAUTION

Applicability: Cameras with an automatic shutter that can be disabled.

Do not disable the automatic shutter in the camera for a long time period (a maximum of 30 minutes is

typical). If you disable the shutter for a longer time period, damage to the detector can occur.

NOTE

The encapsulation rating is only applicable when all the openings on the camera are sealed with their

correct covers, hatches, or caps. This includes the compartments for data storage, batteries, and

connectors.

CAUTION

Applicability: Cameras where you can remove the lens and expose the infrared detector.

Do not use the pressurized air from the pneumatic air systems in a workshop when you remove dust

from the detector. The air contains oil mist to lubricate the pneumatic tools and the pressure is too high.

Damage to the detector can occur.

#T559770; r.18834/22369; en-US

4

Page 11

3

Notice to user

3.1 User-to-user forums

Exchange ideas, problems, and infrared solutions with fellow thermographers around the

world in our user-to-user forums. To go to the forums, visit:

http://www.infraredtraining.com/community/boards/

3.2 Calibration

FLIR Systems recommends that you verify your calibration yearly. You can verify the calibration yourself or with the help of a FLIR Systems Partner. If preferred, FLIR Systems offers a calibration, adjustment, and general maintenance service.

3.3 Accuracy

For very accurate results, we recommend that you wait 5 minutes after you have started

the camera before measuring a temperature.

3.4 Disposal of electronic waste

As with most electronic products, this equipment must be disposed of in an environmentally friendly way, and in accordance with existing regulations for electronic waste.

Please contact your FLIR Systems representative for more details.

3.5 Training

To read about infrared training, visit:

• http://www.infraredtraining.com

• http://www.irtraining.com

• http://www.irtraining.eu

3.6 Documentation updates

Our manuals are updated several times per year, and we also issue product-critical notifications of changes on a regular basis.

To access the latest manuals and notifications, go to the Download tab at:

http://support.flir.com

It only takes a few minutes to register online. In the download area you will also find the

latest releases of manuals for our other products, as well as manuals for our historical

and obsolete products.

3.7 Important note about this manual

FLIR Systems issues generic manuals that cover several cameras within a model line.

This means that this manual may contain descriptions and explanations that do not apply

to your particular camera model.

#T559770; r.18834/22369; en-US

5

Page 12

4

Customer help

4.1 General

For customer help, visit:

http://support.flir.com

4.2 Submitting a question

To submit a question to the customer help team, you must be a registered user. It only

takes a few minutes to register online. If you only want to search the knowledgebase for

existing questions and answers, you do not need to be a registered user.

When you want to submit a question, make sure that you have the following information

to hand:

#T559770; r.18834/22369; en-US

6

Page 13

4

Customer help

• The camera model

• The camera serial number

• The communication protocol, or method, between the camera and your device (for example, HDMI, Ethernet, USB, or FireWire)

• Device type (PC/Mac/iPhone/iPad/Android device, etc.)

• Version of any programs from FLIR Systems

• Full name, publication number, and revision number of the manual

4.3 Downloads

On the customer help site you can also download the following:

• Firmware updates for your infrared camera.

• Program updates for your PC/Mac software.

• Freeware and evaluation versions of PC/Mac software.

• User documentation for current, obsolete, and historical products.

• Mechanical drawings (in *.dxf and *.pdf format).

• Cad data models (in *.stp format).

• Application stories.

• Technical datasheets.

• Product catalogs.

#T559770; r.18834/22369; en-US

7

Page 14

5

Introduction

The FLIR Ax5 cameras have features and functions that make them the natural choice

for anyone who uses PC software to solve problems. Available resolutions include 80 ×

64, 160 × 128, and 320 × 256 pixels.

Among their main features are GigE Vision and GenICam compliance, which makes

them plug-and-play when used with software packages such as IMAQ Vision and Halcon.

Key features:

• Very affordable.

• Compact (40 × 43 × 106 mm/1.57 × 1.69 × 4.17 in.).

• GigE Vision and GenICam compliant.

• GigE Vision lockable connector.

• PoE (power over Ethernet).

• 8-bit monochrome image streaming.

• 14-bit radiometric image streaming.

• High frame rates (60 Hz).

• Synchronization between cameras possible.

• 1x+1x GPIO.

• Compliant with any software that supports GenICam, including National Instruments

IMAQ Vision, Stemmers Common Vision Blox, and COGNEX Vision Pro.

• Lenses: 5°, 9°, 13°, 19°, and 25° (model-dependent).

Typical applications:

• Automation, thermal machine vision.

• Entry-level “high-speed” R&D.

#T559770; r.18834/22369; en-US

8

Page 15

6

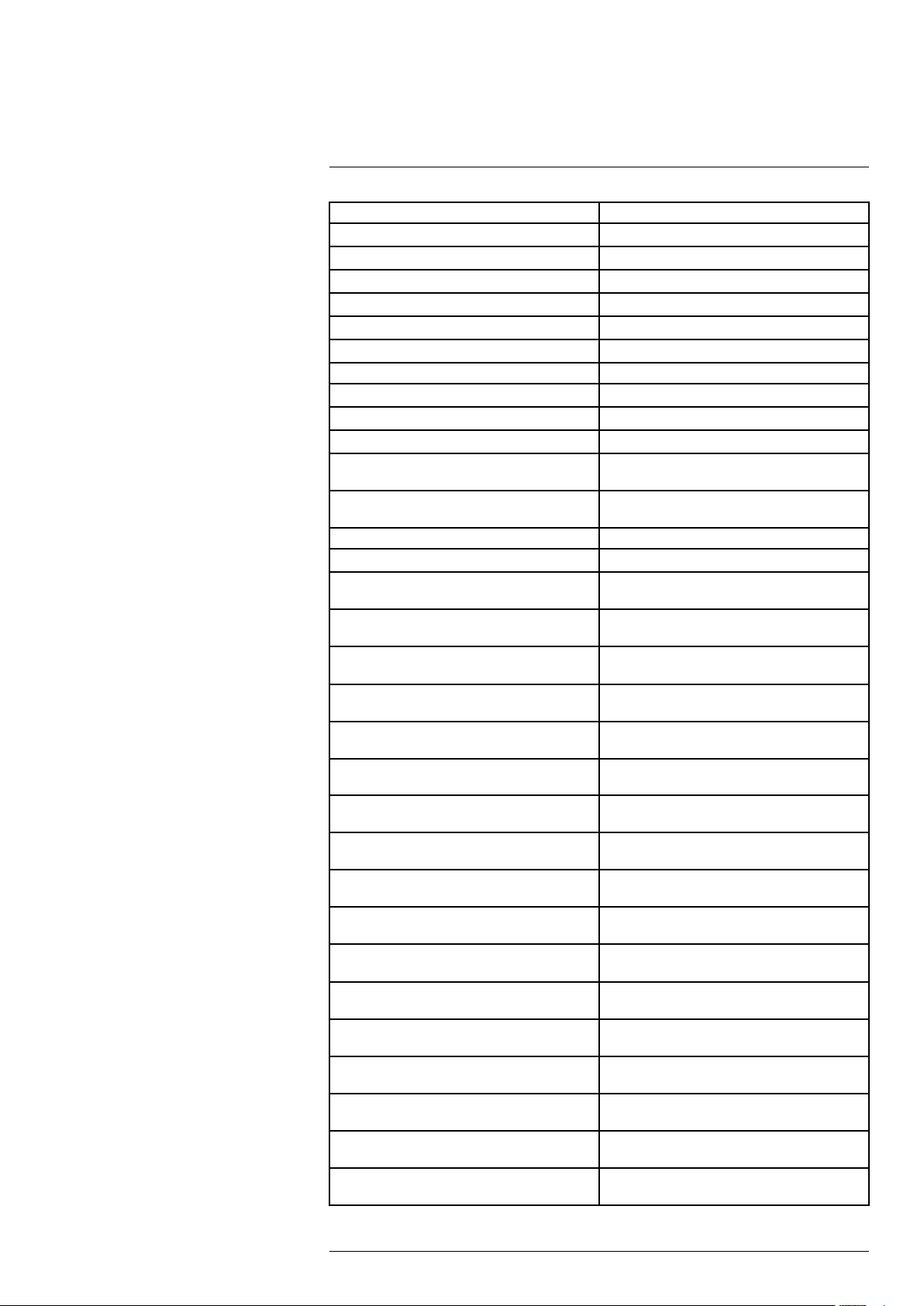

List of accessories and services

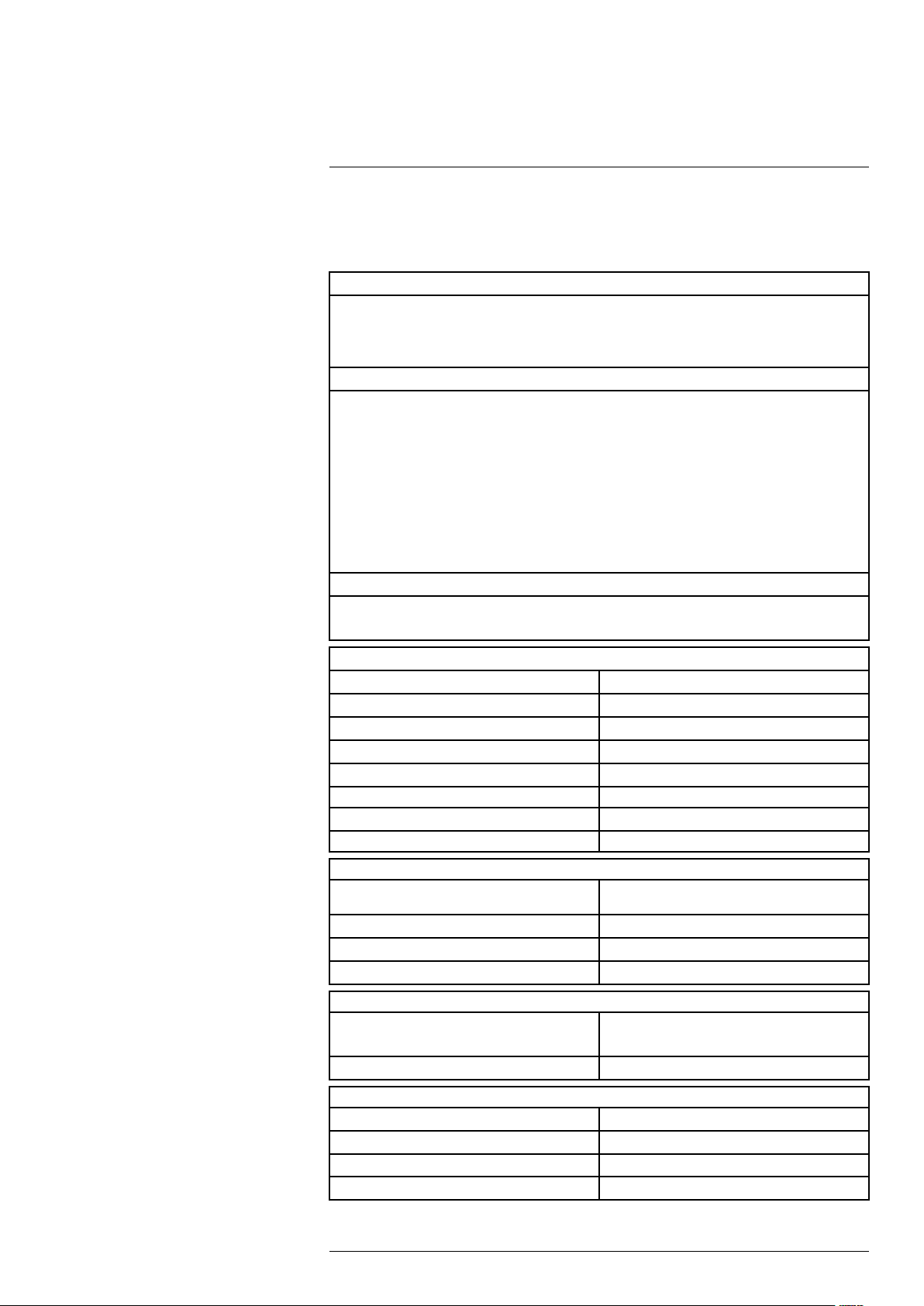

Part number Product name

T198349 Base support

T198348

T127605ACC Cable M12 Pigtail

T127606ACC Cable M12 Sync

T951004ACC Ethernet cable CAT-6, 2m/6.6 ft.

DSW-10000 FLIR IR Camera Player

T198584 FLIR Tools

T198583 FLIR Tools+ (license only)

T198342ACC Focus adjustment tool

T911183 Gigabit PoE injector 16 W, with multi-plugs

ITC-ADV-3021 ITC Advanced General Thermography Course -

ITC-ADV-3029 ITC Advanced General Thermography Course-

ITC-CON-1001 ITC conference fee

ITC-EXP-1041 ITC Customized workshop - per person (per day)

ITC-EXP-1021 ITC In-house training - additional attendance 1

ITC-EXP-1029 ITC In-house training - group up to 10 pers. (per

ITC-EXP-1050 ITC Infrared application and system consultancy

ITC-CER-5105 ITC Level 1 Thermography Course - additional

ITC-CER-5101 ITC Level 1 Thermography Course - attendance,

ITC-CER-5109 ITC Level 1 Thermography Course – group of 10

ITC-CER-5205 ITC Level 2 Thermography Course - additional

ITC-CER-5201 ITC Level 2 Thermography Course - attendance,

ITC-CER-5209 ITC Level 2 Thermography Course – group of 10

ITC-EXP-2036 ITC R&D basics for industry users - group up to 6

ITC-EXP-2025 ITC Short course Fever Screening - additional stu-

ITC-EXP-2021 ITC Short course Fever Screening - attendance 1

ITC-EXP-2029 ITC Short course Fever Screening - inclusive 10

ITC-EXP-1019 ITC Short course Introduction to thermography -

ITC-EXP-1011 ITC Short course Introduction to thermography

ITC-SOW-0001 ITC Software course - attendance 1 pers. (per

ITC-SOW-0009 ITC Software course - group up to 10 pers. (per

Cable kit Mains (UK,EU,US)

attendance, 1 pers.

group of 10 pers.

pers. (per day)

day)

(per day)

student to on site class, 1 pers

1 pers.

pers.

student to on site class, 1 pers

1 pers.

pers.

pers. (2 days)

dent to on site class (2 days)

pers. (2 days)

pers. (2 days)

inclusive 10 pers. (1 day)

-attendance 1 pers. (1 day)

day)

day)

#T559770; r.18834/22369; en-US

9

Page 16

6

List of accessories and services

Part number Product name

ITC-EXP-1001 ITC Training 1 day - attendance 1 pers.

ITC-EXP-1009 ITC Training 1 day - group up to 10 pers.

ITC-EXP-2001 ITC Training 2 days - attendance 1 pers.

ITC-EXP-2009 ITC Training 2 days - group up to 10 pers.

ITC-EXP-3001 ITC Training 3 days - attendance 1 pers.

ITC-EXP-3009 ITC Training 3 days - group up to 10 pers.

ITC-TFT-0100 ITC travel time for instructor

T911112 PoE injector

T198392 Table stand kit

T198371 Transport case Ax5

ITC-TOL-1003 Travel and lodging expenses instructor (Center

and South Africa)

ITC-TOL-1001 Travel and lodging expenses instructor (Europe,

Balcans, Turkey, Cyprus)

ITC-TOL-1005 Travel and lodging expenses instructor (other)

ITC-TOL-1002 Travel and lodging expenses instructor (Russia/

GUS, Middle East, North Africa)

ITC-TOL-1004 Travel and lodging expenses instructor (various)

NOTE

FLIR Systems reserves the right to discontinue models, parts or accessories, and other items, or to

change specifications at any time without prior notice.

#T559770; r.18834/22369; en-US

10

Page 17

7

Mechanical installation

The camera unit has been designed to allow it to be mounted in any position. It has a

mounting interface on the bottom with four metric M3 holes.

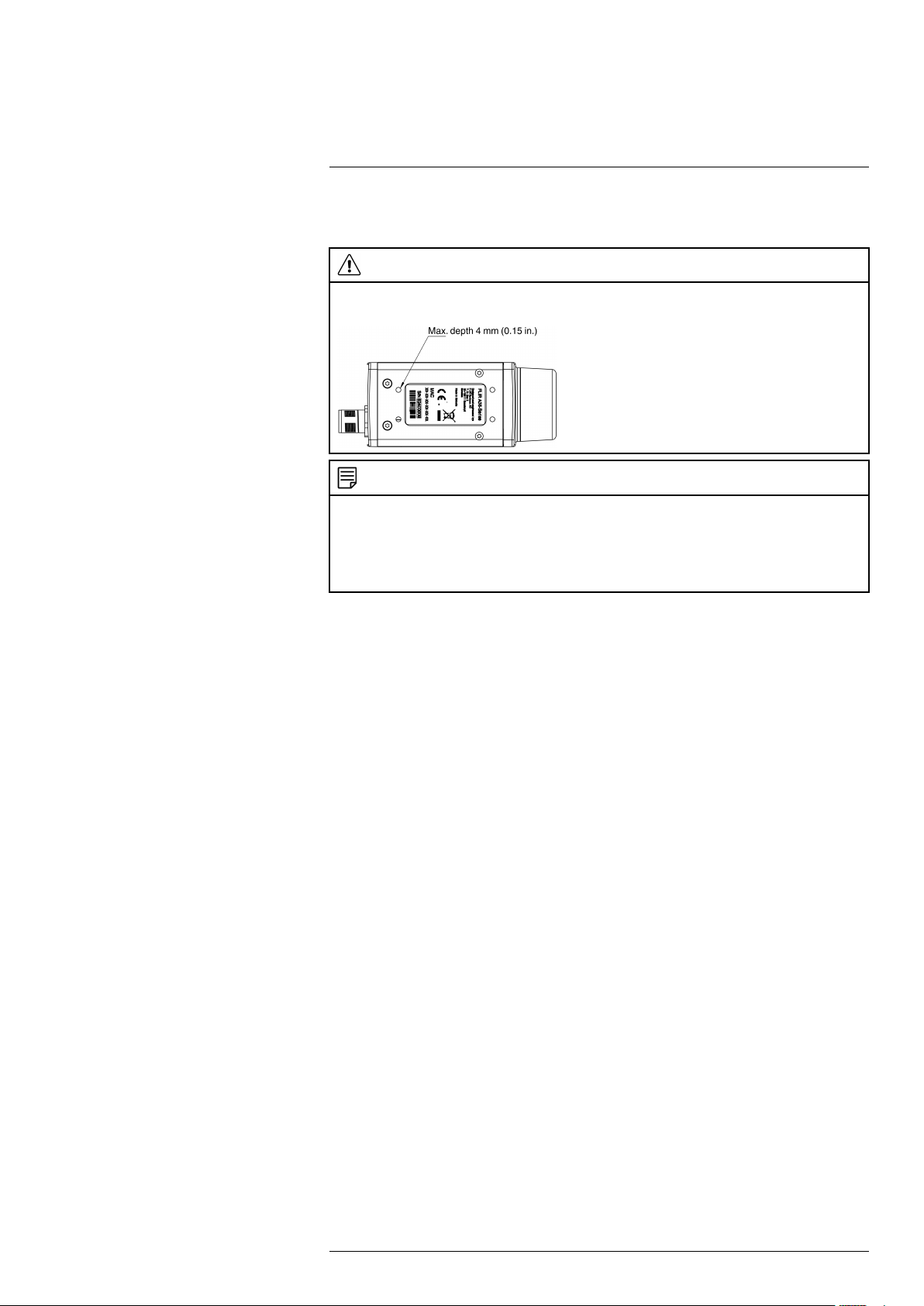

WARNING

Do not use screws that are too long. Using screws that are too long will damage the camera. The maximum depth of the M3 holes is 4 mm (0.15 in.).

NOTE

The camera generates a considerable amount of heat during operation. This is normal. In order to

transfer this heat, it is recommended that the camera is mounted on a base support or a heat sink made

of a material that has a high capacity to transfer heat, e.g., aluminum. FLIR Systems provides P/N

T198349 (base support) for this purpose, but other base supports or heat sinks can be used.

The use of the base support is also strongly recommended in order to minimize temperature drift of the

infrared detector in the camera.

If the camera unit is to be permanently mounted on the application site, certain steps

have to be taken. The camera unit might need to be enclosed in a protective housing

and, depending on the ambient conditions (e.g., temperature), the housing may need to

be cooled by means of water or air. In very dusty conditions the installation might also

need to have a stream of pressurized air directed at the lens, in order to prevent dust

build-up.

When mounting the camera unit in harsh environments, every precaution should be taken when it comes to securing the unit. If the environment exposes the unit to severe vibrations, there may arise a need to secure the mounting screws by means of Loctite or

another industrial brand of thread-locking liquid, as well as to dampen the vibrations by

mounting the camera unit on a specially designed mounting base.

For further information regarding mounting recommendations and environmental enclosures, contact FLIR Systems.

The camera is typically powered using PoE (Power over Ethernet). A PoE injector and

cable kit are available from FLIR Systems. See the part numbers below.

• T198348, Cable kit mains (UK, EU, US).

• T911112, PoE injector.

• T951004ACC, Ethernet cable CAT-6, 2 m/6.6 ft.

#T559770; r.18834/22369; en-US

11

Page 18

8

Focusing the camera

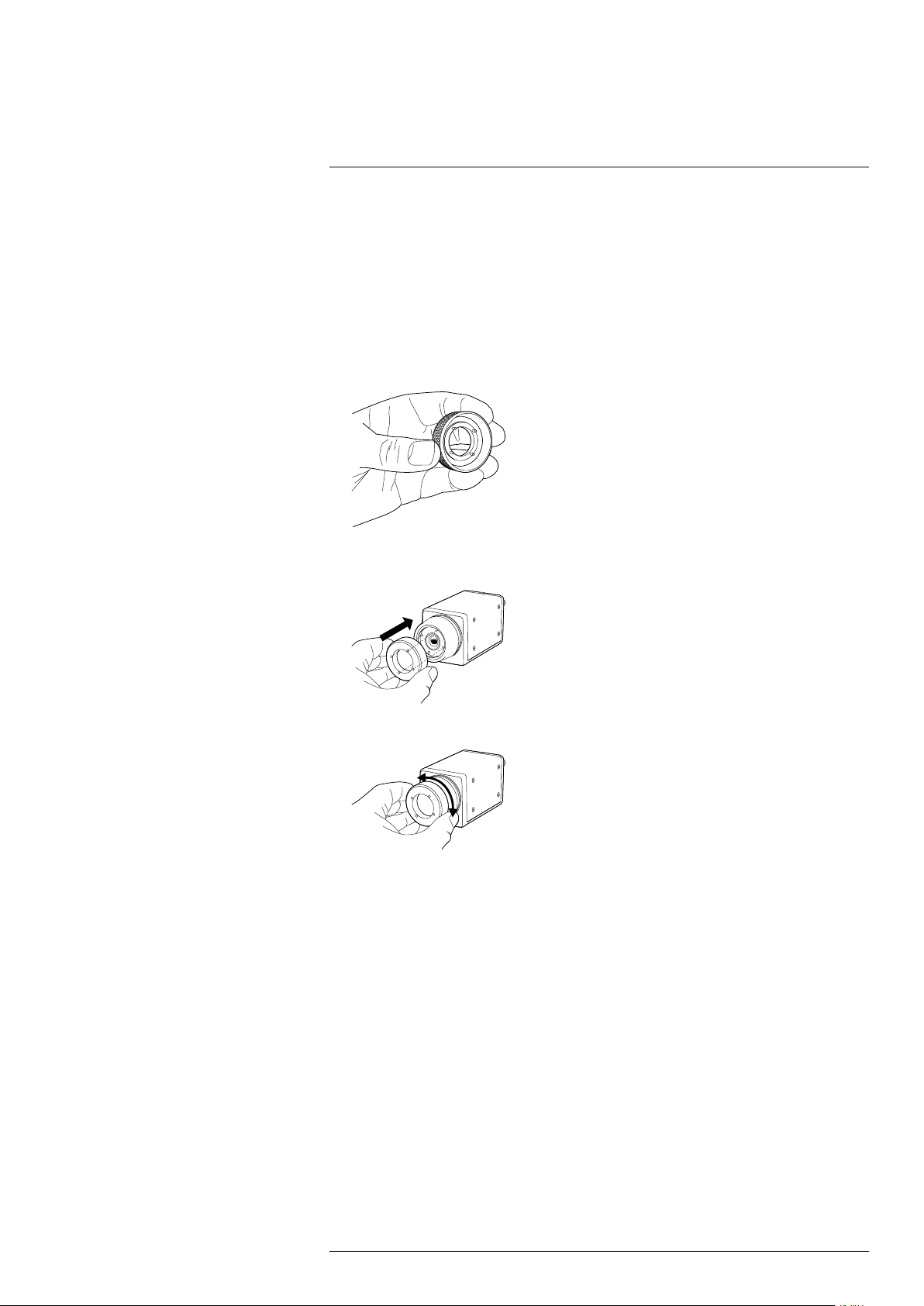

8.1 Focusing cameras with 5, 9, 13, and 19 mm lenses

8.1.1 Necessary tools

Focus adjustment tool (included in the package for cameras with 5, 9, 13, and 19 mm

lenses).

8.1.2 Procedure

Follow this procedure:

1. Note the four pegs on the inside of the focus adjustment tool.

2. Align the four pegs with the corresponding slots on the front of the lens, and push the

focus adjustment tool into position.

3. Rotate the lens.

#T559770; r.18834/22369; en-US

12

Page 19

Focusing the camera8

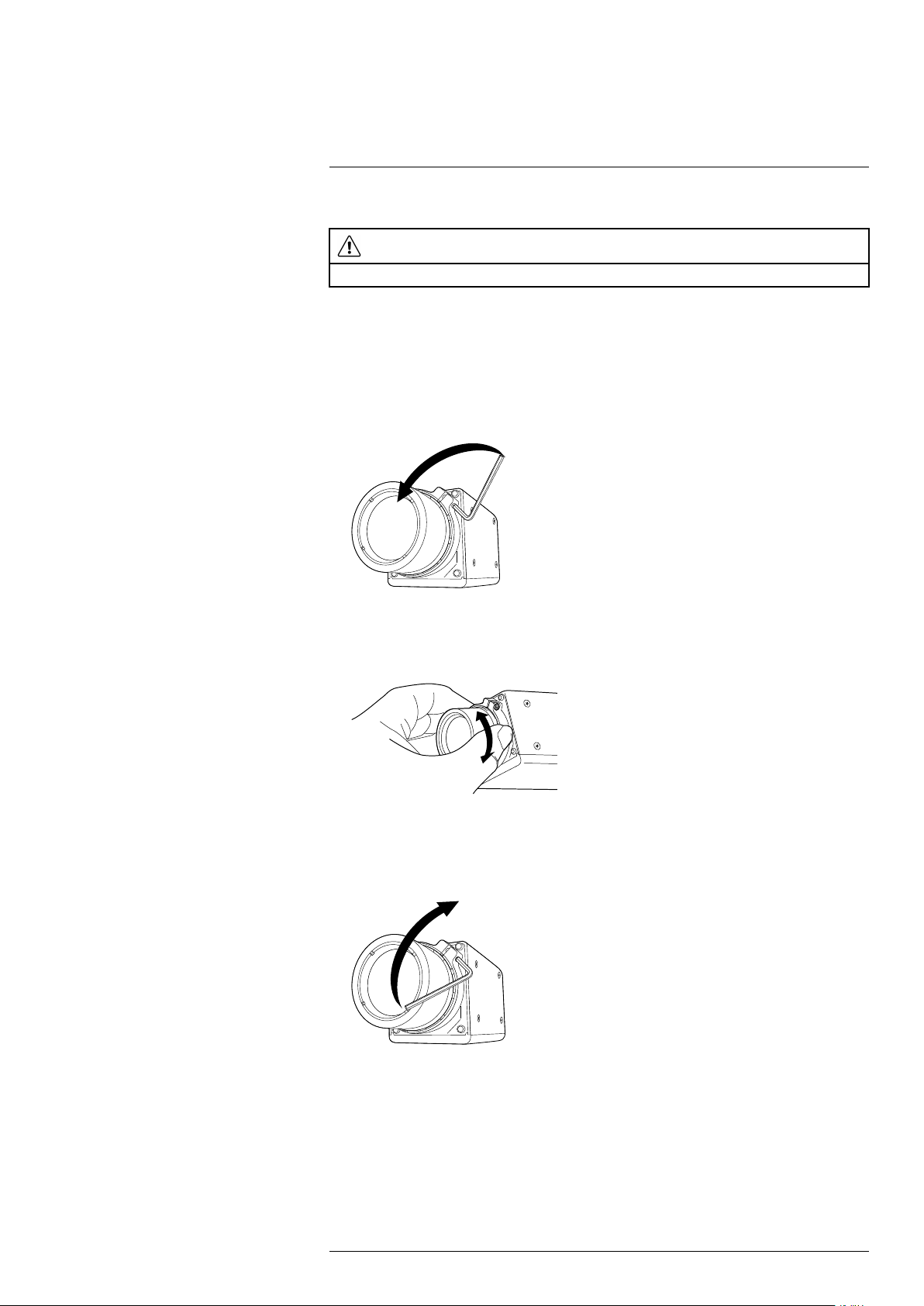

8.2 Focusing cameras with 25 mm lenses

CAUTION

Do not use the focus adjustment tool when focusing cameras with a 25 mm lens.

8.2.1 Necessary tools

Allen wrench, 1.5 mm.

8.2.2 Procedure

Follow this procedure:

1. Unlock the clamp by loosening the Allen screw.

2. Focus the camera by rotating the lens.

3. Lock the clamp by tightening the Allen screw.

#T559770; r.18834/22369; en-US

13

Page 20

9

Downloads

The principal software used to configure and control the camera is FLIR GEV Demo

1.3.0. This software is based on the PleoraeBus SDK and the runtime Pleora GEVPlayer

that comes with the SDK.

Downloads:

• http://support.flir.com/Ax5-software

• Link to download PureGEV SDK Sample (source code): http://support.flir.com/

SwDownload/app/RssSWDownload.aspx?ID=133

• Link to download FLIR GEV Demo 1.3.0 (installer): http://support.flir.com/SwDownload/app/RssSWDownload.aspx?ID=155

The camera is compliant with the following standards. Additional software and documentation resources can be downloaded from these sites.

• GeniCAM: http:www.genicam.org

• Gigabit Ethernet: http://www.ieee802.org/3

#T559770; r.18834/22369; en-US

14

Page 21

10

About I/O, synchronization, and measurement

10.1 FLIR Ax5 General Purpose I/O

The FLIR Ax5 camera has one general-purpose input line and one output line that can

be used in control applications.

Typical usage:

• The output line is asserted when an alarm condition is met.

• The input line is used to trigger an action, for example saving an image.

The output line GPO+ is controlled by the register UserOutputValue. Set this register to

True to assert (level equal to GPIO_PWR) the GPO+ signal, and set to False to de-assert

(level is equal to GPIO_GND).

You can monitor the input line by reading the LineStatus register on a regular basis. The

LineStatus register will returnTrue if the input level is asserted (level equal to GPIO_PWR

voltage), and it will returnFalse if the input line is de-asserted (level is equal to GPIO_

GND).

Another option is to configure the camera to send a GigEVision event when the input line

state is changed. In order to configure the camera for event transmission you need to

modify the following registers:

PLC_Q7_Variable0

EventSelector

EventNotification Enum Set this register to GigEVisionE-

Enum

Enum

Set this register to PLC_I0 (enumeration value 2) to route the

GPI signal

Set this register to PLC_Interrupt_FIFO0_Q7 (enumeration

value 5)

vent (enumeration value 3)

To de-bounce the input signal you also might want to configure the LineDebounceFactor

register. This register controls the width of the window during which spurious transitions

from the input line are filtered out (in increments of ~480 ns). This register is 0 by default,

which means that the de-bouncing is disabled. The maximum value for this register is

65535, which corresponds to a maximum holding time of ~31 ms.

The FLIR GEV Demo 1.3 sample illustrates how to setup the event transmission. C++

source code is available in PureGEV SDK Sample.

Applicable downloads:

• Link to download PureGEV SDK Sample (source code): http://support.flir.com/

SwDownload/app/RssSWDownload.aspx?ID=133

• Link to download FLIR GEV Demo 1.3.0 (installer): http://support.flir.com/SwDownload/app/RssSWDownload.aspx?ID=155

10.2 FLIR Ax5 synchronization

The camera provides an external sync channel that can be used to synchronize the

frame start between two cameras, one configured as the master and the other configured as the slave. It can also be used to synchronize the frame start of a camera with that

of another product.

#T559770; r.18834/22369; en-US

15

Page 22

10

About I/O, synchronization, and measurement

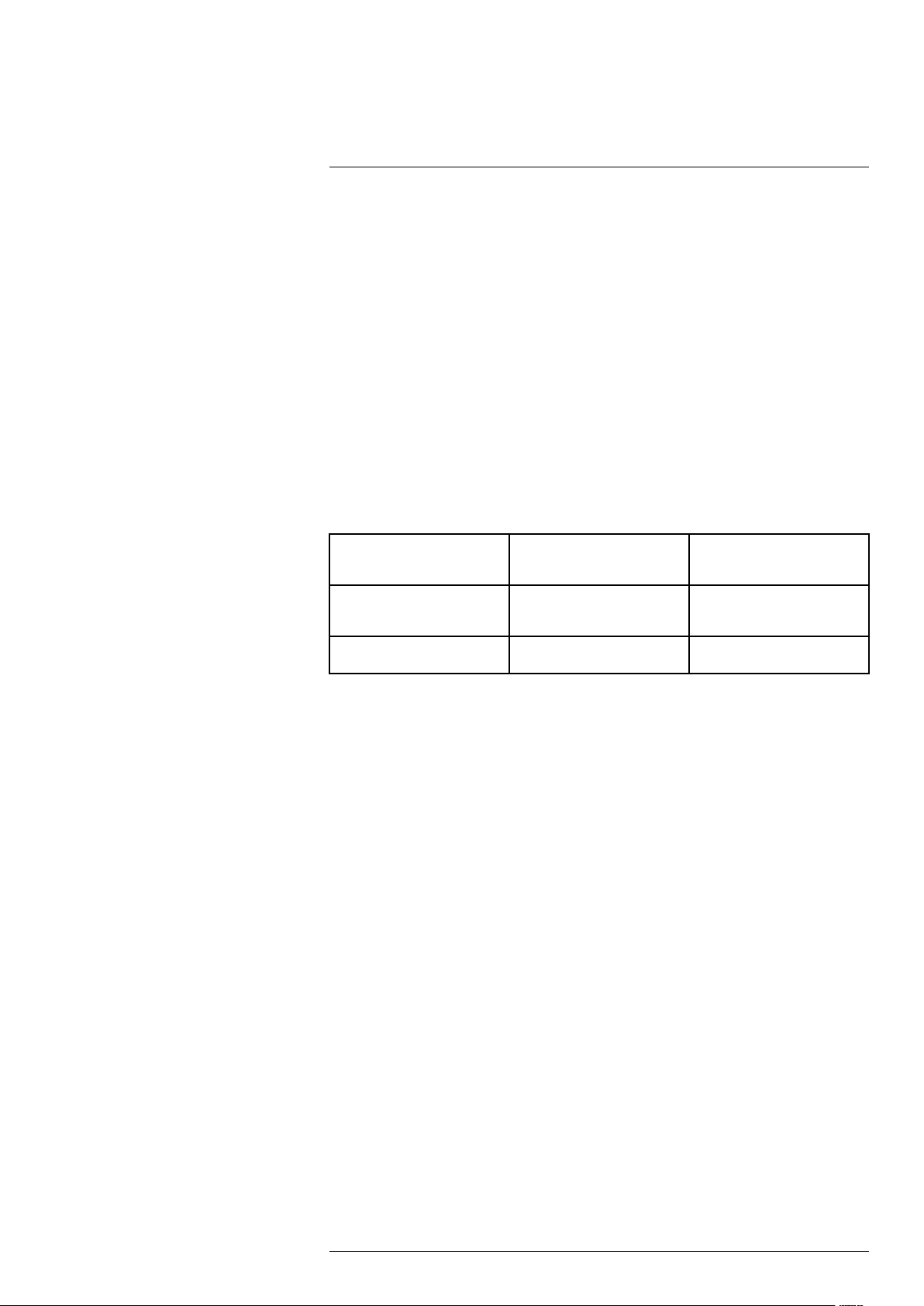

Figure 10.1 Master/slave synchronization between two FLIR Ax5 cameras (NTSC).

NOTE

External synchronization can be applied but only by using an input signal with a frequency of 29.97 Hz

(NTSC).

• The signal voltage (relative to digital GND) is 3.3 V.

• The pulse width (minimum) is 100 ns (will be extended to 1 μs).

Note that the synchronization mode is not persistent. The camera will always return to

SyncMode Disabled after reset or power cycling.

For slow configurations (9 Hz), the output frame rate is a fraction of the sync pulse rate.

Because there is ambiguity as to which received pulse triggers the frame timing, FLIR

does not recommend using the external sync interface with a slow-configured camera.

NOTE

The only difference between ExtSyncMaster and SelfSyncSlave mode is that the incoming sync signal

is relayed to the SYNC_OUT port if set to ExtSyncMaster.

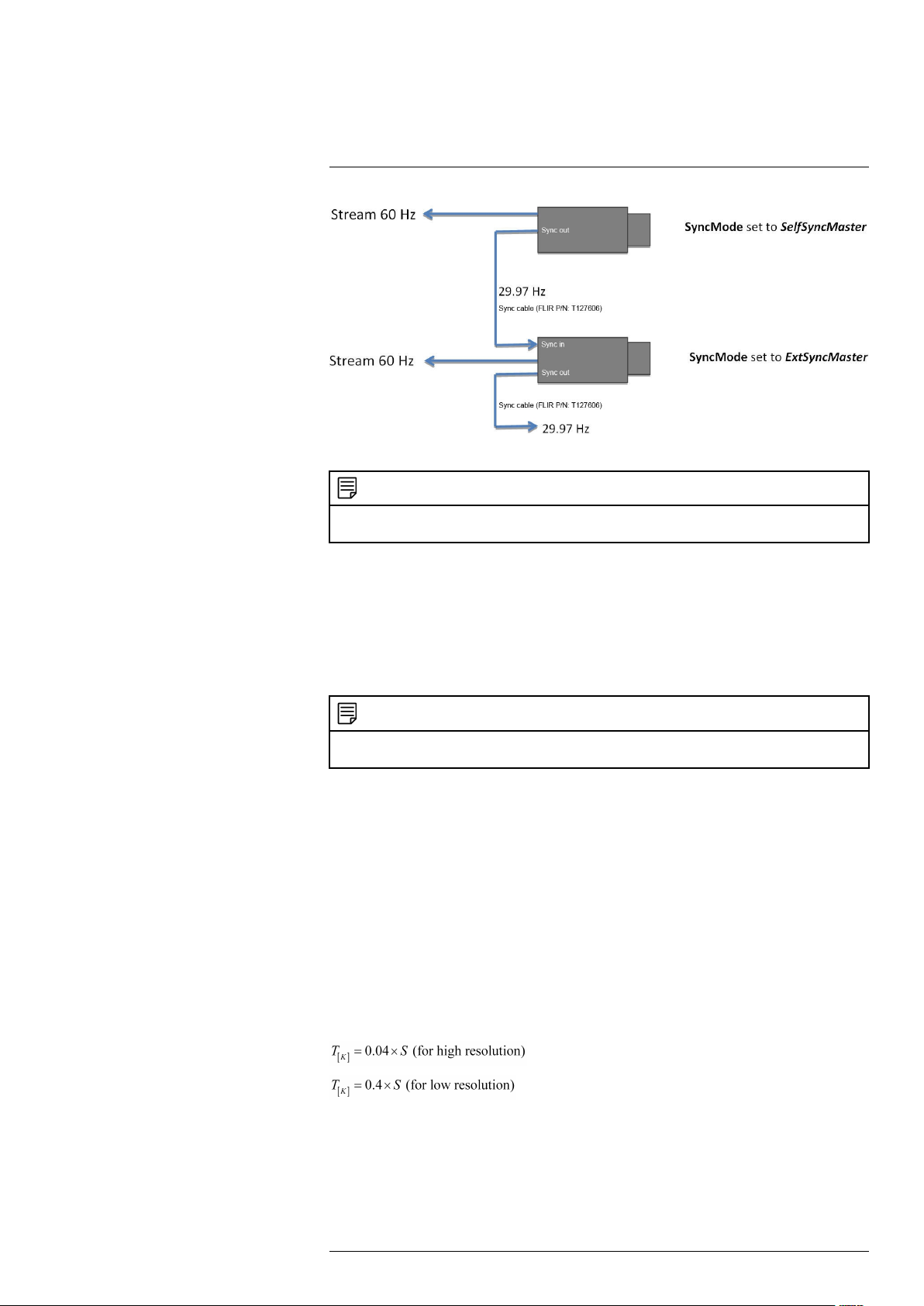

10.3 FLIR Ax5 measurement

The FLIR Ax5 camera has an option to output 14-bit digital video that is temperature

linear.

Each count in the temperature-linear video corresponds to either 0.04 K or 0.4 K in 14-bit

video, depending on the selected resolution.

Temperature-linear output is enabled or disabled with the feature register:

TemperatureLinearMode: On (1) or Off (0)

Temparture-linear resolution is determined with the feature register:

TemperatureLinearResolution: Low 0.4 K (0) or High 0.04 K (1)

If TemperatureLinearMode is On, the signal-to-temperature mapping is calculated us-

ing the equations

S corresponds to the 14-bit pixel value.

If the TemperatureLinearMode is Off, then the camera provides registers that can be

used to convert signal values to temperature. For each measurement range (or gain

mode) there is a set of register values that is used for this conversion.

#T559770; r.18834/22369; en-US

16

Page 23

10

About I/O, synchronization, and measurement

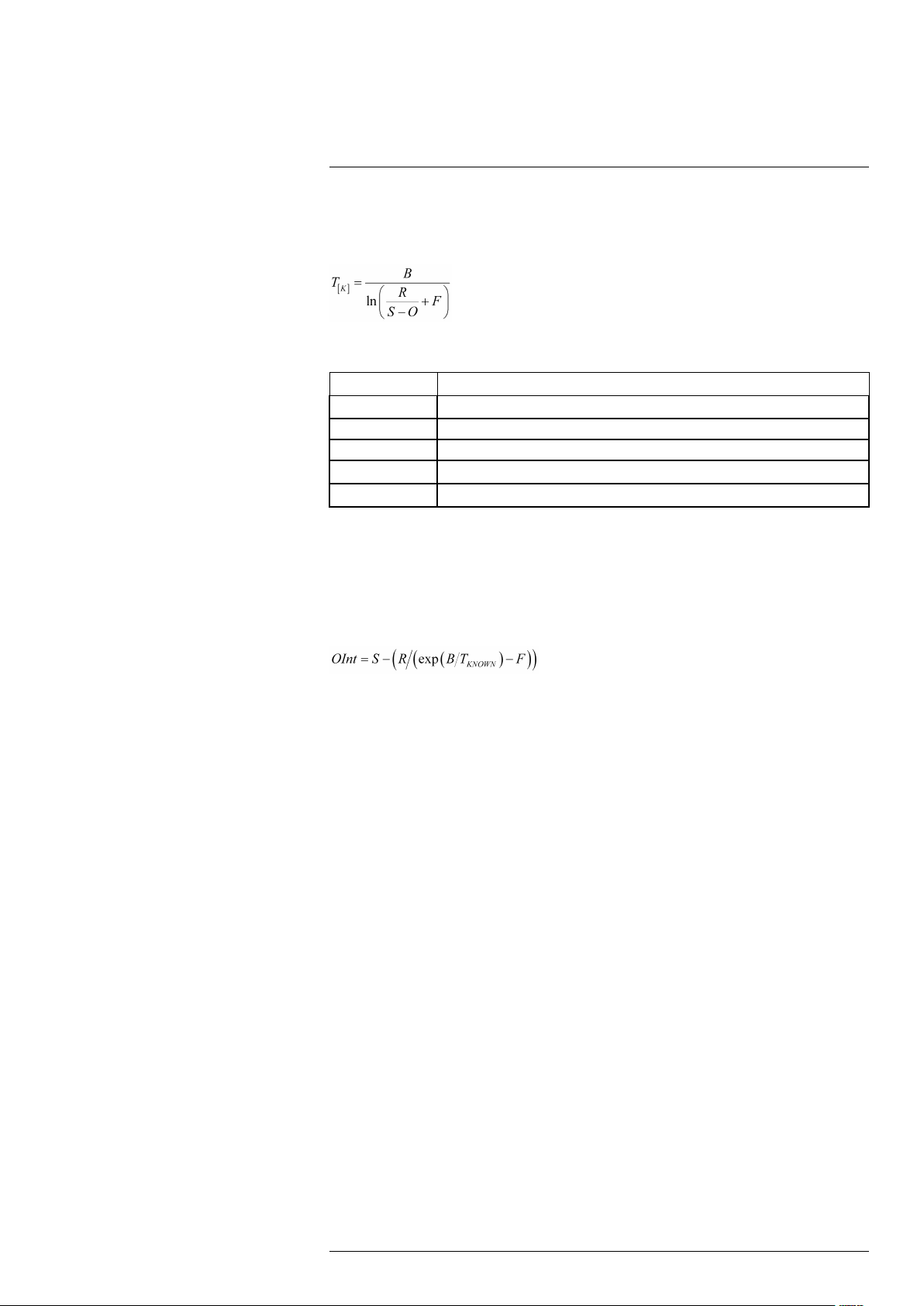

The conversion from the corrected signal S to the temperature T

is performed using

[K]

the external RBFO values for the selected lens and gain mode. The signal-to-temperature mapping is calculated using the equation

ln(x) is the base-e logarithm of the x parameter, and S corresponds to the 14-bit pixel

value.

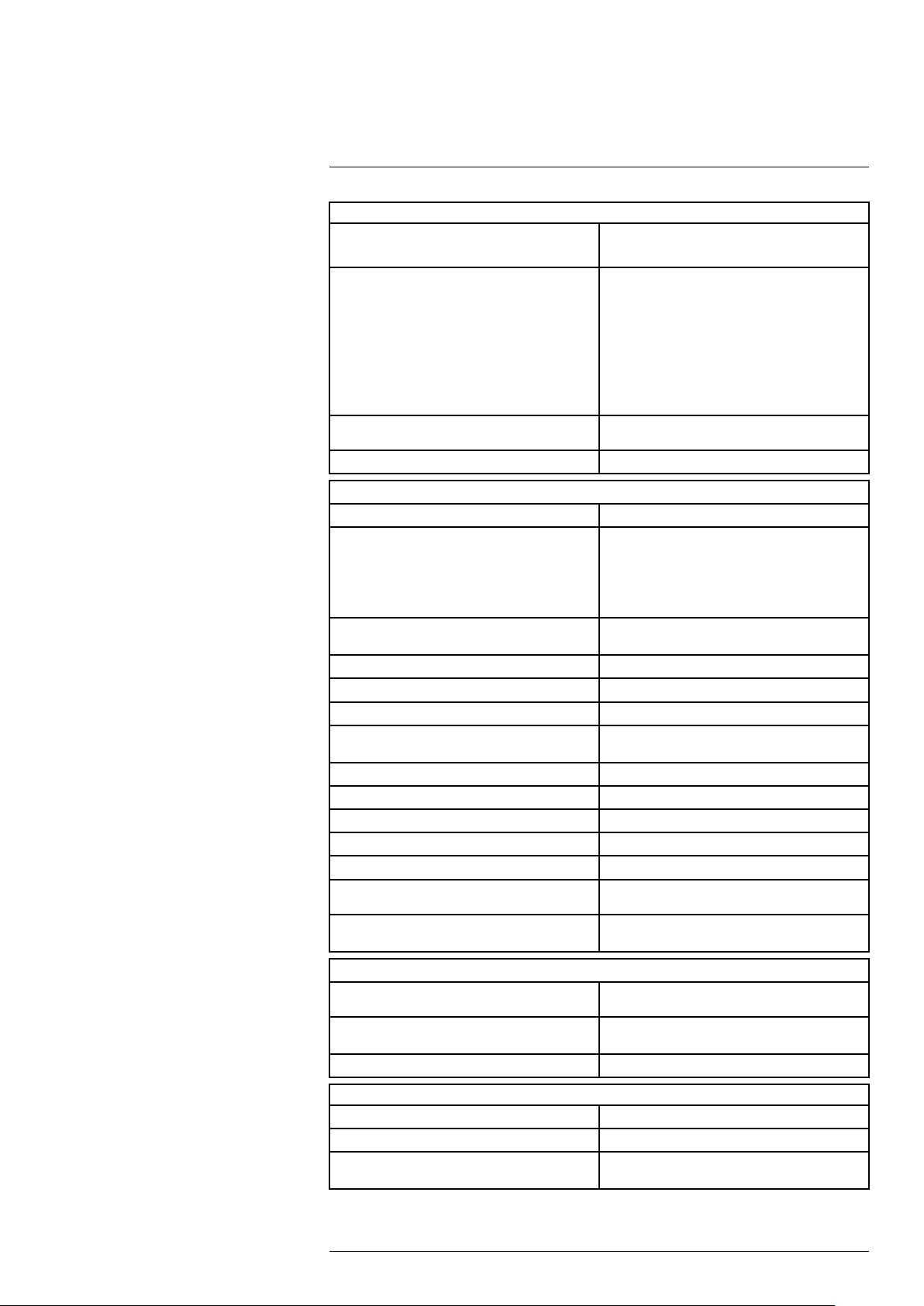

Register name Type

R Integer

B Float

F Float

O Float (handles only positive vales)

OInt Integer (same as O but handles negative values)

Please note that these registers will be automatically updated when switching between

the high gain mode and the low gain mode.

The FLIR GEV Demo sample illustrates how to use this conversion formula.

You also have the option to do your own one-point calibration by adjusting the offset val-

ue (register OInt) by pointing the camera at an accurately known temperature. Knowing

the temperature, you can then calculate the offset value and update the OInt register.

The FLIR GEV Demo sample illustrates how to perform this kind of calibration. Please

note that you will need to save the current settings if you want the new offset value to be

persistent. Use the command register SensorSetDefaults to set all current settings as

power on defaults.

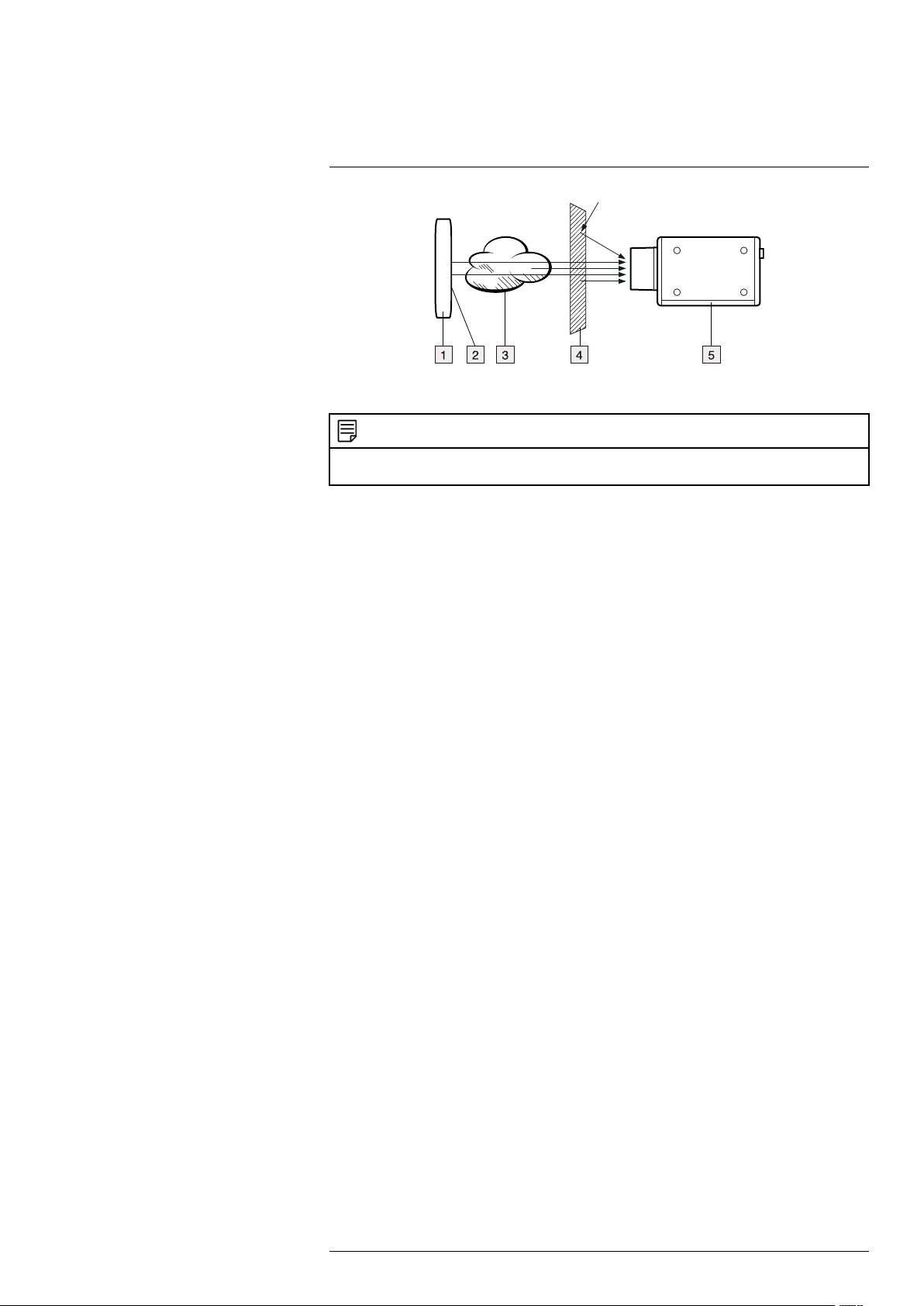

There are additional registers that also affect the temperature linear output. These registers are grouped together as Object Parameter registers. These registers only affect the

transformation of detector signal values to temperature values when the camera is in

temperature linear mode.

ReflectedTemperature: The estimated reflected background temperature for the target

scene.

ObjectEmissivity: The target scene emissivity factor. The default value is 1.0.

WindowTransmission: The estimated transmission factor for the protective window.

The default value is 1.0.

WindowTemperature: The external window temperature T

(in kelvin).

win

AtmosphericTransmission: The estimated transmission factor for the atmosphere between the camera and the scene.

AtmosphericTemperature: The estimated temperature T

for the atmosphere be-

atm

tween the camera and the scene.

The correction for scene parameters is extended to include the following parameters:

#T559770; r.18834/22369; en-US

17

Page 24

10

About I/O, synchronization, and measurement

Figure 10.2 1: Scene, T

; 5: Infrared camera.

dow, T

win

; 2: Reflected background temperature; 3: Atmosphere, T

scene

; 4: External win-

Atm

NOTE

The default values for the object parameters are set to values that will have no impact on the conversion

between detector signal values and corrected signal values.

#T559770; r.18834/22369; en-US

18

Page 25

11

Technical data

11.1 Online field-of-view calculator

Please visit http://support.flir.com and click the FLIR Ax5 camera for field-of-view tables

for all lens–camera combinations in this camera series.

11.2 Note about technical data

FLIR Systems reserves the right to change specifications at any time without prior notice.

Please check http://support.flir.com for latest changes.

#T559770; r.18834/22369; en-US

19

Page 26

Technical data11

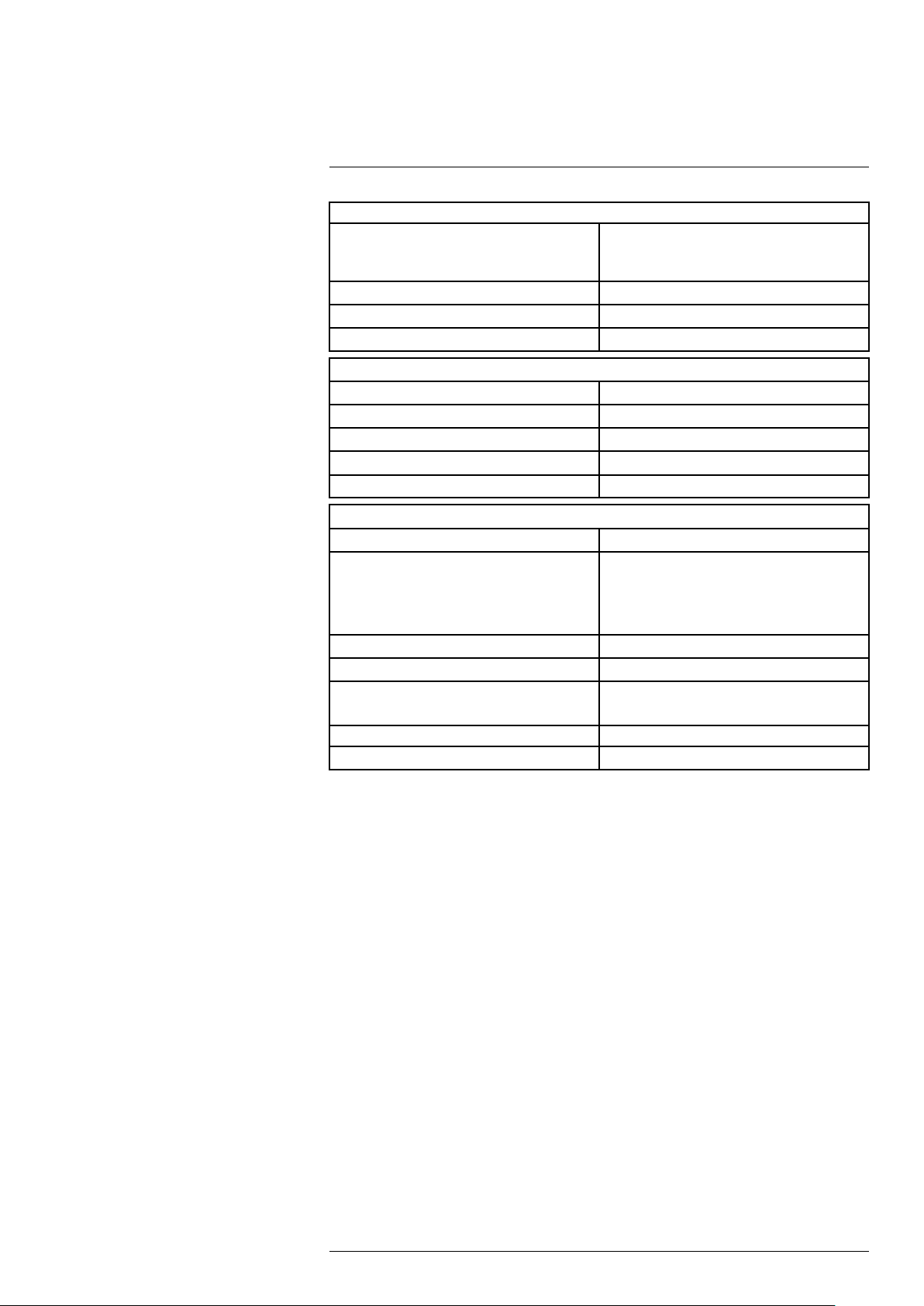

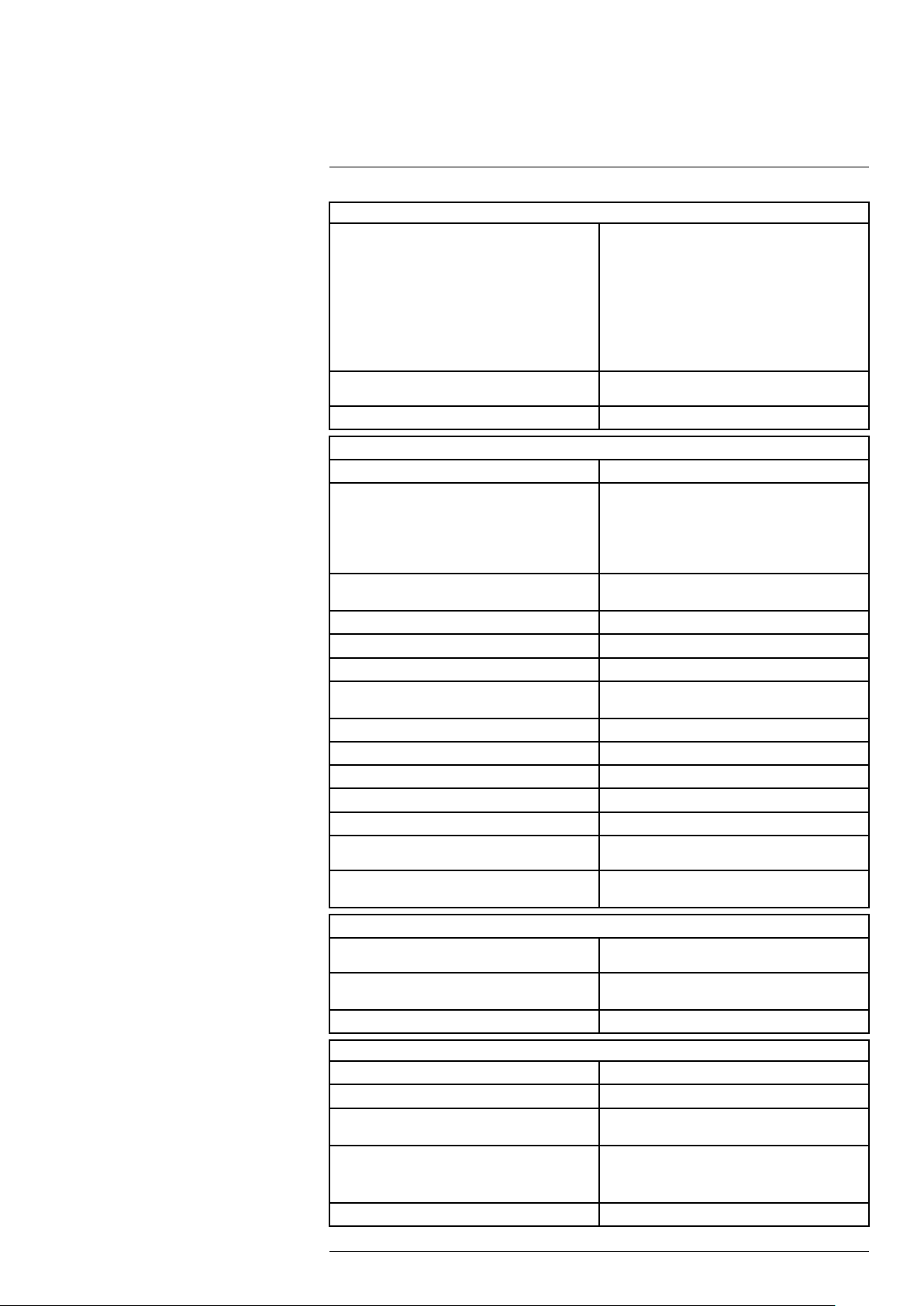

11.3 FLIR A15 f=19 mm

P/N: 62319-0101

Rev.: 22369

General description

The FLIR A15 has features and functions that make it the natural choice for anyone who uses PC software to solve problems and for whom 160 × 128 pixel resolution is sufficient.

Among its main features are GigE Vision and GenICam compliance, which makes it plug-and-play when

used with software packages such as IMAQ Vision and Halcon.

Key features:

• Very affordable.

• Compact (40 mm × 43 mm × 106 mm).

• GigE Vision and GenICam compliant.

• GigE Vision lockable connector.

• PoE (power over Ethernet).

• 8-bit 160 × 128 pixel images streamed at 60 Hz, signal linear.

• 14-bit 160 × 128 pixel images streamed at 60 Hz, signal and temperature linear.

• High frame rates (60 Hz).

• Synchronization between cameras possible.

• 1x+1x GPIO.

• Compliant with any software that supports GenICam, including National Instruments IMAQ Vision,

Stemmers Common Vision Blox, and COGNEX Vision Pro.

Typical applications:

• Automation and thermal machine vision.

• Entry level “high-speed” R&D.

Imaging and optical data

IR resolution 160 × 128 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Focal length 19 mm (0.75 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 60 Hz

Focus Fixed

Detector data

Detector type Focal Plane Array (FPA), Uncooled VOX

Spectral range

Detector pitch 50 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±5°C (±9°F) or ±5% of reading

25° × 19°

2.63 mrad

microbolometer

7.5–13 µm

• –25 to +135°C (–13 to 275°F)

• –40 to +550°C (–40 to +1022°F)

Ethernet

Ethernet Control and image

Ethernet, type Gigabit Ethernet

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

#T559770; r.18834/22369; en-US

20

Page 27

Technical data11

Ethernet

Ethernet, communication GigE Vision ver. 1.2

Client API GenICam compliant

Ethernet, image streaming 8-bit monochrome @ 60 Hz

• Signal linear/ DDE

• Automatic/ Manual

• Flip H&V

14-bit 160 × 128 pixels @ 60 Hz

• Signal linear/ DDE

• Temperature linear

GigE Vision and GenICam compatible

Ethernet, power Power over Ethernet, PoE IEEE 802.3af class 0

Ethernet, protocols TCP, UDP,ICMP, IGMP, DHCP, GigEVision

Digital input/output

Digital input, purpose General purpose

Digital input 1× opto-isolated, "0" <2, "1"=2-12 VDC. NOTE:

Digital output, purpose General purpose Output to ext. device (program-

Digital output 1× opto-isolated, 2–40 VDC, max 185 mA

Digital I/O, isolation voltage 500 VRMS

Digital I/O, supply voltage 2–40 VDC, max 200 mA

Digital I/O, connector type 12-pole M12 connector (shared with Digital Syn-

Synchronization In, purpose

Synchronization In 1×, non-isolated

Synchronization In, type LVC Buffer @3.3V, “0” <0.8 V, “1”>2.0 V.

Synchronization Out, purpose Frame sync Out to control another Ax5 camera

Synchronization Out 1×, non-isolated

Synchronization Out, type LVC Buffer @ 3.3V, ”0”=24 MA max, “1”= –24 mA

Digital Synchronization, connector type 12-pole M12 connector (shared with Digital I/O

Power

Maximum input 12 VDC. If the input is above 12

VDC without a resistor in series there is a risk of

damaging the input. If the input is 24 VDC use a

1.2 kΩ resistor in series. In that case "1" = 3-24

VDC.

matically set)

chronization and External power)

Frame sync In to control camera

max.

and External power)

Power system

External power operation 12/24 VDC, < 3.5 W nominal < 6.0 W absolute

max

External power, connector type 12-pole M12 connector (shared with Digital I/O

and Digital Synchronization )

Voltage Allowed range 10–30 VDC

Environmental data

Operating temperature range –15°C to +50°C (+5°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

to +40°C (+77°F to +104°F)

#T559770; r.18834/22369; en-US

21

Page 28

Technical data11

Environmental data

EMC

Encapsulation IP 40 (IEC 60529) with base support mounted

Shock 25 g (IEC 60068-2-27)

Vibration

Physical data

Weight 0.200 kg (0.44 lb.)

Camera size (L × W × H) 106 × 40 × 43 mm (4.2 × 1.6 × 1.7 in.)

Tripod mounting UNC ¼"-20 (on three sides)

Base mounting 4 × M3 thread mounting holes (bottom)

Housing material Magnesium and aluminum

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

2 g (IEC 60068-2-6)

Shipping information

Packaging, type

List of contents

Packaging, weight

Packaging, size 295 × 200 × 105 mm (11.6 × 7.9 × 4.1 in.)

EAN-13 7332558003992

UPC-12

Country of origin Sweden

Cardboard box

• Infrared camera with lens

• FLIR Tools download card

• Focus adjustment tool

• Printed documentation

• User documentation CD-ROM

4743254000605 (Estonia plant)

845188003555

Supplies & accessories:

• T951004ACC; Ethernet cable CAT-6, 2m/6.6 ft.

• T198349; Base support

• T198348; Cable kit Mains (UK,EU,US)

• T911112; PoE injector

• T198392; Table stand kit

• T911183; Gigabit PoE injector 16 W, with multi-plugs

• T127605ACC; Cable M12 Pigtail

• T127606ACC; Cable M12 Sync

• T198342ACC; Focus adjustment tool

• T198584; FLIR Tools

• T198583; FLIR Tools+ (license only)

• DSW-10000; FLIR IR Camera Player

#T559770; r.18834/22369; en-US

22

Page 29

Technical data11

11.4 FLIR A15 f=19 mm (7.5 Hz)

P/N: 64319-0101

Rev.: 22369

General description

The FLIR A15 has features and functions that make it the natural choice for anyone who uses PC software to solve problems and for whom 160 × 128 pixel resolution is sufficient.

Among its main features are GigE Vision and GenICam compliance, which makes it plug-and-play when

used with software packages such as IMAQ Vision and Halcon.

Key features:

• Very affordable.

• Compact (40 mm × 43 mm × 106 mm).

• GigE Vision and GenICam compliant.

• GigE Vision lockable connector.

• PoE (power over Ethernet).

• 8-bit 160 × 128 pixel images streamed at 7.5 Hz, signal linear.

• 14-bit 160 × 128 pixel images streamed at 7.5 Hz, signal and temperature linear.

• Synchronization between cameras possible.

• 1x+1x GPIO.

• Compliant with any software that supports GenICam, including National Instruments IMAQ Vision,

Stemmers Common Vision Blox, and COGNEX Vision Pro.

Typical applications:

• Automation and thermal machine vision.

• Entry level “high-speed” R&D.

Imaging and optical data

IR resolution 160 × 128 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Focal length 19 mm (0.75 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 7.5 Hz

Focus Fixed

Detector data

Detector type

Spectral range

Detector pitch 50 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±5°C (±9°F) or ±5% of reading

25° × 19°

2.63 mrad

Focal Plane Array (FPA), Uncooled VOX

microbolometer

7.5–13 µm

• –25 to +135°C (–13 to 275°F)

• –40 to +550°C (–40 to +1022°F)

Ethernet

Ethernet Control and image

Ethernet, type

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

Ethernet, communication GigE Vision ver. 1.2

#T559770; r.18834/22369; en-US

Gigabit Ethernet

Client API GenICam compliant

23

Page 30

Technical data11

Ethernet

Ethernet, image streaming 8-bit monochrome @ 7.5 Hz

• Signal linear/ DDE

• Automatic/ Manual

• Flip H&V

14-bit 160 × 128 pixels @ 7.5 Hz

• Signal linear/ DDE

• Temperature linear

GigE Vision and GenICam compatible

Ethernet, power Power over Ethernet, PoE IEEE 802.3af class 0

Ethernet, protocols

Digital input/output

Digital input, purpose

Digital input

Digital output, purpose

Digital output

Digital I/O, isolation voltage 500 VRMS

Digital I/O, supply voltage 2–40 VDC, max 200 mA

Digital I/O, connector type 12-pole M12 connector (shared with Digital Syn-

Synchronization In, purpose Frame sync In to control camera

Synchronization In 1×, non-isolated

Synchronization In, type LVC Buffer @3.3V, “0” <0.8 V, “1”>2.0 V.

Synchronization Out, purpose Frame sync Out to control another Ax5 camera

Synchronization Out

Synchronization Out, type LVC Buffer @ 3.3V, ”0”=24 MA max, “1”= –24 mA

Digital Synchronization, connector type 12-pole M12 connector (shared with Digital I/O

Power

TCP, UDP,ICMP, IGMP, DHCP, GigEVision

General purpose

1× opto-isolated, "0" <2, "1"=2-12 VDC. NOTE:

Maximum input 12 VDC. If the input is above 12

VDC without a resistor in series there is a risk of

damaging the input. If the input is 24 VDC use a

1.2 kΩ resistor in series. In that case "1" = 3-24

VDC.

General purpose Output to ext. device (programmatically set)

1× opto-isolated, 2–40 VDC, max 185 mA

chronization and External power)

1×, non-isolated

max.

and External power)

Power system

External power operation 12/24 VDC, < 3.5 W nominal < 6.0 W absolute

External power, connector type 12-pole M12 connector (shared with Digital I/O

Voltage

Environmental data

Operating temperature range –15°C to +50°C (+5°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

EMC

Encapsulation IP 40 (IEC 60529) with base support mounted

#T559770; r.18834/22369; en-US

max

and Digital Synchronization )

Allowed range 10–30 VDC

to +40°C (+77°F to +104°F)

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

24

Page 31

Technical data11

Environmental data

Shock 25 g (IEC 60068-2-27)

Vibration 2 g (IEC 60068-2-6)

Physical data

Weight 0.200 kg (0.44 lb.)

Camera size (L × W × H) 106 × 40 × 43 mm (4.2 × 1.6 × 1.7 in.)

Tripod mounting UNC ¼"-20 (on three sides)

Base mounting 4 × M3 thread mounting holes (bottom)

Housing material Magnesium and aluminum

Shipping information

Packaging, type Cardboard box

List of contents

Packaging, weight

Packaging, size 295 × 200 × 105 mm (11.6 × 7.9 × 4.1 in.)

EAN-13 7332558005668

UPC-12

Country of origin Sweden

• Infrared camera with lens

• FLIR Tools download card

• Focus adjustment tool

• Printed documentation

• User documentation CD-ROM

845188005870

Supplies & accessories:

• T951004ACC; Ethernet cable CAT-6, 2m/6.6 ft.

• T198349; Base support

• T198348; Cable kit Mains (UK,EU,US)

• T911112; PoE injector

• T198392; Table stand kit

• T911183; Gigabit PoE injector 16 W, with multi-plugs

• T127605ACC; Cable M12 Pigtail

• T127606ACC; Cable M12 Sync

• T198342ACC; Focus adjustment tool

• T198584; FLIR Tools

• T198583; FLIR Tools+ (license only)

• DSW-10000; FLIR IR Camera Player

#T559770; r.18834/22369; en-US

25

Page 32

Technical data11

11.5 FLIR A15 f=9 mm

P/N: 62309-0101

Rev.: 22369

General description

The FLIR A15 has features and functions that make it the natural choice for anyone who uses PC software to solve problems and for whom 160 × 128 pixel resolution is sufficient.

Among its main features are GigE Vision and GenICam compliance, which makes it plug-and-play when

used with software packages such as IMAQ Vision and Halcon.

Key features:

• Very affordable.

• Compact (40 mm × 43 mm × 106 mm).

• GigE Vision and GenICam compliant.

• GigE Vision lockable connector.

• PoE (power over Ethernet).

• 8-bit 160 × 128 pixel images streamed at 60 Hz, signal linear.

• 14-bit 160 × 128 pixel images streamed at 60 Hz, signal and temperature linear.

• High frame rates (60 Hz).

• Synchronization between cameras possible.

• 1x+1x GPIO.

• Compliant with any software that supports GenICam, including National Instruments IMAQ Vision,

Stemmers Common Vision Blox, and COGNEX Vision Pro.

Typical applications:

• Automation and thermal machine vision.

• Entry level “high-speed” R&D.

Imaging and optical data

IR resolution 160 × 128 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Focal length 9 mm (0.35 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 60 Hz

Focus Fixed

Detector data

Detector type Focal Plane Array (FPA), Uncooled VOX

Spectral range

Detector pitch 50 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±5°C (±9°F) or ±5% of reading

48° × 39°

5.56 mrad

microbolometer

7.5–13 µm

• –25 to +135°C (–13 to 275°F)

• –40 to +550°C (–40 to +1022°F)

Ethernet

Ethernet Control and image

Ethernet, type Gigabit Ethernet

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

#T559770; r.18834/22369; en-US

26

Page 33

Technical data11

Ethernet

Ethernet, communication GigE Vision ver. 1.2

Client API GenICam compliant

Ethernet, image streaming 8-bit monochrome @ 60 Hz

• Signal linear/ DDE

• Automatic/ Manual

• Flip H&V

14-bit 160 × 128 pixels @ 60 Hz

• Signal linear/ DDE

• Temperature linear

GigE Vision and GenICam compatible

Ethernet, power Power over Ethernet, PoE IEEE 802.3af class 0

Ethernet, protocols TCP, UDP,ICMP, IGMP, DHCP, GigEVision

Digital input/output

Digital input, purpose General purpose

Digital input 1× opto-isolated, "0" <2, "1"=2-12 VDC. NOTE:

Digital output, purpose General purpose Output to ext. device (program-

Digital output 1× opto-isolated, 2–40 VDC, max 185 mA

Digital I/O, isolation voltage 500 VRMS

Digital I/O, supply voltage 2–40 VDC, max 200 mA

Digital I/O, connector type 12-pole M12 connector (shared with Digital Syn-

Synchronization In, purpose

Synchronization In 1×, non-isolated

Synchronization In, type LVC Buffer @3.3V, “0” <0.8 V, “1”>2.0 V.

Synchronization Out, purpose Frame sync Out to control another Ax5 camera

Synchronization Out 1×, non-isolated

Synchronization Out, type LVC Buffer @ 3.3V, ”0”=24 MA max, “1”= –24 mA

Digital Synchronization, connector type 12-pole M12 connector (shared with Digital I/O

Power

Maximum input 12 VDC. If the input is above 12

VDC without a resistor in series there is a risk of

damaging the input. If the input is 24 VDC use a

1.2 kΩ resistor in series. In that case "1" = 3-24

VDC.

matically set)

chronization and External power)

Frame sync In to control camera

max.

and External power)

Power system

External power operation 12/24 VDC, < 3.5 W nominal < 6.0 W absolute

max

External power, connector type 12-pole M12 connector (shared with Digital I/O

and Digital Synchronization )

Voltage Allowed range 10–30 VDC

Environmental data

Operating temperature range –15°C to +50°C (+5°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

to +40°C (+77°F to +104°F)

#T559770; r.18834/22369; en-US

27

Page 34

Technical data11

Environmental data

EMC

Encapsulation IP 40 (IEC 60529) with base support mounted

Shock 25 g (IEC 60068-2-27)

Vibration

Physical data

Weight 0.200 kg (0.44 lb.)

Camera size (L × W × H) 106 × 40 × 43 mm (4.2 × 1.6 × 1.7 in.)

Tripod mounting UNC ¼"-20 (on three sides)

Base mounting 4 × M3 thread mounting holes (bottom)

Housing material Magnesium and aluminum

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

2 g (IEC 60068-2-6)

Shipping information

Packaging, type

List of contents

Packaging, weight

Packaging, size 295 × 200 × 105 mm (11.6 × 7.9 × 4.1 in.)

EAN-13 7332558003978

UPC-12

Country of origin Sweden

Cardboard box

• Infrared camera with lens

• FLIR Tools download card

• Focus adjustment tool

• Printed documentation

• User documentation CD-ROM

4743254000599 (Estonia plant)

845188003548

Supplies & accessories:

• T951004ACC; Ethernet cable CAT-6, 2m/6.6 ft.

• T198349; Base support

• T198348; Cable kit Mains (UK,EU,US)

• T911112; PoE injector

• T198392; Table stand kit

• T911183; Gigabit PoE injector 16 W, with multi-plugs

• T127605ACC; Cable M12 Pigtail

• T127606ACC; Cable M12 Sync

• T198342ACC; Focus adjustment tool

• T198584; FLIR Tools

• T198583; FLIR Tools+ (license only)

• DSW-10000; FLIR IR Camera Player

#T559770; r.18834/22369; en-US

28

Page 35

Technical data11

11.6 FLIR A15 f=9 mm (7.5 Hz)

P/N: 64309-0101

Rev.: 22369

General description

The FLIR A15 has features and functions that make it the natural choice for anyone who uses PC software to solve problems and for whom 160 × 128 pixel resolution is sufficient.

Among its main features are GigE Vision and GenICam compliance, which makes it plug-and-play when

used with software packages such as IMAQ Vision and Halcon.

Key features:

• Very affordable.

• Compact (40 mm × 43 mm × 106 mm).

• GigE Vision and GenICam compliant.

• GigE Vision lockable connector.

• PoE (power over Ethernet).

• 8-bit 160 × 128 pixel images streamed at 7.5 Hz, signal linear.

• 14-bit 160 × 128 pixel images streamed at 7.5 Hz, signal and temperature linear.

• Synchronization between cameras possible.

• 1x+1x GPIO.

• Compliant with any software that supports GenICam, including National Instruments IMAQ Vision,

Stemmers Common Vision Blox, and COGNEX Vision Pro.

Typical applications:

• Automation and thermal machine vision.

• Entry level “high-speed” R&D.

Imaging and optical data

IR resolution 160 × 128 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Focal length 9 mm (0.35 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 7.5 Hz

Focus Fixed

Detector data

Detector type

Spectral range

Detector pitch 50 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±5°C (±9°F) or ±5% of reading

48° × 39°

5.56 mrad

Focal Plane Array (FPA), Uncooled VOX

microbolometer

7.5–13 µm

• –25 to +135°C (–13 to 275°F)

• –40 to +550°C (–40 to +1022°F)

Ethernet

Ethernet Control and image

Ethernet, type

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

Ethernet, communication GigE Vision ver. 1.2

#T559770; r.18834/22369; en-US

Gigabit Ethernet

Client API GenICam compliant

29

Page 36

Technical data11

Ethernet

Ethernet, image streaming 8-bit monochrome @ 7.5 Hz

• Signal linear/ DDE

• Automatic/ Manual

• Flip H&V

14-bit 160 × 128 pixels @ 7.5 Hz

• Signal linear/ DDE

• Temperature linear

GigE Vision and GenICam compatible

Ethernet, power Power over Ethernet, PoE IEEE 802.3af class 0

Ethernet, protocols

Digital input/output

Digital input, purpose

Digital input

Digital output, purpose

Digital output

Digital I/O, isolation voltage 500 VRMS

Digital I/O, supply voltage 2–40 VDC, max 200 mA

Digital I/O, connector type 12-pole M12 connector (shared with Digital Syn-

Synchronization In, purpose Frame sync In to control camera

Synchronization In 1×, non-isolated

Synchronization In, type LVC Buffer @3.3V, “0” <0.8 V, “1”>2.0 V.

Synchronization Out, purpose Frame sync Out to control another Ax5 camera

Synchronization Out

Synchronization Out, type LVC Buffer @ 3.3V, ”0”=24 MA max, “1”= –24 mA

Digital Synchronization, connector type 12-pole M12 connector (shared with Digital I/O

Power

TCP, UDP,ICMP, IGMP, DHCP, GigEVision

General purpose

1× opto-isolated, "0" <2, "1"=2-12 VDC. NOTE:

Maximum input 12 VDC. If the input is above 12

VDC without a resistor in series there is a risk of

damaging the input. If the input is 24 VDC use a

1.2 kΩ resistor in series. In that case "1" = 3-24

VDC.

General purpose Output to ext. device (programmatically set)

1× opto-isolated, 2–40 VDC, max 185 mA

chronization and External power)

1×, non-isolated

max.

and External power)

Power system

External power operation 12/24 VDC, < 3.5 W nominal < 6.0 W absolute

External power, connector type 12-pole M12 connector (shared with Digital I/O

Voltage

Environmental data

Operating temperature range –15°C to +50°C (+5°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

EMC

Encapsulation IP 40 (IEC 60529) with base support mounted

#T559770; r.18834/22369; en-US

max

and Digital Synchronization )

Allowed range 10–30 VDC

to +40°C (+77°F to +104°F)

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

30

Page 37

Technical data11

Environmental data

Shock 25 g (IEC 60068-2-27)

Vibration 2 g (IEC 60068-2-6)

Physical data

Weight 0.200 kg (0.44 lb.)

Camera size (L × W × H) 106 × 40 × 43 mm (4.2 × 1.6 × 1.7 in.)

Tripod mounting UNC ¼"-20 (on three sides)

Base mounting 4 × M3 thread mounting holes (bottom)

Housing material Magnesium and aluminum

Shipping information

Packaging, type Cardboard box

List of contents

Packaging, weight

Packaging, size 295 × 200 × 105 mm (11.6 × 7.9 × 4.1 in.)

EAN-13 7332558005644

UPC-12

Country of origin Sweden

• Infrared camera with lens

• FLIR Tools download card

• Focus adjustment tool

• Printed documentation

• User documentation CD-ROM

845188005856

Supplies & accessories:

• T951004ACC; Ethernet cable CAT-6, 2m/6.6 ft.

• T198349; Base support

• T198348; Cable kit Mains (UK,EU,US)

• T911112; PoE injector

• T198392; Table stand kit

• T911183; Gigabit PoE injector 16 W, with multi-plugs

• T127605ACC; Cable M12 Pigtail

• T127606ACC; Cable M12 Sync

• T198342ACC; Focus adjustment tool

• T198584; FLIR Tools

• T198583; FLIR Tools+ (license only)

• DSW-10000; FLIR IR Camera Player

#T559770; r.18834/22369; en-US

31

Page 38

Technical data11

11.7 FLIR A15 f=9 mm with SC kit

P/N: 62309-0102

Rev.: 22369

General description

The FLIR A15 has features and functions that make it the natural choice for anyone who uses PC software to solve problems and for whom 160 × 128 pixel resolution is sufficient.

Among its main features are GigE Vision and GenICam compliance, which makes it plug-and-play when

used with software packages such as IMAQ Vision and Halcon.

Key features:

• Very affordable.

• Compact (40 mm × 43 mm × 106 mm).

• GigE Vision and GenICam compliant.

• GigE Vision lockable connector.

• PoE (power over Ethernet).

• 8-bit 160 × 128 pixel images streamed at 60 Hz, signal linear.

• 14-bit 160 × 128 pixel images streamed at 60 Hz, signal and temperature linear.

• High frame rates (60 Hz).

• Synchronization between cameras possible.

• 1x+1x GPIO.

• Compliant with any software that supports GenICam, including National Instruments IMAQ Vision,

Stemmers Common Vision Blox, and COGNEX Vision Pro.

Typical applications:

• Automation and thermal machine vision.

• Entry level “high-speed” R&D.

Imaging and optical data

IR resolution 160 × 128 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Focal length 9 mm (0.35 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 60 Hz

Focus Fixed

Detector data

Detector type Focal Plane Array (FPA), Uncooled VOX

Spectral range

Detector pitch 50 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±5°C (±9°F) or ±5% of reading

48° × 39°

5.56 mrad

microbolometer

7.5–13 µm

• –25 to +135°C (–13 to 275°F)

• –40 to +550°C (–40 to +1022°F)

Ethernet

Ethernet Control and image

Ethernet, type Gigabit Ethernet

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

#T559770; r.18834/22369; en-US

32

Page 39

Technical data11

Ethernet

Ethernet, communication GigE Vision ver. 1.2

Client API GenICam compliant

Ethernet, image streaming 8-bit monochrome @ 60 Hz

• Signal linear/ DDE

• Automatic/ Manual

• Flip H&V

14-bit 160 × 128 pixels @ 60 Hz

• Signal linear/ DDE

• Temperature linear

GigE Vision and GenICam compatible

Ethernet, power Power over Ethernet, PoE IEEE 802.3af class 0

Ethernet, protocols TCP, UDP,ICMP, IGMP, DHCP, GigEVision

Digital input/output

Digital input, purpose General purpose

Digital input 1× opto-isolated, "0" <2, "1"=2-12 VDC. NOTE:

Digital output, purpose General purpose Output to ext. device (program-

Digital output 1× opto-isolated, 2–40 VDC, max 185 mA

Digital I/O, isolation voltage 500 VRMS

Digital I/O, supply voltage 2–40 VDC, max 200 mA

Digital I/O, connector type 12-pole M12 connector (shared with Digital Syn-

Synchronization In, purpose

Synchronization In 1×, non-isolated

Synchronization In, type LVC Buffer @3.3V, “0” <0.8 V, “1”>2.0 V.

Synchronization Out, purpose Frame sync Out to control another Ax5 camera

Synchronization Out 1×, non-isolated

Synchronization Out, type LVC Buffer @ 3.3V, ”0”=24 MA max, “1”= –24 mA

Digital Synchronization, connector type 12-pole M12 connector (shared with Digital I/O

Power

Maximum input 12 VDC. If the input is above 12

VDC without a resistor in series there is a risk of

damaging the input. If the input is 24 VDC use a

1.2 kΩ resistor in series. In that case "1" = 3-24

VDC.

matically set)

chronization and External power)

Frame sync In to control camera

max.

and External power)

Power system

External power operation 12/24 VDC, < 3.5 W nominal < 6.0 W absolute

max

External power, connector type 12-pole M12 connector (shared with Digital I/O

and Digital Synchronization )

Voltage Allowed range 10–30 VDC

Environmental data

Operating temperature range –15°C to +50°C (+5°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

to +40°C (+77°F to +104°F)

#T559770; r.18834/22369; en-US

33

Page 40

Technical data11

Environmental data

EMC

Encapsulation IP 40 (IEC 60529) with base support mounted

Shock 25 g (IEC 60068-2-27)

Vibration

Physical data

Weight 0.200 kg (0.44 lb.)

Camera size (L × W × H) 106 × 40 × 43 mm (4.2 × 1.6 × 1.7 in.)

Tripod mounting UNC ¼"-20 (on three sides)

Base mounting 4 × M3 thread mounting holes (bottom)

Housing material Magnesium and aluminum

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

2 g (IEC 60068-2-6)

Shipping information

Packaging, type

List of contents

Packaging, weight

Packaging, size 370 × 180 × 320 mm (14.6 × 7.1 × 12.6 in.)

EAN-13 7332558003985

UPC-12

Country of origin Sweden

Cardboard box

• Hard transport case

• Infrared camera with lens

• Base support

• Cable tie (2 ea.)

• Ethernet cable CAT-6, 2m/6.6 ft (2 ea.)

• FLIR ResearchIR Standard 4

• Focus adjustment tool

• Gooseneck

• Mains cable kit (UK,EU,US)

• PoE Injector (power over Ethernet)

• Printed documentation

• Table stand

• User documentation CD-ROM

4743254000612 (Estonia plant)

845188003562

Supplies & accessories:

• T951004ACC; Ethernet cable CAT-6, 2m/6.6 ft.

• T198349; Base support

• T198348; Cable kit Mains (UK,EU,US)

• T911112; PoE injector

• T198371; Transport case Ax5

• T198392; Table stand kit

• T911183; Gigabit PoE injector 16 W, with multi-plugs

• T127605ACC; Cable M12 Pigtail

• T127606ACC; Cable M12 Sync

• T198342ACC; Focus adjustment tool

• T198584; FLIR Tools

• T198583; FLIR Tools+ (license only)

• DSW-10000; FLIR IR Camera Player

#T559770; r.18834/22369; en-US

34

Page 41

Technical data11

11.8 FLIR A15 f=9 mm with SC kit (7.5 Hz)

P/N: 64309-0102

Rev.: 22369

General description

The FLIR A15 has features and functions that make it the natural choice for anyone who uses PC software to solve problems and for whom 160 × 128 pixel resolution is sufficient.

Among its main features are GigE Vision and GenICam compliance, which makes it plug-and-play when

used with software packages such as IMAQ Vision and Halcon.

Key features:

• Very affordable.

• Compact (40 mm × 43 mm × 106 mm).

• GigE Vision and GenICam compliant.

• GigE Vision lockable connector.

• PoE (power over Ethernet).

• 8-bit 160 × 128 pixel images streamed at 7.5 Hz, signal linear.

• 14-bit 160 × 128 pixel images streamed at 7.5 Hz, signal and temperature linear.

• Synchronization between cameras possible.

• 1x+1x GPIO.

• Compliant with any software that supports GenICam, including National Instruments IMAQ Vision,

Stemmers Common Vision Blox, and COGNEX Vision Pro.

Typical applications:

• Automation and thermal machine vision.

• Entry level “high-speed” R&D.

Imaging and optical data

IR resolution 160 × 128 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Focal length 9 mm (0.35 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 7.5 Hz

Focus Fixed

Detector data

Detector type

Spectral range

Detector pitch 50 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±5°C (±9°F) or ±5% of reading

48° × 39°

5.56 mrad

Focal Plane Array (FPA), Uncooled VOX

microbolometer

7.5–13 µm

• –25 to +135°C (–13 to 275°F)

• –40 to +550°C (–40 to +1022°F)

Ethernet

Ethernet Control and image

Ethernet, type

Ethernet, standard IEEE 802.3

Ethernet, connector type RJ-45

Ethernet, communication GigE Vision ver. 1.2

#T559770; r.18834/22369; en-US

Gigabit Ethernet

Client API GenICam compliant

35

Page 42

Technical data11

Ethernet

Ethernet, image streaming 8-bit monochrome @ 7.5 Hz

• Signal linear/ DDE

• Automatic/ Manual

• Flip H&V

14-bit 160 × 128 pixels @ 7.5 Hz

• Signal linear/ DDE

• Temperature linear

GigE Vision and GenICam compatible

Ethernet, power Power over Ethernet, PoE IEEE 802.3af class 0

Ethernet, protocols

Digital input/output

Digital input, purpose

Digital input

Digital output, purpose

Digital output

Digital I/O, isolation voltage 500 VRMS

Digital I/O, supply voltage 2–40 VDC, max 200 mA

Digital I/O, connector type 12-pole M12 connector (shared with Digital Syn-

Synchronization In, purpose Frame sync In to control camera

Synchronization In 1×, non-isolated

Synchronization In, type LVC Buffer @3.3V, “0” <0.8 V, “1”>2.0 V.

Synchronization Out, purpose Frame sync Out to control another Ax5 camera

Synchronization Out

Synchronization Out, type LVC Buffer @ 3.3V, ”0”=24 MA max, “1”= –24 mA

Digital Synchronization, connector type 12-pole M12 connector (shared with Digital I/O

Power

TCP, UDP,ICMP, IGMP, DHCP, GigEVision

General purpose

1× opto-isolated, "0" <2, "1"=2-12 VDC. NOTE:

Maximum input 12 VDC. If the input is above 12

VDC without a resistor in series there is a risk of

damaging the input. If the input is 24 VDC use a

1.2 kΩ resistor in series. In that case "1" = 3-24

VDC.

General purpose Output to ext. device (programmatically set)

1× opto-isolated, 2–40 VDC, max 185 mA

chronization and External power)

1×, non-isolated

max.

and External power)

Power system

External power operation 12/24 VDC, < 3.5 W nominal < 6.0 W absolute

External power, connector type 12-pole M12 connector (shared with Digital I/O

Voltage

Environmental data

Operating temperature range –15°C to +50°C (+5°F to +122°F)

Storage temperature range –40°C to +70°C (–40°F to +158°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

EMC

Encapsulation IP 40 (IEC 60529) with base support mounted

#T559770; r.18834/22369; en-US

max

and Digital Synchronization )

Allowed range 10–30 VDC

to +40°C (+77°F to +104°F)

• EN 61000-6-2 (Immunity)

• EN 61000-6-3 (Emission)

• FCC 47 CFR Part 15 Class B (Emission)

36

Page 43

Technical data11

Environmental data

Shock 25 g (IEC 60068-2-27)

Vibration 2 g (IEC 60068-2-6)

Physical data

Weight 0.200 kg (0.44 lb.)

Camera size (L × W × H) 106 × 40 × 43 mm (4.2 × 1.6 × 1.7 in.)

Tripod mounting UNC ¼"-20 (on three sides)

Base mounting 4 × M3 thread mounting holes (bottom)