Page 1

IR Automation Guidebook:

Temperature Monitoring and Control

with IR Cameras

$29.95

Page 2

Page 3

IR Automation Guidebook:

Temperature Monitoring and Control

with IR Cameras

Page 4

ii

The thoughts, ideas, opinions, and recommendations

expressed in this book are intended for informational

purposes only. FLIR accepts no liability for actions taken by

readers in their individual businesses or circumstances.

Published by FLIR Systems Incorporated

This booklet may not be reproduced in any form without

the permission in writing from FLIR Systems Incorporated.

www.goinfrared.com • 1 800 GO-INFRA

© Copyright 2008. All rights reserved.

USA, Canada and Latin America

FLIR Systems Incorporated

America’s Main Oce, USA

Boston, MA

1-800-GO-INFRA (464-6372) or

1-978-901-8000

Europe, Middle East, Asia and Africa

FLIR Systems

International Main Oce, Sweden

Tel: +32 3 287 87 10

Page 5

iii

Contents

Preface iv

Chapter 1

Typical Monitoring and Control Applications 1

Chapter 2

Remote IR Monitoring 5

Chapter 3

Temperature Measurement

for Automated Processes 17

Chapter 4

Combining Machine Vision

and Temperature Measurement 25

Chapter 5

Real-Time Control Issues 32

Appendix A

Glossary 40

Appendix B

Thermographic Measurement Techniques 43

Appendix C

History and Theory of Infrared Technology 45

Appendix D

Command Syntax Examples

for A320 Resource Socket Services 58

Appendix E

Quick Summary of

FLIR IR Cameras

Inside Back Cover

Page 6

iv

Preface

Manufacturing and process engineers

are under constant pressure to make

production systems and processes more

ecient and less costly. Frequently, their

solutions use automation techniques to

improve throughput and product quality.

Automated IR (infrared) radiation imaging

oers the potential for improving a host

of industrial production applications,

including process monitoring and

control, quality assurance, asset

management, and machine condition

monitoring.

This handbook is intended to help those

considering the creation or improvement

of production automation or monitoring

systems with IR cameras. Numerous

application examples will be presented

with explanations of how these IR vision

systems can best be implemented.

Some of the major topics that will be

covered include:

Integration of IR cameras into •

automation systems

Data communications interfaces•

Command and control of •

thermographic cameras

Principles of thermographic •

measurements

Interfacing with a PC or PLC controller•

Standard software packages for IR •

camera systems

These complex matters require attention

to many details; therefore, this handbook

cannot answer every question a system

designer will have about the use of

IR cameras in automated systems. It

is meant to serve only as a roadmap

through the major issues that must be

faced in IR vision system design.

Page 7

1

Typical Monitoring and

Control Applications

Typical Monitoring and

Control Applications

Temperature Measurements

with IR Cameras

Infrared (IR) radiation is not detectable

by the human eye, but an IR camera

can convert it into a visual image that

depicts thermal variations across an

object or scene. IR covers a portion of

the electromagnetic spectrum from

approximately 900 to 14,000 nanometers

(0.9–14 µm). IR is emitted by all objects at

temperatures above absolute zero, and

the amount of radiation increases with

temperature. A properly calibrated IR

camera can capture thermographic images

of target objects and can provide accurate

non-contact temperature measurements

of those objects. These quantitative

measurements can be used in a variety of

monitoring and control applications.

In contrast, other types of IR imagers

provide only relative temperature

dierences across an object or scene.

Hence, they are used to make qualitative

assessments of the target objects,

primarily in monitoring applications

where thermal images are interpreted

based on temperature contrast. One

example is to identify image areas that

correlate to physical anomalies, such as

construction or sub-surface details, liquid

levels, etc.

In some cases, an IR camera is justiably

referred to as a smart sensor. In these

cases the IR camera has built-in logic

and analytics that allows the comparison

of measured temperatures with user-

supplied temperature data. It also has a

digital I/O interface so that a dierential

temperature can be used for alarm and

control functions. In addition, a smart

IR camera is a calibrated thermographic

instrument capable of accurate non-

contact temperature measurements.

IR cameras with these capabilities

operate much like other types of smart

temperature sensors. They have fast,

high-resolution A/D (Analog to Digital)

converters that sample incoming data,

pass it through a calibration function, and

provide temperature readouts. They may

also have other communication interfaces

that provide an output stream of analog

or digital data. This allows thermographic

images and temperature data to be

transmitted to remote locations for

process monitoring and control.

Generally, smart IR cameras are used

in quantitative applications that

require accurate measurements of the

temperature dierence between a

target object and its surroundings. Since

temperature changes in most processes

are relatively slow, the near-real-time data

communications of smart IR cameras are

adequate for many process control loops

and machine vision systems.

Automation Applications

Typical automated applications using

IR cameras for process temperature

monitoring and control include:

Continuous casting, extrusion, and roll •

forming

Discrete parts manufacturing•

Production where contact temperature •

measurements pose problems

Inspection and quality control•

Packaging production and operations•

Chapter 1

Page 8

2

Chapter 1

Environmental, machine, and safety •

monitoring

Temperature monitoring as a proxy for •

other variables

The examples below demonstrate a wide

range of applications that can be served

with IR cameras. Potential applications

are limited only by the imagination of the

system designer.

Plywood Mill Machine Monitoring

Problem: Steam from open vats of hot

water obscures the machinery operator’s

view of the logs as they are maneuvered

for proper alignment in the log vat.

Solution: An IR camera can present an

image to the operator that makes the

cloud of steam virtually transparent,

thereby allowing logs to be properly

aligned in the log vat. This example of

a qualitative application is illustrated in

Figure 1.

Production Testing of Car Seat Heaters

Problem: Using contact temperature

sensors to assure proper operation of

optional car seat heaters slows down

production and is inaccurate if sensors

are not properly placed.

Solution: An IR camera can detect

thermal radiation from the heater

elements inside the seats and provide

an accurate non-contact temperature

measurement.

This quantitative measurement can be

made with a camera that is permanently

mounted on a xture that is swung

into measurement position when

the car reaches a designated point

on the assembly line. A monitor near

that position provides an image with

a temperature scale that reveals the

temperature of the car seat heater

elements, as shown in Figure 2.

The Problem

• Operatorscannotseethroughthesteam

cloudcausedbycondensationincoolerair

temperatures.

The Solution

• IRoersanotherpairof“eyes”tosee

throughthesteamintothelogvatfor

properlogalignment.

Figure 1. Plywood mill application

Page 9

3

Typical Monitoring and Control Applications

Packaging Operations

Problem: On a high-speed packaging

line, ecient methods for nondestructive testing of a glued box seal

are scarce, and most tend to be very

cumbersome. In addition, the glue

application method has a good deal of

variability that must be monitored and

recorded with statistical quality control

routines.

Solution: Since the glue is heated prior

to application, its temperature and

The Problem

• Optionalfeaturesinvehiclescannotbe

inspectedwithoutsometypeofcontact.

• Thisslowsdownproduction.

• 100%inspectionistedious.

The Solution

• AnIRcameracanbepermanentlymountedto

inspecttheseitems.

• AnIRcameracanbeusedinanon-contact

method.

Figure 2. Production testing of car seat heater elements

The Problem

• Detectincorrectlysealedboxes.

• Removefailedunitsfromtheline.

• Generateanalarmiftoomanyboxesfail.

• Logstatisticaldataofpass/fail.

The Solution

• Captureathermalimageofthebox.

• Detectpresenceofgluespots.

• Pass/failoneachbox.

• Logstatistics.

Figure 3. Machine vision box seal quality control

Page 10

4

Chapter 1

locations on the box lid can be monitored

with an IR camera. Moreover, the image

can be digitized in a way that allows this

information to be stored in a statistical

quality control database for trend analysis

and equipment monitoring as shown in

Figure 3.

This is an example of using dierential

temperature as a proxy for another

variable. In this case, temperature

replaces mechanical methods of

inspection/testing.

Summary

The automation examples presented

in this chapter have barely scratched

the surface of the application space

that smart IR cameras can serve. In

the following chapters, more detailed

examples will be presented along

with practical information on the

implementation of automated systems

that exploit the advantages of IR cameras.

These chapters are organized according

to the major types of applications that

typically use IR cameras:

Remote thermographic monitoring•

Non-contact temperature •

measurement for automated processes

Combining IR machine vision with •

temperature measurement

Real-time control and monitoring – •

issues and answers

Page 11

5

Remote IR MonitoringChapter

Remote IR Monitoring

Overview

Infrared radiation is emitted by all objects

at temperatures above absolute zero

and is detectable by IR cameras. Since

these cameras have various means of

communicating thermographic images

and temperatures to remote locations,

they are ideal for remote and unattended

monitoring. Moreover, smart IR cameras

(those with built-in logic, analytics, and

data communications), can compare

the temperatures obtained from their

thermographic images with user-dened

settings. This allows the camera to

output a digital signal for alarm and

control purposes, while also providing

live images.

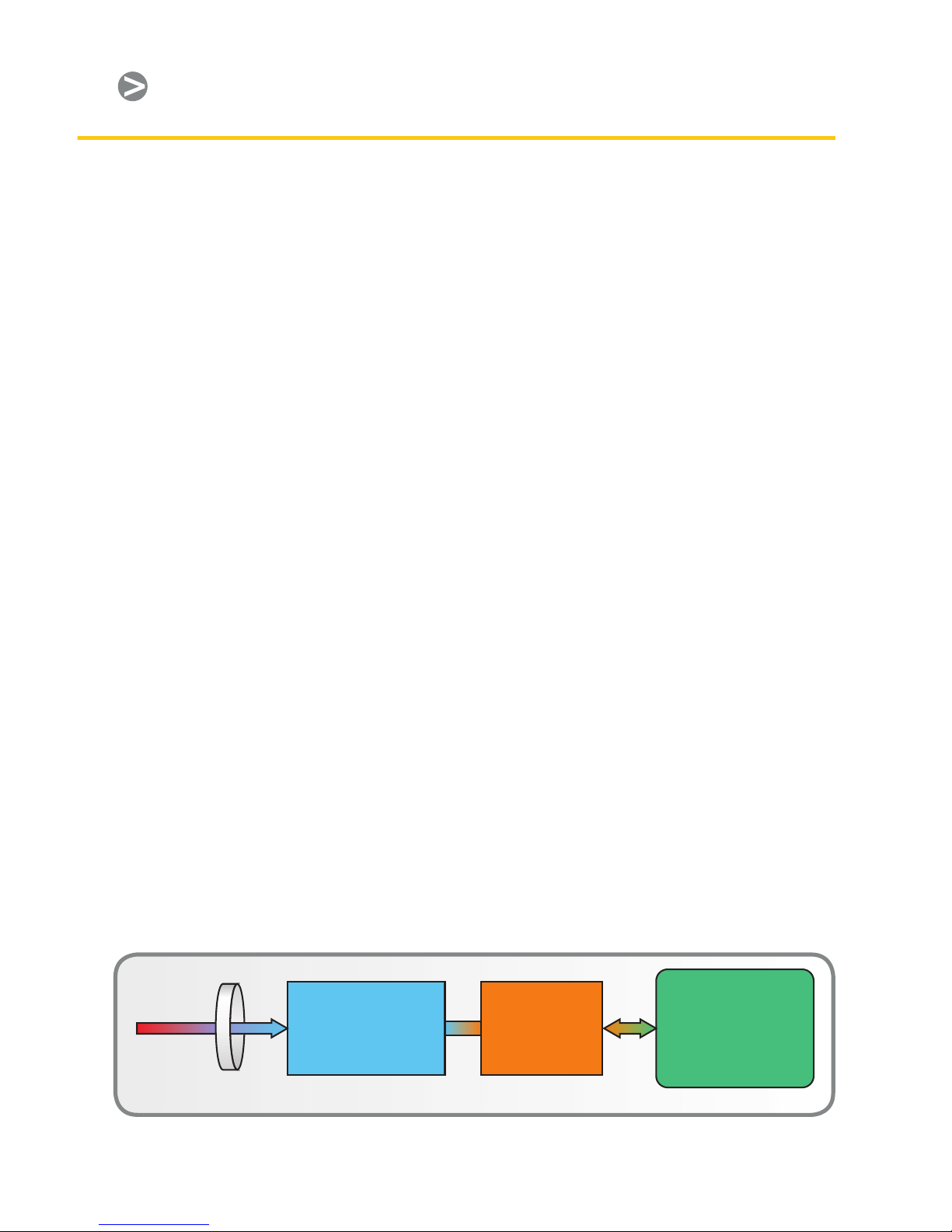

IR Camera Operation

IR camera construction is similar to

a digital video camera. The main

components are a lens that focuses IR

onto a detector, plus electronics and

software for processing and displaying

thermographic images and temperatures

on an LCD or CRT monitor (Figure 1).

Instead of a charge coupled device

that video and digital still cameras use,

the IR camera detector is a focal plane

array (FPA) of micrometer size pixels

made of various materials sensitive to

IR wavelengths. FPA resolution ranges

from about 80×80 pixels up to 1024×1024

pixels. In some IR cameras, the video

processing electronics include the logic

and analytical functions mentioned

earlier. Camera rmware allows the

user to focus on a specic area of the

FPA or use the entire detector area

for calculating minimum, maximum,

and average temperatures. Typically,

temperature measurement precision is

±°C or better.

The camera lens and distance to the

target object results in a eld of view

(FOV) that determines the spot size

covered by each pixel. The pixel’s analog

output represents the intensity of heat

energy received from the spot it covers

on the target object. In FLIR IR cameras,

the A/D converters that digitize the pixel

output have resolutions that range from

8 bits (28 or 0–255 pixels) up to 14 bits

(214 or 0–16383 pixels). The thermographic

image seen on the monitor screen is

the result of a microprocessor mapping

these pixel output values to a color or

gray scale scheme representing relative

temperatures. In addition, radiometric

information associated with the heat

energy impinging on a pixel is stored

for use in calculating the precise

temperature of the spot covered by

that pixel.

IR In

Optics

NIR

MWIR

LWIR

Video

Processing

Electronics

Detector Cooling

Digitization

User Interface

User Control

Video Output

Digital Output

Synchronization In/Out

System Status

Figure 1. Simplied block diagram of an IR camera

Page 12

6

Chapter

Hence, IR cameras with these capabilities

operate much like other types of smart

temperature sensors. Their calibrated

outputs can be accessed via one or more

communication interfaces and monitored

at a remote location. Images saved from

these cameras are fully radiometric1 and

can be analyzed o-line with standard

software packages, such as those

available from FLIR.

Important Criteria in Remote

Monitoring Systems

When considering an IR camera for a

remote monitoring system, some of the

important variables to consider are:

Spot size – the smallest feature in a •

scene that can be measured

FOV (Field of View) – the area that the •

camera sees

Working distance – distance from the •

front of the camera lens to the nearest

target object

Depth of eld – the maximum depth of •

a scene that stays in focus

Resolution – the number of pixels and •

size of the sensor’s active area

NETD (Noise Equivalent Temperature •

Dierence) – the lowest level of heat

energy that can be measured

Spectral sensitivity – portion of •

the IR spectrum that the camera is

sensitive to

Temperature measurement range, •

precision, and repeatability – a

function of overall camera design

1 Radiometry is a measure of how much energy is

radiating from an object, as opposed to thermography,

which is a measure of how hot an object is; the two are

related but not the same.

Another fundamental consideration

is which portion of a camera’s FOV

contains the critical information

required for monitoring purposes. The

objects within the FOV must provide an

accurate indication of the situation being

monitored, based on the temperature

of those objects. Depending on the

situation, the target objects may need

to be in the same position consistently

within the camera’s FOV. Other

application variables related to the

monitored scene include:

Emissivity of the target objects•

Reected temperatures within the FOV•

Atmospheric temperature and •

humidity

These topics will be covered in more

detail in a subsequent chapter.

Remote Asset Monitoring

One type of application where IR cameras

are very useful is in remote monitoring

of property, inventory, and other assets

to help prevent loss and improve safety.

Frequently, this involves storage facilities,

such as warehouses or open areas for

bulk materials. The following example

can serve as a general model for setting

up an IR camera monitoring system for

this type of application.

Hazardous Waste Storage Monitoring. In

this application barrels of chemical waste

products are stored in a covered facility,

but one in which they cannot be totally

protected from moisture. Thus, there is

the possibility of leaks or barrel contents

becoming contaminated by air and

moisture, causing a rise in temperature

due to a chemical reaction. Ultimately,

there is a risk of re, or even an explosion.

Page 13

7

Remote IR Monitoring

While visible light cameras might be

used in such an application, there often

is a line-of-sight problem where many

of the barrels cannot be seen, even with

multiple cameras positioned throughout

the storage area. In addition, smoke or

ames would have to be present before

a visible light camera could detect a

problem. This might be too late for

preventative measures to be taken.

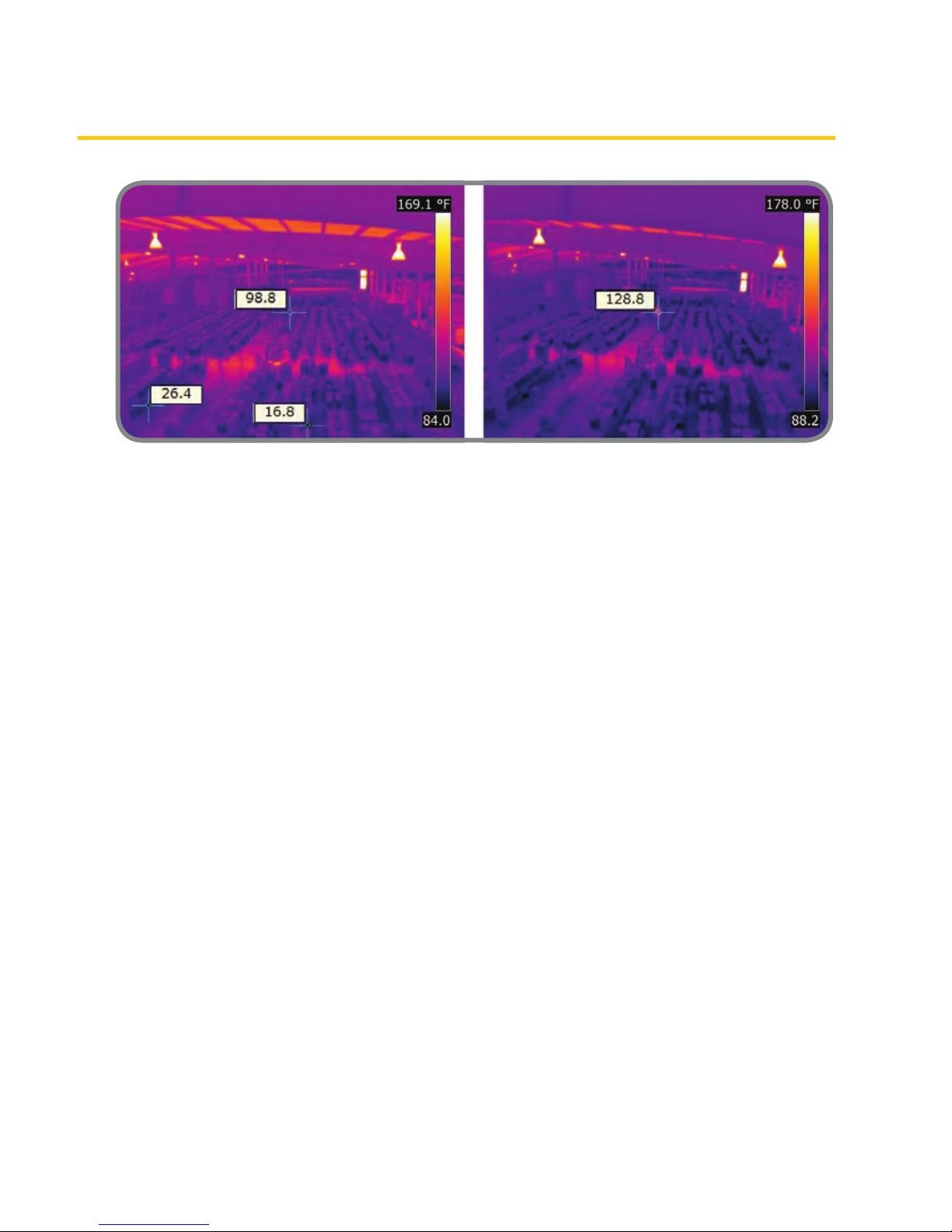

In contrast, stand-alone IR cameras

monitoring the facility can detect a

temperature rise within their FOV before

re occurs (Figures 2a and 2b).

Depending on the camera manufacturer,

several monitoring options are available.

For instance, the FLIR A320 camera

allows a threshold temperature value to

be set internally for alarm purposes. In

addition, the camera’s logic and clock

functions can be congured so that a rise

in temperature must be maintained for a

certain period of time before an alarm is

sent. This allows the system to ignore a

temporary temperature rise in a camera’s

FOV caused by a forklift entering the area

to add or remove barrels. Furthermore,

a hysteresis function can also be used to

prevent an alarm from turning o until

the detected temperature falls well below

the setpoint (Figure 3).

Cameras with a digital I/O interface

typically provide an OFF/ON type of

output for alarm purposes. The digital

I/O output is either o or on; when on, it

is typically a DC voltage or current. For

example, the digital I/O output from a

FLIR A320 camera is 10–30VDC for loads

of 100mA or less. Typically, the digital

I/O output is sent to a PLC (Programble

Logic Controller) that controls the portion

of an alarm system associated with the

monitored area.

A good way to set up the alarm system

is to have all cameras congured so they

have a high level digital output when the

temperature is below the alarm condition

that holds a PLC in its non-alarm state.

When the alarm setpoint temperature is

detected, the camera’s digital I/O output

goes low (typically zero volts) after an

appropriate time delay, causing the PLC

Figure 2a. IR image of a hazardous waste storage

area showing two spot temperature readings

(26.4°F and 16.8°F) that are in the safe range, plus

one reading (98.8°F) that is abnormally high.

Figure 2b. A subsequent image of the same

area shows that the abnormal reading in 2a

has increased further, causing an alarm to

go o.

Page 14

8

Chapter

to go into its alarm state. This creates a

fail-safe system. If power to the camera is

lost, then there is no high level output to

the PLC, which treats that event just as if

a temperature had reached the setpoint,

thereby causing an alarm. This alerts

personnel that they have either lost the

monitoring function or there is indeed a

temperature rise.

Image monitoring. Receiving a warning

based on temperature measurements is

very useful, but the real power of IRbased asset monitoring is in the camera’s

image processing capabilities. Control

room personnel can get live images from

IR cameras that visible light cameras

and other temperature detectors

cannot provide. Again, cameras vary by

manufacturer, but the most versatile ones

oer a variety of data communication

formats for sending thermographic

images to remote locations. Increasingly,

web-enabled cameras are used to allow

monitoring from any location where a PC

is available.

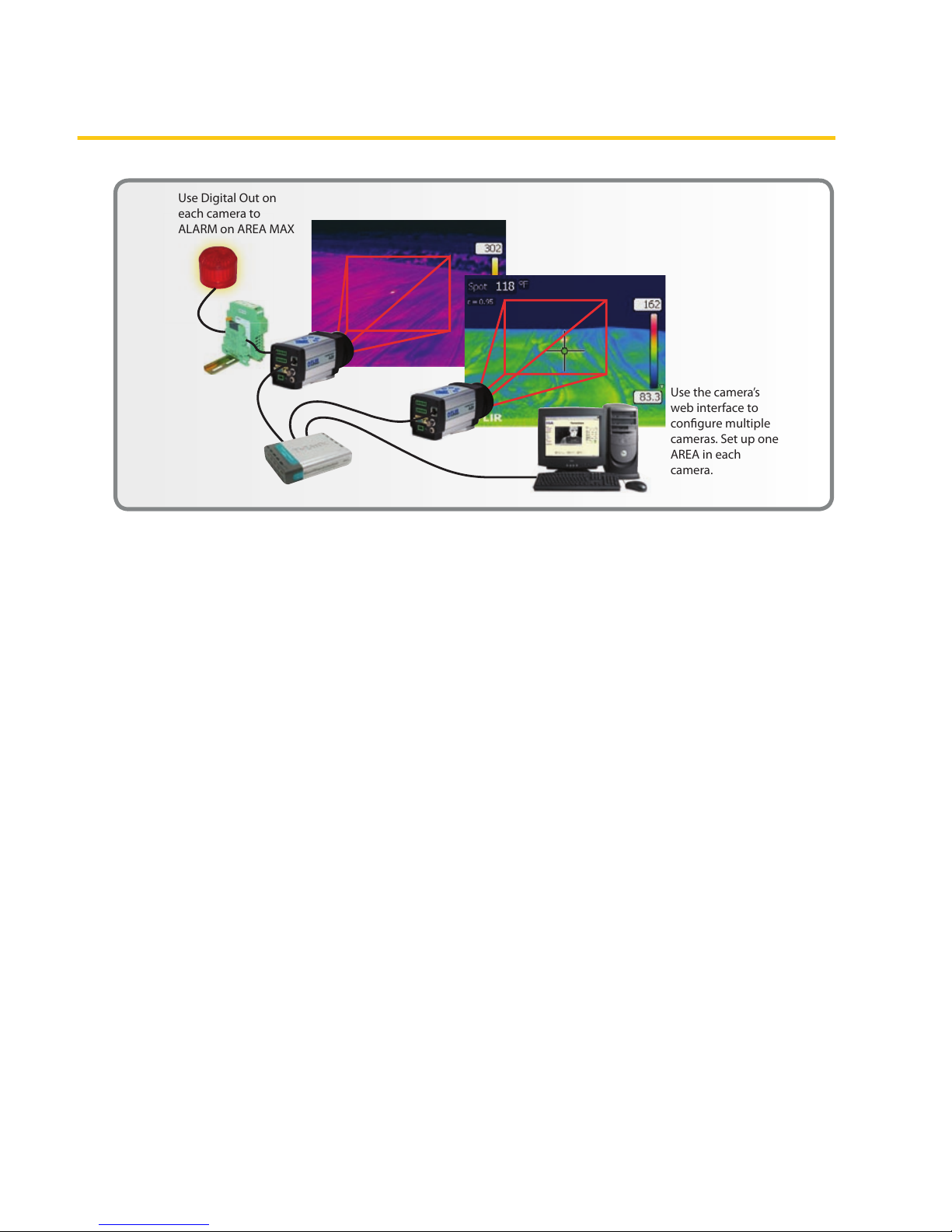

Figure 4 illustrates a system using

the FLIR A320’s Ethernet and TCP/IP

communication protocols in conjunction

with its alarm setpoint capabilities. The

Ethernet portion of the system allows

cable runs of up to 100 meters in length.

By communicating a digital alarm directly

to the PLC, it can immediately activate

a visual and/or audible alarm. The visual

alarm can appear on an annunciator

panel telling the operator where the

alarm originated; the operator then goes

to the PC to look at live image(s) of that

location. Images and temperature data

can be stored for future reference and

analysis.

A320 cameras can also be congured to

automatically send temperature data

and images to a PC via e-mail (SMTP) or

FTP protocol whenever the temperature

setpoint is reached, thereby creating a

record for subsequent review.

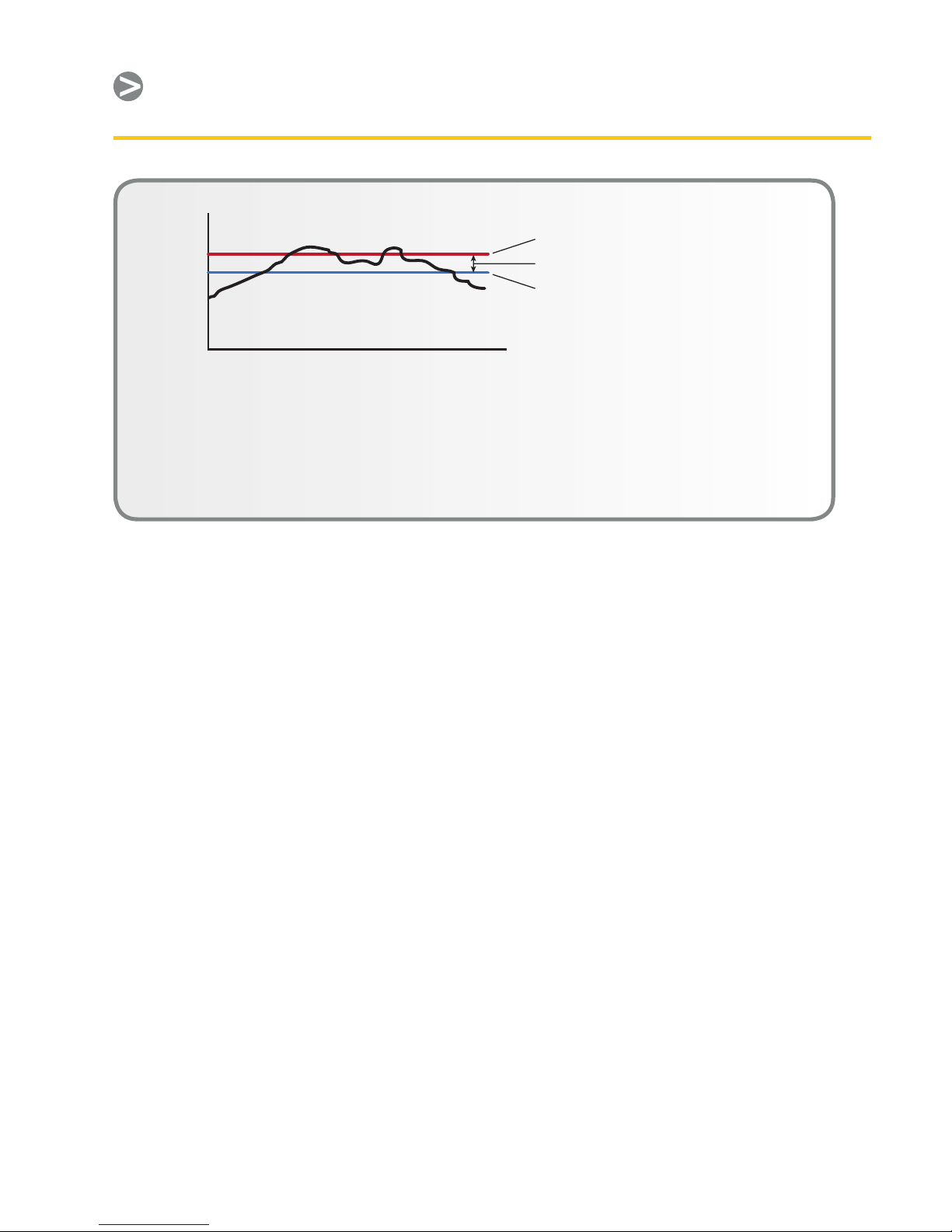

Time

Temperature

Threshold

T e mperature

(Warning On)

Wa rning O

T e mperature

Deadband

O Te mp = On Te mp – Deadband

Hysteresis

• Also known as deadband

• Can be thought of as another threshold setting – where

the smart sensor resets the alarm that was generated

when the original setpoint was compromised

• Used to prevent signal “chatter”

Figure 3. Hysteresis is an important signal processing characteristic of smart IR cameras, which

makes monitoring and control functions much more eective.

Page 15

9

Remote IR Monitoring

In conjunction with a host controller

running FLIR’s IR MONITOR (or other

suitable software), temperature data can

be captured for trend analysis. The A320

can also supply a digital compression

of the camera’s analog video signal,

which can be sent as MPEG-4 streaming

digital video over an Ethernet link to a PC

monitor. IR MONITOR can be used to set

up temperature measurements, image

capture, and camera display functions.

This application allows the PC to display

up to nine camera images at a time

and switch between additional camera

groups as needed. The FLIR IP CONFIG

software can be used to set up each

camera’s IP address.

After the cameras are congured, the

PC used for monitoring does not need

to remain on the network continually.

By using the FTP and SMTP protocols

within the camera, the user can receive

radiometric images upon alarm events

or on a time based schedule. Also, any

available PC with a web browser can be

used to access the cameras web server

for live video and basic control. This web

interface is password protected.

Most IR cameras have an analog

video output in a PAL or NTSC format.

Therefore, another image monitoring

possibility is to use a TV monitor to

display thermographic video. A single

control room monitor can be used with

a switch to view live images from each

camera sequentially. When the cameras

are properly congured, control room

personnel can view scaled temperature

readings for any point or area (minimum,

maximum, and average) in that image.

(See color scales in the screen capture

images depicted in Figure 2.) Not only

will the operator know when there

is excessive heat, he or she can see

where it is.

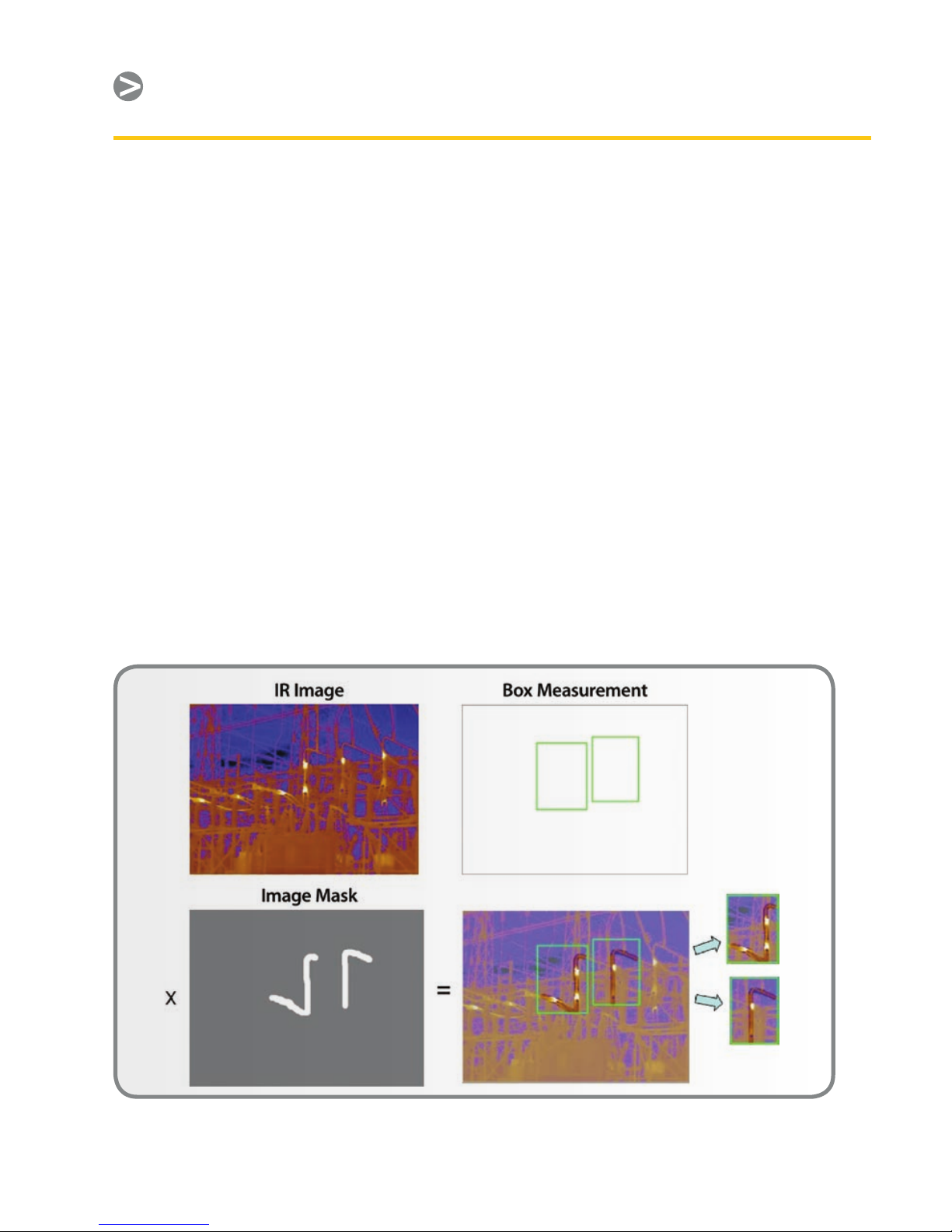

Another example of the innovative

functions available in camera rmware

or external software is a feature called

Figure 4. An example of one type of system conguration for remote IR camera monitoring. The

system uses a digital alarm output for annunciating an over-temperature condition and transmits

streaming MPEG-4 compressed video that allows the scene to be viewed on a PC monitor.

Use Digital Out on

each camera to

ALARM on AREA MAX

Use the camera’s

web interface to

congure multiple

cameras. Set up one

AREA in each

camera.

Page 16

10

Chapter

image masking. This enables the user

to pre-select specic areas of interest

for analysis of temperature data. This

is illustrated in Figure 5, which shows

continuous monitoring of substation

hotspots that indicate problem areas.

A similar type of pattern recognition

software can be used for automated

inspection in metal soldering and

welding and in laser welding of

plastic parts. IR cameras can see heat

conducting through the nished parts

to check the temperature of the areas

where parts are joined together against

a stored value. In addition, the software

can learn a weld path to make sure this

path is correct, which is accomplished

by programming the specic pixels in

an image to be used by the software for

this purpose. Alternatively, the program

developer can save an image of a

“perfect” part and then have the software

look for minimum, maximum, or delta

values that tells the equipment operator

if a part passes inspection. The car seat

heater inspection described in Chapter 1

can be an example of this, and the same

principle is used in the inspection of car

window heater elements by applying

power to them and looking at their

thermographic image.

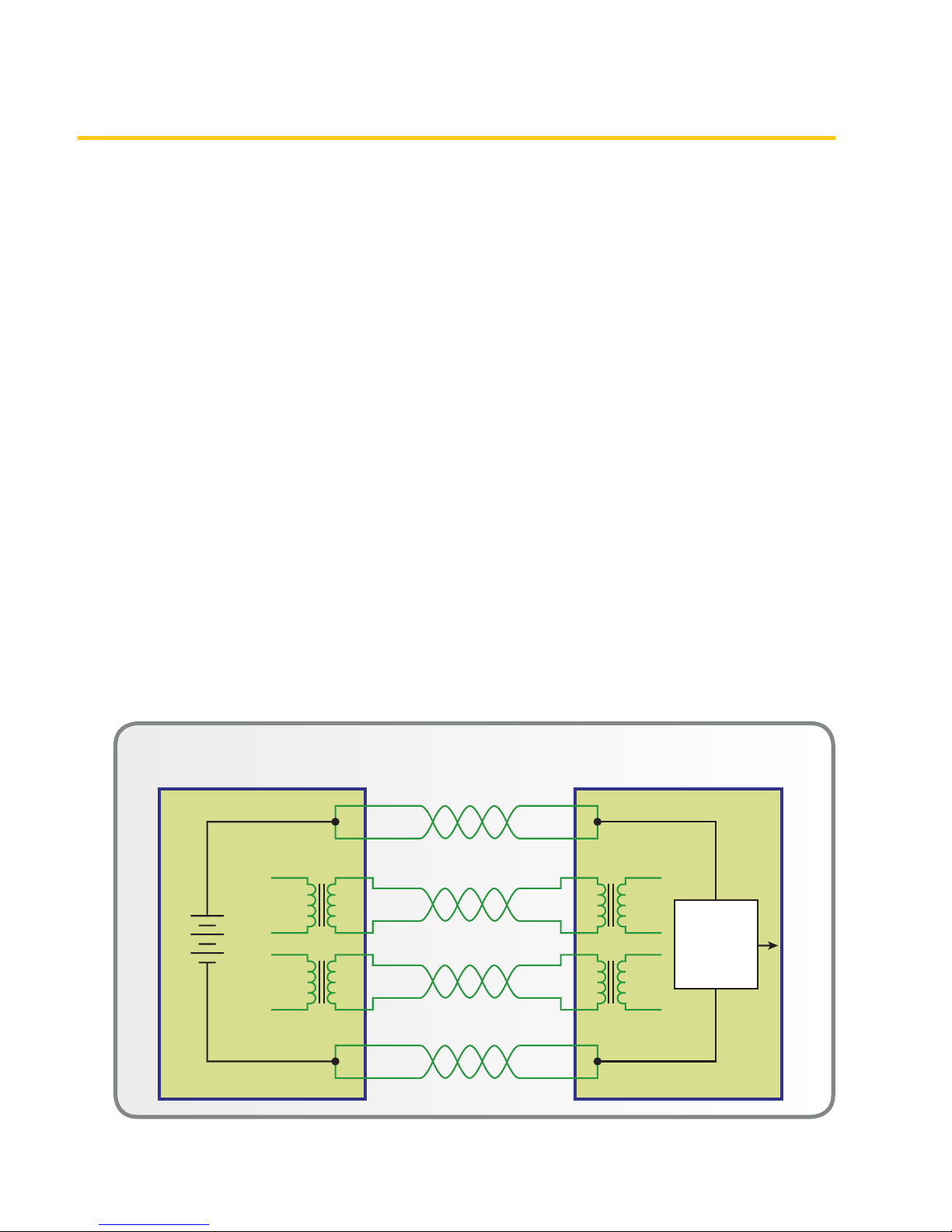

Power over Ethernet. It should be noted

that a camera with Ethernet connectivity

can be powered from a variety of sources,

depending on its design. Typically, a

connection for an external DC supply is

used, or where available, the camera is

powered via PoE (Power over Ethernet).

PoE uses a power supply connected to

the network with spare signal leads not

Figure 5. Masking functionality of the FLIR A320 IR camera, which is also available in some third

party software programs.

Page 17

11

Remote IR Monitoring

otherwise used in 10/100baseT Ethernet

systems. Various PoE congurations are

possible. Figure 6 depicts one in which

the power source is located at one end

of the network. (Gigabit Ethernet uses all

available data pairs, so PoE is not possible

with these systems.)

PoE eliminates the need for a separate

power source and conduit run for

each camera on the network. The

only additional cost is for some minor

electrical hardware associated with PoE.

Many applications encompass areas that

exceed the maximum Ethernet cable

run of 100m. In those cases, there are

wireless and beroptic converter options

that provide o-the-shelf solutions

for communicating over much greater

distances. These are frequently used in

the bulk material storage applications

described below.

Additional Asset Monitoring Situations

Bulk Material Storage. Many bulk

materials are stored in open yards where

air and moisture can help promote

decomposition and other exothermic

reactions that raise the temperature of

the pile. This brings with it the threat

of re, direct monetary loss, and safety

issues for personnel. In addition, there

is the risk of consequential damages

caused by res, including loss of nearby

property, water damage resulting from

re-ghting, and production shutdowns.

Materials that are especially prone to

spontaneous combustion include organic

wastes (compost, etc.), scrap paper

for recycling, wood, coal, and various

inorganic chemicals, such as cement and

chlorine hydrates. Even in the absence

of spontaneous combustion, many

bulk materials like plastics pose a re

hazard due to sparks or other external

ignition sources.

1

5

Spare Pair

Signal Pair

Signal Pair

4

2

TX

+48V

–

RX

DC/DC

Converter

3

6

1

5

4

2

3

6

RX TX

5

Spare Pair

4

5

4

Power Sourcing

Equipment (PSE)

Powered

Device (PD)

Figure 6. Schematic depicting spare-pair PoE delivery using the endpoint PSE arrangement.

Page 18

12

Chapter

In most cases, prevention is less costly

than a cure, and the best prevention is

continuous monitoring of the materials.

The cost of an automated temperature

monitoring system using IR cameras is

a modest and worthwhile investment.

System design can take the same form as

the one described earlier for hazardous

waste barrels. Cameras are congured

to generate a direct alarm output to an

operator when user-dened maximum

temperature thresholds are exceeded.

Audible and visual alarms in a control

room draw the operator’s attention to a

possible spontaneous re development.

Various types of software have been

developed to isolate trouble spots, such

as the waste pile zone monitoring system

depicted in Figure 7.

Although self-ignition usually starts

within the bottom layers of a stock pile,

continuous monitoring of the surface

reveals hot spots at an early stage (Figure

8), so measures can be taken to prevent

a major re from breaking out. Large

storage yards generally require multiple

cameras for total coverage, with the

cameras mounted on metal masts above

the stock piles. This calls for cameras with

housings and other features designed

for reliable operation in harsh industrial

environments.

Critical Vessel Monitoring (CVM). There

are several applications where the

temperature of a vessel and its contents

are critical. The vessels could be used

for chemical reactions, liquid heating,

or merely storage. For large vessels,

the use of contact temperature sensors

poses problems. One reason could be

non-uniform temperatures throughout a

vessel and across its surface. This would

require a large number of contact type

sensors, whose installations can become

quite costly.

For most CVM applications, a few IR

cameras can image nearly 100% of a

vessels surface (Figure 9). Moreover, they

can measure the surface temperature of

the CVM to trend and predict when the

internal refractory will break down and

compromise the mechanical integrity of

the system. If specic regions of interest

(ROIs) must be focused on, IR camera

rmware (or external PC software) allows

the selection of spot temperature points

or areas for measurement.

Again, some variation of the systems

described earlier can be used. Depending

Figure 7. Control room for waste pile processing, and screen capture of the zone monitoring layout,

which uses a FLIR IR camera on a pan-tilt mount for re hazard warning.

Page 19

13

Remote IR Monitoring

Figure 8. Visible light and IR images of a coal pile – the thermographic image clearly identies a hot

spot that is a re about to erupt.

on the application environment, an

explosion proof housing for the camera

may be a requirement. HMI (humanmachine interface) software, such as

SCADACAM iAlert from Pivotal Vision,

can be used to provide a monitoring

overview. This has the ability to combine

all of the camera images into a single

spatial representation of the monitored

area – in this case, a attened-out view

of the vessel. This view can be updated

continuously for a near-real-time

thermographic representation.

Electrical Substation Monitoring. Reliable

operation of substations is crucial for

uninterrupted electrical service. Besides

lightning strikes and large overloads,

aging equipment and connections are

a major cause of infrastructure failures

and service interruptions. Many of these

failures can be avoided with eective

preventative maintenance monitoring.

Often, the temperatures of transformers,

breakers, connections, etc. will begin to

creep up before a catastrophic failure

occurs. Detection of these temperature

increases with IR cameras allows

preventative maintenance operations

Figure 9. CVM monitoring example showing

camera locations, network connections, and PC.

1 Computer

2 CAT-6 Ethernet cable with RJ45

connectors

3 Industrial Ethernet switch with PoE

4 ThermoVision™ A320 cameras

5 Industrial process to be monitored,

e.g., a gasier

Page 20

14

Chapter

before an unplanned outage happens.

(See Figure 10.)

The cameras can be installed on a pan/

tilt mounting mechanism to continually

survey large areas of a substation (Figure

11). A few cameras can provide real-time

coverage of all the critical equipment

that should be monitored. In addition

to preventative maintenance functions,

these cameras also serve as security

monitors for intrusion detection around

the clock.

By combining the cameras’ Ethernet

and/or wireless connectivity with a

web-enabled operator interface, live

images can be transmitted to utility

control rooms miles away. In addition,

trending software can be used to detect

dangerous temperature excursions and

notify maintenance personnel via email

and snapshot images of the aected

equipment.

These features and functions are already

in place at leading utility companies in

the U.S., such as Exel Energy’s “Substation

of the Future.” Companies such as

Exel consider IR monitoring a strategic

investment in automation, which is

part of a common SCADA (Supervisory

Control And Data Acquisition) platform

for maintenance and security operations.

The most advanced systems provide

time-stamped 3-D thermal modeling

of critical equipment and areas, plus

temperature trending and analysis. A

company-wide system of alerts provides

alarms on high, low, dierential, and

ambient temperatures within or between

zones in real time.

The previous examples represent just a

few applications that can benet from

remote IR camera monitoring. A few

other applications where IR temperature

monitoring is being used include:

Oil and gas industries (exploration •

rigs, reneries, are gas ues, natural

gas processing, pipelines, and storage

facilities)

Electric utilities (power generation •

plants, distribution lines, substations,

and transformers)

Figure 10. Visible light and IR images of a substation showing a transformer with excessive

temperature.

Page 21

15

Remote IR Monitoring

Figure 11. Example pan/tilt mounting system.

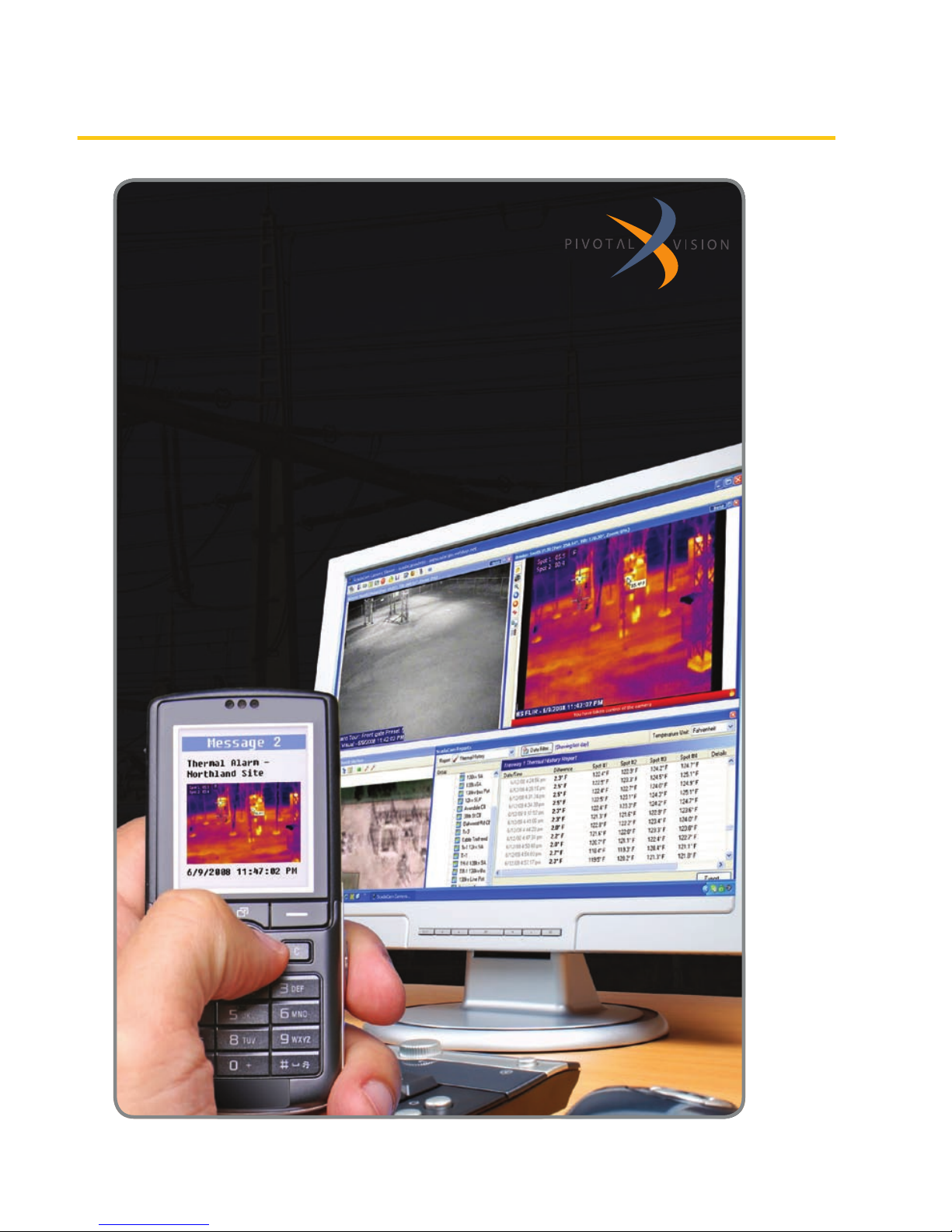

Smarter surveillance for a smarter grid

Meet ScadaCam Intelligent Surveillance, the only system in its price range

that can automatically perform site patrols, monitor equipment temperature,

and scan for security breaches without human supervision.

By combining visual, thermal imaging, and thermographic cameras into a

multifunctional operations and security automation tool, ScadaCam can

detect, validate, and alarm you of problems that could otherwise result in a

major outage – before they occur.

See it in action at www.pivotal-vision.com/tryit

Page 22

16

Chapter

Predictive and preventative •

maintenance (continuous/xed

position monitoring of critical

equipment)

Besides these, there are many qualitative

remote monitoring applications where

imaging is the predominant feature. For

example, IR cameras can be used as part

of an early warning system for forest

res (Figure 12), detecting blazes before

signicant amounts of smoke appear.

Another example is using IR imaging to

look through condensation vapor that

would otherwise obscure an operator’s

view of equipment and processes. This is

being used in coking plants, veneer mills,

and plywood log handling operations,

among others (see Chapter 1, Figure 1).

Summary

As noted in the text, IR camera

temperature data may be used for

qualitative monitoring or for quantitative

temperature measurement and control.

In the former, thermal images are

obtained and interpreted based on

temperature contrast. It can be used

to identify image areas that correlate

to sub-surface details, liquid levels,

refractory, etc.

Quantitative measurements generally

require the IR camera to accurately

determine the temperature dierence

between the target object and its

surroundings. In remote monitoring, this

allows the temperature data to be used

for alarm purposes or to even shut down

equipment. Since temperature changes

slowly in many situations, the near-real-

time data communications of smart IR

cameras are more than adequate for

alarm and control systems.

Figure 12. Ngaro’s IRIS® Watchman forest re early warning system uses a FLIR IR camera.

Page 23

17

Temperature Measurement

for Automated Processes

Temperature Measurement

for Automated Processes

Background

In Chapter the emphasis was on

specic applications where a single

temperature threshold is programmed

into an IR camera, and when the

threshold is reached an alarm is

triggered through a PLC. Multiple

cameras are often required, but viewing

an IR cameras’ thermographic image

is a secondary consideration – to

verify an alarm condition. Chapter 3

focuses on applications where multiple

temperatures within a single camera’s

FOV are important, and that information

is used for some sort of process control

function. In these applications, the

camera is typically integrated with other

process control elements, such as a PC or

PLC using third party software and more

sophisticated communication schemes.

Typical Camera Measurement

Functions

Many IR cameras provide the user with

dierent operating modes that support

correct temperature measurements

under various application conditions.

Typical measurement functions include:

Spotmeter•

Area•

Image mask•

Delta T•

Isotherm•

Temperature range•

Color or gray scale settings•

The last two are used with the others to

provide a visual indication of the range

of temperatures in the camera’s FOV.

Generally, spot and area temperatures

tend to be the most useful in monitoring

and control applications, and most

cameras allow multiple spots or areas to

be set within the thermographic image.

For example, the FLIR A320 camera

supports up to four spots and four areas.

Cursor functions allow easy selection of

an area of interest, such as the crosshairs

of the spot readings in Figure 1. In

addition, the cursor may be able to select

circlular, square, and irregularly shaped

polygon areas.

Figure 1. IR image of a printed circuit board

indicating three spot temperature readings.

Image colors correspond to the temperature

scale on the right.

The spotmeter nds the temperature

at a particular point. The area function

isolates a selected area of an object or

scene and may provide the maximum,

minimum, and average temperatures

inside that area. The temperature

measurement range typically is

selectable by the user. This is a valuable

feature when a scene has a temperature

range narrower than a camera’s full-

scale range. Setting a narrower range

allows better resolution of the images

and higher accuracy in the measured

Chapter 3

Page 24

18

Chapter 3

Figure 2. Gray scale images of a car engine – the left view has white as the hottest temperature and

the right view shows black as the hottest.

temperatures. Therefore, images will

better illustrate smaller temperature

dierences. On the other hand, a

broader scale and/or higher maximum

temperature range may be needed to

prevent saturation of the portion of the

image at the highest temperature.

As an adjunct to the temperature range

selection, most cameras allow a user

to set up a color scale or gray scale to

optimize the camera image. Figure 2

illustrates two gray scale possibilities.

In Figure 1, a so-called “iron scale” was

used for a color rendering. In a manner

similar to the gray scale above, the

hottest temperatures can be rendered

as either lighter colors or darker colors.

Another possibility is rendering images

with what is known as a rainbow scale

(Figure 3).

While choice of color scale is often a

matter of personal preference, there may

be times when one type of scale is better

than another for illustrating the range of

temperatures in a scene.

Figure 3. Rainbow scale showing lower

temperatures towards the blue end of the

spectrum.

Application Examples

Go/No-Go. In these applications, one or

more temperatures are monitored to

make sure they meet process criteria,

and machinery is shut down or product

rejected when a measured temperature

goes above or below the setpoint. A

good example of this is a manufacturer

of automotive door panels that uses

IR cameras to monitor and measure

part temperatures prior to a molding

procedure.

Page 25

19

Temperature Measurement for Automated Processes

This process starts with reinforcing parts

that have been stored in a warehouse.

In either the warehouse or during

transport to the molding line, these

parts can become wet due to moisture

condensation or exposure to inclement

weather. If that happens, they may not

reach a high enough temperature in the

molding press and nished panels will be

of poor quality.

The parts go into the press two at a

time from a conveyor where they are

sealed together and the nished door

panel is molded into the required shape

for a specic car model. If the parts are

wet, this creates steam in the press and

causes mold temperature to be too low.

However, it was found that movement of

wet parts on the conveyor causes their

temperature to be lower than normal. So,

just before the parts go into the press,

the conveyor stops and an IR camera

makes a non-contact measurement

of their temperature. The diagram in

Figure 4 is typical for this type of quality

control application.

The IR camera’s area tools are applied to

the thermographic image to check for

the minimum allowable temperature of

the two parts. If either temperature is

below the setpoint (typically, the ambient

temperature), then a digital I/O output to

a PLC causes an alarm to be sounded and

Figure 4. Typical Go/No-Go QC inspection system using IR cameras.

1 Computer or PLC

2 CAT-6 Ethernet cable with

RJ45 connectors

3 Industrial Ethernet switches

with ber optic ports

4 Fiber optic cable

5 ThermoVision™ A320 or A325

cameras

6 Industrial process to be

monitored, e.g., items on a

conveyor belt

Page 26

20

Chapter 3

the molding line is halted so the parts can

be removed.

For OEMs, preventing bad panels from

getting to the end product avoids a

potential loss of business. Warranty

replacement of a door panel after an end

customer takes possession of the car is an

expensive proposition for the OEM.

The trick is to make sure the camera is

measuring the temperature of the parts

and not the oor beneath the conveyor,

which is within the camera’s FOV and

typically much cooler. This occurs when

the parts are not in the proper position. A

photoelectric detector tells the PLC when

the parts enter the press area; otherwise

its ladder logic ignores the alarm output

from the camera.

Continuous Process Monitoring.

Temperature is an important variable

in many processes. It can either be an

integral part of a process or act as a

proxy for something else. The following

describes an example that encompasses

both of these situations.

Articial ber production typically

involves a continuous extrusion process.

Multiple strands may be extruded

simultaneously or, in the case of nonwoven sheets, a web process may be

involved. In either case, monitoring

the temperature of the material as it

comes out of the extruder can detect

strand breakage or material blockage

and backup in the process. Using an IR

camera for unattended monitoring can

catch these malfunctions early, before

a huge mess is created that causes

a long machinery outage and costly

production losses. In addition, the actual

temperature readings can be used for

trend analysis.

Depending on the application, either the

spot or area measurement functions of

the camera can be used. In the latter case,

it is likely that the application would take

advantage of all the area measurement

capabilities – minimum, maximum, and

average temperatures of the dened

area. If any of these were to fall outside

the user-dened limits, the application

program running on a PC or PLC

could instantly shut down the process

machinery.

In one such application, FLIR

customized the camera rmware to

allow simultaneous monitoring of up

to 10 dierent areas. Figure 5 shows a

monitored area covering six ber strands

coming out of the extruder, along with an

alarm setpoint temperature in the upper

left corner.

Figure 5. Monitoring of articial bers coming

out of an extruder.

As in the case of many remote monitoring

applications, the user may choose to

route the camera’s analog video to a

control room monitor. For cameras

with an Ethernet connection, digitally

Page 27

21

Temperature Measurement for Automated Processes

compressed (MPEG-4) streaming video

can be available for monitoring on a PC

screen. With FLIR’s A320 camera, images

and alarms can be sent to a remote PC via

TCP/IP and SMTP (email) protocols.

While a visible light camera may be able

to detect broken ber strands, an IR

camera can also provide temperature

measurements for trending and statistical

process control (SPC) purposes. In

addition, some textile processes create

steam or condensation vapors that a

visible light camera cannot see through,

but an IR camera can. Thus, an IR camera

provides multiple functions and is more

cost eective.

Data Communications and

Software Considerations

Dierent cameras have dierent video

frame rates. The frame rate governs how

frequently the thermographic image

and its temperature data are updated.

A typical rate might be every 200ms or

so. The camera’s digital communications

protocol could create a small amount of

additional latency in the update process.

Still, because process temperatures tend

to change slowly, collecting temperature

data at this rate provides a wealth of

information for quality control purposes.

In many IR cameras there is some sort

of serial/socket interface that can be

used for communications with the PC

or PLC that is running a control script,

or application. When a system designer

or user is most familiar with PLCs, the

control algorithm can be built around

a virtual PLC created on a PC, which

emulates actual PLC hardware and logic.

In any case, a human-machine interface

(HMI) is created to monitor data coming

from the camera. The details described

below are based on FLIR’s A320 camera,

but should be representative of most

cameras that transmit data over an

Ethernet link.

The only physical interface for digital

data transfer from the FLIR A320 is the

Ethernet port. Only TCP/IP is supported,

but the camera should work seamlessly

on any LAN when the proper IP address,

netmask, and possibly a gateway is set

up in the camera. The two main ways

of controlling the camera are through

the command control interface and the

resource control interface. Digital image

streaming, data le transfer, and other

functionality is provided through the

IP services interface. A lot of software

functionality is exposed through

software resources. These resources

can be reached through the FLIR IP

Resource Socket Service. This is the

camera’s resource control (serial/socket)

interface. Independent of the physical

Ethernet interface, it is possible to access

the camera system using TCP/IP with

telnet, ftp, http, and FLIR Resource Socket

Services (among others).

Most PLCs provide serial/socket interfaces

for Ethernet. One example is AllenBradley’s EtherNet/IP Web Server Module

(EWEB for short). Another example is HMS

Industrial Network’s Anybus X-Gateway

Ethernet interface module, which can

convert this serial socket interface to

many industrial network protocols, such

as EtherNet I/P, Modbus-TCP, Pronet,

Ethernet Powerlink, EtherCAT, FLNet., etc.

Camera setup and data acquisition is

normally done directly through the FLIR IR

MONITOR and IP CONFIG software running

on a PC. Afterward, the camera can be

Page 28

22

Chapter 3

connected on the network for continuous

monitoring and data logging via PC or

PLC control. Typically, the telnet protocol,

accessed by the Windows® PC running

the application program, is used to query

the camera for data. This protocol is also

available for most PLCs. In either case, this

takes place though the camera’s Resource

Socket Services. (Command syntax is

contained in the camera’s ICD manual; a

few examples are listed in Appendix D.)

The system designer or FLIR would

create the message instructions that

allow the PLC to query the camera for

temperature data and thermographic

images in the same way it is done with PC

control. Alternatively, the PLC can hold

the Ethernet port open and call for the

camera to continuously output data to

this port at the maximum rate possible. In

either case, alarm functions and decision-

making is performed by the application

program running on the PLC (or PC if

applicable). (See Figure 6.) Typically,

temperatures and images collected for

trend analysis and statistical process

control purposes are stored on a separate

server connected to the network, which

is running transaction manager software

for downloading and storing data.

1 Computer, PLC, and/

or transaction manager

server

2 CAT-6 Ethernet cable

with RJ45 connectors

3 Industrial Ethernet

switches with ber optic

ports

4 Fiber optic cable

Wireless access points

6 CAT-6 Ethernet cable

with RJ45 connectors.

Powering the camera

using PoE (Power over

Ethernet)

7 Industrial Ethernet

switch

8 ThermoVision A320

cameras monitoring a

process or other target

objects

Figure 6. Generalized IR machine vision system and its communications network

Page 29

23

Temperature Measurement for Automated Processes

Figure 7. Example of a control and data acquisition option for IR cameras

©2008 National Instruments Corporation. All rights reserved. Nati onal Instruments, NI, and ni.com

are trademarks of National Instruments. Other product and company names listed are trademarks

or trade names of their respective companies. 2008-9522-221-101

>>

Get your free 30-day trial version

at ni.com/vision/vbai

800 891 8841

Inspect Faster

with NI Vision Builder AI

National Instruments Vision Builder for Automated Inspection (AI) now

features an innovative state machine editor, taking you from initial

design to deployed vision application faster than ever. Easily integrate

with existing industrial control hardware – no programming required.

NEW! Vision Builder AI

�

Configurable Machine Vision

�

No Programming Required

�

Acquisition from Thousands of Cameras

2008-9522-221-101-D 4/29/08 10:25 AM Page 1

Page 30

24

Chapter 3

For system developers who are writing

or modifying code with Visual Basic, C++,

etc. for customized applications running

on a PC, there are a few options. FLIR’s

Researcher package supports OLE-2,

the Microsoft standard for linking and

embedding data between applications.

Image and temperature data can be

linked from Researcher into other

compliant applications, such as Excel. The

linked data updates automatically, so if a

temperature value changes in Researcher

it will automatically change in the linked

application. In addition, Researcher

provides an automation interface that

can be used to control the software using

Visual Basic or VBA. Other o-the-shelf

options for OLE control include National

Instruments’ MATLAB and LabVIEW®.

However, none of the aforementioned are

OPC (OLE for Process Control) compatible.

There are other out-of-the-box solutions

that do not require the writing of

application source code. One of these is

IRControl from Automation Technology,

GmbH. IRControl simplies automated

processing of complex tasks with its

built in Automation Interface based on

Microsoft® COM/DCOM. All essential

measurement, analysis, and control

functions for FLIR IR cameras are directly

programmable using macro commands.

This allows the execution of control

scripts automatically based on digital

input events. In addition, IRControl

accepts remote control commands sent

over an RS-232 link. Therefore, remote

control of IRControl by other computers

or PLCs is greatly simplied. The software

also includes a comprehensive report

generator.

Summary

A variety of control and data acquisition

options are available for IR cameras

(see Figure 7). They are similar to those

used with visible light cameras that

are employed in machine vision and

automation systems. IR cameras provide

the added advantage of accurate non-

contact temperature measurements

within a single instrument.

Page 31

25

Combining Machine Vision and

Temperature Measurement

Combining Machine

Vision and Temperature

Measurement

Background

Traditionally, visible light cameras have

been a mainstay in machine vision

systems used for automated inspection

and process control. Many of these

systems also require temperature

measurements to assure product quality.

In numerous cases, an IR camera can

supply both an image of the product

and critical temperature data. If the

application will not benet from

thermographic images and non-contact

temperature measurements, then a

visible light camera is certainly less

expensive. If the opposite is true, then an

IR camera should be considered by the

system designer.

As the sophistication of IR cameras

continues to increase, along with

associated hardware and software, their

use in automated systems is growing

rapidly. Because of their combined

imaging and temperature measurement

capabilities, they can be very cost

eective. The main impediment to their

wider usage is system designers’ lack

of familiarity with IR camera features

and the related standards, systems, and

software that support them. This chapter

supplies a good deal of that information.

Machine Vision Applications

As in the case of visible light cameras,

thermographic cameras and their

associated software can recognize the

size, shape, and relative location of

target objects (i.e., they can do pattern

matching). Moreover, the electronics

in newer IR cameras provide fast signal

processing that allows high video frames

rates (60Hz or higher) to capture relatively

fast-moving parts on a production line.

Their A/D converters combine short

integration times with 14- to 16-bit

resolution, which is critical for properly

characterizing moving targets or targets

whose temperatures change rapidly.

Figure 1. Results of automated inspection of ICs

on a circuit board

One example of the latter is automated

inspection of operating ICs on a circuit

board (Figure 1). In some cases, this

involves overload testing in which an

IC is subjected to a current pulse so its

heat loading can be characterized. In one

such case the IC is forward and reverse

biased with current levels outside of

design limits using a pulse that lasts

800ms. The IR camera captures images

during and after the current pulse to

characterize temperature rise and fall.

With a 60Hz frame rate, a new frame can

be captured about every 17ms. In such a

system nearly 50 frames can be captured

during the 800ms pulse, and many more

Chapter 4

Page 32

26

Chapter 4

are typically captured afterward to reveal

heat dissipation characteristics.

In other applications of this sort, a good

image can be stored and compared to

the inspection image by using pixel-bypixel subtraction. Ideally, the resulting

image would be entirely black, indicating

no dierence and a good part. Areas

with excessive temperature dierences

indicate a bad part, making it very easy to

discern unwanted dierences.

There are many other applications

where the combination of non-contact

temperature measurements and imaging

at high frame rates is extremely valuable.

Some automated systems where IR

cameras are already being used include:

Automotive part production and •

assembly lines

Steel mill operations, such as slag •

monitoring and ladle inspection

Casting, soldering, and welding of •

metals and plastics

Food processing lines•

Product packaging•

Non-destructive testing, like sub-•

surface detection of voids in molded

parts

Electric utility equipment monitoring•

R&D, prototyping, and production in •

the electronics industry

An interesting automotive example is

monitoring the temperature distribution

of a pressure casting mold for a safetycritical part (Figure 2). Prior to installation

of the IR machine vision system, the

manufacturer was doing 100% inspection

using an X-ray system to reveal

subsurface imperfections. It was not

practical to do this as an inline procedure,

so the X-rays were taken a few hours after

part production. If the X-rays showed a

signicant problem in parts coming from

a particular mold, this information was

relayed to the production area so that

mold temperatures could be adjusted.

This was a lengthy and costly process that

often resulted in high scrap rates. With

the IR camera system, the mold operator

can immediately check and adjust the

temperature distribution of the mold.

Figure 2. Pressure casting mold and its

temperature distribution – an IR camera

image is used by the operator to adjust the

mold temperatures as required to produce

good parts.

Enabling Technology

Data communications are the backbone

of modern industrial SCADA, PLC, HMI’s,

and Machine Vision systems. Ethernet has

become the de facto standard for such

systems. Considering this, the features of

Page 33

27

Combining Machine Vision and Temperature Measurement

IR cameras that make for practical use in

machine vision applications are Gigabit

Ethernet (GigE) connectivity, GigE Vision™

compliance, a GenICam™ interface, and

a wide range of third party software

that supports these cameras. There are

other hardware features that are also

important.

Generally, ultra-high detector resolutions

are not needed in the targeted

applications, so a typical focal plane

array (FPA) would be 320x240 pixels.

Nevertheless, outputting a 16-bit image

stream of these 76,800 pixels at a 60Hz

frame rate amounts to about 74Mb/

sec. While this is much slower than a

1000baseT Ethernet system is capable of,

multiple cameras may be connected and

there may be a lot of other trac on the

network between image transmissions.

To speed up image transfers, data

analysis and decision-making must take

place outside the camera and is one of

the reasons why there is a good market

for third-party thermographic software.

The other reason is that most machine

vision systems are custom designed

for specic production processes. Of

course, IR camera manufacturers supply

various types of software to support their

products and facilitate application in

these systems.

The goal of the GigE Vision technical

standard is to provide a version of GigE

that meets the requirements of the

machine vision industry. One of the

industry objectives is the ability to mix

and match components from various

manufacturers that meet the standard.

Another is relatively inexpensive

accessories, such as cabling, switches,

and network interface cards (NICs) as well

as the ability to use relatively long cable

runs where required.

The GigE Vision standard, which is based

on UDP/IP, has four main elements:

A mechanism that allows the •

application to detect and enumerate

devices and denes how the devices

obtain a valid IP address.

GigE Vision Control Protocol (GVCP) •

that allows the conguration of

detected devices and guarantees

transmission reliability.

GigE Vision Streaming Protocol (GVSP) •

that allows applications to receive

information from devices.

Bootstrap registers that describe the •

device itself (current IP address, serial

number, manufacturer, etc.).

With GigE capabilities and appropriate

software, an IR machine vision system

does not require a separate frame

grabber, which was typically the case

with visible light cameras in the past.

In eect, the GigE port on the PC is the

frame grabber. Older visible light cameras

that have only analog video outputs

(NTSC and PAL) are limited to much

lower frame rates and video monitor

observations. By using GigE, an IR vision

system not only has higher frame rates,

but can be monitored remotely over

much greater distances compared to

local processing and transmitting data

over USB, Firewire, CameraLink, etc.

In addition, Ethernet components are

inexpensive compared to frame-grabber

cards and related hardware.

A GigE Vision camera typically uses

an NIC, and multiple cameras can be

connected on the network. However, the

drivers supplied by NIC manufacturers

Page 34

28

Chapter 4

use the Windows or Linux IP stack, which

may lead to unpredictable behavior,

such as data transmission delays. By

using more ecient dedicated drivers

compatible with the GigE Vision

standard, the IP stack can be bypassed

and data streamed directly to memory at

the kernel level of the PC system. In other

words, Direct Memory Access (DMA)

transfers are negotiated, which also

eliminates most CPU intervention. Thus a

near-real-time IR vision system is created

in which almost all of the CPU time is

dedicated to processing images.

To make sure a camera is GigE Vision

compliant, look for the ocial stamp

(shown in Figure 3) that can only be

applied if the camera conforms to the

standard.

Figure 3. Ocial trademark for GigE compliant

products

GenICam compliance should also

be considered for an IR camera.

GenICam compliance makes it easier

for developers to integrate cameras

into their IR vision system. The goal of

the GenICam standard is to provide

a generic programming interface for

all kinds of cameras. No matter what

interface technology (GigE Vision,

Camera Link, 1394, etc.) is used, or what

camera features are being implemented,

the application programming interface

(API) should be the same. The GenICam

standard consists of multiple modules

and the main tasks each performs are:

GenApi: conguring the camera•

Standard Feature Names: •

recommended names and types for

common features

GenTL: transport layer interface, •

grabbing images

The GenApi and Standard Feature

Names modules are currently part of the

standard module only. GenTL should be

nished soon.

Common tasks associated with IR

cameras in machine vision systems

include conguration settings, command

and control, processing the image, and

appending temperature measurement

results to the image data stream. In

addition, the camera’s digital I/O can

be used to control other hardware, and

there are triggering and synchronization

functions associated with real-time data

acquisition. GigE Vision makes hardware

independence possible, while GenICam

creates software independence. For

example, in a system with IR cameras

compliant in both and connected to a

GigE network, virtually any application

program can command a camera to

send a 60Hz stream of images that can

be easily captured without dropping

frames and losing important data. This

information can be processed for alarm

functions, trend analysis and statistical

process control.

Third Party Software Expands

Applications

By adhering to the standards described

above, IR camera manufacturers are

making it easier for developers to

integrate their cameras into vision

systems with a broad array of functions

Page 35

29

Combining Machine Vision and Temperature Measurement

#USTOM)MAGING3OLUTIONS

4URNKEY3OLUTIONSFOR

s0ROCESS#ONTROL

s0ROCESS-ONITORING

s.ON$ESTRUCTIVE4ESTING

s#USTOM3YSTEMS

4URNKEY3OLUTIONSFOR

s0ROCESS#ONTROL

s0ROCESS-ONITORING

s.ON$ESTRUCTIVE4ESTING

s#USTOM3YSTEMS

#RITICAL6ESSEL-ONITORING

0ACKAGE3EALING

7ASTE"UNKER-ONITORING

0ETROCHEMICAL0ERIMETER3ECURITY

0LANT-ONITORING

3OLAR0ANEL)NSPECTION

#OMPOSITE-ATERIAL4ESTING

#RITICAL6ESSEL-ONITORING

0ACKAGE3EALING

7ASTE"UNKER-ONITORING

0ETROCHEMICAL0ERIMETER3ECURITY

0LANT-ONITORING

3OLAR0ANEL)NSPECTION

#OMPOSITE-ATERIAL4ESTING

WWWMOVIMEDCOM

s

s

s

s

s

s

s

s

s

s

s

s

s

s

(Figure 4). Camera manufacturers also

supply a variety of software products to

ease integration tasks. For example, the

FLIR A325 comes with three packages that

run on a PC controller:

IP Conguration utility – nds cameras •

on the network and congures them

IR Monitor – displays images and •

temperature data on up to nine

cameras simultaneously

AXXX Control and Image interface •

– low-level descriptions of how to

communicate with the camera,

including image formats and C-code

examples

In addition, optional software developer

toolkits are available (FLIR SDK, LabVIEW

SDK, Active GigE SDK from A&B Software,

etc.) for those creating source code for

custom applications within programming

environments such as Visual Basic, C++,

Delphi, etc. However, the strength of

a camera like the A325 is its ability to

interface with third party software that

eliminates or minimizes the need to

write source code. For example, National

Instrument’s Vision Builder for Automated

Inspection is a congurable package for

building, benchmarking, and deploying

machine vision applications (Figure

5). It does not require the user to write

program code. A built-in deployment

interface facilitates system installation

Figure 4. IR cameras can be used in a broad array of applications

Page 36

30

Chapter 4

and includes the ability to dene

complex pass/fail decisions, control

digital I/O, and communicate with serial

or Ethernet devices, such as PLCs, PCs,

and HMIs. Similar features are available in

Common Vision Blox, a Stemmer Imaging

product that contains hardware- and

language-independent tools and libraries

for imaging professionals.

By using third party software to get much

of the analytics, command, and control

functions out of the camera and onto a

PC, application possibilities are greatly

expanded. One possibility is creating a

mixed camera system. For instance, IR

cameras could be used to supply thermal

images and temperature data, while

visible light cameras could provide “white

light” color recognition.

The food processing industry is one in

which higher level analytics are used with

IR cameras for automated machine vision

applications. A broad area of applications

where IR vision systems excel is in 100%

inspection of cooked food items coming

out of a continuous conveyor oven. A

primary concern is making sure the

items have been thoroughly cooked,

which can be determined by having

the camera measure their temperature,

which is illustrated in Figure 6 for

hamburger patties. This can be done by

dening measurement spots or areas

corresponding to the locations of burgers

as they exit the oven. If the temperature

of a burger is too low, the machine

vision program logic not only provides

an alarm, but also displays an image to

the oven operator to show the specic

burger that should be removed from the

line. As in other applications, minimum,

maximum, and average temperatures can

be collected for specic burgers or the

FOV as a whole and used for trending and

SPC purposes.

Figure 6. IR machine vision image for

checking hamburger doneness by measuring

temperature

In another example involving chicken

tenders, temperature is again used to

check for proper cooking. The pieces

come out of the oven and drop onto

another conveyor in more or less random

locations (Figure 7). The operator can

use the thermographic image to locate

undercooked items within the randomly

spaced parts and then remove them from

the conveyor.

In the production of frozen entrées,

IR machine vision can use pattern

recognition software to check for proper

lling of food tray compartments.

Find any number of

edges

Set up coordinate

systems

Find and match

patterns

Acquire with IEEE 1394

and GigE cameras

Detect and measure

objects

Calibrate measurements

to real-world units

Perform advanced

geometric analysis

Find and measure

straight edges

Find circular edges

Make caliper distance

measurements

Make pass/fail

decisions

Read text (OCR)

Communicate with

external devices suc

h

as PLCs

Measureintensity

Read 1D and 2D

bar codes

Figure 3. Examples of the many functions

available in Vision Builder for automated

inspection

Page 37

31

Combining Machine Vision and Temperature Measurement

Similarly, it can be used for 100%

inspection of the heat-sealed cellophane

cover over the nished entrée. An added

function could be laser marking of a

bad item so it can be removed at the

inspection station.

Summary

IR machine vision and temperature

measurements can be applied to an

innite number of automated processes.

In many cases, they provide images

and information that are not available

with visible light cameras, and they

also complement white light images

where the latter are required. IR cameras

like the FLIR A325 provide a stream of

digitized IR images at fast frame rates for

relatively high-speed processes, which

can be transmitted over GigE networks to

remote locations. Compliance with GigE

Vision and GenICam standards means

that such cameras can be integrated

with a wide variety of similarly compliant

equipment and supported by a broad

range of third party software. Trigger and

synchronization capabilities allow them

to control, or be controlled by, a host of

other types of equipment. The availability

of wireless and beroptic line adapters

allow these cameras to be used almost

anywhere, including over long distances.

Figure 7. An IR temperature measurement

and thermographic image are used to locate

undercooked chicken tenders and stop the line

so bad parts can be removed.

Page 38

32

Chapter

Real-Time Control Issues

Background

Real-time control is an important issue in

most IR machine vision systems used for

automated temperature monitoring and

inspection. Having said that, it should be

noted that real time tends to be a relative

term, the measure of which varies with

the application and user requirements. In

some applications, users would consider

a response time of 100 milliseconds to

meet their denition of real-time. On

the other hand, many electronic events

are extremely fast or short-lived, and a

one-microsecond response might be

needed. As mentioned in earlier chapters,

process temperatures tend to change

relatively slowly, so an IR machine vision

system that can update images and

temperatures every 10-100ms, or even

less frequently, may be adequate.

Hardware and Software Platform

Considerations

In most cases, a PC with a Microsoft

Windows operating system (OS) isn’t

well suited for controlling fast, real-time

applications. Windows is referred to as a

non-deterministic OS because it typically

cannot provide predictable response