Page 1

OWNERS GUIDE TO

INSTALLATION AND OPERATION

4” — 35-85 GPM and

6” — 50-250 GPM

8” — 325-400 GPM

SUBMERSIBLE PUMPS

WARNING

IMPORTANT SAFETY INSTRUCTIONS

RULES FOR SAFE INSTALLATION AND OPERATION

FW1184

0314

Supersedes

0611

1. Read these warnings and instructions carefully.

Failure to follow them could cause serious bodily

injury and/or property damage.

2. Follow all local electrical and safety codes as well

as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

3. The power supply should be a separate circuit,

independent of all other circuits. Be sure it is

equipped with a fuse and disconnect box of ample

capacity.

4. For fire protection, the power supply should be free

of any building, preferably on a direct line from the

transformer. In the event of fire, the wires will not be

destroyed and the water supply not cut-off.

5. Always disconnect power source before performing

any work on or near the motor or its connected load.

If the power disconnect point is out-of-sight, lock it in

the open position and tag it to prevent unexpected

application of power. Failure to do so could result in

fatal electrical shock.

6. DO NOT handle pump with wet hands or when

standing in water as fatal electrical shock could occur.

Disconnect main power supply before handling pump

for any reason.

7. Shut off power source when voltage drops 10% below

the rated voltage of the motor.

8. Protect the power cable from coming in contact with

sharp objects, oil, grease, hot surfaces or chemicals.

DO NOT kink the power cable. If damaged replace

immediately.

9. NEVER leave the control box, fused disconnect

switch, or covers open (either partially or completely)

when not being worked on by a competent electrician

or repairman.

10. Always use caution when operating electrical controls

in damp areas. If possible, avoid all contact with

electrical equipment during thunderstorms or extreme

damp conditions.

11. Install all electrical equipment in protected area to

prevent mechanical damage which could produce

serious electrical shock and/or equipment failure.

12. Pump is designed to pump cold ground water that is

free of air or gases. Decreased pump performance

and life expectancy can occur if the ground water is

not cold (86F/30C) or contains air or gases.

13. Pump and controls must be securely and adequately

grounded as specified in section 250-43 item (A) of

the U.S.A. National Electric Code (NEC) and Section

26-954 Canadian Electrical Code. Failure to do so

could result in a fatal injury.

14. DO NOT use this pump to pump flammable liquids

such as gasoline, fuel oil, kerosene, etc. Failure to

follow the above warning could result in property

damage and/or personal injury.

WARNING: The pump is intended for use in a well. Motor

frame must be connected to power supply ground or fatal

electrical shock may result. Do not use this pump in

swimming pools.

NOTE: Pumps with the “CSA” mark are tested to UL

standard UL778 and certified to CSA standard C22.2 No.

108.

130582

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

1

Page 2

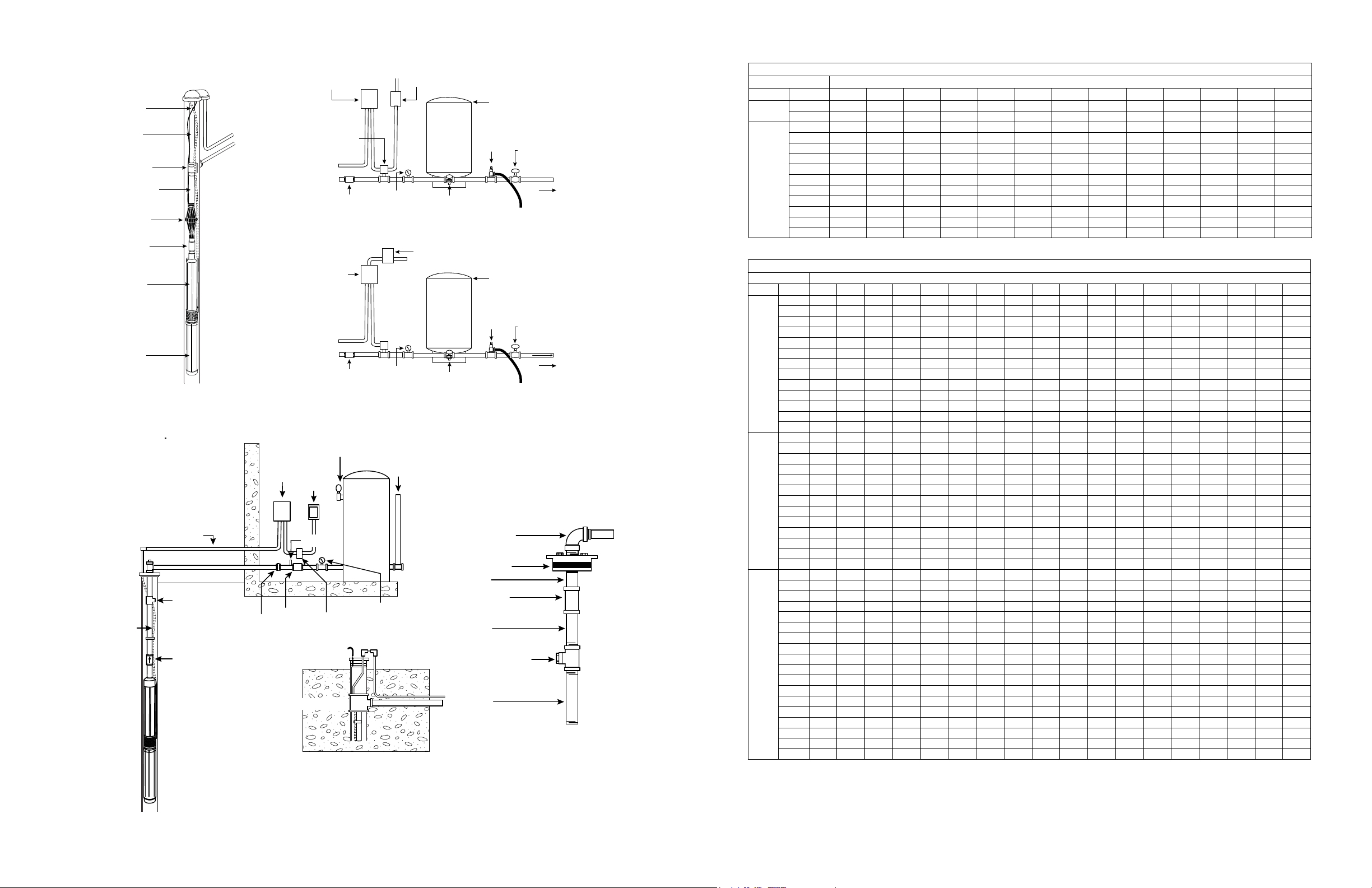

Typical Installation

Submersible

Cable

Riser

Pipe

Pitless

Adapter

Plastic or

Steel Pipe

Torque

Arrestor

Check

Valve

Submersible

Pump

Submersible

Motor

Figure 1 — Typical Installation with Pre-Charged Tank

Submersible Power

Cable to Pump

Bleeder Orifice

Power Cable

Taped

to Pipe

Check Valve

Figure 2 — Typical Installation with Standard Pneumatic Tank

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

Conduit

IL0092

Union

Control

Box

Check

Valve

Magnetic

Starter

Fused

Switch

Box

Snifter

Pressure

Switch

Pitless Unit

Control

Box

Pressure

Switch

Check

Valve

Single Phase Tank/Controls Installation

Check

Valve

Three Phase Tank/Controls Installation

Air Release and

Pressure Gauge

Tank

Relief Valve

2

Fuse Disconnect

Box

Pressure

Gauge

Fuse Disconnect

Box

Pressure

Gauge

Outlet to Service

Drain

Valve

Drain

Valve

Pre-Charged

Pressure

Tank

Pressure

Relief

Valve

Gate

Valve

To Drain

Pre-Charged

Pressure

Tank

Pressure

Relief

Valve

Gate

Valve

To Drain

90º Elbow

Well Seal

Pipe

Coupling

Pipe

Bleeder Valve

Rubber Orifice

Pipe

To

Service

To

Service

IL0093A

CABLE SELECTION

Single Phase, 2-Wire or 3-Wire Cable, 60 Hz (Service Entrance to Motor)

Motor Rating Copper Wire Size

Volts HP 14

115

230

1 foot = .3048 meters

1/3 130 210 340 540 840 1300 1610 1960 2390 2910 3540 4210 5060

1/2 100 160 250 390 620 960 1190 1460 1780 2160 2630 3140 3770

1/3 550 880 1390 2190 3400 5250 6520 7960 9690 11770

1/2 400 650 1020 1610 2510 3880 4810 5880 7170 8720

3/4 300 480 760 1200 1870 2890 3580 4370 5330 6470 7870

1 250 400 630 990 1540 2380 2960 3610 4410 5360 6520

1-1/2 190 310 480 770 1200 1870 2320 2850 3500 4280 5240

2 150 250 390 620 970 1530 1910 2360 2930 3620 4480

3 120* 190 300 470 750 1190 1490 1850 2320 2890 3610

5 0 0 180* 280 450 710 890 1110 1390 1740 2170 2680

7-1/2 0 0 0 200* 310 490 610 750 930 1140 1410 1720

10 0 0 0 0 250 390 490 600 750 930 1160 1430 1760

15 0 0 0 0 170* 270* 340 430 530 660 820 1020 1260

Three Phase, 3-Wire, 60 Hz, 200 and 230 Volts (Service Entrance to Motor)

Motor Rating Copper Wire Size

Volts HP 14 12 10 8 6 4 3 2 1 0 00 000 0000 250 300 350 400 500

200V

60Hz 3

Phase

3 Wire

230V

60Hz 3

Phase

3 Wire

460V

Phase

3 Wire

CAUTION: Use of wire size smaller than listed will void warranty.

(*) Meet the U.S. National Electrical Code ampacity only for individual conductor 60ºC cable. Only the lengths without * meet the code for jacketed 60ºC cable. Local code

Maximum lengths shown maintain motor voltage at 95% of service entrance voltage, running at maximum nameplate amperes. If service entrance voltage will be at least motor nameplate

voltage under normal load conditions, 50% additional length is permissible for all sizes.

This table is based on copper wire. If aluminum wire is used it must be two (2) sizes larger. Example: When the table calls for #12 copper wire you would use #10 aluminum wire.

Single phase control boxes may be connected at any point of the total cable length.

Cables #14 to #0000 are AWG sizes.

1/2 710 1140 1800 2840 4420

3/4 510 810 1280 2030 3160

1 430 690 1080 1710 2670 4140 5140

1-1/2 310 500 790 1260 1960 3050 3780

2 240 390 610 970 1520 2360 2940 3610 4430 5420

3 180 290 470 740 1160 1810 2250 2760 3390 4130

5 110* 170 280 440 690 1080 1350 1660 2040 2490 3050 3670 4440 5030

7-1/2 0 0 200 310 490 770 960 1180 1450 1770 2170 2600 3150 3560

10 0 0 0 230* 370 570 720 880 1090 1330 1640 1970 2390 2720 3100 3480 3800 4420

15 0 0 0 160* 250* 390 490 600 740 910 111 0 1340 1630 1850 2100 2350 2570 2980

20 0 0 0 0 190* 300* 380 460 570 700 860 1050 1270 1440 1650 1850 2020 2360

25 0 0 0 0 0 240* 300* 370* 460 570 700 840 1030 1170 1330 1500 1640 1900

30 0 0 0 0 0 0 250* 310* 380* 470 580 700 850 970 111 0 1250 1360 1590

1/2 930 1490 2350 3700 5760 8910

3/4 670 1080 1700 2580 4190 6490 8060 9860

1 560 910 1430 2260 3520 5460 6780 8290

1-1/2 420 670 1060 1670 2610 4050 5030 6160 7530 9170

2 320 510 810 1280 2010 3130 3890 4770 5860 7170 8780

3 240 390 620 990 1540 2400 2980 3660 4480 5470 6690 8020 9680

5 140* 230 370 590 920 1430 1790 2190 2690 3290 4030 4850 5870 6650 7560 8460 9220

7-1/2 0 160* 260 420 650 1020 1270 1560 1920 2340 2870 3440 4160 4710 5340 5970 6500 7510

10 0 0 190* 310 490 760 950 1170 1440 1760 2160 2610 3160 3590 4100 4600 5020 5840

15 0 0 0 210* 330 520 650 800 980 1200 1470 1780 2150 2440 2780 3110 3400 3940

20 0 0 0 0 250* 400 500 610 760 930 1140 1380 1680 1910 2180 2450 2680 3120

25 0 0 0 0 0 320* 400 500 610 750 920 1120 1360 1540 1760 1980 2160 2520

30 0 0 0 0 0 260* 330* 410* 510 620 760 930 1130 1280 1470 1650 1800 2110

1/2 3770 6020 9460

3/4 2730 4350 6850

1 2300 3670 5770 9070

1-1/2 1700 2710 4270 6730

2 1300 2070 3270 5150 8050

3 1000 1600 2520 3970 6200

5 590 950 1500 2360 3700 5750

7-1/2 420 680 1070 1690 2640 4100 5100 6260 7680

60

Hz 3

10 310 500 790 1250 1960 3050 3800 4680 5750 7050

15 0 340* 540 850 1340 2090 2600 3200 3930 4810 5900 7110

20 0 0 410* 650 1030 1610 2000 2470 3040 3730 4580 5530

25 0 0 0 530* 830 1300 1620 1990 2450 3010 3700 4470 5430

30 0 0 0 430* 680 1070 1330 1640 2030 2490 3060 3700 4500 5130 5860

40 0 0 0 0 500* 790 980 1210 1490 1830 2250 2710 3290 3730 4250

50 0 0 0 0 0 640* 800 980 1210 1480 1810 2190 2650 3010 3420 3830 4180 4850

60 0 0 0 0 0 540* 670* 830* 1020 1250 1540 1850 2240 2540 2890 3240 3540 4100

75 0 0 0 0 0 0 0 680* 840* 1030 1260 1520 1850 2100 2400 2700 2950 3440

100 0 0 0 0 0 0 0 0 620* 760* 940* 1130 1380 1560 1790 2010 2190 2550

requirements may vary.

12 10 8 6 4 3 2 1 0 00 000 0000

3

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

Page 3

ell Screen

IL0096

Pump on.

Water enters

the reservoir

System Filled.

Pump Off

READ THESE INSTRUCTIONS COMPLETELY BEFORE INSTALLATION

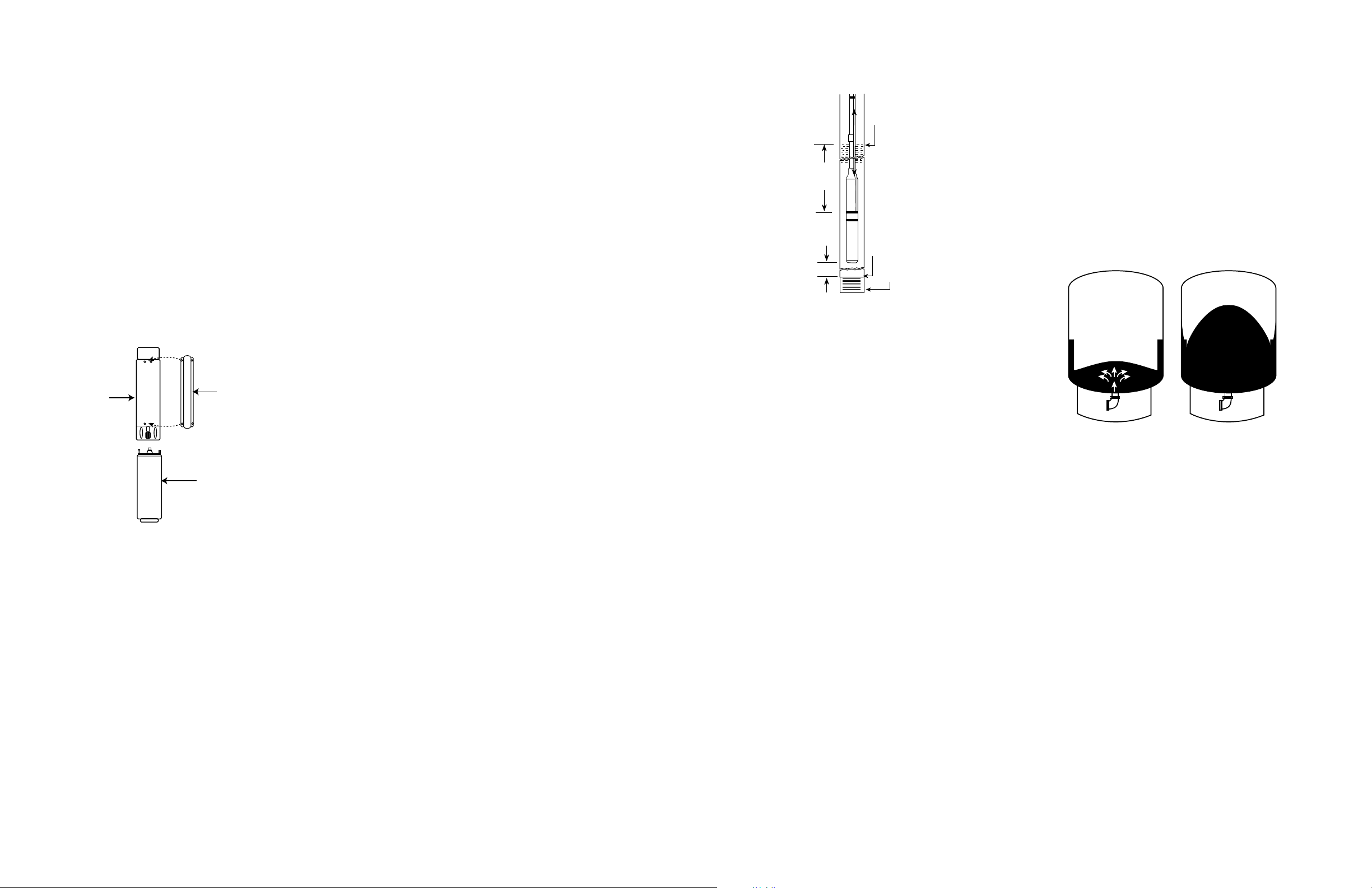

ASSEMBLY

CAUTION: Be sure pump size corresponds with

horsepower size of motor. If pump size exceeds

recommended motor, overloading of motor and damage to

the motor could result.

1. If not yet assembled, check that the pump and motor

mounting faces are free from dirt.

2. Assemble the pump liquid end and motor together

so that mounting faces are in contact. Then tighten

assembly bolts evenly.

NOTE: Apply non-toxic FDA approved waterproof grease

such as Mobile 102, Texaco CYGNUS2661 or equivalent

to the coupling before assembly of pump coupling to

motor shaft. This will prolong spline life and prevent

abrasives from entering the spline area.

3. Check for free rotation of the pump and motor. A

slight drag is permissible.

4. Assemble the pump lead guard over the motor leads.

CAUTION: Do not cut or pinch lead wire during assembly.

5. Assemble suction screen to pump mounting ring.

Lead Wire

Liquid

End

IL0094B

Figure 3

PRE-INSTALLATION

To save possible added expense and extra trips, observe

and complete as many as possible of the following

precautions and pre-installation procedures before going

to the job site or beginning the installation.

IMPORTANT PRECAUTIONS

1. Prior to installation, inspect the pump for damage.

Check for free pump and motor rotation. A slight

drag is permissible.

2. Check to make certain that the voltage of the motor

end and control agree with the available phase and

voltage. Check power source. Check electrical

supply for correct fusing, correct wire size, and

adequate grounding and transformer size.

Guard

Motor

WARNING: Since most submersible pump problems are

electrical, it is very important that all electrical work be

done properly. Therefore, all electrical hook-up work

or electrical service work should be done by a qualified

electrician or service man only!

3. Throughout installation, take care not to damage

the insulation of the electrical cable or motor leads.

Never support the weight of the unit by electrical

cable or motor leads.

4. Before the pump is installed, the well should be

pumped free of sand and other foreign matter with

a test pump. The warranty is void if it is used to

clean the well.

5. Follow wiring directions in the control box and make

momentary tests to see that motor runs. (It is normal

to hear some noise from the pump when you are

momentarily testing it). Do not run pump dry for

more than three (3) seconds.

MAJOR WELL COMPONENTS (see Figures 1 & 2)

1. Submersible Pump — A submersible pump is a multistage centrifugal. Each stage consists of an impeller

and diffuser. Water pressure increases in equal

amounts as it passes from stage to stage. The more

stages, the higher the pressure the pump will develop.

2. Submersible Motor — Submersible pumps can

be powered by either single phase or three phase

motors. Make certain that the motor corresponds

with the horsepower required by the pump. Failure

to do so, could result in overloading of the motor and

motor damage.

3. Control Box — Single phase submersible motors

require the use of an above ground control box for

starting. Operation of these motors without control

boxes or with incorrect boxes can result in failure of

motors which will void the warranty.

4. Magnetic Starters and Overload Protection —

Three phase submersible motors require the use

of an above ground magnetic starter and overload

protection. Operation of these motors without or

incorrect starters and protectors will result in the

failure of motor which will void the warranty. See

Magnetic Starter Chart for the correct selection of

magnetic starters and ambient compensated quick

trip protectors.

5. The Well — The well should be sand free and have

a sufficient flow of water to supply the pump. Clear

well of sand and any other foreign matter with a test

pump before installing the new submersible pump.

CAUTION: Using the submersible pump to clean the well

will void the warranty.

6. When drilling a new well in an area where sand is a

problem, a sand screen should be installed to protect

the pump and motor.

7. The well should be straight so damage during

installation does not occur to the pump or motor by

becoming lodged in a crooked well casing.

8. The complete pump and motor should be submerged

at least twenty feet below the draw down level of the

well, and the motor should be a minimum of ten feet

off the bottom of the well (Figure 4).

Drawdown

Water Level

20 Ft.

Top of W

10 Ft. Min.

Figure 4

Bottom of Well

9. The Piping — Install the pump with pipe of the same

diameter as the discharge port of the pump or larger.

NOTE: Use of pipe smaller that the discharge port of the

pump will restrict the capacity of the pump and lower its

operating performance.

10. Check Valve — A check valve is required on all

submersible installations. This valve maintains water

within the pipe when the pump is running. A line check

should be installed within 25 feet of the pump and

below the draw down level of the water supply.

a. For well depths exceeding 200 feet, it is suggested

that an additional check valve be installed every

100 feet.

b. An additional check valve should be installed in the

horizontal line between the well top and the pressure

tank (See Figures 1 & 2).

CAUTION: Make certain that the check valve is pointing in

the right direction, arrow pointing towards the tank.

11. Torque Arrester — To center the pump as it is

being lowered into the well, a torque arrester is

recommended. This will also minimize the pump

whipping due to the starting torque of the motor (See

Figure 2).

NOTE: On plastic pipe installations a torque arrester

must be installed. Cable guards should also be installed.

12. Pressure Tank — The purpose of the pressure tank

is to allow an amount of water to be drawn before the

pressure drops enough to cause the pump to start.

Without a pressure tank, the pump would start and

stop continuously when water is drawn. There are

two types of pressure tanks, the standard tank that

requires an air volume control and the pre-charged

tank.

a. On a standard pneumatic tank system, air is

introduced to compensate for that which is

absorbed by the water. Each time the pump

cycles air is added to the tank through a bleeder

and snifter valve. The excess air is released by

a float assembly (air volume control) in the upper

side tapping of the tank (See Figure 2).

b. In a pre-charged tank, a flexible diaphragm or

bladder separates the air and water areas of the

tank. The air chamber is pre-charged by means of

a tire valve with pressure 2 PSI less than the cuton pressure of the pump. Because the air is not

in contact with the water, it cannot be absorbed by

the water. Therefore, the original charge of air is

never lost.

13. In pre-charged tank systems, none of the fittings for

air introduction or air level control are required (Figure

1). The piping in the well is also different for the two

systems. The pre-charged tank system does not

require a bleeder orifice assembly, which simplifies

the installation.

Figure 5

14. The tank size should be selected to keep the pump

starts per day as low as practical for maximum life.

Excessive motor cycling accelerates motor bearing

and spline wear, pump wear and contact erosion.

Use as a guide, 100 starts per day (24 hours) on

single phase motors and 300 starts per day on three

phase units.

15. Pressure Switch — The pressure switch provides

for automatic operation. The pump starts when the

pressure drops to the switch cut-in setting and stops

when the pressure reaches the switch cut-out setting.

The pressure switch must be installed as close to the

tank as possible (Figures 1 & 2).

16. Pressure Relief Valve — A properly sized pressure

relief valve must be installed on any installation where

the pump pressure can exceed the pressure tank’s

maximum working pressure or on systems where

the discharge line can be shut off or obstructed. The

relief valve drain port should be piped to a drain

(Figures 1 & 2).

WARNING: Not providing a relief valve can cause extreme

over pressure, which could result in personal and/or

property damage.

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

4

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

5

Page 4

IL0099

IL0097

Staked Connector

Rubber Tape

PVC Electrical Tape

2” 2”

2” 2”

17. Pitless Adapter — A pitless adapter provides below

grade discharge while maintaining above grade

access to the well. Placed below the frost line they

are frost proof and also prevent well contamination

by providing a water tight seal between the vertical

drop pipe and the horizontal service pipe connection

(Figure 1).

18. Well Seal — On well seal installations the piping in

the well projects above the well and is connected

above ground to the system piping by means of a

tee or elbow. Since the plumbing is above ground, it

must be protected from freezing (Figure 2).

19. Submersible Cable — Submersible power cable

must be UL listed for submersible pump application.

Selecting the proper cable size is important.

Undersized cable results in a too low voltage supply to

the pump motor and ultimate motor failure. Oversized

cable is costly and not necessary. Refer to cable

selection chart for proper cable selection. Cable is

selected for the maximum pump setting plus the offset

distance to the service entrance.

20. Ground Wire — The National Electric Code (NEC 250-

43) requires a separate ground wire be run down the

well to the submersible pump and to be connected to

all exposed metal parts of the pump and motor. Refer

to the most recent National Electric Code (NEC) for

additional grounding information. All wiring should be

done by a competent electrician.

INSTALLATION

SUBMERSIBLE CABLE INSTALLATION

1. Check power source. Check electrical supply for

correct fusing, correct wire size, and adequate

grounding and transformer size.

WARNING: Since most submersible pump problems are

electrical, it is very important that all electrical work be

done properly. Therefore, all electrical hook-up work

or electrical service work should be done ny a qualified

electrician or serviceman only!

2. Follow wiring directions in the control box and make

momentary tests to see that the motor runs. Do not

run pump dry for more than three (3) seconds. If

test is satisfactory, proceed to Step 3 (cable splice).

3. First check cable size against the Submersible

Wire Size Chart. Use extreme care; this is a very

important step. If required length falls between

two wire sizes, use the larger of the two wire sizes

(smaller number).

IMPORTANT: Use of wire sizes smaller than those

specified in the charts will cause low starting voltage,

may cause early pump failure and will void the warranty.

Larger wire sizes may always be used for better operating

economy.

4. Splice motor leads to submersible cable with

commercially available potting, heat shrink splicing

kits or by careful tape splicing. Tape splicing should

use the following procedure.

a) Strip individual conductor of insulation only as far

as necessary to provide room for a stake type

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

connector. Tubular connectors of the staked type

are preferred. If connector O.D. is not as large as

cable insulation, build-up with rubber electrical tape.

b) Tape individual joints with rubber electrical tape,

using two layers; the first extending two inches

beyond each end of the conductor insulation end,

the second layer two inches beyond the ends of

the first layer. Wrap tightly, eliminating air spaces

as much as possible.

c) Tape over the rubber electrical tape with #33

Scotch electrical tape, (Minnesota Mining Co.)

or equivalent, using two layers as in step “B”

and making each layer overlap the end of the

preceding layer at least two inches.

5. In the case of a cable with three conductors encased

in a single outer sheath, tape individual conductors as

described, staggering joints. Total thickness of tape

should be less than the thickness of the conductor

insulation.

GROUND WIRE INSTALLATION

WARNING: Motor frame must be connected to power

supply ground or fatal electrical shock may result.

Figure 6

NOTE: All electrical wiring should be done by a

competent electrician.

1. Grounding the submersible pump is accomplished

by running a copper grounding wire from the pump

motor to the main electrical system ground.

2. The ground wire to be used must be of the same

size as the submersible power cable. It may be

insulated or bare. If insulated, it must be green, with

or without yellow stripe(s). The ground wire may be

part of, or separate from, the supply cable. It may be

continuous or spliced above the pump along with the

supply cable.

3. The motor lead wire assembly includes a green

insulated ground lead. Splice the ground wire to the

green insulated lead as shown in Figure 6.

4. The other end of the ground wire will be connected to

the power supply grounding terminal or to the control

panel ground bar if it is connected to the power

supply ground.

NOTE: See section entitled Grounding for detailed

grounding instructions.

6

INSULATION AND CONTINUITY TEST

1. It is recommended that this test be done when the

splicing is complete and pump is being test run in

a tank of water. This test can be repeated after

installation in well but before the final electrical hookup is made to the control box or pressure switch (see

Figures 7 & 8).

Figure 7

Figure 8

2.

Zero the ohmmeter by clipping the leads together and

adjusting the zero ohm knob until the needle indicates

zero. Zero the ohmmeter before each use or every time

selector switch is changed.

3. Clip one ohmmeter lead to bare cable end.

4. Clip the other lead to edge of steel tank in which

pump and cable are submerged. If pump is already

in the well, clip lead to discharge pipe metal well

casing or bare ground wire.

5. A reading of less that 1,000,000 ohms indicates that

cable or splice is grounded. Slowly raise cable from

the water at the ohmmeter end. When trouble spot

moves clear of the water, needle will move toward

infinity reading. In an old installation with the pump in

the well, a reading of 20,000 ohms or less indicates

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

a breakdown in the insulation; in this case pull the

pump.

PUMP INSTALLATION

1. The following pump installation instructions use

Schedule 80 PVC pipe or galvanized pipe. If either

of these two types are used, a foot clamp or vise will

be required to hold the PVC or galvanized pipe when

connecting the next pipe length.

2. Install the pump in a well which is sand-free, straight,

and has sufficient flow of water to supply the pump.

Clear well of sand and any other foreign matter with a

test pump before installing the submersible pump.

NOTE: Using the submersible pump to clean the well

will void the warranty. When drilling a new well in an

area where sand is a problem, a sand screen must be

installed to protect the pump and motor.

3. Chlorinate the well first. Drop 24 to 48 HTH (chlorine)

tablets into the well before lowering the pump into the

well. This will prevent contamination and the growth

of iron bacteria which could later plug the well and the

pump. The chlorinated water will be pumped out of

the system when testing the pump flow.

4. BE SURE the top edge of the well casing is perfectly

smooth; sharp or jagged edges can cut or scrape the

cable and cause a short.

5. Install a line check valve within 25 feet of the pump

and below the draw down level of the water supply.

The check valve should be the same size as the

discharge outlet of the pump or larger.

NOTE: Use of pipe smaller that the discharge tapping of

the pump will restrict the capacity of the pump and lower

its operating performance.

6. When connecting the first length of pipe and

placing the pump in the well casing, care should be

maintained to center the pump in the well. It is easier

to handle the pump if a short piece of pipe is installed

first, rather than a long piece. Install the check valve

at the end of the first piece of pipe prior to lowering

the pump into the well. Maintain alignment as the

pump is placed and lowered into the well, a torque

arrester is recommended. Position the torque arrestor

to within 6” of the pump discharge and clamp arrestor

to pipe. Wrap the pipe with enough tape at top and

bottom of torque arrestor to keep it from sliding up the

pipe while the pump is being lowered into the well.

7. If not already done, splice the electrical cable to the

motor leads. The cable and ground wire should be

taped to the discharge pipe. Tape the cable about 5

feet above the discharge and every 20 feet thereafter.

Install cable guards if required to eliminate rubbing

against the well casing. Do not let the cable drag

over the edge of the well casing. Never allow the

weight of the pump to hang on the cable alone.

7

Page 5

IL0100

Fused Disconnect

Switch

Ground

Pressure

Switch

Ground

L1 L2

R Y B

Control Box

To Motor

Ground

Red

Yellow

Black

Lightning

Arrestor

SW

IL0102

Pressure

Switch

3

2

L1 L2 L3

Fused Disconnect

Switch

Lightning

Arrestors

V

M

W

T1

T2

X2

T3

Motor

Ground

T3

T1

Fused Disconnect

Switch

Ground

Pressure Switch

Ground

L1 L2

R Y B

Control Box

To Motor

Ground

Red

Yellow

Black

Lightning

Arrestor

IL0100

8. Lower the pump into the well slowly without forcing.

Use a vise or foot clamp to hold the pipe while

connecting the next length. A boom, tripod or

pump setting rig is recommended. Lower pump to

approximately 10 feet below maximum draw down

of the water if possible and keep approximately 10

feet from the bottom. DO NOT set pump on bottom

of well. Before each new length of pipe is added,

attach the coupling to the top of the pipe length. This

will provide a stop for the foot clamp to hold while the

next section of pipe is being installed.

9. On a standard tank with an air volume control a

bleeder orifice is required. Install the bleeder orifice

in the discharge pipe 5 feet or more below the snifter

valve. See Figure 2 and the table below.

Distance Table

Tank Size

Gallons

42

82

120

220

315

525

Depth From Horizontal Check

Valve To Bleeder Orifice

5

10

15

15

20

20-35

Installations that use a pre-charged pressure tank

do not require a bleeder orifice.

WELL SEAL/PITLESS ADAPTER INSTALLATION

1. All installations should have a well seal. Make sure

the seal is seated and tighten the bolts evenly.

NOTE: Be sure to assemble the tee to the pipe above

the well seal to prevent dropping the pipe and pump

down the well as you lower it.

IMPORTANT: Well seal and piping must be protected

from freezing.

2. On a pitless adapter installation, the connection to the

system supply line is made below ground. Install the

pitless adapter following the instructions included with

particular brand or design being used in the installation.

NOTE: Follow ALL applicable state and local plumbing

codes.

PRELIMINARY TEST RUN

1. When pump is at desired depth, install throttle valve

for preliminary test run. Wire single phase motors

through the control box, following instructions in box

regarding color coding of wires, etc. Wire 3-phase

motors through a magnetic starter. Test cable for

continuity with an ohmmeter.

2. With pump discharge throttled, run pump until water

is clear of sand or any other impurities. Gradually

open discharge.

CAUTION: Be sure you do not stop pump before water

runs clear. This may take several hours. If pump stops

with sand in it, it will lock.

3. If pump lowers water in the well far enough to lose

prime, either lower pump in the well (if possible) or

throttle discharge to capacity of the well.

4. If well is low capacity, use a low water level control.

5. On 3-phase units, establish correct motor rotation

by running in both directions. Change rotation by

exchanging any two of the three motor leads. The

rotation that gives the most water flow is always the

correct rotation.

PRESSURE TANK INSTALLATION

1. On a new installation, install the pressure tank along

with the pressure switch, pressure gauge, pressure

relief valve, check valve, gate valves and unions as

shown in Figures 1 & 2.

2. On replacement pump installations be sure that the

tank system is in good operating condition, as a

water logged tank may cause pump failure.

ELECTRICAL HOOK-UP

WARNING: Since most submersible pump problems are

electrical, it is very important that all electrical work be

done properly. Therefore, all electrical hook-up work

or electrical service work should be done by a qualified

electrician or serviceman only!

WARNING: Always disconnect power source before

working on or near motor, its connected load or control

box and wiring. If the power disconnect is out of sight,

lock it in the open position and tag to prevent unexpected

application of power.

1. Proceed with electrical hook-up matching cable colors

and following the wiring diagrams (Figures 9, 10 &11)

or inside the lid of the control box.

WARNING: Connect motor leads momentarily for correct

rotation before installing pump in well.

FUSE SIZES

Figure 9 — Single Phase Control Box

Figure 10 —

Single Phase Control Box with Contactor

Figure 11 — Three Phase Magnetic Starter

1. For proper sizing of fuses for fuse disconnect box,

see Motor Data Charts. Improperly sized fuses will

result in fuses blown or circuit breakers tripped.

GROUNDING

Proper Grounding of Submersible Motors

1. The purpose of grounding any electrical apparatus is

to prevent an electrical shock hazard if exposed metal

becomes connected to an electrical circuit. This can

occur from a defect in construction of the electrical

equipment, physical damage, or a breakdown in the

insulation of the equipment. Grounding prevents

shock hazard by keeping exposed metal from

reaching a voltage level which could endanger

anyone coming in contact with the electrical

equipment. Fault current is “drained” by the ground

conductor, and if the fault is severe enough, the

circuit will be opened by the fuse or circuit breaker.

2. The U.S. National Electrical Code (NEC) requires that

motor-operated water pumps, including submersible

type regardless of voltage, shall be grounded. The

Canadian Electrical Code specifically discusses

grounding requirements for submersible pumps.

Interpretation of these and other codes may vary

in different states and localities, but all applicable

national, state, and local codes should always be

followed.

3. Any submersible motor which is to be run tested out

of the well should be grounded to prevent possible

shock hazard during the test.

NOTE: Always disconnect all power when making

ohmmeter check and while pulling or installing a pump.

4. The most logical way to “frame” ground a submersible

motor is normally as follows:

a. Run an extra wire with the motor power conductors.

This wire must be sized to meet Table 250-95 in the

U.S. National Electrical Code. If code information

is unavailable, using the same size wire as the

power conductors is normally adequate.

b. The ground wire may be insulated or bare. If

insulated, it must be green with or without yellow

stripe(s). The ground wire may be part of, or

separate from the supply cable. It may be

continuous or spliced above the pump along with

the supply cable.

c. Connect the green or bare ground wire to the

green ground wire of the submersible motor lead

assembly. If the lead wire assembly does not

include a separate ground wire, attach a lug to

the ground wire and place the lug over one of the

motor studs above the pump intake flange so the

pump will not be cocked. The ground lug will then

be secured with the nut which holds the pump on

the motor.

d. Connect the other end of the ground wire to the

power supply grounding terminal or to the control

panel ground bar if it is connected to the power

supply ground.

e. All connections should be tight and corrosion

resistant, including screws, lugs or clamps.

Grounding Control Boxes

1. It is recommended the control box grounding terminal

always be connected to circuits which include a

grounding conductor. In fact, this is a requirement

of the National Electrical Code. If the circuit has no

grounding conductor and no metal conduit from the

box to supply panel, use a wire at least as large as

line conductors and connect from supply panel to the

control box and to the motor lead ground wire.

WARNING: Failure to ground the box frame can result in a

fatal electrical shock hazard if a circuit fault occurs.

WARNING: Serious or fatal electrical shock may result

from failure to connect all metal plumbing, and the motor

if outside a drilled well, to the power supply grounding

terminal with wire no smaller than motor cable wires. Do

not use motor in swimming area.

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

8

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

9

Page 6

IL0104

Grounding Lightning Arrestors In Control Boxes

IL0103

Pump Body

Stainless Steel

Worm Gear Clamps

Intake Screen

Flow Inducer Screen

(Corrosion Resistant

Material)

Submersible Motor Centering Bolt

Corrosion Resistant

(3 Places)

All Water Flows

Past Motor

1. When the box has a lightning arrestor, it must be

grounded, metal to metal, all the way to the water

strata for the lightning arrestor to be effective.

Grounding the arrestor to a driven ground rod

provides little or no protection for the motor.

SUBMERSIBLE MOTOR COOLING

1. When the pump is set below any screen openings

or below the bottom of the casing a top feeding well

condition can exist which reduces the rate of cooling

water flow past the motor.

2. If the flow rate is less than specified a flow indicator

sleeve or an alternate method of increasing water

velocity past the motor must be used for proper

cooling.

Minimum Velocity Past the Motor

4” dia. motor – .25 ft./sec. (7.62 cm/sec)

6” dia. motor – .5 ft./sec/ (15.24 cm/sec)

3. A flow inducer sleeve is a tube over the motor, closed

off above the pump intake and extended to the bottom

of the motor or lower. The sleeve material is corrosion

resistant metal or heavy plastic (See Figure 12).

Figure 12

4. A flow inducer sleeve should always be used when

the pump is in an open body of water. Make sure

that such an installation is grounded.

Required Cooling Flow

Minimum GPM required for motor cooling in water

up to 86ºF (30ºC).

Inches

Casing or

Sleeve I.D.

4

5

6

7

8

10

12

14

16

4” High

Thrust Motor

.25 ft/sec

GPM

1.2

7

13

20

30

50

80

110

150

6” Motor

.5 ft/sec

GPM

—

—

9

25

45

90

140

200

280

8” Motor

.5 ft/sec

GPM

—

—

—

—

10

55

110

170

245

SERVING SUBMERSIBLE MOTOR AND CONTROLS

1. The following is included to assist in motor installation

and servicing. These procedures are limited to the

motor and control system: they do not include pump

requirements.

TIGHTENING LEAD CONNECTOR JAM NUT

1. It is recommended that possible damage from removal

may prevent resealing. Torque the jam nut from 15 to

20 lb. ft. on 4” motor and 60 to 70 lb. ft. on a 6” motor.

CABLE IDENTIFICATION WHEN COLOR CODE IS

LOST

(Single Phase Only)

If the colors on the individual drop cables cannot be

determined and the leads cannot be positively identified,

proceed as follows:

1. Disconnect all three drop cables from the control box.

For temporary identification, tie a numbered tag to

each cable (1, 2, 3).

2. Using an ohmmeter, check the resistance

between cables as follows:

Unknown Value Known Value

Cable 1 to Cable 2

Cable 1 to Cable 3

Cable 2 to Cable 3

Lowest - Black to Yellow

Intermed. - Red to Yellow

Highest - Black to Red

NOTE: The “yellow” cable is that giving lowest and

intermediate readings and the “red” cables gives highest

and intermediate readings.

Example:

• 1 to 2 gives 7 ohms (highest reading)

• 1 to 3 gives 5 ohms (intermediate reading)

• 2 to 3 gives 2 ohms (lowest reading)

• Cable 3 gave both intermediate and lowest reading

• Cable 3 is the yellow cable

• Cable 1 gave both highest and intermediate readings

• Cable 1 is the red cable

• Cable 2 is the black cable

The actual ohm values are not important. The method

works regardless of the actual ohm readings; what

matters is which reading is highest, which intermediate,

and which lowest.

THREE PHASE POWER UNBALANCE

1. A full three phase supply is recommended for all

three phase motors, consisting of three individual

transformers or one three phase transformer.

So-called “open” delta or wye connections using only

two transformers can be used, but are more likely to

cause problems from current unbalance.

2. Transformer ratings should be no smaller than listed

in the table for supply power to the motor alone.

Open Wye or Delta systems often suffer from line

unbalance, which can cause poor motor performance,

nuisance overload tripping, or premature motor

failure. For the best performance current unbalance

should not exceed 5 percent. If the unbalance cannot

be corrected by rolling leads, contact the power

company.

Transformer Capacity Required for

Submersible Motors

Smallest KVA Rating — Each

Open WYE or

2 Transformers

DE LTA

2

2

3

5

7.5

10

15

15

20

25

30

35

40

50

65

Transformer

Closed WYE or

DE LTA

3 Transformers

1.5

7.5

10

10

15

20

20

25

30

40

1

2

3

5

5

Motor

HP

1-1/2

2

3

5

7-1/2

10

15

20

25

30

40

50

60

75

100

Total

Effective

KVA

Required

3

4

5

7.5

10

15

20

25

30

40

50

60

75

90

120

INSULATION RESISTANCE

Unbalance Formula

Percent

Current = Max difference from average x 100

Unbalance average

Example:

Currents are 80, 79, 84 amps (Lines 1-2 & 3)

Avg. Currents = 80 + 79 + 84 = 81

3

Percent

Current

Unbalance

84 - 81 x 100 = 3.7%

81

Open Delta

Full Three Phase

Figure 13

Insulation resistance tests indicate the value of the motor,

cable, and splice insulation system by measuring

resistance in ohms between motor leads and ground.

Low readings indicate a breakdown somewhere in the

insulation system.

1. Set ohmmeter to RX100K or highest scale. (For best

results use a megohmmeter).

2. Short meter leads together and adjust indicator to

zero.

3. Be sure power is turned off!

4. Connect one meter lead to a motor lead and the other

meter lead to ground.

a. If motor is out of water, measure from lead to

motor frame.

b. If motor is installed in water, ground reference

should be metal well casing (if submerged), metal

drop pipe, or an extra wire extending into the

ground water.

5. Readings and Conditions, motor installed in well:

a. 2,000,000 ohms or more - insulation completely

acceptable.

b. 500,000 to 2,000,000 ohms - insulation in

reasonably good condition. Acceptable. Should

be considered marginal for new motor.

c. 20,000 to 500,000 ohms - insulation seriously

damaged, but motor may still operate.

d. Less than 20,000 ohms - severe insulation

damage. Motor probably not operable.

WINDING RESISTANCE

Winding resistance tests indicate whether or not windings

are internally correct, shorted, or open. Winding

resistance should be considered independently of

insulation resistance readings.

1. Set ohmmeter to RX1. Short meter leads together

and adjust indicator to zero.

2. Be sure power is turned off.

3. Connect ohmmeter between two motor leads.

MAINTENANCE

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

10

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

11

Page 7

a. Three wire single phase: Yellow-Black indicates

main winding resistance; Yellow-Red indicates

start winding resistance.

b. Three phase: Resistance values should be equal

on all three phases: Yellow-Black; Yellow-Red;

Black-Red.

4. Correct readings should be equal to the Line-to-Line

resistance values from the specifications section for a

given motor, plus the resistance of the drop cable from

the table below.

5. Conditions:

Resistance (Ohms) Per 100 Feet of Copper Cable

(Round Trip)

AWG 14 12 10 8 6 4 2 0

Ohms .5 .3 .2 .12 .08 .05 .03 .02

a. If one ohm value is less than specified, that

winding is shorted.

b. If one ohm value is greater than specified, that

winding is open, or there is a poor connection in

that circuit.

c. On 3-wire single phase, if one ohm value is

greater than specified and one ohm value is less

than specified, the leads are mixed. See the

section entitled “Cable Identification When Color

Code Is Lost.”

ONE YEAR LIMITED WARRANTY

This product is warranted for one year from the date of purchase or two

years from the date of manufacture, whichever occurs first. Subject to the

conditions hereinafter set forth, the manufacturer will repair or replace to the

original consumer, any portion of the product which proves defective due to

defective materials or workmanship. To obtain warranty service, contact the

dealer from whom the product was purchased. The manufacturer retains

the sole right and option to determine whether to repair or replace defective

equipment, parts or components. Damage due to conditions beyond the

control of the manufacturer is not covered by this warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects or malfunctions

resulting from failure to properly install, operate or maintain the unit in

accordance with printed instructions provided; (b) to failures resulting

from abuse, accident or negligence or use of inappropriate chemicals or

additives in the water; (c) to normal maintenance services and the parts

used in connection with such service; (d) to units which are not installed in

accordance with normal applicable local codes, ordinances and good trade

practices; and (e) the unit is used for purposes other than for what it was

designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired

or replaced under this warranty must be returned to the manufacturer at

Kendallville, Indiana or such other place as the manufacturer may designate,

freight prepaid.

TESTING LOAD CURRENT AMPS

To test load current amps a clamp-on ammeter is

required. Since the ammeter measures current flow, the

motor must be running.

1. Pull the motor lead wire, being measured, (red, yellow

or black) away from all other wires.

2. Set ammeter to the highest scale. (If starting a motor

leave on the scale until current settles down).

3. Place tongs of meter around wire.

4. Change meter scale to one that gives the best

accuracy. This will be a reading between mid scale

and full scale.

5. Compare reading with current load amps on motors

data chart.

6. Test each motor lead.

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER

EXPRESS WARRANTIES, AND MAY NOT BE EXTENDED OR MODIFIED

BY ANYONE. ANY IMPLIED WARRANTIES SHALL BE LIMITED TO

THE PERIOD OF THE LIMITED WARRANTY AND THEREAFTER ALL

SUCH IMPLIED WARRANTIES ARE DISCLAIMED AND EXCLUDED. THE

MANUFACTURER SHALL NOT, UNDER ANY CIRCUMSTANCES, BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES,

SUCH AS, BUT NOT LIMITED TO DAMAGE TO, OR LOSS OF, OTHER

PROPERTY OR EQUIPMENT, LOSS OF PROFITS, INCONVENIENCE, OR

OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY TYPE

OR NATURE. THE LIABILITY OF THE MANUFACTURER SHALL NOT

EXCEED THE PRICE OF THE PRODUCT UPON WHICH SUCH LIABILITY

IS BASED.

This warranty gives you specific legal rights, and you may have other rights

which vary from state to state. Some states do not allow limitations on

duration of implied warranties or exclusion of incidental or consequential

damages, so the above limitations may not apply to you.

WARRANTY VALID IN CANADA AND MEXICO.

Single Phase Control Box Checking and Repairing Procedures

CAUTION: Turn power off and discharge capacitors before using ohmmeter.

TEST PROCEDURE

General Procedures 1. Disconnect line

2. Inspect for damaged or burned parts, loose connections, etc.

3. Check for misconnections against diagram in control box

4. If problem has not been found, check motor per Motor Data Chart and

control box as indicated below

Use of Ohmmeter 1. Ohmmeter such as Simpson Model #372 or #260, Triplett Model #630 or

#666 may be used

2. Whenever scales are changed, short ohmmeter leads and “zero balance”

meter

Ground (Insulation Resistance) Test 1. Ohmmeter Setting: Highest scale (usually R x 100K or 4 x 10,000)

2. Terminal Connections: One ohmmeter lead to “Ground” terminal on control

box and touch other lead to each of the other terminals on terminal board

3. Ohmmeter Reading: Pointer should remain at (∞) and not deflect

Overload Protector 1. Ohmmeter Setting: R x 1

2. Terminal Connections: Connect one ohmmeter lead to Terminal Black and

other lead to:

a. Terminal L

b. Terminal L

3. Ohmmeter Reading: Should be 0 to 0.5 ohms maximum

Capacitor Tests 1. Ohmmeter Setting: R x 1,000

2. Terminal Connections: One ohmmeter lead to relay terminal #1 and other to

black terminal on terminal board

3. Ohmmeter Reading: Pointer should swing toward “zero” and “float” back

to (∞). Capacitor is shorted if pointer does not move back to (∞), open if it

does not move from (∞)

4. If reading is not as above, disconnect capacitor from overload and test each

component

Relay Coil Test

(potential relays only)

Relay Contact Test

(potential relays only)

Contactor Test 2. Ohmmeter setting R x 100.

1. Ohmmeter Setting: 4 x 1,000 (or R x 100)

2. Terminal Connections: #6 and #2 on Relay

3. Ohmmeter Reading:

Most of the cases of inoperative relay contacts can be detected as follows:

1. Ohmmeter Setting: 4 x 1.

2. Terminal Connections: Terminal #1 and Terminal #2 on Relay.

3. Ohmmeter Reading: Should be “zero”.

NOTE: This test verifies “making” of contacts. If it is desired to test

“Opening” and closing of contacts:

a. Connect control box components in control box as indicated on diagram in

control box cover.

b. Connect three leads from motor of correct rating to control box terminal

board.

c. Connect power source voltage to L

d. Current in Red lead should momentarily be a high value - then drop

(within one second) to values on Motor Data Chart

1. Disconnect one coil lead.

3. Check coil resistance: 180 to 1400 ohms.

4. Remove contact cover and inspect contacts.

in four-terminal boxes

¹

in five-terminal boxes.

²

G.E. 4.5 - 7.0 (4500-7000 ohms)

Cardinal 2.8 - 4.2 (2800-4200 ohms

and L².

¹

For 230 Volt Boxes

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

12

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

13

Page 8

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Fuses blow when motor starts 1. Incorrect voltage

2. Incorrect fuses

3. Defective pressure switch

4. Control box malfunction

5. Bound pump

6. Defective cable or motor winding

7. Shorted or open motor winding

Motor runs but fuses blow 1. Incorrect voltage

Motor does not start and fuses

do not blow

Pump runs, but delivers little or

no water

Pump keeps running 1. Pressure switch

Pump starts too often 1. Pressure switch

2. Overheated protectors

3. Improperly wired control box

4. Defective motor or cable

5. Defective pump

6. Defective installation

1. No power

2. Defective pressure switch

3. Defective wiring

1. Air locked pump

2. Low water level in well

3. Pump rotation wrong

4. Check valve stuck or installed improperly

5. Leak in drop pipe

6. Pump screen locked

7. Worn pump

8. Loose or broken motor shaft

2. Low level well

3. Leak in system

4. Worn pump

2. Leak in system

3. Check valve

4. Air supply (waterlogged tank - air under

pressure absorbed into the water)

1. Contact power company if voltage is incorrect after

first checking for correct wire size. See Wire Size

Chart

2. Replace with proper fuses

3. Replace pressure switch or clean contacts

4. Correct faulty wiring or tighten loose contacts

5. Sand bound pump can sometimes be corrected

by temporarily reversing black and red leads in

control box then returning to normal. If pump does

not rotate freely, it must be pulled and cleaned or

realigned and the well condition corrected

6. The pump must be pulled and the cable

disconnected and inspected. Damaged cable

should be correctly spliced or replaced. If cable is

good, the motor winding is grounded

7. The pump must be pulled and motor or drop cable

repaired or replaced

1. Contact power company in incorrect

2. Shade box, provide ventilation or move box away

from heat source

3. Rewire correctly

4. If ground, short or open circuit is indicated pump

must be pulled for repair

5. Pull pump, clean and repair

6. Pull pump, rechecking components and installation

1. Replace fuses or reset circuit breaker. Contact

power company if no power is reaching box

2. Clean contact points or replace switch

3. Correct faulty wiring or connections

1. Normal delivery may resume if pump is started and

stopped at one minute intervals

2. Throttle pump delivery through restricting valve.

Lower pump setting if depth of well is adequate

3. Check wiring connections

4. Replace or reinstall properly

5. Raise pipe, check for leak and replace damaged

section

6. Clean screen and reset at less depth. It may be

necessary to clean well

7. Pull pump and replace worn impellers, casing or

other close fitting parts

8. Check for damaged shafts if coupling is loose and

replace worn or defective units

1. Clean points or replace switch

2. Throttle pump output or reset pump to lower level.

Do not lower if sand may clog pump

3. Replace damaged section

4. Pull pump and replace

1. Reset limit or replace switch

2. Repair or replace tank or pipes

3. Remove and replace if defective

4. Clean or replace. Drain and recharge tank

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

14

Loading...

Loading...