Page 1

OWNER'S

SPM SERIES

FW0501

MANUAL

Lawn and Turf Pumps

Electric Motor Driven

SAFETY WARNINGS

BEFORE OPERATING OR

INSTALLING THIS PUMP, READ

THIS MANUAL AND FOLLOW

ALL SAFETY RULES AND

OPERATING INSTRUCTIONS.

SAFETY

CAUTION

• Review instructions before operating.

WARNING - ELECTRICAL PRECAUTIONS

All wiring, electrical connections, and system grounding must

comply with the National Electrical Code (NEC) and with any local

codes and ordinances. Employ a licensed electrician.

CAREFULLY READ THESE SAFETY

MESSAGES IN THIS MANUAL AND ON PUMP.

WARNING - RISK OF ELECTRICAL SHOCK

• Have an electrician provide electrical power to the motor.

• Motor must be grounded and terminal cover in place to reduce

electrical shock hazard.

• Keep motor operating area as dry as possible.

• A ground fault interrupter (GFI) protected circuit is recommended for use with any electrical device operating near water.

• Always disconnect power before servicing.

• Not investigated for use in swimming pool areas.

APPLICATION

This pump is suitable for installations where the vertical distance

from the pump to the water level does not exceed 25 ft. In all

PERFORMANCE

Flow in GPM Flow in L/min.

PUMP at total head (ft.) at total head (Meters)

MODEL HP 25 50 75 100 125 150 1 0 2 0 3 0 4 0 5 0

SPM30 3 110 92 71 40 371 276 110

SPM50 5 141 121 98 66 560 466 348 148

INSTALLATION

PUMP LOCATION: The pump should be installed in a clean, dry

and ventilated location which provides adequate drainage and

room for servicing and protection from freezing temperatures. It

should be bolted down evenly on a good foundation, preferably

concrete, to prevent the development of unnecessary stress.

Locating the pump as close as possible to the source of water

supply reduces the friction losses in the suction pipe and provides

for maximum capacities.

SUCTION PIPE: It is recommended that only new clean pipe or

installations, friction losses in the suction pipe must be taken into

consideration.

hose be used and the size be the same as that of the pump

suction tapping. If the pump is installed any appreciable distance

away from the source of water supply, the suction pipe should be

increased by one size. The suction pipe must always slope

upwards from the water source to the pump to avoid air pockets

in the line. In cases where the pump has to be reprimed often and

it is not necessary that a lot of water be delivered, it is advisable

to use a 90° or 45° elbow on the suction line. This enables the

pump to prime sooner and also prevents kinking of the hose. In

cases where a maximum volume of water is required over a pro-

236222 0403

Page 2

longed period of time, the suction line should be led almost horizontally to the pump. Non-toxic thread compound should be used on all

pipe joints and connections should be thoroughly tightened. A

strainer should be connected to the bottom end of the suction pipe

and it should be well submerged at all times.

WARNING - RISK OF ELECTRICAL SHOCK

• WIRING: Make sure the voltage and frequency of the power

supply agrees with that stamped on the motor nameplate. If

in doubt, check with the power company.

WARNING - ELECTRICAL PRECAUTIONS

All wiring, electrical connections, and system grounding must

comply with the National Electrical Code (NEC) and with any local

codes and ordinances. Employ a licensed electrician.

SINGLE PHASE: Determine incoming voltage to motor. Where

possible, use 230V. Connect wiring to terminal board located inside

motor end cover. Be sure voltage connections agree with wiring

diagram on motor nameplate.

THREE PHASE: Three Phase motors require magnetic starters,

and can run in either direction, depending on how they are connected to the power supply.

OPERATION - PRIMING THE PUMP

To Check for Proper Rotation: Remove the motor end cover.

This exposes the motor shaft. If hookup is correct, the shaft will

rotate clockwise. If rotation is not clockwise, reverse any two leads

to the starter. The rotation will now be correct.

WARNING - RISK OF ELECTRICAL SHOCK

GROUNDING THE MOTOR: WIRING TO THIS PUMP MUST

BE INSTALLED AND MAINTAINED IN ACCORDANCE WITH

THE NATIONAL ELECTRICAL CODE OR YOUR LOCAL

ELECTRIC CODE. IF MORE INFORMATION IS NEEDED,

CALL YOUR LOCAL LICENSED ELECTRICIAN OR YOUR

POWER COMPANY.

It is recommended that a permanent ground connection be made to

the unit using a conductor of appropriate size from a metal underground water pipe or a grounded lead in the service panel. Do not

ground to a gas supply line. Do not connect to electric power supply

until unit is permanently grounded. Connect the ground wire to the

approved ground and then connect to the terminal provided.

WARNING:

PRIMING THE PUMP: A priming plug is provided in the top of the

casing to fill the pump with water. Once filled and the priming plug

replaced, the pump will prime. The priming time depends upon the

vertical and horizontal distance between the pump and the water

level. The pump should prime itself time after time as long as the

built-in check valve functions.

CAUTION:

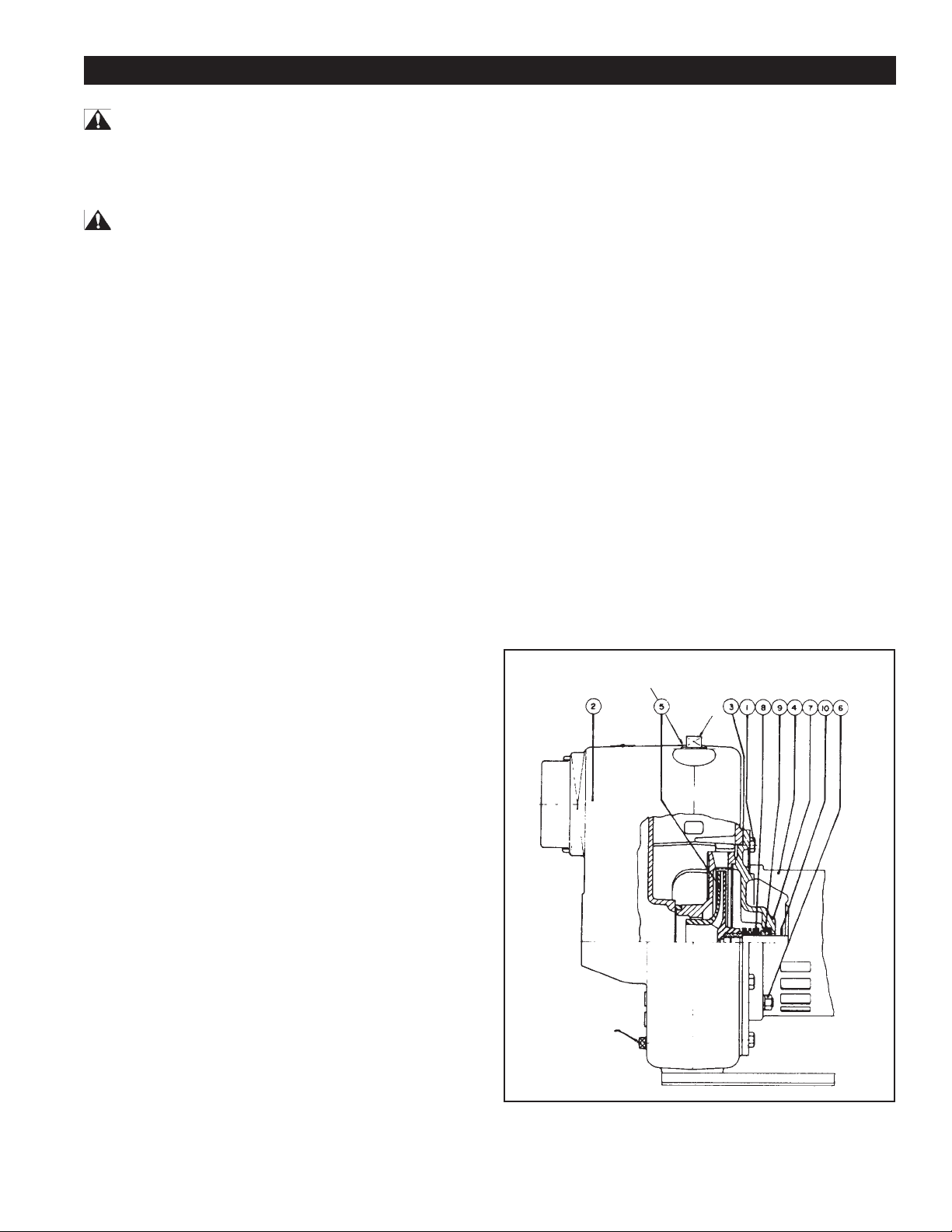

PRIMING UNDER PRESSURE: (Refer to Figure 1) Should it be

necessary to prime under pressure, place a check valve on the

discharge line of the pump and a pet cock or a ball type air bleeder

in place of the priming plug, or an air bleed line with a gate valve

connected to the discharge line. It will then be possible for the liquid

to remain in the discharge pipe and allow the pump to bleed off the

remaining air, thereby facilitating priming.

IMPELLER ROTATION: The impeller must rotate in a counterclockwise direction as seen facing the pump from the front of the

casing. In the event of wrong rotation for electric motor models,

refer to the instructions furnished with the motor. The rotation of

three phase motors can be changed by interchanging any two lead

wires.

STARTING THE PUMP: Never operate the pump dry as this may

damage the seal. If an exceptionally long suction line is used, the

water in the pump casing may become overheated or vapour

locked. Should this occur, replace the water in the casing with cold

water and continue priming.

DRAINING: Should the pump be subject to freezing temperatures,

it will be necessary to drain the pump completely. To drain, remove

the drain plug located at the bottom of the front face of the pump

casing and the priming plug and make sure that the drain

DO NOT RUN THE PUMP BEFORE PRIMING IT, SINCE THE SEAL AND IMPELLER COULD BE PERMANENTLY

DAMAGED.

DO NOT run the pump before filling the pump

case with liquid, as it may damage the seal.

hole is not restricted. After all the water has been drained,

operating the pump for a few seconds will ensure that the impeller

is devoid of water (make sure that the suction line is also devoid

of water).

STORAGE OF PUMP: Drain liquid from pump to prevent freezing. It is recommended that a good rust inhibitor be put in the

liquid end to prevent excessive corrosion. Be sure motor is kept

dry and covered. When restoring the use of the pump, replace all

plugs and make sure all connections are tightly sealed. After a

complete check is made, make the initial prime according to

directions under the section, Priming the Pump.

Figure 1

Gate Valve

(Min. 3/4")

2

Check Valve

Gate Valve

Discharge

Pump

Air Bleed Line

Suction Line

Strainer

Page 3

MAINTENANCE

WARNING - ELECTRICAL PRECAUTIONS

All wiring, electrical connections, and system grounding must

comply with the National Electrical Code (NEC) and with any local

codes and ordinances. Employ a licensed electrician.

WARNING - RISK OF ELECTRICAL SHOCK

• Have an electrician provide electrical power to the motor.

• Motor must be grounded and terminal cover in place to reduce

electrical shock hazard.

• Keep motor operating area as dry as possible.

• A ground fault interrupter (GFI) protected circuit is recom-

mended for use with any electrical device operating near water.

• Always disconnect power before servicing.

• Not investigated for use in swimming pool areas.

LUBRICATION:

a) The pump requires no lubrication.

b) For electric motor models, refer to instructions provided

by the motor manufacturer.

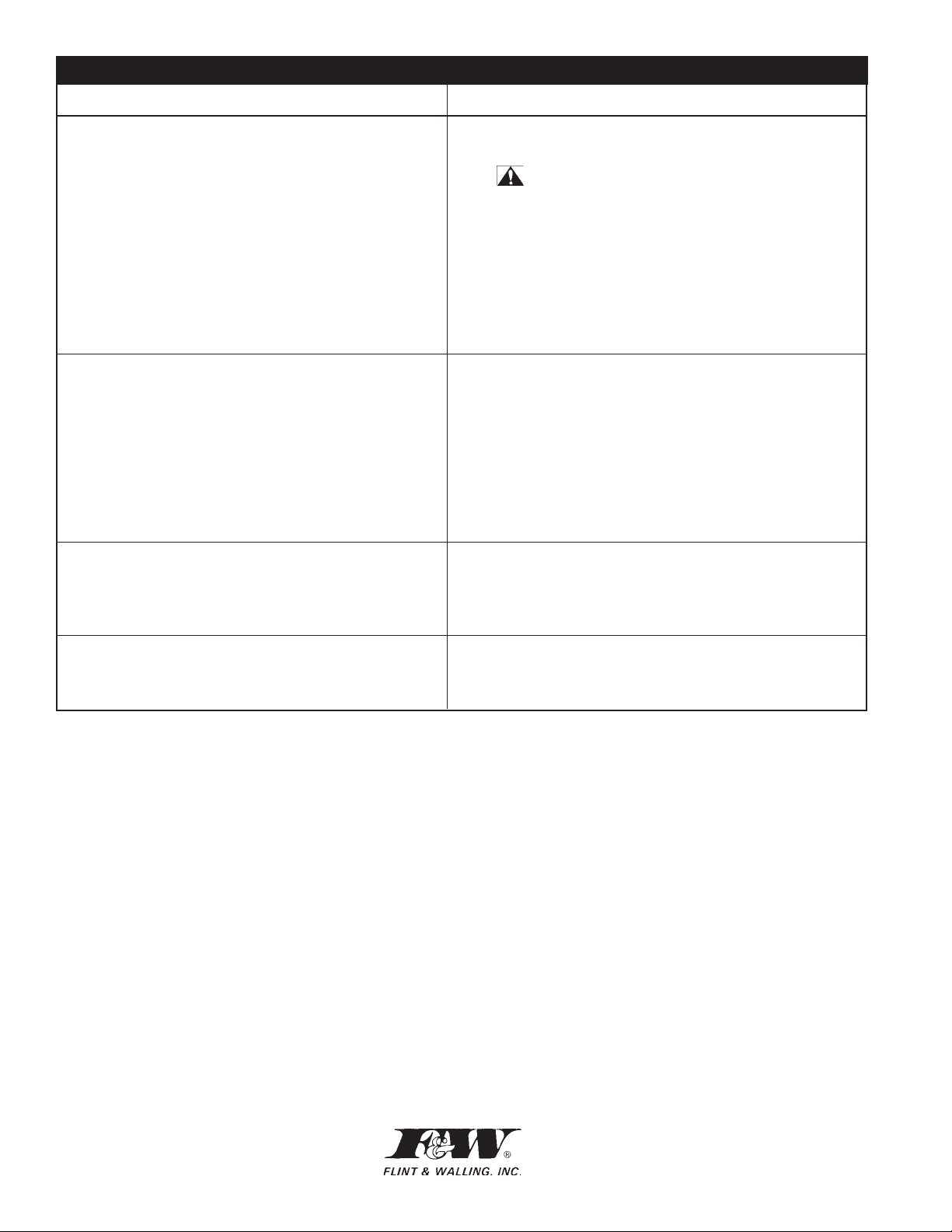

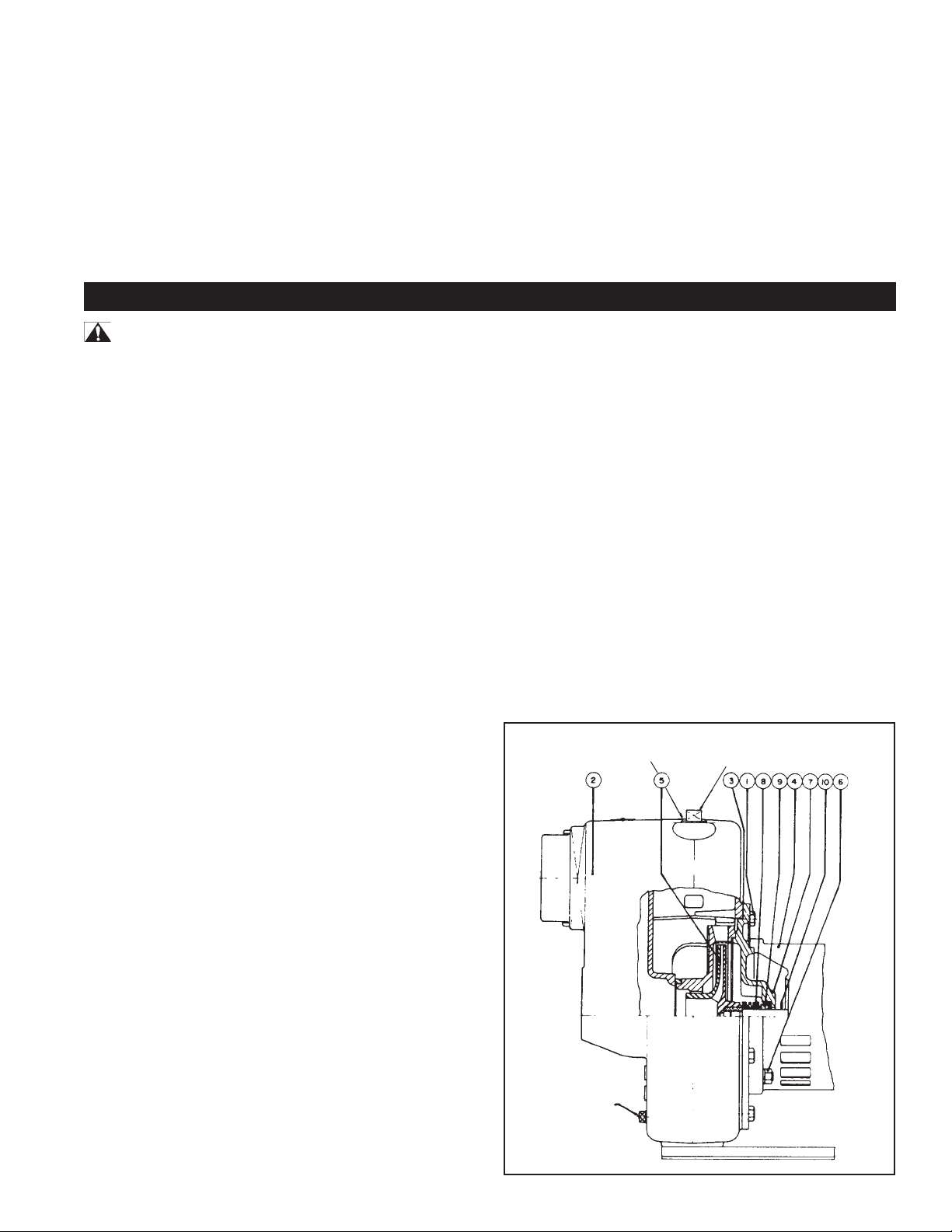

REPLACING MECHANICAL SEAL:

(Refer to Figure 2)

TO DISASSEMBLE:

TO REASSEMBLE:

a) Clean all parts thoroughly.

b) Wet the rubber part of the seal seat with soap solution

and press it into its housing in the seal plate or adapter,

smooth ceramic surface facing outwards.

c) Assemble the seal plate or adapter to the motor.

d) Oil the seal and slip it into the motor shaft. Make sure

the sealing face is towards the ceramic seat.

e) Replace the impeller.

f) Reassemble to the casing and diffuser ring. It is

recommended to use a new gasket (3).

g) Reconnect the suction and discharge piping and re-

connect the electrical wiring.

PRECAUTIONS

a) Whenever pump is dismantled and then reassembled,

always check to see that the impeller rotates freely within

the casing.

b) The SPM models have a flinger (10) on the shaft. This

flinger must not be removed.

a) Remove the bolts (1) and remove the casing (2).

b) Remove the impeller (unscrew impeller or remove retain-

ing bolt depending upon the model).

c) Slip the seal off the shaft.

d) Remove the four bolts and lift the adapter (7) off the motor.

Take care not to damage the seal seat.

e) If the seat (9) needs to be replaced, push it out of the

adapter from the motor side.

Figure 2

Drain Plug

Discharge

Priming

Plug

3

Page 4

TROUBLESHOOTING GUIDE

TROUBLES AND CAUSE REMEDY

Failure to Pump:

1. Pump not properly primed. 1. Make sure pump casing and suction line are full of water.

See priming instructions.

2. Speed too low. 2.

3. Total head more than for which pump was intended. 3. A pump designed for higher head needed.

4. Suction lift is too great. 4. Locate pump closer to source of water. Make sure suction

Reduced Capacity and/or Head:

1. Air pockets or leaks in suction line. 1. Check suction piping.

2. Clogged impeller. 2. Remove and clean.

3. Strainer too small or clogged. 3. Use larger strainer or clean.

4. Insufficient submergence of suction line. 4. Add lengths of suction pipe to keep submerged end well

5. Excessive suction lift. 5. If caused by suction pipe friction, enlarge piping.

6. Total head more than that for which the pump was 6. A pump designed for higher head is needed.

intended.

7. Excessively worn impeller. 7. Order replacement parts using Repair Parts List.

WARNING - ELECTRICAL PRECAUTIONS

All wiring, electrical connections and system grounding

must comply with the National Electrical Code (NEC) and

with any local codes and ordinances. Employ a licensed

electrician. Check voltage at motor terminals and at meter

when pump is operating. If low, refer to wiring instructions

or check with your power company. Check loose connections.

piping is large enough.

below the water surface.

Otherwise, move pump closer to water level.

Pump Loses Prime:

1. Air leaks in suction line. 1. Check suction piping.

2. Excessive lift and operating too near shut-off point. 2. Move pump nearer water level.

3. Water level drops while pumping, uncovering suction 3. Check water supply. Add length of pipe to suction to

piping. keep submerged end under water.

Mechanical Troubles and Noise:

1. Bent shaft and/or damaged bearings. 1. Take motor to authorized motor repair shop.

2. Suction and/or discharge piping not properly 2. See that all piping is supported to relieve strain on pump

supported and anchored. assembly.

WATER SYSTEMS ONE-YEAR LIMITED WARRANTY

This product is warranted for one year from the date of purchase

or two years from the date of manufacture, whichever occurs first.

Subject to the conditions hereinafter set forth, the manufacturer will

repair or replace to the original consumer, any portion of the

product which proves defective due to defective materials or

workmanship. To obtain warranty service, contact the dealer from

whom the product was purchased. The manufacturer retains the

sole right and option to determine whether to repair or replace

defective equipment, parts or components. Damage due to conditions beyond the control of the manufacturer is not covered by this

warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects or malfunctions

resulting from failure to properly install, operate or maintain the unit

in accordance with printed instructions provided; (b) to failures

resulting from abuse, accident or negligence; (c) to normal maintenance services and the parts used in connection with such service;

(d) to units which are not installed in accordance with normal

applicable local codes, ordinances and good trade practices; and

(e) the unit is used for purposes other than for what it was

designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired or

replaced under this warranty must be returned to the manufacturer

at Kendallville, Indiana or such other place as the manufacturer may

designate, freight prepaid.

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER

EXPRESS WARRANTIES, AND MAY NOT BE EXTENDED OR

MODIFIED BY ANYONE. ANY IMPLIED WARRANTIES SHALL BE

LIMITED TO THE PERIOD OF THE LIMITED WARRANTY AND

THEREAFTER ALL SUCH IMPLIED WARRANTIES ARE DISCLAIMED

AND EXCLUDED. THE MANUFACTURER SHALL NOT, UNDER ANY

CIRCUMSTANCES, BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL

OR SPECIAL DAMAGES, SUCH AS, BUT NOT LIMITED TO DAMAGE

TO, OR LOSS OF, OTHER PROPERTY OR EQUIPMENT, LOSS OF

PROFITS, INCONVENIENCE , OR OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY TYPE OR NATURE. THE

LIABILITY OF THE MANUFACTURER SHALL NOT EXCEED THE PRICE

OF THE PRODUCT UPON WHICH SUCH LIABILITY IS BASED.

This warranty gives you specific legal rights, and you may have

other rights which vary from state to state. Some states do not

allow limitations on duration of implied warranties or exclusion of

incidental or consequential damages, so the above limitations may

not apply to you.

FOR YOUR WARRANTY PROTECTION, THE WARRANTY REGISTRATION MUST BE COMPLETED AND RETURNED TO THE WARRANTY INFORMATION CENTER WITHIN TEN DAYS OF INSTALLATION. WARRANTY VALID IN CANADA AND MEXICO.

95 North Oak Street • Kendallville, IN 46755 • 800-345-9422

Flint and Walling reserves the right to make design improvements and

pricing modifications as necessary and without notice.

Page 5

MANUEL DU

SÉRIE SPM

FW0501F

PROPRIÉTAIRE

Pompe pour Gazon et Pelouse

Actionnée par Moteur Électrique

CONSIGNES DE SÉCURITÉ

AVANT D'INSTALLER OU

D'UTILISER CETTE POMPE,

PRIÈRE DE LIRE LE PRÉSENT

GUIDE ET SUIVRE TOUTES

LES RÈGLES DE SÉCURITÉ ET

INSTRUCTIONS D'UTILISATION.

SÉCURITÉ

CAUTION

• Passez les instructions en revue avant d’utiliser la pompe.

MISE EN GARDE

- PRÉCAUTIONS ÉLECTRIQUES

Tous câblage, connexions électriques et mise à la terre des

systémes doivent se conformer au Code National d'Electricité

(NEC) et aux codes et ordonnances locaux. Employez un

électricien autorisé.

LIRE ATTENTIVEMENT LES AVIS DE

SÉCURITÉ SE TROUVANT DANS LE

PRÉSENT MANUEL ET SUR LA POMPE.

MISE EN GARDE

- RISQUE DE CHOC ÉLECTRIQUE

• Faire appel à un électricien pour l’alimentation électrique du

moteur.

• Le moteur doit être mis à la terre et le couvercle des bornes

correctement installé afin de réduire les risques

d’électrocution.

• Garder la zone de travail aussi sèche que possible.

• L’usage d’un circuit protégé par interrupteur de défaut à la terre

(GFI) est recommandé avec tout appareil électrique

fonctionnant dans l’eau ou à proximité de celle-ci.

• Toujours couper l’alimentation avant de procéder à l’entretien.

• Cette pompe n’est pas conçue pour être utilisée dans la région

d'une piscine.

UTILISATION

Cette pompe convient aux installations dont la distance verticale

entre la pompe et l’eau à pomper ne dépasse pas 25 pieds. Dans

RENDEMENT

Débit en GPM (US) Débit en L/min.

Modèle de Hauteur totale (pi) Hauteur totale (mètres)

pompe CV 25 50 75 100 125 150 10 20 30 40 50

SPM30 3 110 92 71 40 371 276 110

SPM50 5 141 121 98 66 560 466 348 148

INSTALLATION

EMPLACEMENT DE LA POMPE : Il est conseillé d’installer la

pompe dans un endroit propre, sec et aéré offrant un bon

drainage, de l’espace pour l’entretien et une protection contre le

gel. Il faudrait la boulonner bien à plat à une assise solide, de

préférence en béton, afin de prévenir les contraintes inutiles.

Pour réduire les pertes de charge dans la conduite d’aspiration

et obtenir le débit maximal, rapprocher le plus possible la pompe

de l’eau à pomper.

CONDUITE D’ASPIRATION : Il est recommandé d’utiliser un

tuyau ou un boyau neuf et propre dont le diamètre est égal au

tous les cas, il faut tenir compte des pertes de charge dans la

conduite d’aspiration.

taraudage de l’orifice d’aspiration. Si la pompe se trouve à une

distance assez importante de la source d’alimentation en eau, le

diamètre de la conduite d’aspiration devrait être plus grand. La

conduite d’aspiration doit toujours être placée en pente

ascendante à partir de la source d’eau vers la pompe, pour éviter

la formation de poches d’air dans la conduite. Dans les cas où la

pompe doit être réamorcée souvent et qu’un grand débit d’eau

n’est pas nécessaire, il est conseillé d’utiliser un coude de 90° ou

de 45° dans la conduite d’aspiration. L’amorçage peut ainsi se

faire plus rapidement et prévenir le tortillement du boyau. Si un

volume d’eau important est requis pendant une période

prolongée

236222f 0403

Page 6

prolongée, la conduite d’aspiration devrait être aussi à l’horizontale

que possible par rapport à la pompe. Il est également conseillé

d’enduire les joints et les raccords de tuyau, d’une graisse pour

filetage non toxique et de bien les serrer. L’extrémité inférieure de la

conduite d’aspiration devrait être munie d’une crépine immergée en

tout temps.

AVERTISSEMENT

- RISQUE DE CHOC ÉLECTRIQUE

• CÂBLAGE : S’assurer que le voltage et la fréquence de

l’alimentation en électricité sont conformes aux instructions se

trouvant sur la plaque du fabricant du moteur. Dans le doute,

vérifier auprès de votre compagnie d’électricité.

AVERTISSEMENT

- PRÉCAUTIONS RELATIVES À L’ÉLECTRICITÉ

Le câblage, les connexions électriques et les mises à la terre des

systèmes doivent être conformes au Code national de l’électricité

(NEC) et aux ordonnances et codes locaux. Faire appel à un

électricien autorisé.

MOTEUR MONOPHASÉ : Établir d’abord le voltage d’entrée au

moteur. Si la chose est possible, utiliser un courant de 230V.

Brancher le câblage au panneau de raccordement situé sous le

couvercle du moteur. S’assurer que les raccords de voltage sont

les mêmes que ceux du schéma de montage figurant sur la plaque

du fabricant du moteur.

Pour déterminer si le moteur tourne dans le bon sens, enlever

le couvercle du moteur. L’arbre moteur est maintenant exposé. Si

le branchement du moteur est bien effectué, l’arbre tournera dans

le sens des aiguilles d’une montre. Si la rotation de l’arbre est dans

le sens contraire des aiguilles d’une montre, inverser deux des

conducteurs de branchement du démarreur. Le moteur tournera

alors dans le bon sens.

AVERTISSEMENT

- RISQUE DE CHOC ÉLECTRIQUE

MISE À LA TERRE DU MOTEUR : LE CÂBLAGE DE CETTE

POMPE DOIT ÊTRE INSTALLÉ ET ENTRETENU

CONFORMÉMENT AU CODE NATIONAL DE L’ÉLECTRICITÉ

OU AUX ORDONNANCES ET CODES D’ÉLECTRICITÉ

LOCAUX. POUR DE PLUS AMPLES RENSEIGNEMENTS,

CONSULTEZ UN ÉLECTRICIEN AUTORISÉ OU VOTRE

PROPRE COMPAGNIE D’ÉLECTRICITÉ.

Il est recommandé de munir l’unité d’une prise à la terre

permanente, au moyen d’un conducteur de dimension appropriée,

fixé à une conduite d’eau souterraine ou une conduite avec mise à

la terre dans le panneau de service. Éviter de brancher l’unité à une

source d’alimentation en gaz avant qu’elle soit correctement mise

à la terre. Brancher le fil de masse à la mise à la terre approuvée,

puis raccorder le fil à la borne accompagnant la pompe.

MOTEUR TRIPHASÉ : Un moteur triphasé doit être muni d’un

démarreur magnétique. La rotation de ce genre de moteur peut se

faire dans les deux sens, selon le branchement de l’alimentation

électrique.

FONCTIONNNEMENT - AMORÇAGE DE LA POMPE

AVERTISSEMENT :

AMORÇAGE DE LA POMPE : Pour amorcer la pompe, il faut

enlever le bouchon d’amorçage se trouvant sur le dessus du boîtier,

remplir le boîtier d’eau et remettre le bouchon en place. La durée

d’amorçage est fonction de la distance horizontale et verticale entre

la pompe et le niveau de l’eau. La pompe devrait s’amorcer

automatiquement à chaque utilisation, tant que le clapet de retenue

intégré fonctionne.

AVERTISSEMENT : NE JAMAIS faire démarrer la pompe à

AMORÇAGE SOUS PRESSION : (Voir figure 1). S’il faut amorcer

la pompe sous pression, placer un clapet de retenue sur la conduite

de refoulement de la pompe et remplacer le bouchon d’amorçage

par un robinet de purge d’air ordinaire ou sphérique , ou installer une

conduite du purgeur d’air et un robinet-vanne sur la conduite de

refoulement. Le liquide pourra alors demeurer dans la conduite de

refoulement et l’action du robinet-vanne facilitera l’amorçage de la

pompe.

DE NE PAS FAIRE FONCTIONNER LA POMPE À SEC AVANT L’AMORÇAGE, SINON LE JOINT D’ÉTANCHÉITÉ

ET LA ROUE DE TURBINE SERAIENT ENDOMMAGÉS DE FAÇON PERMANENTE.

sec, car la garniture d’étanchéité

pourrait s’endommager.

Figure 1

Robinet-vanne

(Min. 3/4")

Clapet de retenue

Robinet-vanne

Refoulement

Pompe

Conduite de

purgeur d'air

Tuyauterie

d'aspiration

Crépine

ROTATION DE LA ROUE DE TURBINE : Vue de face, devant le

boîtier, la rotation devrait se faire dans le sens contraire des aiguilles

d’une montre. Si la rotation d’une pompe actionnée par un moteur

électrique ne s’effectue pas dans le bon sens, consulter le mode

d’emploi du moteur. Il est possible de modifier le sens de rotation

d’un moteur triphasé en inversant deux fils conducteurs.

2

Page 7

MISE EN MARCHE : Ne jamais faire fonctionner la pompe à sec,

car la garniture d’étanchéité pourrait s’endommager. Si la

conduite d’aspiration est très longue, l’eau contenue dans le

boîtier peut surchauffer ou produire une cavitation. Le cas

échéant, remplacer l’eau du boîtier par de l’eau froide et

continuer l’amorçage.

VIDANGE : Si la pompe est exposée au gel, il faudra la vidanger

complètement. Pour ce faire, enlever le bouchon de vidange

situé dans la partie inférieure du devant du boîtier ainsi que le

bouchon d’amorçage et s’assurer que l’orifice de vidange n’est

pas obstrué. Dès que toute l’eau est évacuée, faire fonctionner la

pompe pendant quelques secondes pour éliminer toute eau

ENTRETIEN

MISE EN GARDE

- PRÉCAUTIONS ÉLECTRIQUES

Tous câblage, connexions électriques et mise à la terre des

systémes doivent se conformer au Code National d'Electricité

(NEC) et aux codes et ordonnances locaux. Employez un

électricien autorisé.

MISE EN GARDE

- RISQUE DE CHOC ÉLECTRIQUE

• Faire appel à un électricien pour l’alimentation électrique du

moteur.

• Le moteur doit être mis à la terre et le couvercle des bornes

correctement installé afin de réduire les risques

d’électrocution.

• Garder la zone de travail aussi sèche que possible.

• L’usage d’un circuit protégé par interrupteur de défaut à la terre

(GFI) est recommandé avec tout appareil électrique

fonctionnant dans l’eau ou à proximité de celle-ci.

• Toujours couper l’alimentation avant de procéder à l’entretien.

• Cette pompe n’est pas conçue pour être utilisée dans la région

d'une piscine.

LUBRIFICATION :

a) Cette pompe n’exige aucune lubrification.

b) Pour la lubrification du moteur électrique, consulter le

mode d’emploi du fabricant.

subsistante dans la roue (veiller également à l’évacuation de

toute eau dans la conduite d’aspiration).

ENTREPOSAGE DE LA POMPE : Évacuer tout le liquide

contenu dans la pompe afin de prévenir les bris causés par le gel.

Il est recommandé d’appliquer un bon agent antirouille dans le

boîtier afin d’empêcher la formation excessive de corrosion.

S’assurer que le moteur est toujours au sec et couvert. Au

moment de remettre la pompe en marche, remplacer tous les

bouchons et vérifier l’étanchéité parfaite de tous les

raccordements. Après une vérification complète, amorcer la

pompe en suivant les directives de la rubrique Amorçage.

REMONTAGE :

a) Bien nettoyer toutes les pièces.

b) Mouiller la partie en caoutchouc de l’embase de la

garniture d’étanchéité mécanique avec une eau

savonneuse et remettre la pièce dans son logement,

dans la plaque d’étanchéité ou l’adaptateur, la surface

de céramique donnant vers l’extérieur.

c) Remonter la plaque d’étanchéité ou l’adaptateur sur le

moteur.

d) Huiler la garniture d’étanchéité mécanique et le faire

glisser sur l’arbre moteur. Bien s’assurer que la surface d’étanchéité donne vers l’embase de céramique.

e) Revisser la roue de turbine.

f) Remonter le tout dans le boîtier et remettre en place

l’anneau de retenue du diffuseur. Il est conseillé d’installer

un nouveau joint d’étanchéité (3).

g) Raccorder les canalisations d’aspiration et de

refoulement et brancher de nouveau les fils électriques.

PRÉCAUTIONS

a) Au moment de démonter et de remonter la pompe, il

faut toujours vérifier si la roue tourne librement dans le

boîtier.

b) L’arbre des pompes de la série SPM est muni d’une

bride (10) qu’il ne faut jamais enlever.

REMPLACEMENT DE LA GARNITURE

D’ÉTANCHÉITÉ MÉCANIQUE : Voir la figure 2

DÉMONTAGE :

a) Dévisser les boulons (1) et retirer le boîtier (2).

b) Enlever la roue (en la dévissant ou en enlevant le boulon

de retenue, selon le modèle).

c) Faire glisser la garniture d'étanchéité mécanique hors de

l'arbre.

d) Enlever les quatre boulons et soulever l'adaptateur (7)

pour le séparer du moteur. Prendre bien soin de ne pas

endommager l'embase de la garniture d'étanchéité.

e) S'il faut remplacer l'embase (9), l'extraire de l'adaptateur

du côté du moteur.

Figure 2

3

Bouchon de

vidange

Refoulement

Bouchon d'amorçage

Page 8

GUIDE DE DÉPANNAGE

PROBLÈMES ET CAUSES PROBABLES SOLUTIONS

Aucun pompage :

1. La pompe n’est bien amorcée. 1. S’assurer que le boîtier et la conduite d’aspiration sont remplis d’eau.

2. Le régime est trop faible. 2.

3. La hauteur totale requise ne correspond pas aux 3. Pompe conçue pour une hauteur totale plus élevée.

caractéristiques de la pompe.

4. La hauteur géométrique d’aspiration est trop élevée. 4. Rapprocher la pompe de la source d’alimentation en eau. S’assurer

Perte de débit et (ou) de charge :

1. Fuites ou poches d’air dans la conduite d’aspiration. 1. Inspecter les canalisations d’aspiration.

2. Obstruction de la roue de turbine. 2. Retirer et nettoyer la roue de turbine.

3. Crépine trop petite ou obstruée. 3. Installer une plus grande crépine ou nettoyer celle en place.

4. La conduite d’aspiration n’est pas bien immergée. 4. Rajouter des sections à la conduite d’aspiration afin d’en maintenir

5. La hauteur géométrique d’aspiration est trop élevée. 5. Si le problème est causé par un frottement à l’intérieur de la conduite

6. La hauteur totale ne correspond pas aux 6. Il faut installer une pompe dont la hauteur totale est plus élevée.

caractéristiques de la pompe.

7. La roue est trop usée. 7. Commander une nouvelle pièce. Consulter la liste des pièces de

Perte d’amorçage :

1. Fuites d’air dans la conduite d’aspiration. 1. Inspecter les canalisations d’aspiration.

2. Hauteur géométrique d’aspiration trop élevée et trop rapprochée 2. Rapprocher la pompe du niveau de l’eau.

de la pression à débit nul.

3. Le niveau d’eau baisse pendant le pompage et met la conduite 3. Vérifier la source d’eau. Rajouter une section à la conduite d’aspiration

d’aspiration à l’air libre. afin d’en maintenir l’extrémité dans l’eau.

Suivre les directives d’amorçage.

AVERTISSEMENT

-PRÉCAUTIONS RELATIVES À L’ÉLECTRICITÉ

Le câblage, les connexions électriques et les mises à la terre des

systèmes doivent être conformes au Code national de l’électricité (NEC)

et aux ordonnances et codes locaux. Consulter un électricien autorisé.

Vérifier le voltage aux bornes du moteur et le voltmètre pendant le

pompage. Si le voltage est trop faible, consulter les directives de

montage électrique ou communiquer avec votre compagnie

d’électricité. S’assurer que tous les raccords sont bien serrés.

que les conduites d’aspiration sont de dimension adéquate.

l’extrémité bien immergée.

d’aspiration, accroître le diamètre des canalisations. Sinon, rapprocher

la pompe de l’eau à pomper.

rechange.

Problèmes mécaniques et bruits :

1. Arbre voilé ou paliers endommagés ou les deux. 1. Faire vérifier le moteur dans un atelier de réparation reconnu.

2. Les canalisations d’aspiration ou de refoulement ne 2. S’assurer que toutes les canalisations sont bien assujetties et

sont pas bien soutenues ou assujetties. n’exercent aucune contrainte sur l’installation de la pompe.

WATER SYSTEMS - GARANTIE LIMITÉE D’UN AN

Ce produit porte un garantie d’un an à compter de la date d’achat ou

de deux ans à compter de la date de fabrication, selon la période qui

se termine la première. Sous réserve des conditions exposées ciaprès, le fabricant s’engage à réparer ou à remplacer sans frais

pour le client initial, toute partie du produit qui s’avère comporter des

défauts de matériaux ou de fabrication. Pour vous prévaloir de la

garantie, le cas échéant, communiquez avec votre revendeur de

pompe. Le fabricant se réserve exclusivement le droit de déterminer

s’il doit réparer ou remplacer l’appareil, les pièces ou les éléments.

Cette garantie ne couvre pas les dommages dont la cause est

indépendante de sa volonté.

LA GARANTIE NE S’APPLIQUE PAS DANS LES CAS SUIVANTS: (a)

Défauts ou anomalies de fonctionnement entraînées par la nonconformité de l’installation, de l’utilisation ou de l’entretien du produit

avec les instructions écrites fournies. (b) Défaillances causées par

l’usage abusif, par un accident ou par la négligence. (c) Entretien

normal et pièces nécessaires pour assurer cet entretien. (d)

Installation du matériel ne respectant pas les exigences des codes

et réglementation pertinents en vigueur ou non effectuée dans les

règles de l’art. (e) Utilisation du produit dans des applications pour

lesquelles il n’a pas été conçu ou fabriqué.

RETOUR DES ÉLÉMENTS GARANTIS: Tout article à réparer ou à

remplacer en vertu de la présente garantie doit être expédié au

fabricant, port payé, à Kendallville, Indiana, ou en un autre endroit

que le fabricant peut désigner.

LA GARANTIE FOURNIE EN VERTU DES PRÉSENTES REMPLACE

TOUTE AUTRE GARANTIE EXPRESSE, ET NUL NE PEUT L’ÉTENDRE

OU LA MODIFIER. TOUTE GARANTIE IMPLICITE SE LIMITE À LA

PÉRIODE DE LA GARANTIE LIMITÉE, APRÉS LAQUELLE TOUTES

TELLES GARANTIES IMPLICITES SONT NULLES ET NON AVENUES.

LE FABRICANT NE POURRA EN AUCUN CAS ÊTRE TENU

RESPONSABLE DE DOMMAGES-INTÉRÊTS DIRECTS, INDIRECTS OU

SPÉCIAUX TELS, SANS S’Y LIMITER, ENDOMMAGEMENT OU PERTE

D’AUTRES BIENS OU MATÉRIELS, PERTES DE PROFITS, PRÉJUDICES

OU AUTRES DOMMAGES-INTÉRÊTS DIRECTS OU INDIRECTS DE

TOUT ORDRE ET DE TOUTE NATURE. LA RESPONSABILITÉ. du

fabricant ne pourra dépasser le prix payé pour le produit qui est à

l’origine de cette responsabilité.

La présente garantie confère certains droits particuliers. Vous

pouvez avoir d’autres droits en vertu de la loi, que varie d’une

province et d’un état à l’autre. Il est possible que les lois en vigueur

dans votre région interdisent la limitation de la durée des garanties

implicites ou l’exclusion de dommages-intérêts directs ou indirects,

auquel cas les restrictions ci-dessus ne s’appliquent pas.

POUR VALIDER LA PROTECTION ASSURÉE PAR LA GARANTIE,

VOUS DEVEZ REMPLIR LA CARTE DE GARANTIE ET LA FAIRE

PARVENIR AU FABRICANT DANS DANS LES DIX JOURS SUIVANT

LA DATE D’INSTALATION

95 North Oak Street • Kendallville, IN 46755 • 800-345-9422

Flint and Walling se réserve le droit d'améliorer la conception

et de modifier les prix au besoin, sans avis préalable.

Page 9

MANUAL DEL

SERIE SPM

FW0501S

PROPIETARIO

Bombas Para Jardín y Césped

Con Motor Eléctrico

ADVERTENCIAS DE SEGURIDAD

LEA ESTE MANUAL Y SIGA

TODAS LAS REGLAS DE

SEGURIDAD ANTES DE

INSTALAR U OPERAR ESTA

BOMBA.

SEGURIDAD

CUIDADO

• Revise cuidadosamente las instrucciones antes de usarla.

ADVERTENCIA

- PRECAUCIONES ELÉCTRICAS

Todo cableado, conexiones eléctricas y sistemas de contacto a

tierra deben cumplir con el Código Eléctrico Nacional (NEC) y con

cualquier código y ordenanza local. Contrate los servicios de un

electricista con licencia.

LEA CUIDADOSAMENTE ESTOS

MENSAJES DE SEGURIDAD EN ESTE

MANUAL Y EN LA BOMBA.

ADVERTENCIA

- RIESGO DE DESCARGA ELÉCTRICA

• Haga que un electricista le conecte la electricidad al motor.

• El motor debe estar conectado a tierra y la tapa del terminal

debe estar puesta para reducir el peligro de descarga

eléctrica.

• Mantenga el área de operación del motor lo más seca posible.

• Se recomienda se use un circuito protegido por un interruptor

por contacto a tierra (GFI) con cualquier aparato eléctrico que

opere cerca del agua.

• Desconecte siempre el suministro eléctrico antes de darle

servicio.

• No se ha investigado su uso para el área de piscinas.

APLICACIÓN

Utilice estas bombas para aplicaciones donde la distancia

vertical desde la bomba hasta el nivel del agua no sea mayor de

RENDIMIENTO

Flujo en GPM en Flujo en Litros por Minuto

Modelo de presión total (pies) en presión total (Metros)

bomba CV 25 50 75 100 125 150 10 20 30 40 50

SPM30 3 110 92 71 40 371 276 110

SPM50 5 141 121 98 66 560 466 348 148

INSTALACIÓN

UBICACIÓN DE LA BOMBA: Instale la bomba en un lugar

limpio, seco y ventilado, con drenaje adecuado, suficiente

espacio para darle servicio y protegido contra temperaturas

congelantes. Se le debe empernar niveladamente a unos

buenos cimientos, de preferencia de concreto, para evitar

cualquier tensión innecesaria. El ubicar la bomba lo más cerca

posible de la fuente de agua reducirá las pérdidas por fricción en

la tubería de succión y proporcionará las capacidades máximas.

TUBERÍA DE SUCCIÓN: Se recomienda se utilice solamente

25 pies. En todas las instalaciones se debe tomar en

consideración la pérdida por fricción en las tuberías de succión.

tuberías o mangueras nuevas y limpias y del mismo tamaño que

la toma de succión de la bomba. Si la bomba está lejos de la

fuente de agua, la tubería de succión se debe aumentar un

tamaño. Incline la tubería de succión siempre hacia arriba para

evitar bolsas de aire en la misma. En casos en los que se tenga

que cargar la bomba frecuentemente y donde no se necesite

bombear grandes cantidades de agua, se recomienda se use un

codo de 90° o 45° en la línea de succión. Esto le permite a la

bomba cargarse más rápidamente y también evita que la

manguera se pliegue. En los casos en que se necesite un

dddddd

236222s 0403

Page 10

volumen máximo de agua por largos períodos de tiempo, la línea de

succión debe estar casi horizontal con la bomba. Utilice un sellador

no tóxico para rosca en todas las uniones de las tuberías, y las

conexiones deben estar bien ajustadas. Se debe conectar un filtro

o colador en el extremo inferior de la tubería de succión y éste debe

estar bien sumergido en todo momento.

ADVERTENCIA

- PELIGRO DE DESCARGA ELÉCTRICA

• CABLEADO: Asegúrese que el voltaje y la frecuencia del

suministro eléctrico concuerde con los indicados en la placa

de marca del motor. Si tiene dudas, comuníquese con la

compañía eléctrica.

ADVERTENCIA

- PRECAUCIONES ELÉCTRICAS

Todo el cableado, las conexiones eléctricas y los sistemas de

contacto a tierra deben cumplir con el Código Eléctrico Nacional

(NEC) y con todas las ordenanzas y códigos locales. Contrate a un

electricista calificado.

MONOFÁSICOS: Determine cuál es el voltaje de entrada al motor.

Utilice 230V cuando sea posible. Conecte el cableado al tablero del

terminal ubicado dentro de la tapa del motor. Asegúrese que las

conexiones de voltaje concuerden con el diagrama de cableado en

la placa de marca del motor.

Para verificar la rotación correcta: Quite la tapa del motor,

dejando expuesto el eje del motor. Si la conexión es correcta, el eje

girará en el mismo sentido que las manecillas del reloj. Si la

rotación es al contrario, intercambie cualquiera de dos cables que

van al arrancador. La rotación estará ahora corregida.

ADVERTENCIA

- PELIGRO DE DESCARGA ELÉCTRICA

CÓMO CONECTAR EL MOTOR A TIERRA: EL CABLEADO A

ESTA BOMBA DEBE SER INSTALADO Y MANTENIDO DE

ACUERDO AL CÓDIGO ELÉCTRICO NACIONAL O A SU CÓDIGO LOCAL. SI NECESITA MAYOR INFORMACIÓN, LLAME

A SU ELECTRICISTA AUTORIZADO LOCAL O A SU COMPAÑÍA ELÉCTRICA.

Se recomienda se haga una conexión a tierra permanente para la

unidad, utilizando un conductor del tamaño adecuado desde una

tubería metálica subterránea de agua o un conductor conectado a

tierra en el panel de servicio. No la conecte a tierra con una tubería

de suministro de gas. No la conecte al suministro eléctrico hasta

que la unidad esté conectada a tierra permanentemente. Conecte

el cable de contacto a tierra con un contacto a tierra aprobado y

luego conéctela al terminal provisto.

TRIFÁSICOS: Los motores trifásicos requieren arrancadores

magnéticos y pueden funcionar en cualquier dirección, dependiendo de cómo estén conectados al suministro eléctrico.

FUNCIONAMIENTO - CÓMO CARGAR LA BOMBA

AVISO

CÓMO CARGAR LA BOMBA: La bomba tiene un tapón de

cargado ubicado en la parte superior del cuerpo de la bomba para

llenarlo con agua. Una vez llenada y después que vuelva a colocar

el tapón de cargado, la bomba se cargará. El tiempo de cargado

depende de las distancias verticales y horizontales entre la bomba

y el nivel de agua. La bomba se debe cargar sola una y otra vez

mientras que la válvula de chequeo incorporada funcione.

CUIDADO: NO haga funcionar la bomba antes de llenar

CARGADO BAJO PRESIÓN: (Vea la Fig. 1). Si fuera necesario

cargar la bomba bajo presión, instale una válvula de chequeo en la

línea de descarga de la bomba y un grifo de descompresión o un

purgador de aire del tipo de bola en lugar del tapón de cargado, o una

línea de purgado de aire con una válvula de compuerta conectada

a la línea de descarga. Esto permitirá que el líquido se quede en la

tubería de descarga y que la bomba purgue el aire que quede,

facilitando así el cargado.

: NO OPERAR LA BOMBA ANTES DE CARGARLA, EL SELLO Y EL PROPULSOR PODRÍAN DAÑARSE PERMANENTEMENTE.

el cuerpo de la misma con agua, ya que puede

dañar el sello.

Figura 1

Válvula de Compuerta

(Min. 3/4")

Válvula de chequeo

Válvula de

Compuerta

Descarga

Bomba

Línea de purgado de aire

Línea de succión

Colador

ROTACIÓN DEL PROPULSOR: El propulsor debe girar en

sentido contrario a las manecillas del reloj cuando se ve la bomba

desde el frente del cuerpo de la misma. Si el propulsor rotara en

sentido contrario en los modelos con motores eléctricos, vea las

instrucciones proporcionadas con el motor. La rotación de los

motores trifásicos se puede invertir intercambiando cualquiera de

dos cables.

2

Page 11

CÓMO PRENDER LA BOMBA: Nunca haga funcionar la bomba

en seco, ya que podría dañar el sello. Si se usa una línea de

succión excepcionalmente larga, el agua en el cuerpo de la

bomba se puede recalentar y la línea de succión se puede

bloquear con el vapor. Si esto ocurre, reemplace el agua en el

cuerpo de la bomba con agua fría y continúe el cargado.

DRENAJE: Si la bomba va a estar expuesta a temperaturas

congelantes, será necesario drenar la bomba completamente.

Para hacer esto, quite el tapón de drenaje ubicado en la parte

inferior frontal del cuerpo de la bomba, y el de cargado, y

asegúrese que el agujero de drenaje no esté bloqueado. Una vez

que se haya drenado toda el agua, haga funcionar la bomba por

MANTENIMIENTO

unos segundos para sacar todo el líquido del propulsor

(asegúrese que la línea de succión también esté sin agua).

ALMACENAMIENTO DE LA BOMBA: Drene el líquido de la

bomba para evitar el congelamiento del mismo. Se recomienda

se use un buen antioxidante en el líquido para evitar la corrosión

excesiva. Asegúrese que el motor se mantenga seco y cubierto.

Cuando vuelva a usar la bomba, vuelva a colocar todos los

tapones y asegúrese que todas las conexiones estén bien

ajustadas y selladas. Luego de una revisión completa, haga el

cargado inicial de acuerdo a las instrucciones bajo la sección

Cómo Cargar la Bomba.

ADVERTENCIA

- PRECAUCIONES ELÉCTRICAS

Todo el cableado, las conexiones eléctricas y los sistemas de

contacto a tierra deben cumplir con el Código Eléctrico Nacional

(NEC) y con todas las ordenanzas y códigos locales. Contrate a un

electricista calificado.

ADVERTENCIA

- RIESGO DE DESCARGA ELÉCTRICA

• Haga que un electricista le conecte la electricidad al motor.

• El motor debe estar conectado a tierra y la tapa del terminal

debe estar puesta para reducir el peligro de descarga

eléctrica.

• Mantenga el área de operación del motor lo más seca posible.

• Se recomienda se use un circuito protegido por un interruptor

por contacto a tierra (GFI) con cualquier aparato eléctrico que

opere cerca del agua.

• Desconecte siempre el suministro eléctrico antes de darle

servicio.

• No se ha investigado su uso para el área de piscinas.

LUBRICACIÓN:

a) La bomba no necesita lubricación.

b) Para los modelos de motores eléctricos, vea las

instrucciones proporcionadas por el fabricante del motor.

CÓMO REEMPLAZAR EL SELLO MECÁNICO:

(Vea la Fig. 2)

CÓMO DESARMARLA:

CÓMO VOLVERLA A ENSAMBLAR:

a) Limpie completamente todas las piezas.

b) Moje la parte de goma del asiento sellador con una

solución jabonosa y presiónelo dentro de su caja en la

plancha selladora o en el adaptador, con el lado liso de

cerámica hacia el exterior.

c) Ensamble la plancha selladora o el adaptador al motor

eléctrico.

d) Aceite el sello y deslícelo sobre el eje. Asegúrese que

el lado sellador esté hacia el asiento de cerámica.

e) Vuelva a colocar el propulsor.

f) Vuelva a ensamblarlo al cuerpo de la bomba y al anillo

difusor. Se recomienda se use una nueva junta (3).

g) Vuelva a conectar las tuberías de succión y descarga

y vuelva a conectar el cableado eléctrico.

PRECAUCIONES

a) Cuando la desensamble y vuelva a ensamblar,

asegúrese siempre que el propulsor gire libremente

dentro del cuerpo de la bomba.

b) Los modelos SPM tienen un anillo de goma (10) en el

eje. Este anillo de goma no se debe quitar.

Figura 2

Descarga

Tapón de cargado

a) Quite los pernos (1) y el cuerpo de la bomba (2).

b) Quite el propulsor (destornille el propulsor o quite el perno

de retención, dependiendo del modelo).

c) Deslice el sello fuera del eje.

d) Quite los cuatro pernos y levante el adaptador (7) fuera del

motor. Tenga cuidado de no dañar el asiento sellador.

e) Si tiene que reemplazar el asiento (9), presiónelo fuera del

adaptador desde el lado del motor.

Tapón de

descarga

3

Page 12

GUÍA PARA SOLUCIONAR PROBLEMAS

PROBLEMAS Y SUS CAUSAS SOLUCIONES

No bombea:

1. La bomba no está cargada correctamente. 1. Asegúrese que el cuerpo de la bomba y la línea de succión estén

llenas de agua. Vea las instrucciones de cargado.

2. La velocidad es muy lenta. 2.

ADVERTENCIA - PRECAUCIONES ELÉCTRICAS

Todo el cableado, las conexiones eléctricas y los sistemas de contacto

a tierra deben cumplir con el Código Eléctrico Nacional (NEC) y con

todas las ordenanzas y códigos locales. Contrate a un electricista

calificado. Revise el voltaje en los terminales del motor y en el medidor

cuando la bomba esté funcionando. Si está bajo, vea las instrucciones

de cableado o consulte con su compañía eléctrica. Asegúrese que no

haya conexiones flojas.

3. La presión total es mayor para la que la bomba se diseñó. 3. Se necesita una bomba diseñada para mayor presión.

4. La altura de succión es demasiada. 4. Coloque la bomba más cerca de la fuente de agua. Asegúrese

que la tubería de succión es lo suficientemente grande.

Capacidad y/o presión reducidas:

1. Fugas o bolsas de aire en la línea de succión. 1. Revise la tubería de succión.

2. Propulsor atorado. 2. Sáquelo y límpielo.

3. El colador es muy pequeño o está atorado. 3. Utilice un colador más grande o limpio.

4. La línea de succión no está suficientemente sumergida. 4. Añada tramos a la tubería de succión para mantenerla sumergida y bien

por debajo del nivel del agua.

5. La altura de succión es demasiada. 5. Si es causada por la fricción de la tubería de succión, use una tubería

más grande. Caso contrario, coloque la bomba más cerca al nivel de

agua.

6. La presión total es mayor para la que la bomba se diseñó. 6. Se necesita una bomba diseñada para mayor presión.

7. El propulsor está excesivamente gastado. 7. Pida las piezas de repuesto usando la Lista de Piezas de Repuesto.

La bomba pierde la carga:

1. Fuga de aire en la línea de succión. 1. Revise la tubería de succión.

2. La altura de succión es excesiva y está funcionando muy 2. Coloque la bomba más cerca al nivel de agua.

cerca del punto de apague.

3. El nivel del agua baja cuando se bombea, dejando la 3. Revise el suministro de agua. Añada tramos a la tubería de succión

tubería de succión al descubierto. para mantenerla sumergida y bien por debajo del nivel del agua.

Problemas y ruidos mecánicos:

1. Eje doblado y/o rodamientos dañados. 1. Lleve el motor a una tienda autorizada de reparaciones.

2. Las tuberías de succión y/o descarga no están debidamente 2. Asegúrese que todas las tuberías estén bien apoyadas para aliviar la

apoyadas o sujetadas. tensión sobre el conjunto de la bomba.

SISTEMAS DE AGUA - GARANTIA LIMITADA POR UN AÑO

Este producto está garantizado por un año a partir de la fecha de

compra, o por dos años a partir de la fecha de fabricación,

cualquiera que ocurra primero, y está sujeta a las condiciones mas

adelante descritas. El fabricante reparará o remplazará al

comprador original cualquier parte del producto que demuestre

estar en condiciones defectuosas, debido a materiales o mano de

obra defectuosa. Para obtener servicios o reparaciones

amparados por la garantía, es necesario contactar al distribuidor en

donde el producto fue adquirido. El fabricante se reserva el

derecho exclusivo y es su opción determinar si el equipo, las

piezas, o los componentes defectuosos serán sustituidos o

reparados. Los daños debido a condiciones fuera del control del

fabricante no estan cubiertos bajo esta garantía.

ESTA GARANTIA NO SE APLICA A: (a) Defectos o averias como

resultado de fallos de instalación, operación, o mantenimiento de

acuerdo con las instrucciones impresas proporcionadas, (b) Daños

como resultado de abusos, accidentes, o descuidos, (c) servicios

normales de mantenimiento a las piezas utilizadas relacionadas con

tal servicio, o buenas prácticas del comercio, (d) unidades que no

fueron instaladas de acuerdo con reglamentos aplicables locales o

de acuerdo con el ejercicio de buenas prácticas del comercio, o (e)

uso de la unidad para finalidades mas que aquellas para la que fue

diseñada y fabricada.

DEVOLUCION DE COMPONENTES GARANTIZADOS: Cualquier

reparación o remplazo que sea necesario bajo esta garantía tendrá

que ser devuelta al fabricante en Kendalville, Indiana o a cualquier

otro lugar estipulado por el fabricante, con el importe pagado.

LA GARANTIA AQUI MENCIONADA SUSTITUYE OTRAS

GARANTIAS EXPRESAS, LA CUAL NO PODRA SER EXTENDIDA NI

MODIFICADA POR NADIE. CUALQUIER GARANTIA INVOLUCRADA

SERA LIMITADA AL PERIODO DE TIEMPO DE LA GARANTIA

ESTABLECIDA Y EN LO ADELANTE TODAS DICHAS GARANTIAS

SERAN RECHAZADAS Y EXCLUIDAS. EL FABRICANTE NO PODRA

SER BAJO NINGUNA CIRCUNSTANCIA, RESPONSABLE POR DAÑOS

IMPORTANTES, O ESPECIALES, TALES COMO, PERO SIN TENER

QUE LIMITARSE A, DAÑOS O PERDIDA DE OTRA PROPIEDAD O

EQUIPO, PERDIDA DE GANANCIAS, INCONVENIENTES, U OTROS

DAÑOS FORTUITOS Y COMO RESULTADO DE CUALQUIER TIPO O

NATURALEZA. LA RESPONSABILIDAD DEL FABRICANTE NO

EXCEDERA EL PRECIO DEL PRODUCTO SOBRE EL CUAL SE BASA

TAL RESPONSABILIDAD.

Esta garantía le da derechos legales específicos, y usted tal vez

tendrá otros de acuerdo, a las leyes locales.

PARA PROTEGER SU GARANTIA, HAY QUE LLENAR LA FICHA DE

GARANTIA ADJUNTA Y DEVOLVERLA AL FABRICANTE DENTRO

DE DIEZ DIAS DESPUES DE LA INSTALACION DEL EQUIPO

ADQUIRIDO.

95 North Oak Street • Kendallville, IN 46755 • 800-345-9422

Flint and Walling se reserva el derecho de hacer mejoras de diseño y

modificaciones de precios como sea necesario y sin previo aviso.

Loading...

Loading...