Page 1

ECONOMY 1/2 HP

SHALLOW WELL

JET PUMP

FW1005

0706B

Supersedes

0706

IL0607

IMPORTANT INSTALLATION PRECAUTIONS

Please read and save these instructions. Read carefully before attempting to assemble, install, operate

or maintain the product described. Protect yourself and others by observing all safety information.

Failure to comply with instructions could result in personal injury and/or property damage! Retain

instructions for future reference.

95 North Oak St. • Kendallville, IN 46755

© Copyright 2006. All rights reserved.

1

Page 2

General Safety Information

Carefully read and follow all safety instructions

in this manual and on pump. Keep safety labels

in good condition. Replace missing or damaged

safety labels.

This is a SAFETY ALERT SYMBOL. When you

see this symbol on the pump or in the manual,

look for one of the following signal words and

be alert to the potential for personal injury or

property damage.

Warns of hazards that will cause

serious personal injury, death or major property

damage if ignored.

Warns of hazards that can cause

serious personal injury or death, if ignored.

Warns of hazards that can cause

minor personal injury, product or property damage if

ignored.

Indicates factors

concerned with operation, installation, assembly or

maintenance which could result in damage to the

machine or equipment if ignored.

NOTE: Indicates special instructions which are

important but are not related to hazards.

Do not use to pump flammable or explosive

fluids such as gasoline, fuel oil, kerosene,

etc. Do not use in flammable and/or

explosive atmospheres.

Hazardous pressure! Install pressure

relief valve in discharge pipe. Release all

pressure on system before working on any

component.

This product contains chemicals

known to the State of California to cause cancer and

birth defects or other reproductive harm.

NOTE: Pumps with the cCSAus mark are tested to

UL Standard UL778 and certified to CSA Standard

C22.2 No. 108.

1. Wear safety glasses when working with pumps.

2. Pump water only with this pump.

3. Periodically inspect pump and system

components.

4. Protect electrical cord. Replace or repair

damaged or worn cords immediately.

5. Do not insert finger or any object into pump or

motor openings.

6. Do not allow pump or any other system

component to freeze. Freezing may damage

system, leading to injury or flooding. Allowing

pump or system components to freeze will void

the warranty.

7. An acceptable motor switch shall be provided at

the tme of installation.

Never examine, make wiring

changes or touch the motor before disconnecting the

main electrical supply switch.

Unpacking

1. Open carton and remove package that has been

packed with the pump. This package contains

the pressure switch.

2. Remove pump from carton.

3. Check for loose, missing or damaged parts.

1” NPT

1-1/4” NPT

Suction Port

Drain Plug

Discharge

Por t

1/2” Priming

Por t

Figure 1

Junction Box

Pressure

Switch

IL0607

Pre-Installation

For installation the following general materials may

be required:

• PVC cement (if plastic pipe is used)

• Teflon tape

• Pipe, pipe couplings and fittings

• 1” nipple (for discharge)

• 1” tee or 90° elbow (for discharge)

* 1” pipe plug if tee is used

• 1-1/4” foot valve (for cased wells)

• 1-1/4” check valve (for driven wells)

• Single pipe well seal for 1-1/4” pipe (cased or

dug wells)

• Copper electrical wire (See Wiring in Electrical)

• Romex strain relief for pressure switch

Assembly

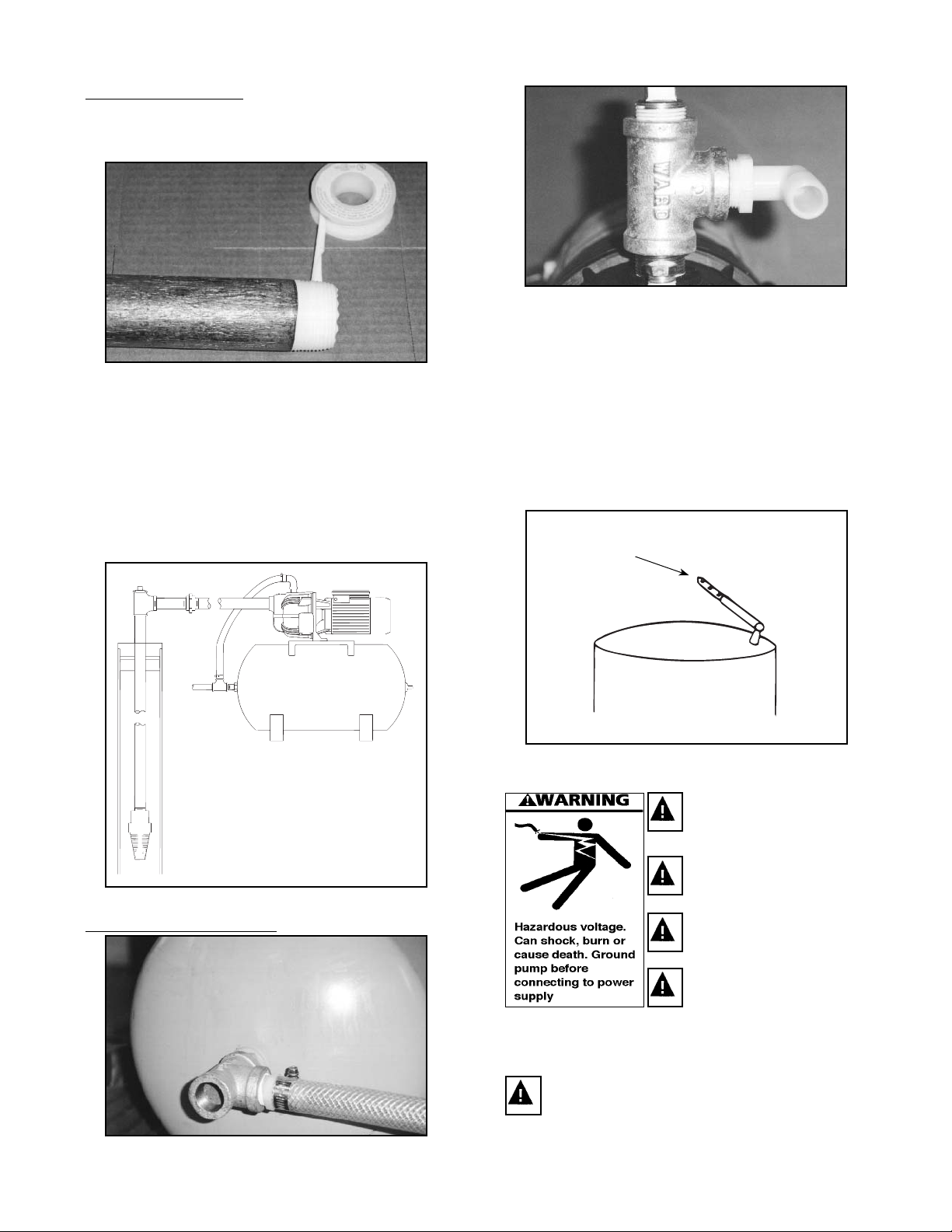

1. Apply two (2) wraps of Teflon tape to threads of

the pressure switch screw. Refer to Electrical

section for pressure switch wiring.

© Copyright 2006. All rights reserved.

2

Page 3

Assembly (Continued)

2. Screw in pressure switch to 1/4” tapping on side

of pump hand tight. Tighten pressure switch with

wrench.

3. Use Teflon tape or pipe joint compound for

making all threaded connections to the pump.

4. Assemble 3/4” pipe to discharge port of pump.

Assemble suction pipe with union to front

of pump. Unions installed near pump and

well will aid in servicing. Leave room to use

wrenches.Tighten joints to approximately 140 ft.

lbs.

5. Bolt pump to solid, level foundation. Support all

piping connected to the pump.

2. Screw elbow fitting to discharge tee. Push flexible

hose onto elbow. Tighten clamp with screwdriver.

3. Connect service line to tank Tee.

4. NOTE: DO NOT install a check valve between

pump and pressure tank. This will cause the

pressure switch to malfunction.

IMPORTANT: Your pump pressure switch is set for

a 20-40 PSI (1.4 - 2.8 Kg/cm2) range and requires

a tank pre-charge of 18 PSI for proper operation

(See Figure 7.)

Checking Tank Pre-Charge

Check pressure

with tire gauge

IL0155

Figure 2

Pressure Tank Installation

1. Assemble tank Tee to end of tank. Screw flexible

hose to tank Tee.

© Copyright 2006. All rights reserved.

Pre-Charged Pressure

Tank

IL0167

Figure 3

Ground motor before

connecting to electrical

power supply

Failure to ground motor

can cause severe or fatal

electrical shock hazard

Do not ground to a gas

supply line.

To avoid dangerous or fatal

electrical shock, turn off

power to motor before

working on electrical

connections.

Supply voltage must be within ±10% of

nameplate voltage. Incorrect voltage can

cause fire or seriously damage motor and

voids warranty. If in doubt, consult a licensed

electrician.

3

3

Page 4

This pump has not been evaluated for use in

swimming pool areas.

Assembly (Continued)

To reduce the risk of electric shock, install with

motor and all electrical components above

the top grade level of sump. This pump is not

submersible.

Use wire size specified in wiring Chart C. If

possible connect pump to a separate branch

circuit with no other appliances on it. If motor

wiring diagram differs from diagram shown

below, follow diagram on motor.

Wire motor for correct

voltage. See “Electrical”

section and Motor Data

Charts A & C of this

manual, and motor

nameplate.

Ground motor before

connecting to electrical

power supply

Meet national electrical

code and local codes for

all wiring.

Do not handle a pump or pump motor with wet

hands, or when standing on a wet or damp

surface or in water.

Follow wiring instructions in this manual when

connecting to power lines.

MOTOR

M

GREEN

GROUND

WIRE

MOTOR

LINE

LINE

LINE 1

POWER SUPPLY

LINE 2

GREEN

GROUND

WIRE

IL0626

Figure 3

Make certain that the power

supply conforms to the electrical specifications of the

motor supplied. See Motor Data Chart A.

Specific Wiring Procedure 115V or 230V

1. The motors are prewired from factory for use

with 115V service. Motors are dual voltage

(115/230V), and may be field connected for

230V service.

2. To change voltage, remove the junction box

access cover (See Figure 1).

3. Move the switch to 230V position. (See Figure

4).

115

230

IMPORTANT: Do not use an extension cord

or splice wires. Joints should be made in an

approved junction box. If the above information

or the following wiring diagrams are confusing,

consult a licensed electrician.

Always disconnect power

source before performing any work on or near the

motor or its connected load.

Never run pump dry or against

a closed discharge. To do so can or may cause pump

to overheat, damaging seal and possibly causing

burns to persons handling pump. Fill pump with

water before starting.

Wiring the Pressure Switch

1. Remove pressure switch cover to expose wiring

terminals.

2. Insert motor wires through side hole of pressure

switch and attach to the two inside terminals

marked “motor” (See Figure 3.)

3. Connect the green ground wire of the motor and

the power supply to the switch ground terminals.

4. Connect the power supply wire to the two

pressure switch terminals marked “line” and

replace the switch cover.

IL0165

Figure 4

Replace access cover before

starting or operating pump. Failure to do so can

result in personal injury.

Priming the Pump

Do not touch an operating

motor or engine. They are designed to operate at high

temperatures.

IMPORTANT: Pump must be primed. Make sure

pump is full of water before running. Failure to do

so will cause damage to the pump and void the

warranty.

This pump has been evaluated

for use with water only.

© Copyright 2006. All rights reserved.

4

Page 5

Priming

Por t

1. During the first few hours of operation, inspect

the pump, piping and any auxiliary equipment

used in connection with the unit.

2. Check for leaks, excessive vibration or unusual

noise.

IMPORTANT: Flow into well must at least equal

flow out through pump! See Performance Chart B.

Main Power Box

IL0126

Figure 5

1. Remove priming plug.

2. Fill pump and suction pipe with water until water

runs out of the priming port.

3. Replace priming plug, hand tight.

IL0125

To Ser vice

Suction

Fuse Box or Switch

Elbow

Pressure Switch

Pre-Charged

Pressure Tank

IL0157

Figure 6

4. Start the pump. Unit should pump water within

30 seconds. If not, stop pump and repeat steps

1 through 3. On first use of pump, it may be

necessary to re-prime the unit three or four

times before all the air is out of suction pipe.

IMPORTANT: If the pump fails to build prime,

there may be an air pocket in the pump case.

To break up trapped air, connect 1/4” plastic

tube, using a brass ferrule connector, to the

priming air vent port. (Not supplied.)

IMPORTANT: With the pump case completely

full of water and the priming tee plug in place,

submerge tubing into a bucket of water. Turn

on power to motor. When pump builds up

pressure, turn off power, remove tubing and

ferrule connector and replace 1/4” plug (See

Figure 6.)

5. Once the pump is primed, tighten the priming

plug. Remember to close the faucets.

Once the preceding instructions have been

completed, the pump can be started.

© Copyright 2006. All rights reserved.

Figure 7

Never examine, make wiring

changes or touch the motor before disconnecting the

main electrical supply switch. The thermal device may

have opened the electrical circuit.

Motor Protection

All single phase motors have built-in thermal

protection for all voltages. The overload protects

the motor against burnout due to low voltage, high

voltage and other causes. The device is automatic

and resets itself once the temperature has dropped

to a safe point. Frequent tripping of the device

indicates trouble in the motor or power lines, and

immediate attention is needed.

Disconnect power supply and

de-pressurize system before servicing pump or

removing any component.

Lubrication

The motor has pre-lubricated bearings. No

lubrication is required.

5

Page 6

Winterizing

If pump is located in an area subject to freezing

temperature, the pump should be drained when it is

not in service or in danger from freezing.

Winterizing (Continued)

1. Disconnect power.

2. Slowly and carefully release all water pressure.

3. Drain suction pipe to a point below the frost line.

4. Drain all piping exposed to freezing

temperatures.

5. Remove the 1/4” drain plug located on the

bottom of the pump body (See Figure 1).

6. Remove the priming plug from service tee to

vent pump.

7. Drain pressure tank.

Pump Disassembly

To disassemble the pump, refer to Fig. 14 and the

following instructions.

1. Disconnect power to motor.

2. Remove for (4) hex bolts (Ref. No. 18) and

remove the pump body (Ref. No. 10) from motor.

3. Remove three (3) hex bolts and washers (Ref.

No. 17) and remove diffuser (Ref. No. 7) and

diffuser plate (Ref. No. 9).

NOTE: The seal ring (Ref. No. 6) is generally

reusable. However, check to see if cut or damaged

and replace if necessary.

Cleaning/Replacing Impeller

(See Figure 15)

NOTE: First, follow instructions under “Pump

Disassembly”.

1. With diffuser removed, (Ref. No. 7) the exposed

impeller can now be cleaned.

2. Remove impeller (Ref. No. 5) by unthreading

counter-clockwise while looking into the eye of

impeller. To hold motor shaft, remove two (2)

screws (Ref. No. 16) and remove motor end cap.

Use the screwdriver shaft at the back of motor

shaft.

3. To reinstall, reverse steps 1 and 2 and re-mount

diffuser.

4. Re-assemble the pump body (Ref. No. 10) to the

motor bracket (Ref. No. 19).

NOTE: Because damage to the shaft seal can

occur in disassembly, a new seal will be required.

Mechanical Seal Replacement

(See Figure 15)

1. Follow instructions under “Pump Disassembly”.

2. Follow steps 1 and 2 under “Cleaning/Replacing

Impeller”.

3. Remove the mechanical seal assembly.

a. Using two screwdrivers, pry the rotary

portion of the seal assembly (carbon ring,

Buna-N gasket and spring) off the end of

the shaft.

b. Using two (2) screwdrivers, pry the ceramic

seal and rubber gasket from the recess of

the mounting ring (See Figure 9).

The precision lapped faces of

the mechanical seal are easily damaged. Handle

the replacement seal carefully. Short seal life will

result if seal faces (ceramic & carbon) are nicked,

scratched or dirty.

4. Clean the seal cavity of the motor bracket and

the motor shaft thoroughly.

5. Wet outer edge of rubber cup on ceramic seat

with liquid soap solution. Use sparingly (one

drop only).

NOTE: Liquid soap solution — one drop of liquid

soap combined with one teaspoonful of water.

6. With thumb pressure, press ceramic seal half

firmly and squarely into seal cavity. Polished

face of ceramic seat is up. If seal will not seat

correctly, remove, placing seal face up on bench.

Reclean cavity. Seal should now seat correctly

(See Figure 10).

7. If seal does not seat correctly after recleaning

cavity, place a cardboard washer over polished

seal face and carefully press into place using

a piece of standard clean 3/4” pipe as a press

(See Figure 11).

IMPORTANT: Do not scratch seal face.

8. Dispose of cardboard washer and recheck seal

face to be sure it is free of dirt, foreign particles,

scratches and grease.

9. Inspect shaft to be sure it is free of nicks and

scratches.

10. Apply liquid soap solution sparingly (one drop is

sufficient) to inside diameter of rubber rotating

member.

11. Slide rotating seal member (carbon face down

toward ceramic face) and spring over the shaft.

IMPORTANT: Be sure not to nick or scratch carbon

face of seal when passing it over threaded shaft

end of shaft shoulder. The carbon surface must

remain clean, or short seal life will result.

12. Hold motor shaft with flat blade screwdriver and

screw impeller onto shaft. Tightening impeller

will automatically locate seal in correct position.

13. If removed for inspection remount seal ring and

diffuser to the motor mounting ring.

14. Reassemble the pump body (Ref. No. 10) to the

motor mounting bracket.

© Copyright 2006. All rights reserved.

6

Page 7

Remove Mechanical Seal

Cased/Dug Well Installation

IL0168

If necessary, press

with cardboard and

pipe

Figure 8

Press in Seal

Figure 9

IL0173

3/4” pipe

- press

carefully

Suction Pipe

Well Seal

Driven Point Installation

Steel Drive Pipe

Well Point

Figure 11

Priming Plug

Priming Tee

10 - 20’

At

Least

5 Feet

IL0170

Check Valve

Drive Coupling

Standing

Water Level

(Pump Off)

Drawdown

Water

Level

(Pump

On)

Cardboard

washer

protects seal

face

IL0169

Seal

Seal Cavity

Figure 10

Well Pipe Installation

Use the installation method below which matches

your well type.

Figure 12

Suction

Support

Screening

protects foot

Pipe

Pipe

valve

Driven Point

IL0171

Lake Installation

Priming Plug

Priming Tee

Foot Valve

Always

Submerged

IL0172

Foot valve off

bottom to keep

dirt out of system

Figure 13

© Copyright 2006. All rights reserved.

7

Page 8

TROUBLESHOOTING CHART

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

A. MOTOR WILL NOT

RUN

1. Disconnect switch is off.

2. Fuse is blown.

1. Be sure switch is on

2. Replace fuse

B. MOTOR RUNS HOT

AND OVERLOAD

KICKS OFF

C. MOTOR RUNS

BUT NO WATER IS

DELIVERED

(*) NOTE: Check prime

before looking for

other causes. Unscrew

priming plug and see

if there is water in

priming hole

3. Starting switch is defective.

4. Pressure switch contacts are dirty.

1. Motor is wired incorrectly.

2. Voltage is too low.

3. Pump cycles too frequently.

1. Pump in a new installation did not pick

up prime through:

a. Improper priming

b. Air leaks

c. Leaking foot valve

*2. Pump has lost its prime through:

a. Air leaks

3. Disconnect power; replace starting switch

4. Disconnect power and file contacts with emery

board or nail file

1. Refer to instructions on wiring

2. Check with power company. Install heavier

wiring if wire size is too small. See wiring

instructions

3. See section below on too frequent cycling

1. In new installation

a. Re-prime according to instructions

b. Check all connections on suction line, air

volume control and ejector

c. Replace foot valve

2. In installation already in use:

a. Check all connections on suction line, air

volume control, ejector and shaft seal

D. PUMP DOES NOT

DELIVER WATER

TO FULL CAPACITY

(ALSO CHECK POINT

3 IMMEDIATELY

ABOVE)

b. Water level below suction of pump

3. Ejector or impeller is plugged

4. Check valve or foot valve is stuck in

closed position

5. Pipes are frozen

6. Foot valve and/or strainer are buried in

sand

1. Water level in well is lower than

estimated.

2. Steel piping (if used) is corroded or

limed, causing excess friction

3. Offset piping is too small in size

b. Lower suction line into water and re-

prime. If receding water level in a shallow well

operation exceeds suction lift, a deep well pump

is needed

3. Clean ejector or impeller

4. Replace check valve or foot valve

5. Thaw pipes. Bury pipes below frost line. Heat

pit or pump house

6. Raise foot valve and/or strainer above well

bottom

1. A deep well jet pump may be needed (over 25

ft. to water)

2. Replace with plastic pipe where possible,

otherwise with new steel pipe

3. Use larger offset piping

© Copyright 2006. All rights reserved.

8

Page 9

TROUBLESHOOTING CHART (Continued)

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

E. PUMP PUMPS WATER,

BUT DOES NOT SHUT

OFF

1. Pressure switch is out of adjustment

or contacts are “frozen”

2. Faucets have been left open

1. Adjust or replace pressure switch

2. Close faucets

F. PUMP CYCLES TOO

FREQUENTLY

G. AIR SPURTS FROM

FAUCETS LITTLE OR

NO

WATER

3. Ejector or impeller is clogged

4. Water level in well is lower than

estimated

1. Standard pressure tank is waterlogged

and has no air cushion

2. Pipes leak

3. Faucets or valves are open

4. Foot valve leaks

5. Pressure switch is out of alignment

6. Air change too low in pre-charged

tank

1. Pump is picking up prime

2. Leak in suction side of pump

3. Clean ejector or impeller

4. Check possibility of using a deep well jet

pump

1. Drain tank to air volume control tapping. Check

air volume control for defect. Check for air leaks

at any connection

2. Check connections

3. Close faucets or valves

4. Replace foot valve

5. Adjust or replace pressure switch

6. Disconnect electrical power and open faucets

until all pressure is relieved. Using automobile

tire pressure gauge, check air pressure in tank

at the valve stem located at top of tank. Air

pressure should be 2 PSI below pump pressure

switch cut-in setting. Check air valve for leaks,

using soapy solution, and replace core if

necessary.

1. As soon as pump picks up prime, all air will be

ejected

2. Check suction piping

3. Well is gaseous

4. Intermittent over-plumbing of well

© Copyright 2006. All rights reserved.

9

3. Change installation as described in manual

4. Lower foot valve if possible, otherwise restrict

discharge side of pump to match well delivery

Page 10

Specifications Chart A

Motor

HP

Volts Phase HZ RPM

1/2 115/230V 1 60 3450 115V

Motor

Connected

For

Pressure

Switch

Setting

30/50 PSI

Suction

Discharge

Inlet Outlet H W L

1-1/4” 1” 8” 10” 17” 36

Dimensions

Pump Performance Chart B

HP

1/2

Suction Lift

(Feet)

5

15

25

Gallons Per Minute Capacity At Discharge Pressure PSI

20 30 40 50

10.1

7.3

4.5

9.6

7.0

4.2

7.8

4.5

3.8

5.5

3.2

2.7

Shut Off PSI

Wiring And Fuse Size Chart C

Motor

HP

1/2 115/230V 9.5/4.7 14/14 12/14 12/14 12/14 10/12 15A 20A 30A

(†) Fusetrons are recommended instead of fuses on all motor circuits.

Volts

Max.

Load

Amps

Distance In Feet From Motor To Service Panel

Wire Size AWG - Copper

0-50

Ft.

50-100

Ft.

100-150

Ft.

150-200

Ft.

200-300

Ft.

Branch Fuse

Rating†

Wire Size

14 12 10

Ship

Wt.

Lbs.

80

79

79

WATER SYSTEMS ONE-YEAR LIMITED WARRANTY

This product is warranted for one year from the date of purchase or two years

from the date of manufacture, whichever occurs first. Subject to the conditions

hereinafter set forth, the manufacturer will repair or replace to the original

consumer, any portion of the product which proves defective due to defective

materials or workmanship. To obtain warranty service, contact the dealer from

whom the product was purchased. The manufacturer retains the sole right and

option to determine whether to repair or replace defective equipment, parts or

components. Damage due to conditions beyond the control of the manufacturer

is not covered by this warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects or malfunctions resulting

from failure to properly install, operate or maintain the unit in accordance with

printed instructions provided; (b) to failures resulting from abuse, accident or

negligence; (c) to normal maintenance services and the parts used in connection

with such service; (d) to units which are not installed in accordance with normal

applicable local codes, ordinances and good trade practices; and (e) the unit is

used for purposes other than for what it was designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired or

replaced under this warranty must be returned to the manufacturer at Kendallville,

Indiana or such other place as the manufacturer may designate, freight prepaid.

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER EXPRESS

WARRANTIES, AND MAY NOT BE EXTENDED OR MODIFIED BY ANYONE.

ANY IMPLIED WARRANTIES SHALL BE LIMITED TO THE PERIOD OF

THE LIMITED WARRANTY AND THEREAFTER ALL SUCH IMPLIED

WARRANTIES ARE DISCLAIMED AND EXCLUDED. THE MANUFACTURER

SHALL NOT, UNDER ANY CIRCUMSTANCES, BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES, SUCH AS, BUT NOT LIMITED

TO DAMAGE TO, OR LOSS OF, OTHER PROPERTY OR EQUIPMENT,

LOSS OF PROFITS, INCONVENIENCE , OR OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY TYPE OR NATURE. THE LIABILITY

OF THE MANUFACTURER SHALL NOT EXCEED THE PRICE OF THE

PRODUCT UPON WHICH SUCH LIABILITY IS BASED.

This warranty gives you specific legal rights, and you may have other rights

which vary from state to state. Some states do not allow limitations on duration

of implied warranties or exclusion of incidental or consequential damages, so the

above limitations may not apply to you.

FOR YOUR WARRANTY PROTECTION, THE WARRANTY REGISTRATION

MUST BE COMPLETED AND RETURNED TO THE WARRANTY

INFORMATION CENTER WITHIN TEN DAYS OF INSTALLATION. WARRANTY

VALID IN CANADA AND MEXICO.

© Copyright 2006. All rights reserved.

10

Loading...

Loading...