Page 1

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL

CVSM30, CSM30, CVSM45, CSM45, CST45,

CSIM34, CSM60, CSIM68

PP0132

0611

Supersedes

0410

AUTOMATIC WATER

CONDITIONERS

FILL IN FOR FUTURE REFERENCE

MODEL NO:___________________________________________

DATE INSTALLED:______________________________________

DEALER:______________________________________________

023366

Page 2

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

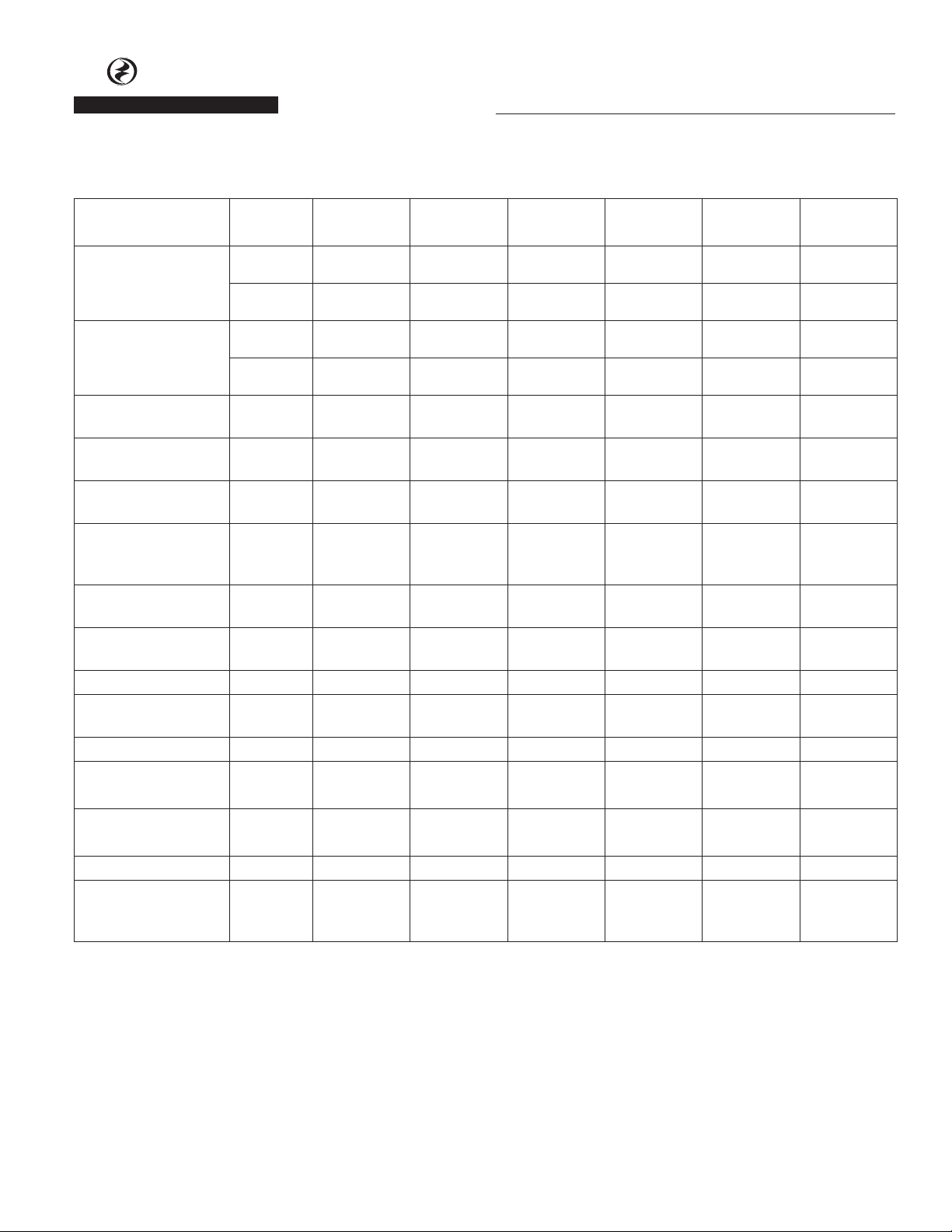

Model Number Units

Automatic Water Conditioners

SPECIFICATION TABLE

CVSM30

CSM30

CSM60

CVSM45

CSM45

CST45 CSIM34 CSIM68

Exchange Capacity

Kilograins

Salt Per

Regeneration

Lbs. / Regen.

Max. Service Flow

Operating Pressure

Mineral Tank Size

Brine Tank Size

Softener Resin

Shipping Weight Lbs.

Overall Height Inches 52 62 52 52 52 60

Regeneration

(1)

Pressure drop not to exceed 15 PSI

(2)

Product materials and workmanship are protected with a written warranty

(3)

Untreated water provided during all steps of regeneration

*Requires 1.0 cu. ft. fine mesh resin plus 30 lbs. garnet underbed

**Requires 2.0 cu. ft. fine mesh resin plus 60 lbs. garnet underbed

(1)

Pipe Size

Range

Maximum

Operating

Temperature

(Dia. x Ht.)

(Dia. x Ht.)

Salt Storage Lbs. 225 225 225 225 225 225

Volume

Tannin Resin Cu. Ft. N/A N/A N/A .5 N/A N/A

Electrical

Max. Drain

Flow During

(2)

(3)

(3)

Max 30,000 60,000 45,000 30,000 34,000 68,000

Min 18,000 32,000 27,000 18,000 18,000 34,000

Max 15 30 22 15 15 30

Min 6 12 9 9 9 12

GPM 8 12 9 5 10 12

In / Out -

Inches

PSI 30 - 125 30 - 125 30 - 125 30 - 125 30 - 125 30 - 125

Degrees F 110 110 110 110 110 110

Inches 8 x 44 10 x 54 10 x 44 10 x 44 10 x 44 12 x 52

Inches 14 x 14 x 34 14 x 14 x 34 14 x 14 x 34 14 x 14 x 34 14 x 14 x 34 14 x 14 x 34

Cu. Ft. 1.0 2.0 1.5 1.0 1.0* 2.0**

Volt

Freq.

GPM 1.3 2.7 2.2 2.2 2.7 2.7

1 1 1 1 1 1

120 Volts

60 Hz

90

92

120 Volts

60 Hz

147

120 Volts

60 Hz

120

122

120 Volts

60 Hz

116.5 120.5 175.5

120 Volts

60 Hz

120 Volts

60 Hz

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

2

Page 3

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

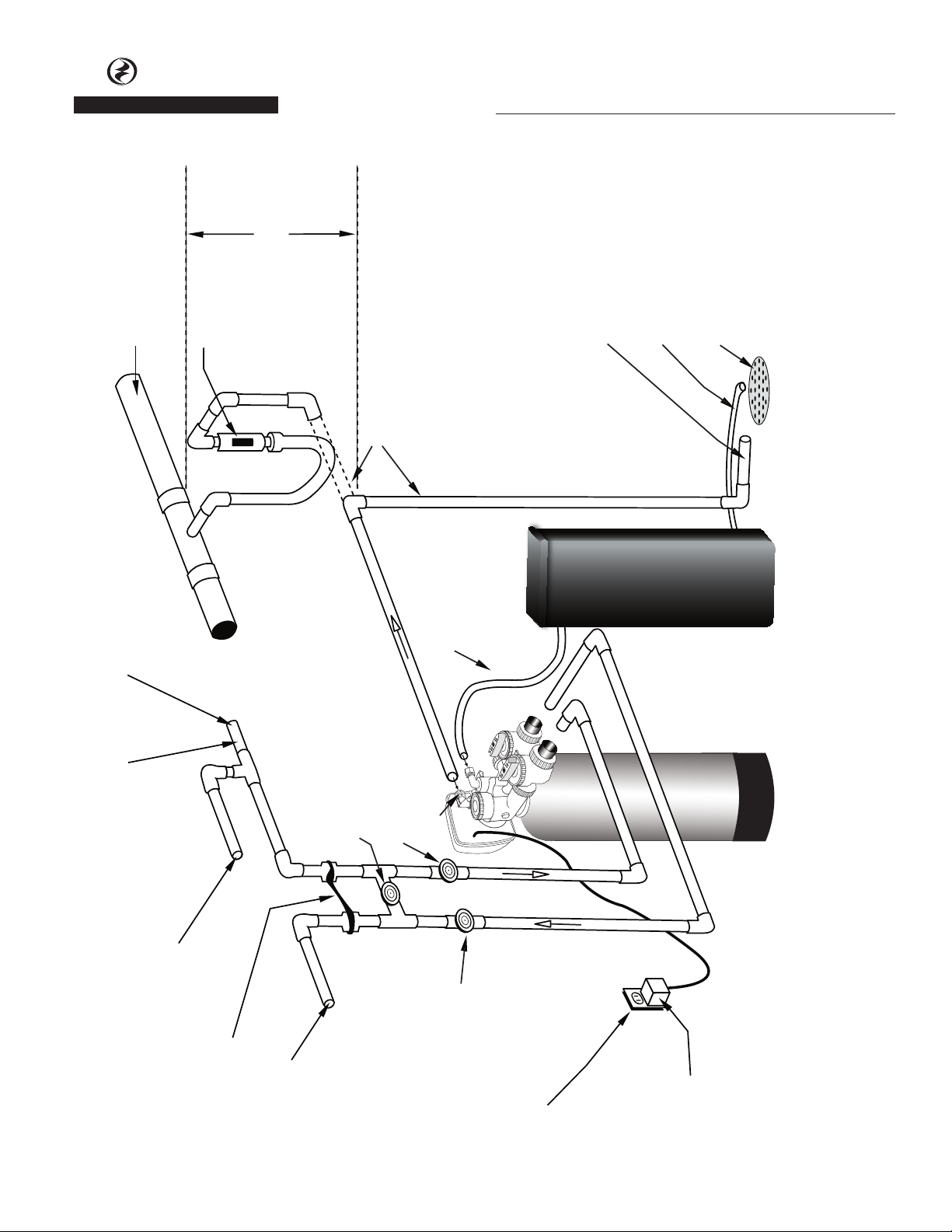

Connection to sanitary sewer line

(optional)

Sanitary sewer line

Air gap device

Maximum drain pipe

elevation above drain

port is 5 ft.

Drain

Automatic Water Conditioners

IL1054

Do not make a direct connection

to the drain. An air gap must

Brine Tank Overflow drain 1/2” ID

diameter minimum size

(gravity flow)

Drain line 1/2” diameter ID

minimum size

Sanitary Drain, Floor Drain or

be present.

Laundry Tubs are acceptable.

Drain Trap

Cold hard water inlet

30 p.s.i. minimum pressure

3/4” minimum pipe size

High Pressure Warning:

If feedwater pressure is known to be above

125 PSI, it is strongly recommended that a

pressure reducing valve be installed at this point.

Manual Bypass Valve

(Normally Closed)

(optional)

Manual Inlet Valve

Drain Port

(optional)

Brine Line Tubing

Assembly

Brine Tank

Assembly

Mineral Tank

Typical Water Softener Installation

Hard water to Sprinklers and any

dersired unsoftened fixtures

Ground Strap

Softened Water Outlet

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

Manual Outlet Valve

(optional)

110-125 Volt

Continuous Power Supply

Transformer

3

Page 4

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

INSTALLATION FITTING ASSEMBLIES

Installation fittings connect to the control valve or

the bypass valve using nuts that only require hand

tightening. Hand tight nut connections between

control valve and installation fittings, control valve and

bypass valve, and bypass valve and installation fittings

allow for ease serviceability. Do not use a pipe wrench

to tighten nuts on installation fittings. Hand tighten

only.

Split ring retainer design holds the nut on and allows

load to be spread over the entire nut surface area,

reducing the chance for leakage. The split ring design

incorporated into the installation fittings allows

approximately 2 degrees off axis alignment to the

plumbing system. The installation fittings are designed

to accommodate minor plumbing misalignments but

are not designed to support the weight of a system or

the plumbing.

When assembling the installation fitting package,

connect the fitting to the plumbing system first and

then attach the nut, split ring and o-ring. Heat from

soldering or solvent cements may damage the nut,

split ring or o-ring. Solder joints should be cool and

solvent cements should be set before installing the nut,

split ring and o-ring. Avoid getting primer and solvent

cements on any part of the o-rings or split rings, bypass

valve or control valve. Solvent cements and primers

should be used in accordance with the manufacturer’s

instructions.

Slip the nut onto the fitting first, then the split ring

second and the o-ring last. Hand tighten the nut. If the

fitting is leaking, tightening the nut will not stop the

leak. Remove the nut, remove the fitting, and check

for damage or misalignment of the o-ring.

Do not use pipe dope or other sealant on threads.

Teflon tape must be used on the threads of the 1”

NPT connection and on the threads for the drain line

connection. Teflon tape is not necessary on the nut

connection or caps because of o-ring seals.

Do not use Vaseline, oils or other unacceptable

lubricants on o-rings. A silicon lubricant may be used

on black o-rings.

BYPASS VALVE - CSM MODELS ONLY

The bypass valve easily connects to the control valve

body using nuts that only require hand tightening.

Hand tighten nut connections between control valve

and fittings, control valve and bypass valve, and

bypass valve and installation fittings allow for easy

serviceability. The split ring retainer design holds the

nut on and allows load to be spread over the entire

nut surface area, reducing the chance for leakage.

The split ring design, incorporated into the bypass,

allows approximately 2 degrees off axis alignment

to the plumbing system. The bypass is designed to

accommodate minor plumbing misalignments but is

not designed to support the weight of a system or the

plumbing.

Avoid getting primer and solvent cements on any

part of the o-rings or split rings, bypass valve or

control valve. Do not use pipe dope or other sealant

on threads. Teflon tape is not necessary on the caps

because of o-ring seals.

Do not use Vaseline, oil or other unacceptable

lubricants on o-rings. A silicon lubricant may be used

on black o-rings.

A. GENERAL

1. Shut off all water at main supply valve.

2. Shut off the fuel supply to water heater.

3. Open faucets (hot and cold) nearest pump or water

meter to relieve pressure and drain system.

4. Move softener into the installation position.

Loosely attach all fittings to measure for bypass

valve assembly (if used), or manual bypass valve.

5. Level the unit. Place shims under cabinet or brine

tank as needed. (Do Not use metal shims.)

6. Cut the cold water supply line as required.

7. Install the bypass valve assembly if used.

B. PLANNING INSTALLATION

1. All installation procedures must conform to local

plumbing, electrical and sanitation codes and

ordinances.

2. It is recommended that outside faucets for lawn

service be on the hard water line, ahead of the

softener, to conserve softened water, save salt and

prevent lawn damage.

3. If this isn’t practical, use the convenient integral

bypass valve assembly.

CAUTION: The inlet water temperature MUST NOT

exceed 110° F.

4. Do not locate softener where ambient temperature

drops below 40° F.

5. Allow space around the softener for ease of

servicing.

6. The softener drain lines must never be solidly

connected to the sewer line. (Always provide an

air gap at the END of the drain line). Valve drain

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

4

Page 5

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

line must not be elevated over 5’ from the top of

the softener on well systems, and not over 8’ on

municipal water systems.

7. The salt storage cabinet or brine tank is a gravity

drain, and this drain line must be lower than the

drain fitting on the side wall of the cabinet.

8. Move the softener into position and connect to

bypass assembly (if used). The integral manual

bypass option is a connection which eliminates the

need for a 3-valve manifold. This makes installation

easier and provides a more convenient method of

bypassing.

9. IMPORTANT: Be sure that the water inlet line is

connected to the “inlet” side of the bypass valve

or to the inlet fitting. (Bypass valve inlet/outlet

fittings are marked.) If water lines are reversed,

(inlet/outlet) resin may be forced from the water

softener into the household plumbing system. If

this occurs, household plumbing system must be

flushed clean.

C. CONNECT ALL FITTINGS (refer to previous

page)

CAUTION: Care must be used when working with

copper tubing. Do not allow the flame from torch

to contact any portion of the Valve assembly.

1. Attach 1/2” ID drain line to drain elbow with insert

and nut.

2. Do not elevate the drain line over 5’ above the top

of the valve (8’ on municipal systems) or exceed 25’

in length at either height.

CAUTION: An air gap must be provided upon

sewer entry. (Conform to local plumbing and

sanitation codes and ordinances).

3. The salt storage cabinet or brine tank provides an

overflow. Attach 1/2” ID flexible plastic tubing to

the overflow fitting and direct it to the drain. DO

NOT connect to the main drain line. Use a separate

gravity flow line.

D. PRESSURE TEST THE INSTALLATION

The plumbing system can now be checked for any

possible leaks.

1. Put the unit into backwash. To do this, push and

hold the

valve stops cycling, unplug the unit. With water

supply off, put the bypass into the service position.

2. Open water supply line valve very slowly. Water

should escape slowly from the drain line. If water

enters too quickly, resin may be lost to the drain.

REGEN

button for 3-5 seconds. When the

3. When all of the air has been purged from the

mineral tank (water flows steadily from the drain),

open the main supply valve fully.

4. Allow water to run to drain until clear. CHECK FOR

LEAKS!

5. Plug the unit back in.

6. Manually step the unit through the remaining

steps, stopping at the fill cycle. (To do this, push

REGEN

the

screen). Once the piston has stopped moving,

push the

Continue until FILL appears on the screen. The

unit will now fill the brine tank to the appropriate

level. (This sequence is for softeners with post fill

brine).

7. Allow control to return to the home position.

8. CHECK FOR LEAKS!

9. Make sure the power cord is plugged into a

properly grounded wall receptacle.

button. The unit will say Brine on the

REGEN

button again to the next cycle.

E. PROGRAMMING THE CONTROL VALVE

When in operation, normal user displays such as time

of day, gallons remaining or days remaining before

regeneration are shown. When stepping through

a procedure, if no buttons are pressed within five

minutes, the display returns to a normal user display.

Any changes made prior to the five minute time out

are incorporated. The one exception is current flow

rate display under the diagnostic procedure. The

current flow rate display has a 30 minute time out

feature.

CONTROL VALVE CYCLES OF OPERATION

REGENERATION CYCLES

1st Cycle Backwash Normal

2nd Cycle Brine / Slow Rinse

3rd Cycle Backwash Normal

4th Cycle Rapid Rinse

5th Cycle Brine Tank Refill

General Operation

When the system is operating, one of two displays

will be shown. Pressing

the displays. One of the displays is always the current

time of day. The second display is gallons remaining.

Capacity remaining is the number of gallons that

will be treated before the system goes through a

regeneration cycle. The user can scroll between the

displays as desired.

will alternate between

NEXT

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

5

Page 6

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

If the system has called for a regeneration

that will occur at the present time of

regeneration, the words “REGEN TODAY” will

appear on the display.

When water is being treated (i.e. water

is flowing through the system), the word

“SOFTENING” flashes on the display.

Automatic Water Conditioners

REGEN TODAY will be

displayed if a regeneration

is expected “Tonight.”

IL1067

STEP 1U

STEP 2U

STEP 3U

AM

PM

IL1068

Set Time of Day

The user must set the time of day. Time of day should only need to be

set initially, and after power outages lasting more than 8 hours, if the

battery has been depleted and a power outage occurs, or when daylight

saving time begins or ends. If a power outage lasting more than 8 hours

occurs, the time of day will flash on and off, which indicates the time of

day should be reset. If a power outage lasts less than 8 hours and the time

of day flashes on and off, the time of day should be reset and the battery

replaced.

STEP 1U - Press

STEP 2U - Current Time (hour): Set the hour of the day using or

buttons. AM/PM toggles after 12. Press

STEP 3U - Current Time (minutes): Set the minutes of the day using

or buttons. Press

previous step.

Power Loss

If the power goes out, the system will keep time for up to 8 hours or until

the battery is depleted. If a power outage of more than 8 hours occurs,

the time of day will flash on and off, which indicates the time of day

should be reset. The system will remember the rest. If a power outage

lasts less than 8 hours and the time of day flashes on and off, the nonrechargeable battery should be replaced.

Error Message

If the word “ERROR” and a number are alternately flashing on the

display, contact the installer for help. This indicates that the valve was not

able to function properly.

SET CLOCK

NEXT

to go to step 3U.

NEXT

to exit Set Clock. Press

REGEN

to return to

IL1069

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

6

Page 7

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

STEP 1I

STEP 2I

STEP 3I

STEP 4I

STEP 5I

RETURN TO

NORMAL MODE

Manual Regeneration

Sometimes there is a need to regenerate the system

sooner than when the system calls for it, usually

referred to as manual regeneration. There may be a

period of heavy water usage because of guests or a

heavy laundry day.

REGEN TODAY will

Flash if a regeneration

is expected “Tonight.”

To initiate a manual regeneration at the present

delayed regeneration time, press and release

The words “REGEN TODAY” will flash on the display to

indicate that the system will regenerate at the present

delayed regeneration time. If you pressed the

button in error, pressing the button again will cancel

the request.

To initiate a manual regeneration immediately, press

and hold the

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

REGEN

IL1070

button for three seconds. The

Setting Hardness, Day Override and Regeneration Time

STEP 1I: Press

STEP 2I - Hardness: Set the amount of hardness in grains of hardness as calcium

carbonate per gallon using the or buttons. The default is 20 with value

ranges from 1 to 150 in 1 grain increments. Note: The grains per gallon can be

increased if soluble iron needs to be reduced. Press

STEP 3I - Day Override: Set Day Override using or buttons. Factory set to

“off” for all units except CST45. Factory set to “3” for CST45. Press

to Step 4I.

STEP 4I - Next Regeneration Time (hour): Set the hour of day for regeneration

using or buttons. AM/PM toggles after 12. The default time is 2:00 a.m.

Press

STEP 5I - Next Regeneration Time (minutes): Set the minutes of day for

regeneration using or buttons. Press

Settings. Press

Regeneration Mode

Typically, a system is set to regenerate at a time of lower water usage. An

example of a time with lower water usage is when a household is asleep. If

there is a demand for water when the system is regenerating, untreated water

will be used.

When the system begins to regenerate, the display

will change to include information about the

step of the regeneration process and the time

remaining for that step to be completed. The

system runs through the steps automatically and

will reset itself to provide treated water when the regeneration has been

completed.

to go to step 5I. Press

NEXT

IL1071

REGEN

REGEN

and simultaneously for 3 seconds.

NEXT

to return to previous step.

NEXT

SET CLOCK

SET CLOCK

REGEN

.

REGEN

to return to previous step.

system will begin to regenerate immediately. The

request cannot be cancelled.

You can manually step through the cycles by pressing

the

REGEN

NOTE: Program Timer “Lockout” Feature

The Program Timer is initially set to allow access to all

Programming, Diagnostic and History screens.

The Installer can limit access to (lockout) most screens

by activating the Lockout Feature.

Activating “Lockout” allows the user to view and

change only Water Hardness, Days Override, Time of

Regeneration and Time of Day.

Activate “Lockout” Feature: Press then

then then

appear in the display.

De-activate “Lockout” Feature: Press then

then then

in the display.

button.

NEXT

to exit Installer Display

in sequence. LOC will briefly

. UNLOC will briefly appear

to go to step 3I.

to go

NEXT

NEXT

NEXT

IL1073

7

Page 8

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

Bypass Valve - CSM Series Only

The bypass valve is typically used to isolate the

control valve from the plumbing system’s water

pressure in order to perform control valve repairs or

maintenance. The bypass valve is particularly unique

in the water treatment industry due to its versatility

and state of the art design features. The full flow

bypass valve incorporates four positions, including

a diagnostic position that allows service personal to

work on a pressurized system while still providing

untreated bypass water to the facility or residence.

The completely non-metallic, all plastic design allows

Figure 1

NORMAL OPERATION

“Treated”

Water Exits

Supply

Water Enters

for easy access and serviceability without the need for

tools.

The bypass body and rotors are glass filled Noryl

1

and

the nuts and caps are glass filled polypropylene. All

seals are self-lubricating EPDM to help prevent valve

seizing after long periods of non-use. Internal o-rings

can easily be replaced if service is required.

The bypass consists of two interchangeable plug valves

that are operated independently by red arrow shaped

handles. The handles identify the flow direction of

the water. The plug valves enable the bypass valve to

operate in four positions.

Figure 2

BYPASS OPERATION

“Untreated”

Water Exits

Supply

Water Enters

IL1043

Normal Operation:

The inlet and outlet handles point in the direction of flow indicated

by the engraved arrows on the control valve. Water flows through

the control valve during normal operation and this position also allows the control valve to isolate the media bed during the regeneration cycle.

Figure 3

DIAGNOSTIC MODE

Supply

Water Exits

Diagnostic:

The inlet handle points in the direction of flow and the outlet handle

points to the center of bypass valve, system water pressure is allowed

to the control valve and the plumbing system while not allowing

water to exit from the control valve to the plumbing.

Noryl1 is a trademark of General Electric

Supply

Water Enters

IL1045

IL1044

Bypass:

The inlet and outlet handles point to the center of the bypass, the

control valve is isolated from the water pressure contained in the

plumbing system. Untreated water is supplied to the plumbing

system.

Figure 4

SHUT OFF MODE

No

Water Exits

Shut Off:

The inlet handle points to the center of the bypass valve and the

outlet handle points in the direction of flow, the water is shut off to

the plumbing system. If water is available on the outlet side of the

softener it is an indication of water bypass around the system (i.e. a

plumbing connection somewhere in the building bypasses the system).

Supply Water is shut off

from the house and the

valve

IL1046

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

8

Page 9

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

Description Qty

No.

Part

1 023406 Motor 1

2 023407 PC Board 1

3 023408 Piston Assy. 1

4 023409 Seal Assy. 1

5 023410 O-Ring Kit 1

6 127001 Mineral Fill Funnel 1

7 023362 Service Tool 1

No.

Item

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

8 023411 Transformer 110V - 12V 1

9

Page 10

remier

Proper fl ow washer orientation

directs water fl ow towards the

washer face with rounded edge.

Flow washer indentifi cation

numbers must be visible after

installation.

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Injector Cap, Injector Screen, Injector, Plug,

O-Ring, Refill and Refill Port Plug, & Drain

Line - 3/4”

Automatic Water Conditioners

16

�

17

18

28

23

24

21

27

20

31

25a, 25b

19

30

26

�

32

�

33

34

35

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

22

29

IL1062

10

Page 11

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

4

1

2

3

Item Description CSM30 CSM60 CSM45 CVSM30 CVSM45 CST45 CSIM34 CSIM68

1

2 Mineral 023356 (2) 023356 (2) 023355 023356 (2) 023355

3 Distributor 023361 023487 023361 023360 023360 023360 023360 023488

4

5 Salt Grid 023322 023322 023322 N/A N/A 023322 023322 023322

6 Brine Valve 023324 023324 023324 023324 023324 023324 023324 023324

Mineral

Tank

Brine Tank

Assy.

134800 134803 023319 134800 023319 023319 023319 023483

023413 023413 023413 023413 023413 023413 023413 023413

5

023356

136203

6

IL1063

023356

023359

(2) 023356

(2) 023359

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

11

Page 12

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

39

Automatic Water Conditioners

38

37

36

IL1064

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

12

Page 13

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

46

45

46

Connectors

5

49

023329

Set of 2

Bypass Valve

Less Fittings

023328

48

44

50

47

41

42

43

41

42

43

49

48

IL1051

IL1052

44

50

47

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

13

Page 14

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Table 15 - Troubleshooting Procedures

Problem Possible Cause Solution

1. Timer does not display time of

day

2. Timer does not display correct

time of day

3. No softening/filtering display

when water is flowing

4. Control valve regenerates at

wrong time of day

5. ERROR followed by code

number

1001 Error Code - Unable to

recognize start of regeneration

1002 Error Code -

Unexpected stall

1003 Error Code -

Motor ran too long, timed out

trying to reach next cycle position

1004 Error Code -

Motor ran too long, timed out

trying to reach home position

If other Error Codes display, contact

the factory

ERROR Reset Procedure:

1. Correct error condition

2. Press

simultaneously for three seconds

NEXT

and

REGEN

Automatic Water Conditioners

a. Transformer unplugged a. Connect power

b. No electric power at outlet b. Repair outlet or use working outlet

c. Defective transformer c. Replace transformer

d. Defective PC board d. Replace PC board

a. Switched outlet a. Use uninterrupted outlet

b. Power outage b. Reset time of day

c. Defective PC board c. Replace PC board

a. Bypass valve in bypass position a. Put bypass valve in service position

b. Meter connection disconnected b. Connect meter to PC board

c. Restricted/stalled meter turbine c. Remove meter and check for rotation or

foreign material

d. Defective meter d. Replace meter

e. Defective PC board e. Replace PC board

a. Power outages a. Reset control valve to correct time of day

b. Time of day not set correctly b. Reset to correct time of day (A.M./P.M.)

c. Time of regeneration incorrect c. Reset regeneration time (A.M./P.M.)

d. Control valve set at “on 0”

(immediate regeneration)

e. Control Valve set at NORMAL +

“on 0”

a. Control valve has just been

serviced

b. Foreign matter is lodged in control

valve

c. High drive forces on piston c. Replace piston(s) and spacer stack

d. Control valve piston not in home

position

e. Motor not inserted fully to engage

pinion, motor wires broken or

disconnected, motor failure

f. Drive gear label dirty or damaged,

missing or broken gear

g. Drive bracket incorrectly aligned to

back plate

h. PC board is damaged or defective h. Replace PC board

i. PC board incorrectly aligned to

drive bracket

d. Check control valve set-up procedure

regeneration time option

e. Check control valve set-up procedure

regeneration time option

1.

Press

or unplug power source jack (black wire)

and plug back in to reset control valve

b. Check piston and spacer stack assembly

for foreign matter

assembly

d.

Press

seconds or unplug power source jack

(black wire) and plug back in to reset

control valve

e. Check motor and wiring. Replace motor if

necessary

f. Clean drive gear(s)

g. Re-seat drive bracket properly

i. Ensure PC board is correctly snapped on to

drive bracket

NEXT

NEXT

and

and

REGEN

REGEN

for 3 seconds,

for three

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

14

Page 15

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Conditioners

Problem Possible Cause Solution

6. Control valve stalled in

regeneration

7. Control valve does not

regenerate automatically when

REGEN

held

8. Control valve does not

regenerate automatically but

does when

depressed

9. Time of day flashes on and off a. Power has been out more than

button is depressed and

REGEN

button is

a. Motor not operating a. Replace motor

b. No electric power at outlet b. Repair outlet or use working outlet

c. Defective transformer c. Replace transformer

d. Defective PC board d. Replace PC board

e. Broken drive gear or drive cap

assembly

f. Broken piston retainer e. Replace piston kit assembly

g. Broken main or regenerant piston g. Replace piston kit assembly

a. Transformer unplugged a. Connect transformer

b. No electric power at outlet b. Repair outlet or use working outlet

c. Broken drive gear or drive cap

assembly

d. Defective PC board d. Replace PC board

a. Bypass valve in bypass position a. Put control valve in service position

b. Meter connection disconnected b. Connect meter to PC board

c. Restricted/stalled meter turbine c. Remove meter and check for rotation or

d. Defective motor d. Replace meter

e. Defective PC board e. Replace PC board

f. Set-up error f. Check control valve set-up procedure

two hours

b. The transformer was unplugged

and then plugged back into the

wall outlet

c. The transformer plug was

unplugged and then plugged back

into the board

d.

The

were pressed to reset the valve

NEXT

and

REGEN

buttons

e. Replace piston kit assembly

c. Replace piston kit assembly

foreign material

a. Reset the time of day

b. Reset the time of day

c. Reset the time of day

d. Reset the time of day

Premier Products Water Treatment | 95 North Oak St. | Kendallville, IN 46755 | 800-545-2206 | flintandwalling.com

Copyright © 2011 Flint & Walling All Rights Reserved.

15

Loading...

Loading...