Page 1

Installation Instructions and Parts Manual

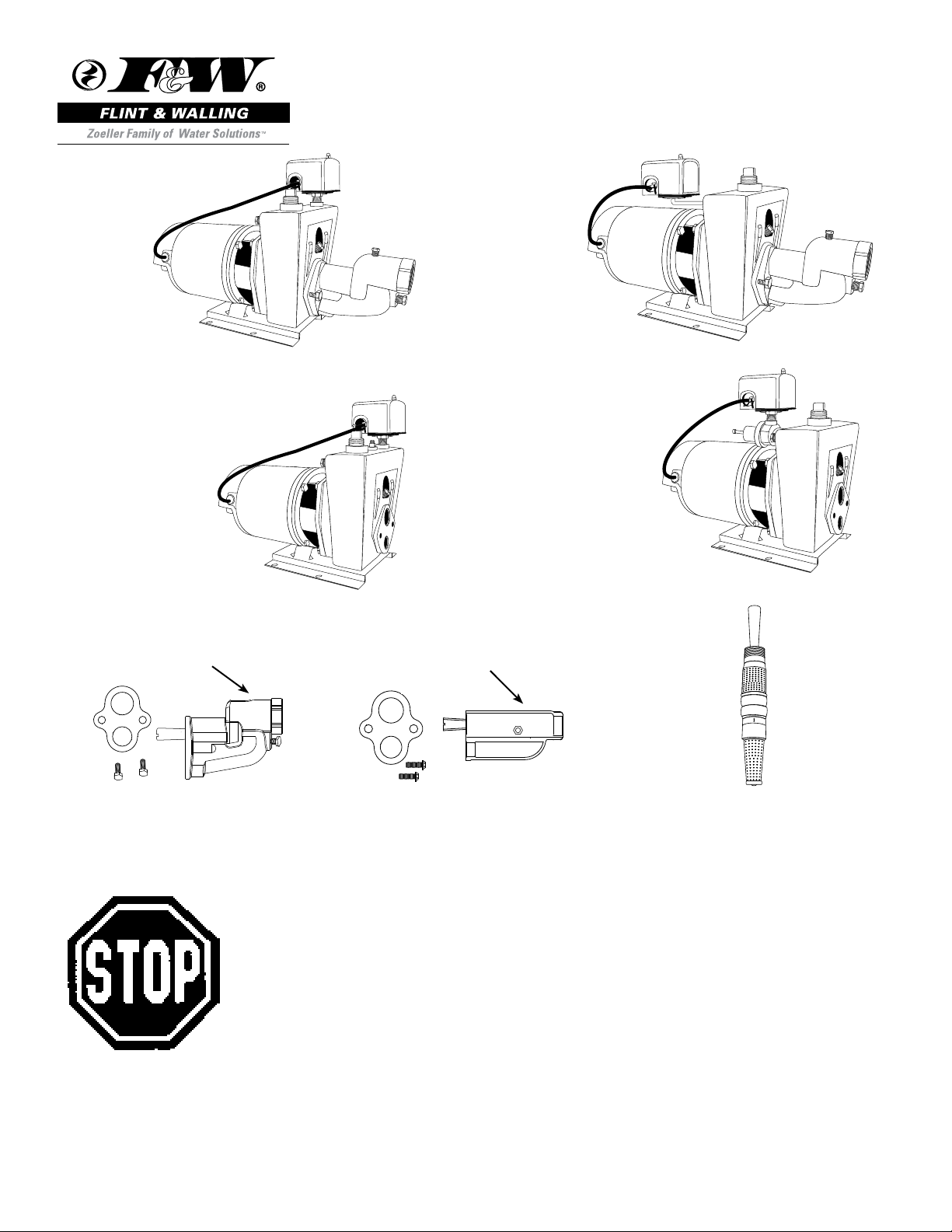

TOP

IL0194

®

“CPJ” SERIES JET PUMPS

Shallow Well Jet Pumps

1/3 - 1/2 HP “CPJS”

SHALLOW WELL

1/2 HP “CPJ”

CONVERTIBLE

Top

IL0189

3/4 - 1-1/2 HP “CPJS”

SHALLOW WELL

Convertible Jet Pumps

IL0192

3/4 - 1-1/2 HP “CPJ”

CONVERTIBLE

Ejectors (Purchase separately)

Top, if used for

shallow well

IL0190

IL0188

IL0195

Shallow Well Ejector for lifts to 25

ft.

For loose, missing or damaged parts, or if the

unit does not seem to be operating properly,

please call before returning unit to the place of

purchase

Monday thru Friday - 7:30 am to 5:00 pm EST

Convertible Ejector For Shallow

or Deep well applications (4 inch

inside diameter wells).

Phone: 1-800-742-5044

Service Hours:

Single Pipe Deep Well

Ejector (2 inch inside

diameter wells).

132463 A

Page 2

SAFETY INFORMATION

DANGER:

1. Always disconnect power source before performing any

work on or near the motor or its connected load. If the

power disconnect point is out-of-sight, lock it in the open

position and tag it to prevent unexpected application of

power. Failure to do so could result in fatal electrical

shock.

2. Do not handle the pump with wet hands or when

standing in water as fatal electrical shock could occur.

Disconnect main power before handling unit for ANY

REASON!

3. RISK OF ELECTRIC SHOCK. These pumps have not

been investigated for use in swimming pool areas.

WARNING:

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

2. Replace damaged or worn wiring cord immediately.

3. Do not kink power cable and never allow the cable

to come in contact with oil, grease, hot surfaces, or

chemicals.

4. Wire motor to correct supply voltage - see motor

nameplate and wiring diagrams and check voltage of

power supply.

5. Unit must be securely and adequately electrically

grounded. This can be accomplished by wiring the unit

to a ground metal-clad raceway system or by using a

separate ground wire connected to the bare metal of the

motor frame or other suitable means.

6. This product contains chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm.

7. Hazardous Pressure! Install pressure relief valve in

discharge pipe. Release all pressure on system before

working on any component.

8. Do not use to pump ammable or explosive uids

such as gasoline, fuel oil, kerosene, etc. Do not use in

ammable and/or explosive atmospheres.

CAUTION:

1. Protect the power cable from coming in contact with

sharp objects.

2. Be careful when touching the exterior of an operating

motor - It may be hot enough to be painful or cause

injury.

3. Make certain that the power source conforms to the

requirements of your equipment.

4. Do not run pump dry.

5. Pump and plumbing must be full of water before startup.

6. Do not pump water which contains sand, mud, silt, or

debris

NOTE: Pumps with the “UL” Mark and pumps with the

“US” mark are tested to UL Standard UL778.CSA certied

pumps are certied to CSA Standard C22.2 No. 108. (CUS)

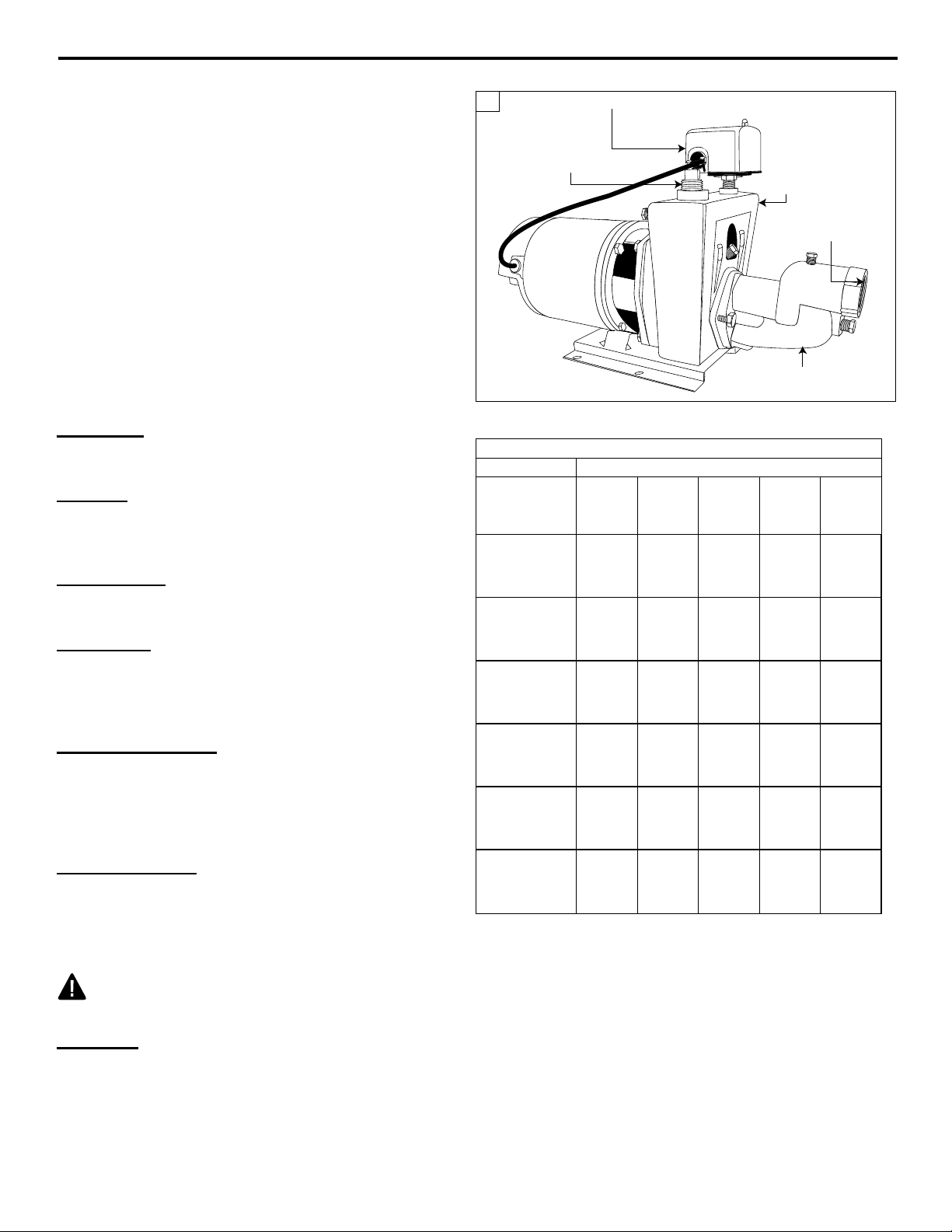

PRODUCT SPECIFICATIONS

“CPJ” Series Pump & Motor Specications Chart 1

Pump

Model

No.

CPJ03SB 1/3 115/230* 115 8.6 4.3 30-50 3/4 1-1/4 CPJ05B 1/2 115/230* 115 13 6.5 30-50 3/4 1-1/4 1

CPJ05SB 1/2 115/230* 115 13 6.5 30-50 3/4 1-1/4 CPJ07B 3/4 115/230* 230 14 7 30-50 1 1-1/4 1

CPJ07SB 3/4 115/230* 230 14 7 30-50 1 1-1/4 CPJ10B 1 115/230* 230 18 9 30-50 1 1-1/4 1

CPJ10SB 1 115/230* 230 18 9 30-50 1 1-1/4 CPJ15B 1-1/2 115/230* 230 21 10.5 30-50 1 1-1/4 1

CPJ15SB 1-1/2 115/230* 230 21 10.5 30-50 1 1-1/4 All motors are single phase, 60 Hz., 3450 RPM.

Motors marked with * are dual voltage and can be changed to either 115V or 230V by following the wiring diagram on

motor decal.

HP

Motor

Voltage

Motor

Wired

For

Motor Max. Amps Pressure

Switch

115V 230V Discharge Suction Pressure

Setting

PSI

Tapping Size (inches)

2

Page 3

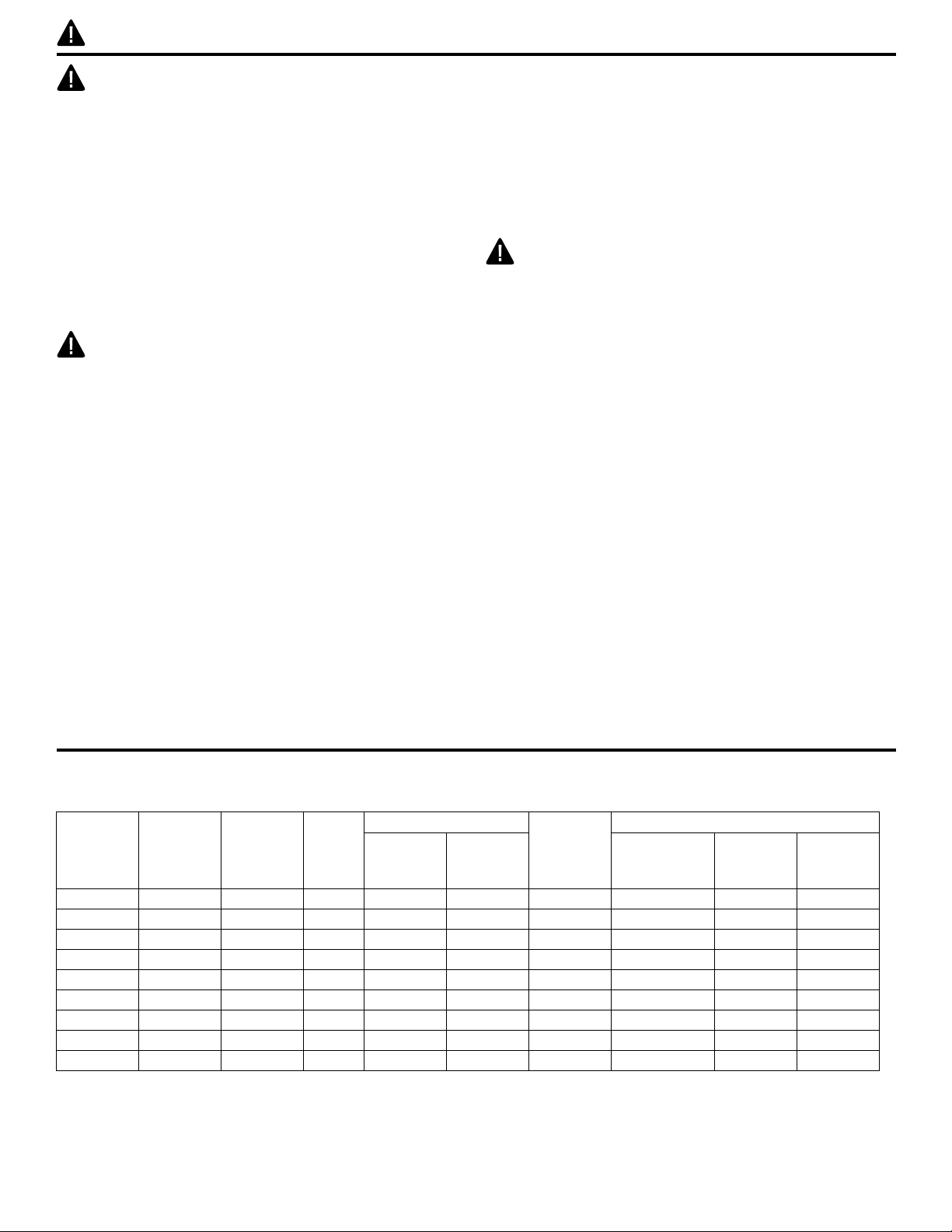

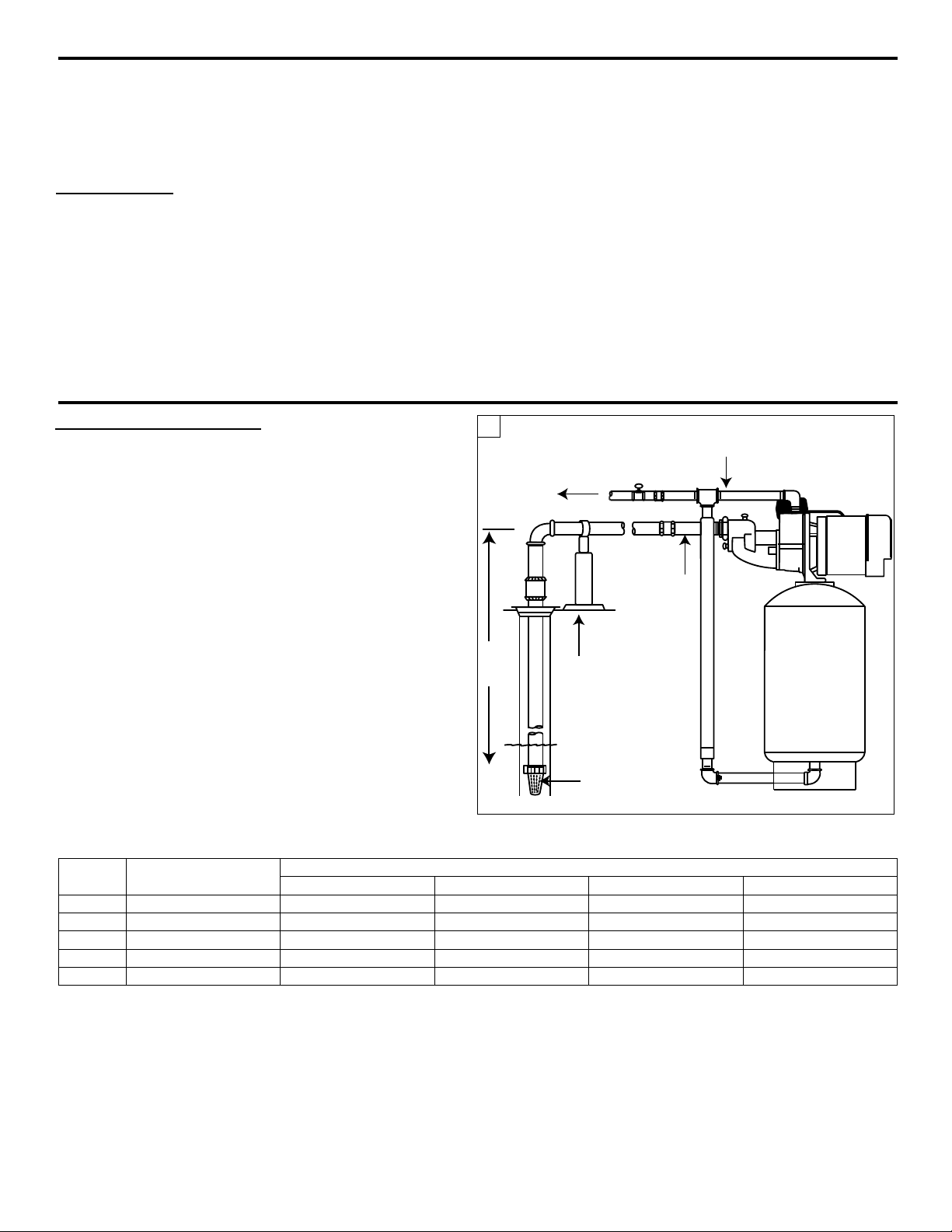

GENERAL PUMP INFORMATION

3/4 or 1 in.

Typical Pump Setup

Convertible jet pumps are designed for use in these

applications:

1. Shallow wells (0 - 25 ft. lift) where ejector bolts to pump

(Fig. 1)

2. Deep wells where well ID is 4” or more and a two pipe

ejector is installed in the well. (Fig. 2)

1

Suction

Lift

25 ft.

Max

2

Suction

Lift

Discharge

to Home

Pipe

Support

Water Level

Foot Valve

Suction

Pipe See

Table B

3/4 or 1 in.

Discharge Pipe

1-1/4 in.

Suction

Pipe

IL1187

Discharge

to Home

Discharge

Pipe

Water

Level

Pressure

Pipe See

Table B

Pipe

Support

Ejector

4 in. ID Well

IL1184

Foot Valve

3

Page 4

GENERAL PUMP INFORMATION

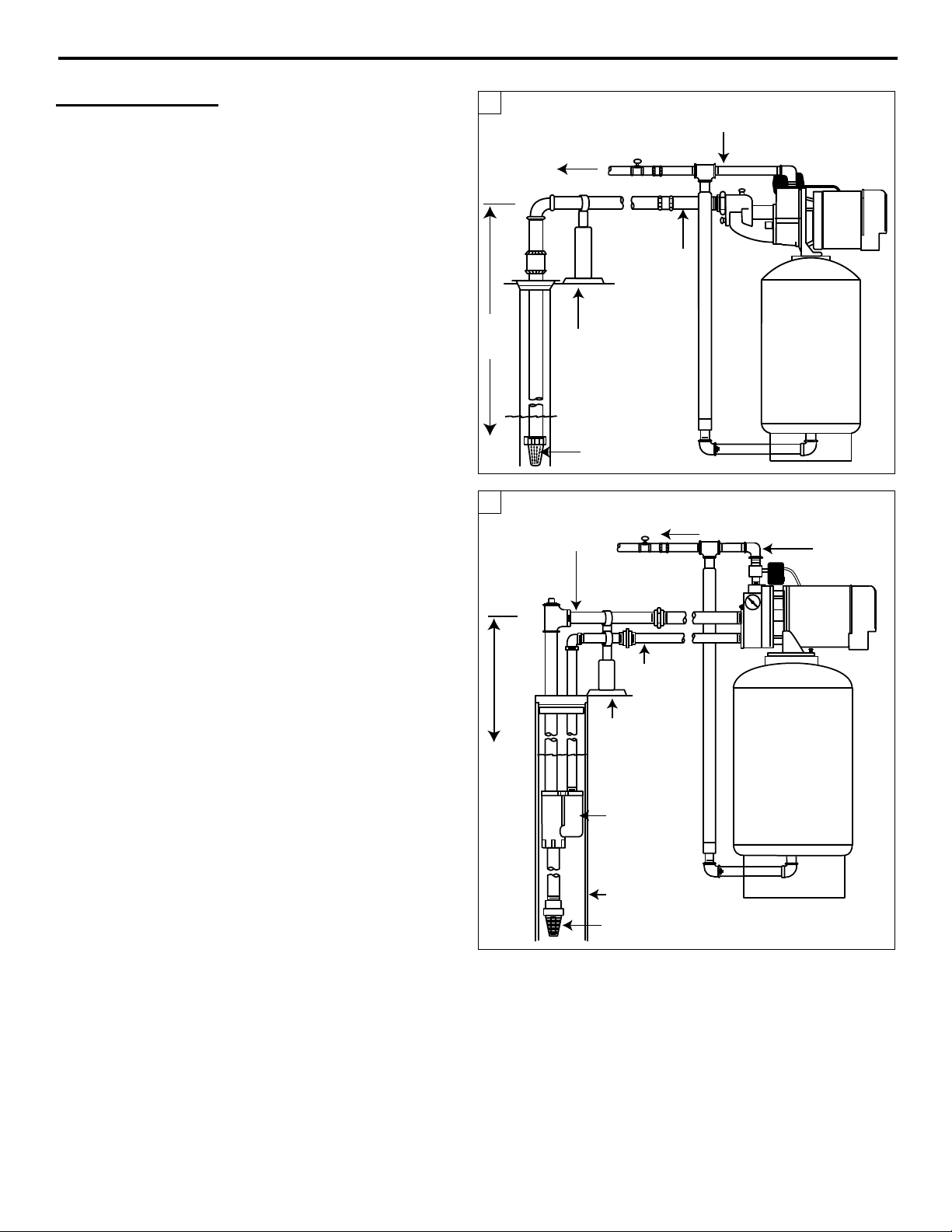

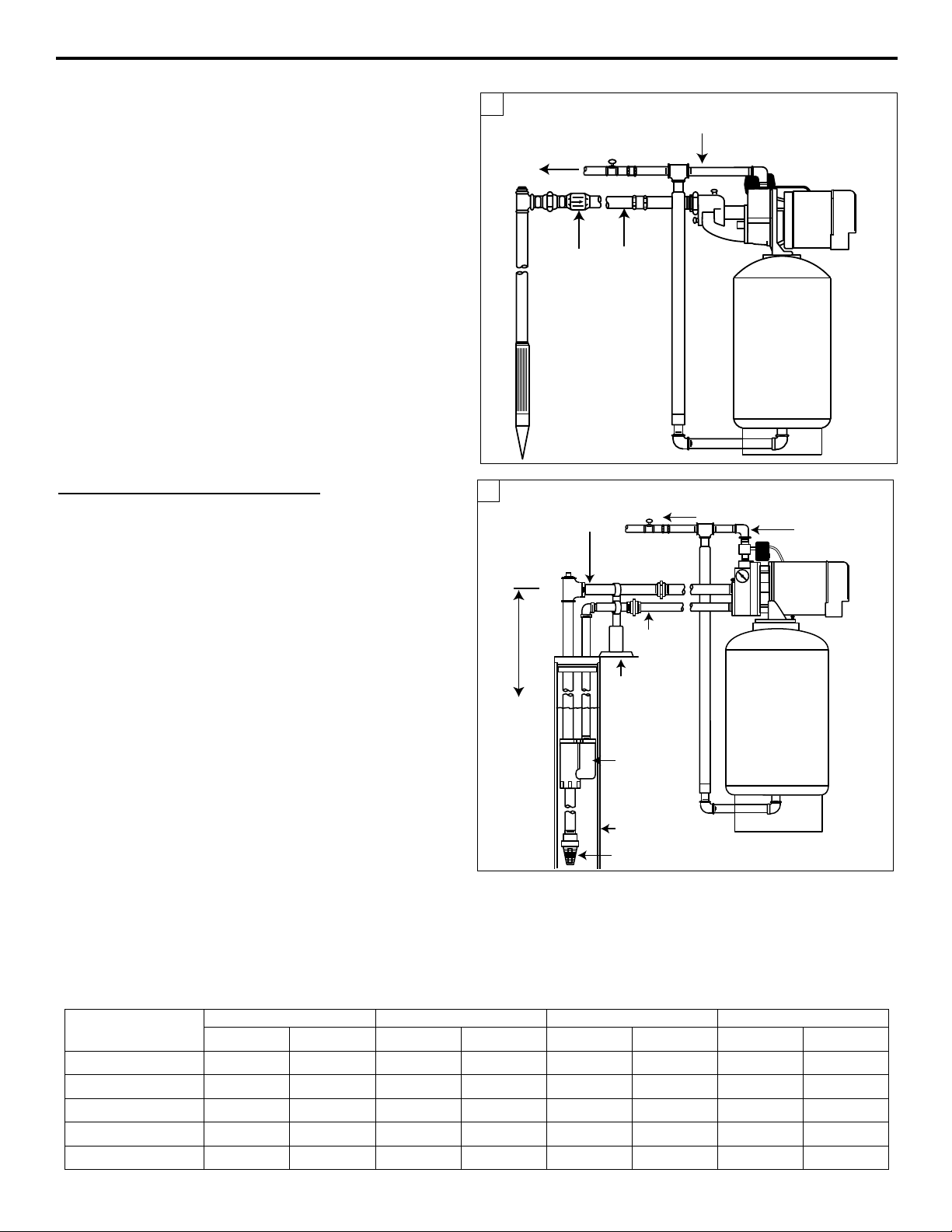

3. Deep wells where well ID is 2” or more and a single

pipe (packer) ejector is installed in the well. (Fig. 3)

4. CPJ Convertible 3/4 - 1-1/2 HP (Fig. 4)

3

4

Suction

Pipe See

Table B

Pipe

Support

2 in. ID Well

Discharge

to Home

3/4 or 1 in.

Discharge

Pipe

Foot Valve

IL0209

Pressure Switch

5. CPJ Convertible 1/2 HP (Fig. 5)

Diaphragm

Control Valve

Pressure

Gauge Tapping

5

Pressure Switch

Priming Port

Discharge

Priming Port

Suction

Pressure

IL0188

Flow Control Screw

Discharge

Suction

Pressure

IL0192

4

Page 5

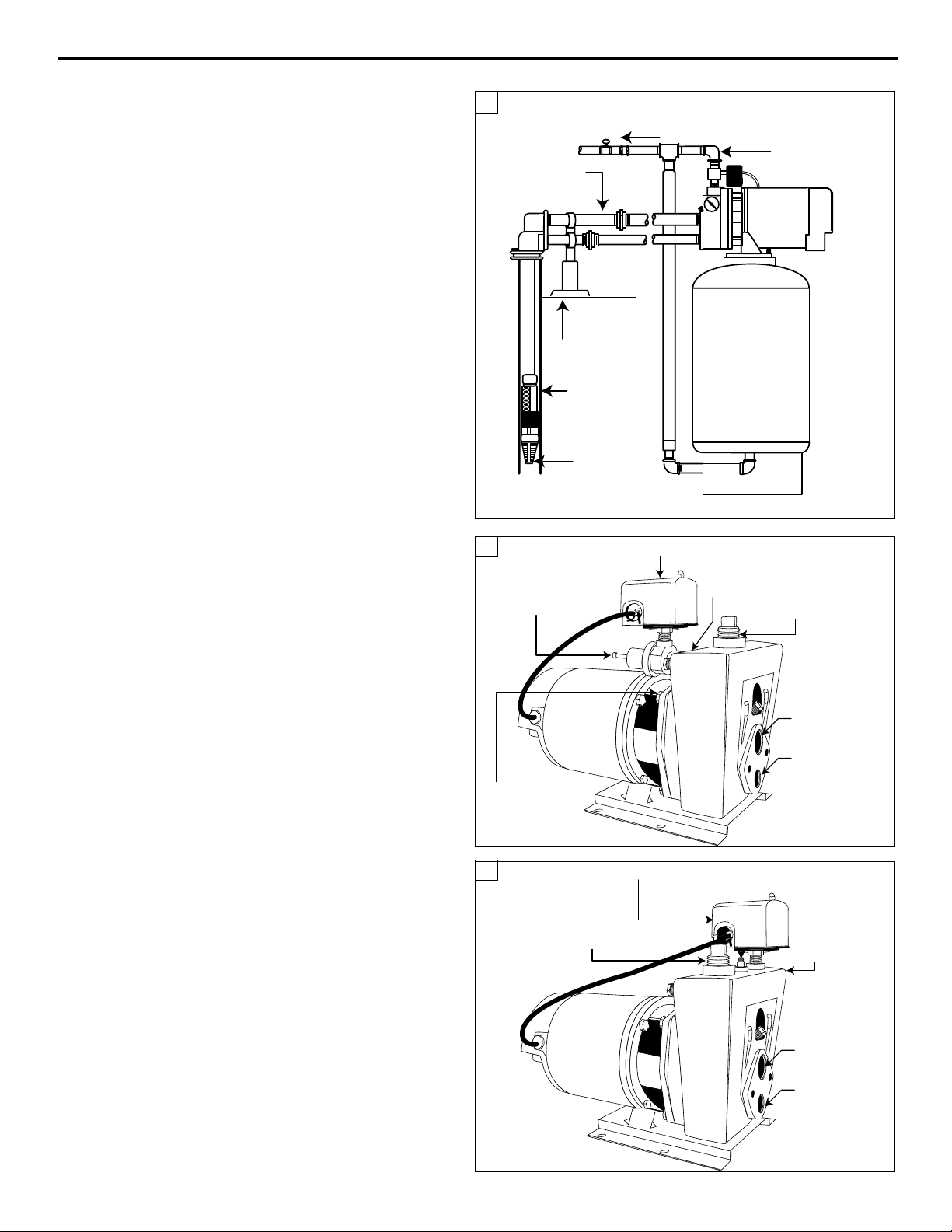

GENERAL PUMP INFORMATION

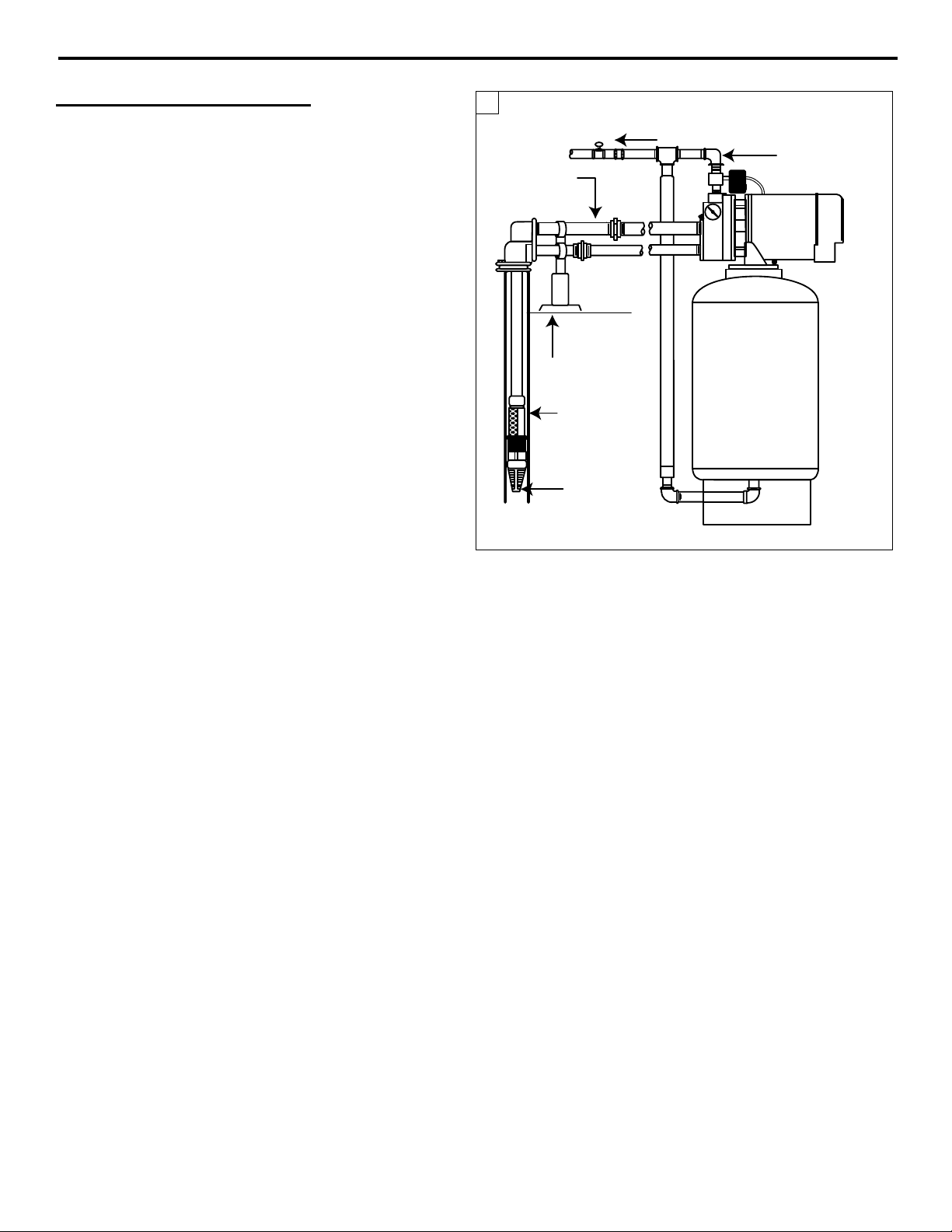

6. CPJ Shallow Well 1/3 - 1/2 HP (Fig. 6)

Ventilation

Ventilation and drainage must be provided to prevent

damage to the motor from heat and moisture.

Freezing

The pump and all piping must be protected from freezing.

If freezing weather is forecast, drain pump or remove

completely from the system.

Water Supply

The water source must be able to supply enough water to

satisfy the capacity of the pump and water needs.

Suction Lift

Suction lift is the vertical distance from the lowest level

of the water to the pump intake. See performance charts

on page 2 and 3 to determine how far your pump can lift

water.

Horizontal Distance

The horizontal distance is the horizontal measurement

between the pump suction and the water source. This

distance may affect the ability of the pump to operate. If it

is over 100 feet, call the manufacturer for assistance at

1-800-742-5044.

Pipe And Fittings

Use galvanized steel or NSF PW Schedule 40 PVC pipe

and ttings. This material is designed for water pressure

and will seal against air and water under pressure. Do Not

Use: DWV ttings, as these are designed for drains without

pressure and will not seal properly. (Fig. 1, 2 & 3)

6

Pressure Switch

Priming Port

Discharge

Suction

Shallow Well Ejector

IL0189

WIRE SIZE CHART CHART 2

Recommended Copper Wire and Fuse Sizes

HP Rating of Single Phase Motors

Distance

from Motor

to Meter

0-50’

115V

230V

50-100’

115V

230V

100-150’

115V

230V

150-200’

115V

230V

200-300’

115V

230V

Fuse Size

115V

230V

*Not economical to run in 115V. Use 230V.

1/3 1/2 3/4 1 1-1/2

14 GA

14 GA

14 GA

14 GA

14 GA

14 GA

12 GA

14 GA

12 GA

14 GA

Amps

15

15

12 GA

14 GA

12 GA

14 GA

12 GA

14 GA

12 GA

14 GA

10 GA

14 GA

Amps

20

15

12 GA

14 GA

12 GA

14 GA

10 GA

14 GA

10 GA

12 GA

8 GA

12 GA

Amps

20

15

10 GA

14 GA

10 GA

14 GA

10 GA

12 GA

8 GA

12 GA*10 GA

6 GA

10 GA*10 GA

Amps

30

15

10 GA

12 GA

8 GA

12 GA

6 GA

12 GA

Amps

30

20

CAUTION: The entire system must be air and water

tight for efcient operation and to maintain prime.

Wire Size:

The wire size is determined by the distance from the power

source to the pump motor, and the horsepower rating of the

motor. See the wire chart for proper wire size.

5

Page 6

PREPARATION

Before beginning installation of product, make sure all parts are present. If any part is missing or damaged, do not

attempt to assemble the product. Contact customer service for replacement parts.

Estimated Installation Time: 2 hours.

Tools required

Pipe wrenches (2)

Wire strippers

Needle-nose pliers

Phillips screwdriver

NOTE: For a successful installation, take time to study your application for the correct pipe size and appropriate ttings.

The illustrations in these instructions will assist you with required and optional ttings. Sch. 40 PVC plastic pipe and

ttings were used in these instructions.

Wire cutters

Adjustable wrench

Pipe tape

Pipe dope

INSTALLING PIPING IN WELL

Shallow Well Application

- Where Suction Lift Is Less Than 25 Feet

On single pipe installations (Fig. 1) attach foot valve to the

end of the suction pipe and set in the well, making certain

the valve is below the water level. The foot valve should

at least ve (5) feet from the bottom of the well to prevent

sand from being drawn into the system.

1

Suction

Lift

3/4 or 1 in.

Discharge Pipe

Discharge

to Home

1-1/4 in.

Suction

Pipe

25 ft.

Max

Pipe

Support

Water Level

Foot Valve

IL1187

RECOMMENDED SUCTION PIPE SIZES FOR SHALLOW WELL PUMP CHART 5

Motor

HP

1/3 1’ 1” 1-1/4” 1-1/2” 2”

1/2 1” 1” 1-1/2” 1-1/2” 2”

3/4 1-1/4” 1-1/4” 1-1/2” 2” 2”

1 1-1/4” 1-1/4” 1-1/2” 2” 2”

1-1/2 1-1/4” 1-1/4” 1-1/2” 2” 2”

Vertical Piping Size

Length of Offset from Well

0-20’ 20-100’ 100-200’ 200-400’

6

Page 7

INSTALLING PIPING IN WELL

3/4 or 1 in.

When connecting a drive point (Fig. 2) a check valve must

be used in the suction line in place of a foot valve. For easy

priming connect the check valve as close to the well as

possible.

All piping from the well to the pump should slope slightly

upward with no sagging. Support suction pipe between

water source and pump. Unions in the suction line near

the pump and well will aid in servicing. Be sure to leave

enough room so that wrenches can be used easily.

Deep Well (Double Pipe System)

Where water level is greater than 25 feet and inside

diameter of well is four (4) inches or larger (Fig. 1).

1. Attach the foot valve to the ejector using a galvanized

steel or plastic nipple. Add enough 1 in. pressure pipe

and 1-1/4 in suction pipe to submerge ejector 10 to 15’

below pumping water level, making certain foot valve is

at least ve (5) feet from bottom of well. If pressure pipe

and suction pipe of the same diameter are used, be sure

to identify them clearly so that they will be connected to

the proper tappings of the pump.

If a known well leak exists, replace nipple with 21 feet

of 1” tail pipe between the ejector and the foot valve.

This will provide a continuous source of water for the

pumping system.

2. Check pipe and foot valve for leaks by lling pipes with

water. A continuous loss of water indicates a leak in the

piping, foot valve or unions, and must be corrected.

3. If no leaks are found, proceed to WELL TO PUMP

CONNECTION (SUCTION PIPE). For long offset

distances, see Table B for proper pipe size.

4. All piping from the well to the pump should slope slightly

upward with no sagging. Support suction pipe between

water source and pump. Unions in the suction line near

the pump and well will aid in servicing. Be sure to leave

enough room so that wrenches can be used easily.

2

1

Discharge

to Home

Check

Valve

Suction

Lift

Water

Level

Suction

Pipe See

Table B

Pipe

Support

3/4 or 1 in.

Discharge Pipe

1-1/4 in.

Suction

Pipe

IL1188

Discharge

to Home

Discharge

Pipe

Pressure

Pipe See

Table B

Ejector

4 in. ID Well

IL1184

Foot Valve

PIPE SIZES REQUIRED FOR OFFSET PIPING FOR DEEP WELL EJECTOR INSTALLATION TABLE B

Distance Well to

Pump

0-25’ 1-1/4” 1” 1-1/4” 1” 1-1/4” 1” 1-1/4” 1”

25-50’ 1-1/4” 1” 1-1/4” 1-1/4” 1-1/2” 1-1/4” 1-1/2” 1-1/4”

50-75’ 1-1/4” 1-1/4” 1-1/4” 1-1/4” 1-1/2” 1-1/2” 1-1/2” 1-1/2”

75-100’ 1-1/2” 1-1/4” 1-1/2” 1-1/4” 1-1/2” 1-1/2” 2” 1-1/2”

100-150’ 1-1/2” 1-1/4” 1-1/2” 1-1/2” 2” 1-1/2” 2” 2”

1/3 HP 1/2 HP 3/4 HP 1 & 1-1/2 HP

Suc. Press. Suc. Press. Suc. Press. Suc. Press.

7

Page 8

INSTALLING PIPING IN WELL

Deep Well (Single Pipe System)

Application - Where pumping water level is greater than 25

feet and inside diameter of well is 2, 2-1/2 or 3 inches. (Fig

1)

On single pipe deep well installations, clean, sound well

casing must be used to give a tight seal.

NOTE: This application requires a well adapter for the top

of the well.

NOTE: Pre-soak packer leathers for approximately two

hours before installation.

1. Attach foot valve directly to bottom of ejector assembly.

Ejector must be submerged 10 to 15 feet below

pumping water level and the foot valve must be at least

ve (5) feet from bottom of well.

2. Attach foot valve and packer ejector to suction pipe

(presoak packer leathers for approximately two (2)

hours). Push the assembly down the well. Some force

may be required to push the ejector down the casing.

3. As each section is lowered, check for leaks by pouring

water into the suction pipe.

4. Attach well adapter to suction pipe, lower over casing

top and tighten adapter ange.

5. If no leaks are found, proceed to WELL TO PUMP

CONNECTION (SUCTION PIPE) using piping of

the same diameter as the suction pipe (1-1/4”) and

pressure pipe (1”) tappings of the pump. For long offset

distances, see Table B for the proper pipe size.

6. Unions in suction and discharge piping near pump

and well will aid in servicing. Be sure to leave enough

surrounding room so that wrenches can be used easily.

1

Suction

Pipe See

Table B

Pipe

Support

2 in. ID Well

Discharge

to Home

3/4 or 1 in.

Discharge

Pipe

Foot Valve

IL0209

8

Page 9

WELL TO PUMP CONNECTION (SUCTION PIPE)

IL1187

1. Attach ejector to face of pump with two (2) bolts and

gasket provided. Venturi tube on the ejector inserts into

the top tapping of the face of the pump (Fig. 1).

2. Make the connection to your well. Wrap all threaded

ttings with pipe tape 5 times or apply a pipe paste (pipe

dope) to ensure an air tight connection. (Fig. 2)

1

Priming Port

2

Venturi

Tube

This Side

Up

Ejector

Glue

3. The use of a union (optional) will assist with easy

connection and disconnect. (Fig. 3)

4a. NOTE: For drilled (cased) wells, a foot valve is

required in the well at the end of the pipe to maintain

prime. (Fig 4a)

3

4a

IL1346

Suction

Lift

Discharge

to Home

1-1/4 in.

Suction

Pipe

3/4 or 1 in.

Discharge Pipe

Glue

25 ft.

Max

Pipe

Support

Water Level

Foot Valve

9

Page 10

WELL TO PUMP CONNECTION (SUCTION PIPE)

IL1396

4b. For driven wells, a check valve is required at the top of

the well to maintain prime. Flow arrow must point toward

pump. (Fig. 4b)

5. Finish the connection to your well with additional pipe and

ttings as needed. (Fig. 5)

4b

5

IL1475

Pump

Flow Arrow

Deep Well Application Only:

1. Make the connection to your well. Wrap all threaded

ttings with pipe tape 5 times or apply a pipe paste

(pipe dope) to ensure an air tight connection. (Fig. 1)

2. Finish the connection to your well with additional pipe and

ttings as needed. (Fig. 2)

IL1397

1

Tape

2

10

Page 11

PUMP TO PRESSURE TANK CONNECTION (DISCHARGE PIPE)

Shallow Well Application Only:

1. Begin the connection to the pressure tank. Using a 3/4

in. x 3 in. galvanized nipple, wrap the threads 5 times

with pipe tape and apply pipe paste (pipe dope) and

install in top of pump.

(Fig. 1)

2. Install a 3/4 x 3/4 x 3/4 in. galvanized tee tting.

(Fig. 2)

1

IL1397

2

3. Install a 3/4 in. MPT x 1/4 in. FPT galvanized bushing

and pressure gauge (optional), or a pipe plug. Do

not tighten, as you will prime your pump later at this

location. (Fig. 3)

4. Continue with ttings and pipe to the pressure tank.

A 3/4 in. union (optional) for easy connection and

disconnection. (Fig. 4)

3

4

Glue

11

Page 12

PUMP TO PRESSURE TANK CONNECTION (DISCHARGE PIPE)

Deep Well Application Only:

1. To begin the connection to the pressure tank, loosely

assemble ow control body to pump head. Using

Teon tape, position the discharge outlet of the control

body facing right as you look directly into the face of

the pump

2. Assemble the pressure switch in the 1/4” tapping

adjacent and to the right of the discharge outlet of

the control valve (Fig. 2). Refer to Pump Electrical

Connection section for pressure switch wiring.

1

Control

Body

2

Flow

Control

Screw

3. Tighten ow control body. (Fig. 3)

4. Install optional pressure gauge in 1/4” tapping on side

of pump body. Face of gauge should be positioned so

that dial can be read easily (Fig. 4).

3

3

12

Page 13

Glue

Adapter

Pipe

PUMP TO PRESSURE TANK CONNECTION (DISCHARGE PIPE)

5. Continue with ttings and pipe to the pressure tank.

A 3/4 in. union is optional but recommended for easy

connection and disconnection. (Fig. 5)

CAUTION: Install a pressure relief valve on any

installation where the pump pressure can exceed the

maximum working pressure of the tank.

TANK TO HOUSE CONNECTION

1. Most pressure tanks will have a 1 inch inlet elbow on

the bottom. Connect to this elbow with a 1 in. MPT x 1

in. slip (glue) adapter and short piece of pipe. (Fig 1)

5

Glue

1

2. Install a 1 in. elbow. (Fig. 2)

2

Elbow

Glue

13

Page 14

TANK TO HOUSE CONNECTION

3. Attach a 1 in. slip (glue) x 3/4 in. FPT adapter and

3/4 in. MPT x 3/4 in. slip. (Fig. 3)

4. Install a 3/4 in. union (optional) and continue with

pipe and 3/4 in. x 3/4 in. x 3/4 in. tee. (Fig. 4)

3

Coupling

Adapter

Glue

4

Tee

Glue

Union

5. Make the connection to the house plumbing. From the

tee, install pipe and shut off valve (optional). (Fig 5)

6. Completed installation with piping and tank is shown

(Fig. 6)

5

Shut off valve

Glue

To House

Plumbing

6

14

IL1386

Page 15

PUMP ELECTRICAL CONNECTIONS

STAR

®

C

US

LR90197

UL Std. No. 778

ENCLOSURE 3

starwatersystems.com

Pump: ES05S Rev: B

Motor: 98L105

Improper installation may result in re, explosion, electrical short or injury. Replace all covers

CAUTION: All wiring should be performed by a

qualied electrician in accordance with the National

Electric Code and local electric codes.

CAUTION: Connect the pump to a separate electrical

circuit with a dedicated circuit breaker. Refer to the

Wire Size Chart for proper fuse size.

WARNING: Under-size wiring can cause motor failure

and even re. Use proper wire size specied in the

Wire size chart.

WARNING: Replace damaged or worn wiring cord

immediately.

WARNING: Do not kink power cable and never allow

the cable to come in contact with oil, grease, hot

surfaces, or chemicals.

CAUTION: Protect the power cable from coming in

contact with sharp objects.

CAUTION: Make certain that the power source

matches the pump requirements. This pump has a

dual voltage motor and can run on 115V or 230V. See page

20. 1/2 HP pumps are wired from the factory to run on 115V.

3/4 & 1 HP pumps are wired from the factory to run at 230V.

WARNING: The pump must be properly grounded

using the proper wire cable with ground.

WARNING: Always disconnect pump from electricity

before performing any work on the motor.

Y

E

L

L

O

W

WIRING DIAGRAM

Check Voltage of Power Source

115 Volts

Single Phase

L1

A

W

H

I

T

E

DO NOT CONNECT ANY GROUND WIRE

Before Connecting

Line

L2

B

R

G

E

R

D

E

Y

L1

W

Y

T

A

N

TO THESE LEADS

H

E

I

L

T

L

E

O

W

230 Volts

Single Phase

Line

A

G

R

E

Y

L2

B

T

R

A

E

N

D

Wiring The Pressure Switch

1. CAUTION: Make certain that the power source matches

the pump requirements. This pump has a dual voltage

motor and can be wired by the customer to run on 115V

or 230V. (Fig. 1)

NOTE: To change pump voltage, see wiring diagram on this

page or step-by-step instructions on page 18.

2. Screw the pressure switch into the 1/4 in. opening on the

side of the ow control and remove the switch cover. (Fig.

2)

1

HP: 1/2 PH 1 Hz 60

Volts 115/230 S.F. 1.2 Amps 6.4/3.2

S.F. Amps: 8.6/4.3 RPM 3450 Type C

Duty: Cont. Temp 65C KVA Code G

Frame 56L Ins Class B

Factory prewired for 115V Thermally protected automatic

Check voltage of power source Use copper conductors only

ELECTRICAL HAZARD

before operating. Ground motor in accordance with local and national electrical codes.

Disconnect power source before touching internal parts. Motors equipped with automatic

protection may restart without warning.

See instruction manual for proper installation procedure.

Se reporter au manuel d’instructions pour suivre la procédure adéquate d’installation.

2

IL1401

15

Page 16

PUMP ELECTRICAL CONNECTIONS

3. Insert an electrical wire strain relief into the opening

in the side of the pressure switch closest to the motor.

(Fig. 3)

4. Thread the cable from the pump motor through the

strain relief into the pressure switch cavity and tighten

both screws on the strain relief. Do not crush wire.

(Fig. 4)

3

IL1372

4

Wire from

motor

5. Connect the two motor wires of the motor cable to the

two inside terminals on the pressure switch. (Fig. 5)

6. Connect the green ground wire from the motor cable

to one of the green ground screws at the bottom of the

pressure switch. (Fig. 6)

IL1373

5

Wire from

motor

IL1374

6

Wire from

motor

16

Ground Screws

IL1375

Page 17

Wire from

Wire from

Ground Screws

PUMP ELECTRICAL CONNECTIONS

7. Insert an electrical wire strain relief into the opening in

the opposite side of the pressure switch. (Fig. 7)

8. Thread the cable from the power supply through the

strain relief and tighten both screws on the strain relief.

Do not crush wire. (Fig. 8)

7

Strain

Relief

8

Pressure

Switch

Wire from

power

supply

Wire from

motor

motor

9. Connect the two wires from the power supply to the

two outside terminals on the pressure switch. (Fig. 9)

10. Connect the green ground wire from the power

supply to the remaining green ground screw in the

pressure switch and re-attach the pressure switch

cover. (Fig. 10)

9

10

Wire from

power

supply

Outside

terminal

Wire from

power

supply

motor

Outside

terminal

Wire

from

motor

17

Page 18

PUMP ELECTRICAL CONNECTIONS

STAR

®

C

US

LR90197

UL Std. No. 778

ENCLOSURE 3

starwatersystems.com

Pump: ES05S Rev: B

Motor: 98L105

6.4/3.2

Improper installation may result in re, explosion, electrical short or injury. Replace all covers

Disconnect power source before touching internal parts. Motors equipped with automatic

To change from 115V to 230V

11. The motor of this pump is dual voltage and can run

on either 115V or 230V. In general, 230V is more

economical to run, and requires a smaller wire size.

Most models are factory preset to run at 115V.

NOTE: See pump label to verify voltage prewired at

the factory. (Fig. 11)

12. For 230V service, change the following wires on the

terminal board:

a. Using a pair of needle nose pliers, pull the gray

wire with the female ag connector from the “A”

terminal spade post. Place it to the right on the

“B” terminal space post. (Fig. 12a)

HP: 1/2 PH 1 Hz 60

11

Volts 115/230 S.F. 1.2 Amps

S.F. Amps: 8.6/4.3 RPM 3450 Type C

Duty: Cont. Temp 65C KVA Code G

Frame 56L Ins Class B

Factory prewired for 115V Thermally protected automatic

Check voltage of power source Use copper conductors only

ELECTRICAL HAZARD

before operating. Ground motor in accordance with local and national electrical codes.

protection may restart without warning.

See instruction manual for proper installation procedure.

Se reporter au manuel d’instructions pour suivre la procédure adéquate d’installation.

12a

L1

A B

L2

b. Pull the red wire with the female ag connector

from the “L2” terminal. Place it to the left on the

“B” terminal space post. (Fig. 12b)

c. Reinstall the rear motor cover. (Fig. 12)

NOTE: To change models from 230V to 115V, simply

reverse instructions above.

12b

12c

L1

G R AY

A B

G R AY

RED

230V

L2

RED

18

Page 19

PUMP PRIMING & STARTUP

Shallow Well Application Only:

CAUTION: All pumps must be primed (lling the

cavity with water) before they are rst operated. This

may take several gallons of water, as the suction line will

be lled in addition to the pump cavity.

1. Remove the 1/2 in. priming plug with pressure gauge

and air relief plug. (Fig. 1)

2. Slowly ll pump cavity until water comes out of air

relief hole on top of the pump.

(Fig. 2)

1

Priming plug

with pressure

gauge

Air relief plug

2

3. Replace air relief plug and continue adding water to

pump cavity until water reaches the top of the priming

plug. (Fig. 3)

4. Thread in priming plug and then open optional ball

valve if installed by turning handle to line up with the

pipe. (Fig. 4)

5. Turn on breaker to start pump

IMPORTANT: If the pump hums instead

of pumping or turns off repeatedly, shut pump off

immediately.

Check voltage. Make sure your incoming voltage

matches the pump wiring voltage. See wiring guide in the

instructions.

3

4

19

Page 20

PUMP PRIMING & STARTUP

Deep Well Application Only:

CAUTION: All pumps must be primed (lling the

cavity with water) before they are rst operated. This

may take several gallons of water, as the suction line will

be lled in addition to the pump cavity.

1. Remove the 1/2” priming plug. (Fig. 1)

2. Fill pump cavity with water until full and replace

priming plug. (Fig. 2)

1

2

3. Tighten ow control screw completely by turning

clockwise, then loosen two turns. Now start the pump.

(Fig. 3)

4. If pump is properly primed, pressure will quickly build

and register on the gauge mounted directly on the

pump body. If pressure does not build repeat priming

operation. All air must be vented from the drive and

suction pipes as well as the body before the pump will

prime. The pump body may need to be lled several

times in order to achieve the prime. (Fig. 4)

3

IL1409

4

Pressure

Gauge

20

Page 21

PUMP PRIMING & STARTUP

IL1409

5. With pump operating at high pressure, open two or more

faucets and slowly unscrew the ow control screw until

maximum ow is obtained. This steady pressure will be

minimum operating pressure and should agree with the

pressure shown below. The ow control screw diverts

the proper amount of water to operate the ejector. (Fig.

5)

AVERAGE OPERATING PRESSURE CHART 7

HP Pressure Setting

1/3

1/2

3/4

1

1-1/2

5

24 PSI

27 PSI

38 PSI

46 PSI

53 PSI

The correct control valve setting will depend on the type of well installation and pressure switch setting for the particular

pump.

NOTE: Flow control is not required for shallow well applications.

IMPORTANT: If the pump fails to prime within ve minutes:

Turn power off at the breaker box. Look for leaks or a milky color in the discharged water, which indicates an air leak. Re-

prime if necessary, following steps 1 through 5 above. Reset breaker at the breaker box. All connections must be water

and air tight in order for pump to operate.

CARE AND MAINTENANCE

MAINTENANCE

Lubrication

The pumps and motors require no lubrication. The ball

bearings of the motor have been greased at the factory

and under normal operating conditions should require no

further greasing.

Freezing

1. Drain the entire system if there is danger of freezing.

A drain plug is provided at the bottom of the pump

case for this purpose. (Fig. 1)

1

IL0192

PREVENT PUMP

DAMAGE!

Remove plug in

freezing weather

21

Page 22

CARE AND MAINTENANCE

Rotary Seal Assembly Replacement

CAUTION: Make certain that the power supply is

disconnected before attempting to service the unit!

The rotary seal assembly must be handled carefully

to avoid damaging the precision lapped faces of the

sealing components.

1. Disengage pump body from motor and mounting ring.

2. Remove diffuser and unthread impeller from the motor

shaft. The motor shaft can be held by using a 9/16”

open end wrench on the ats located in the middle of

the mounting ring.

3. The rotary seal will come loose at this time. Use a

screwdriver (or similar instrument) to pry the ceramic

seal and rubber gasket from the recess of the mounting

bracket.

CAUTION: Be careful not to damage the motor

shaft or recess surface.

4. Clean the recess and motor shaft thoroughly.

5. Install the new rotary seal assembly:

a. Insert the ceramic seal and the rubber gasket into

the recess.

NOTE: To help facilitate installation, apply one drop of

liquid soap solution to the outside diameter of the rubber

gasket. Make certain that the ceramic seal is kept clean

and free of dirt and/or oil.

Liquid Soap Solution: One drop of liquid soap combined

with one teaspoon of water.

b. Slip the remaining parts of the rotary seal assembly

onto the motor shaft.

NOTE: Apply a light coating of liquid soap solution to the

inside diameter of the rubber drive ring.

6. Replace the impeller and diffuser removed in Step 2.

7. Reassemble the pump body to the motor and mounting

bracket.

MOTOR REPLACEMENT

The motor can be replaced with any standard Nema 56J

jet pump motor (of proper HP for each pump) by referring

to the following instructions.

1. Follow steps as outlined under Rotary Seal

Replacement and Pump Disassembly.

2. Remove cap screws that connect the motor to the

mounting ring and pull motor away.

3. Replace motor with standard Nema 56J jet pump motor

by positioning motor against the mounting frame and

assembling with four (4) cap screws.

Because damage to the shaft seal can occur in

disassembly, a new seal will be necessary.

4. Follow steps 4, 5, 6 & 7 of Rotary Seal Assembly to

reassemble the remainder of the pump.

22

Page 23

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Little or no

discharge

Pump will not

deliver water or

develop pressure

Loss of suction 1. Air leak in suction line 1. Repair or replace

Pump vibrates

and/or makes

excessive noise

Pump will not start

or run

1. Casing not initially lled with water 1. Fill pump casing

2. Suction lift too high, or too long 2. Move pump closer to water source

3. Hole or air leak in suction line 3. Repair or replace. Use pipe tape and pipe

sealing compound

4. Foot valve too small 4. Match foot valve to piping or install one size

larger foot valve.

5. Foot valve or suction line not submerged deep

enough in water

6. Motor wired incorrectly 6. Check wiring diagram

7. Casing gasket leaking 7. Replace

8. Suction or discharge line valves closed 8. Open

1. No priming water in casing 1. Fill pump casing

2. Leak in suction line 2. Repair or replace

3. Discharge line is closed and priming air has

nowhere to go

4. Suction line (or valve) is closed 4. Open

5. Foot valve is leaking 5. Replace foot valve

6. Suction screen clogged 6. Clean or replace

2. Suction lift too high 2. Lower suction lift, install foot valve and prime

3. Insufcient inlet pressure or suction head 3. Increase inlet pressure by adding more water

4. Clogged foot valve or strainer 4. Unclog

1. Mounting plate or foundation not rigid enough 1. Reinforce

2. Foreign material in pump 2. Disassemble pump and clean

3. Impeller damaged 3. Replace

4. Worn motor bearings 4. Replace

1. Improperly wired 1. Check wiring diagram on motor

2. Blown fuse or open circuit breaker 2. Replace fuse or close circuit breaker

3. Loose or broken wiring 3. Tighten connections, replace broken wiring

4. Stone or foreign object lodged in impeller 4. Disassemble pump and remove foreign object

5. Motor shorted out 5. Replace

6. Thermal overload has opened circuit 6. Allow unit to cool, restart after reason for

5. Submerge lower in water

3. Open ball valve

to tank or increasing back pressure

overload has been determined

23

Page 24

REPAIR PARTS

IL0190

IL0189

IL0191

IL0188

FORM NO. FW0030

SUPERSEDES 0109

0712

CONVERTIBLE and SHALLOW WELL JET PUMP REPAIR PARTS

“CPJ” and “CPJS” SERIES

(For Pricing Refer To Repair Parts Price List)

1

13

2

4

3

11

6

5

10

7

8

15

13

9

12

14

16

SERVICE KIT FOR JET PUMPS

MODEL NO KIT CONTAINS

1

KF01

2

KF02

3

KF03

4

KF16

5

KF04

1. Applies to 1/3HP, CPJ Jet Pumps

2. Applies to 1/2HP, CPJ & CPH Jet Pumps

3. Applies to 3/4HP, CPJ & CPH Jet Pumps

4. Applies to 1HP, CPJ & CPH Jet Pumps and

VPH10

5. Applies to all Horizontal Cast Iron Jet Pumps

Impeller, Diffuser, Rotary

Seal, Quadraseal, Diffuser

Rubber

Rotary Seal, Quadraseal

(2), Diffuser Rubber

16

“CPJ” Convertible

3/4 to 1-1/2 HP

“CPJS” Shallow Well

1/3 to 1/2 HP

“CPJS” Shallow Well

3/4 to 1-1/2 HP

HORSEPOWER 1/3 1/2 3/4 1 1-1/2

MODEL NO.:”CPJ” Convertible

ITEM

“CPJS” Shallow Well

PART

NO.

CPJ03

CPJ03S

CPJ03SB

CPJ05

CPJ05B

CPJ05S

CPJ05SB

CPJ07

CPJ07B

CPJ07S

CPJ07SB

CPJ10

CPJ10B

CPJ10S

CPJ10SB

DESCRIPTION QTY

1

Motor, Nema J (Thd)

Motor Cover w/Screws

Screws, Cover

†

Motor Lead Wire

2

Mounting Ring

3

Hex Hd. Cap Screws 3/8 x 3/4”

4

Ring, Square Cut

5

Seal, Rotary w/Spring

6

Impeller

7

Diffuser

8

Rubber, Diffuser

9

Pump Body

10

Plug, Priming

11

Base

12

Hex Hd. Cap Screws 3/8 x 1/2”

13

Control Valve “CPJ”

14

Plug w/Gasket “CPJS”

15

Pressure Switch

16

Shallow Well Ejector Package

†

Ejector Gasket Pkg. w/Bolts

†

Ejector Gasket

021301R

021302

* 135314

1 3 110 0

132428

*

132430A

*

132404

130969

98J103

1

2

136135A

8

132583

1

139348††

132424

1

132582

3/4” NPT

1

2

124330

128794

132527

SW03E-1626

1

1

98J105

1

2

136135A

135314

8

132583

1

139349††

132424

1

132582

3/4” NPT

1

2

124330

128794

132527

SW05E-1630

1

1

98J107

1

2

136135A

136137

8

132429

1

134137

132425‡

1

132418

1” NPT

1

2

132446

-

132527

SW07E-1432

1

1

98J110

136135A

136137

132429

134138

132425‡

132418

1” NPT

132446

132527

SW10E-1334

(*) Standard Hardware Item

(†) Not Shown

(††) Impeller w/ 138138 Seal Ring

(‡) Diffuser w/ 134240 Insert

24

CPJ15

CPJ15S

98J115

1

2

1

2

136136A

136137

8

8

132429

1

1

132417

132464

1

1

132418

1” NPT

1

2

1

2

133383

-

-

132527

SW15E-1238

1

1

1

1

Loading...

Loading...