Page 1

Operating Instructions & Parts Manual

!

!

!

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal

injury and/or property damage! Retain instructions for future reference.

FW1442

0313

Supersedes

0411

Pump Station

Add-on Kit

KEY FEATURES OF THE ARTESIAN DRIVE PUMP

STATION ADD-ON KIT:

The duplex kit is designed as an add on to the Single

pump Artesian Drive pump station to increase the

capacity of the pumping station without adding an

additional drive. The duplex kit, must match the HP of

the pump station that it is to be added to for proper

operation. When added to the pump station, the single

phase pump will turn on when the drive is running the

three phase pump at full speed and still cannot reach

the system pressure set point. When the single phase

pump is running, depending upon demand, the drive

may shut off the 3-phase pump. After the single phase

pump has started and demand decreases, when the

pressure increase to 5 PSI above the set point the drive

will start up the three phase pump again and then shut

down the single phase pump. To reduce the chance of

damage to the single phase pump and motor that can

occur with short cycling, the single phase motor will

remain running for a minimum of 1 minute even if

the system pressure rises above the set point. Once the

single phase motor turns off, it will also remain off for

one minute before it will turn back on even if the pressure drops below the system set point.

If plumbing cannot withstand

maximum pump pressure plus incoming pressure,

a pressure control valve shuld be installed after

the check valve on the single phase pump and set

10 psi above the system pressure set point on the

drive. This will prevent any damage to the system

plumbing in the event a sudden drop in water

demand creates maximum deadhead pressure.

Only shaded areas

included in package

Figure 1

General Safety Information

Carefully read and follow all safety instructions

in this manual and on pump. Keep safety labels in

good condition. Replace missing or damaged safety

labels.

This is a SAFETY ALERT SYMBOL. When you

see this symbol on the pump or in the manual,

look for one of the following signal words and

be alert to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major property

damage if ignored.

Warns of hazards that CAN cause

serious personal injury or death, if ignored.

Warns of hazards that MAY

cause minor personal injury, product or property

damage if ignored.

IMPORTANT: Indicates factors concerned with

operation, installation, assembly or maintenance

which could result in damage to the machine or

equipment if ignored.

NOTE: Indicates special instructions which are

important but are not related to hazards.

Read these warnings and

instructions carefully. Failure to follow could

result in serious bodily injury and/or property

damage.

Electrical installations

shall be in accordance with National Electric

Code (NEC) and all applicable local codes

and ordinances. A licensed electrician should

1 (FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

023507 B

Page 2

perform installation.

!

!

!

!

!

!

!

!

Be sure system is connected to

a circuit equipped with a fuse or circuit breaker of

the correct rating.

Always disconnect power

source before performing any work on or near

the controller, motor or its connected load. If the

power disconnect point is out-of-sight, lock it

in the open position and/or tag it to prevent unexpected

application of power. Failure to do so could result in fatal

electrical shock or bodily injury.

DO NOT handle pump with wet

hands or when standing in water as fatal electrical

shock could occur. Disconnect main power supply

before handling system for any reason.

Protect the power cable from

coming in contact with sharp objects, oil, grease,

hot surfaces or chemicals. DO NOT kink the power

cable. If damaged replace immediately.

NEVER leave the control box,

fused disconnect switch, or covers open (either

partially or completely) when not being worked on

by a competent electrician or repairman.

Always use caution when operating

electrical controls in damp areas. If possible, avoid all

contact with electrical equipment during thunderstorms

or extreme damp conditions.

Install all electrical equipment

in protected area to prevent mechanical damage

which could produce serious electrical shock and/or

equipment failure.

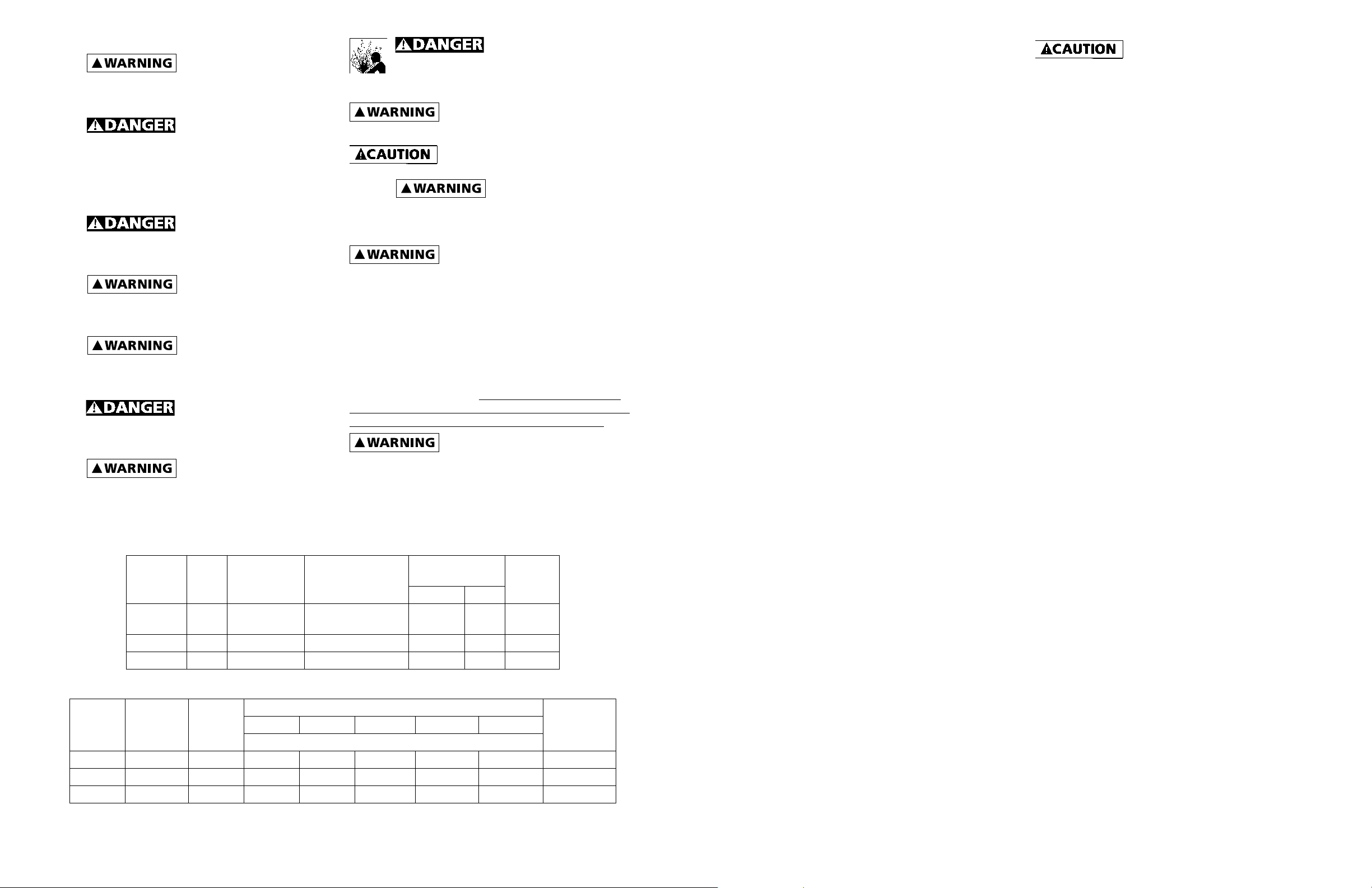

Single Phase Motor Data: Chart A

MODEL HP

C22231H 3

C22251H 5 230V 230V - 27.4 H

C22271H 7-½ 230V 230V - 34.5 H

Minimum Wire Size Charge (Gauge): Chart B

HP Volts Phase

3 115/230 1 8/12 8/12 4/10 4/10 2/8 40/20

5 230 1 8 8 8 8 6 40

7.5 230 1 6 6 6 6 4 50

IMPORTANT: Wire charts are for reference only. Consult local and state codes for approved wire sizes.

MOTOR

VOLTAGE

115/208-

230V

Distance in Feet From Motor To Service Panel

0-50ft 50-100ft 100-150ft 150-200ft 200-300ft

Connected Motor

DO NOT use this system to pump

flammable liquids such as gasoline, fuel oil, kerosene,

etc. Failure to follow the above warning could result in

property damage and/or personal injury.

This product contains chemicals known

to the State of California to cause

cancer and birth defects or other reproductive harm.

Do not pump water above 140 degrees

Fahrenheit.

This unit not tested for use in

swimming pool areas.

Before Getting Started

may result from failure to connect the ground

terminal to the motor, Artesian Drive controller,

metal plumbing, or other metal near the motor

or cable, using wire no smaller than motor

cable wires. To minimize risk of electrical shock,

disconnect power before working on or around

the Artesian Drive system. CAPACITORS INSIDE

THE ARTESIAN DRIVE CONTROLLER CAN STILL

HOLD LETHAL VOLTAGE EVEN AFTER POWER HAS

BEEN DISCONNECTED. ALLOW 10 MINUTES FOR

DANGEROUS INTERNAL VOLTAGE TO DISCHARGE

BEFORE REMOVING ARTESIAN DRIVE COVER.

swimming areas.

Factory

Voltage

230V 32.2 16.1 G

Wire Size

Serious or fatal electrical shock

Do not use motor or system in

Service Factor

Motor Amps

115V 230V

Code

Letter

Breaker Size

(Amps)

Instructions:

ACTIVATE DUPLEX OPTION IN DRIVE:

When the Artesian drive pump station leaves the factory, the default setting it to have the Duplex Mode

turned off. To change settings:

1. Press & release M button to display flashing number on left hand side of display (i.e. 01). Using v &

^ buttons scroll until you reach 10 flashing on left

hand side.

2. Press & release M button and then Press & release &

^ buttons to scroll display to show L3 on right hand

side.

3. Press & release M button and use v & ^ buttons to

scroll until you reach 70 flashing on left hand side.

4. Press & release M button and CodE flashes on the

right hand side. Press & release ^ until Co 3 is displayed.

5. Press & release M button. Using v & ^ scroll the

value between OFF to ON.

6. Press & release M button to return to having 61 on

left of screen flashing. Using v & ^ buttons scroll to

10 flashing on left hand side.

7. Press & release M button then press & release ^ button until LoC is displayed. Press & release M button

twice to return to standard screen.

8. Turn off power to drive & skid system in preparation for mechanical & electrical installation of the

duplex kit.

MECHANICAL INSTALLATION:

• Mount pump support to pump station skid straddling existing pump as shown in Figure 1 using ¼”

bolts, washers & lock washers.

• Mount starter box to side of the pump support with

¼” bolts, nuts, washers & lock washers.

• With help set single phase pump on top of pump

support and secure with 3/8” bolts, nuts, washers &

lock washers.

• Using Teflon tape or pipe dope on the threads,

install a 2” union on discharge of pump and screw

check valve into the union tightening with a

wrench 1-2 turns past hand tight to prevent leaks.

• Note: For suction lift applications, a service T with

a threaded in priming plug should be installed on

the intake pipe of the pump for priming purposes.

If possible for suction lift applications, it is recommended to use a separate drop pipe (not shown

in illustrations) into the water source to allow for

easier priming.

• Plumb with desired 2” piping (not supplied) as show

in Figure 1 from check vale and “T” into discharge

manifold.

Because of the 1 minute minimum

run time of the single phase pump, the system

plumbing & fixtures must be able to withstand

full deadhead system pressure (maximum pump

pressure + incoming PSI). If the plumbing system

cannot handle deadhead pressure, a pressure

control valve needs to be installed after the check

valve installed on the single phase pump and set

6-10 PSI above system pressure set on the drive of

the pump station.

• Note: For serviceability, unions & isolation vales

should be installed to allow replacement of either

pump without disturbing the other.

ELECTRICAL INSTALLATION:

• Install, ground, wire and maintain this installation

in accordance with your local electrical code and all

other codes and ordinances that apply. Consult your

local building inspector for local code information.

All electrical work should be performed by qualified

personnel.

• Ground the starter permanently using a wire of size

and type specified by local or United States National

Electrical Code. Do not ground to a gas supply line.

• Connect ground wire first. Connect to ground first

and then connect ground wire to motor starter

box. Connect starter ground to green grounding

terminal located inside of the motor terminal box.

Ground connection MUST be made to this terminal.

Do not connect motor to electrical power supply

until unit is permanently grounded; otherwise serious or fatal electrical shock hazard may be caused.

• IMPORTANT: Check local and/or United States

National Electric Codes for proper grounding information.

• Power should supplied with a correctly fused disconnect switch to provide protection. Consult Local

or National Electrical Codes for proper fuse protection based on motor nameplate.

• Whenever possible, the pump should be powered

from a separate branch circuit of adequate capacity

to keep voltage drop to a minimum during starting and running. For longer runs, increase wire size

in accordance with the Wire Selection guide. (See

Chart B). IMPORTANT: Wire charts are for reference

only. Consult local and state codes for approved

wire sizes.

• See Figure 4 for wiring from power circuit to starter

and to motor.

• For proper electrical connections to the motor, refer

to the connection diagram located on the nameplate or inside the terminal box of the motor. Make

sure connections are correct for the voltage being

supplied to the motor.

2 (FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

3 (FW1442)

Page 3

• Install provided heaters onto starter. Note: the heat-

To Properly Protected

ers provide over current protection for the motor.

This starter with heaters installed does not provide

protection from short circuits.

• Connect Starter L1 and Overload relay terminal X2

with wire rated for system power and route enough

wire to connect them to Drive terminals T5 & T6

respectively.

• IMPORTANT: For priming purposes only, temporarily

wire nut the wires together instead of connecting

to T5 and T6. After full prime, connect to T5 and T6.

• Connect Starter L2 to Coil terminal W with wire

rated for system power.

• Install temperature sensor wire provided onto ¼”

quick connect terminals of the temperature sensor

located near the pump discharge (Figure 2) to drive

terminals B2 & B7 (Figure 3) (Note: The new temperature sensor wires will share B2 & B7 drive terminals with factory installed wires.)

Figure 2 Temperature Sensor Location

Operation

Unit must be full of fluid before

operating. Do not run dry, or against a closed

discharge. Do not pump dirty water or abrasive

liquids. To do so will cause pump failure and will

void the warranty.

VALVES

The suction inlet valve should be in the full open position and hose bib valve should be partially open, allowing some back pressure to be exerted against the pump

when starting up. Close hose bib valve after priming up

is completed.

PRIMING

IMPORTANT: Before starting the pump it is absolutely

necessary that both pumps and the suction pipe be

completely filled with water. Before the entire duplex

pump system is fully operational, the single phase

pump, needs to be completely primed and run before

returning power to the variable frequency drive.

IMPORTANT: Before priming, verify control wires are

temporarily connected with a wire nut instead of being

connected to drive terminals T5 & T6.

PRIMING OF PRESSURE BOOST INSTALLATIONS

Priming is simple when pump is connected to a pressure

source such as a city main or above ground tank filled

to a level of 4 ft. above pump inlet.

1. Open inlet valves fully on suction and open hose

bib on skid system manifold.

2. To relieve trapped air, allow water supply to run a

minimum of 2 minutes before starting the pump.

3. Turn on power to the single phase pump and run

no longer than two (2) minutes. Unit should build

pressure & pump water. If not, repeat the sequence

above.

4. Once all air has been evacuated and the pump has

been primed, close hose bib and turn off power.

5. IMPORTANT: Once priming has been completed &

power has been turned off, remove the wire nut

connecting control wires and connected them to

drive terminals T5 & T6 (Figure 3).

T6T5T4T3T2T1

Transducer Wire - Black

B1

B4

B3B2

B7B6B5

Transducer Wire - Red

Jumper Wire

Temperature Sensor Wire - Red

Temperature Sensor Wire - Black

1

Transducer Cable

Temperature Sensor Cable

2

Figure 3 Drive Control Circuit Terminals

Starter Control Wires

IL1140

Disconnect Circuit

L1 L2

Motor Starter

Coil Terminals

Line Terminals

L1 L2 L3

Overload Relay

Terminals

Drive

Terminals

Figure 4 Starter Wiring

T5

T6

NC

T1 T2 T3

X2

Starter Control Wires

Install Heaters

Load Terminals

Pump

Motor

IL1139

PRIMING FOR SUCTION LIFT INSTALLATIONS

On suction lift applications prime the unit as follows:

1. Remove priming plug from service tee and fill pump

and suction pipe with water.

2. Jog the pump motor by applying power on and off

several times to free air trapped inside the pump.

3. After jogging the pump, refill with water and

repeat the priming sequence several times to be

sure all air is out of the pump and suction pipe.

4. Open hose bib on skid system manifold, start the

pump and run no longer than two (2) minutes. Unit

should build pressure & pump water. If not, repeat

the sequence above.

NOTE: On first use of pump, it may be necessary to reprime the unit three (3) or four (4) times before all air is

out of the suction pipe.

5. Once all air has been evacuated and the pump has

been primed, close hose bib and turn off power.

6. IMPORTANT: Once priming has been completed &

power has been turned off, remove the wire nut

connecting control wires and connected them to

drive terminals T5 & T6 (Figure 3).

START-UP PROCEDURE

Once the preceding instructions have been completed,

the entire system can be started:

1. Verify that all values installed on the intake side of

the pumps are open & the isolation value is closed

if installed on the discharge side of the system.

2. Verify that the 3-phase pump is primed. For gravity

fed systems, this can be accomplished by opening

hose bib valve installed on the system manifold to

allow the water pressure to push out the air from

the pump. For suction lift systems, fill the pump

and intake piping with external water source until

water begins coming out the open hose bib valve.

3. Close hose bib valve.

4. Supply electrical power to Pump Station by turning

on the user installed disconnect to the ON position

and allow system to pressurize and check for leaks

on plumbing installed.

5. Once pressure has been established, partially crack

open the station isolation valve (while maintaining

pressure) and open valves farthest away from pump

station to bleed air out of the system & piping

6. When the whole Main Line has been bled of air,

fully open the discharge isolation valve.

7. Supply electrical power to single phase pump by

truing on the user installed disconnect to the ON

position. When demand exceeds the capacity of the

three phase pump, the single phase motor will start

up for a minimum of one minute.

8. During the first few hours of operation, inspect the

pump, piping and any auxiliary equipment used in

connection with the unit.

9. Check for leaks, excessive vibration or unusual

noises.

MAINTENANCE:

For proper maintenance of the pump, please follow

instructions in enclosed End suction centrifugal pumps

instructions FW0300/134984.

4 (FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

5 (FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

Page 4

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Low or no discharge 1. Incorrect rotation 1. Refer to wiring diagram

2. Insufficient inlet pressure or

suction head (NPSH Required)

3. Total head too high 3. Lower discharge head

4. Leak in suction line 4. Repair or replace

5. Impeller clogged or damaged 5. Clean or replace

6. Wrong size piping 6. Make needed adjustments

7. Casing gasket leaking 7. Replace gasket

8. Suction or discharge line valves

closed

9. Mechanical seal leaking 9. Replace

Loss of suction 1. Insufficient inlet ressure or suction

head (NPSH Required)

2. Clogged strainer 2. Clean or replace

Pump vibrates and/

or makes excessive

noise

Pump leaks at shaft 1. Damaged or worn mechanical seal 1. Replace

Pump will not start

or run

Motor problems 1. Various 1. Consult qualified electrician

Pinholes in the

casting. Liquid

dripsp around seal

area but is not seal

1. Mounting plate or foundation not

rigid enough

2. Foreign material in pump 2. Clean

3. Damaged impeller 3. Replace

4. Cavitation present 4. Check suction line for proper size and be sure

2. Corrosion due to character of

liquid pumped

1. Improperly wired 1. Refer to wiring diagram

2. Blown fuse or open circuit breaker 2. Replace fuse or close circuit breaker

3. Loose or broken wiring 3. Tighten connections and replace broken wiring

4. Impeller clogged 4. Clean

5. Motor shorted out 5. Replace

2. Overloading motor. Too much

water delivery

3. Liquid heavier and more viscous

than water

4. Seal binding 4. Replace

5. Rotor binding 5. Repair or replace

6. Voltage and frequency lower than

rating

7. Defects in motor 7. Repair or replace

1. Cavitation caused by insufficient

inlet pressure or suction head

(NPSH Required)

2. Increase inlet pressure by adding more fluid to

fluid source. (See Spec’s for minimum NPSH

Required)

8. Open

1. Increase inlet pressure by adding more fluid to

fluid source. (See Spec’s for minimum NPSH

Required)

1. Reinforce

valve is open. Remove excessive loops in suction

line. (See Spec’s for minimum NPSH Required)

2. Discontinue pumping liquid and consult factory

2. Restrict outlet by closing down valve in discharge

line

3. Consult factory

6. Reconnect to rated voltage and frequency

1. Increase inlet pressure by adding a higher level of

fluid to source or increasing inlet pressure. (See

Spec’s for minimum NPSH Required)

CONTINGENCY OPTIONS

For some applications, a contingency plan is needed

if the system is unable to deliver the required water

in the event of a component failure which causes one

pump to fail. The contingency plans below will allow

the working pump to deliver water until the failed

component is repaired/replaced, even if the single

pump cannot meet the pressure demands required by

the application.

1. Problem: Single phase pump or starter failure.

Effect: Single phase pump does not run when

demand is reached. Drive continues to run 3-phase

pump, but system drops below set pressure when

demand is high. User Contingency action: None.

Long term user action: Repair/replace failed single

phase component.

2. Problem: Three Phase pump failure (drive not

tripped on fault). Effect: Three phase pump does

not run. Single phase motor is controlled by the

drive and runs 1 minute on, 1 minute off on low

water demand or continuously with higher demand.

User Contingency action: None. Long term user

action: Repair/replace failed 3-phase pump.

3. Problem: Drive fails. Effect: Neither pump runs.

User Contingency action: With power turned off to

both drive and single phase motor, remove control

wires from drive terminals T5 & T6 and wire nut

together. Hook up a hose to hose bib and route

back to supply tank or drain and open hose bib

valve. (This is done to guarantee a minimum flow of

water thought the pump when there is no demand

for water and prevent damage to the pump that

can occur when the pump is run deadhead.) Turn

power on to single phase pump – Note: Pump will

run continuously. Long term user action: Replace

drive.

4. Problem: Transducer Fails (Drive Trips tr cL1). Effect:

Neither pump runs. User Contingency action: With

power turned off to both drive and single phase

motor, remove control wires from drive terminals T5

& T6 and wire nut together. Hook up a hose to hose

bib and rout back to supply tank or drain and open

hose bib valve. (This is done to guarantee a minimum flow of water thought the pump when there

is no demand for water and prevent damage to the

pump that can occur when the pump is run deadhead.) Turn power on to single phase pump – Note:

Pump will run continuously. Long term user action:

Replace transducer.

6 (FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

7 (FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

Page 5

8 (FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

Loading...

Loading...