Page 1

Commander® Pro 100

SUBMERSIBLE SYSTEM

Installation, Operation and Trouble-Shooting Manual

FW1206

0608

Supersedes

NEW

Owner Information

System Model Number ____________________________

Pump Model / Date Code __________________________

Pump Serial Number (Silver Label) ___________________

Motor Model / Date Code __________________________

Motor Serial Number (Silver Label) ___________________

Controller Model / Date Code _______________________

Dealer _________________________________________

Address ________________________________________

Install Date _____________________________________

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

Table of Contents

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Piping & General Information. . . . . . . . . . . . . . . . . . . . . 3

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Controller Location Selection . . . . . . . . . . . . . . . . . . . . . 5

Controller Installation / Wiring . . . . . . . . . . . . . . . . . . . . 6

Start-up Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . 7

Smart Reset Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Toll Free Help Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

023050

1

Page 2

IMPORTANT SAFETY INSTRUCTIONS

RULES FOR SAFE INSTALLATION AND OPERATION

1. Read these warnings and instructions carefully. Failure

to follow them could cause serious bodily injury and/or

property damage.

2. Follow all local electrical and safety codes as

well as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

3. The power supply should be a separate circuit,

independent of all other circuits. Be sure it is equipped

with a fuse and disconnect box of ample capacity.

4.

For fire protection, the power supply should be

free of any building, preferably on a direct line from the

transformer. In the event of fire, the wires will not be

destroyed and the water supply not cut-off.

5.

Always disconnect power source before

performing any work on or near the motor or its

connected load. If the power disconnect point is out-ofsight, lock it in the open position and tag it to prevent

unexpected application of power. Failure to do so could

result in fatal electrical shock.

6. DO NOT handle pump with wet hands or when

standing in water as fatal electrical shock could occur.

Disconnect main power supply before handling pump

for any reason.

7. Shut off power source when voltage drops below 210

on 230 volt installations.

8. Protect the power cable from coming in contact with

sharp objects, oil, grease, hot surfaces or chemicals.

DO NOT kink the power cable. If damaged replace

immediately.

9. NEVER leave the control box, fused disconnect switch,

or covers open (either partially or completely) when

not being worked on by a competent electrician or

repairman.

11.Install all electrical equipment in protected area to

prevent mechanical damage which could produce

serious electrical shock and/or equipment failure.

12.Pump is designed to pump cold ground water that is

free of air or gases. Decreased pump performance and

life expectancy can occur if the ground water is not cold

(86ºF/30ºC) or contains air or gases.

13. Pump and controls must be securely and

adequately grounded as specified in section 250-43

item (A) of the U.S.A. National Electric Code (NEC) and

Section 26-954 Canadian Electrical Code. Failure to do

so could result in a fatal injury.

14.DO NOT use this pump to pump flammable liquids such

as gasoline, fuel oil, kerosene, etc. Failure to follow the

above warning could result in property damage and/or

personal injury.

15. The pump is intended for

use in a well. Motor frame must be connected to power

supply ground or fatal electrical shock may result. Do not

use this pump in swimming pools.

16. This product contains chemicals

known to the State of California to cause cancer and birth

defects or other reproductive harm.

NOTE: Pumps with the “CSA” mark are tested to UL

standard UL778 and certified to CSA standard C22.2 No.

108.

10. Always use caution when operating electrical

controls in damp areas. If possible, avoid all contact

with electrical equipment during thunderstorms or

extreme damp conditions.

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

2

Page 3

Section 1

System Components

Please be sure that you have all major system

components necessary to properly install the

Commander® Pro 100 Submersible pump system. Other

components may also be necessary depending on the

application requirements.

1. Submersible Pump End

2. Submersible Motor

3. CP Water Controller - SubDrive 100

4. Pressure Switch (packaged with controller)

5. Pressure Relief Valve (purchased separately)

6. Pressure Gauge (purchased separately)

Section 2

Piping

General Information

The Commander® Pro 100 system is capable of flows up

to 40 GPM. Discharge piping is recommended to be 1.25”

for installations in which flows will exceed 12 GPM. The

use of smaller pipe will increase friction losses and can

severely limit the maximum capacity of the system.

This pump may be capable of pressures exceeding 325

PSI under maximum conditions, select pipe accordingly.

Consult your pipe supplier to determine the best pipe

material for the installation

Pump Inspection

Prior to installation check the pump, motor, controller and

tank for shipment damage.

Pressure Tank

Use a minimum 4.5 gallon tank to ensure optimum

pressure regulation. An existing, or larger tank can be

used with this system, if desired.

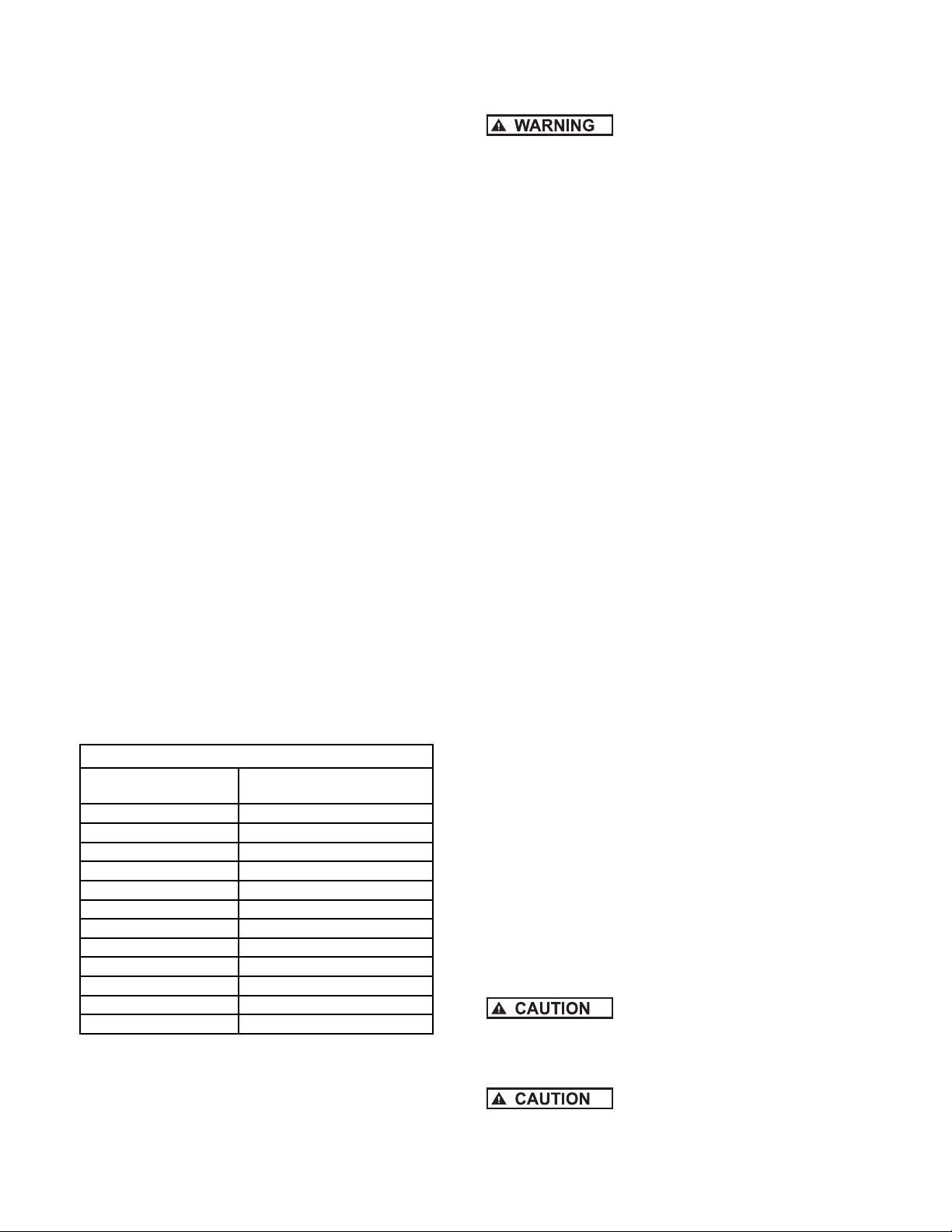

Pressure Setting Guide

System Pressure

(at Pressure Sensor)

25 18

30 21

35 25

40 28

45 32

50 (factory set) 35

55 39

60 42

65 46

70 49

75 53

80 56

Pressure Relief Valve

The pressure relief valve and the discharge outlet need

a flow rating which exceeds the flow capacity of the

installation at the relief pressure. When located in an area

where a water leak or relief valve blow-off may damage

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

Pressure Tank Setting (PSI)

(+/- 2 psi)

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

property connect an adequate drain line to the pressure

relief valve. Run the line to a suitable drain or to an area

where the water will not damage property.

Not providing an adequate relief

valve can cause extreme overpressure which could

result in personal and/or property damage. It is

recommended that you manually activate the valve

monthly to keep it in good working order.

Discharge Pipe

When discharge piping requires an adapter it is

recommended that a stainless steel adapter be used.

Galvanized fittings or pipe should not be connected

directly to the stainless steel discharge head of the

Commander Pro pump as galvanic corrosion may occur.

Barb type connectors should always be double clamped.

Torque arrestors are not required on this installation due

to the soft starting characteristics of the Commander® Pro

100 motor and controller

Check Valve

A check valve is factory installed in the discharge head

of the Commander® Pro 100 submersible pump. This

maintains water within the pipe when the pump is not

operating. For well depths exceeding 125 feet, an

additional check valve should be installed every 125 feet.

Safety Rope

A safety rope eyelet is provided at the discharge of the

pump. It is recommended to attach a nylon safety rope.

This will assist in the removal of the pump and also

prevent loss of the unit in the bottom of the well due to a

loose fitting or pipe deterioration.

Section 3

Pump Installation

1. The following installation instructions as shown

use 160 PSI plastic pipe. Schedule 80 PVC pipe or

galvanized pipe may also be used. If either of these

two types are used, a foot clamp will be required to

hold the PVC or galvanized pipe while connecting the

next length of pipe.

2. Lay the pump a foot or two from the well, pointing

outward (pump discharge away from the well).

3. Lay out plastic pipe, safety rope, hose clamps, piping,

tape, submersible cable, etc.

4. Assembly of all components that go into the well

should be made horizontally on the ground, and then

lowered into the well.

5. Install a stainless steel pipe adapter in the pump

discharge tapping, using teflon tape.

Do not use pipe wrench on any part

of pump except the cast discharge of the pump.

6. Unroll plastic pipe in a straight line away from the

pump.

Be sure working surface is smooth

to avoid damage to the plastic pipe and electric cable.

Cut off sealed end of plastic pipe with a hacksaw.

3

Page 4

7. Position two hose clamps over end of the plastic

pipe. Slide plastic pipe over the plastic pipe adapter

all the way to the shoulder. Position the clamp

tightening screws opposite each other and away from

the motor lead wires to prevent insulation damage.

Tighten the hose clamps and tape clamp tab ends to

pipe with plastic tape.

8. Splice the electric cable to the pump leads.

Heat shrink tubing and Sta-kon connectors are

recommended. It is necessary that the splice be

water tight.

9. Unroll the electric cable along side of the plastic pipe.

Be sure not to damage wire insulation, and that all

kinks are straightened out.

10. Cut the plastic pipe to proper length.

11. Slide cable guards over plastic pipe and submersible

cable. One at 15 ft. above the pump and one every

25 ft. thereafter. Secure guards in position with

retaining clamps or tape.

12. Attach assembly used to plastic pipe with two

stainless steel hose clamps. Tighten clamps securely.

Be sure to assemble the elbow

on the pipe above the well seal. This will prevent

dropping of the pump and piping into the well as you

lower it.

90° Elbow

Adapter

LOWERING PUMP INTO THE WELL

Never support the weight of pump

and piping by the electric cable, as this weight will

break the cable connections.

15. The pump is now ready to be lowered into the well.

A helper will be needed to handle the other end of

the assembly. With the plastic pipe and wire cable

assembly over your shoulder, lift the pump, being

very careful not to kink the plastic pipe.

16. Guide the pump and piping into the well. Protect the

cable when lowering to prevent scraping or damage

by the edge of the well casing.

17. The helper brings his end of the assembly forward as

needed. Keep the pipe, cable, and rope free of grass

or other foreign matter.

Well Seal

Coupling

Adapter

13. Tape electric cable to pipe about every five feet. Use

only 1-1/2 to 2 wraps of tape, so as to allow for some

movement of the cable. Tape spliced connections to

pipe to eliminate rubbing against well casing. Leave

four to five feet of slack, at the upper end to allow for

plastic pipe stretch.

14. Tie safety rope, through eyelet on top of pump. Tape

end of rope to prevent unraveling. Tape safety rope

to pipe every 20 feet. Do not leave any slack in rope.

Tie securely on bottom side of well seal or pitless

adapter and tape end of rope.

18. When the entire assembly is in the well, make sure

well seal is seated. Tighten the four bolts in well seal

evenly.

Section 4

Controller Location Selection

The CP WATER SD100 standard NEMA 1controller is

intended for indoor use and for operation in ambient

temperatures up to 125° F (50° C). For outdoor

installations, a system with a NEMA 4 rated controller

must be used. (Models with 7th and 8th characters

of “N4”). To ensure maximum weather protection, the

unit must be mounted vertically with the cover properly

aligned and secured with all lid screws. The following

recommendations will help in selection of the proper

location of the CP WATER SD100 unit:

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

4

Page 5

1. A tank tee is recommended for mounting the tank,

pressure sensor, pressure gauge, and pressure relief

valve at one junction. If a tank tee is not used, the

pressure sensor should relocated within 6 ft. (1.8

meters) of the pressure tank to minimize pressure

fluctuations. There should be no elbows between the

tank and pressure sensor.

2. The unit should be mounted on a sturdy supporting

structure such as a wall or supporting post please account for the fact that the unit weighs

approximately 17 lbs. for NEMA 1 models and 22.0

lbs. for NEMA 4 models.

3. The electronics inside the CP WATER SD100 are aircooled. As a result, there should be at least 6 inches

of clearance on each side and below the unit to allow

room for air flow.

There should be at least 6 inches of

clearance on each side and below the unit to allow

room for proper air flow. There are to be no elbows

between the tank and pressure switch.

4. The CP WATER SD 100 should only be mounted

with the wiring end oriented downward. The controller

should not be placed in direct sunlight or other

locations subject to extreme temperatures or humidity

(mounting location should not be subjected to

freezing conditions or condensation).

5. The mounting location should have access to 230V

electrical supply and to the submersible motor wiring.

WIRE SIZING

Maximum wire lengths connecting the CP100 controller

to the main circuit box. (Based on 3% voltage drop at

230V)

Copper Wire Size (AWG) 12* 10 86432

Maximum Length (Feet) 85 140 220 345 550 680 895

*Wire with 90° C insulation only.

Maximum wire lengths connecting the motor to

the CP100 controller

Copper Wire Size (AWG) 14 12 10 8 6

Maximum Length (Feet) 320 510 810 1280 2010

Due to the inherent voltage changing

characteristics of variable frequency drives (VFD), there

is additional stress placed on the insulation of the wire

between the controller and the motor compared to a

standard pump system. Extra care must be taken when

using Unjacketed Flat Parallel Pump Cable to ensure that

the insulation on each of the separated wires is the same

thickness. Care must also be taken to ensure a proper

seal with shrink tubing on any splices. Failure to take

these precautions can lead to “wire burn through” that will

shut down the system. Under these circumstances, no

permanent damage usually occurs to the controller or motor.

For further details call Technical Support at

1-800-742-5040.

IL0837

SEPARATED WIRE

1. NOTE: DO NOT USE ALUMINUM WIRE.

2. Use 20 Amp circuit breaker for 230V supply

Controller Installation Procedure - SD100

1. Disconnect electrical power at the main breaker

2. Drain the system (if applicable)

3. Install pressure sensor - the pressure sensor has a

1/4 - 18 National Pipe Thread (NPT) connection.

4. Remove the CP WATER SD100 cover by removing

the three lid screws. Install the unit to the wall using

three mounting screws (not included).

Wiring Connections

1. Verify that the power has been shut off at the main

breaker.

2. Verify that the dedicated branch circuit for the CP

WATER SD100 is equipped with a 20 AMP circuit

breaker.

3. Remove the CP WATER SD100 lid.

4. Feed the motor leads through the opening on the

bottom right side of the unit and connect them to the

terminal block positions marked (green ground wire),

Red (Black) Yellow (Brown) and Black (Blue)

5. Feed the 230V power leads through the larger

opening on the bottom left side of the CP WATER

SD100 controller and connect them to the terminals

marked L1, GND, and L2 .

6. Feed the pressure sensor leads through the smaller

opening on the bottom left side of the CP WATER

SD100 unit and connect the red and black leads to

the terminals marked “1” and “2” (interchangeable)

with a small screwdriver (provided).

7. Use the appropriate strain relief or conduit

connectors.

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

5

Page 6

8. Replace the cover. Do not over-tighten the screw.

9. Connect the other end of the pressure sensor cable

with the two spade terminals to the pressure sensor.

The connections are interchangeable.

Remove rubber end cap

to adjust pressure. Use

7/32” allen wrench

Pressure sensor

boot

IL0026

A 10 foot section of cable is provided with the CP

WATER SD100 to connect to the pressure sensor.

Lengths of up to 100 feet can be used, provided the

appropriate shielded cabling is used. Consult the

factory for proper cable specification.

10. Set the pressure tank pre-charge to 70% of the

desired water pressure setting. To check the tank’s

pre-charge, de-pressurize the water system by

opening a tap. Measure the tank pre-charge with a

pressure gauge at its inflation valve and make the

necessary adjustments.

11. The pressure sensor communicates the system

pressure to the CP WATER SD100 controller. The

sensor is preset at the factory to 50 psi, but can

be adjusted by the installer using the following

procedure:

a. Remove the rubber end-cap.

b. Using a 7/32” Allen wrench (provided), turn the

adjusting screw clockwise to increase pressure

and counter-clockwise to decrease pressure. The

adjustment range is between 25 and 80 psi (1/4

turn = approximately 3 psi).

c. Replace the rubber end cap.

d. Reset the pressure tank pre-charge to the

appropriate pressure

12. Cover the pressure sensor terminals with the rubber

boot provided.

Start-Up Operation

Apply power to the controller. A steady green light

indicates that the CP WATER SUBDRIVE 100 has power

but the pump is not running. The green light will flash

continuously when the pump is running.

NOTE: Conventional private water systems intermittently

fill a pressure tank as commanded by a standard pressure

switch (e.g. 30 - 50 psi). The CP WATER SD100 maintains

a constant pressure at the pressure sensor up to the

maximum capability of the motor and pump. Although

the pressure is constant at the pressure sensor, pressure

drops may be noticeable in other areas of the home when

additional taps are opened. This is due to limitations in the

plumbing and will be more pronounced the further the taps

are from the pressure sensor. This would be true of any

system, and if observed, should not be interpreted as a

failure in the performance of the CP WATER SD100.

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

6

Page 7

SYSTEM TROUBLESHOOTING

Should an application or system problem occur, built-in diagnostics will protect the system. The red “FAULT” light on the

front of the CP WATER SD100 controller will flash a given number of times to indicate the nature of the fault. In some

cases, the system will shut itself off until corrective action has been taken. Fault codes and the recommended corrective

action for each are listed in the following table.

# of

Flashes

1

2

3

4

5

6

Fault Possible Cause Corrective Action

Motor underload

Under voltage

Locked pump

Open circuit

Short circuit

Overpumped or dry well. Worn pump.

Broken motor shaft. Blocked pump or

screen

Low line voltage

Motor/pump misaligned. Abrasives or sand

bound pump

NOT USED

Loose connection. Defective motor or

cable

Defective cable, splice or motor

Wait for well to recover and automatic restart timer

to time out. If the problem does not correct, check

motor and pump. See description of “Smart Reset”

below troubleshooting chart.

Check for loose connections. Check line voltage.

Report low voltage to the power company. Unit

will start automatically when the proper power is

supplied.

Unit will attempt to free a locked pump. If

unsuccessful, check the motor and pump.

Check motor wiring. Make certain all connections

are tight. Make certain proper motor is installed.

Cycle input power* to reset.

Check motor wiring. *Cycle input power to reset.

7

*”Cycle input power” means, turn the power off until both lights fade off and then apply power again.

Overheated

controller

High ambient temperature. Direct sunlight

exposure. Obstructed air flow.

This fault automatically resets when the

temperature returns to a safe level.

Description Part Number

Pressure Switch 020627

100’ Pressure Switch Cord 020628

Controller - Standard 023045

Controller - NEMA 4 023046

Motor 137462

Pump end for CP10007LT (N4LT) CP10007RP

Pump end for CP10010LT (N4LT) CP10010RP

Pump end for CP10019LT (N4LT) CP10019RP

Pump end for CP10027LT (N4LT) CP10027RP

Pump end for CP10035LT (N4LT) CP10035RP

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

7

Page 8

TROUBLESHOOTING GUIDE

Symptom Possible Cause Corrective Action

Water flow rate is not as high

as expected

Excessive pressure

fluctuations

Motor runs continuously with

no flow demand from the

house.

Motor is running backwards.

Temperature in the controller is

too high. If the controller’s heat

exchanger becomes too hot, the

controller will reduce the speed

of the pump to lower the power

consumption.

Pump capacity cannot supply the

demand

Waterlogged tank.

Pressure tank is too small for flow

rating of the pump.

Leak in the pitless adapter.

Leak in the household or outdoor

plumbing.

Switch two of the three wires leading from the

controller to the motor (3-phase motor).

Make sure there is at least 6 inches of room

around the controller for movement of air.

Use pump with higher flow rating (if head

requirement is still satisfied).

Check tank for bladder damage - replace if

necessary.

Reset the tank pre-charge pressure (should be

70% of pressure sensor setting).

Use larger tank (4 gal tank minumum).

Re-seat the pitless adapter

Check for leaky faucets, valves and pipe fittings

and repair.

Smart Reset

If a motor underload fault condition occurs, the most likely

cause is an overpumped or dry well. To allow the well to

recover, the CP WATER SD100 will wait 30 seconds to 5

minutes, determined by duration of the previous run time,

before restarting the motor. For example the first time the

fault occurs, the CP WATER SD100 will wait 30 seconds

before attempting to restart the pump. If the system would

then run for 1 minute and an underload fault reoccurs, the

controller will wait 4 minutes before attempting to restart

the pump. This schedule allows for the minimum off-time

possible based on the recovery time of the well.

TOLL FREE HELP LINES:

Flint & Walling, Inc. . . . . . . . . . . . . . . . . . . . . . . 800-345-9422

Franklin Electric Service Hotline . . . . . . . . . . . 800-348-2420

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

020324

8

Loading...

Loading...