Page 1

OWNERS GUIDE TO INSTALLATION

AND OPERATION

FW0078

0310

Supersedes

0110

READ THESE INSTRUCTIONS CAREFULLY

Read these installation instructions in detail before installing your pump. Be sure to check the

following:

1. Be certain the motor is connected for the correct line voltage being used (check motor

nameplate).

2. Be certain the pump is completely primed before starting. Otherwise damage may occur to the

seal.

Every pump is tested before leaving the factory, and its performance depends largely on the

installation.

END SUCTION CENTRIFUGAL PUMPS

IL0412

GENERAL SAFETY INFORMATION

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and

the Occupational Safety and Health Act (OSHA).

2. Replace damaged or worn wiring cord

immediately.

3. Do not kink power cable and never allow the

cable to come in contact with oil, grease, hot

surfaces or chemicals.

4. Protect the power cable from coming in contact

with sharp objects.

5. Be careful when touching the exterior of an

operating motor - it may be hot enough to be

painful or cause injury.

6. Make certain that the power source conforms

to the requirements of your equipment.

7. Always disconnect power source before

performing any work on or near the motor or

its connected load. If the power disconnect

point is out-of-sight, lock it in the open position

and tag it to prevent unexpected application

of power. Failure to do so could result in fatal

electrical shock.

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Drain Plug

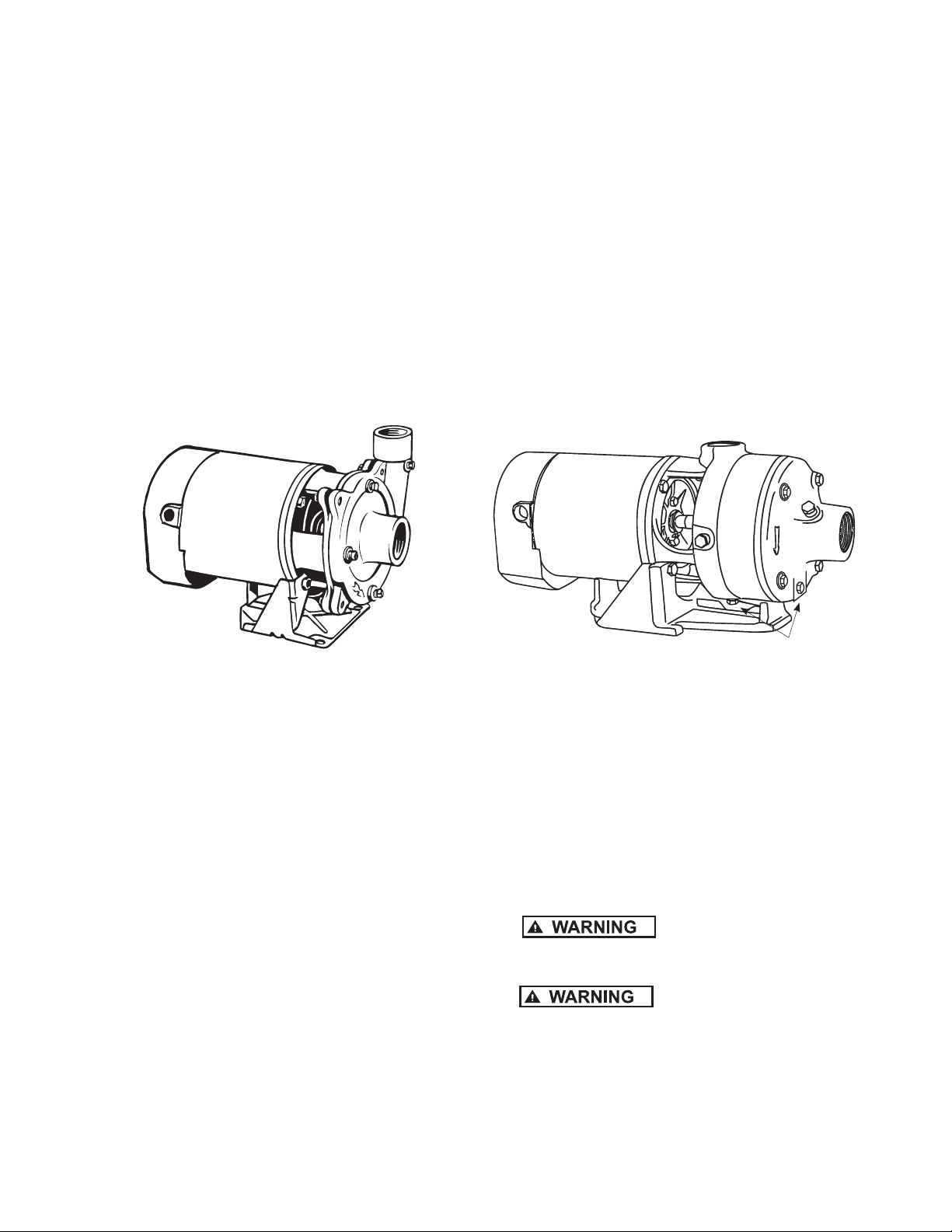

Figure 2 - CJ101 SeriesFigure 1 - CJ103 Series

8. Do not handle the pump with wet hands or

when standing in water as fatal electrical shock

could occur. Disconnect main power before

handling unit for ANY REASON!

9. Unit must be securely and adequately

electrically grounded. This can be

accomplished by wiring the unit to a ground

metal-clad raceway system or by using a

separate ground wire connected to the bare

metal of the motor frame or other suitable

means.

10.

pump has not been investigated for use in

swimming pool areas.

11.

chemicals known to the State of California

to cause cancer and birth defects or other

reproductive harm.

NOTE: Pumps with the “CSA” mark are tested to

UL standard UL778 and certified to CSA standard

C22.2 No. 108.

1

Risk of electric shock. This

This product contains

130441

IL0201

Page 2

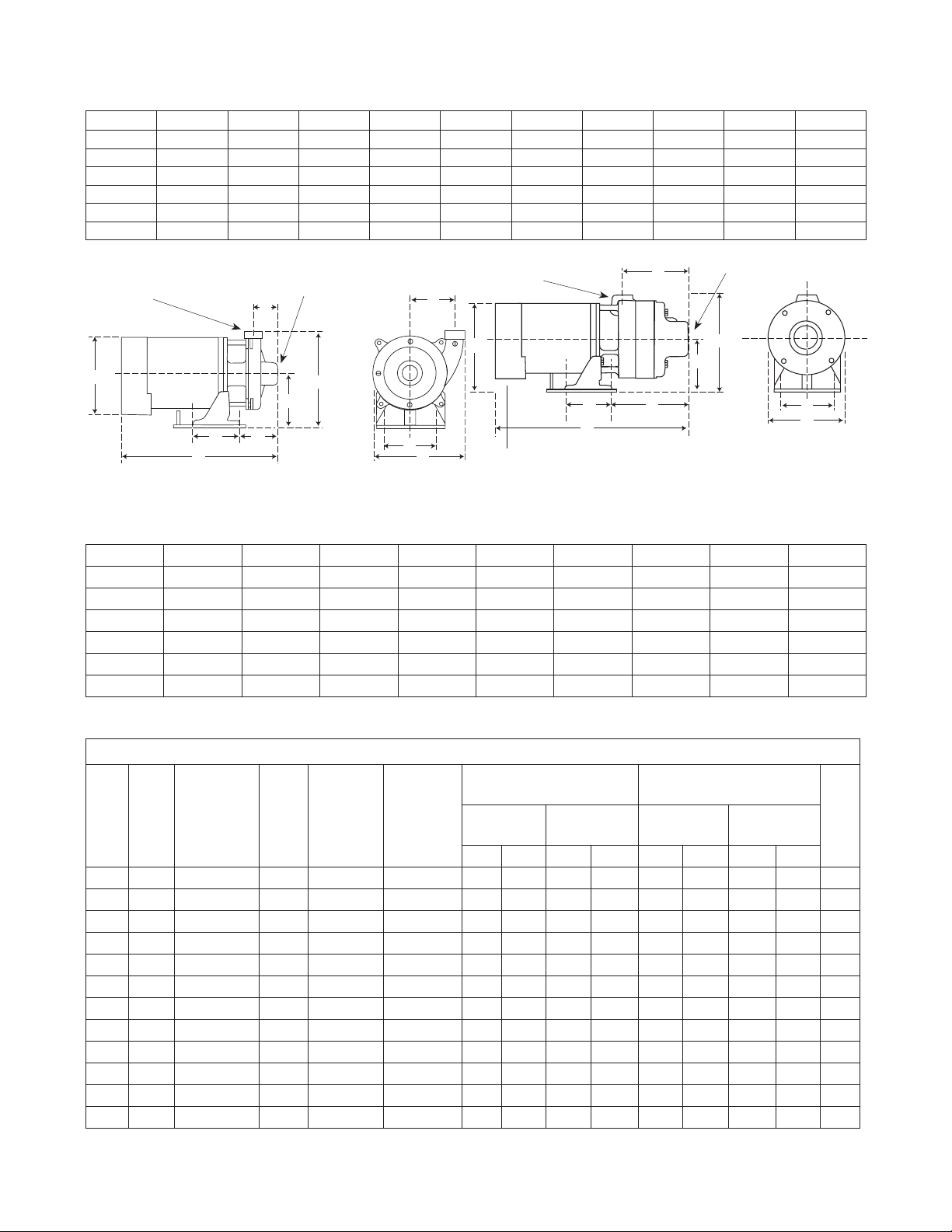

Dimensions (In Inches) CJ103 Series Chart A

HP A B C D E F G H J K

1/3 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/2 8-1/4 8-1/8 13-1/4 3-7/8

1/2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 13-1/2 3-7/8

3/4 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 14 3-7/8

1 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 14-1/2 3-7/8

1-1/2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 15-1/8 3-7/8

2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 15-5/8 3-7/8

1-1/2” Suction

F

1-1/4” Discharge

1-1/2” Suction

F

1-1/4” Discharge

K

E

D

B

G

IL0395

H

A C

J

Figure 3 - CJ103 Single Stage Booster Pump

E

D

IL0396

H

A

J

B

G

Figure 4 - CJ101B Two and Three Stage Booster Pump

C

CJ101 Series Chart B

HP A B C D E F G H J

3/4 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 17-7/8

1 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 18-3/8

1-1/2 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 19

2 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 19-1/2

2 * 4 4-5/8 9-7/16 4-13/16 8-3/4 8-1/8 7 8-1/8 21-3/8

3 * 4 4-5/8 9-7/16 4-13/16 8-3/4 8-1/8 7 8-1/8 21-3/8

(*) Three Stage

Motor Data Chart C

MOTOR

HP PH VOLTS HZ RPM

1/3 1 115/230 60 3450 11 5 V 8.6 4.3 — — 26.0 13.0 — — K

1/2 1 115/230 60 3450 11 5 V 13.0 6.5 — — 36.0 18.0 — — K

3/4 1 115/230 60 3450 11 5 V 14.0 7.0 — — 52.0 26.0 — — K

1 1 115/230 60 3450 230V 18.0 9.0 — — 70.0 39.0 — — L

1-1/2 1 115/230 60 3450 230V 21.0 10.5 — — 98.0 49.0 — — J

2 1 115/230 60 3450 230V 25.0 12.5 — — 116.0 58.0 — — H

3 1 230 60 3450 230V — 13.5 — — — 53.0 — — D

3/4 3 208-230/460 60/50 3450/2850 230V — — 3.5 1.75 — — 19.0 9.5 K

1 3 208-230/460 60/50 3450/2850 230V — — 4.5 2.25 — — 26.9 13.5 K

1-1/2 3 208-230/460 60/50 3450/2850 230V — — 5.7 2.85 — — 33.5 16.8 K

2 3 208-230/460 60/50 3450/2850 230V — — 7. 4 3.0 — — 44.0 22.0 K

3 3 208-230/460 60 3450 230V — — 9.8 4.9 — — 48.0 24.0 D

VOLTAGE

(FACTORY)

CONNECT.

SERVICE FACTOR MOTOR

AMPS

THREE

PHASE

11 5 V 230V 230V 460V 11 5 V 230V 230V 460V

PHASE

LOCKED ROTOR AMPS

SINGLE

PHASE

THREE

PHASE

KVASINGLE

2

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Page 3

IL0413

IL0414

Street Supply

Line Strainer

or Filter

(Optional)

Union

Gate/Ball Valve

(Normally Open)

Check Valve

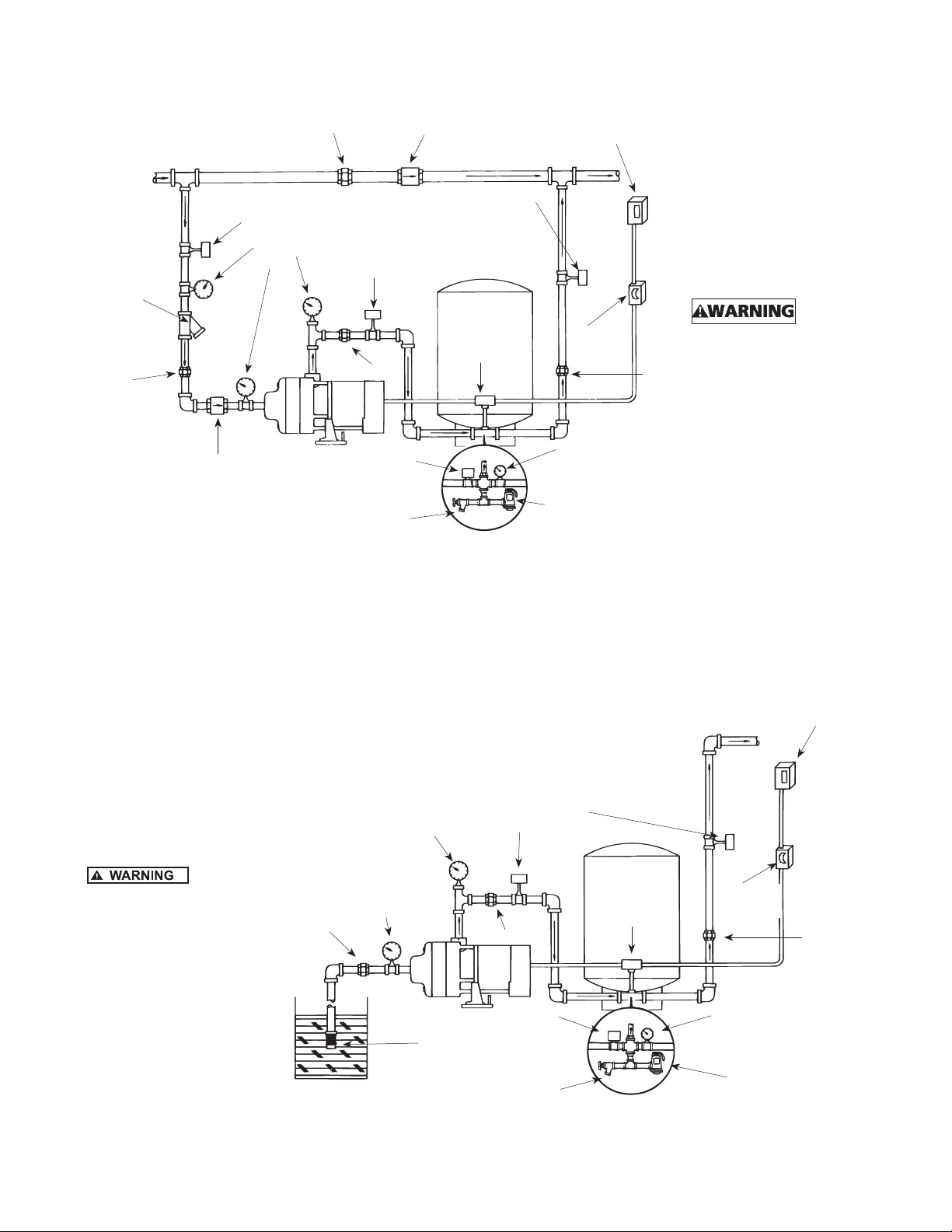

Typical Installations

Union

Pressure

Gauge

Gate/Ball Valve

(Normally Open)

Union

Pressure Switch

Drain

Check Valve

Gate/Ball Valve

(Normally Open)

Pressure Tank

Pressure

Switch

Main Power Box

Fuse Box

or Switch

Union

Pressure Gauge

Pressure Relief Valve

To size pressure tank

properly, match the

drawdown of the tank

to the capacity of the

pump.

(*) For manual

operation, omit the

pressure tank and

pressure switch. Wire

motor direct to fuse

box.

Install

a pressure relief valve

on any installation

where pump pressure

can exceed the pressure

tank’s maximum working

pressure or on systems

where the discharge

line can be shut off or

obstructed. Extreme

over pressure can result

in personal injury or

property damage.

Figure 5

To size pressure tank

properly, match the

drawdown of the tank

to the capacity of the

pump.

(*) For manual

operation, omit the

pressure tank and

pressure switch. Wire

motor direct to fuse

box.

Install

a pressure relief valve

on any installation

where pump pressure

can exceed the pressure

tank’s maximum working

pressure or on systems

where the discharge

line can be shut off or

obstructed. Extreme

over pressure can result

in personal injury or

property damage.

Union

Vacuum

Gauge

Pressure

Gauge

Pressure Switch

Foot Valve

with Strainer

Gate/Ball Valve

(Normally Open)

Union

Drain

Pressure Tank

Pressure

Switch

Main Power Box

Fuse Box

or Switch

Union

Pressure Gauge

Pressure Relief Valve

Figure 6

3

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Page 4

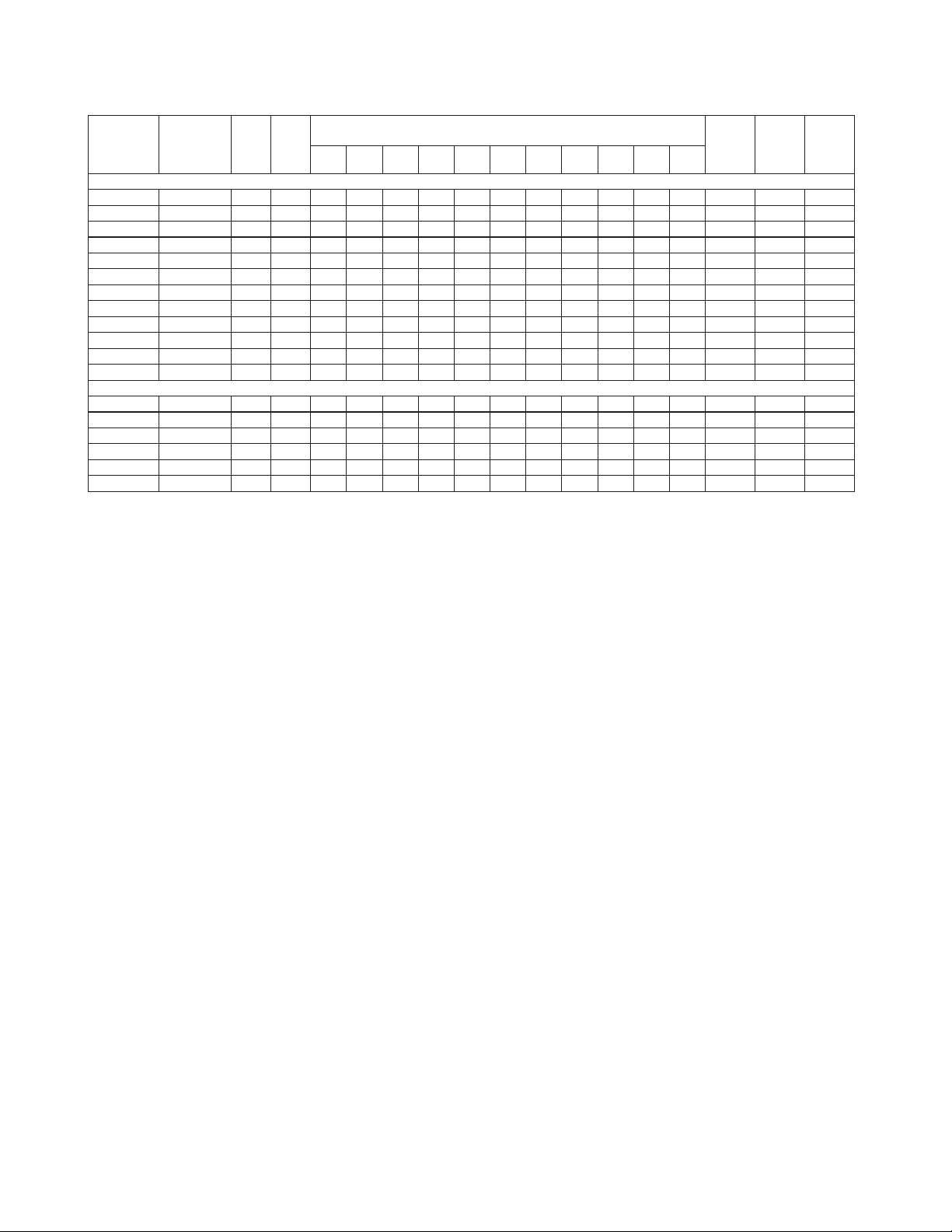

Pump Performance Chart D

Single

Phase

Model No.

CJ103031 - 1/3 1 41 30 10 27 10 0 200°F

CJ103051 CJ103053 1/2 1 48 40 27 30 10 0 200°F

CJ103071 CJ103073 3/4 1 62 58 46 31 33 10 0 200°F

CJ103101 CJ103103 1 1 70 66 58 48 34 40 10 0 200°F

CJ103151 CJ103153 1-1/2 1 * 75 70 61 51 36 44 10 0 200°F

CJ103201 CJ103203 2 1 * * 79 77 68 57 45 10 0 200°F

CJ101B071 CJ101B073 3/4 2 * * 32 29 25 22 5 53 160 200°F

CJ101B101 CJ101B103 1 2 * * 35 32 29 27 23 3 62 160 200°F

CJ101B151 CJ101B153 1-1/2 2 * * 42 39 37 34 28 19 68 160 200°F

CJ101B201 CJ101B203 2 2 * * 45 44 43 40 34 26 70 160 200°F

CJ101C201 CJ101C203 2 3 * * 42 41 40 38 35 31 27 20 7 93 160 200°F

CJ101C301 CJ101C303 3 3 * * 51 50 49 43 41 40 35 29 21 95 160 200°F

CJ101P071 CJ101P073 3/4 2 * * 31 28 23 20 48 160 160°F

CJ101P101 CJ101P103 1 2 * * 34 31 30 29 19 60 160 160°F

CJ101P151 CJ101P153 1-1/2 2 * * 46 44 41 37 31 14 61 160 160°F

CJ101P201 CJ101P203 2 2 * * 45 44 42 39 31 21 65 160 160°F

CJ101D201 CJ101D153 2 3 * * 41 40 38 37 33 29 24 17 89 160 160°F

CJ101D301 CJ101D303 3 3 * * * 46 45 45 42 38 33 27 18 93 160 160°F

To convert to feet of head, multiply by 2.31.

* Operation of pump in this range may result in m otor damage.

Do not exceed the maximum case pressure and maximum liquid temperature rating of the pump.

Suction & Discharge Tapping: 1-1/2” X 1-1/4”

Motor Voltage: Single phase: 1/3 - 115V; 1/2 thru 2 HP - 115/230V; 3 HP - 230V, 60HZ

Three phase: 1/2 thru 2 HP - 208-230/460V - 50/60HZ

3 HP - 208-230/460V - 60HZ

Three

Phase

Model No.

HP Stage

15 20 25 30 35 40 50 60 70 80 90

THERMOPLASTIC IMPELLER MODELS

GPM at Total Pressure in PSI

Press.

BRASS IMPELLER MODELS

Max.

PSI

Max.

Case

Press.

PSI

Max.

Liquid

Temp.

INSPECTION AND STORAGE

When unpacking the unit, inspect carefully for any

damage that may have occurred during shipment.

If the unit is received sometime before it can be

used, it should be inspected, recrated and stored

in a dry location.

LOCATION

IMPORTANT: In installations where property

damage might result from an inoperative or

leaking pump due to power outages, discharge

line blockage or any other reason, a back-up

system (s) and/or warning system (s) should be

used.Install a gate valve and union in the suction

and discharge lines. For removal of the pump for

service, close the gate valve and disconnect the

union.

1. Locate pump as close to the fluid source as

possible.

2. Place unit where the motor electrical

components and piping are protected from the

weather and extremes of heat, humidity and

below freezing temperatures.

3. Mount unit in a dry location that is easily

accessible for inspection and maintenance. If

a dry location is not available, mount it on a

foundation well above the wet floor.

4. Allow ample clearance around unit for free air

circulation.

5. CJ103 Series pumps incorporate a discharge

port on the pump casing that can be adjusted

in 90 increments. If necessary, adjust the

discharge port to accommodate the specific

application. Pump performance will not be

affected by the position of the discharge port.

SUCTION LIMITATIONS

1. Units are non self-priming. Normally after

being primed the total suction lift of the pump

is 25 feet. Suction lift varies depending upon

elevation (altitude) and water temperature. See

Practical Suction Lift chart.

2. Where liquids at or near their boiling points

are being handled, the supply must be located

above the suction, so that the available NPSH

will be greater than that required by the unit.

4

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Page 5

Practical Suction Lifts at Various Elevations and

IL0415

Water Temperatures in Degrees Fahrenheit

Altitude 60º 80º 100º 120º 140º 160º 180º 200º

Sea Level -22 -21 -20 -18 -15 -10 -4 +5

2000 -20 -19 -18 -16 -12 -7 -1 +8

4000 -17 -16 -15 -13 -10 -4 +2 +12

6000 -15 -14 -13 - 11 -7 -2 +6 +16

8000 -13 -12 -10 -8 -4 +2 +9 —

10000 -10 -9 -8 -6 -2 +4 +13 —

This table gives the maximum permissible suction lift or

the minimum head permitted on the suction side of a pump

at various altitudes and liquid temperatures. A minus sign

before a number indicates suction lift. A plus sign before a

number indicates minimum head. These figures are to be

used as a guide.

PIPING

1. Use galvanized piping, rigid plastic or other

suitable pipe that will not collapse under

suction or rupture due to pressure.

2. The diameter of the suction and discharge pipe

should be no smaller than the corresponding

tappings of the pump (see Figure 3 & 4). If long

runs are encountered larger pipe should be

used. Smaller pipe will reduce the capacity of

the pump.

3. All joints and connections should have Teflon

tape or pipe sealing compound (male threads

only) applied and drawn up tightly.

The entire system must be air and

water tight for efficient operation.

PUMP INSTALLATION

Refer to Figures 5, 6, and 7 for typical installations.

Both the suction and discharge pipe should be

supported at a point near the pump to avoid

strains being placed on the pump.

Pressure Gauge

Priming Plug

Discharge Tee

Suction Pipe Installed with

Gradual Rise to Pump Inlet

Level

Rigid

Foundation

Figure 7

Pipe

Support

5. On suction lift installations, a foot valve located

in the water or a check valve located as close

to the water as possible will reduce priming

time of the pump and help maintain prime. A

strainer must be used on the suction line to

filter out dirt and debris.

6. A priming tee installed in the pump discharge

port allows water to be poured into the pump

case and suction piping, which is required for

priming on suction lift installations.

7. Install a gate valve and union in the suction and

discharge lines. For removal of the pump for

service, close the gate valve and disconnect the

union.

Do not use a globe valve or other

restricting type of valve at the discharge. This will

seriously restrict the capacity of the pump.

8. Pressure Gauges - Properly sized vacuum or

pressure gauges can be installed in both the

suction and discharge pipe. The gauges will

enable observation of the pump’s performance

as well as detecting cavitation, vapor binding or

other unstable operation.

1. If the pump is used as part of a permanent

installation, secure to a rigid foundation with

appropriate fasteners.

2. Locate the pump as close to the water as

possible, keeping the suction pipe as short as

conditions permit.

3. Avoid dips or pockets in offset piping or air

will accumulate at high points which will make

priming difficult.

4. The suction pipe should slope upward to the

pump inlet. A horizontal suction line must have

a gradual rise to the pump.

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Use only components that are rated

higher than shut-off pressure of the system. Do not

exceed the pump’s maximum case pressure as listed in

the following table.

capacity must be installed on any installation where

the pump pressure can exceed the pressure tank’s

maximum working pressure or on systems where

the discharge line can be shut-off or obstructed.

Not providing a relief valve can cause extreme over

pressure which could result in personal injury and/or

property damage.

5

Models

CJ103 100 PSI

CJ101 160 PSI

A pressure relief valve of adequate

Maximum Case

Pressure

Page 6

ELECTRICAL

nameplate or figures 8, 9 & 10.

Ground motor before connecting

to electrical power supply.

Connect the motor frame to

Hazardous voltage.

Can shock, burn

or cause death.

Failure to follow

warnings can

cause fatal or

severe shock

hazard or

equipment failure.

equipment grounding conductor by

using green screw. Do not connect

green ground wire to any of the motor

leads.

Do not ground to a gas supply

line.

Turn off power to motor before working on electrical

connections.

Supply voltage must be within ±10% of nameplate

voltage. If in doubt consult a licensed electrician.

Use wire size specified in wiring Chart E. If possible,

connect pump to a separate branch circuit with no other

appliances on it. If wiring diagram on motor model plate

differs from diagram shown in figures 8, 9 & 10, follow

diagram on motor.

All wiring should be performed by a qualified electrician

and in accordance with the national and local electric

codes.

WIRING

1. Motor voltages will vary depending upon the

motor horsepower and phase. Refer to the

motor nameplate and the Motor Data Chart

(Chart C) for voltage and electrical data.

Make certain that the power supply

conforms to the electrical specifications of the motor

supplied. Failure to do so may cause premature motor

failure and will void the warranty.

2. To change voltage, remove the rear access

cover, which is held in place with two (2)

screws. For proper electrical connection, refer

to the connection diagram located on the motor

SINGLE PHASE

L1

Y

W

E

H

L

I

L

T

O

E

W

115 VOLTS

LINE

A

G

R

A

Y

L2

B

R

T

E

A

D

N

SINGLE PHASE

L1

Y

W

E

H

L

I

L

T

O

E

W

230 VOLTS

LINE

A

B

G

R

A

Y

L2

R

T

E

A

D

N

IL0180

Replace rear access cover before

starting or operating pump. Failure to do so can result

in personal injury.

MOTOR PROTECTION

1. All single phase motors have built in thermal

protection for all voltages. The overload

protects the motor against burnout from

overload of low voltage, high voltage and other

causes. The device is automatic and resets

itself once the temperature has dropped to

a safe point. Frequent tripping of the device

indicates trouble in the motor or power lines

and immediate attention is needed.

Never examine, make wiring changes

or touch the motor before disconnecting the main

electrical supply switch. The thermal device may have

opened the electrical circuit.

2. Three phase motors do not have a built in

thermal protection. It is recommended that a

properly sized magnetic or manual starter (both

with properly sized heaters) be used with all

three phase motors. Install starters following

instructions of the starter manufacturer. See

Figure 11 for magnetic starter wiring diagram.

3. All motors (single and three phase) should be

equipped with a correctly fused disconnect

switch to provide protection. consult local

or national electric codes for proper fuse

protection based on motor data chart (see

Charts C & E).

PRIMING

1. Before starting any centrifugal pump, it is

absolutely necessary that both the casing and

suction pipe be completely filled with liquid.

This priming can be accomplished by any of

the following methods:

2. When the liquid supply level is above the center

line of the pump, it is primed by opening the

suction and discharge valves. The inflowing

liquid will displace the air and fill the suction

Low Voltage

230V

5

4

7

889

2

1

L

L

2

1

L

3

IL0182

L

High Voltage

460V

566

4

7

23 3

1

L

1

2

9

L

3

Figure 9 - Wiring Diagram for Single Phase

1/3-2 HP

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Figure 10 - Wiring Diagram for Three Phase

6

Page 7

line, pump casing, and discharge line up to the

level of supply.

3. Where the pump is operating with suction

lift and the suction line is equipped with a

foot valve, remove the priming plug from the

discharge tee (see Figures 5-8) and fill the

pump body and suction pipe completely with

water. No additional water will be needed for

subsequent start-ups unless the pump body is

drained.

4. After the pump is turned on it will require 2-5

minutes before all air is evacuated from the

suction line and water begins to flow. If there

is no water after 5 minutes, turn the pump off

and check the following:

5. Any air leaks on the suction line must be

eliminated.

6. Suction pipe inlet should be a minimum of 5

feet below the water level.

7. Total suction lift cannot be greater than 25 feet.

8. Any restrictions in the discharge pipe, such as a

closed valve must be eliminated.

NOTE: Unit must be full of liquid before operating.

Never run dry, or against a closed discharge. Dry

running or running unit against a closed discharge

will cause damage to the shaft seal. Do not pump

dirty water or abrasive liquids, otherwise the same

may occur as if running dry.

MOTOR ROTATION

1. Single phase models are one (1) rotation only

(counterclockwise when facing the pump

suction tapping) and cannot be reversed.

Fused

Disconnect

Switch

Lightning

Arrestor

L3

X2

T3

T3

Pressure

Switch

T1

T1

L2

MV W

T2

T2

Motor

L1

03

02

IL0102

#10 or Heavier Copper Ground Wire, Connect

to 10 Ft. Ground Rod or Well Casing

Figure 11 - Magnetic Starter Wiring Diagram Three Phase

2. Proper rotation of pump impeller is critical for

three phase pumps. Pump motor should turn

counterclockwise (CCW) when facing pump

suction tapping. Momentarily “bump” (apply

power for less than a second) the motor to check

for proper rotation. To change rotation on three

phase units, interchange any two (2) incoming

line (power) leads.

IL0416

Figure 12 - Correct Motor Rotation

Chart E

DISTANCE FROM

MOTOR TO FUSE

BOX METER,

OR ELECTRICAL

OUTLET

0-50’ 14 14 12 14 12 14 10 14 10 12 10 12 10 14 14 14 14 14 14 14 14 14 14

50-100’ 14 14 12 14 12 14 10 14 8 12 8 12 10 14 14 14 14 14 14 14 14 14 14

100-150’ 14 14 12 14 10 14 10 12 6 12 6 12 10 14 14 14 14 14 14 14 14 14 14

150-200’ 12 14 12 14 10 12 8 12 * 10 * 10 10 14 14 14 14 12 14 12 14 12 14

200-300’ 12 14 10 14 8 12 6 10 * 10 * 10 8 14 14 12 14 12 14 10 12 10 12

Breaker Size

(Amps)

(*) Not economical to run in 115 volt, use 230 volts

1/3 HP 1/2 HP 3/4 HP 1 HP 1-1/2 HP 2 HP 3 HP 3/4 HP 1 HP 1-1/2 HP 2 HP 3 HP

115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 230V 230V 460V 230V 460V 230V 460V 230V 460V 230V 460V

15 15 20 15 20 15 30 15 30 20 30 20 30 15 15 15 15 15 15 15 15 15 15

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

MINIMUM COPPER WIRE SIZE CHART (GAUGE)

SINGLE PHASE MOTORS THREE PHASE MOTORS

7

Page 8

MAINTENANCE

Lubrication

The pumps and motors require no lubrication.

The ball bearings of the motor have been greased

at the factory. Under normal operating conditions

they should require no further greasing.

Winterizing your Pump

Cracked pump housings caused by freezing are

not covered by warranty. To protect your pump

from freezing, for best results remove the pump

and store in a warm environment. If pump cannot

be removed from your system, remove both

drain plugs, one on the suction flange and one

at the bottom rear of the pump (see fig 2 in the

instructions.) Allow the water to completely drain

from the pump. Re-install both drain plugs and fill

pump with RV type antifreeze. Antifreeze also acts

as a rust inhibitor. It will help keep rust build up to

a minimum and seals lubricated inside the pump

while it is not in use.

ROTARY SEAL ASSEMBLY REPLACEMENT

Disassembly

When disassembling the pump, care

should be taken not to damage the gaskets. If torn or

damaged, replace with new gasket (see parts list).

1. Remove the four (4) pump through bolts that

connect the mounting ring to the pump body.

Remove the pump body, taking care not to

damage the gasket or o-ring.

2. Remove the impellers. CJ103 Models are

single stage units, having one impeller. Using

a 9/16” open end wrench, hold the motor shaft

flat and unthread the impeller by turning it

counterclockwise. The motor shaft flat area is

located in the middle of the mounting ring.

3. CJ101 models are multi stage units, having

two or more impellers and one or more

intermediate stages. Using an 11/16” open

end wrench on the motor shaft extension

flat, remove the first impeller by turning or

counterclockwise. Remove the intermediate

stage (stages) taking care not to damage the

gasket (gaskets) and unthread the remaining

impellers.

4. Remove the mechanical seal assembly. The

rotary portion of the seal assembly (carbon

ring, Buna-N gasket and spring) will easily slide

off the end of the shaft. The ceramic portion

can be pried out of the rubber seating using

two (2) screwdrivers (see Figure 13).

Reassembly

The precision lapped faces of the

mechanical seal are easily damaged. Handle the

replacement seal carefully. Short seal life will result if

seal faces (ceramic & carbon) are nicked, scratched or

dirty.

1. Clean the seal cavity of the mounting ring and

the motor shaft thoroughly.

2. Apply liquid soap (one drop only) to the outside

of the Buna-N gasket that houses the ceramic

seal seat. With thumb pressure, press the

ceramic seat, polished face up, squarely into

the seal cavity (see Figure 14).

3. If seal does not seat squarely, remove and

reclean the seal cavity. Place a cardboard

washer over the polished seal face and carefully

press into place using a piece of pipe or tubing

(see Figure 15). Discard cardboard washer.

4. Apply liquid soap (one drop only) to the inside

diameter of the rubber drive ring. Slip rubber

drive ring (carbon face down) and the spring

over the shaft.

5. Reassemble the pump by following the reverse

order of the disassembly instructions.

MOTOR REPLACEMENT

1. Nema J motors can be replaced in the field

with any standard Nema J jet pump motor by

referring to the following instructions and the

attached parts list.

Figure 13 - Remove Mechanical Seal

IL0173

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

IL0168

Figure 14 - Press in Seal

3/4” Pipe

- Press

Carefully

IL0169

Figure 15 - If Necessary, Press with

Cardboard and Pipe

8

NOTE:

Cardboard Washer

Protects Seal Face

Seal

Seal

Cavity

Page 9

2. Follow steps as outlined under Rotary Seal

Replacement to remove the pump body,

diffuser, impeller and rotary seal.

3. Remove bolts that connect the motor to the

mounting ring and pull motor away.

4. Replace motor with standard Nema J jet

pump motor by positioning motor against the

connected at the bottom of the mounting frame

with two (2) 3/8” x 1/2” cap screws.

5. Follow steps of Rotary Seal Assembly to

reassemble the remainder of the pump.

BECAUSE DAMAGE TO THE SHAFT SEAL IS

MOST LIKELY TO OCCUR IN DISASSEMBLY, A

NEW SEAL WILL BE NECESSARY.

mounting frame and assembling with four (4)

3/8” x 3/4” cap screws. The mounting base is

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Little or no

discharge

Loss of suction 1. Air leak in suction line 1. Repair

Pump vibrates

and/or makes

excessive noise

Pump will not start

or run

Pumps leaks at

shaft

1. Pump not primed 1. Prime unit

2. Total head too high 2. Shorten suction lift and/or discharge

head

3. Suction head higher than

3. Lower pump inlet

pump designed for

4. Impeller clogged 4. Clean

5. Incorrect rotation 5. Refer to wiring information

6. Leak in suction line 6. Repair or replace

7. Inadequate foot valve 7. Make needed adjustments

8. Impeller damaged 8. Replace

9. Foot valve or suction line not

9. Submerge lower in water

submerged deep enough in

water

10. Insufficient inlet pressure or

suction head

10. Increase inlet pressure by adding

more fluid to fluid source

11. Wrong size piping 11. Make needed adjustments

12. Casing gasket leaking 12. Replace gasket

13. Suction or discharge line

13. Open

valves closed

2. Suction head too high 2. Lower pump inlet

3. Insufficient inlet pressure or

suction head

3. Increase inlet pressure by adding

more fluid to fluid source

4. Clogged foot valve or strainer 4. Clean or replace

1. Mounting plate or foundation

1. Reinforce

not rigid enough

2. Foreign material in pump 2. Clean

3. Damaged impeller 3. Replace

4. Cavitation present 4. Check suction line for proper size and

be certain valve is open. Remove

excessive loops in suction line

5. Worn motor bearings 5. Replace

6. Bent impeller shaft 6. Replace

1. Improperly wired 1. Refer to wiring diagram

2. Blown fuse or open circuit

2. Replace fuse or close circuit breaker

breaker

3. Loose or broken wiring 3. Tighten connections and replace

broken wiring

4. Impeller clogged 4. Clean

5. Motor shorted out 5. Replace

1. Worn mechanical seal 1. Replace

2. Bent impeller shaft 2. Replace

9

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Page 10

CENTRIFUGAL PUMP REPAIR PARTS

“CJ103” SERIES

(For Pricing Refer To Repair Parts Price List)

FORM NO. FW0039

SUPERSEDES 1009

PAGE 4-1A REPAIR PARTS

0110

1

3

10

HP 1/3 1/2 3/4 1 1-1/2 2

STAGE 1 1 1 1 1 1

SINGLE PHASE

BRASS IMPELLER

CJ103031 CJ103051 CJ103071 CJ103101 CJ103151 CJ103201

THREE PHASE

ITEM

BRASS IMPELLER

SINGLE PHASE

PLASTIC IMPELLER

MODEL

NO.

CJ103P031 CJ103P051 CJ103P071 CJ103P101 CJ103P151 CJ103P201

THREE PHASE

PLASTIC IMPELLER

DESCRIPTION

PART

NO.

11Motor, Nema J - 1PH

Motor, Nema J - 3 PH

Motor Access Cover

Screws, Access Cover

‡

Slinger Washer

2

Mounting Ring

3

Hex Hd. Cap Screws 3/8 x 3/4”

4

Seal, Rotary w/Spring

5

Impeller - Brass

5A

Impeller - Plastic

5B

Clearance Ring

6

Ring, Square Cut †

7

Body Assembly - Brass Impeller

Body Assembly - Plastic Impeller

‡

Suction Clearance Ring-Brass

8

Pipe Plugs, 1/8” NPT

910Hex Hd. Cap Screws 3/8 x 1”

Base

(*) Standard hardware item

(‡) Not shown

(†) For pumps with paper gasket, replace with part number 127782

(

∆) Kit Includes: Access Cover, Screws & Wiring Diagrams

021301R

021302

126905

134107

*

131100

132583

021439

*

*

125855

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

98J103

—

1

2

1

1

4

1

130403A

133426

N/A

1

127870

1

127869A

4

4

1

5A

2

4

6

9

5B

7

5

8

IL0417

CJ103053 CJ103073 CJ103103 CJ103153 CJ103203

CJ103P053 CJ103P073 CJ103P103 CJ103P153 CJ103P203

QTY.

98J105

98J305

1

2

1

1

4

1

126900A

139222

138138

1

127870

1

127869A

4

4

1

98J107

98J307

1

2

1

1

4

1

127805

021280

134240

1

127780

1

N/A

4

4

1

98J110

98J310

1

2

1

1

4

1

127804

135248

134240

1

127780

1

N/A

4

4

1

98J115

98J315

1

2

1

1

4

1

127806

021279

134240

1

127780

1

N/A

4

4

1

98J120

98J320

127848

127780

10

1

2

1

1

4

1

N/A

N/A

1

N/A

N/A

4

4

1

Page 11

FORM NO. FW0040

0310

SUPERSEDES 0110

PAGE 4-2A REPAIR PARTS

CENTRIFUGAL PUMP REPAIR PARTS

“CJ101” SERIES

(For Pricing Refer To Repair Parts Price List)

1

2

4

13

12

3

6

5

8

9

Detail of

Intermediate Stage

Assembly

Square

Cut Ring

HP 3/4 1 1-1/2 2 2 3

STAGE 2 2 2 2 3 3

SINGLE PHASE - BRASS IMPELLER

ITEM

THREE PHASE - BRASS IMPELLER

SINGLE PHASE - PLASTIC IMPELLER

THREE PHASE - PLASTIC IMPELLER

MODEL

NO.

CJ101B071 CJ101B101 CJ101B151 CJ101B201 CJ101C201 CJ101C301

CJ101B073 CJ101B103 CJ101B153 CJ101B203 CJ101C203 CJ101C303

CJ101P071 CJ101P101 CJ101P151 CJ101P201 CJ101D201 CJ101D301

CJ101P073 CJ101P103 CJ101P153 CJ101P203 CJ101D203 CJ101D303

DESCRIPTION PART NO. QTY

11Motor, Nema J - 1 PH

Motor, Nema J - 3 PH

Motor Cover w/Screws

Screws, Cover

‡

Slinger Washer

2

Shaft

3

Mounting Ring

4

Hex Hd. Cap Screws 3/8 x 3/4”

5

Seal, Rotary w/Spring

6

Impeller, Brass

6

Impeller, Thermoplastic

7

Spacer, Shaft

8

Gasket

9

Intermediate Stage Assy-Brass**

9

Intermediate Stage Assy-Plastic**

‡

Suction Clearance Ring

‡

Hub Clearance Ring

‡

Square Cut Ring Interm. Stg.

10

Suction Flange Assembly-Brass

10

Suction Flange Assembly-Plastic

‡

Suction Clearance Ring

‡

Suction Bearing

11

Pump thru Bolts 3/8” x 3-1/4”

11

Pump thru Bolts 3/8” x 5”

12

Base w/ Bolts 3/8” x 1-1/4”

13

1/4" NPT Plug

(*) Standard hardware item

(†) For quantity required — See number of stages

(‡) Not shown

(**) Includes two castings, square cut ring, suction and hub clearance ring - See Detail Drawing

(∆) Kit Includes: Access Cover, Screws & Wiring Diagrams

021301R

021302

126905

125204

*

131100

133380

130968

131239B

023405

130957

131282

020240

125227A

023404

130957

020053

*

020054

*

98J107

98J307

1

2

1

135279A

1

2

1

†135280A

†133425

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

98J110

98J310

1

2

1

135279A

1

2

1

†135281A

†133427

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

8

98J115

98J315

135279A

†126900A

†139180

7

IL0159

1

2

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

6

98J120

98J320

1

2

1

135279A

1

2

1

†126901A

†128472

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

10

11

98J120

98J320

1

2

1

136612A

1

2

1

†139126A

†139221

2

3

2

2

2

2

2

1

1

1

1

-4

1

4

13

13

98J630

98J330

1

2

1

136612A

1

2

1

†136951A

†139104

2

3

2

2

2

2

2

1

1

1

1

-4

1

4

11

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2010. All rights reserved.

Loading...

Loading...