Page 1

OWNERS GUIDE TO INSTALLATION

AND OPERATION

END SUCTION CENTRIFUGAL PUMPS

READ THESE INSTRUCTIONS CAREFULLY

Read these installation instructions in detail before

installing your pump. Be sure to check the following:

1. Be certain the motor is connected for the correct

line voltage being used (check motor nameplate).

2. Be certain the pump is completely primed before

starting. Otherwise damage may occur to the

seal.

Every pump is tested before leaving the factory, and

its performance depends largely on the installation.

FW0300

0111

Supersedes

0309

GENERAL SAFETY INFORMATION

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

2. Replace damaged or worn wiring cord immediately.

3. Do not kink power cable and never allow the cable

to come in contact with oil, grease, hot surfaces, or

chemicals.

4. Protect the power cable from coming in contact with

sharp objects.

5. Be careful when touching the exterior of an

operating motor - it may be hot enough to be painful

or cause injury.

6. Make certain that the power source conforms to the

requirements of your equipment.

7. Always disconnect power source before performing

any work on or near the motor or its connected load.

If the power disconnect point is out-of-sight, lock it in

the open position and tag it to prevent unexpected

application of power. Failure to do so could result in

fatal electrical shock.

8. Do not handle the pump with wet hands or when

standing in water as fatal electrical shock could

occur. Disconnect main power before handling unit

for ANY REASON!

9. Unit must be securely and adequately electrically

grounded. This can be accomplished by wiring the

unit to a ground metal-clad raceway system or by

using a separate ground wire connected to the bare

metal of the motor frame or other suitable means.

10. WARNING: Risk of electric shock. This pump has

not been investigated for use in swimming pool

areas.

11. WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

INSPECTION AND STORAGE

1. Immediately upon receipt of shipment, inspect and

check the shipping document and report to the

Transportation Company’s local agent any damage

or shortage. If the unit is received sometime before

it can be used, it should be inspected, recrated and

stored in a dry location.

2. Unless otherwise specifically agreed, all capacity,

head and efficiency guarantees are based on factory

test when handling clear, cold, fresh water at a

temperature not over 85°F.

LOCATION

IMPORTANT: In installations where property damage

might result from an inoperative or leaking pump due

to power outages, discharge line blockage or any other

reason, a back-up system(s) and/or warning system(s)

should be used.

1. Locate pump as close to the fluid source as possible.

CAUTION: The unit should be placed where the motor

and electrical components are protected from the

weather and extremes of heat, humidity and below

freezing temperatures.

2. Mount unit in a dry location that is easily accessible

for inspection and maintenance. Allow ample

clearance around the unit for free air circulation.

134984

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

1

Page 2

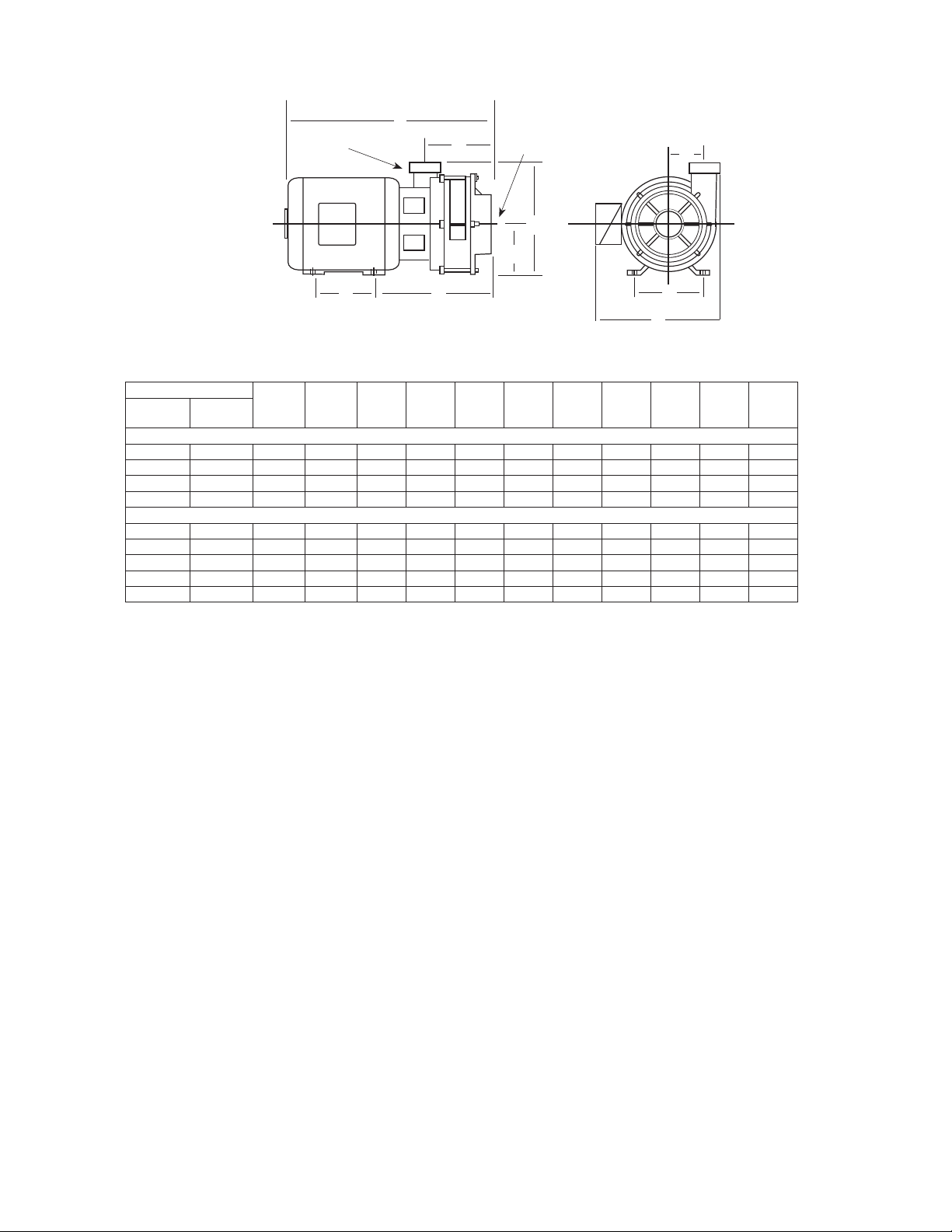

DIMENSIONS in INCHES

J

2” Discharge

F

3” Suction

E

D

K

A C

Figure 1

C22000 SERIES

Catalog Number

1 Phase 3 Phase

C22131 — 3 182JM 4.50 7.50 10.24 4.50 10.81 4.06 12.12 19.49 3.44

— C22133 3 145JM 5.00 5.50 9.49 3.50 9.81 4.06 10.50 17.87 3.44

C22151 — 5 184JM 5.50 7.50 10.24 4.50 10.81 4.06 12.12 20.49 3.44

— C22153 5 182JM 4.50 7.50 10.24 4.50 10.81 4.06 12.12 20.49 3.44

C22231 — 3 182JM 4.50 7.50 12.49 4.50 10.81 6.31 12.12 20.49 3.44

— C22233 3 145JM 5.00 5.50 11. 74 3.50 9.81 6.31 10.50 20.12 3.44

C22251 — 5 184JM 5.50 7.50 12.49 4.50 10.81 6.31 12.12 22.74 3.44

— C22253 5 182JM 4.50 7.50 12.49 4.50 10.81 6.31 12.12 22.74 3.44

— C22273 7-1/2 184JM 5.50 7.50 12.49 4.50 10.81 6.31 12.12 22.74 3.44

Dimensions shown above are approximate maximum dimensions for standard pumps equipped with open drip

proof motors.

HP

Motor

Frame

Size

A B C D E F G J K

SINGLE STAGE 3500 RPM

TWO STAGE 3500 RPM

If a dry location is not available mount it on a

foundation well above the wet floor.

WARNING: Do not handle the pump with wet hands or

when standing in water as fatal electrical shock could

occur. Disconnect main power before handling unit

for ANY REASON!

Pumps incorporate a discharge port on the pump

3.

casing that can be adjusted in 90° increments. If

necessary adjust the discharge port to accommodate

the specific application. Pump performance will not

be affected by the position of the discharge port.

SUCTION LIMITATIONS

1. Units are non self-priming. Normally after being

primed the total suction lift of the pump is 15 feet.

2. Where liquids at or near their boiling points are

being handled, the supply must be located above

the suction, so that the available NPSH will be

greater than that required by the unit.

PIPING

1. Do not use the pump as support to the piping. The

pipe must be independently supported near the

pump so that no strains will be transmitted to the

unit. Failure to do so will cause premature pump

failure and will void the warranty.

2. Suction and discharge sizes are selected for proper

performance of the pumping unit and are not

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

B

G

IL1000

intended to determine the suction and discharge

pipe sizes. Pipe sizes must be determined by the

user based on the system requirements.

3. Install both a union and a gate valve (not furnished)

on the suction and discharge side of the pump for

service convenience.

CAUTION: Do not use a globe or other restricting

type of valve at the discharge. Globe valves seriously

restrict the capacity of the pump.

All joints and connections should have pipe sealing

4.

compound (male threads only) applied and drawn

up tightly.

CAUTION: The entire system must be air and water

tight for efficient operation.

SUCTION PIPING

1. Suction piping should be short in length, as direct

as possible, and never smaller in diameter than the

pump suction opening.

2. Use galvanized piping, rigid plastic or other suitable

pipe that will not collapse under suction.

3. The suction pipe should slope upward to the pump

inlet. A horizontal suction line must have a gradual

rise to the pump. Any high point in the pipe will

become filled with air and thus prevent proper

operation of the pump. When reducing the piping

to the suction opening diameter use an eccentric

2

Page 3

reducer with the eccentric side down to avoid air

IL1001

pockets. Never use a straight taper reducer in a

horizontal suction line, as it tends to form an air

pocket in the top of the reducer and the pipe.

Valves in Suction Piping

1. If the pump is operating under static suction lift

conditions, a foot valve may be installed in the

suction line to avoid the necessity of priming each

time the pump is started.

2. When foot valves are used, or where there are other

possibilities of “liquid hammer”, close the discharge

valve before shutting down the pump.

3. The pump must never be throttled by the use of

a valve on the suction side of the pump. Valves

should be used only to isolate the pump for

maintenance purposes, and should always be

installed in positions to avoid air pockets.

DISCHARGE PIPING

1. On long horizontal runs it is desirable to maintain as

even a grade as possible. Avoid high spots, such as

loops, which will collect air and throttle the system

or lead to erratic pumping.

Valves In Discharge Piping

1. A check valve and gate valve should be installed

in the discharge. The check valve, placed between

the pump and the gate valve, protects the pump

from excessive pressure, and prevents liquid from

running back through the pump in case of power

failure. The gate valve is used in priming and

starting, and when shutting the pump down.

Pressure Gauges

1. Properly sized pressure gauges can be installed

in both the suction and discharge openings in the

gauge taps which are provided. The gauges will

enable the operator to easily observe the operation

of the pump, and also determine if the pump is

operating in conformance with the performance

curve. If cavitation, vapor binding or other unstable

operation should occur, widely fluctuating discharge

pressure will be noted.

ELECTRICAL CONNECTIONS

GROUNDING

1. To reduce the risk of electric shock. The motor must

be securely and adequately grounded to a grounded

metal raceway system or by using a separate

grounding wire connected to bare metal on the

motor frame, or to the grounding screw located

inside motor terminal box, or other suitable means.

Refer to National Electric Code (NEC Article 250

[Grounding]) for additional information.

2. All wiring should be preformed by a qualified

electrician and in accordance with the National

Electric Code, Local Electric Codes and the

Occupational Safety and Health Act (OSHA).

WARNING: Failure to connect the motor frame to

equipment grounding conductor by using green screw

may result in serious electrical shock.

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

WIRING CONNECTIONS

1. This unit is not water proof and is not intended to

be used in showers, saunas, or other potentially

wet locations. The motor is designed to be used

in a clean dry location with access to an adequate

supply of cooling air. Ambient temperature around

the motor should not exceed 104°F (40°C). For

outdoor installations motor must be protected by a

cover that does not block airflow to and around the

motor. This unit is not weatherproof nor is it able to

be submersed in water, or any other liquid.

2. Motor voltages will vary depending upon the motor

horsepower, phase and manufacturer. Refer to the

motor nameplate for voltage and electrical data.

WARNING: Make certain that the power supply

conforms to the electrical specifications of the motor

supplies. Failure to do so may cause premature motor

failure and will void the warranty.

3. For proper electrical connections, refer to the

connection diagram located on the nameplate

or inside the terminal box of the motor. Make

sure connections are correct for the voltage being

supplied to the motor.

4. Whenever possible, the pump should be powered

from a separate branch circuit of adequate capacity

to keep voltage drop to a minimum during starting

and running. For longer runs, increase wire size

in accordance with the Wire Selection Guide. (See

Figures 3 & 4)

Suction Pipe Installed

Increaser

Gate Valve

Check Valve

Figure 2

With Gradual Rise To

Pump Inlet

Pipe

Support

Eccentric

Reducer

Center Line

of Pipe

Level

NOTE: Wire charts are for reference only. Consult

local and state codes for approved wire sizes.

WARNING: Always disconnect power source before

performing any work on or near the motor or its

power source. Failure to do so could result in

personal injury or fatal electrical shock.

3

Page 4

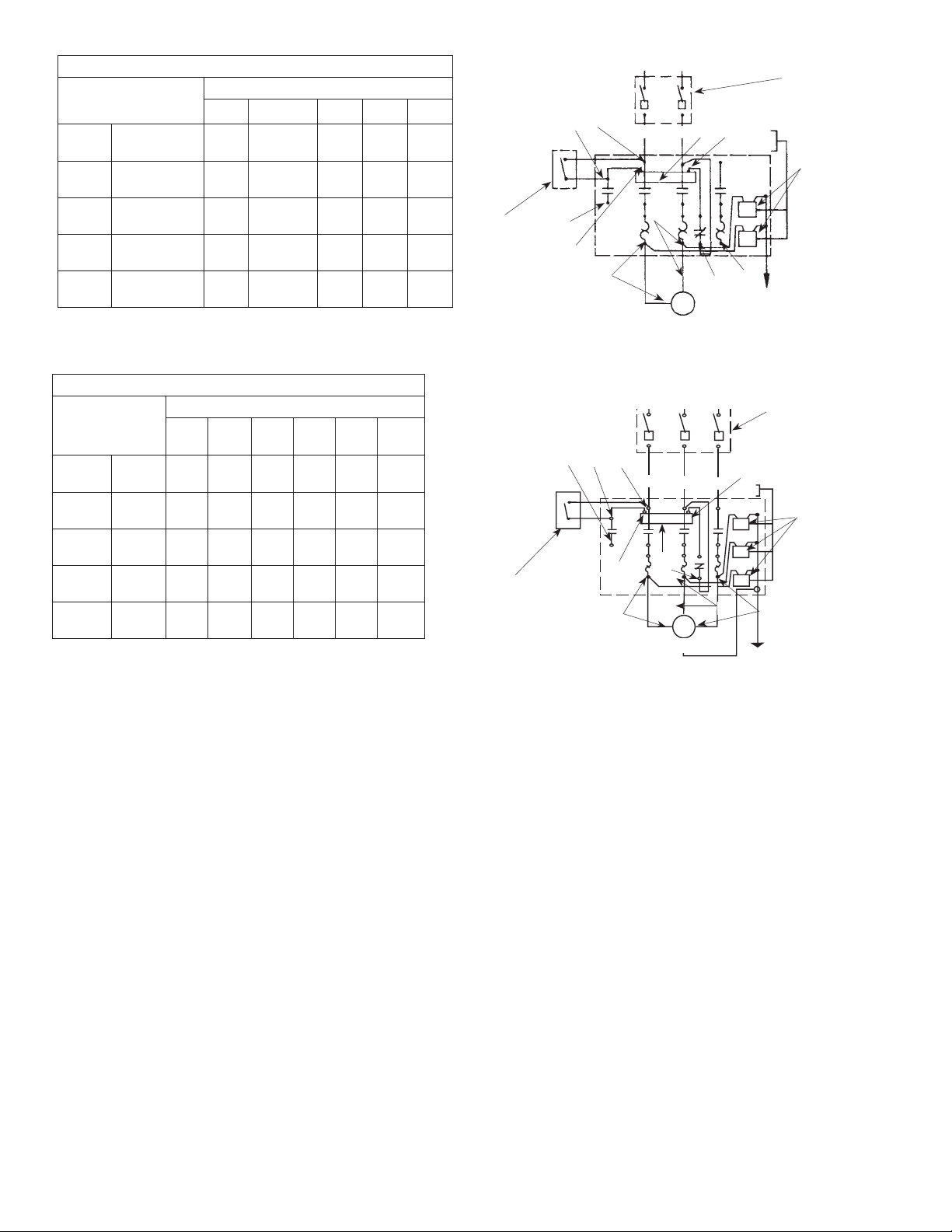

SINGLE PHASE

IL0102

Distance From Motor

To Fuse Box Meter,

or Electrical Outlet

100 ft.

150 ft.

200 ft.

300 ft.

500 ft.

11 5 V

230V

11 5 V

230V

11 5 V

230V

11 5 V

230V

11 5 V

230V

Recommended Copper Wire Size

1HP 1-1/2 HP 2 HP 3 HP 5 HP

10

14

6

12

6

12

*

12

*

10

12

12

10

8

6

6

*

6

*

4

10

10

8

*

8

4

*

8 4

4

*

8

6

*

*

6

4

*

*

4

2

(*) Not economical to run at 115V, use 230V.

Figure 3

THREE PHASE

Distance From

Motor To Fuse

Box Meter, or

Electrical Outlet

100 ft.

150 ft.

200 ft.

300 ft.

500 ft.

230V

460V14141212121212121012812

230V

460V1414121212121012812612

230V

460V1414121212121012812612

230V

460V121412121012812610

230V

460V10141012812610

Recommended Copper Wire Size

1-1/2

1HP

2 HP 3 HP 5 HP

HP

7-1/2

HP

4

10

4

2

8

8

Figure 4

MOTOR PROTECTION

WARNING: Never examine, make wiring changes

or touch the motor before disconnecting the main

electrical supply switch.

Motors may or may not have built-in thermal

1.

overload protection depending upon the

horsepower size, phase, type and motor

manufacturer. Refer to the motor nameplate for

overload protection information. It is recommended

that a properly sized magnetic or manual starter

(both with properly sized heaters) be used with all

motors. Install starters following instructions of the

starter manufacturer. See Figure 5 & 6 for magnetic

starter wiring diagram.

2. All motors (single and three phase) should be

equipped with a correctly fused disconnect switch

to provide protection. Consult Local or National

Electrical Codes for proper fuse protection based on

motor nameplate.

3. Undersize wiring can cause motor failure (low

voltage), frequent cut-out of motor overload

protector, television interference and even fire.

Make certain the wiring is adequately sized (Figure

3 & 4), well insulated and connected to a separate

circuit outside the building in case of fire.

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

Magnetic Starter Wiring

Diagram - Single Phase

1

-

3

L1

L2

W

M

6

-

4

-

Pressure

Switch

2

V

T2

Fused

Disconnect

Switch

Lightning

Arrestors

2

-

0

Warning: Connect

motor leads

momentarily for

correct rotation

T1

#10 Or Heavier Copper Ground Wire,

Connect To 8 ft. Ground Rod Or Well Casing

X2

Motor

T3

Figure 5

2

Pressure Switch

Magnetic Starter Wiring

Diagram - Three Phase

3

1

L1

L2

M

V

X2

T1

T2

Motor

#10 Or Heavier Copper Ground Wire,

Connect To 8 ft. Ground Rod Or Well Casing

L3

T2

Fused Disconnect

Switch

W

Lightning

Arrestors

T3

Figure 6

OPERATION

PRIOR TO STARTING

1. Before the pump is started initially, make the

following inspections:

• Check Rotation - Be sure that the pump operates in

the direction indicated by the arrow on the pump

casing, as serious damage can result if the pump

is operated with incorrect rotation. Rotation is

always counterclockwise facing the pump suction.

Operating the pump in reverse rotation may cause

extensive damage.

• Check all connections to motor and starting device

with wiring diagram. Check voltage, phase and

frequency on motor nameplate with line circuit.

ALL PUMPS WITH 3 PHASE MOTORS MUST BE

INSTALLED WITH A MAGNETIC STARTER WHICH

PROVIDES 3-LEG PROTECTION FOR MOTOR.

FAILURE TO USE CORRECT STARTER WILL VOID THE

WARRANTY.

PRIMING

1. Before starting any centrifugal pump it is absolutely

necessary that both the casing and suction pipe be

4

Page 5

completely filled with liquid. This priming can be

accomplished by any of the following methods.

2. When the liquid supply level is above the center

line of the pump, it is primed by opening the

suction and discharge valves. The inflowing liquid

will displace the air and fill the suction line, pump

casing, and discharge line up to the level of supply.

3. Where the pump is operating with suction lift and

the suction line is equipped with a foot valve, the

system is filled with liquid by filling through the

discharge piping.

STARTING

1. Follow the steps below in the order indicated to start

pump:

• Close gate valve in discharge line.

• Open gate valve in suction line.

• Turn on power to pump motor.

2. When pump is operating at full speed, immediately

open the discharge gate valve slowly.

3. If the pump does not prime properly, or loses it

prime during start-up it should be shut-down and

the condition corrected before the procedure is

repeated.

NOTE: The gate valve in the discharge line should

always be closed when the pumps is started. The

excessive current required by the motor to start under

full load will in time cause motor trouble. A centrifugal

pump primed and operated at full speed with the

discharge gate valve closed usually requires much less

power than when it is operating at its rated capacity

and head with the discharge gate valve open.

OPERATING CHECKS

1. After initial start-up:

• Check the pump and piping to assure there are no

leaks.

• Check and record pressure gauge readings for

future reference.

• Check and record voltage, amperage per phase.

STOPPING PUMP

1. When stopping pump always close the discharge

valve first.

2. Pump should never run for any length of time with

both suction and discharge valves closed due to

danger of building up pressures and temperatures.

MAINTENANCE

LUBRICATION

1. The pump and motor requires no lubrication. The

ball bearings of the motor have been greased at the

factory. Under normal operating conditions they

should require no further greasing.

FREEZING

1. Drain the entire system if there is danger of freezing.

A drain plug is provided at the bottom of the pump

case for this purpose.

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

ROTARY SHAFT SEAL

1. The mechanical shaft seal should be replaced if

water is noticed around the motor shaft. Remove

case and impeller and, using two screw drivers to

pry on each side, remove seal stationary seat. Clean

seat area of frame, install new stationary seat with

ceramic surface facing out and slide new rotating

element over shaft sleeve with hard carbon surface

against ceramic seat. Be sure to keep all surfaces

clean. Lubricating seal parts with water will help the

installation of the seal. Reinstall impeller and pump

case.

CAUTION: Make certain that the power supply is

disconnected before attempting to service the unit!

Failure to do so could result in personal injury or fatal

electrical shock.

MOTOR

1. Keep motor clean and dry. It is drip-proof when

installed horizontally and the windings are protected

from excess humidity, but extreme conditions

should be avoided when possible. If motor fails to

run, be sure power is on, all switches or electrical

controls are closed, fuses are in order and all

electrical connection are tight. (Motor must be

repaired by Authorized Repair Station under terms

of guarantee.)

FAILURE TO PUMP

1. If the motor runs, but no water is pumped, be

sure pump is primed, that there are no air leaks in

suction piping, that all gate valves are open and all

check valves operate.

NET POSITIVE SUCTION HEAD (NPSH)

1. NPSH combines all of the factors limiting the

suction side of a pump; internal pump losses,

static suction lift, friction losses, vapor pressure

and atmospheric conditions. It is important

to differentiate between REQUIRED NPSH and

AVAILABLE NPSH.

NPSH REQUIRED

1. REQUIRED NPSH is a factor designed into a pump

and measurable in the test laboratory by the

manufacturer. Testing facilities can determine losses

in the suction piping, static lift and barometric

pressures.

NPSH AVAILABLE

1. The term for providing sufficient pressure on the

suction, at the impeller eye, to prevent “boiling”

is known as NPSH AVAILABLE. It is a function of

the pumping system and consists of pressure on

the liquid at its source, the elevation of the liquid

with respect to the impeller centerline, losses in the

suction piping and vapor pressure of the liquid.

2. If the available NPSH is not equal to, or greater than

that required by the pump, it must be increased.

This is usually done by increasing the static head,

Hz.

5

Page 6

NPSH FORMULAS

PROPOSED INSTALLATION

1. To calculate the NPSH available in a proposed

application, the following formula is recommended:

Hsv = Hp ± Hz - Hf - Hvp

2. Hsv-Available NPSH expressed in feet of fluid

3. Hp-Absolute pressure on the surface of the liquid

where the pump tanks suction, expressed in feet.

This could be atmospheric pressure or vessel

pressure (pressurized tank).

4. Hz-Static elevation of the liquid above, or below the

centerline of the impeller, expressed in feet.

5. Hf-Friction and entrance head loss in the suction

piping, expressed in feet.

6. Hvp-Absolute vapor pressure of the fluid at the

pumping temperature, expressed in feet of fluid.

PROPERTIES OF WATER

Temperature

ºF

60 0.26 0.59 0.999

85 0.60 1.4 0.996

100 0.95 2.2 0.993

120 1.69 3.9 0.989

130 2.22 5.0 0.986

140 2.89 6.8 0.983

150 3.72 8.8 0.981

160 4.74 11. 2 0.977

170 5.99 14.2 0.974

180 7.51 1 7. 8 0.970

185 8.38 20.0 0.969

190 9.34 22.3 0.966

195 10.38 24.9 0.964

200 11.53 27.6 0.963

202 12.01 28.8 0.962

204 12.51 30.0 0.961

206 13.03 31.2 0.960

208 13.57 32.6 0.960

210 14.12 33.9 0.959

212 14.70 35.4 0.958

214 15.29 37.0 0.957

216 15.90 38.4 0.956

218 16.54 40.0 0.956

220 1 7. 1 9 41.6 0.955

222 17.86 43.3 0.954

224 18.56 45.0 0.953

226 19.28 46.8 0.953

228 20.02 48.6 0.952

230 20.78 50.5 0.951

240 24.97 61.0 0.947

250 29.83 73.2 0.943

300 67.00 168.6 0.918

350 134.60 349.0 0.891

Absolute Vapor

Pressure

PSI Ft. Water

Specific

Gravity

6

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

Altitude

(Feet)

-1000 31.0 15.2 32.5 213.8

-500 30.5 15.0 34.6 212.9

0.0 29.9 14.7 33.9 212.0

+500 29.4 14.4 33.3 211.1

+1000 28.9 14.2 32.8 210.2

+1500 28.3 13.9 32.1 209.3

+2000 27.8 13.7 31.5 208.4

+2500 27.3 13.4 31.0 207.4

+3000 26.8 13.2 30.4 206.5

+3500 26.3 12.9 29.8 205.6

+4000 25.8 12.7 29.2 204.7

+4500 25.4 12.4 28.8 203.8

+5000 24.9 12.2 28.2 202.9

+5500 24.4 12.0 27.6 201.9

+6000 24.0 11. 8 27.2 201.0

+6500 23.5 11.5 26.7 200.1

+7000 23.1 11. 3 26.2 199.2

+7500 22.7 11.1 25.7 198.3

+8000 22.2 10.9 25.2 197.4

+8500 21.8 10.7 24.7 169.5

+9000 21.4 10.5 24.3 165.5

+9500 21.0 10.3 23.8 194.6

+10000 20.6 10.1 23.4 193.7

+15000 16.9 8.3 19.2 184.0

Barometer

Inches

Mercury

Atmospheric

Pressure

PSIA (ft. water)

Boiling

Point ºF

Page 7

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Low or no discharge 1. Incorrect rotation 1. Refer to wiring diagram

2. Insufficient inlet pressure or suction head

(NPSH Required)

3. Total head too high 3. Lower discharge head

4. Leak in suction line 4. Repair or replace

5. Impeller clogged or damaged 5. Clean or replace

6. Wrong size piping 6. Make needed adjustments

7. Casing gasket leaking 7. Replace gasket

8. Suction or discharge line valves closed 8. Open

9. Mechanical seal leaking 9. Replace

Loss of suction 1. Insufficient inlet ressure or suction head

(NPSH Required)

2. Clogged strainer 2. Clean or replace

2. Increase inlet pressure by adding more fluid to fluid

source. (See Spec’s for minimum NPSH Required)

1. Increase inlet pressure by adding more fluid to fluid

source. (See Spec’s for minimum NPSH Required)

Pump vibrates and/or

makes excessive noise

Pump leaks at shaft 1. Damaged or worn mechanical seal 1. Replace

Pump will not start or

run

Motor problems 1. Various 1. Consult qualified electrician

Pinholes in the casting.

Liquid dripsp around

seal area but is not seal

1. Mounting plate or foundation not rigid

enough

2. Foreign material in pump 2. Clean

3. Damaged impeller 3. Replace

4. Cavitation present 4. Check suction line for proper size and be sure valve is

2. Corrosion due to character of liquid

pumped

1. Improperly wired 1. Refer to wiring diagram

2. Blown fuse or open circuit breaker 2. Replace fuse or close circuit breaker

3. Loose or broken wiring 3. Tighten connections and replace broken wiring

4. Impeller clogged 4. Clean

5. Motor shorted out 5. Replace

2. Overloading motor. Too much water

delivery

3. Liquid heavier and more viscous than

water

4. Seal binding 4. Replace

5. Rotor binding 5. Repair or replace

6. Voltage and frequency lower than rating 6. Reconnect to rated voltage and frequency

7. Defects in motor 7. Repair or replace

1. Cavitation caused by insufficient

inlet pressure or suction head (NPSH

Required)

1. Reinforce

open. Remove excessive loops in suction line. (See Spec’s

for minimum NPSH Required)

2. Discontinue pumping liquid and consult factory

2. Restrict outlet by closing down valve in discharge line

3. Consult factory

1. Increase inlet pressure by adding a higher level of fluid

to source or increasing inlet pressure. (See Spec’s for

minimum NPSH Required)

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

7

Page 8

CENTRIFUGAL PUMP REPAIR PARTS

“C22000” SERIES

(For Pricing Refer To Repair Parts Price List)

1

15

2

3

8

4

9

PAGE 4-5A REPAIR PARTS

10

11

13

FORM NO. FW0043

SUPERSEDES 1007

8

0309

14

Qty.

021434 Repair Kit

Kit Includes:

Item

Part No. & Description

No.

Two Stage

2

1

4

3

12

5

8

6

1 3 136559 Seal Assembly

1

•

1

1

2

136576 O-Ring, Cap Screw

•

136572 O-Ring, Impeller

•

136569 O-Ring, Impeller

8

124638 Gasket

15

Single Stage

7

IL0200

Product may not be exactly as shown.

ITEM HORSEPOWER 3 5 3 5 7-1/2

STAGE 1 1 2 2 2

SINGLE PHASE C22131 C22151 C22231 C22251 —

THREE PHASE C22133 C22153 C22233 C22253 C22273

DESCRIPTION PART NUMBER

1

Motor — 1 Phase

1

Motor — 3 Phase

2

Mounting Ring

3

Seal Assembly

•

Key 3/16 x 27/32”

•

Key 3/16 x 2-1/32”

4

Impeller

•

O-Ring, Impeller

5

Retainer, Impeller

6

Cap Screw 1” Long

•

O-Ring, Cap Screw

7

Lock Washer 3/8” S.S.

8

Gasket

9

Intermediate Stage w/Clearance Ring

•

Clearance Ring - Large

•

Clearance Ring - Small

10

Impeller (Front)

11

Retainer, Impeller

•

O-Ring, Impeller

12

Cap Screws 2-1/4” Long

•

O-Ring, Cap Screw

13

Lock Washer 3/8” S.S.

14

Suction Flange Assembly w/Clearance Ring

•

Clearance Ring

•

Pipe Plug 1/4” NPT

15

Hex Hd. Cap Screws 3/8 x 1”

16

Hex Hd. Cap Screws 3/8 x 1-1/4”

17

(*) Standard hardware item

(•) Notshown

Hex Hd. Cap Screws 3/8 x 3-1/4”

134962

134965

136556

136559

136560

—

136561

136569

136570

136573

136576

120649

124638 (1)

—

—

—

—

—

—

—

—

—

023089

125176

* (4)

* (4)

* (6)

—

124638 (1)

8

134963

134966

136556

136559

136560

—

136562

136569

136570

136573

136576

120649

—

—

—

—

—

—

—

—

—

023089

125176

* (4)

* (4)

* (6)

—

134962

134965

136556

136559

—

134977

136563

136569

—

—

—

—

124638 (2)

136578

125176

136577

136564

136571

136572

136575

136576

120649

023089

125176

* (5)

* (4)

—

* (6)

134963

134966

136556

136559

—

134977

136565

136569

—

—

—

—

124638 (2)

136578

125176

136577

136566

136571

136572

136575

136576

120649

023089

125176

* (5)

* (4)

—

* (6)

95 North Oak Street • Kendallville, IN 46755

Copyright 2011. All Rights Reserved.

17

14

16

—

134967

136556

136559

—

134977

136567

136569

—

—

—

—

124638 (2)

136578

125176

136577

136568

136571

136572

136575

136576

120649

023089

125176

* (5)

* (4)

—

* (6)

Loading...

Loading...