Page 1

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL

CBW10, CBW10D, CBW20, CBW20D

CCF10, CCF10D, CCF20, CCF20D

(Addendum Included)

AUTOMATIC WATER

PP0131

0611

Supersedes

0610

FILTERS

SPECIFICATION TABLE

Units

Cont. GPM 3 3 5 5

Service Flow

Pipe Size In/Out - Inches 1” 1” 1” 1”

Operating Pressure Range PSI 30 - 125 30 - 125 30 - 125 30 - 125

Max Operating Temperature Degrees F 110 110 110 110

Mineral Tank Size (Dia. x Ht.)

Shipping Weight Lbs. 47.5 137 57.5 235

Overall Height Inches 52 52 60 60

Drain Flow During Regeneration

NOTE:

(1)

Pressure drop not to exceed 15 psi.

(2)

Product materials and workmanship are protected with a written warranty.

(3)

Untreated water provided during all steps of regeneration.

(1)

Peak GPM 8 8 10 10

(2)

(3)

Inches 10 x 44 10 x 44 12 x 52 12 x 52

GPM 5.3 6.5 7.5 7.5

CBW10,

CBW10D

CCF10,

CCF10D

CBW20,

CBW20D

CCF20,

CCF20D

FILL IN FOR FUTURE REFERENCE

MODEL NO:___________________________________________

DATE INSTALLED:______________________________________

DEALER:______________________________________________

023367

Page 2

remier

IL1037

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Connection to sanitary sewer line

(optional)

Sanitary sewer line

Maximum drain pipe

Air gap device

elevation above drain

port is 5 ft.

Drain

Automatic Water Filters

Sanitary Drain, Floor Drain or

Laundry Tubs are acceptable.

Do not make a direct connection

to the drain. An air gap must

Drain line 1/2” ID diameter

minimum size

be present.

Drain Trap

Cold filtered water inlet

30 p.s.i. minimum pressure

1” minimum pipe size

High Pressure Warning:

If feedwater pressure is known to be above

125 psi, it is strongly recommended that a

pressure reducing valve be installed at this point.

Manual Bypass Valve

(Normally Closed)

(optional)

Manual Inlet Valve

Drain Port

(optional)

Typical Water CBW Installation

Assembly

Filter Tank

Unfiltered water to Sprinklers and any

dersired unfiltered fixtures

Ground Strap

Filter Water Outlet

Manual Outlet Valve

(optional)

110-125 Volt

Continuous Power Supply

Transformer

2

Page 3

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Filters

INSTALLATION FITTING ASSEMBLIES

Installation fittings connect to the control valve or the

bypass valve using nuts that only require hand tightening.

Hand tight nut connections between control valve and

installation fittings, control valve and bypass valve, and

bypass valve and installation fittings allow for ease

serviceability. Do not use a pipe wrench to tighten nuts

on installation fittings. Hand tighten only.

Split ring retainer design holds the nut on and allows load

to be spread over the entire nut surface area reducing the

chance for leakage. The split ring design, incorporated

into the installation fittings allows approximately 2

degrees off axis alignment to the plumbing system. The

installation fittings are designed to accommodate minor

plumbing misalignments but are not designed to support

the weight of a system or the plumbing.

When assembling the installation fitting package,

connect the fitting to the plumbing system first and then

attach the nut, split ring and o-ring. Heat from soldering

or solvent cements may damage the nut, split ring or

o-ring. Solder joints should be cool and solvent cements

should be set before installing the nut, split ring and

o-ring. Avoid getting primer and solvent cements on any

part of the o-rings or split rings, bypass valve or control

valve. Solvent cements and primers should be used in

accordance with the manufacturer’s instructions.

Slip the nut onto the fitting first, then the split ring

second and the o-ring last. hand tighten the nut. If the

fitting is leaking, tightening the nut will not stop the

leak. Remove the nut, remove the fitting, and check for

damage or misalignment of the o-ring.

Do not use pipe dope or other sealant on threads. Teflon

tape must be used on the threads of the 1” connection

and on the threads for the drain line connection. Teflon

tape is not necessary on the nut connection or caps

because of o-ring seals.

Do not use Vaseline, oils or other unacceptable lubricants

on o-rings. A silicon lubricant may be used on black

o-rings.

BYPASS VALVE

The bypass valve easily connects to the control valve

body using nuts that only require hand tightening. Hand

tighten nut connections between control valve and

fittings, control valve and bypass valve, and bypass valve

and installation fittings allow for easy serviceability. The

split ring retainer design holds the nut on and allows load

to be spread over the entire nut surface area reducing the

chance for leakage. The split ring design, incorporated

into the bypass, allows approximately 2 degrees off axis

alignment to the plumbing system. The bypass is designed

to accommodate minor plumbing misalignments but is

not designed to support the weight of a system or the

plumbing.

Avoid getting primer and solvent cements on any part

of the o-rings or split rings, bypass valve or control valve.

Do not use pipe dope or other sealant on threads. Teflon

tape is not necessary on the caps because of o-ring seals.

Do not use Vaseline, oil or other unacceptable lubricants

on o-rings. A silicon lubricant may be used on black

o-rings.

A. GENERAL

1. Shut off all water at main supply valve.

2. Shut off the fuel supply to water heater.

3. Open faucets (hot and cold) nearest pump or water

meter to relieve pressure and drain system.

4. Move filter into the installation position. Loosely

attach all fittings to measure for bypass valve

assembly (if used), or manual bypass valve.

5. Level the unit. (Do Not use metal shims.)

6. Cut the cold water supply line as required.

7. Install the bypass valve assembly if used.

B. PLANNING INSTALLATION

1. All installation procedures must conform to local

plumbing, electrical and sanitation codes and

ordinances.

2. It is recommended that outside faucets for lawn

service be on the hard water line, ahead of the filter,

to conserve filtered water.

3. If this isn’t practical, use the convenient integral

bypass valve assembly.

CAUTION: The inlet water temperature MUST NOT

exceed 120° F.

4. Do not locate filter where ambient temperature

drops below 40° F.

5. Allow space around the filter for ease of servicing.

6. The filter drain lines must never be solidly connected

to the sewer line. (Always provide an air gap at the

END of the drain line). Valve drain line must not be

elevated over 5’ from the top of the filter on well

systems, and not over 8’ on municipal water systems.

7. Move the filter into position and connect to bypass

assembly (if used). The integral manual bypass option

is a connection which eliminates the need for a

3-valve manifold. This makes installation easier and

provides a more convenient method of bypassing.

8. IMPORTANT: Be sure that the water inlet line is

connected to the “inlet” side of the bypass valve or

to the inlet fitting. (Bypass valve both inlet/outlet

fittings are marked.) If water lines are reverse, (inlet/

outlet) filter mineral may be forced from the water

filter into the household plumbing system. If this

3

Page 4

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Filters

occurs, household plumbing system must be flushed

clean.

C. CONNECT ALL FITTINGS

(refer to previous page)

CAUTION: Care must be used when working with copper

tubing. Do not allow the flame from torch to contact any

portion of the Valve assembly.

1. Attach 3/4” drain line to drain elbow with insert and

nut.

2. Do not elevate the drain line over 5’ above the top of

the valve (8’ on municipal systems) or to exceed 25’ in

length at either height.

CAUTION: An air gap must be provided upon sewer

entry. (Conform to local plumbing and sanitation

codes and ordinances).

1. Media was shipped boxed under media tank.

Carefully unscrew control valve. Be sure to “plug” the

top of the distributor tube using tape or some other

means. Do not allow filter media to enter inside of

distributor tube. (See Fig. 3)

2. Pour the separately boxed media into media tank.

3. Lubricate o-rings on control valve with silicone

lubricant. DO NOT USE PETROLEUM JELLY.

4. Lubricate bypass valve o-rings with silicone lubricant

and secure to the control valve using adapter

couplings, clips and screws.

5. Cut main supply line as required to fit plumbing to

the inlet and outlet of bypass valve. Make certain

water flow enters through the Inlet and discharges

through the Outlet of the bypass valve.

6. Attach drain line to drain line fitting. Position drain

line over drain and secure firmly. To prevent back

siphoning, be sure to have adequate air gap of at

least 2 inches.

7. Make certain bypass valve is in the “bypass” position.

Turn on power to well pump or open main supply

valve completely.

8. Plug control valve into a non-switched 115v power

source.

9. Manually stage filter to the backwash position (see

service manual).

10. Open inlet valve and allow the unit to fill SLOWLY.

This will allow air to escape from the media tank.

Once water continually flows to drain, open both

inlet and outlet valves fully.

11. Check for leaks and allow filter to backwash for at

least 10 minutes or until water flowing from drain

runs clear.

12. Allow unit to fully regenerate (see service manual).

13. Models CBW10D, CBW20D, CCF10D and CCF20D have

a dome hole/plug located in the upper dome of the

mineral tank. This is used to replenish mineral as

required. DO NOT remove dome hole plug without

first depressurizing the tank.

Dome Hole (”D” suffix models only)

Distributor Tube

Media Tank

Filter Media

Gravel - preinstalled

INSPECTION AND HANDLING YOUR FILTER

Be sure to inspect the equipment for shipping damage

and notify the transportation company if damage exists.

Handle the filter with care, as damage can result if

dropped or if the filter is set on a sharp object.

CONDUCT A THOROUGH WATER TEST

Your water should have a thorough analysis prior to the

selection of water conditioning equipment. Enter your

analysis below:

WATER ANALYSIS

IRON (fe) __________ ppm

Manganese (Mn) __________ ppm

pH __________

Tannins __________ ppm

Hydrogen Sulfide (H2S) __________ ppm

NOTE: Hydrogen Sulfide must be tested at the well site.

Failure to conduct an “on site” analysis will result in

inaccurate test results.

LOCATING EQUIPMENT CORRECTLY

The location of your filter should be selected carefully. A

variety of conditions will contribute to proper location as

follows:

1. Locate as close as possible to the source of water

supply.

2. Locate as close as possible to drain, i.e. laundry tub or

floor drain.

4

Page 5

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Filters

3. Locate in correct relationship to other water

treatment equipment (See Figure 1).

4. Allow sufficient area around the equipment for

service.

FACTS TO REMEMBER WHILE PLANNING

YOUR INSTALLATION

1. All installation procedures MUST conform to local and

state plumbing codes.

2. If lawn sprinkling, a swimming pool or geothermal

heating/cooling are to be treated by the Chemical

Free filter, a larger model filter MUST be selected to

accommodate the higher flow rate demands.

3. IMPORTANT: Always use Teflon tape on threaded

plastic fittings. NEVER use pipe dope, as it will

deteriorate the plastic fittings.

CHECK WATER PRESSURE

Minimum water pressure required at the inlet of the

filter is 20 psi. IF PRESSURE IS OVER 100 PSI, A PRESSURE

REGULATING VALVE MUST BE INSTALLED TO REDUCE

WATER PRESSURE.

NOTE: Pressure regulating valve must be installed in

water line ahead of the air induction assembly.

CHECK PUMPING RATE OF WELL PUMP

The pumping rate of your well pump must be sufficient

to properly backwash the filter. Check backwash flow rate

required for specific filter model.

Water Pressure Low _____ psi

High _____ psi

Pumping Rate _________ GPM

FILTERED

SOFT WATER

FILTERED WATER

WATER

SOFTE NER

WATER

FILTER

PRESSURE

TANK

PRESSURE

SWITCH

WELL WATE R

FROM PUMP

IL1039

Figure 1 - Standard Installation

5

Page 6

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Addendum for CCF Series

Automatic Water Filters Only

BEFORE INSTALLING YOUR FILTER

INSPECTION AND HANDLING YOUR FILTER

Be sure to inspect the equipment for shipping damage

and notify the transportation company if damage exists.

Handle the filter with care, as damage can result if

dropped or if the filter is set on a sharp object.

CONDUCT A THOROUGH WATER TEST

Your water should have a thorough analysis prior to the

selection of water conditioning equipment. Enter your

analysis below:

WATER ANALYSIS

IRON (fe) __________ ppm

Manganese (Mn) __________ ppm

pH __________

Tannins __________ ppm

Hydrogen Sulfide (H2S) __________ ppm

NOTE: Hydrogen Sulfide must be tested at the well site.

Failure to conduct an “on site” analysis will result in

inaccurate test results.

LOCATING EQUIPMENT CORRECTLY

The location of your filter should be selected carefully. A

variety of conditions will contribute to proper location as

follows:

1. Locate as close as possible to the source of water

supply.

2. Locate as close as possible to drain, i.e. laundry tub or

floor drain.

3. Locate in correct relationship to other water

treatment equipment (See Figure 1).

4. Allow sufficient area around the equipment for

service.

4. IMPORTANT: Always use Teflon tape on threaded

plastic fittings. NEVER use pipe dope, as it will

deteriorate the plastic fittings.

CHECK WATER PRESSURE

Minimum water pressure required at the inlet of the

filter is 30 psi. IF PRESSURE IS OVER 125 PSI, A PRESSURE

REGULATING VALVE MUST E INSTALLED TO REDUCE

WATER PRESSURE.

NOTE: Pressure regulating valve must be installed in

water line ahead of the air induction assembly.

CHECK PUMPING RATE OF WELL PUMP

The pumping rate of your well pump must be sufficient

to properly backwash the filter. Check backwash flow rate

required for specific filter model.

Water Pressure Low _____ PSI

High _____ PSI

Pumping Rate _________ GPM

INSTALLATION

INSTALLING THE AIR INDUCTION ASSEMBLY

1. Shut off all water at the main supply. On a private

well system, turn off power to the pump and drain

pressure tank. Make sure pressure is relieved from

complete system by opening nearest faucet to drain

system. SHUT OFF FUEL SUPPLY TO WATER HEATER.

2. Cut main supply line as required to fit air induction

assembly in plumbing between well pump and

pressure tank. Air induction assembly may be installed

in a vertical or horizontal position. Position air

induction assembly so that the flow adjusting screw

is accessible for adjustment by screwdriver. Install

unions to facilitate air induction assembly removal

and inspection. Be certain the Flow Arrow on air

induction assembly points toward the pressure tank

FACTS TO REMEMBER WHILE

PLANNING YOUR INSTALLATION

1. All installation procedures MUST conform

to local and state plumbing codes.

2. All water MUST pass through the air

induction assembly, pressure tank and

the Chemical-Free Iron Filter (See Figure

1)

3. If lawn sprinkling, a swimming pool or

geothermal heating/cooling are to be

treated by the Chemical Free filter, a

larger model filter MUST be selected

to accommodate the higher flow rate

demands.

IRON FREE

SOFT WATER

IRON FREE WATER

WATER

SOFTENER

Figure 1 - Standard Installation

WATER

FILTER

PRESSURE

TANK

PRESSURE

SWITCH

AIR INDUCTION

ASSEMBLY

WELL WATER

FROM PUMP

IL1040

6

Page 7

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Addendum for CCF Series

Automatic Water Filters Only

and pressure control switch is located on pressure

tank side of the air induction assembly (See Figure

2). Allow 8” of straight pipe on both sides of air

induction assembly.

SUCTION

PORT

FLOW A DJUSTIN G SCRE W

WATER FLOW WATER FLOW

IL1041

Figure 2 - Air Induction Assembly

INSTALLING THE FILTER

1. Media was shipped separately. Carefully unscrew

the control valve. Be sure to “plug” the top of the

distributor tube using tape or some other means. Do

not allow filter media to enter inside of distributor

tube (See Figure 3).

Dome Hole (”D” suffix models only)

Distributor Tube

Media Tank

Filter Media

Gravel - preinstalled

Figure 3 - Media Tank Cutaway

2. Pour the separately shipped media into media tank.

3. Replace control valve on media tank. Lubricate

o-rings on control valve with silicone lubricant. DO

NOT USE PETROLEUM JELLY.

4. Lubricate bypass valve o-rings with silicone lubricant

and secure to the control valve using adapter

couplings, clips and screws.

5. Cut main supply line as required to fit plumbing to

the inlet and outlet of bypass valve. Make certain

water flow enters through the Inlet and discharges

through the Outlet of bypass valve.

6. Attach drain line to drain line fitting. Position drain

line over drain and secure firmly. To prevent back

siphoning, be sure to have adequate air gap of at

least 2 inches.

7. Make certain bypass valve is in the “bypass” position.

Turn on power to well pump or open main supply

valve completely.

8. Plug control valve into a non-switched 115V power

source.

9. Manually stage filter to the backwash position (see

service manual).

10. Open inlet valve and allow the unit to fill SLOWLY.

This will allow air to escape from the media tank.

Once water continually flows to drain, open both

inlet and outlet valves fully.

11. Check for leaks and allow filter to backwash for at

least 10 minutes, or until water flowing from drain

runs clear.

12. Allow unit to fully regenerate (see service manual).

13. Models CCF10D and CCF20D have a dome hole/plug

located in the upper dome of the mineral tank. This

is used to replenish mineral as required. DO NOT

remove dome hole plug without first depressurizing

the tank.

ADJUSTING THE AIR INDUCTION ASSEMBLY

1. Open nearest faucet until pump starts, then close

faucet.

2. Place finger lightly over SUCTION PORT (See figure 2).

A slight suction should be detected for approximately

ONE-THIRD of pumping cycle. (Do not confuse with

one-third of PRESSURE RANGE).

3. If suction duration is too short, increase by turning

FLOW ADJUSTING SCREW CLOCKWISE. To decrease

duration, turn COUNTER CLOCKWISE.

4. Repeat steps 1 through 3 until proper setting is

obtained.

NOTE: When the duration of the suction is too long, cold

water may have a “milky” appearance caused by excess

air in the system. Correct this condition by reducing the

duration of suction. This condition is commonly associated

with bladder type pressure tanks In extreme cases where

elimination of excess air prevents system from performing

satisfactorily, it may be necessary to install a standard airto-water type pressure tank with an air relief valve.

SUCTION

PORT

FLOW A DJUSTIN G SCRE W

WATER FLOW WATER FLOW

IL1041

Figure 2

7

Page 8

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Filters

D. PRESSURE TEST THE INSTALLATION

The plumbing system can now be checked for any

possible leaks

1. Open the water supply inlet valve very slowly. Once

the mineral tank is full of water, slowly open the

outlet on the bypass. Open a faucet down stream

from the filter & allow the air to escape. DO NOT

INITIATE A BACKWASH UNTIL MEDIA IS SATURATED.

2. Allow water to run until clear. CHECK FOR LEAKS!

3. Plug the unit in.

4. Make sure the power cord is plugged into a properly

grounded wall receptacle.

E. PROGRAMMING THE CONTROL VALVE

How To Set Time Of Day

The user can set the time of day. Time of day should only

need to be set initially, and after extended power outages

or when daylight saving time begins or ends and at the

time of start-up. If an extended power outage occurs, the

time of day will flash on and off which indicates the time

of day should be reset.

SET

HOUR

STEP 1U - press

.

STEP 2U - Current Time (hour):

Set the hour of the day using

buttons. AM/PM toggles

or

after 12.

STEP 3U - press

SET

HOUR

button to

complete and return to display

mode.

MIN. FILL

MIN. FILL

REGEN

REGEN

HOUR

REGEN

REGEN

HOUR

SET

HOUR

SET

HOUR

3

3

TIME-HOUR

PM

DAY S TO

REGEN

IL1075

TIME-HOUR

PM

DAY S TO

REGEN

IL1075

How To Change Time of Backwash and Days

Between Backwashes

STEP 1 - From normal mode,

press

simultaneously for 3 seconds and

release.

STEP 1A - Backwash Time:

Set the clock to the hour the

backwash should occur by using the

buttons. An arrow will point to p.m. after 12 (factory

default is 1 a.m.). Press

SET

HOUR

&

buttons

HOUR

SET

REGEN

MIN. FILL

REGEN

HOUR

SET

HOUR

and

to go to step 1B.

3

OR

TIME-HOUR

PM

DAY S TO

REGEN

IL1074

STEP 1B - Setting Days Between Backwash:

Use the

backwashes (factory default is 3 days).

Press

and buttons to set the days between

SET

HOUR

to return to Normal mode.

Backwash Mode

Typically a system is set to backwash at a time of low

water usage. An example of a time with low water usage

is when a household is asleep. If there is a demand for

water when the system is backwashing, untreated water

will be used.

When the system begins to backwash, the display will

change to include information about the step of the

backwash process. The system runs through the steps

automatically and will reset itself to provide treated

water when the backwash has been completed.

Manual Backwash

Sometimes there is a need to

backwash the system, sooner than

REGEN

MIN. FILL

REGEN

HOUR

SET

HOUR

when the system calls for it, usually

referred to as manual backwash.

To initiate a manual backwash at

the preset delayed backwash time,

press and release

and

REGEN

MIN. FILL

REGEN

HOUR

SET

HOUR

simultaneously. An arrow point on

the display indicates that the system

will backwash at the preset delayed backwash time. If you

pressed the

and buttons in error, pressing the

buttons again will cancel the request.

To initiate a manual backwash immediately, press and

hold the

and buttons simultaneously for four

seconds. The system will begin to backwash immediately.

The request cannot be cancelled. You can manually step

through individual cycles by pressing the

button until

display reaches normal mode.

Power Loss

If the power goes out for less than two hours, the system

will automatically reset itself. If an extended power

outage occurs, the time of day will flash on and off which

indicates the time of day should be reset. The system will

retain the other information entered by your plumbing

professional.

3

1

TIME-HOUR

PM

DAYS TO

REGEN

OR

TIME-HOUR

PM

DAYS TO

REGEN

IL1042

8

Page 9

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Bypass Valve

The bypass valve is typically used to isolate the control

valve from the plumbing system’s water pressure in order

to perform control valve repairs or maintenance. The

bypass valve is particularly unique in the water treatment

industry due to its versatility and state of the art design

features. The bypass valve incorporates four positions

including a diagnostic position that allows service

personal to work on a pressurized system while still

providing untreated bypass water to the facility or

residence. Its completely non-metallic, all plastic, design

allows for easy

access and serviceability without the need for tools.

Automatic Water Filters

The bypass body and rotors are glass filled Noryl and the

nuts and caps are glass filled polypropylene. All seals are

self-lubricating EPDM to help prevent valve seizing after

long periods of non-use. Internal o-rings can easily be

replaced

if service is required.

The bypass consists of two interchangeable plug valves

that are operated independently by red arrow shaped

handles. The handles identify the flow direction of the

water. The plug valves enable the bypass valve to operate

in four positions.

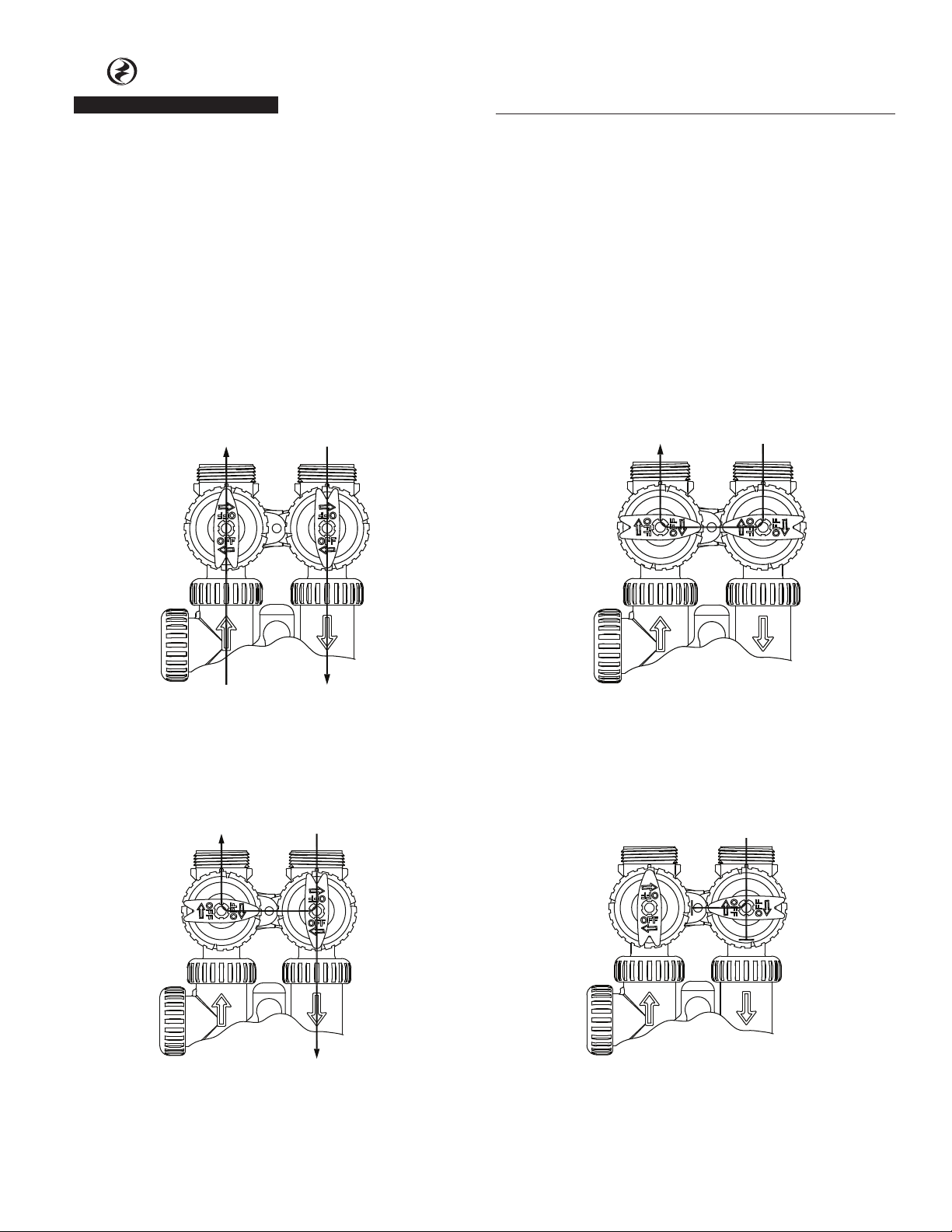

Figure 1

NORMAL OPERATION

“Treated”

Water Exits

Normal Operation:

The inlet and outlet handles point in the direction of flow indicated

by the engraved arrows on the control valve. Water flows through

the control valve during normal operation and this position also allows the control valve to isolate the media bed during the regeneration cycle.

Figure 3

Supply

Water Enters

IL1043

DIAGNOSTIC MODE

Supply

Water Exits

Supply

Water Enters

Figure 2

BYPASS OPERATION

“Untreated”

Water Exits

Bypass:

The inlet and outlet handles point to the center of the bypass, the

control valve is isolated from the water pressure contained in the

plumbing system. Untreated water is supplied to the plumbing

system.

Figure 4

Supply

Water Enters

IL1044

SHUT OFF MODE

No

Water Exits

Supply Water is shut off

from the house and the

valve

IL1045

Diagnostic:

The inlet handle points in the direction of flow and the outlet handle

points to the center of bypass valve, system water pressure is allowed

to the control valve and the plumbing system while not allowing

water to exit from the control valve to the plumbing.

Shut Off:

IL1046

The inlet handle points to the center of the bypass valve and the

outlet handle points in the direction of flow, the water is shut off to

the plumbing system. If water is available on the outlet side of the

softener it is an indication of water bypass around the system (i.e. a

plumbing connection somewhere in the building bypasses the system).

9

Page 10

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Automatic Water Filters

6

7

Turn counter-clockwise to remove.

Turn clockwise to install.

IL1049

Funnel

IL1047

Service Tool

8

IL1061

Transformer

Description Qty

No.

Part

No.

Item

1 023406 Motor 1

2 023412 PC Board 1

3 023408 Piston Assy. 1

4 023409 Seal Assy. 1

5 023410 O-Ring Kit 1

6 127001 Mineral Fill Funnel 1

7 023362 Service Tool 1

8 023411 Transformer 110V-12V 1

10

Page 11

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Item Description CBW10 CBW10D CBW20 CBW20D CCF10 CCF10D CCF20 CCF20D

1

2 Mineral tank 023319 023320 023483 023491 023319 023320 023483 023491

3 Mineral * * * * 023358 023358 023358(Qty 2) 023358(Qty 2)

4 Gravel 135523 135523 023529 023529 135523 135523 023529 023529

1

2

Distributor

tube / screen

Automatic Water Filters

023360 023360 023488 023488 023360 023360 023488 023488

Qty

Application* Part # Description

Iron Removal 135514 Birm

Acid Neutralizer 023357 Calcite

Sediment 135518 Filter-AG

Taste & Odor 135516 Activated Carbon

CBW10

CBW10D

1 Box

1 CF

CBW20

CBW20D

2 Boxes

2 CF

3

4

Bypass Valve Less

Connectors

023328

Connectors

023329

Set of 2

IL1052

Air Inducer

CCF10 Only

021708

IL1053

11

Page 12

remier

remier

P

P

roducts

roducts

®

P

P

WATER TREATMENT

Problem Possible Cause Solution

1. Timer does not

display time of day

2. Timer does not

display correct time

of day

3. Control valve

regenerates at

wrong time of day

4. E1, E2, or E3

E1 - Unable to recognize

start of regeneration

E2 - Unexpected stall

E3 - Motor ran too

long, timed out trying

to reach the next cycle

position or trying to

reach home position

5. Control valve stalled

in regeneration

7. Control valve does

not regenerate

automatically when

UP and DOWN

button is depressed

and held

8. Control valve does

lnot regenerate

automatically but

does when UP and

DOWN button is

depressed and held

Automatic Water Filters

Table 6 - Troubleshooting Procedures

a. AC adapter unplugged a. Connect power

b. No electric power at outlet b. Repair outlet or use working outlet

c. Defective transformer c. Replace transformer

d. Defective PC board d. Replace PC board

a. Switched outlet a. Use uninterrupted outlet

b. Power outage b. Reset time of day

c. Defective PC board c. Replace PC board

a. Power outages a. Reset control valve to correct time of day

b. Time of day not set correctly b. Reset to correct time of day

c. Defective PC board c. Reset regeneration time

a. Control valve has just been serviced a. Press SET HOUR and DOWN for 3 seconds or

unplug power source jack (black wire) from

the circuit board and plug back in to reset

control valve.

b. Foreign matter is lodged in control valve b. Check piston and spacer stack

assembly for foreign matter.

c. High drive forces on piston c. Replace piston(s) and spacer stack assembly

d. Control valve piston not in home position d. Press SET HOUR and DOWN for 3 seconds or

unplug power source jack (black wire) from

the circuit board and plug back in to reset

control valve

e. Motor not inserted fully to engage pinion,

motor wires broken or disconnected, motor

failure

f. Drive gear label dirty or damaged, missing

or broken gear

g. Drive bracket incorrectly aligned to back

plate

h. PC board is damaged or defective h. Replace PC board

i. PC board incorrectly aligned to drive

bracket

a. Motor not operating a. Replace motor

b. No electric power at outlet b. Repair outlet or use working outlet

c. Defective AC adapter c. Replace AC adapter

d. Defective PC board d. Replace PC board

e. Broken drive gear or drive cap assembly e. Replace piston kit

f. Broken piston retainer f. Replace piston kit

g. Broken main or regenerant piston g. Replace piston kit

a. AC adapter unplugged a. Connect AC adapter

b. No electric power at outlet b. Repair outlet or use working outlet

c. Broken drive gear or drive cap assembly c. Replace drive gear or drive cap assembly.

d. Defective PC board d. Replace PC board

a. Defective PC board a. Replace PC board

b. Set-up error b. Check control valve set-up procedure

e. Check motor and wiring. Replace

motor if necessary

f. Clean drive gear

g. Reseat drive bracket properly

i. Ensure PC board is correctly snapped on to

drive bracket

12

Loading...

Loading...