Page 1

Operating Instructions & Parts Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Booster Pump Flow Protector

FW1023

1106

Supersedes

NEW

Control Box

115V SPECIFICATIONS

Enclosure . . . . . . . . . . . . . . . . . . . . NEMA 1 Indoor Use Only

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Maximum HP Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/4

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60

Contact Rating . . . . . . . . . . . . . . . . . . . 15 Amps @ 115/Volts

Flow Sensor

Contact Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . .Max 20VA

Min. Flow for Contat Closure . . . . . . . . . . . . . . . . . . .1 GPM

Pressure Rating . . . . . . . . . . . . . . . . . . . . . . . . Max. 150 PSIG

Temperature Rating . . . . . . . . . . . . . . . . . . . . . . 32 to 140˚ F

Inlet and Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . 1” Slip PVC

General Safety Information

Carefully read and follow all safety instructions in this

manual and on pump. Keep safety labels in good condition.

Replace missing or damaged safety labels.

This is a SAFETY ALERT SYMBOL. When you

see this symbol on the pump or in the manual,

look for one of the following signal words and

be alert to the potential for personal injury or

property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property damage if ignored.

!

personal injury or death, if ignored.

Warns of hazards that CAN cause serious

Control Box

230V SPECIFICATIONS

Enclosure . . . . . . . . . . . . . . . . . . . . NEMA 1 Indoor Use Only

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Maximum HP Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60

Contact Rating . . . . . . . . . . . . . . . . . . . 20 Amps @ 230/Volts

Flow Sensor

Contact Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . .Max 20VA

Min. Flow for Contat Closure . . . . . . . . . . . . . . . . . . .1 GPM

Pressure Rating . . . . . . . . . . . . . . . . . . . . . . . . Max. 150 PSIG

Temperature Rating . . . . . . . . . . . . . . . . . . . . . . 32 to 140˚ F

Inlet and Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . 1” Slip PVC

!

Hazardous

voltage. Can

shock, burn or

cause death.

Ground pump

before connecting

to power supply.

Verify motor is wired for correct

voltage. See motor wiring diagram provided

by the pump or motor manufacturer.

Ground motor before connecting to

power supply.

Meet United States National Electrical

Code and local codes for all wiring.

Do not handle a pump, pump motor

or control unit with wet hands or when

standing on a wet or damp surface or in

water.

Warns of hazards that MAY cause minor

personal injury, product or property damage if ignored.

IMPORTANT: Indicates factors concerned with operation,

installation, assembly or maintenance which could result in

damage to the machine or equipment if ignored.

NOTE: Indicates special instructions which are important but

are not related to hazards.

FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • www.flintandwalling.com

Follow wiring instructions in this manual when

connecting to power lines.

!

performing any work on or near the motor or its connected

load.

1

Always disconnect power source before

022354

Page 2

Do not use to pump flammable or explosive

fluids such as gasoline, fuel oil, kerosene,

etc. Do not use in flammable and/or explosive

atmospheres.

Hazardous pressure! Install pressure relief

valve in discharge pipe. Release all pressure on

system before working on any component.

1. Make workshop child proof - use padlocks, master

switches; remove starter keys.

2. Wear safety glasses when working with pumps.

3. Wear a face shield and proper apparel when pumping

hazardous chemicals.

4. Keep work area clean, uncluttered and properly lighted;

replace all unused tools and equipment.

5. Provide guarding around moving parts.

6. Keep visitors at a safe distance from the work area.

7. Periodically inspect pump and system components.

8. Protect electrical cord. Replace or repair damaged or

worn cords immediately.

9. Do not insert finger or any object into pump or motor

openings.

!

to the State of California to cause cancer and birth defects or

other reproductive harm.

!

not been investigated for use in swimming pool areas.

This product contains chemicals known

Risk of Electric Shock. This controller has

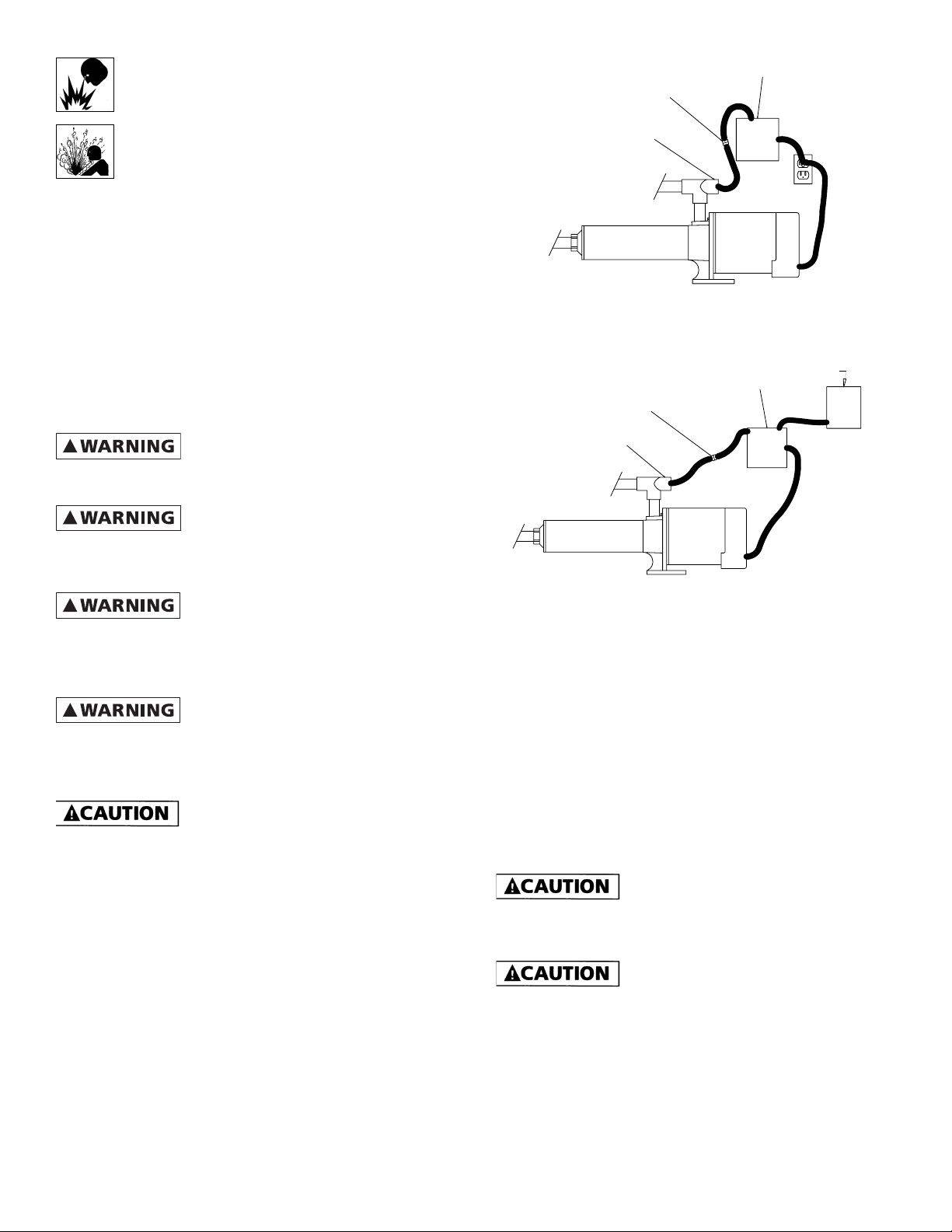

OUTLET

Figure 1

OUTLET

CONNECTORS

FLOW

SENSOR

INLET

115 VOLT INSTALLATION

CONNECTORS

FLOW

SENSOR

INLET

ELECTRONIC CONTROL

F&W

ELECTRONIC CONTROL

F&W

PAT.

PEND

IL0631

115 VOLT

CONTROLLER #2

FUSE DISCONNECT OR

BOOSTER

BREAKER BOX

230 VOLT

LOCATION

!

damage and/or personal injury might result from an

inoperative or leaking pump due to power outages,

discharge line blockage, or any other reason, a backup

system(s) should be used.

!

installation where pump pressure can exceed the plumbing’s

maximum working pressure or on systems where the

discharge line can be shut off or obstructed. Extreme over

pressure can result in personal injury or property damage.

intended to be used in showers, saunas or other potentially

wet locations. For outdoor installations, control unit must

be protected from the elements by a cover. This unit is not

weatherproof nor is it able to be submersed in water or any

other liquid.

In any installation where property

Install a pressure relief valve on any

This unit is not waterproof and is not

DESCRIPTION

For pressure boosting systems, the electronic flow sensorcontrol unit monitors the flow of water and automatically

shuts off the motor when the flow drops below 1.0 GPM.

Once the flow has increased above 1.0 GPM, the unit will

automatically turn the motor back on to boost the system

pressure. The device protects against dry run or dead head

conditions that are caused by a low yield water supply or

an obstructed water discharge. Note: This electronic flow

protection system is designed to be used with a positive

supply of water feeding the pump.

NOTE: The unit will not function if the pump is used in a

suction lift application.

230 VOLT INSTALLATION

IL0629

Figure 2

INSTALLATION

1. Electronic flow protector box should be located within six

feet of the pump motor and power supply and should be

mounted to a solid surface.

Note: Follow all recommended installation procedure for

pump as provided by pump manufacture.

2. Plumb flow sensor on into the inlet side of the pump,

making sure that your water supply line is feeding the

inlet port of the flows sensor and the outlet port of the

flow sensor is plumbed to the inlet port of the pump (See

Figures 1 & 2). Use standard medium bodied PVC solvent

cement to attach piping to flow switch.

Care should be taken to use the minimum

recommended amount of PVC cement to insure that no

excess cement enters into the sensor of the unit and causes a

malfunction which can void the warranty.

If dirt, sand, debris or other particulate is

present in the supply water, install a strainer or filter on the

inlet side of the flow sensor to insure proper operation of

sensor and pump.

3. Plug the two red wires from the electronic flow protector

box into the two red wires on the flow sensor.

2

FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • www.flintandwalling.com

Page 3

WIRING PROCEDURES FOR 115V CONTROL

Make certain that the power supply

conforms to the electrical specifications of the motor

supplied. If the motor wiring must be changed to conform to

your specific voltage requirements, consult documentation

provided with the pump motor for correct procedure.

1. Install and maintain your pump in accordance with your

local electrical code and all other codes and ordinances

that apply. Consult your local building inspector for local

code information.

2. Plug the 115V power cord from the electronic flow

protector box into a properly grounded 115V receptacle.

3. Plug a properly sized and grounded power cord from the

pump motor into the “piggy back” outlet of the power

cord of the electronic flow protector.

IMPORTANT: Check local and/or United States National

Electric Codes for proper grounding information.

6. Connected black and white wires as specified by local or

United States National Electrical code to the disconnected

supply voltage.

230 VOLT INSTALLATION

FLOW SENSOR

PRESSURE

RELIEF VALVE

TO DRAIN

Figure 4

CONNECTORS

PRESSURE GAUGE

LINE FILTER

230 VOLT

ELECTRONIC FLOW PROTECTOR

F&W

GATE/BALL VALVE

FROM

WATER SOURCE

GATE/BALL VALVE

(NORMALLY OPEN)

FUSE DISCONNECT OR BREAKER BOX

IL0628

115 VOLT INSTALLATION

ELECTRONIC FLOW PROTECTOR

CONNECTORS

WALL HYDRANT

HIGH PRESSURE

REINFORCED HOSE

HOSE

ADAPTER

FLOW

SENSOR

Figure 3

WIRING PROCEDURES FOR 230V CONTROL

Make certain that the power supply

conforms to the electrical specifications of the motor

supplied. If the motor wiring must be changed to conform to

your specific voltage requirements, consult documentation

provided with the pump motor for correct procedure.

1. Feed the lead wire labeled Output (Motor) from the

electronic flow protector to the terminal block of the

motor.

2. Connect the green ground wire first to the grounding

terminal provided on the motor frame. Ground connection

MUST be made to this terminal. Do not connect motor to

electrical power supply until unit is permanently grounded;

otherwise serious or fatal electric shock hazard may be

caused.

3. Attach the black and white wires to the power

supply terminals or wires of the pump motor, consult

documentation provided with the pump motor for correct

location and wiring procedures.

4. Feed the lead wire labeled Input Power from the electronic

flow protector to your 230V electrical power supply.

5. Connect the green ground wire first to the grounding

terminal within the electrical supply box as specified by

local or United States National Electrical code. Do not

ground to a gas supply line. Do not connect the electronic

flow protector to electrical power supply until unit is

permanently grounded; otherwise serious or fatal electric

shock hazard may be caused.

FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • www.flintandwalling.com

INLET

SPRAY

NOZZLE

F&W

115 VOLT

PRESSURE RELIEF

VALV E

OUTLET

HOSE ADAPTER

TO DRAIN

HIGH PRESSURE

REINFORCED HOSE

IL0630

OPERATION:

Priming of the pump is automatic when pump is connected to

a positive supply of water such as a hydrant or city main.

1. Disconnect power to the electronic flow protector and

pump. (Unplug 115V model, turn off disconnect to 230V

model.)

2. Open values and/or nozzle on suction and discharge side of

the pump.

3. To relieve trapped air, allow water supply to run a

minimum of 30 seconds before starting the pump.

4. Connect power to the electronic flow protector and pump.

(Plug in the 115V model, turn on disconnect to 230V

model.)

5. As long as there is at least 1.0 GPM of water flowing

through the pump, the pump will continue to run. If the

water supply or discharge valve and/or nozzle is closed,

which causes less that 1.0 GPM of water to flow through

the pump, the electronic flow protector will turn off the

pump in 20 to 30 seconds. Once the flow has returned to

at least 1.0 GPM, the flow protector will turn the pump

back on.

3

Page 4

Troubleshooting Chart / Booster Systems

Symptom Possible Cause(s) Corrective Action

Pump won’t

start or run

at full speed

Pump fails

to continue

to run

Pump

operates,

but delivers

little

or no water

1. Blown fuse or open circuit breaker 1. Replace fuse or close circuit breaker. See wire size chart for

proper break/fuse size

2. Power supply in OFF position 2. Turn power on

3. Incorrect voltage at motor (check

voltage with motor running)

4. Loose, broken or incorrect wiring 4. Rewire any incorrect circuits. Tighten connections, replace

5. Defective motor 5. Replace motor

6. Pump hydraulic components clogged/

worn/damaged or seized

7. Flow sensor installed incorrectly 7. Plumb flow sensor correctly with water supply entering inlet

8. There is no positive supply of water to

the pump.

1. Manual or solenoid valves plumbed

into system restricting flow

2. In-line filter restricting flow 2. Check all in-line filters to be sure they are not plugged or

3. Low line voltage 3. See low line voltage corrective action (above)

4. Inadequate water supply to booster

pump

3. Low voltage

a. Voltage must be within ± 10% of motor rated voltage.

Check incoming voltage. Contact power company

b. Make certain that voltage of motor matches voltage of

power supply. See motor name plate and motor wiring

diagrams

c. Check wire size from main switch to pump. See wire size

chart for correct wire size

defective wires

6. Replace worn parts or entire pump. Clean parts if required

side of the flow sensor and the outlet side plumbed to the

pump inlet.

8. Provide a positive supply of water to the pump.

1. a Check all valves on pump inlet and discharge sides of

system to be sure they are opened properly to allow

flow to and from the pump

b. Bleed trapped air in pump which keeps water from

reaching the pump. (Normally

due to closed valve in discharge plumbing)

restricted

4. Check pressure on inlet side of booster to be sure positive

pressure is maintained to the booster pump

5. Undersized piping 5. Replace undersized piping

6. Worn or defective pump parts or pump. 8. Replace worn parts or entire plugged impeller Clean parts if

7. Suction lift too great 9. Pump should be operated under

flooded suction only

8. Pump not primed 10. Prime pump - Make certain inlet pipe is drawn up tight and

pump and pipe are full of water

Excessive

noise while

pump in

operation

Pump leaks 1. Worn mechanical seal (leaks at shaft) 1. Replace shaft (rotary) seal

1. Pump not secured to firm foundation 1. Secure properly

2. Piping not supported 2. Make necessary adjustments

3. Restricted inlet line 3. Clean or correct

4. Cavitation (noise like marbles in pump) 4. Increase inlet pipe size back to source

5. Worn motor bearings 5. Replace bearings or motor

2. Worn o-ring seals 2. Replace o-ring seals, located inside both ends of the stainless

steel shell

4

FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • www.flintandwalling.com

Loading...

Loading...