Page 1

Operating Instructions & Parts Manual

!

!

!

!

!

!

!

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal

injury and/or property damage! Retain instructions for future reference.

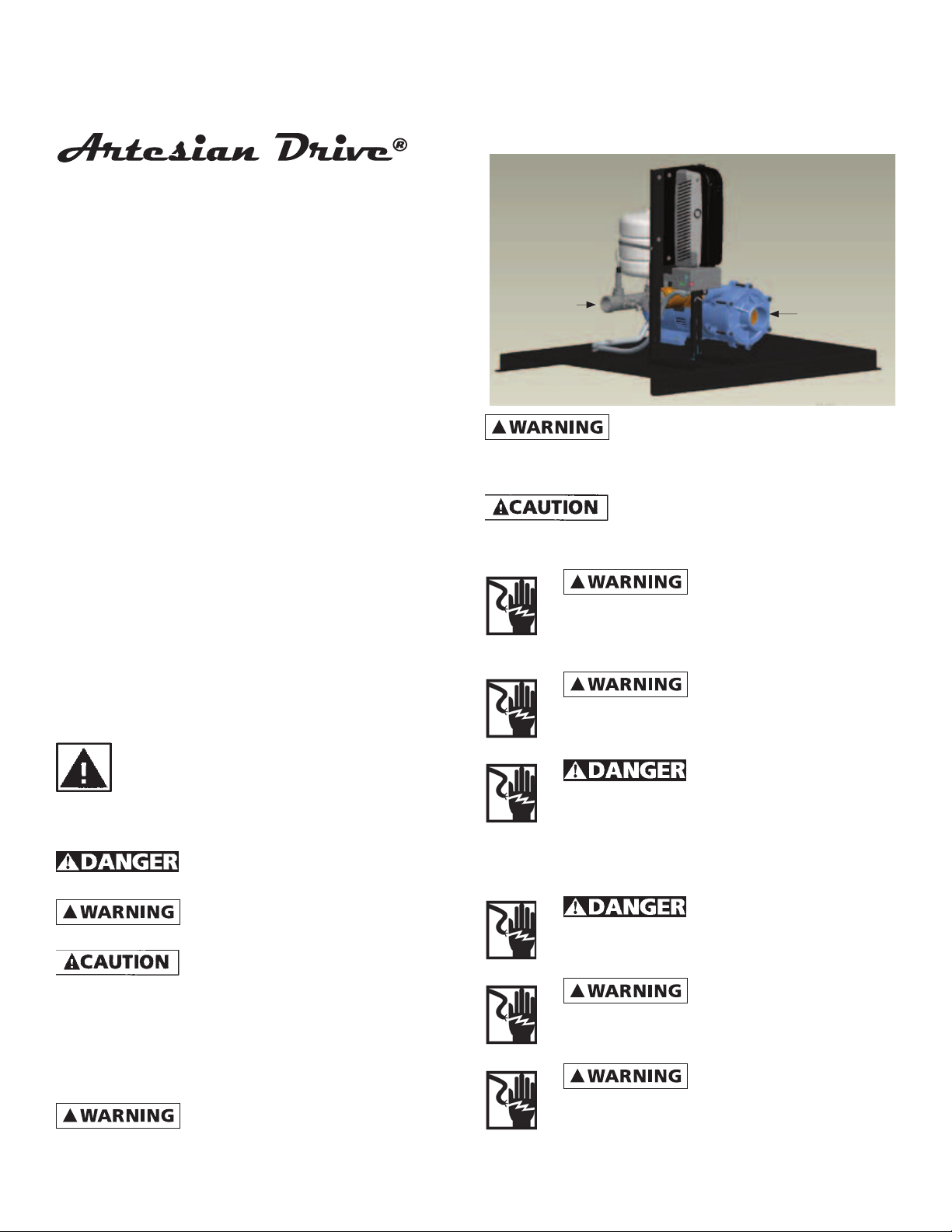

Pump Station

Models ADW2W31, ADW2W51,

ADW2W71, ADW2W73

Discharge

KEY FEATURES OF THE ARTESIAN DRIVE PUMP STATION

INCLUDE:

• Constant water pressure with a wide range of settings

(30-80 psi) (Note: The maximum obtainable system

pressure is limited by the performance of the pump

installed)

• Smaller pressure tank can be used

• No in-rush (power-on transient) current

• Low motor start-up current (soft-starting)

• Active Power Factor Correction minimizes input RMS

current

• Protection features

- Dry run conditions – using intelligent load monitoring

(see Page 6)

- High voltage / lightning surge

- Low line voltage

- Short circuit

General Safety Information

Carefully read and follow all safety instructions in

this manual and on pump. Keep safety labels in good

condition. Replace missing or damaged safety labels.

Manifold

Figure 1

controller can still hold a lethal voltage even after power

has been removed. Allow 10 minutes for dangerous internal

voltage to discharge before opening the unit.

capacitors with the Artesian Drive. Damage will result to both

motor and drive.

perform installation.

Capacitors inside the Artesian Drive

Do not use power factor correction

Electrical installations

shall be in accordance with National Electric

Code (NEC) and all applicable local codes

and ordinances. A licensed electrician should

Be sure system is connected

to a circuit equipped with a fuse or circuit

breaker of the correct rating.

Pump Intake

FW1365

0411

Supersedes

0610

this symbol on the pump or in the manual, look for one of

the following signal words and be alert to the potential for

personal injury or property damage.

personal injury, death or major property damage if ignored.

personal injury or death, if ignored.

personal injury, product or property damage if ignored.

IMPORTANT: Indicates factors concerned with operation,

installation, assembly or maintenance which could result in

damage to the machine or equipment if ignored.

NOTE: Indicates special instructions which are important but

are not related to hazards.

carefully. Failure to follow could result in serious bodily injury

and/or property damage.

This is a SAFETY ALERT SYMBOL. When you see

Warns of hazards that WILL cause serious

Warns of hazards that CAN cause serious

Warns of hazards that MAY cause minor

Read these warnings and instructions

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Always disconnect power

source before performing any work on or near

the controller, motor or its connected load. If

the power disconnect point is out-of-sight, lock

it in the open position and/or tag it to prevent unexpected

application of power. Failure to do so could result in fatal

electrical shock or bodily injury.

DO NOT handle pump with wet

hands or when standing in water as fatal electrical

shock could occur. Disconnect main power supply

before handling system for any reason.

Protect the power cable from

coming in contact with sharp objects, oil, grease,

hot surfaces or chemicals. DO NOT kink the

power cable. If damaged replace immediately.

NEVER leave the control box,

fused disconnect switch, or covers open (either

partially or completely) when not being worked

on by a competent electrician or repairman.

1 (FW1365)

023423

Page 2

Always use caution when

!

!

!

!

!

!

!

!

!

operating electrical controls in damp areas. If possible,

avoid all contact with electrical equipment during

thunderstorms or extreme damp conditions.

Install all electrical equipment

in protected area to prevent mechanical damage

which could produce serious electrical shock and/

or equipment failure.

DO NOT use this system to pump

flammable liquids such as gasoline, fuel oil, kerosene,

etc. Failure to follow the above warning could result

in property damage and/or personal injury.

This product contains chemicals known

to the State of California to cause

cancer and birth defects or other reproductive harm.

Do not pump water above 140 degrees

Fahrenheit.

the drive until power has been removed and 10 minutes have

passed for internal voltages to discharge!

UNDERLOAD SENSITIVITY

The Artesian Drive controller is configured at the factory

to ensure detection of Underload faults in a wide variety

of pumping applications including dead head and run dry

conditions. In very rare cases (as with certain pumps in

shallow wells) this trip level may result in nuisance faults. If

the pump is installed in a shallow well, activate the controller

and observe system behavior. Once the controller begins to

regulate pressure, check operation at several flow rates to

make sure the default sensitivity does not induce nuisance

Underload trips. If it becomes necessary to desensitize the

Underload trip level, please call of Technical Support at 1-800345-9422 for further details.

Serious or fatal electrical shock may result

from contact with internal electrical components. DO NOT,

under any circumstances, attempt to modify connections to

the drive until power has been removed and 10 minutes have

passed for internal voltages to discharge!

This unit not tested for use

in swimming pool areas.

How it Works

SYSTEM DIAGNOSTICS

In addition to regulating system pressure and accurately

controlling motor operation, the Artesian Drive continuously

scans the system and can detect a variety of abnormal

conditions. If there is elevated risk of damage to a part of

the system, the drive will protect the system and display a

code for the fault. If possible, the drive will try to restart itself

when the fault condition passes.

PUMP SIZING – ARTESIAN DRIVE (CENTRIFUGAL)

The Artesian Drive is configured at the factory for use with

standard 3-phase motors and pumps.

NOTE: The Artesian Drives are factory programmed to

F&W pumps to provide optimum performance and motor

protection. The Artesian Drive can be used with other

pumps, but the maximum motor amperage needs to be

compared to the factory programmed current value (refer

to the Specifications section under the appropriate model).

If the maximum motor current varies more than 5% from

the programmed value, the motor current value in the drive

needs to be changed for motor protection and optimum

performance. For details on how to change this value in the

drive, please contact Technical Support at 1-800-345-9422.

event of a motor overload.

DRIVE CONFIGURATION

When sized correctly, the Artesian Drive systems are ready

to go right out of the box and need no configuration.

Under certain circumstances there are several programming

parameters that can be changed to accommodate non

standard systems. For further information to change these

parameters, please call Technical Support at 1-800-345-9422

from contact with internal electrical components. DO NOT,

under any circumstances, attempt to modify connections to

The motor rated current must be set

correctly to avoid a risk of fire in the

Serious or fatal electrical shock may result

Before Getting Started

from failure to connect the ground terminal to the motor,

Artesian Drive controller, metal plumbing, or other metal

near the motor or cable, using wire no smaller than motor

cable wires. To minimize risk of electrical shock, disconnect

power before working on or around the Artesian Drive

system. CAPACITORS INSIDE THE ARTESIAN DRIVE CONTROLLER

CAN STILL HOLD LETHAL VOLTAGE EVEN AFTER POWER HAS

BEEN DISCONNECTED. ALLOW 10 MINUTES FOR DANGEROUS

INTERNAL VOLTAGE TO DISCHARGE BEFORE REMOVING

ARTESIAN DRIVE COVER.

areas.

IMPORTANT: This equipment should be installed by technically

qualified personnel. Failure to install it in compliance

with national and local electrical codes and within F&W

recommendations may result in electrical shock hazard, fire

hazard, unsatisfactory performance, or equipment failure.

Installation information is available directly from F&W at our

toll-free number 1-800-345-9422.

three phase motors. Use of this unit with improperly sized

motors may result in damage to both motor and electronics.

Serious or fatal electrical shock may result

Do not use motor or system in swimming

Use Artesian Drive only with properly sized

Controller Location Selection

The drive’s enclosure is NEMA 1 rated

and is intended for indoor use only. It

should be mounted in a location that provides protection

from water spray/drips and only be accessed by trained and

authorized personnel.

The Artesian Drive controller is intended for operation in

ambient temperatures up to 104°F (40°C) at 230 VAC input.

Installation Guidance and Instructions

INITIAL CONDITIONS AND PRECAUTIONS

1. The Pump Station should be installed on flat surface rated

for the weight of the pump station. A properly sized

concrete slab is recommended.

2. Installation should be performed by licensed or qualified

personnel.

2 (FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Page 3

3. The Pump Station shall be lifted with proper lifting

!

!

!

!

!

equipment (i.e. fork lift). Be sure all necessary lifting

equipment is used properly.

4. DO NOT ATTEMPT TO USE DRIVE SUPPORT BRACKET FOR

LIFTING THE PUMP STATION. The bracket will not support

the overall weight of the pump station.

5. The pump station must be installed according NEC and

local electrical codes. Proper electrical disconnect MUST be

installed in view of the pump station.

6. Ensure compliance with all applicable local, state, and

OSHA regulations when installing, operating, repairing, or

maintaining the pump station.

7. The pump station is manufactured to best ensure operator

safety under normal operating conditions. The manufacturer

will not take any responsibility for personal or equipment

damage if the equipment has been modified or if the

safeguards have been modified. Any proposed modifications

must be carefully documented (to include a risk analysis) by

the party proposing the modification; and coordinated with

and approved by the manufacturer. Otherwise, the customer

assumes all responsibility for its actions and subsequent

consequences.

INSTALLATION PROCEDURE

1. Position the skid in final location and attach to pad as

necessary. NOTE: For serviceability of the pump and

protection of discharge plumbing fixtures down line of the

pump station, it is recommended to incorporate unions and

isolation valves on the intake and discharge plumbing. If

deemed applicable, a bi-pass loop with properly placed

valves should also be incorporated into the installation.

2. Install plumbing to the intake of the pump. Note: For

proper functionality of the system it is not recommended

that a pipe size smaller than 2-1/2” is use on the intake of

the pump. Note: For suction lift applications, intake pipe

plumbing needs to allow for suction pipe to be filled by

external water source to prime the pump. Note: If the water

source for the pump station is susceptible to containing

debris, an appropriately sized filter should be installed prior

to the pump intake which should be checked & cleaned

regularly to avoid clogging the pump and/or degrade system

performance.

3. Install plumbing to discharge manifold. Note: For proper

functionality of the system it is not recommended that a pipe

size smaller than 2” is use on the discharge manifold. Note:

To avoid causing damage to the system, when tightening

onto the threads of the discharge manifold, a pipe wrench

should be used on the manifold to keep the manifold from

turning.

4. With supply power OFF, connect power supply cables to L1

& L3 terminals for single phase power supplied drives or L1,

L2 & L3 terminals for three phase supplied drives. Attach

ground wire to grounding lug on drive. See Figures 4 - 6 on

page 7 & 8 for depictions of each HP power supply wiring

connections.

3 & 5 HP Models: To avoid a fire hazard and

maintain validity of the UL listing, torque the power terminal

screws to 12 lb.-in. (1.4 N-m).

7.5 HP 3 Phase Model: To avoid a fire hazard

and maintain validity of the UL listing, torque the power

terminal screws to 13.2 lb.-in. (1.5 N-m).

and maintain validity of the UL listing, torque the power

terminal screws to 21.6 lb.-in. (2.5 N-M).

7.5 HP 1 Phase Model: To avoid a fire hazard

Wiring Connections

CIRCUIT BREAKER AND WIRE SIZING

The minimum circuit breaker size and maximum allowable

wire lengths for connection of motor to the Artesian Drive

are given in the following table:

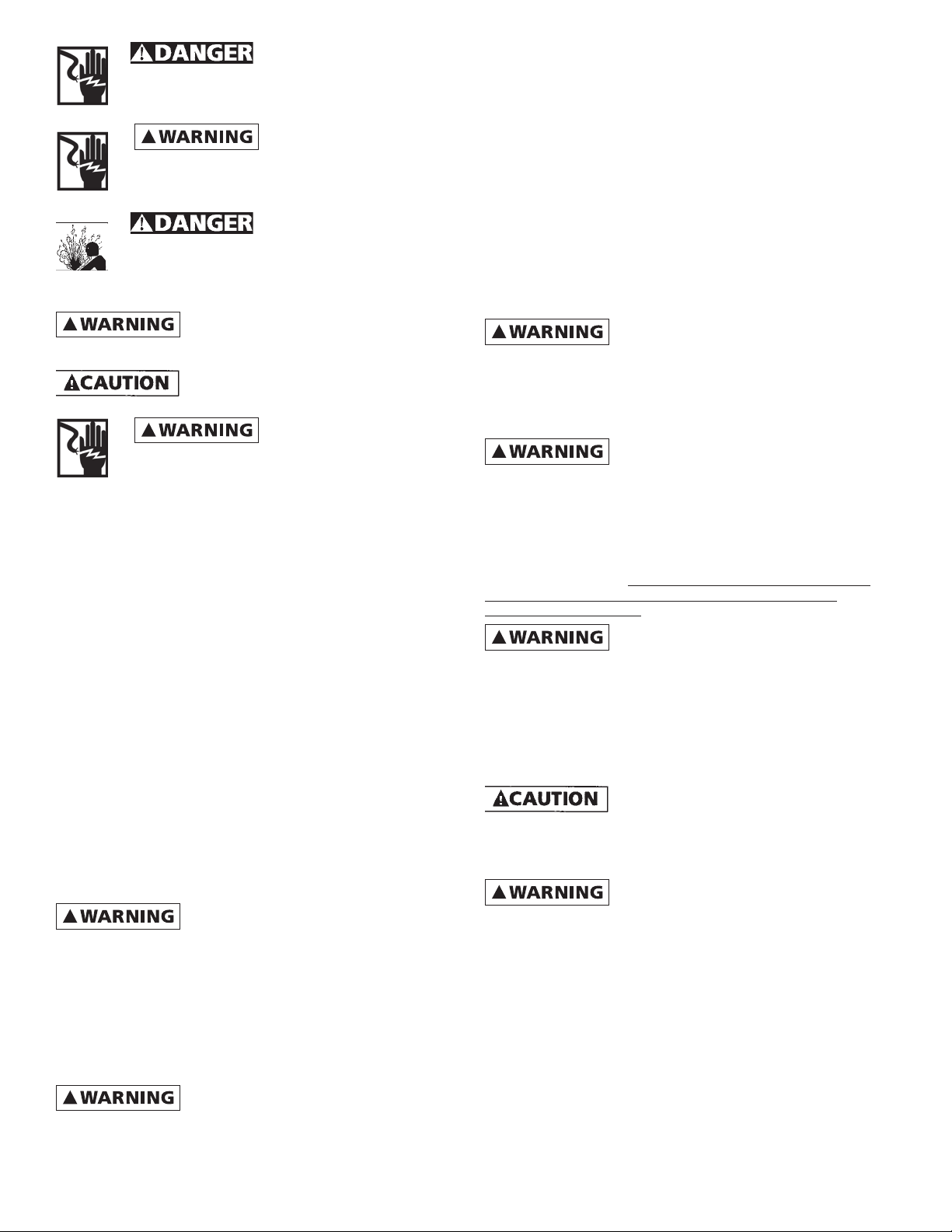

TABLE 1: MINIMUM BREAKER SIZE AND MAXIMUM

CABLE LENGTH (IN FEET)

Drive

Model

ADW2W31 10 14 325 30 9.6

ADW2W51 8 12 325 30 15.0

ADW2W71 6 10 325 50 22.0

ADW2W73 8 10 325 30 22.0

Recommended

Input Cable

Recommended

Motor Cable

NOTE:

• Maximum allowable wire lengths are measured between

the controller and motor.

• Aluminum wires should not be used with the Artesian

Drive.

• Wire sizing between the service entrance and the

controller must be sufficient to provide the required

maximum input amps to the controller while conforming

to local standards and codes.

The pressure tank pre-charge setting should be 70% of the

system pressure sensor setting as indicated in the following

table.

TABLE 2: PRESSURE TANK AIR PRECHARGE (PSI)

System Pressure (at Pressure

Sensor)

30 21

35 25

40 28

45 32

50 35

55 39

60 42

65 46

70 49

75 53

80* 56

areas.

by the internal filtering, permanent fixed ground connections

must be made using two independent conductors each with

a cross-section equal to or exceeding that of the supply

conductors. The drive is provided with two ground terminals

marked PE to facilitate this for 3 & 5 HP models.

Do not use motor or system in swimming

Because of the leakage current produced

NOTE: Ensure that the system is properly grounded all the

way to the service entrance panel. Improper grounding may

result in the loss of voltage surge protection and interference

filtering.

Maximum

Cable

Length to

Motor (Ft.)

Recommended

Breaker

Maximum

Continuous

Pressure Tank Precharge

Setting (± 2 PSI)

Current

3 (FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Page 4

!

from failure to connect the motor, the Artesian Drive, metal

plumbing and all other metal near the motor, or cable to the

power supply ground terminal, using wire no smaller than

motor cable wires. To reduce risk of electrical shock, disconnect

power before working on or around the water system.

START-UP PROCEDURES

Proper operation of the pump station requires that operators

do not deviate from these procedures. Deviation from these

procedures can result in serious/fatal injury to personnel and/

or damage to the Pump Station.

1. Open any user installed value on the intake side of the pump

and verify that the isolation value is closed if installed on the

discharge side of the system

2. Verify that the pump is primed. For gravity fed systems, this

can be accomplished by opening hose bib valve installed on

the system manifold to allow the water pressure to push out

the air from the pump. For suction lift systems, fill the pump

and intake piping with external water source until water

begins coming out the open hose bib valve.

3. Close hose bib valve.

4. Supply electrical power to Pump Station by truing on the

user installed disconnect to the ON position and allow system

to pressurize and check for leaks on plumbing installed.

Serious or fatal electrical shock may result

Caution: Never hang or store items on

pump station piping or components.

5. Once pressure has been established, partially crack open the

station isolation valve (while maintaining pressure) and open

valves farthest away from pump station to bleed air out of

the system & piping

6. When the whole Main Line has been bled of air, fully open

the discharge isolation valve.

7. As long as the display is lit up the system has power. When

the display shows . or flashes PLC as shown, the system

is active, but the pump is not running. The display will show

. as shown (where the numbers may be fluctuating)

when the pump is running.

IL0748

Figure 2

HOW TO ADJUST SYSTEM PRESSURE SETPOINT

Press and release M button to display flashing number on left

hand side of display (i.e. 01).

Using ↑ and ↓ buttons, scroll until you reach 10 flashing on

left hand side.

Press and releae M button and then press & release ↑ button

to scroll display to show L3 on right hand side.

Press and release M button and use ↑ and ↓ to scroll until you

reach 61 flashing on left hand side.

Press and release M button and CodE flashes on the right

hand side.

Press & release ↑ until Co 3 is displayed.

Press & release M button to make the 0 of 50 begin flashing.

Using ↑ and ↓, scroll the value to the pressure set point in PSI

desired. The pressure rating has a maximum value of 100 PSI.

Press and release M button to return to having 61 on left of

screen flashing.

Using ↑ and ↓ buttons, scroll to 10 flashing on left hand side.

Press & release M button, then press & release ↑ button until

LoC id displayed.

Press & release M button twice to return to standard screen.

4 (FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Page 5

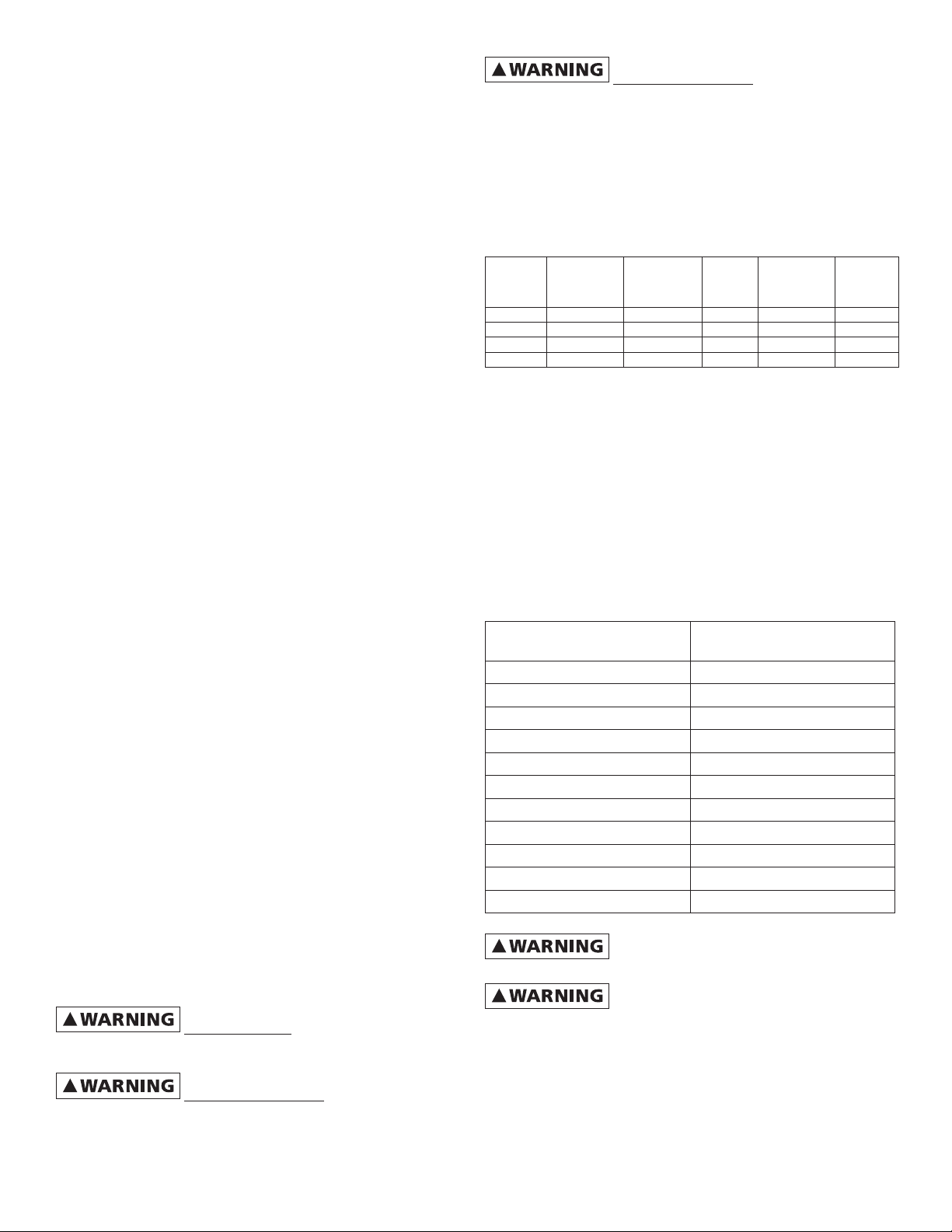

DIAGNOSTIC FAULT CODES

!

Should an application or system problem occur, built-in

diagnostics will protect the system. The display will change

to indicate the nature of the fault. In some cases, the system

will shut itself off until corrective action has been taken. Fault

TABLE 3: DIAGNOSTIC FAULT CODES

DISPLAY CODE FAULT POSSIBLE CAUSE CORRECTIVE ACTION

. Short Circuit When fault is indicated

. Over Current When fault is indicated while

.

(Number other than

0.0 & motor is not

running)

. . Overheated Controller High ambient temperature.

. Controller Stopped Loose jumper wire Re-insert jumper wire into control

c

Motor Underload Air-locked pump. Overpumped

or dry well. Worn pump.

Damaged shaft or coupling.

Pump deadhead. Blocked pump

or screen.

Water Over Temp Pump running deadhead

because of transducer failure or

clogging of transducer pressure

point

Undervoltage Low line voltage. Misconnected

input leads.

immediately after powerup, short circuit due to loose

connection, defective cable,

splice or motor.

motor is running, over current

due to loose debris trapped

in pump, or water demand

is exceeding pump & motor’s

capability.

Open Circuit Loose connection. Defective

motor or cable.

Direct sunlight. Obstruction of

air-flow.

Loss of Transducer Signal Unconnected or failed

transducer

codes and the recommended corrective action for each are

listed in the following chart.

Do not attempt to carry out internal

repairs. Return a faulty drive to the

supplier for repair.

Wait for well to recover and

automatic restart timer to time out.

If the problem does not correct,

check motor and pump. See

description of “Intelligent Reset” on

Page 18.

Clean out pressure port of transducer

or replace transducer.

Check for loose connections. Check

line voltage. Report low voltage

to the power company. Unit will

start automatically when the proper

power is supplied.

Check motor wiring. Turn power off

till display darkens then apply power

again to reset.

Check pump.

With power off, check motor, motor

wiring and splices. Make certain all

connections are tight. Apply power

again to reset.

This fault automatically resets when

the temperature returns to a safe

level.

terminals B2 & B4.

Reconnect or replace transducer

5 (FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Page 6

TABLE 4 SYSTEM TROUBLESHOOTING GUIDE

Symptom Possible Cause Corrective Action

Motor/Pump is running backwards. Reverse connection of motor cable wires at connection

point U & V.

Pump capacity cannot supply the demand. Use pump with higher flow rating (if head requirement is

still satisfied).

Water flow rate

is not as high as

expected.

Excessive

pressure

fluctuations.

Motor runs

continuously

with no flow

demand.

UNDERLOAD INTELLIGENT RESET

(Display showing )

If a motor Underload fault condition occurs, the most likely

cause is an overpumped well (dry well) or loss of incoming

feed water to the pump. In a dry well situation to allow the

well to recover, the Artesian Drive controller will wait 30

seconds to 5 minutes, determined by the amount of time

the motor had been running before sensing the underload,

before restarting the motor. For example, the first time the

fault occurs and the pump has been running 6 minutes, the

controller stops the motor and will wait 30 seconds before

attempting to restart the pump. If the system would then run

for 2 minutes and an underload fault recurs, the controller

will wait 3 minutes before attempting to restart the pump.

This schedule allows for the minimum off-time possible based

on the recovery time of the well or water feed supply.

If there is an obstruction (such as a closed valve) between the

pump and the pressure sensor, the controller will also sense

an underload is this “dead head” condition stopping the

motor to avoid damaging the pump.

6.0

Temperature in the controller is too high. If

the controller’s heat exchanger becomes too

hot, the controller will reduce the switching

frequency to the motor to lower the power

consumption.

Disconnected or broken wire feeding motor. Check motor, motor wiring and splices. Make certain all

Waterlogged tank. Check tank for bladder damage. Replace if necessary.

Pressure tank is too small for flow rating of

the pump.

Leak in the household or outdoor plumbing. Check for leaky faucets, valves and/or pipe fittings and

Leak in the pitless adapter. Re-seat the pitless adapter. Replace seal as needed.

Make sure there is at least 4 inches of room around the

controller for movement of air. Avoid direct sunlight.

Reduce ambient temperature below 104°F (40°C). Increase

input voltage if below 230 VAC.

connections are tight.

Reset the tank pre-charge pressure (should be 70% of

pressure sensor setting).

Use larger tank (refer to Table 3 on Page 4 for minimum

Pressure Tank size).

repair.

OVER-TEMPERATURE

The Artesian Drive controller is designed for full power

operation in ambient temperatures up to 104°F (40°C)

as long as the input voltage is kept at 230 VAC. Under

extreme thermal conditions, the controller will reduce the

switching frequency in an attempt to avoid shutdown. If the

temperature of the controller is still too hot the controller will

shut itself off to avoid causing damage to itself. Full pump

output is restored when the controller temperature cools to a

safe level.

NOTE: The Artesian Drives are factory programmed to

F&W pumps to provide optimum performance and motor

protection. The Artesian Drive can be used with other

pumps, but the maximum motor amperage needs to be

compared to the factory programmed current value (refer

to the Specifications section under the appropriate model).

If the maximum motor current varies more than 5% from

the programmed value, the motor current value in the drive

needs to be changed for motor protection and optimum

performance. For details on how to change this value in the

drive, please contact Technical Support at 1-800-345-9422.

5.0

4.0

3.0

2.0

Off Time (Min.)

1.0

0.0

Figure 12

0 1 2 3 4 5 6 7 8

Run Time (Min.)

IL0750

6 (FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Page 7

TABLE 5 DRIVE SPECIFICATIONS AND DIMENSIONS

Model Number ADW2W31 ADW2W51 ADW2W71 ADW2W73

Voltage 180 - 264 ac Single or Three Phase Single Phase Three Phase

Input from power

source

Output to Motor

(Three Phase )

For Use With

Pressure Setting

Operating

Conditions

RMS = ROOT MEAN SQUARED

* The electrical characteristics of motors vary slightly. See Amp draw on motor nameplate. If the maximum motor current value (Amp draw)

is more than 5% of the programmed value of the Drive, the Drive will need to be set to the current value of the motor to provide proper

protection..

Frequency 50/60 Hz

Current (Max) - RMS

Power Factor 1.0 ( constant )

Voltage Voltage Automatically Adjust with Frequency (0 thru 230 Volts)

Frequency Range 15 - 60 Hz

Current, Factory Programmed*

(RMS, Each Phase)

Current (Max)

(RMS, Each Phase)

Motor Standard 60 Hz. Pump & 230 Volt 3 Phase Motor Combination

Reference HP Rating* 3 5 7.5 7.5

Factory preset 50 PSI

Adjustable Range 30 - 80 PSI

Temperature

(@ 230 VAC input)

Relative Humidity Max 95% Non-condensing

23.2 Amps 1ø

(11.9 Amps 3ø)

9.6 Amps 14.5 Amps 21.0 Amps 21.0 Amps

9.6 Amps 15.0 Amps 22.0 Amps 22.0 Amps

29.5 Amps 1ø

(15.7 Amps 3ø)

10° to 40° C ( 14° to 104° F. )

48.9 Amps 1ø 22.6 Amps 3ø

T6T5T4T3T2T1

Power Supply Connections

1ø shown

( for 3ø, connect power to

L1, L2, L3)

L2

L3

L1

U

V

PEPE

GND

Power

Lines

Mounting Screw

Locations

Power Supply from

Circuit Breaker

W

Ground

Wires

Transducer Wire - Black

B1

B4

B3B2

B7B6B5

Transducer Wire - Red

Jumper Wire

Temperature Sensor Wire - Red

B2

B4

B5

L2

L3

L1

U

V

W

PEPE

Temperature Sensor Wire - Black

1

Transducer Cable

GND

Temperature Sensor Cable

2

Power to Motor

Starter Control Wires

IL1140

Figure 4 - Controller Installation

3 & 5 HP

Pressure Sensor Leads

IL1076

7 (FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Page 8

IL1077

Power Supply

Connections

Figure 5 - Controller Installation

7.5 HP 3ø

GND

B2B4B5

Power Supply

Connections

Figure 6 - Controller Installation

7.5 HP 1ø

IL1078

8 (FW1365)

95 North Oak St. • Kendallville, IN 46755 • 1-800-345-9422

Loading...

Loading...