Page 1

Contents

Conveyor module XTUC S11 ........................................................................ 3

Conveyor module XTUC S51 ........................................................................ 4

Conveyor module XTUC J51/J52.................................................................. 4

Conveyor module XTUC L51/L52.................................................................. 4

Conveyor module XTUC U51/U52................................................. ... ............. 4

Conveyor module XTUC Z51/Z52 ................................................................. 4

Conveyor module XTUC F51/F52 ................................................................. 4

Conveyor module XTUC Q51/Q52................................................................ 5

Support module XTUF S01A ......................................................................... 6

Support module XTUF S02A ......................................................................... 6

Support module XTUF S03A ......................................................................... 6

Support module XTUF S04............................................................................ 6

Stop function module XTUS P11................................................................... 7

Locating function module XTUL P11A................................. ... ... .... ... ... ... ... .... 8

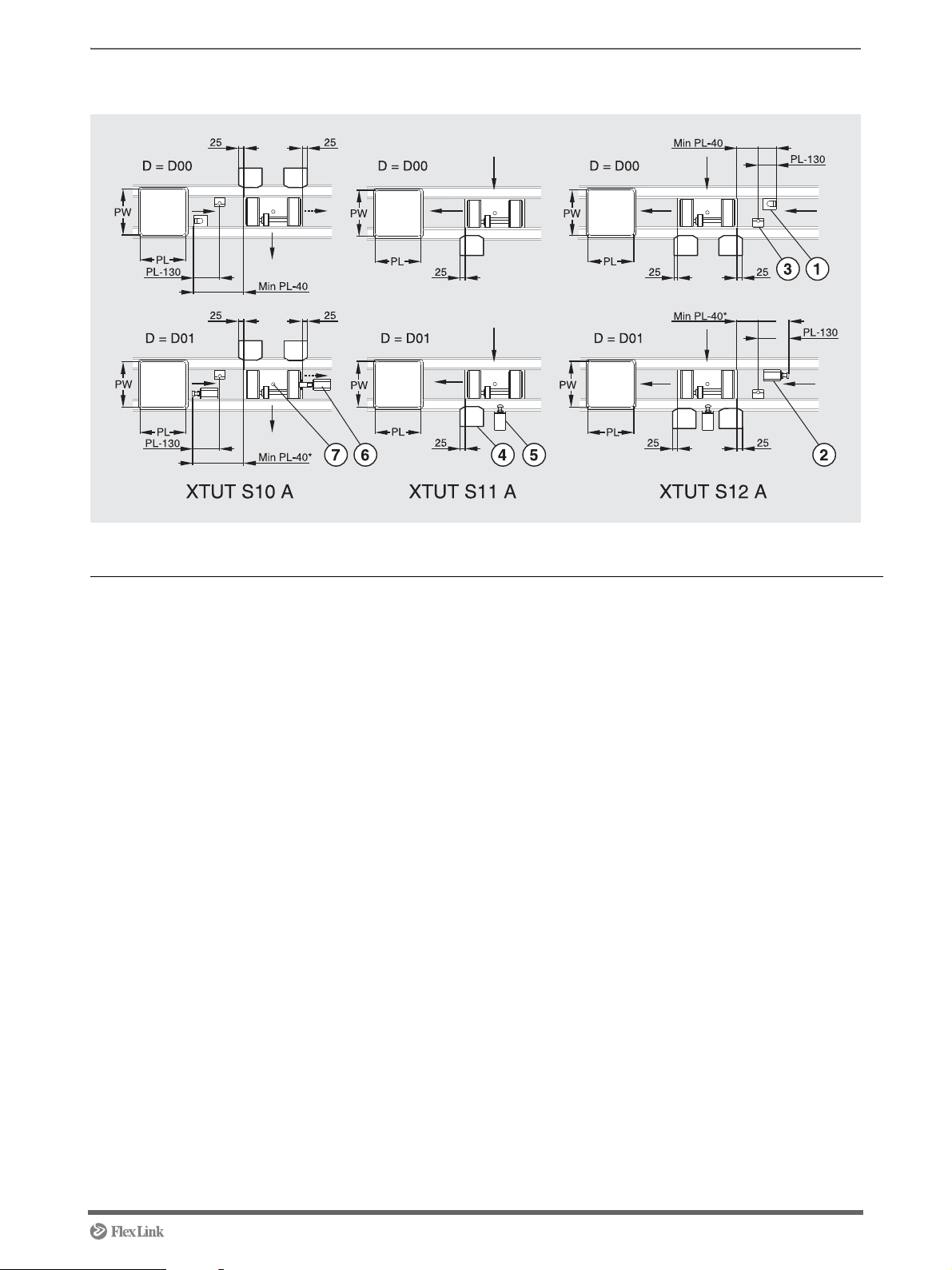

Transfer function module XTUT S10 A................... ... ... .... ... ... ....................... 9

Transfer function module XTUT S11 A................... ... ... .... ... ... ....................... 9

Transfer function module XTUT S12 A................... ... ... .... ... ... ....................... 9

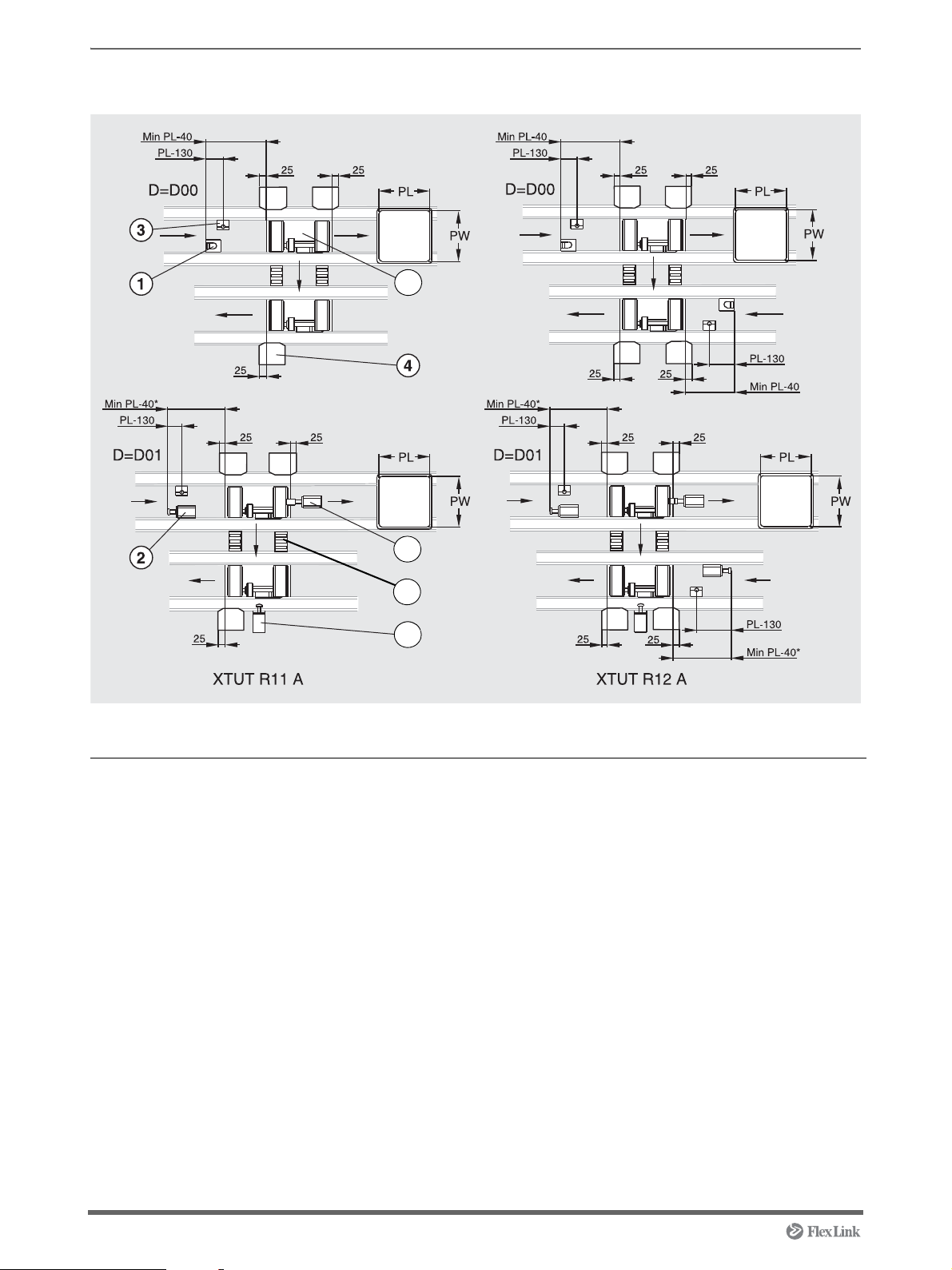

Transfer function module XTUT R11 A........................................................ 10

Transfer function module XTUT R12 A........................................................ 10

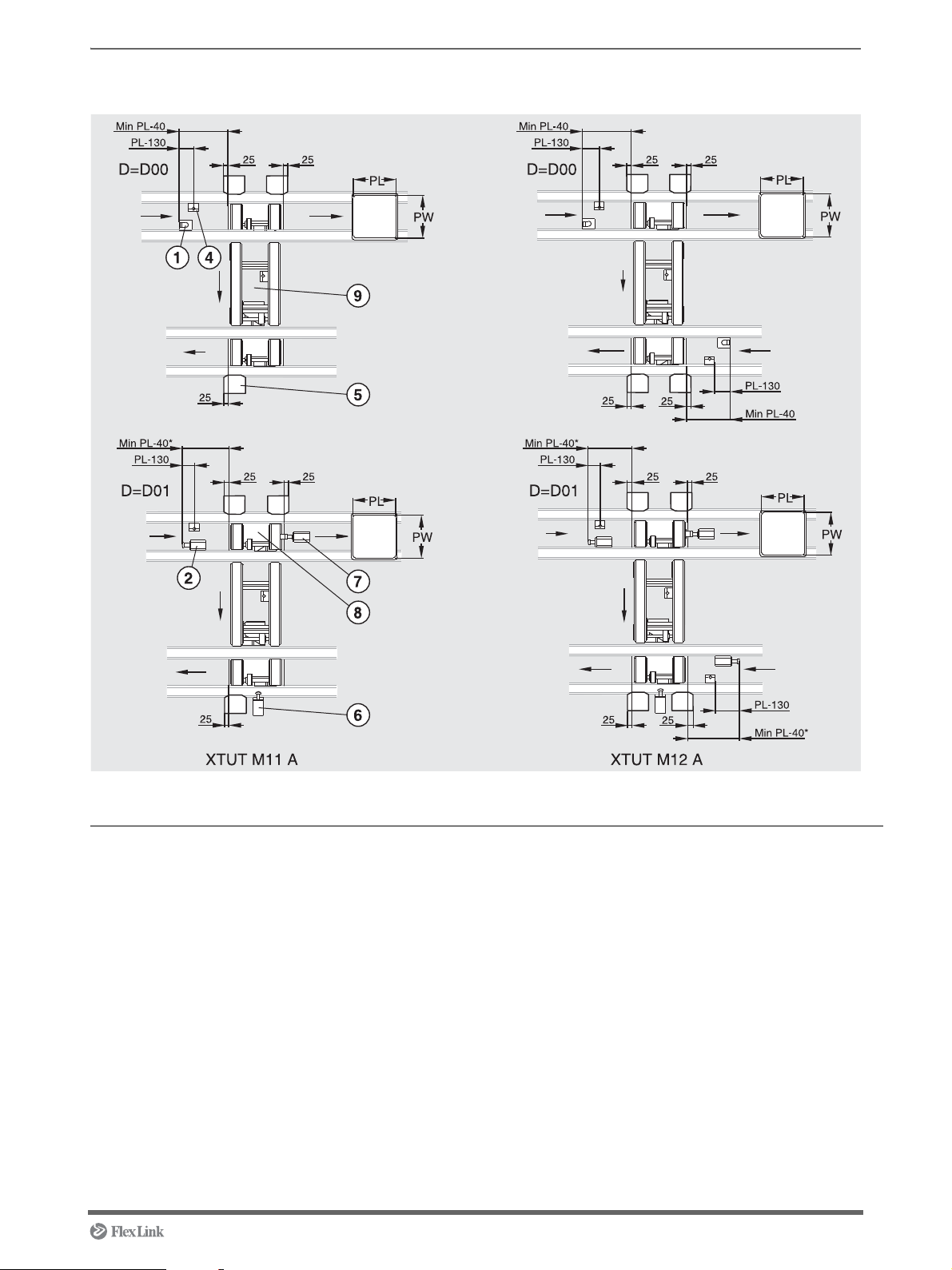

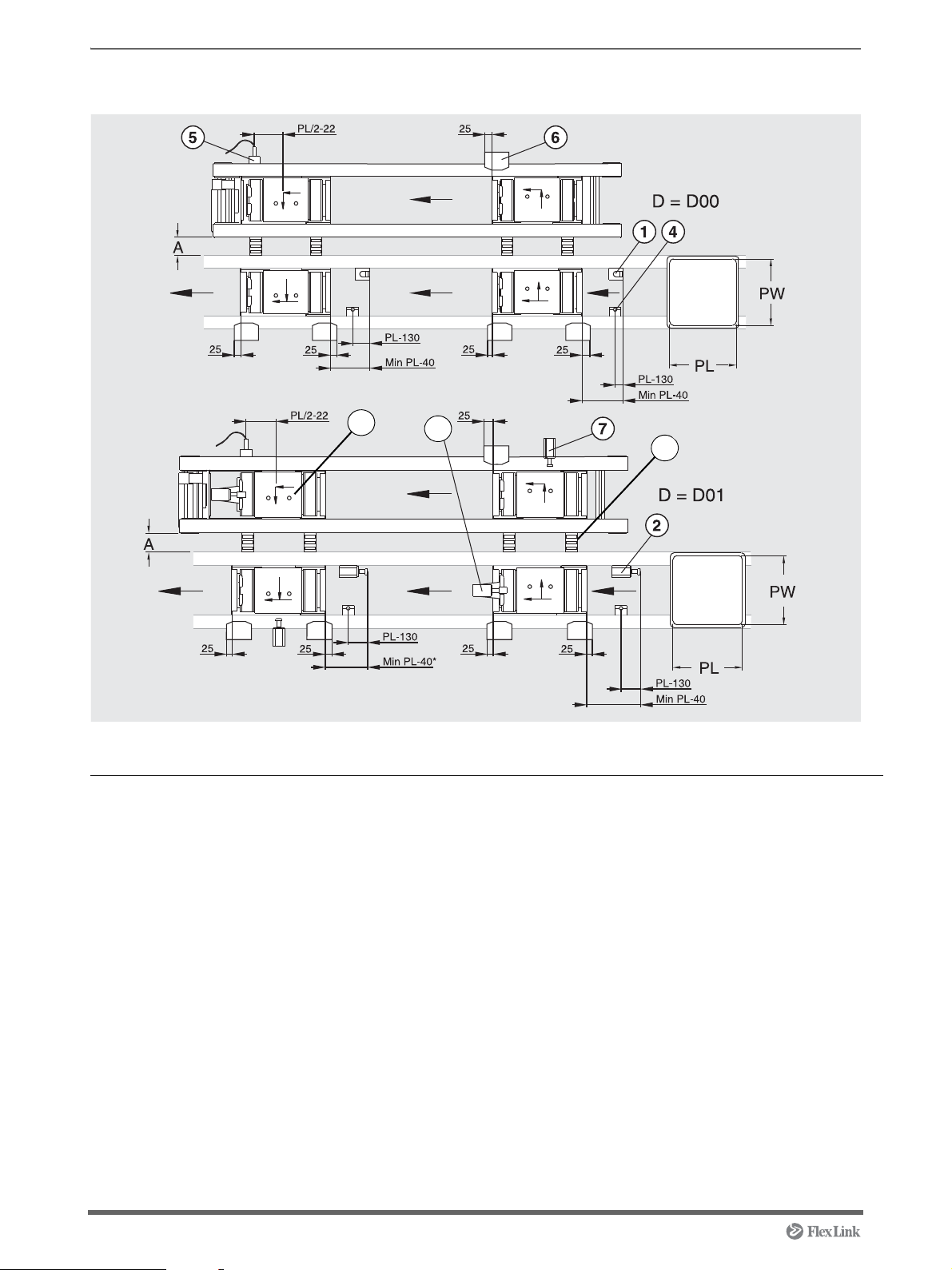

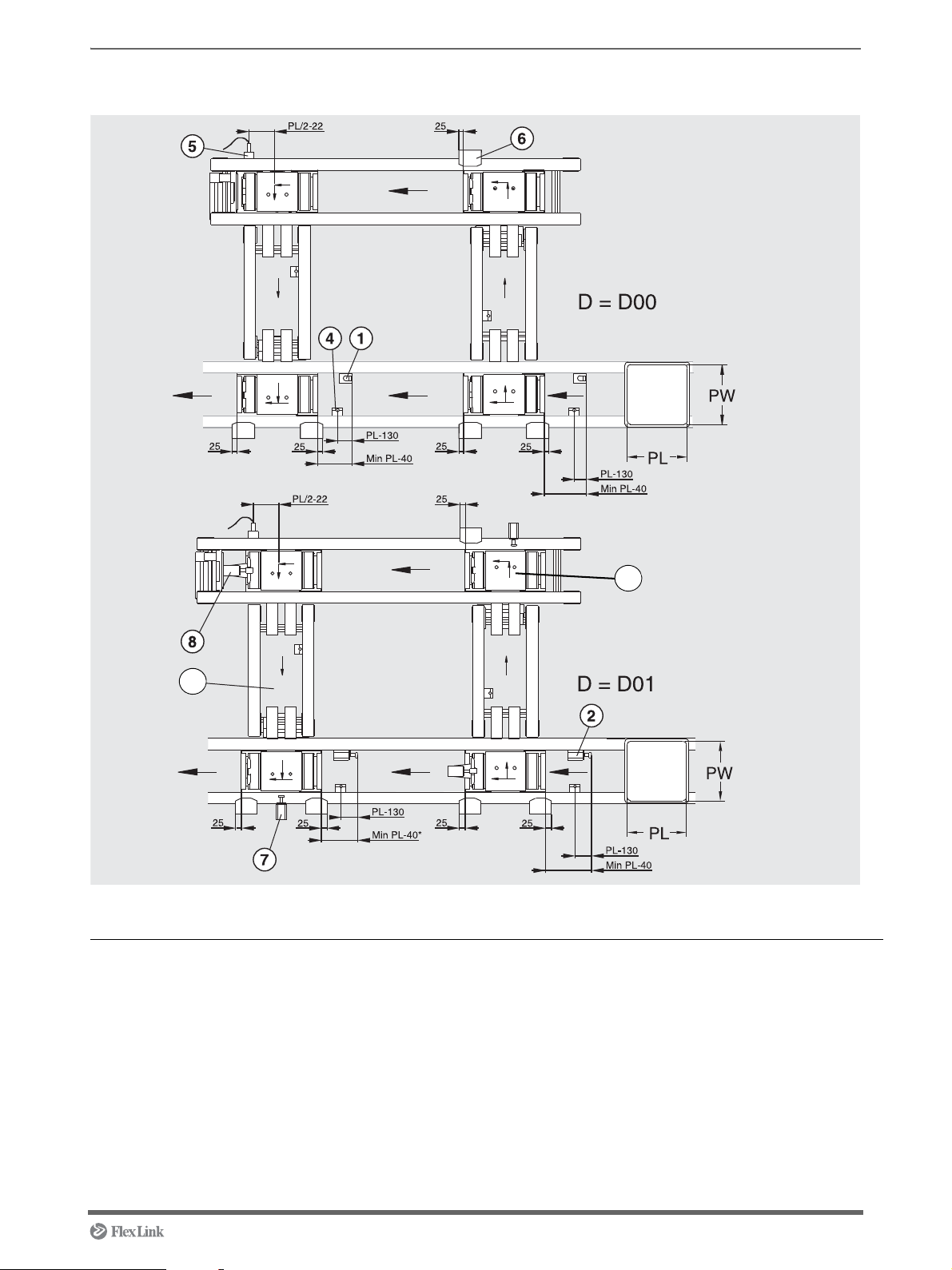

Transfer function module XTUT M11 A ....................................................... 11

Transfer function module XTUT M12 A ....................................................... 11

Work station function module XTUW R11 A................................................ 12

Work station function module XTUW M11 A ............................................... 13

Work station function module XTUW T11 A ................................................ 14

Work station function module XTUW Q11 A................................................ 15

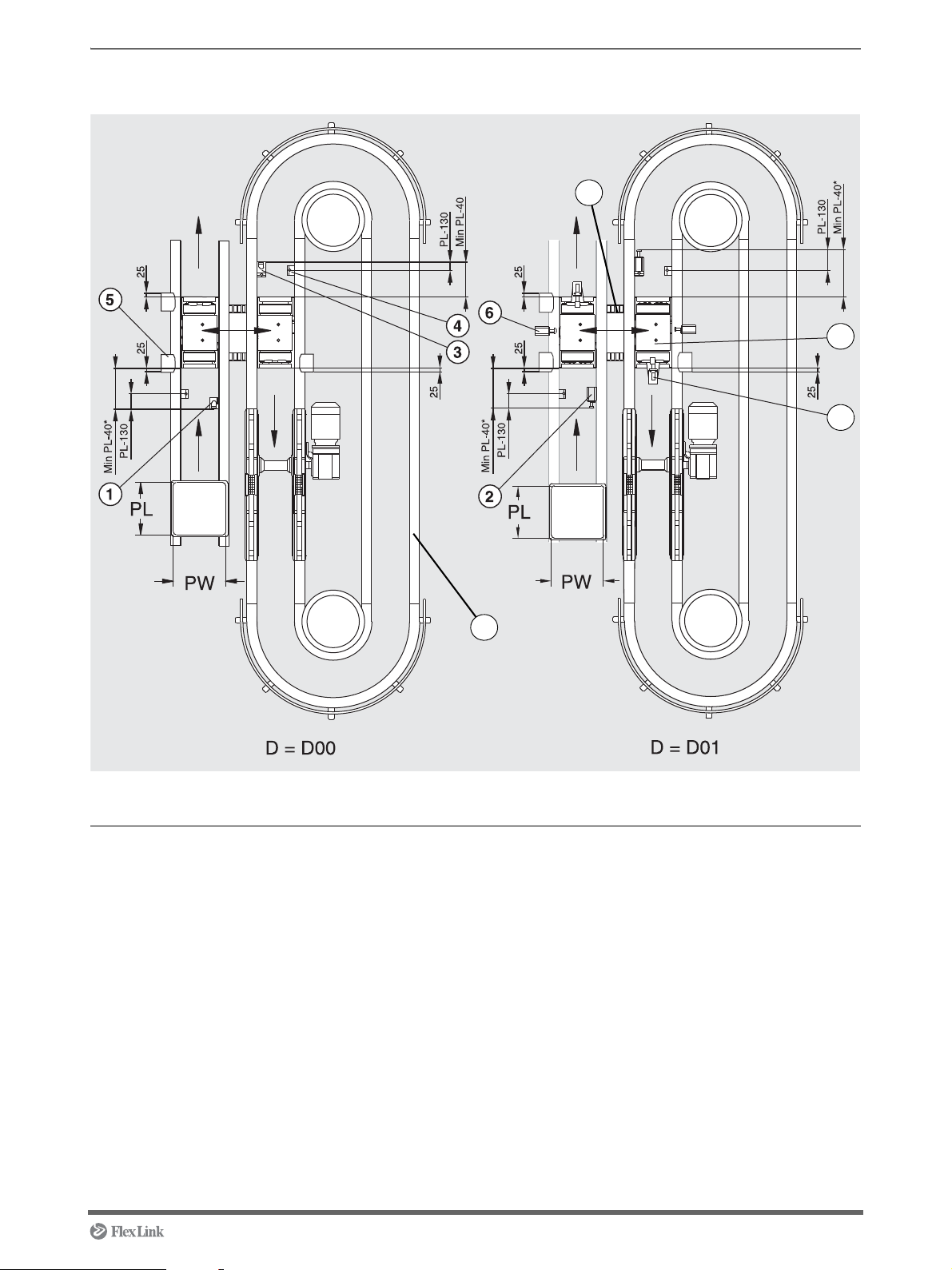

Lift and rotate module XTUR P11................................................................ 16

Lift and locate module XTUL P12................................................................ 17

Mounting instructions................................................................................... 18

Appendix A: EC declaration of incorporation............................................... 74

5113235 2

Page 2

2 5113235

Page 3

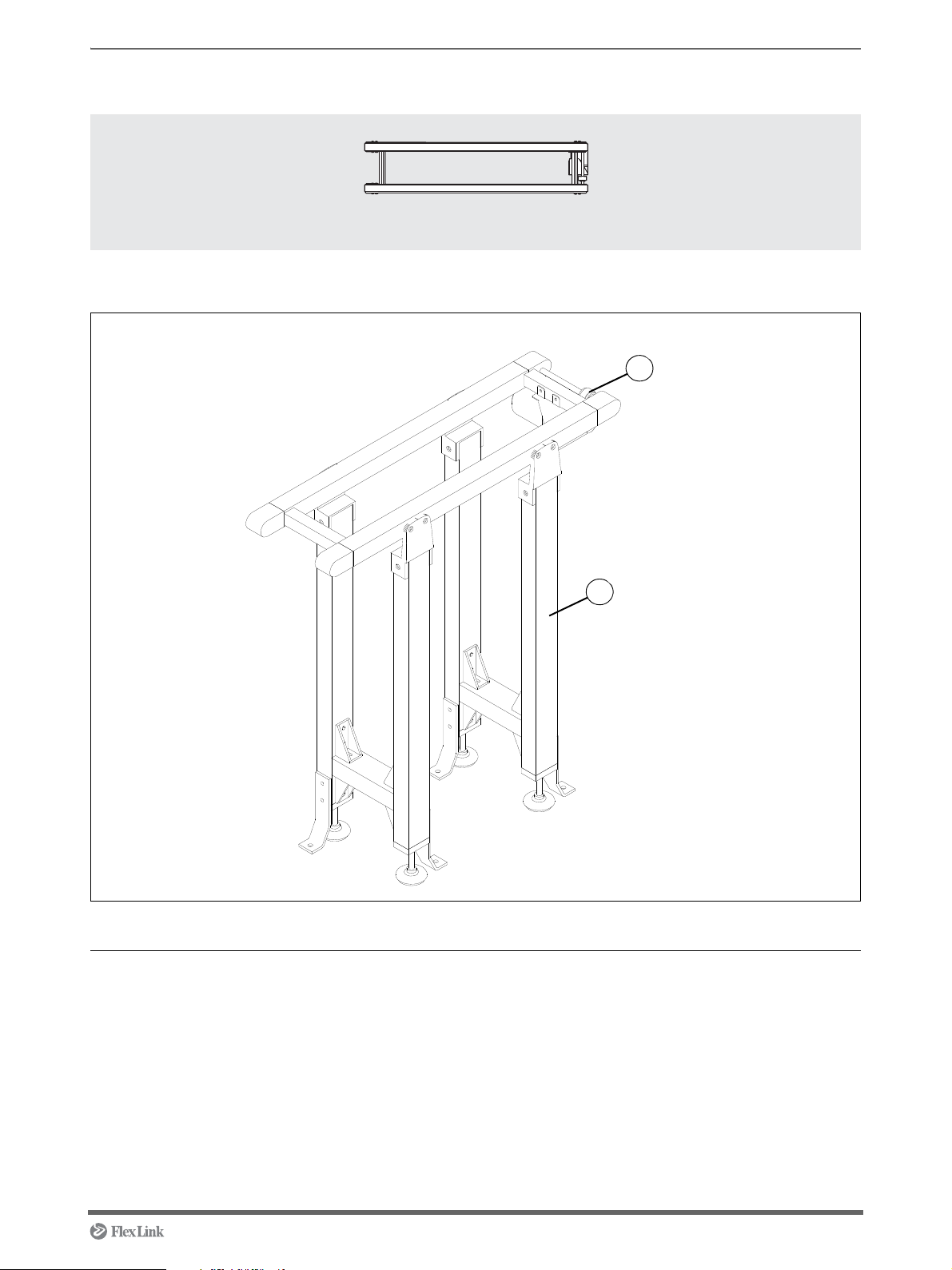

Conveyor module S11 Compact

XTUC S11

1

2

Overview

Assembly order

Pos Name Instruction

1 Connecting motor See page 19

2 Mounting support module See page 35

5113235 3

Page 4

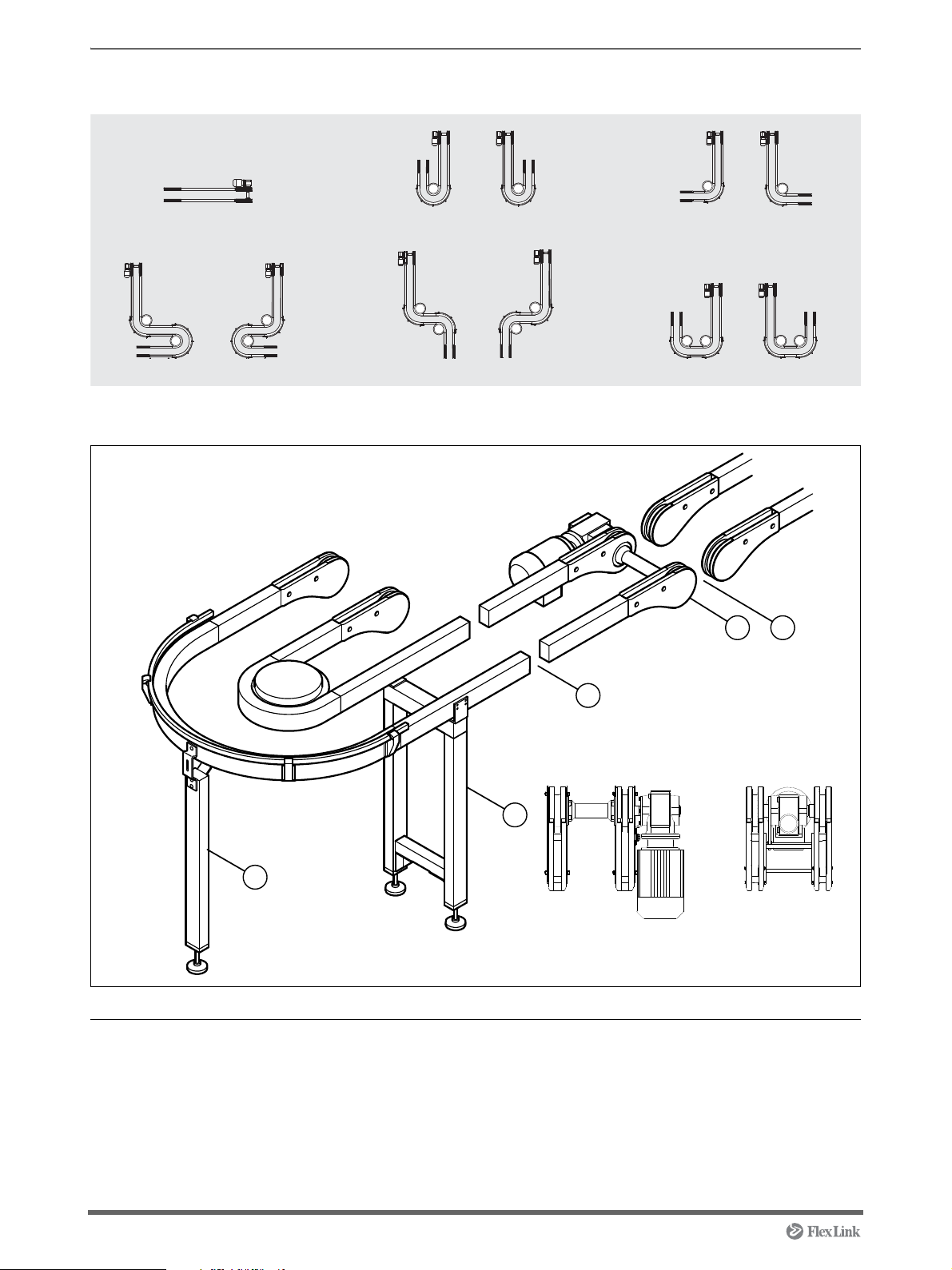

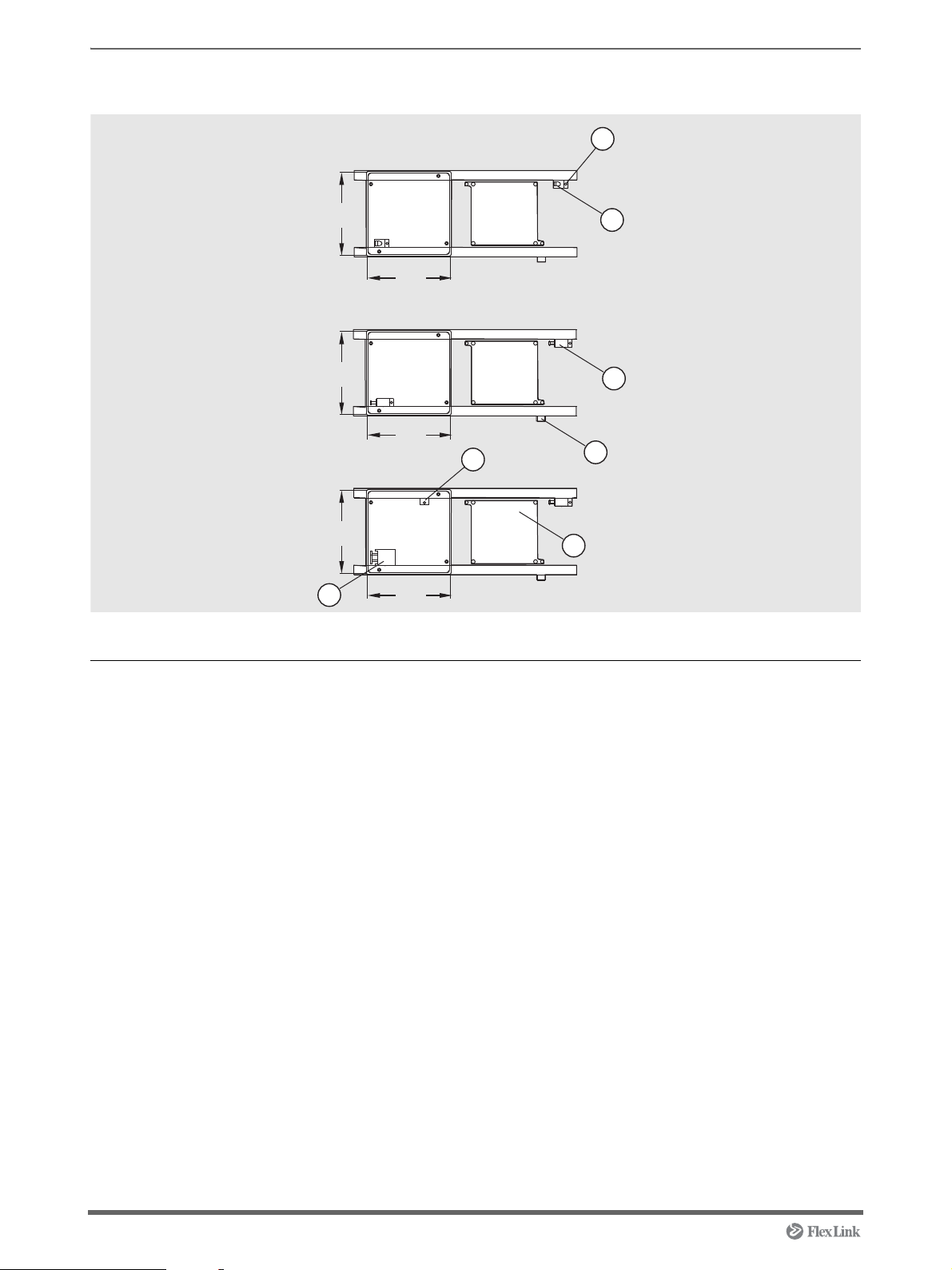

Conveyor modules

XTUC J51

XTUC J52

XTUC F51

XTUC F52

XTUC L51

XTUC L52

XTUC S51

XTUC U51

XTUC U52

XTUC Z51

XTUC Z52

1

2

3

4 5

Motor type L/R Motor type M/HM

Overview

Assembly order

Pos Name Instruction

1 Mounting support module See page 35

2 Mounting support module in bend See page 35

3 Docking XT conveyor sections See page 20

4 Mounting chain to XT conveyor modules See page 22

5 Connecting an XT conveyor module in line with another XT

4 5113235

conveyor:

-Motor type L or R See page 31

-Motor type M or HM See page 33

Page 5

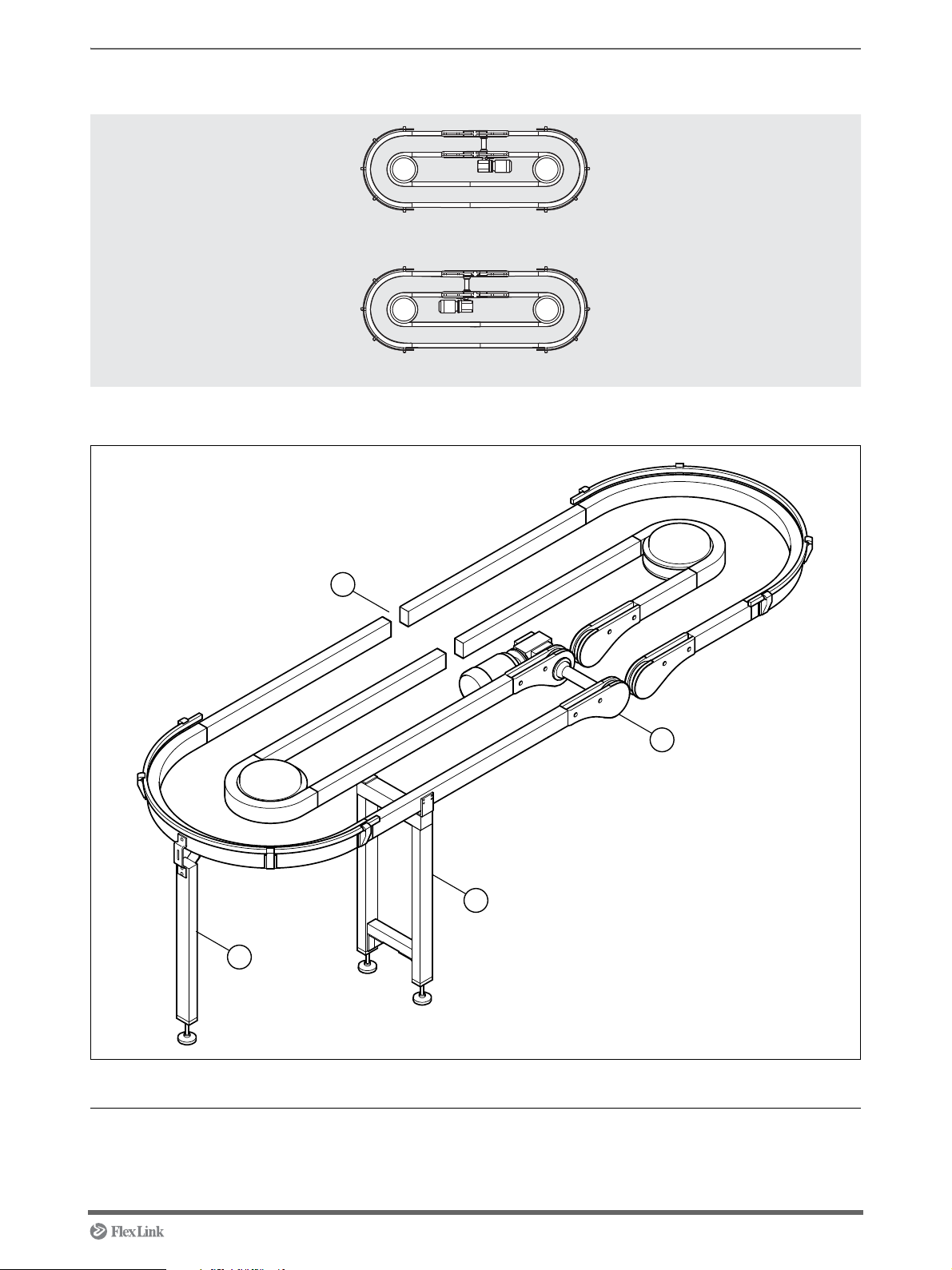

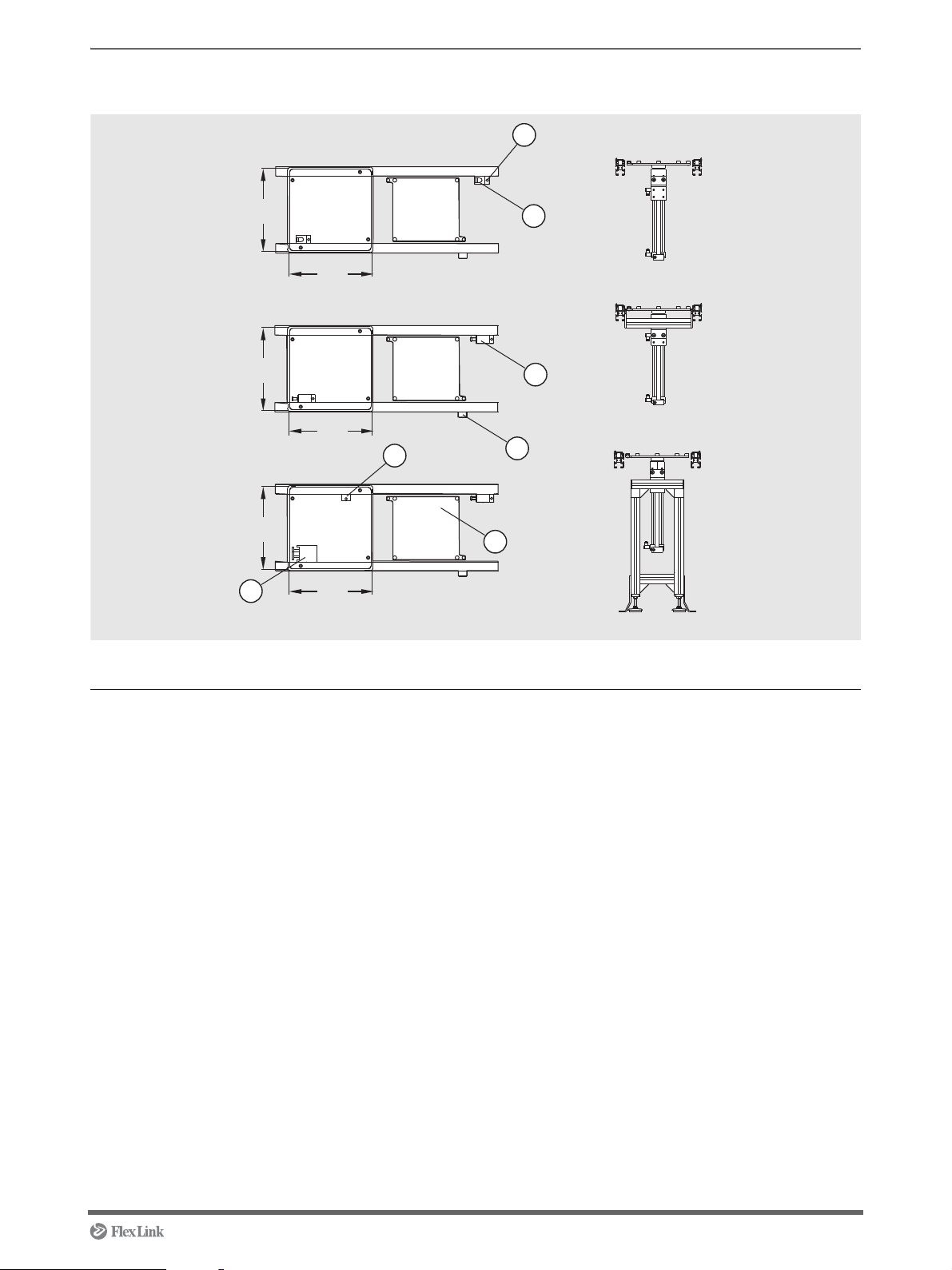

Conveyor module

XTUC Q51

XTUC Q52

1

2

3

4

Overview

Assembly order

Pos Name Instruction

1 Mounting support module See page 35

2 Mounting support module in bend See page 35

3 Docking XT conveyor sections See page 20

4 Mounting chain to XT conveyor module See page 26

5113235 5

Page 6

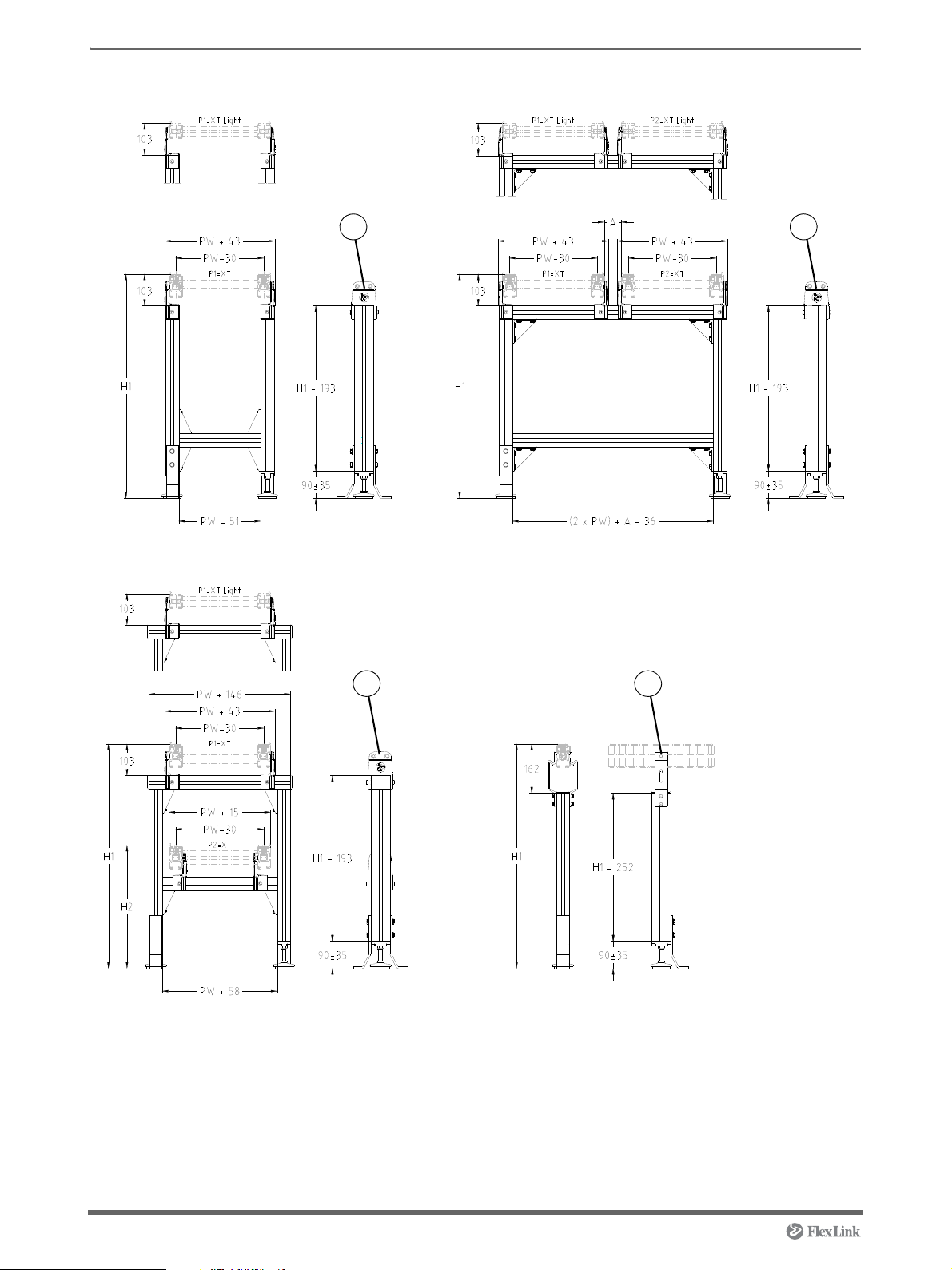

Support module S01A/S02A/S03A/S04

S 01A

S 03A

S 02A

S 04

1

1 1

1

Overview

Pos Name Instruction

1 Mounting support module See page 35

6 5113235

Page 7

Stop function module P11

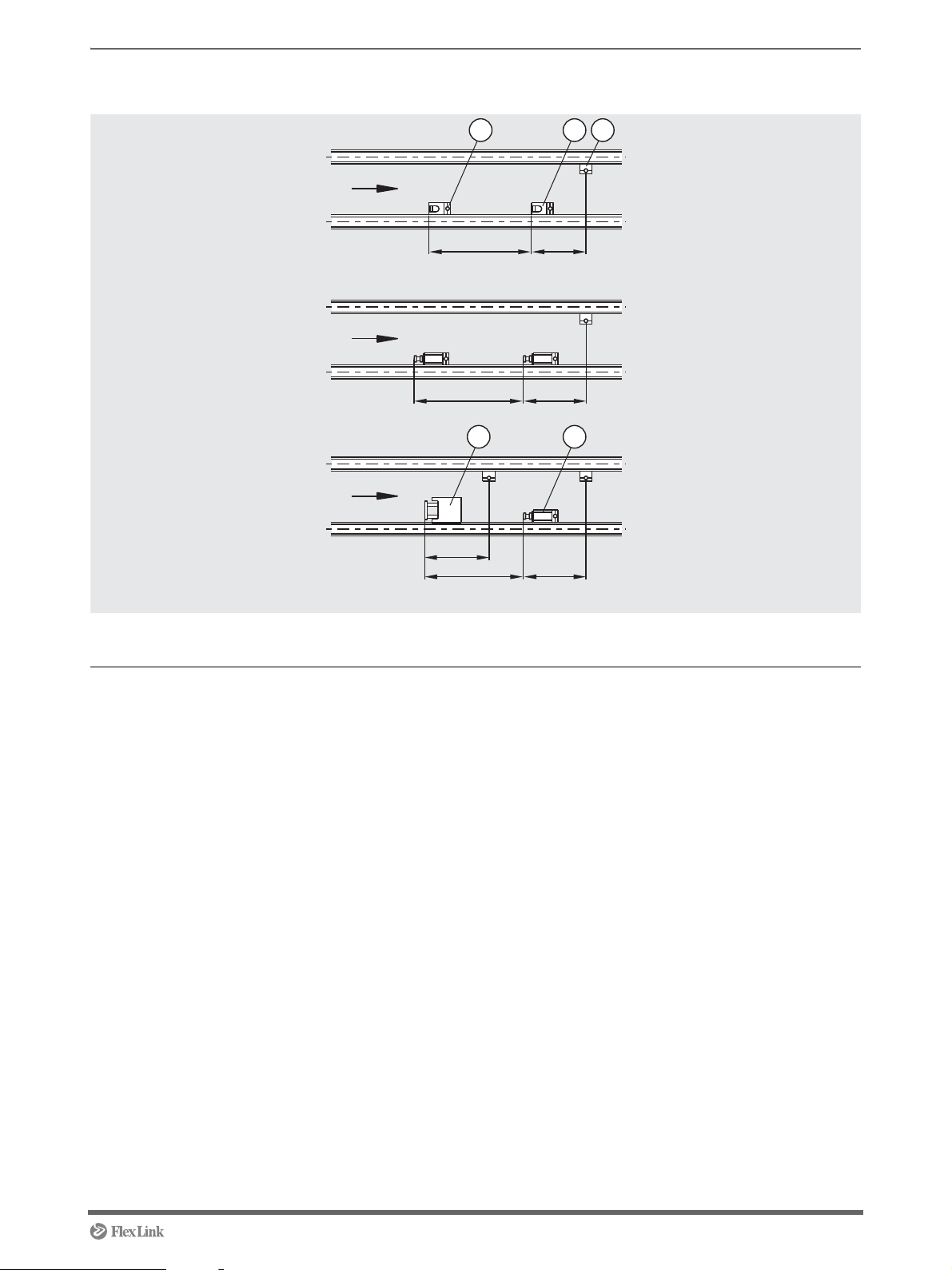

D = D00

D = D01

D = D02

PL-54

PL-54*

PL-54*

PL-54*

min PL+20

min PL+20*

min PL+20*

14

23

5

XTUS P11

Overview

* With stop heel compressed

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Pallet stop device damped XTPD D100 See page 42

4 Sensor bracket XTPB V001 See page 43

5 Sensor bracket XTPB V002 See page 45

5113235 7

Page 8

Locating function module P11A

Overview

Placement of stop and sensor brackets, see Stop function module P11.

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Pallet stop device damped XTPD D100 See page 42

4 Sensor bracket XTPB V001 See page 43

5 Sensor bracket XTPB V002 See page 45

6 Locating station XTPX P11A See page 52

8 5113235

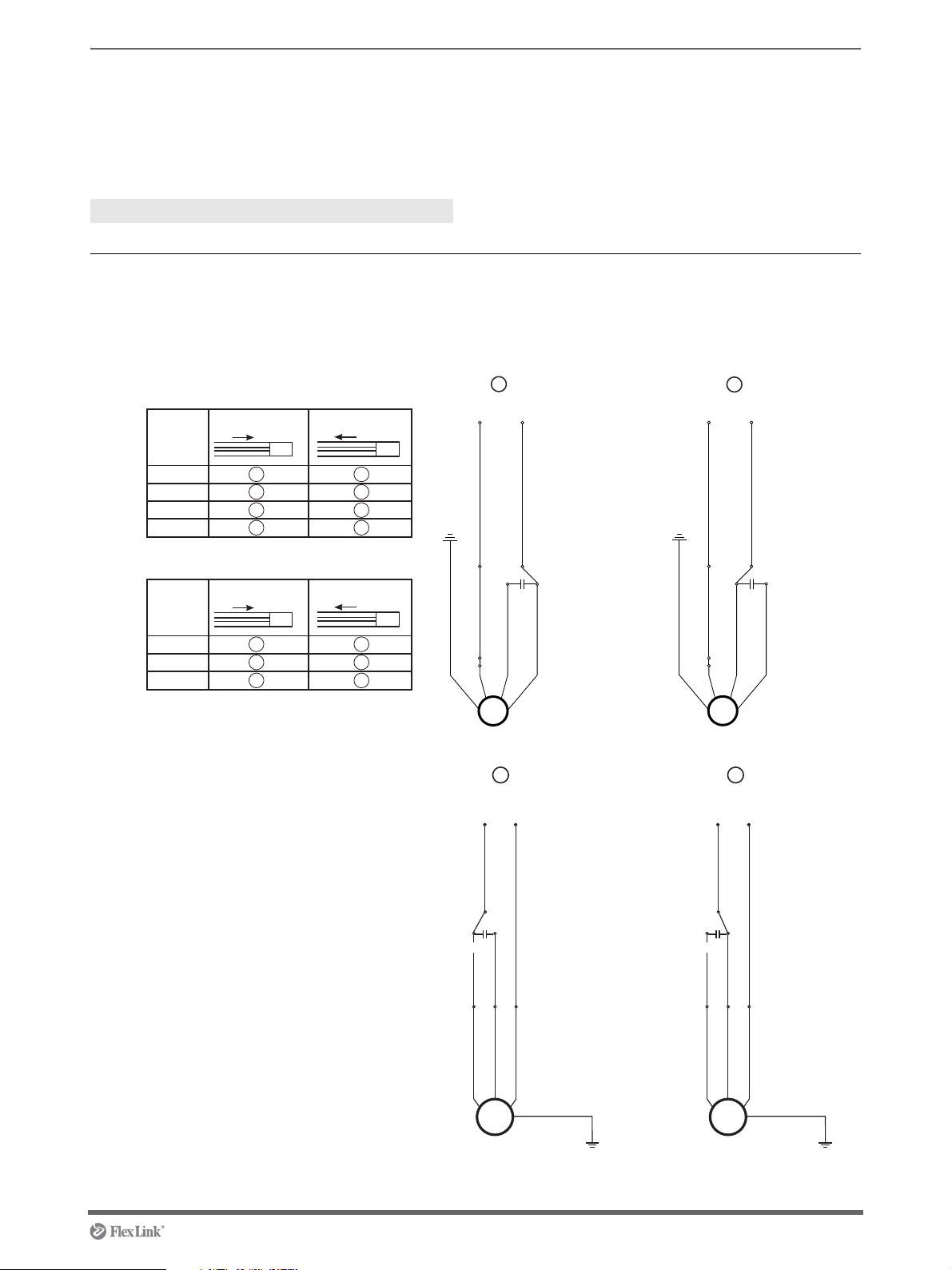

Page 9

Transfer module S10 A/S11 A/S12 A

Overview

* With stop heel compressed

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Sensor bracket XTPB V002 See page 45

4 Position sensor XTPB V003 See page 46

5 Damper XTPA CM35 See page 49

6 Damper XTPA MC35 PW A See page 57

7 Mounting transfer unit XTPT See page 57

5113235 9

Page 10

Transfer module R11 A/R12 A

8

5

7

6

Overview

* With stop heel compressed

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Sensor bracket XTPB V002 See page 45

4 Position sensor XTPB V003 See page 46

5 Damper XTPA CM35 See page 49

6 Roller kit 5049865, 5050117 See page 50

7 Damper XTPA MC35 PW A See page 57

8 Mounting transfer unit XTPT See page 57

10 5113235

Page 11

Transfer module M11 A/M12 A

Overview

* With stop heel compressed

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Sensor bracket (not in picture) XTPB V001 See page 43 (only for option Q01)

4 Sensor bracket XTPB V002 See page 45

5 Position sensor XTPB V003 See page 46

6 Damper XTPA CM35 See page 49

7 Damper XTPA MC35 PW A See page 57

8 Mounting transfer unit XTPT See page 57

9 Mounting connecting kit 5050034 See page 51

5113235 11

Page 12

Work station module R11 A

10

8

9

Overview

* With stop heel compressed

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Sensor bracket (not in picture) XTPB V001 See page 43 (only for option S01 &

L01).

4 Sensor bracket XTPB V002 See page 45

5 Sensor bracket XTPB H001 See page 48

6 Position sensor XTPB V003 See page 46

7 Damper XTPA CM35 See page 49

8 Roller kit 5049865, 5050117 See page 50

9 Damper XTPA MC35 PW A See page 57

10 Mounting transfer unit XTPT See page 57

12 5113235

Page 13

Work station module M11 A

9

10

Overview

* With stop heel compressed

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Sensor bracket (not in picture) XTPB V001 See page 43 (only for option Q01,

4 Sensor bracket XTPB V002 See page 45

5 Sensor bracket XTPB H001 See page 48

6 Position sensor XTPB V003 See page 46

7 Damper XTPA CM35 See page 49

8 Damper XTPA MC35 PW A See page 57

9 Mounting transfer unit XTPT See page 57

10 Mounting connecting kit 5050034 See page 51

5113235 13

S01 & L01).

Page 14

Work station module T11 A

6

8

7

Overview

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Sensor bracket (not in picture) XTPB V001 See page 43 (only for option Q01,

S01 & L01).

3 Sensor bracket XTPB V002 See page 45

4 Sensor bracket XTPB H001 See page 48

5 Position sensor XTPB V003 See page 46

6 Roller kit 5049865,

5050117

7 Mounting connecting kit 5050034 See page 51

8 Mounting transfer unit XTPT See page 57

See page 50

14 5113235

Page 15

Work station module Q51 A

10

9

8

7

Overview

* With stop heel compressed

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device damped XTPD D35 See page 40

3 Sensor bracket XTPB V001 See page 43

4 Sensor bracket XTPB V002 See page 45

5 Position sensor XTPB V003 See page 46

6 Damper XTPA CM35 See page 49

7 Roller kit 5049865, 5050117 See page 50

8 Damper XTPA MC35 PW A See page 57

9 Mounting transfer unit XTPT See page 57

10 Mounting conveyour module XTUC Q51 See page 5

5113235 15

Page 16

Lift and rotate module P11

PW

PL

PW

PW

PL

PL

5

3

7

6

2

1

4

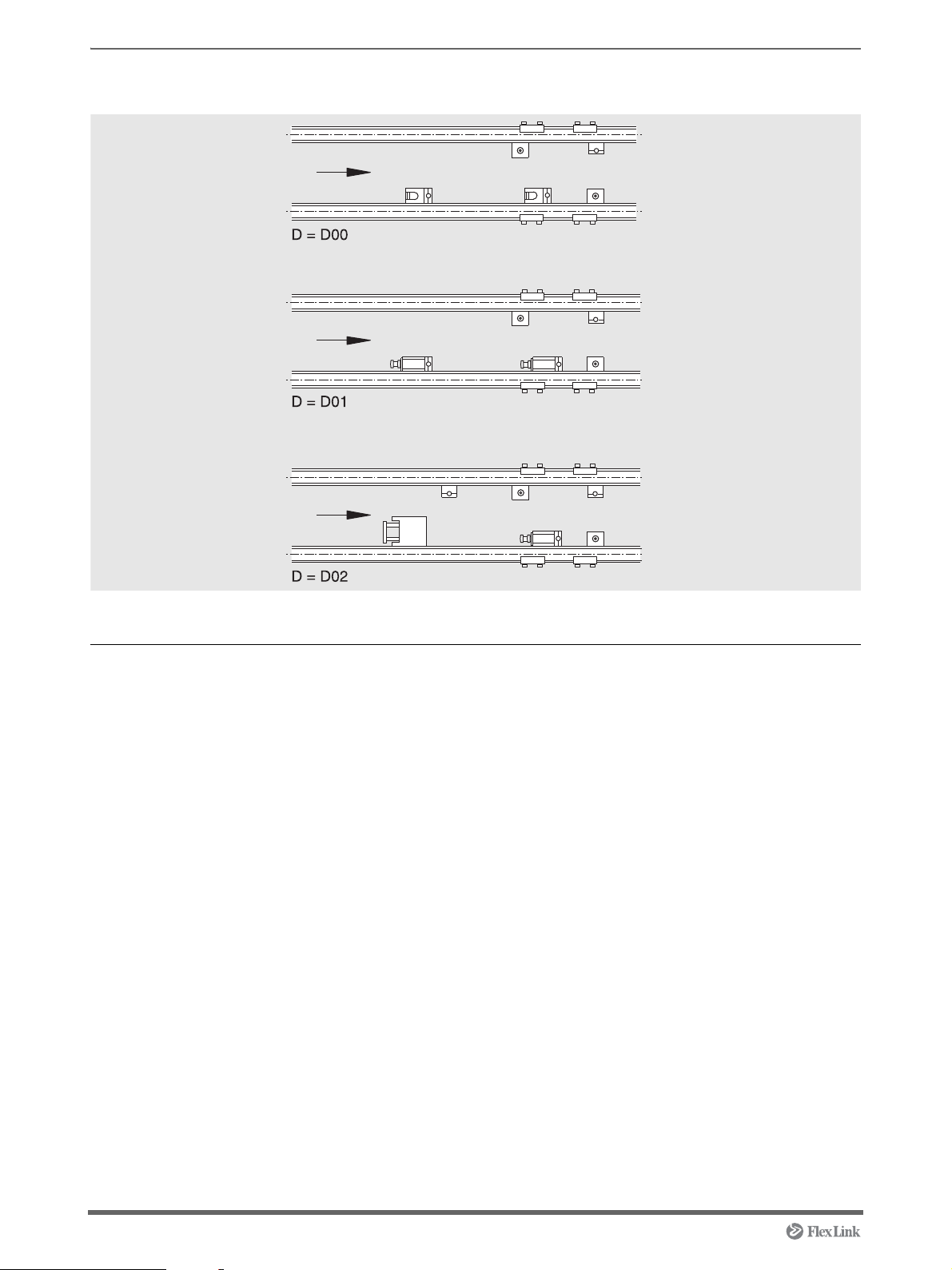

D = D00

D = D01

D = D02

Overview

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device, damped XTPD D35 See page 40

3 Pallet stop device, damped XTPD D100 See page 42

4 Sensor bracket XTPB V001 See page 43

5 Sensor bracket XTPB V002 See page 45

6 Sensor bracket XTPB H001 See page 48

7 Mounting lift and rotate unit XTUR P11 See page 68

16 5113235

Page 17

Lift and locate module P12

PW

PL

PW

PW

PL

PL

5

3

7

6

2

1

4

D = D00

D = D01

D = D02

F = F00

F = F01

F = F02

Overview

Pos Name Designation Instruction

1 Pallet stop device XTPD U200 See page 38

2 Pallet stop device, damped XTPD D35 See page 40

3 Pallet stop device, damped XTPD D100 See page 42

4 Sensor bracket XTPB V001 See page 43

5 Sensor bracket XTPB V002 See page 45

6 Sensor bracket XTPB H001 See page 48

7 Mounting lift and locate unit XTUL P12 See page 70

5113235 17

Page 18

Mounting instructions

Contents

Connecting motor XTUC S11...................................................................... 19

Docking XT conveyor sections ............................................ ... ... .... ... ... ... ... .. 20

Mounting chain to XT conveyor modules – End drive ................................. 22

Mounting chain to XT conveyor modules – Catenary drive ......................... 26

Connecting XT conveyor modules in line – Side mounted motor................ 31

Connecting XT conveyor modules in line – Centre mounted motor ............ 33

Mounting support module............................................................................ 35

Mounting pallet stop device XTPD U200..................................................... 38

Mounting pallet stop device XTPD D35....................................................... 40

Mounting pallet stop device XTPD D100..................................................... 42

Mounting sensor bracket XTPB V001.......................................................... 43

Mounting sensor bracket XTPB V002.......................................................... 45

Mounting position sensor XTPB V003......................................................... 46

Mounting sensor bracket XTPB H001 ......................................................... 48

Mounting damper CM 35............................................................................. 49

Mounting roller kit ........................................................................................ 50

Mounting connecting kit 5050034. ... .... ... ... ... ... .... ... ... ... .... ... ... ..................... 51

Mounting pallet locating station XTPX P11A............................................... 52

Mounting transfer unit XTPT M1.......................... ... ... ... .... ... ... ... .................. 57

Mounting transfer unit XTPT M2.......................... ... ... ... .... ... ... ... .................. 60

Mounting transfer unit XTPT L............................. ... ... ... .... ... ... ..................... 63

Mounting damper MC 35 PW A................................................................... 67

Mounting lift and rotate unit XTUR P11 ....................................................... 68

Mounting lift and locate unit XTUL P12 ....................................................... 70

18 5113235

Page 19

Connecting motor XTUC S11

Brown (No 2) On S8R25GE grey)

Brown (No 2) On S8R25GE grey)

Green/yellow

GND

Green/yellow

GND

Capacitor Capacitor

1

2

Neutral

Phase

Neutral

Phase

3 4

50 , 230V

Hz

60Hz,115V

Forward

Forward Reverse

Reverse

Speed

m/min

Speed

m/min

54

10

15

20

M

M

6

12

18

M

M

3

3 4

3 4

4 3

2 1

1 2

1 2

Black (No 3)

White (No 1)

Black (No 3)

White (No 1)

Green/Yellow (No 4)

Black (No 3)

White (No 1)

Grey (No 2)

Phase

Neutral

T/P

Capacitor

Green/Yellow (No 4)

Black (No 3)

White (No 1)

Grey (No 2)

Phase

Neutral

T/P

Capacitor

M

MMM

MM

GND

GND

Introduction

NOTE! The capacitor must alwa ys be encapsulated to

prevent electric shock.

Tools

- -

Instruction

1 Connect the motor according to wiring diagram

below.

5113235 19

Page 20

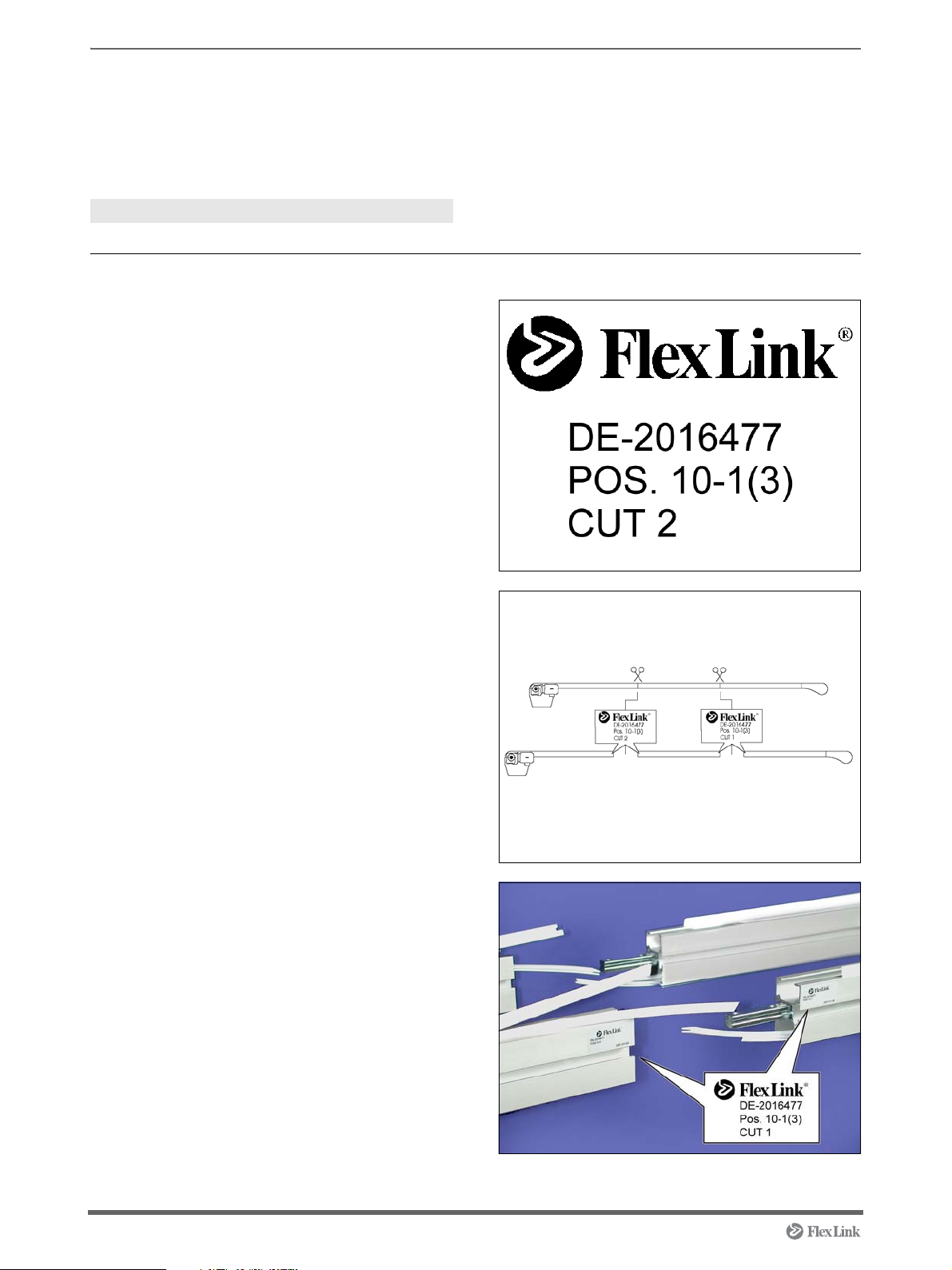

Docking XT conveyor sections

Introduction

This instruction is only valid for conveyor XT. NOTE! A short or narrow conveyor can easily fall over.

Always anchor the conveyor to the floor!

Tools

Allen key 4 mm

Instruction

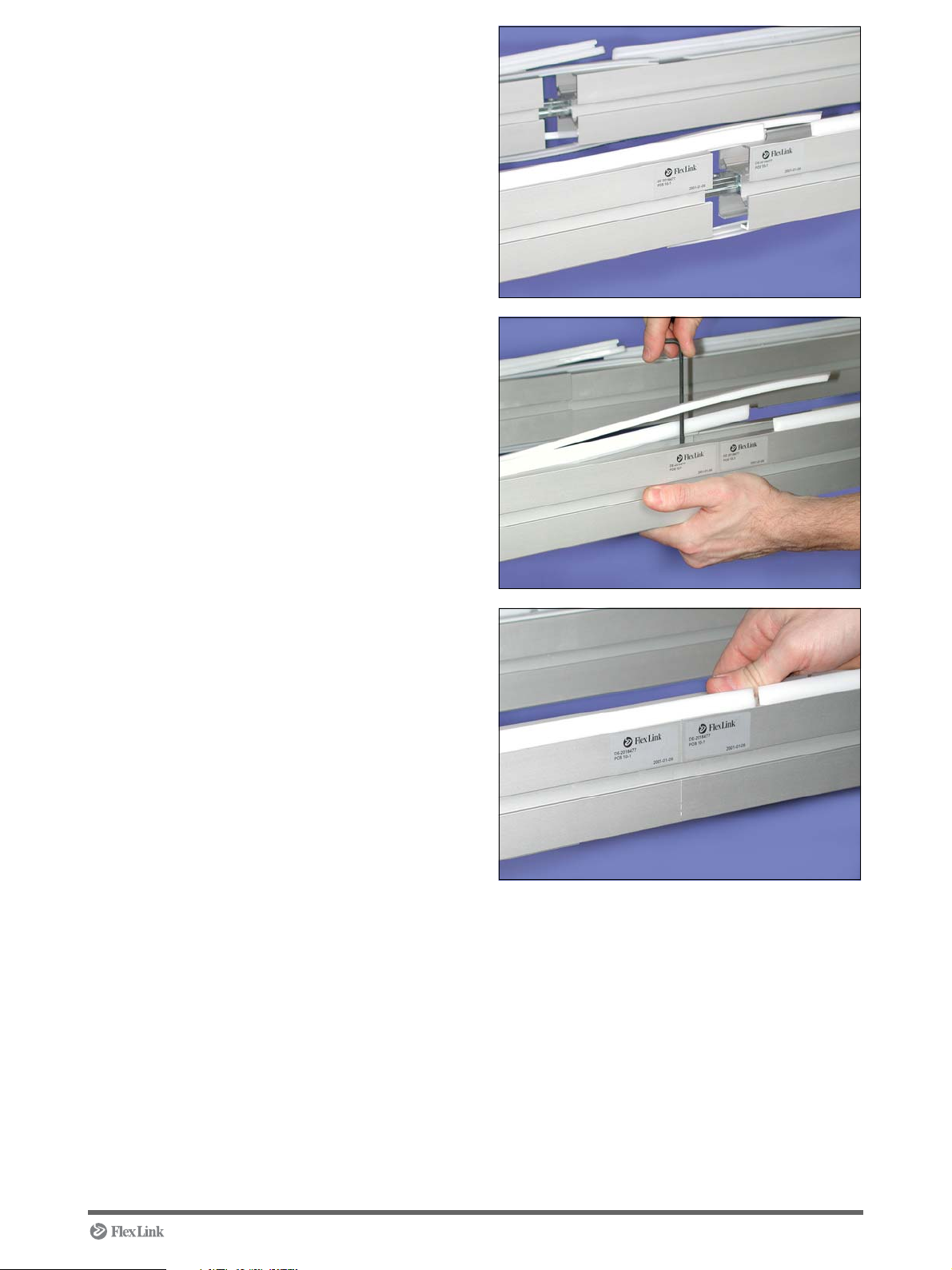

1 The section labels indicate following:

First row is the order number.

Second row indicates the item position on the

order and which individual among a quantity, e.g.

Pos. 10 first conveyor of three.

The third row indicates which cut it is.

Two sections with identical labels should be

connected to each other.

2 Unpack the conveyor sections and arrange them

so that beam ends with identical labels are facing

each other. Place the conveyor sections on the

same level and in line with each other.

3 Dock the conveyor sections to each other.

20 5113235

Page 21

4 Make sure that the conveyor section ends fit

together properly.

5 Tighten the screws. Use the 4 mm allen key.

Torque value for tightening: 8 Nm

6 Press the slide rail in place.

5113235 21

Page 22

Mounting chain to XT conveyor modules – End drive

Introduction

Valid for motor types M and HM (centre mounted

motor) and L and R (side mounted motor). If nothing

else is specified the instruction step is valid for both

centre and side mounted motor.

Tools

Box wrench 10 mm

Box wrench 7 mm

Skip joint pliers

Pin insertion tool

Screwdriver

Instruction

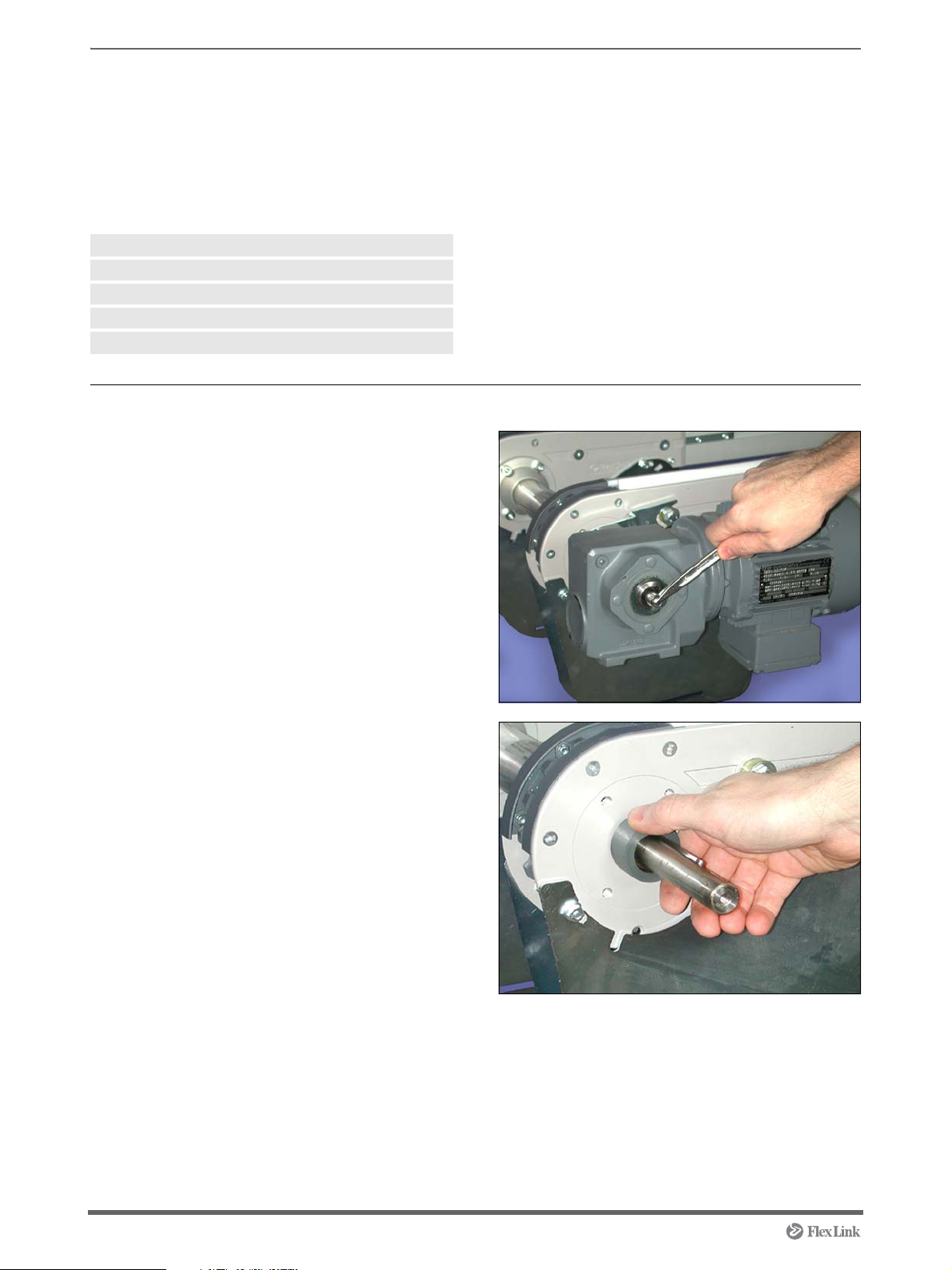

1 Side mounted motor:

Use the screwdriver to remove the plastic cap on

the motor. Loosen the screw for the motor with

the 10 mm socket wrench.

2 Side mounted motor:

Lift off the motor and remove the plastic sleeve.

22 5113235

Page 23

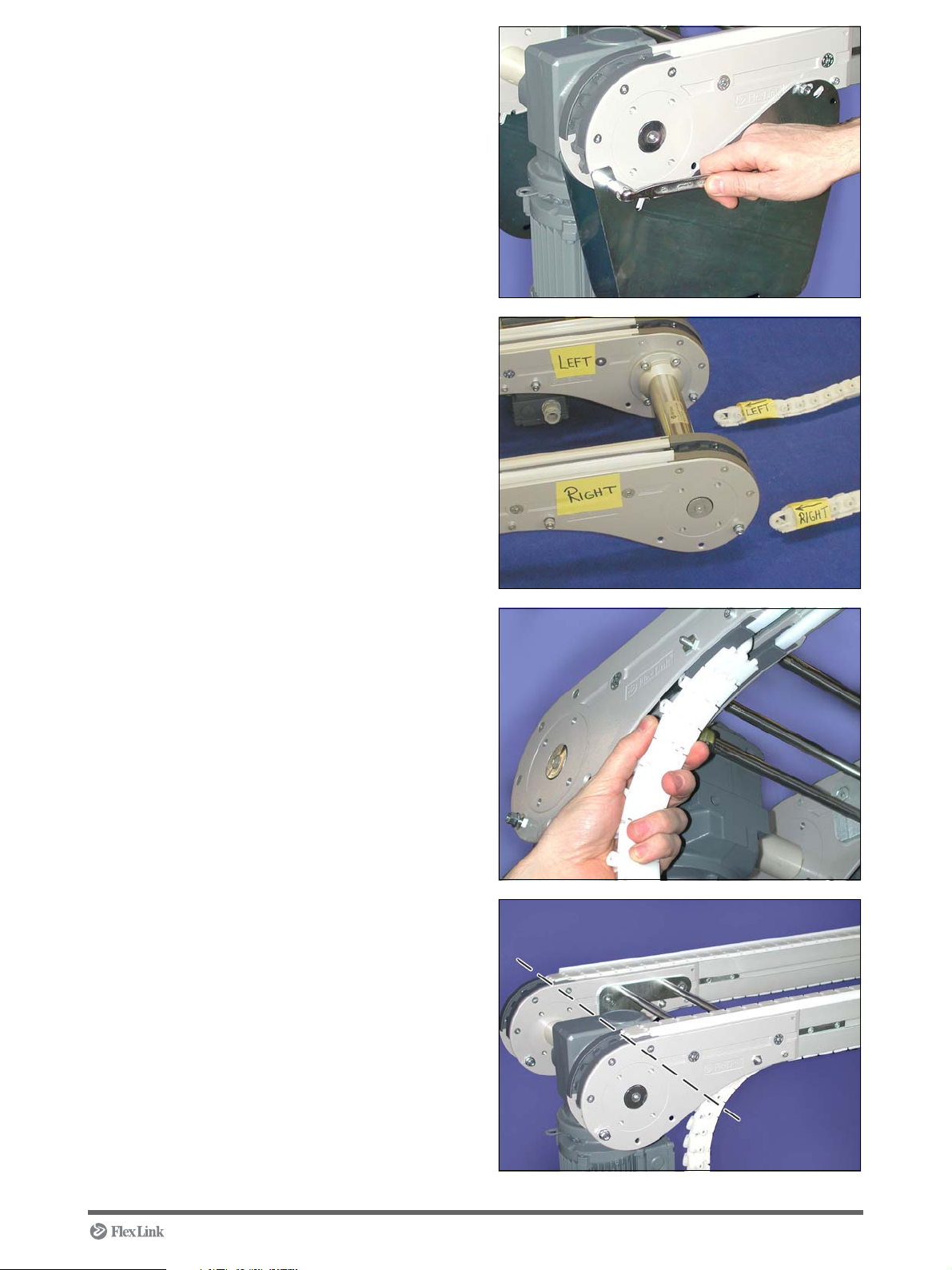

3 Remove the nuts for the slack protection. Use a

10 mm box wrench.

4 Notice the label Left and Right on the chain.

Mount the chain to the conveyor with similar

mark.

5 Insert the chain from below, with the nose for-

ward.

Repeat the same procedure with the other chain.

6 Feed the chains into the conveyor until they

reach the drive wheel at the driving end.

5113235 23

Page 24

7 Centre mounted motor (A):

B

A

Check rib down

A

Remove the fan cover. Use the 7 mm box

wrench. Feed the chains to the drive wheel and

turn the fan until the chains are hanging a bit

below the conveyor.

Side mounted motor (B):

Feed the chains to the drive wheel and turn the

drive shaft until the chains are hanging a bit

below the conveyor.

CAUTION! Make sure that the chain enters the

drive wheel correctly. Risk for the plastic guides

to brake.

8 Use a pair of slip joint pliers to insert the pin half-

way into the chain link.

9 Join the chain ends. Make sure that the joint ball

has not been removed and re-assembled upside

down.

CAUTION! Wrongly positioned joint ball will lead

to chain damage when running the chain.

10 Press the pin through the chain. Use the pin

insertion tool.

TIP! Use a clamp (A) to keep the chain stretched.

24 5113235

Page 25

11 Make sure that the pin snaps in to the correct

position (centered).

12 Centre mounted motor:

Fit the fan cover to the motor and tighten the

screws. Use the 7 mm box wrench. Fit the slack

protections and tighten the nuts. Use the 10 mm

box wrench.

Side mounted motor:

Fit the slack protections and tighten the nuts.

Use the 10 mm box wrench.

13 Side mounted motor:

Fit the plastic sleeve on the drive shaft.

14 Side mounted motor:

Fit the motor on the drive shaft and tighten the

screw. Use a 10 mm socket wrench. Fit the

plastic cap.

CAUTION! Make sure that the torque arm fork

has entered the cage in a correct way. An

unlocked rotating motor can cause personal

injury.

5113235 25

Page 26

Mounting chain to XT conveyor module – Catenary drive

Introduction

The chain only runs on top of the conveyor.

Tools

Box wrench 10 mm

Skip joint pliers

Pin insertion tool

Screwdriver

Instruction

1 Use the screwdriver to remove the plastic cap on

the motor. Loosen the screw for the motor with

the 10 mm socket wrench.

2 Lift off the motor and remove the plastic sleeve.

26 5113235

Page 27

3 Notice the label Left and Right on the chain.

Mount the chain to the conveyor with similar

mark.

4 Insert the chain from below, with the nose for-

ward.

CAUTION! Make sure that you start feeding the

chain in the idler end unit and towards the driving

unit or it might lead to a chain damage.

5 Catch the chain and feed it via the idler end into

the conveyor. Repeat the same procedure with

the other chain.

6 Feed the chains into the conveyor until they

reach the drive wheel at the driving end.

5113235 27

Page 28

7 Feed the chains to the drive wheel and turn the

Check rib down

drive shaft until the chains are hanging a bit

below the conveyor.

CAUTION! Make sure that the chain enters the

drive wheel correctly. Risk for the plastic guides

to brake.

8 Use a pair of slip joint pliers to insert the pin half-

way into the chain link.

9 Join the chain endings. Make sure that the joint

ball has not been removed and re-assembled

upside down.

CAUTION! Wrongly positioned joint ball will lead

to chain damage when running the chain.

10 Press the pin through the chain. Use the pin

insertion tool.

28 5113235

Page 29

11 Make sure that the pin snaps in to the correct

position (centered).

12 Fit the slack protection covers to end position.

13 Fit and tighten the screws (4 x M6). Use the 10

mm box wrench.

14 Fit the plastic sleeve on the drive shaft.

5113235 29

Page 30

15 Fit the motor on the drive shaft.

16 Fit and tighten the screw. Use the 10 mm socket

wrench. Fit the plastic cap.

CAUTION! Make sure that the torque arm fork

has entered the cage in a correct way. An

unlocked rotating motor can cause personal

injury.

17 Place the roller bridge between the conveyors.

30 5113235

Page 31

Connecting an XT conveyor module, side mounted motor in line with another XT conveyor

Introduction

Use connecting kit 5049594, which connects a side

mounted end drive unit (L and R), to an idler end unit.

Tools

Allen key 5 mm

Box wrench 13 mm

Instruction

1 Make sure that the conveyors are on the same

level and in line with each other.

Loosen the screw for the torque arm. Use the 13

mm box wrench. Lower the motor.

CAUTION! Fit one connecting plate at a time to

ensure the unit remains intact, never

for more than one connecting plate at a time.

loosen screws

2 Loosen the screws (3 x M8) on the side plates.

Use the 5 mm allen key.

CAUTION! Fit one connecting plate at a time to

ensure the unit remains intact, never

screws for more than one connecting plate at a

time.

loosen

5113235 31

Page 32

3 Fit the connecting plate and tighten the screws.

Use the 5 mm allen key.

4 Turn up the motor. Fit and tighten the screw for

torque arm. Use the 13 mm box wrench.

CAUTION! Make sure that the torque arm fork

has entered the cage in a correct way. An

unlocked rotating motor can cause personal

injury.

5 Fit the remaining connecting plates. Place the

roller bridge between the conveyors.

CAUTION! Fit one connecting plate at a time to

ensure the unit remains intact, never

screws for more than one connecting plate at a

time.

6 Use a ruler to make sure that the roller bridge is

in the correct vertical position. Max distance

between ruler and roller: 1 mm.

If needed, loosen the screws for the connecting

plates again and adjust until the necessary

space is obtained.

loosen

32 5113235

Page 33

Connecting an XT conveyor module, centre mounted motor in line with another XT conveyor

Introduction

Use connecting kit 5050564, which connects a centre

mounted end drive unit (M and HM), to an idler end

unit

.

Tools

Allen key 5 mm

Box wrench 13 mm

Instruction

1 Make sure that the conveyors are on the same

level and in line with each other.

Loosen the screws (4 x M8) on the side plates.

Use the 5 mm allen key.

CAUTION! Fit one connecting plate at a time to

ensure the unit remains intact, never

screws for more than one connecting plate at a

time.

loosen

CAUTION! Fit one connecting plate at a time to

ensure the unit remains intact, never

for more than one connecting plate at a time.

loosen screws

2 Fit the connecting plate and tighten the screws.

Use the 5 mm allen key.

5113235 33

Page 34

3 Fit the screws (4 x M8) to the inside of the side

plates at the driving end

4 Loosen the screws on the inside of the side plate

at the idler end. Use the 5 mm allen key. Fit the

inner connecting plate and tighten the screws.

Use a 13 mm box wrench and 5 mm allen key.

5 Fit the remaning plates. Place the roller bridge

between the conveyors.

CAUTION! Fit one connecting plate at a time to

ensure the unit remains intact, never

screws for more than one connecting plate at a

time.

6 Use a ruler to make sure that the roller bridge is

in the correct vertical position. Max distance

between ruler and roller: 1 mm.

If needed, loosen the screws for the connecting

plates again and adjust until the necessary

space is obtained.

loosen

34 5113235

Page 35

Mounting support module

XT

XT

Compact

Introduction

NOTE! Always place a support module near the

motor, where the weight is high.

CAUTION! A short conveyor, which has the point of

gravity near the motor, can easily cause the conveyor

to tilt.

Tools

Allen key 5 mm

Allen key 6 mm

Box wrench 13 mm

Box wrench 19 mm

Drilling-machine

Instruction

1 Place the support modules beside each other.

Make sure that the support modules has the

same height. If needed, adjust the feet. Use the

19 mm box wrench.

If nothing else is specified the instruction steps are

valid for all support modules.

2 XTUF S01A/S02A/S03A

There are different brackets for fitting the support

module on to an XT or XT Compact conveyor.

The XT bracket is a little bit lower than the XT

Compact bracket and uses M8 screws instead of

M5.

Loosen the screws (2xM8) on one of the

brackets of the support module using a 6 mm

Allen key.

NOTE! If the support is made for more than one

conveyor loosen one bracket in a pair for each

conveyor.

5113235 35

Page 36

3 XTUF S01A/S02A/S03A

XT Conveyor:

Insert the slot nuts (4 x M8) in the conveyor Tslot. Place the support module in the correct

position by tilting aside the loose bracket. Fit the

screws (4 x M8) and tighten with the 6 mm Allen

key. Tighten the screws (2 x M8) on the loose

bracket using the 6 mm Allen key.

XT Compact Conveyor:

Insert the slot nuts (4 x M5) in the conveyor Tslot. Place the support module in the correct

position by tilting aside the loose bracket. Fit the

screws (4 x M5) and tighten with the 5 mm Allen

key. Tighten the screws (2 x M8) on the loose

bracket using the 6 mm Allen key.

4 XTUF S04

Insert the slot nuts (2 x M8) in the conveyor T-slot

at the centre of the bend.

Place the support module in correct position. Fit

and tighten the screws (2 x M6). Use the 13 mm

box wrench.

5 Fit the slot nuts (2 x M8) to the support beam T-

slot.

Fit the foot and tighten the screws (2 x M8). Use

the 13 mm box wrench.

36 5113235

Page 37

6 Mount the foot to the surface.

5113235 37

Page 38

Mounting pallet stop device XTPD U200

Introduction

The stop can be placed on the inside of the conveyor

at either the left (stop at pallet front) or right side (stop

at pallet back). If nothing else is specified the

instruction steps are valid for both XT and XT

Compact conveyors.

Tools

Allen key 6 mm

Allen key 5 mm

Instruction

1 XT conveyor:

Insert the slot nuts (2 x M8) in the conveyor Tslot. Insert the bushings to the stop unit.

2 XT conveyor:

Fit the screws (2 x M8).

NOTE! The stop flange shall face against the

pallet direction of travel.

38 5113235

Page 39

3 XT conveyor:

P

a

l

l

e

t

d

i

r

e

c

t

i

o

n

Use the 6 mm Allen key to tighten the screws.

Torque value for tightening: 25 Nm.

4 XT Compact conveyor:

Mount the bracket on the unit. Fit and tighten the

screws (2 x M6) with the 5 mm Allen key. Torque

value for tightening: 10 Nm.

5 XT Compact conveyor:

Insert the slot nuts (2 x M6) in the conveyor Tslot.

Fit and tighten the screws (2 x M6). Use the 5

mm Allen key. Torque value for tightening: 10

Nm.

NOTE! The stop flange shall face against the

pallet direction of travel.

5113235 39

Page 40

Mounting pallet stop device XTPD D35

Introduction

The stop can be placed on the inside of the conveyor

at either the left (stop at pallet front) or right side (stop

at pallet back). If nothing else is specified the

instruction steps are valid for both XT and XT

Compact conveyors.

Tools

Allen key 6 mm

Allen key 5 mm

Instruction

1 XT conveyor:

Insert the slot nuts (2 x M8) in the conveyor Tslot. Insert the bushings to the stop unit.

2 XT conveyor:

Fit the screws (2 x M8).

NOTE! The stop flange shall face against the

pallet direction of travel.

3 XT conveyor:

Use the 6 mm Allen key to tighten the screws.

Torque value for tightening: 25 Nm.

CAUTION! Too high torque can cause the unit to

get jamed.

40 5113235

Page 41

4 XT Compact conveyor:

P

a

l

l

e

t

d

i

r

e

c

t

i

o

n

Mount the bracket on the unit. Fit and tighten the

screws (2 x M6) with the 5 mm Allen key. Torque

value for tightening: 10 Nm.

5 XT Compact conveyor:

Insert the slot nuts (2 x M6) in the conveyor Tslot.

Fit and tighten the screws (2 x M6). Use the 5

mm Allen key.

NOTE! The stop flange shall face against the

pallet direction of travel.

6 Pre adjust the damping screw according to the

following:

a) Turn the screw clockwise towards the “+” sign

until it reaches the end position. When you have

reached the end position turn it counter

clockwise 360° towards the “-” sign.

b) Fine adjust the damping when the system is

running. Turn the screw to the “+” sign to

increase the damping and to the “-” sign to

decrease the damping.

CAUTION! Heavy pallets in combination with an

over damped stop can damage the stop.

7 Mount the cover.

5113235 41

Page 42

Mounting pallet stop device XTPD D100

Introduction

Mount the stop inside of the XT conveyor beam.

Tools

Allen key 6 mm

Instruction

1 Insert the slot nuts (2xM8) in the conveyor T-slot.

Insert the bushings to the stop unit.

2 Fit the screws (2 x M8).

NOTE! The stop flange shall face against the

pallet direction of travel.

3 Tighten the screws with the 6 mm Allen key.

Torque value for tightening: 25 Nm.

42 5113235

Page 43

Mounting sensor bracket XTPB V001 to pallet stop device XTPD U200 or XTPD D35

Introduction

The sensor is not included in sensor bracket V001. If

nothing else is specified the instruction steps are valid

for both XTPD U200 and XTPD D35.

Tools

Allen key 3 mm

Screwdriver

Instruction

1XTPD D35

Remove the cover with a screwdriver.

2 XTPD U200

Use the screws (2 x M4) to mount the sensor

bracket to the stop unit.

5113235 43

Page 44

3XTPD D35

Use the screws (2 x M4) to mount the sensor

bracket to the stop unit.

4 Fit the sensor to the sensor bracket.

5 Tighten the screws. Use the 3 mm Allen key.

44 5113235

Page 45

Mounting sensor bracket XTPB V002

Introduction

The sensor is not included in sensor bracket XTPB

V002.

Tools

Allen key 5 mm

Allen key 3 mm

Instruction

1 Insert the slot nuts (2 x M6) in the conveyor T-

slot. Fit the screws (2 x M6). The arrow shows

the upper holes for fitting on XT Compact

conveyor.

2 Use the 5 mm Allen key to tighten the screws.

3 Fit the sensor to the sensor bracket. Tighten the

screws. Use the 3 mm Allen key.

5113235 45

Page 46

Mounting position sensor XTPB V003

Introduction

The sensor is not included in position sensor XTBP

V003.

Mount the position sensor on the outside of

conveyor XT or XT Compact. If nothing else is

specified the instruction steps are valid for both XT

and XT Compact conveyors.

Tools

Allen key 3 mm

Allen key 5 mm

Allen key 6 mm

Instruction

1 Fit the sensor to the sensor bracket.

2 Tighten the screws. Use the 3 mm Allen key.

46 5113235

Page 47

3 XT conveyor:

Insert the slot nuts (2 x M8) in the conveyor Tslot. Mount the bushings to the sensor bracket.

XT Compact conveyor:

Insert the slot nuts (2 x M6) in the conveyor Tslot.

4 XT conveyor:

Fit the screws (2 x M8).

XT Compact conveyor:

Fit the screws (2 x M6). The arrow shows the

upper holes for fitting on XT Compact conveyor.

5 XT conveyor:

Use the 6 mm Allen key to tighten the screws.

XT Compact conveyor:

Use the 5 mm Allen key to tighten the screws.

5113235 47

Page 48

Mounting sensor bracket XTPB H001

Introduction

The sensor is not included in sensor bracket XTBP

H001.

Mount the bracket on the outside of conveyor

XT or XT Compact.

Tools

Allen key 3 mm

Allen key 5 mm

Instruction

1 Insert the slot nuts (2 x M6) in the conveyor T-

slot. Fit the screws (2 x M6). The arrow shows

the upper holes for fitting on XT Compact

conveyor.

2 Use the 5 mm Allen key to tighten the screws.

3 Fit the sensor to the sensor bracket. Tighten the

screws. Use the 3 mm Allen key.

48 5113235

Page 49

Mounting damper CM 35

Introduction

Mount the damper outside of conveyor XT or XT

Compact.

Tools

Box wrench 10 mm

Screwdriver

Instruction

1 Insert the slot nuts (2 x M6) in the conveyor T-

slot. Fit the screws (2 x M6).

The arrow shows the upper holes for fitting on XT

Compact conveyor.

2 Tighten the screws. Use the 10 mm box wrench.

3 Pre adjust the damping screw according to the

following:

a) Turn the screw clockwise towards the “+” sign

until it reaches the end position. When you have

reached the end position turn it counter

clockwise 360° towards the “-” sign.

b) Fine adjust the damping when the system is

running. Turn the screw to the “+” sign to

increase the damping and to the “-” sign to

decrease the damping.

CAUTION! Heavy pallets in combination with an

over damped stop can damage the stop.

5113235 49

Page 50

Mounting roller kit

Introduction

Use roller kit 5049865 (65 mm) or roller kit 5050117

(45 mm).

Tools

Box wrench 10 mm

Instruction

1 Insert the slot nuts (4 x M6) in the conveyor T-

slot.

2 Mount the roller to the conveyor. Fit and tighten

the screws (4 x M6). Use the 10 mm box wrench.

The arrow shows the upper holes for fitting on XT

Compact conveyor.

The distance between the two flanges shall be:

Pallet Length (PL) + 2 mm.

3 Place the conveyors parallel to each other. Make

sure that the conveyors are on the same level

and in a horizontal position.

Fit and tighten the screws (4 x M6). Use the 10

mm box wrench.

50 5113235

Page 51

Mounting XT Compact conveyor perpendicular to XT or XT Compact conveyor

Introduction

Use connecting kit 5050034.

Tools

Box wrench 8 mm

Instruction

1 Loosen the screws on the XT Compact conveyor

(2 x M5). Use the 8 mm box wrench. Insert the

slot nut (1 x M5) in the conveyor T-slot.

2 Mount the bracket. Fit and tighten the screws

(2 x M5). Use the 8 mm box wrench.

3 Fit and tighten the screw (1 x M5). Use the 8 mm

box wrench. The arrow shows the upper holes for

fitting on XT Compact conveyor.

5113235 51

Page 52

Mounting pallet locating station XTPX P11A

Introduction

Mount the locating station on conveyor XT or XT

Compact. If nothing else is specified the instruction

step is valid for both XT and XT Compact conveyor.

Tools

Soft faced hammer

Allen key 6 mm

Adjustable wrench

Box wrench 10 mm

Piece of slide rail 4 pcs

Instruction

1 Mount the pins to the locating units.

2 Use a soft faced hammer and hit the pin carefully

until it reaches the end position.

52 5113235

Page 53

3 XT conveyor:

Insert the slot nuts (2xM8) in the conveyor T-slot.

Mount the bushings to the locating unit.

XT Compact conveyor:

Insert the slot nuts (2xM6) to the conveyor.

4 XT conveyor:

Fit the screws (2 x M8).

XT Compact conveyor:

Fit the screws (2 x M6). The arrow shows the

upper holes for fitting on XT Compact conveyor.

5 Do not tighten the screws permanently. Use the 6

mm Allen key.

6 Press the pistons out.

5113235 53

Page 54

7 Use a adjustable wrench to turn the non-cylindri-

cal locating pin to a position according to step 8.

8 Locating pin position.

9 Place a pallet on top of the locating pins and

press the pallet down to the conveyor surface.

10 Tighten the two locating units to the conveyor

beams. Use a set-square to get the pistons in

line with the pallet bushings. Use the conveyor

beam as a reference.

54 5113235

Page 55

11 Mount the four brackets. To get the correct verti-

cal space between pallet and bracket use a piece

of slide rail (thickness approx. 2 mm) as a tempo

rary distance piece at each bracket.

Press each bracket down towards the pallet

before tightening the screws.

wrench

The arrow shows the upper holes for fitting on XT

Compact conveyor.

12 When all brackets are mounted use the 6 mm

Allen key to gently press the two pistons down.

.

Use the 10 mm box

-

13 Remove the pallet.

14 Dismount the temporary distance pieces (slide

rails) from the brackets.

5113235 55

Page 56

15 Finally, turn the non-cylindrical locating pin to a

position according to step 16.

Doing this, the locating station is no longer

sensitive to the individual pallet tolerances that

may occur between the two pallet bushings.

16 Locating pin position.

56 5113235

Page 57

Mounting transfer unit XTPT M1

Introduction

Mount the transfer unit on the inside of conveyor XT or

XT Compact.

Tools

Allen key 3 mm

Box wrench 8 mm

Box wrench 10 mm

Instruction

1 Loosen the screws (2×M5) that hold the top

cover plate. Use the 3 mm Allen key. Please note

the two loose washers under the cover plate.

CAUTION! Ensure that a pallet can not fall off the

conveyor if it should pass the transfer unit by mistake.

2 In the plastic bag enclosed in the shipment you

find the necessary slot nuts and bolts to attach

the transfer to the conveyor. Insert the slot nuts in

the T-slots on the conveyor beam. For conveyor

XT use XCAN 6 slot nuts (the larger ones) and

M6x12 bolts, for XT Compact use XFAN 6 slot

nuts and M6x10 bolts.

5113235 57

Page 58

3 Loosen the screws that hold the side cover on

the motor side. Use the cross-slotted screw

driver. This is done to make attachment of the

transfer easy.

4 Use a cross beam, e.g. a wood plank, to get the

transfer hanging in position between the con

veyor beams. The cross beam is fastened in one

of the slot nuts for the top cover plate. Insert the

bolts for the fastening of the transfer in the holes

(4×M6). The upper holes are for conveyor XT

Compact, the lower for conveyor XT.

-

5 Remove the cross beam. Make sure that the

transfer unit is hanging by its weight and in cor

rect level. Tighten the screws. Use the 10 mm

box wrench.

6 Mount the top cover plate. Do not forget the two

washers working as distances. Use the 3 mm

Allen key. Mount the side cover plate. Use the

cross-slotted screw driver.

-

58 5113235

Page 59

7 Check the pallet direction of travel. Loosen the

four screws (4 x M5) that hold the guide plate that

will act as a stop plate, lift the plate to its top posi

tion and tighten the screws. Use the 8 mm box

wrench. If damped option, please see

damper MC 35 PW A” on page 67.

8 Attach the motor cable, the pneumatic tubes and

the connections for the sensor cables.

“Mounting

-

5113235 59

Page 60

Mounting transfer unit XTPT M2

Introduction

Mount the transfer unit on the inside of conveyor XT or

XT Compact.

Tools

Allen key 3 mm

Allen key 5 mm

Box wrench 8 mm

Box wrench 10 mm

CAUTION! Ensure that a pallet can not fall off the

conveyor if it should pass the transfer unit by mistake.

Instruction

1 Loosen the screws (4×5 mm) that hold the top

cover plate. Use the 3 mm Allen key.

2 In the plastic bag enclosed in the shipment you

find the necessary slot nuts and bolts to attach

the transfer to the conveyor. Insert the slot nuts in

the T-slots on the conveyor beam. For conveyor

XT use XCAN 6 slot nuts (the larger ones) and

M6×12 bolts, for XT Compact use XFAN 6 slot

nuts and M6×10 bolts.

60 5113235

Page 61

3 Loosen the screws (2×M8) that connect the drive

unit to the transfer unit. Use the 5 mm Allen key.

4 Put the drive unit on top of the beams of the main

conveyor next to the position where you are to

mount the transfer unit.

5 Fit the transfer unit to the conveyor beams. Use

the 10 mm box wrench.

6 Fit the drive unit back into the transfer unit. Make

sure that the motor cable is put in a safe position,

e.g. not directly under the adjusting screw or too

close to the cylinder. Attach the screws, 2×M8.

Use the 5 mm Allen key.

7 Attach the top cover plate. Use the 3 mm Allen

key.

5113235 61

Page 62

8 Check the pallet direction of travel. Loosen the

four screws (4×M5) that hold the guide plate that

will act as a stop plate. Lift the plate to its top

position and tighten the screws. Use the 8 mm

box wrench. If damped option, please see

“Mounting damper MC 35 PW A” on page 67.

9 Attach the motor cable, the pneumatic tubes and

the connections for the sensor cables.

62 5113235

Page 63

Mounting transfer unit XTPT L

mid position

right position

Introduction

Mount the transfer unit on the inside of conveyor XT or

XT Compact.

Tools

Allen key 5 mm

Box wrench 10 mm

Instruction

1 Find the mid position of the transfer unit's

position on the conveyor beam.

CAUTION! Ensure that a pallet can not fall off the

conveyor if it should pass the transfer unit by mistake.

2 Measure (PW - 90)/2 to the left and to the right of

the centre position.

5113235 63

Page 64

3 In the plastic bag enclosed in the shipment you

left/right position

right position

find the necessary slot nuts and bolts to attach

the transfer to the conveyor. Insert the slot nuts in

the T-slots on the conveyor beam. For conveyor

XT use XCAN 6 slot nuts (the larger ones) and

M6×16 bolts, for XT Compact use XFAN 6 slot

nuts and M6×14 bolts.

4 Disassemble the four mounting brackets.

5 Mount the four mounting brackets on the con-

veyor beam at the measured position found in

instruction no. 2. Use the 10 mm box wrench.

Make sure that the brackets are perpendicular to

the conveyor beam.

6 Mount the motor half of the transfer unit to the

brackets using the eight M6 screws. Use the 5

mm Allen key.

64 5113235

Page 65

7 Adjust the motor half of the transfer unit to make

sleeve sleeve

connecting

piece

it perpendicular to the conveyor beam.

8 Mount the other half of the transfer unit to the

brackets. Use only one screw on each side of the

transfer unit. This is to make the unit half able to

rotate.

9 Dock the two transfer unit halves by connecting

the telescopic shaft. Do not forget the sleeve on

the shaft of the motor half of the transfer unit.

10 Docking is complete.

5113235 65

Page 66

11 Use the remaining six screws to fasten the transit

unit half without motor.

12 Measure the transfer unit regarding the pallet

length (PL). From guide to stop the measure

should be PL+3 mm (approx). Adjust the transfer

unit half without motor to make it parallel to the

other transfer unit half.

13 Tighten the final screws holding the mounting

brackets on the transfer half without motor. Use

the 10 mm box wrench.

66 5113235

Page 67

Mounting damper MC 35 PW A

Introduction

Mount the damper on the transfer unit.

Tools

Box wrench 8 mm

Box wrench 10 mm

Instruction

1 Fit the damper MC35 to the stop plate sent along

with the damping kit. Tighten the screws (2×M6).

Use the 10 mm box wrench. Do not forget the

steel washer.

2 Loosen the screws (4 or 5×M5) that hold the stop

plate that is already on the transfer unit. Use the

8 mm box wrench. Remove the stop plate.

3 Fit the stop plate with the damper and tighten the

screws (4 or 5×M5). Use the 8 mm box wrench.

5113235 67

Page 68

Mounting lift and rotate unit XTUR P11

Introduction

If nothing else is specified the instruction steps are

valid for both XT and XT Compact conveyors.

Tools

Allen key 4 mm

Allen key 5 mm

Allen key 6 mm

Box wrench 10 mm

Box wrench 19 mm

Box wrench 24 mm

Instruction

1 Insert the four M6 slot nuts into the conveyor T-

slot.

CAUTION! Running this module without enclosure

can cause personal injury.

2 Loosen the four M6 screws holding the top plate

using the 5 mm Allen key. Remove the top plate.

68 5113235

Page 69

3 Fit the lift and locate unit from above. Fit the four

A

B

C

M6 screws and tighten them with a 4 mm Allen

key.

4 Fit the top plate and tighten the four M6 screws

using the 5 mm Allen key. Torque value for tight

ening: 10 Nm.

Note! Make sure that the top plate has not been

turned 90° by mistake. The top plate must be

positioned according to the picture when the

rotate actuator has reached end position.

-

5 To adjust the height of the module, use the 5 mm

Allen key and a 10 mm box wrench to loosen the

four M6 screws on the brackets.

XT Compact conveyor – press the unit down to

bottom end position.

XT conveyor – press the unit up to upper end

position.

Tighten the four screws.

6 If necessary, fineadjust the end positions (A) of

the rotate actuator. Use a 19 mm and 24 mm box

wrench.

Use the non-return throttle valves (B) to adjust

the speed of the pneumatic rotate actuator. Use

a small screwdriver.

Use the non-return throttle valves (C) to adjust

the speed of the pneumatic lift cylinder. Use a

small screwdriver.

5113235 69

Page 70

Mounting lift and locate module XTUL P12

M8 (4×)

Attachment device

Introduction

If nothing else is specified this instruction step is valid

for all mounting options (F00, F01 and F02).

Tools

Allen key 4 mm

Allen key 5 mm

Allen key 6 mm

Box wrench 19 mm

Box wrench 24 mm

Instruction

1 If F=F00

Place the unit on your attachment device and

tighten the four M8 screws using a 5 mm Allen

key.

NOTE! The horizontal plane on the attachment

device and the plane on the conveyor chains

must be parallel.

CAUTION! Running this module without enclosure

can cause personal injury.

2 If F=F01

Insert the four M6 slot nuts into the conveyor Tslot. Mount the support frame onto the conveyor

and tighten the four M6 screws using a 4 mm

Allen key.

The upper holes on the brackets are for mounting

the support frame onto an XT Compact

conveyor.

70 5113235

Page 71

3 If F=F01

correct position

Insert the four M8 slot nuts into the T-slot on the

underside of the support frame beams.

4 Move the angle brackets on the lift and locate

unit down to their bottom position. Turn them

180°.

5 If F=F01

Pull the top plate to its fully ejected position. Fit

the lift and locate unit from above by turning it 90°

so that the angle brackets do not collide with the

support frame beams. Lover the unit until the

angle brackets are below the support frame

beams and turn it back 90°.

6 If F=F01

Fit the four M8 screws and tighten them with a

5 mm Allen key.

5113235 71

Page 72

7 If F=F02

Put the support frame in position below and

between the conveyor beams. Insert the four M8

slot nuts into the T-slot on the upper side of the

support frame beams.

CAUTION! The horizontal plane on the support

frame and the plane on the conveyor chains must

be parallel.

8 If F=F02

Mount the unit on top of the support frame and

tighten the four M8 screws using a 5 mm Allen

key.

9 Adjust the support, unit and/or the conveyor so

that the lift and locate device is positioned cor

rectly.

10 To adjust the height of the module stroke. Place a

pallet on the top plate and press it up to the cor

rect position. Fix the top plate in that position.

-

-

72 5113235

Page 73

11 Use the 6 mm Allen key to loosen the screws on

A

the clamps. Press the clamps tight to the guiding

unit and tighten the screws. Torque value for

tightening: 20 Nm.

Lower the top plate again.

12 To fineadjust the height, loosen the check nut on

the cylinder rod piston using a 24 mm and a

19 mm box wrench. Turn the rod piston with one

box wrench and keep the top plate still with the

other box wrench until the correct height is

gained. Tighten the check nut.

13 Use the non-return throttle valves (A) to adjust

the speed of the pneumatic cylinder. Use a small

screwdriver.

5113235 73

Page 74

Appendix

74 5113235

Loading...

Loading...