Page 1

Conveyor assembly manual

Table of contents

Introduction .................................................................2

About this manual ..................................................2

Installation site preparations ..................................2

Tools ......................................................................3

Fasteners ...............................................................4

Cutting FlexLink beams .........................................5

Assembly.....................................................................6

Introduction ............................................................6

Feet........................................................................7

Beam connectors .................................................15

Conveyor beams ..................................................19

Drive units ............................................................22

Idler units .............................................................24

Slide rail and support rail .....................................26

Chain ................................................................... 33

Guide rail system ................................................. 38

Angle plates......................................................... 46

Drip trays and drip catchers................................. 47

Front piece........................................................... 52

Final preparations ................................................ 54

Conveyor system XK ........................................... 55

XK pallet system.................................................. 58

Start-up and testing .................................................. 65

Safety considerations .......................................... 65

Slip clutch adjustment.......................................... 66

Start-up................................................................ 67

Troubleshooting ................................................... 68

1

Page 2

Introduction

About this manual

Introduction

The main purpose of this manual is to help self-building

end users, with little or no prior experience, to assemble

a FlexLink conveyor system.

Each chapter includes detailed instructions and pictures showing how to assemble the different parts. Most

pictures in the manual include parts from the XL conveyor system, but all instructions are applicable to the

XS, XL, XM, XH and XK systems unless otherwise noted.

Operations that apply only to the XK conveyor system are

described in a separate chapter.

Installation site preparations

Assembly planning

Work systematically:

1 Prepare by studying your assembly drawing.

2 Ensure that the necessary tools are available.

3 Make sure you have all the materials and components

needed to assemble the conveyor system. Check with

the parts list.

4 Make sure you have enough floor space to mount the

conveyor system.

5 Check to see if the floor at the installation site is even,

so that all feet can be properly attached to the floor.

Document disposition

The document is divided into the following five main

parts:

• Installation site preparations

• Tools and fasteners

• Cutting FlexLink beams

• Assembly

• Start-up and testing

Assembly order

The following list can be used as a checklist during your

conveyor assembly work:

Activity Starts on

Cut all beams into suitable lengths page 5

Connect feet and structural beams page 7

Mount conveyor beam support brackets page 19

Assemble conveyor beams and mount

them on to the support structure

Mount drive and idler units to the ends of

the conveyor

Mount slide rail on to the conveyor beam page 26

Loosen the drive unit slip clutch page 34

Run a short piece of chain through the

conveyor to check that there are no

obstructions

Assemble and mount the chain on to the

conveyor

Mount guide rail, drip trays and other

accessories on to the conveyor

Tighten the slip clutch to a suitable friction

Read Final preparations at the end of

this manual

Go to page 55 for special information relating to conveyor system XK.

page 21

page 22

page 34

page 33

page 38

page 66

page 54

2 Introduction

Page 3

Tools

General tools

To assemble a FlexLink conveyor, you will need most of

the tools listed on the following pages. Not all are essential, but they will make your assembly work easier and

more efficicient.

Hand tools

10 and 13 mm box wrench

Cutters (for cutting slide rail)

Set of metric Allen keys

Roller thread fluteless tap and tap wrench (M6 and M8)

Countersink bit

Tape measure

In addition, the tools listed below can be useful:

Files

Socket wrench

Screw-driver

Pliers

Knife (for cutting off plastic screw heads)

Soft faced hammer

Clamp (for chain installation)

Level

Power tools

Cross-cut circular saw for aluminium

Hand drill

Drill bit (for fixing of slide rail):

XS: ∅3,2 mm, XL/XM/XH/XK: ∅4,2 mm

FlexLink tools

Rivet crimping pliers

XS (∅ 3 mm):

3924776

XL/XM/XH (∅ 4 mm):

3925800

Rivet crimping clamp

XS (∅ 3 mm):

3924770

XL/XM/XH (∅ 4 mm):

3923005

The riveting tools have replaceable pads. By replacing the pads

you can use the same riveting

tool for 3 mm and 4 mm rivets.

Drill fixture for installation of

slide rail

XS (∅ 3,2 mm):

3924774

XL/XM/XH/XK (∅ 4,2 mm):

3920500

Mounting tool for slide rail

XS/XL: XLMR 140

XM: XMMR 140

XH: XHMR 200

XK: XKMR 200

Mounting toolkit for guide rail (XK)

3926757

Each kit is delivered with two tools.

Pin insertion tool for chain

XS/XL: XLMJ 4

XM: XMMJ 6

XH: XHMJ 6

XK: XKMJ 8

Guide rail bending machine

3922963 (not shown)

Drill fixture for fastener yokes

XCAD 18

To drill for fastener yokes

(page 17–18), the 10 mm

drill insert has to be

removed. The drill insert is

secured by a locking screw.

With the stop tongue down, the fixture is inserted into

the T-slot of the beam until stop, and then locked. The

hole will be drilled 22 mm from the beam end and centered by the fixture.

Introduction 3

Page 4

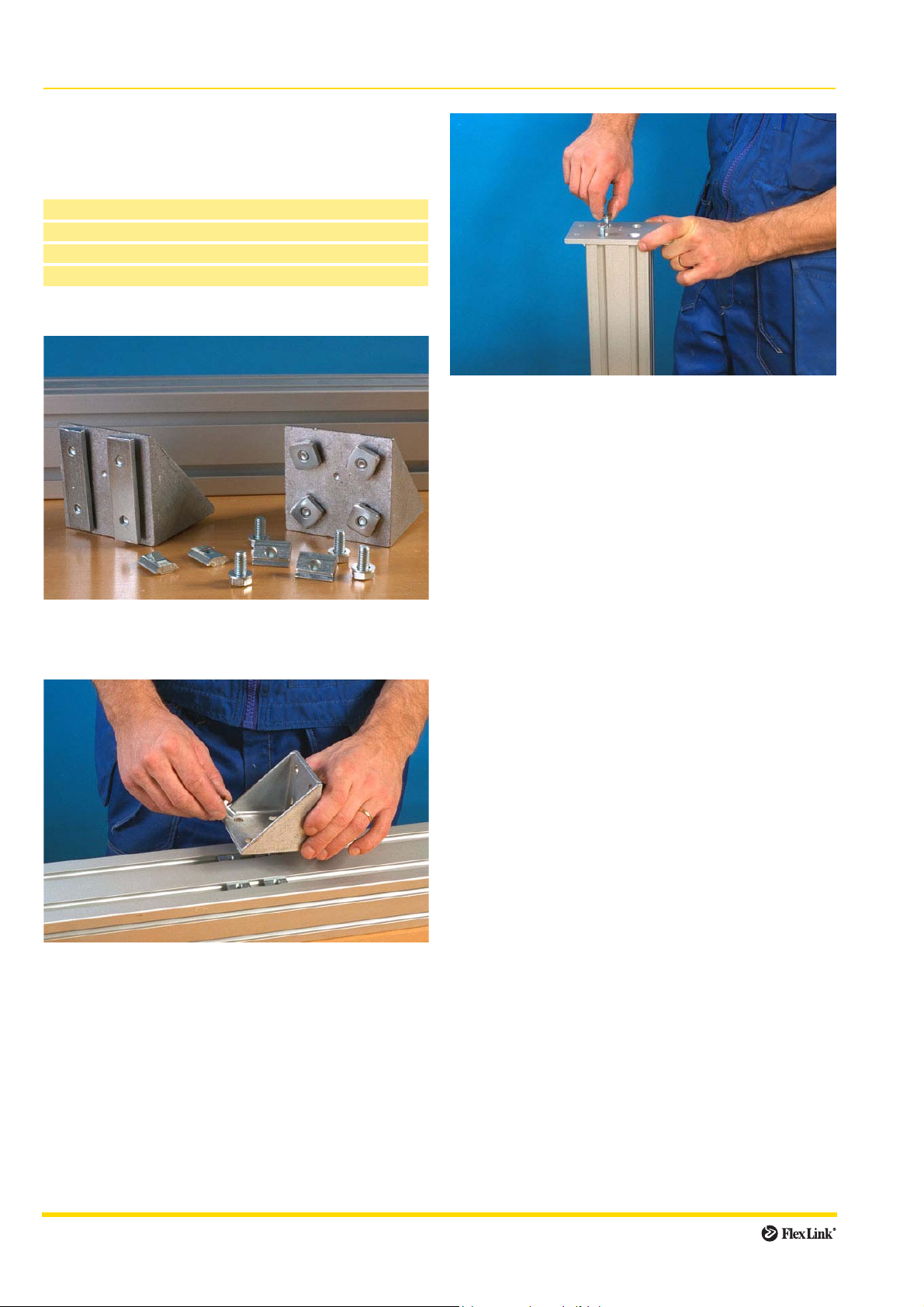

Fasteners

1. Standard screws, nuts, washers

M6S, MC6S, MF6S, M6M, BRB 8,4×16, XLAL

2. Slot nuts and square nuts

3. Connecting strips

X..CJ

Connecting strips are used for joining beams together,

end to end. Use Allen key and set screws when attaching

the connecting strip to the beam.

4. T-bolts

XCAN, XLAQ

Square nuts can be used in support beams and small

beams instead of XCAN nuts, but they can also be used

in conveyor beams as opposed to XCAN nuts. They do

not stay in place in vertical positions and have to be

inserted from the beam end.

When using XLAQ square nuts, remember to put in a

sufficient number before completing the assembly.

XCAN

On the support beam, the slot nut can be entered into the

T-slot from the beam side. It will stay in position in vertical

T-slots because of a thin leaf spring.

For small beams (e.g. XCBB ..×24×44), the nut must

be entered from the beam end because of the design of

those beams.

XLAT

T-bolts can be entered from the beam side, and when

turned 90° they will stay in place after tightening with nuts

(XLAN 8) and washers (BRB 8,4×16). The indication

groove in the T-bolt should be at 90° to the conveyor Tslot.

T-bolts are used when attaching support brackets,

guide rails and drip trays to the conveyor beam. Do not

use T-bolts with support beams!

IMPORTANT

Slot nuts can not be used with conveyor beams. (This

does not apply to the XK conveyor system.)

4 Introduction

Page 5

Cutting FlexLink beams

Beam lengths

If you have ordered 3 m or 6 m beams, they will need to

be cut into suitable lengths before assembly. Study your

drawing to determine the beam lengths that are required.

The FlexLink catalogue 5147, chapter CS, contains a formula for calculation of cutting lengths for support beams.

Saw requirements

The circular cross-cut saw for aluminium must have a

higher speed than when cutting steel, and a carbide tip

blade adapted for aluminium products in order to give a

nice and clean cut.

The saw should have the ability of cutting the largest

profile in one single cutting action.

Working site

You should use a special area for cutting beams in order

to keep the assembly area clean.

Quality of cut

If burrs are evident, they must be removed prior to

assembly.

Make sure the cut is straight for proper assembly.

SAFETY

All safety precautions issued by the cutting saw manufacturer should be followed at all times.

Introduction 5

Page 6

Assembly

Introduction

Component groups

The basic FlexLink conveyor structure consists of five

component groups:

• support structure

• conveyor beams, straight sections and bends

• drive and idler units

•chain

• other accessories (guide rail, drip trays etc.)

The first step in the assembly process is to assemble the

support structure, which consists of feet, support beams

and beam connectors. Most conveyor support designs

are based on vertical support beams combined, if necessary, with horizontal support beams. There are also a

number of different feet and beam connectors, so check

which ones are used in your application. Some examples

are shown below.

IMPORTANT

You must work in accordance with your layout, and make

sure that the conveyor is supported at regular intervals

not exceeding 3 m.

6 Assembly

Page 7

Feet

Introduction

Feet are attached to the support beams, and come in a

number of configurations. Follow the mounting instructions for the type of foot used in your application.

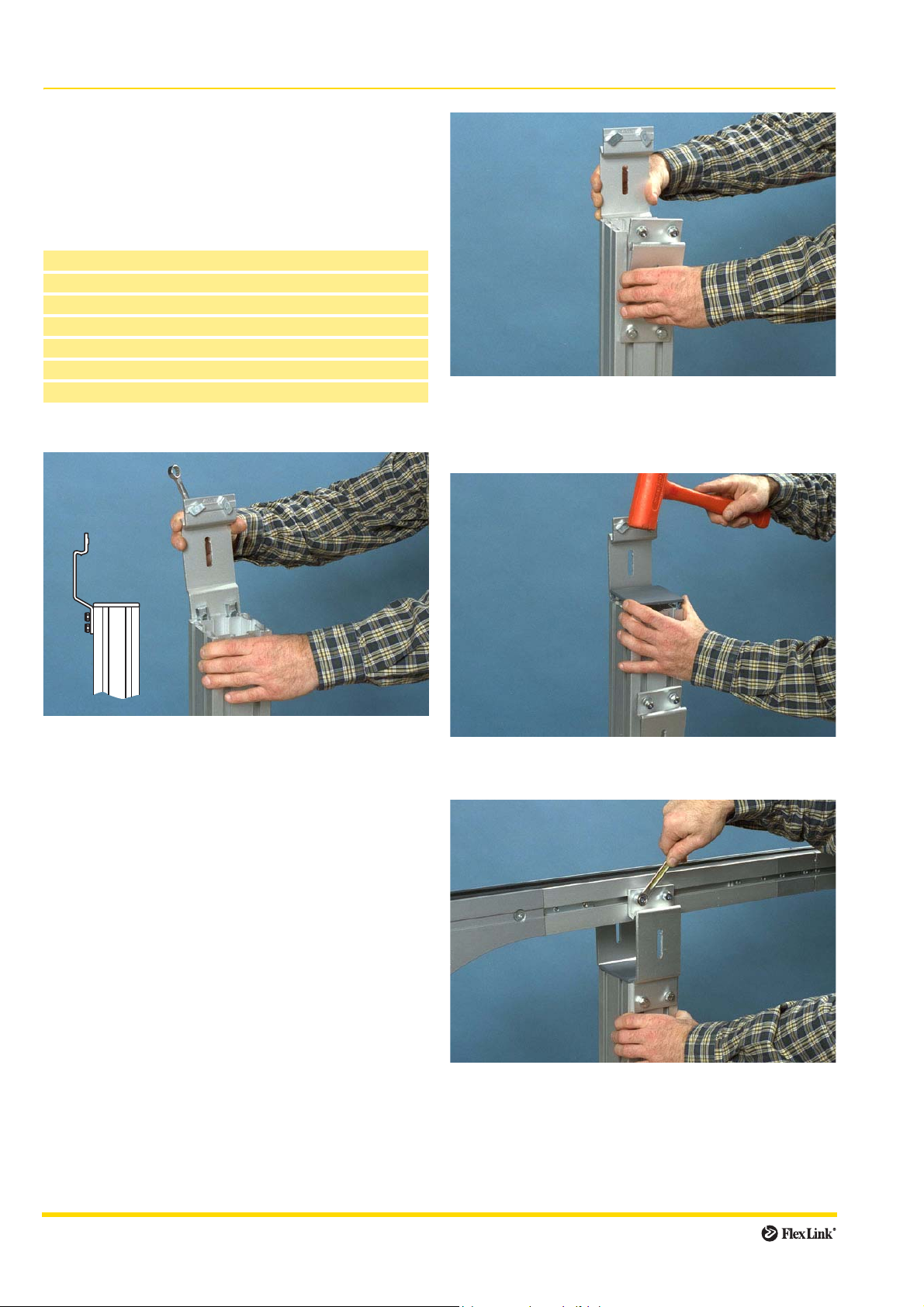

Mounting feet

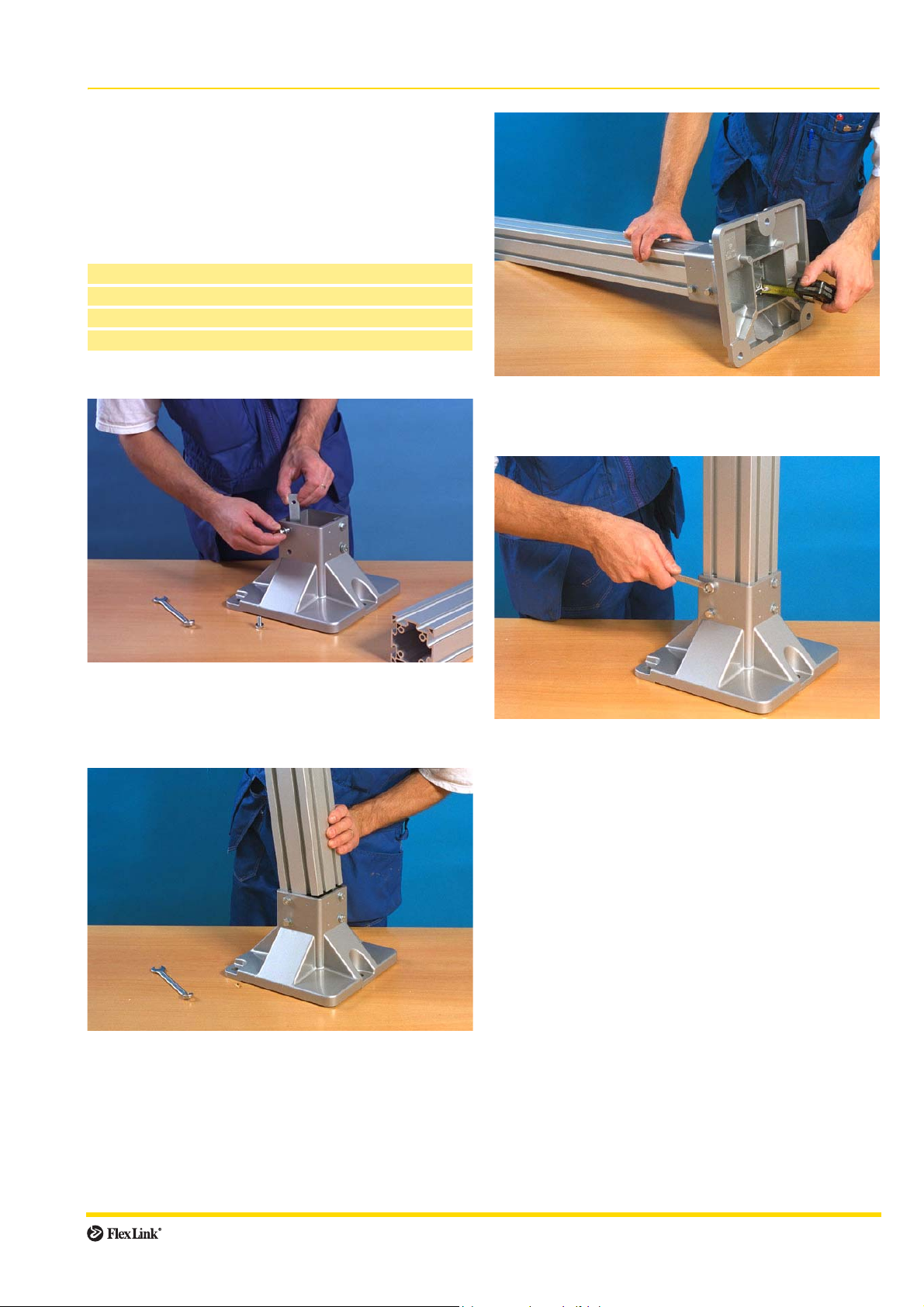

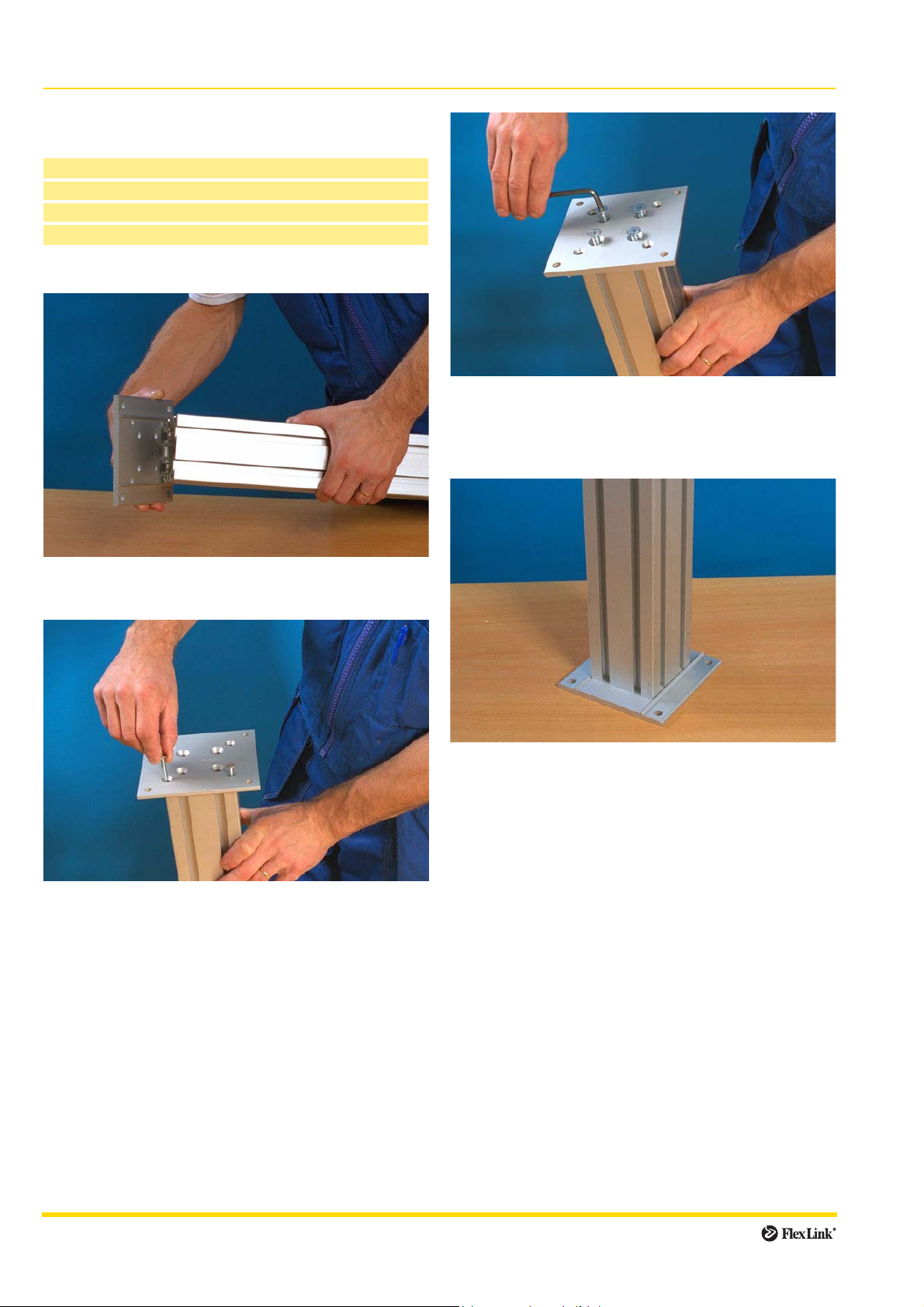

XCFF:

Box wrench 13 mm

Connecting strips (included

Hex head screws (included) M6S 8×16

Washers (included) BRB 8,4×16

Mounting

1 Insert hex head screws and washers into the holes on

the side of the foot.

Use the screws to fasten connecting strips to the inner

side of the foot. Tighten loosely.

:

3 Raise the beam from the bottom of the foot approxi-

mately 50 mm, to allow for height adjustment later in

the assembly.

4 Tighten the screws using a wrench.

2 Slide the connecting strips into the structural beam T-

slots.

Assembly 7

Page 8

Feet (continued)

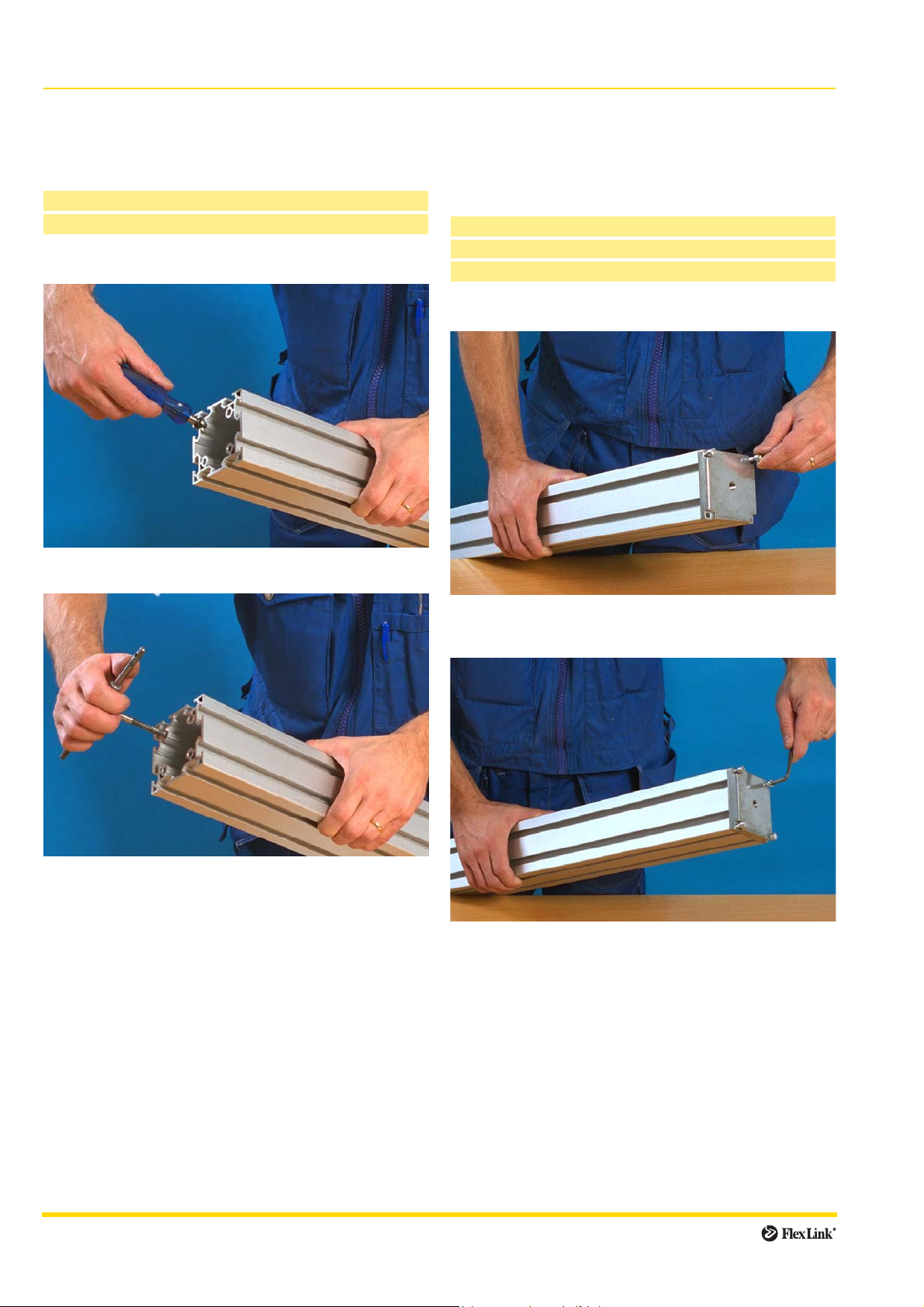

Deburring and threading beam ends

Before mounting foot plate XCFB 88/44 F, end plate

XCFE and mounting plate XCFB, the holes in the beam

cross-section must be deburred and threaded.

Countersink

Roller thread fluteless tap M6/M8

Mounting:

1 Deburr the holes using a countersink.

Attaching feet using end plates

XCFE

End plates are used as attachment for adjusting feet and

castors, and are screwed onto the support beam ends

before the actual foot is mounted.

Countersink

Roller thread fluteless tap M6/M8

Allen key 5 mm

Mounting:

2 Thread the holes using a 6 mm or 8 mm roller thread

fluteless tap, depending on beam and component

type.

1 Attach the end plate to the beam by inserting four hex

socket head screws into the holes on the end plate.

2 Tighten the screws using an Allen key.

8 Assembly

Page 9

Feet (continued)

Mounting adjusting feet

XCFS 12×68

Wrench 19 mm

Nut (included) M12

Washer (included) For M12 screw

Mounting:

1 Screw the foot onto the XCFE end plate.

2 Tighten the nut using a wrench.

XLFS 8

Foot XLFS 8 can be mounted directly onto beams XCBM/

XCBR 44 or directly into any T-slot.

Connection to beam XCBM/XCBR 44:

1 Attach an end plate to the beam end.

2 Screw the foot onto the end plate and tighten with nut.

Connection to structural beam T-slot:

1 Insert a slot nut into the structural beam T-slot.

2 Screw the foot onto the beam and tighten with nut.

Assembly 9

Page 10

Feet (continued)

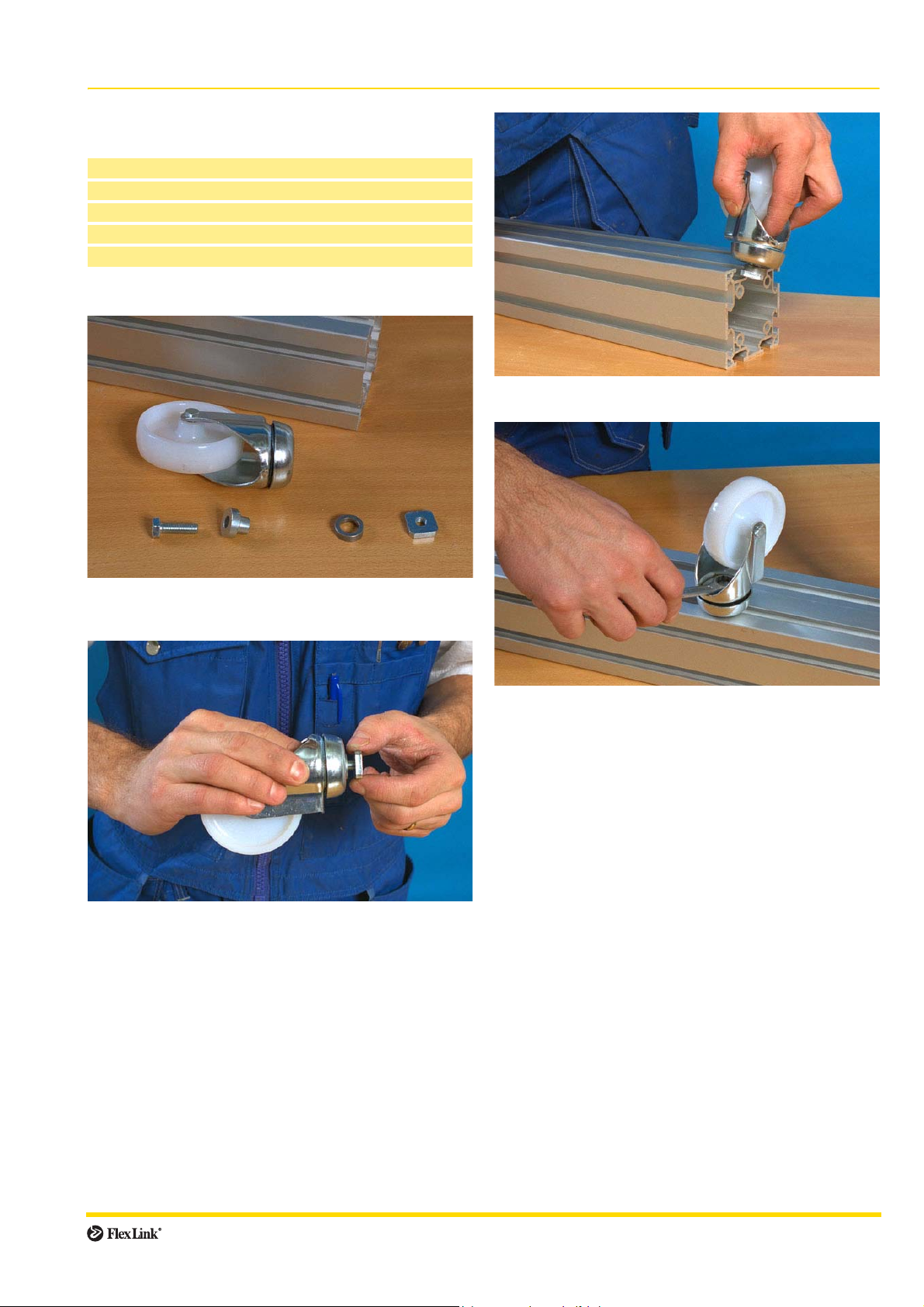

Mounting castors onto end plate

XCAG 80

Allen key 5 mm

Screw (included) K6S 12×25

Washer (included) For M12 screw

Mounting:

1 Insert screw (K6S 12×25) into the screw hole located

on the castor yoke. Add washer.

2 Screw the castor onto the XCFE mounting plate using

an Allen key.

10 Assembly

Page 11

Feet (continued)

Mounting castors to structural beam T-slot:

XCAG 80

Box wrench 13 mm

Screw (included) M6S 8×25

Filling washer (included) 3905065

Washer (included) BRB 8,4×16

Slot nut (included) XLAQ 8

Mounting:

3 Slide the foot into the structural beam T-slot.

1 The picture shows the mounting order for castor fas-

teners.

2 Insert screw and filling washer into the screw hole

located on the castor yoke. Add washer and slot nut.

4 Screw the castor onto the beam using a wrench.

Assembly 11

Page 12

Feet (continued)

Mounting foot plates

XCFB...F

Countersink

Roller thread fluteless tap M8

Allen key 5 mm

Hex socket head screws MF6S 8×30

Mounting:

b) For the XCBM 88×88 beam, you can also use four

M8 screws at the centre of the plate.

For the XCBM 44×44 beam, you can also use one M8

screw at the centre of the plate.

1 Deburr and thread beam ends before mounting the

foot plate. (See page 8)

2 a) Mount the foot plate onto an XCBL 88×88 mm light

support beam using four M6 screws at the corners of

the plate.

Mount the foot plate onto an XCBL 44×44 mm light

support beam using four M6 screws at the corners of

the beam.

12 Assembly

Page 13

Feet (continued)

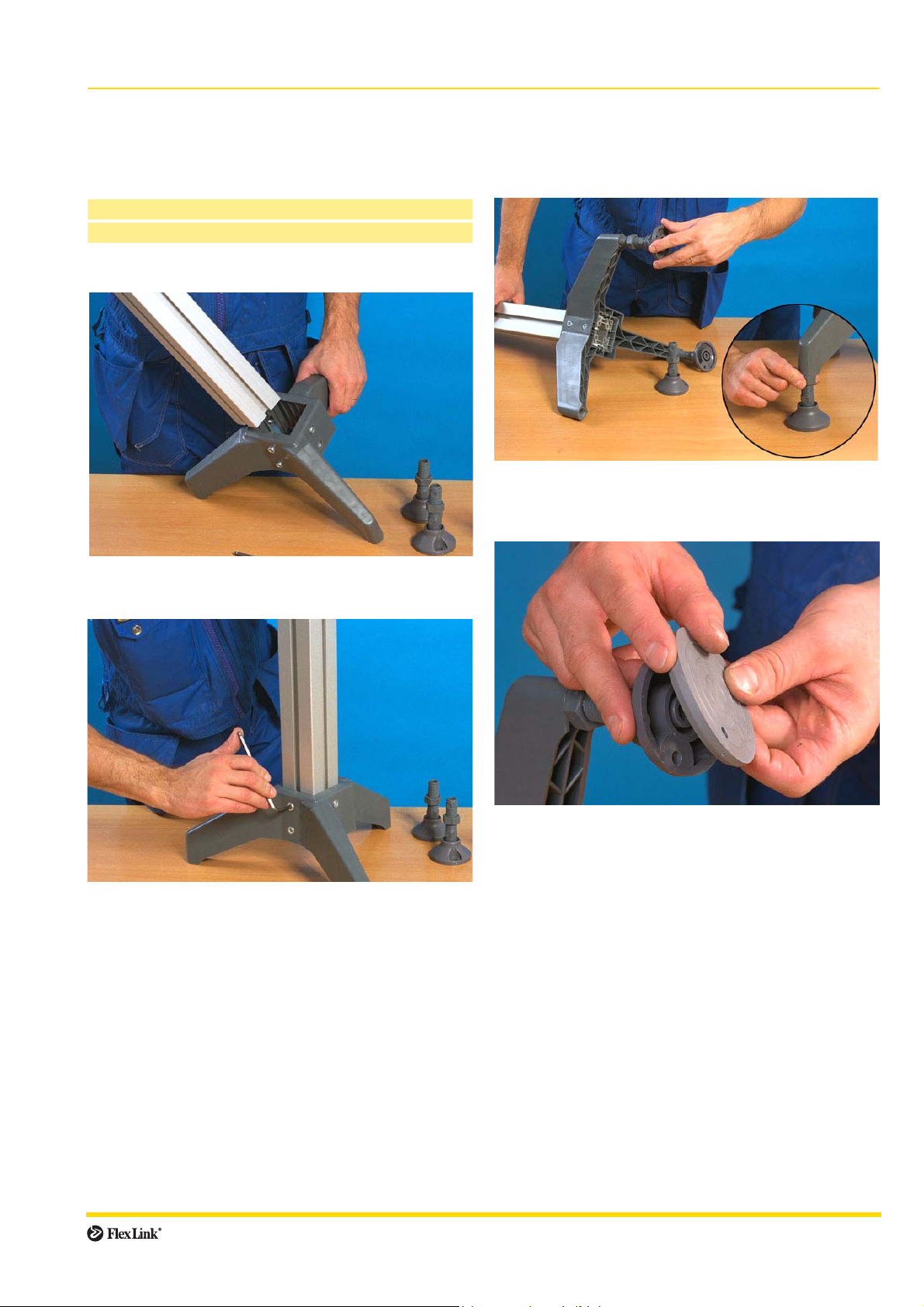

Mounting polyamide feet

XEFG

Polyamide feet are used with 64 mm structural beams

only.

Allen key 5 mm

Hex socket head screws (included) MC6S 8×16

Mounting:

Adjusting mounts and vibration absorbers

XLFS 20 P, XLFJ 69

Mounting:

1 Adjusting mounts are screwed onto the bottom of the

foot and fastened with the locking nuts that are

included.

1 Mount the foot onto the beam end by sliding the foot

compression clamps into the beam T-slot.

2 Tighten the screws. The recommended tightening

torque is 15 Nm.

2 Vibration absorbers are snapped on to the bottom of

the adjusting mounts.

Assembly 13

Page 14

Feet (continued)

Height adjustment assembly

XEFU 500

Used with XEFG 70 T foot only.

Allen key 5 mm

Lock brackets (included) 3903139

Hex socket head screws (included) MC6S 8×20

Mounting:

3 Tighten screws using an Allen key. The recom-

mended tightening torque is 15 Nm.

1 Attach the height adjustment assembly to the foot by

sliding the lock brackets into the slots on the beam.

2 Insert screws.

4 Insert the beam into the adjustment assembly and set

it at the required height.

Fasten the beam using the adjustment assembly lock-

ing levers.

14 Assembly

Page 15

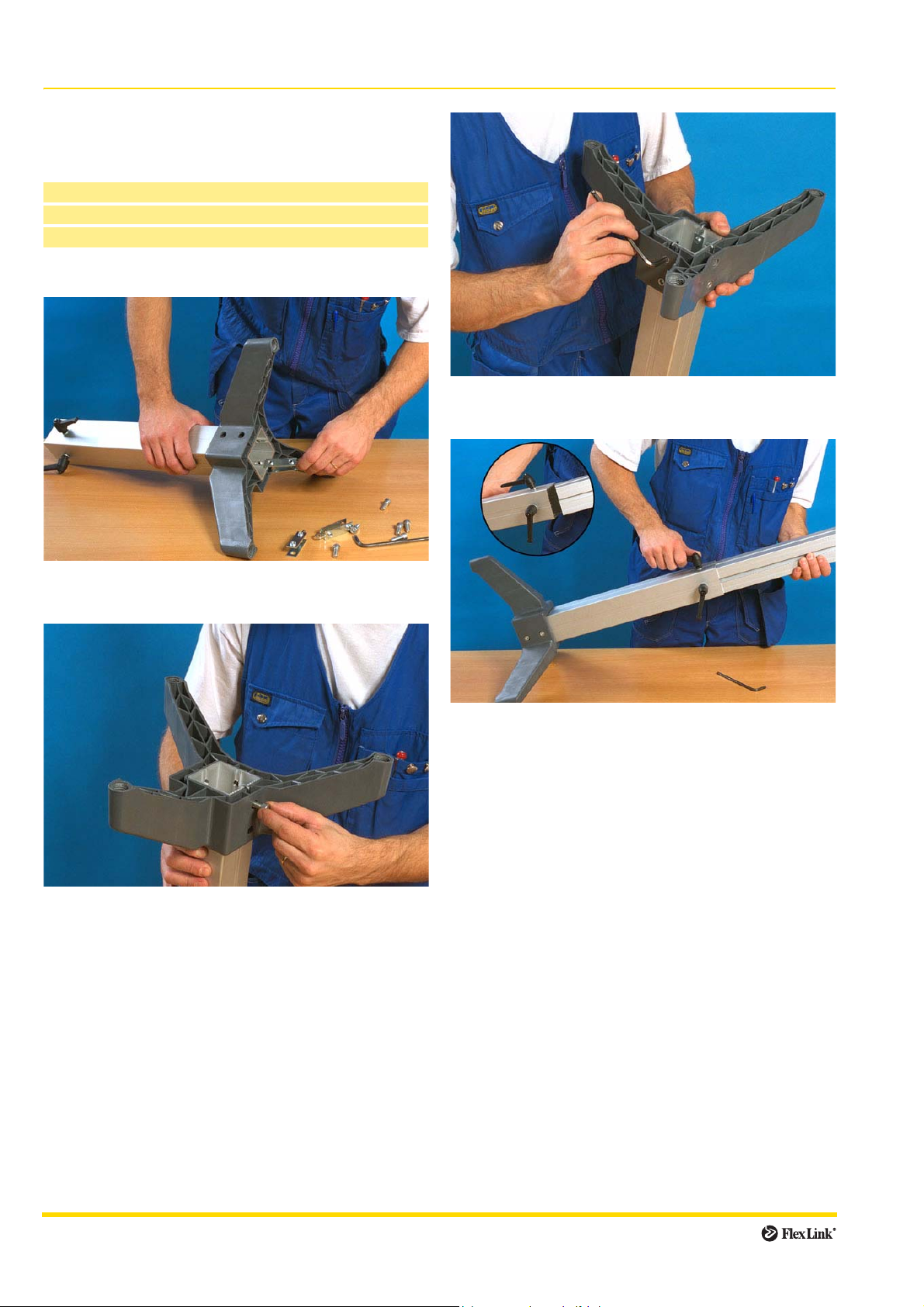

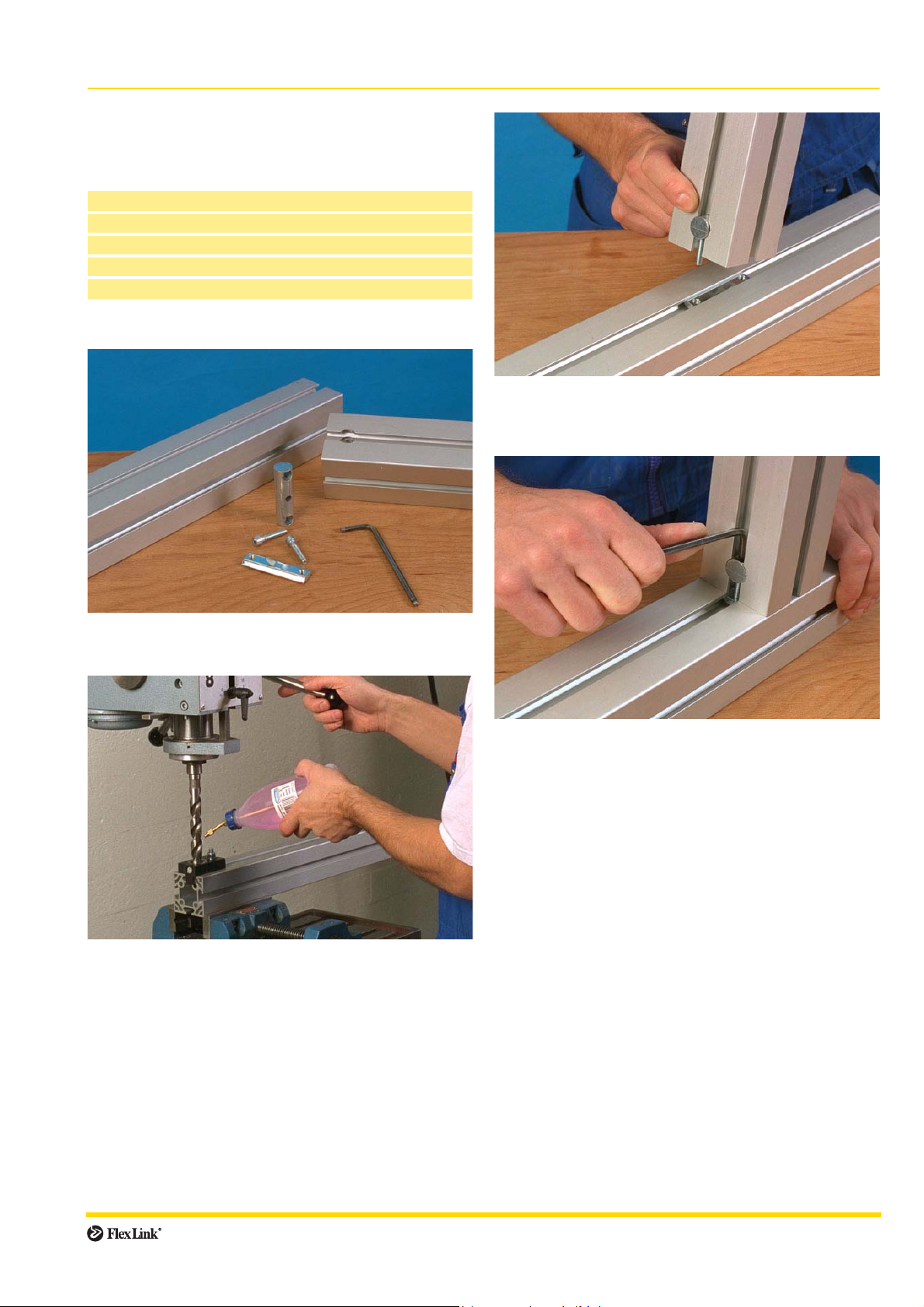

Beam connectors

Introduction

Structural beams can be connected to each other in a

number of ways. Three different methods are described

on the following pages.

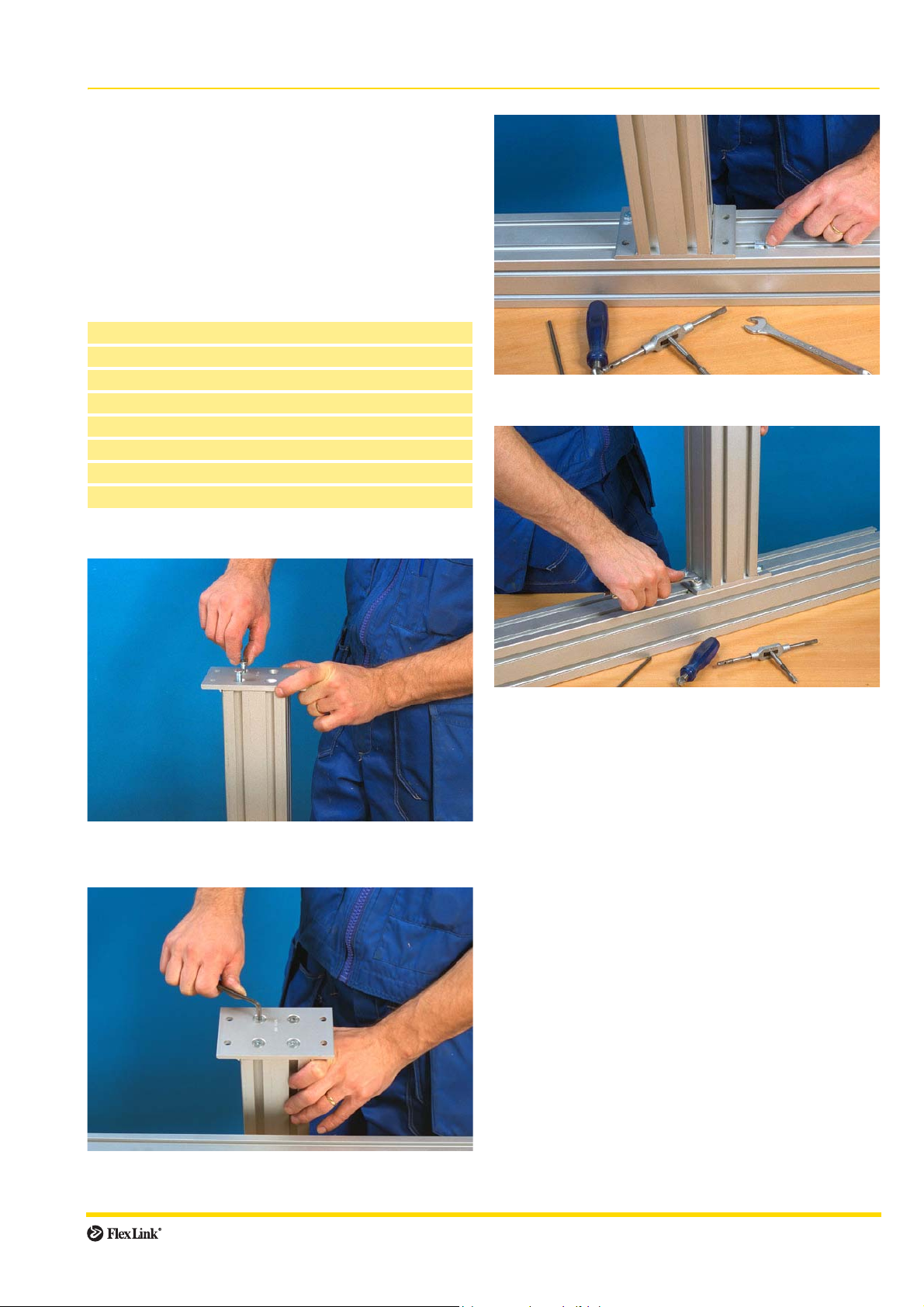

Connecting beams using mounting plates

XCFB

Deburr and thread beam ends before assembly. (See

page 8):

Countersink

Roller thread fluteless tap M6

Box wrench 10 mm

Allen key 5 mm

Hex socket head screws MF6S 8×30

Hex head screws M6S 8×16

Washers BRB 8,4×16

Slot nuts M8 thread

Mounting:

1

1

3 Insert slot nuts into the T-slots of the transverse beam.

1

1 Attach a mounting plate to the beam end using

MF6S 8×30 hex socket head screws and washers.

1

4 Screw the mounting plate onto the side of the trans-

verse beam using hex head screws M6S 8×16.

2 Tighten the screws using an Allen key.

Assembly 15

Page 16

Beam connectors (continued)

Connecting beams using angle brackets

XMFA, XLFA

Angle brackets are used to connect beams end-to-side or

side-to-side.

Box wrench 10 mm

Screws M6S 8×16

Slot nuts M8 thread

Washers BRB 8,4×16

Mounting:

3 Mount the angle bracket to the transverse beam in the

same manner. Tighten all screws.

1 Three different kinds of slot nuts can be used when

mounting angle brackets: connecting strip

XLCJ 5×76, square nut XLAQ 8 or slot nut XCAN 8.

2 Insert the required amount of slot nuts into the struc-

tural beam T-slot. Mount the angle bracket using

screws and washers.

16 Assembly

Page 17

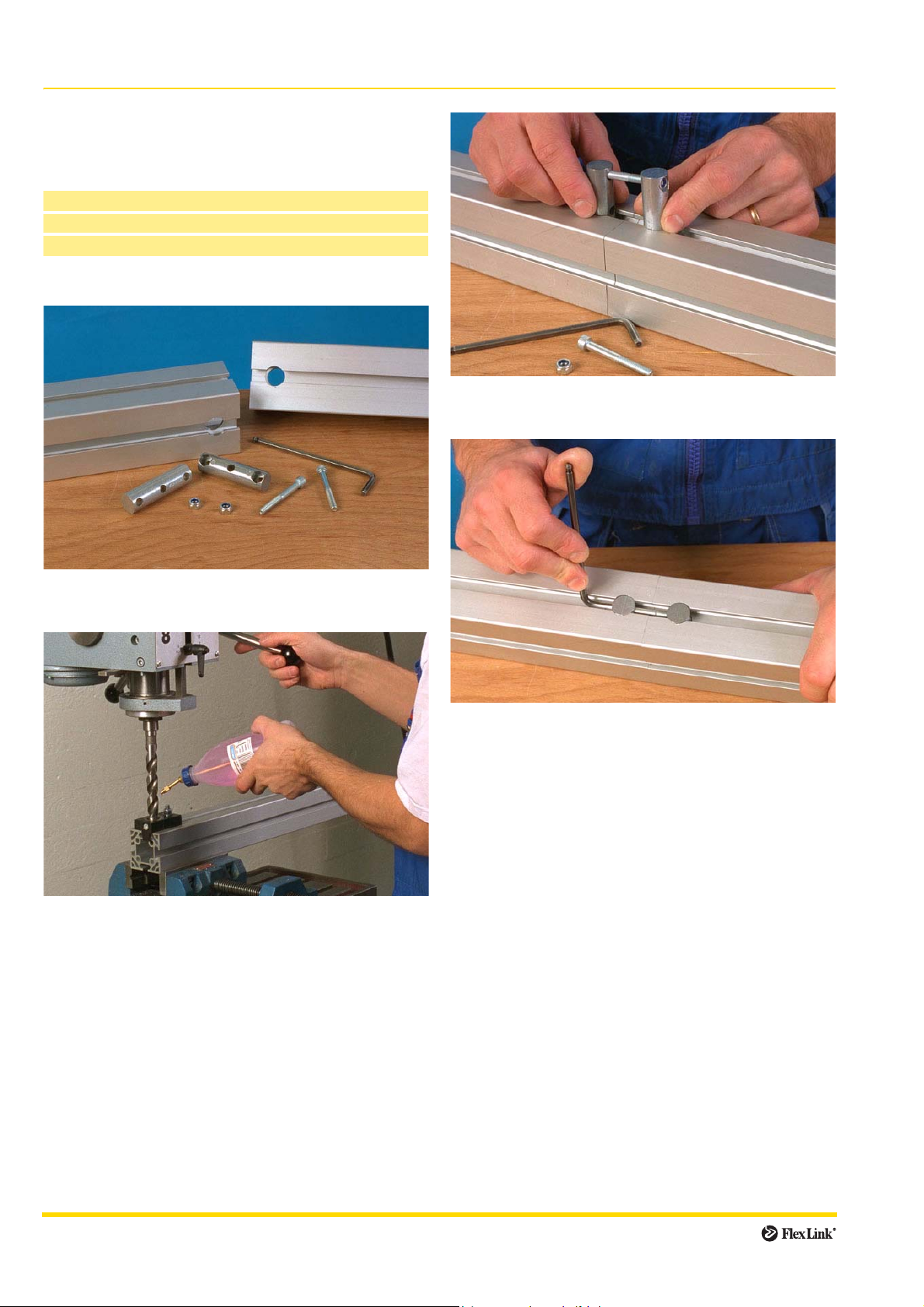

Beam connectors (continued)

Connecting beams using fastener yokes 1

XCAF

Method 1 – beam end against beam side

Drill ∅ 18,25

Drill fixture XCAD 18

Allen key 5 mm

Hex socket head screws (included) MC6S

Slot nut (included)

Mounting:

3 Place a fastener yoke in the hole and insert one 6×30

hex head screw on each side. Insert a slot nut into the

transverse beam.

1 The fastener yokes shown in the pictures are for

64 mm structural beams.

2 Use an XCAD 18 drill fixture to drill a 18,25 mm hole

through the end of the beam. While drilling in aluminium, be sure to lubricate the drill bit with methylated

spirits.

4 Tighten the screws using an Allen key. (The recom-

mended tightening torque for a lubricated joint is

10 Nm.)

Assembly 17

Page 18

Beam connectors (continued)

Connecting beams using fastener yokes 2

XCAF

Method 2 – beam end against beam end

Allen key 5 mm

Screws MC6S 6×50

Nuts XLAN 6

Mounting:

3 Connect the two fastener yokes with one screw and

nut. Place the yokes in the holes of the beams.

1 Two fastener yokes are required when mounting

beam end against beam end.

2 Use an XCAD 18 drill fixture to drill a 18,25 mm hole

through the end of the beam. While drilling in aluminium, be sure to lubricate the drill bit with methylated

spirits.

4 Connect the yokes on the other side of the beam.

Tighten both screws.

18 Assembly

Page 19

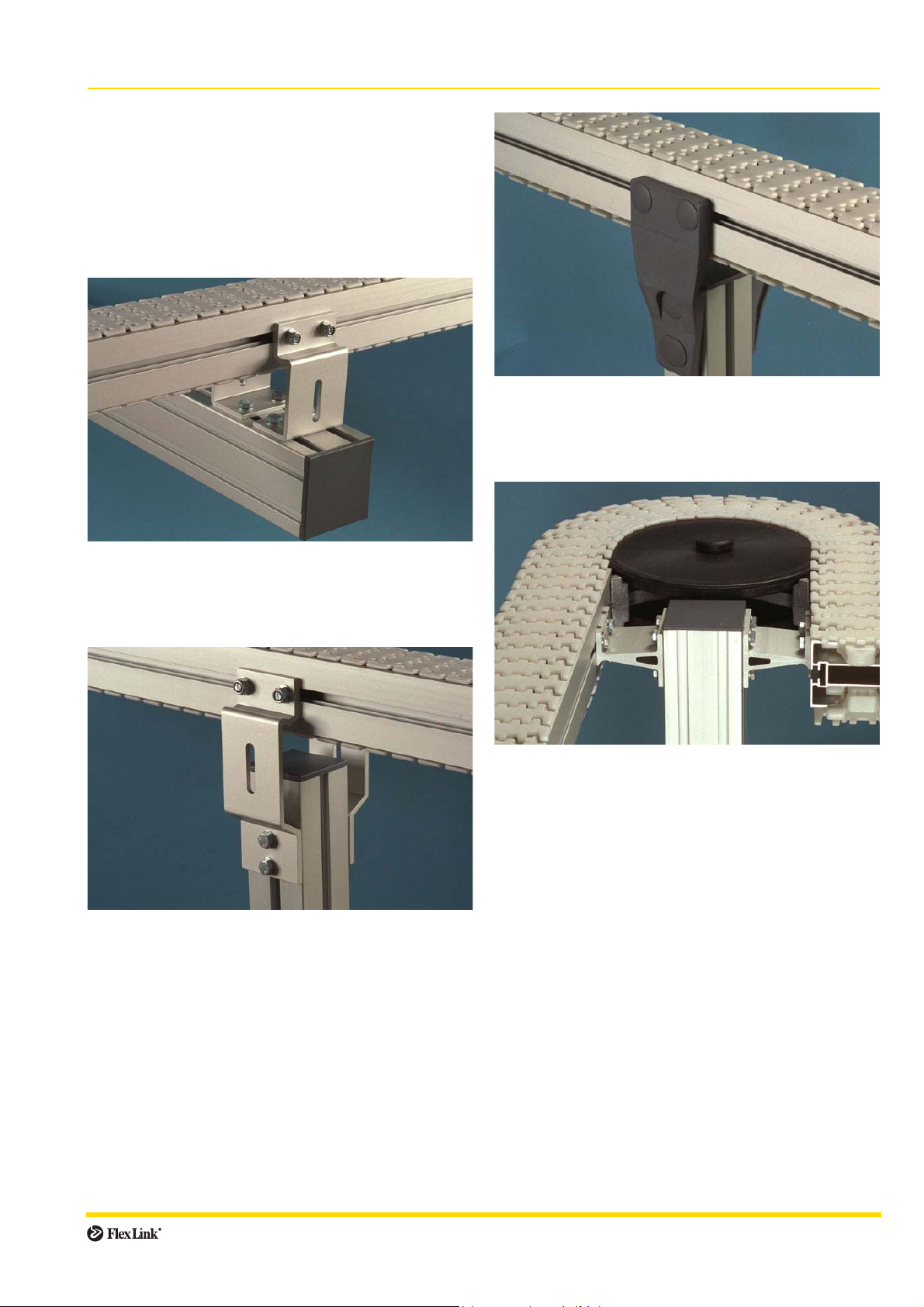

Conveyor beams

Introduction

Conveyor beams are mounted on to the support structure

by means of support brackets. There are three different

types of conveyor beam support brackets. They all serve

the same purpose but are connected to the structural

beams in different ways.

Beam support brackets

Type B: X..CS.. (polyamide)

When attaching plastic beam support brackets, always

use a flat washer between nut and bracket. The nuts can

be covered by plastic plugs.

Type A: XLCT..

Type A brackets are used with crossing 64 mm or 88 mm

support beams. These brackets can also be used as drip

tray connectors

Type B: X..CS.. (aluminium)

Type B brackets are used with vertical support beams

and are made from either aluminium or polyamide. The

aluminium types can be used instead of drip tray brackets. (See example on page 48)

Type C: XLCU 73

Type C brackets are used for connecting two parallel conveyor beams to an 88 mm vertical support beam.

Assembly 19

Page 20

Conveyor beams (continued)

Mounting conveyor beam support brackets

X..CT, X..CU, X..CS

Start by erecting structural beams and attach one conveyor beam support bracket to each beam.

It may be easier not to mount the second bracket until

slide rail has been mounted and, if using catenary or end

drive unit, the chain has been installed.

Box wrench 13 mm

Hex head screws M6S 8×16

Slot nuts XCAN 8

Washers BRB 8,4×16

T-bolts XLAT 17

Nuts XLAN 8

Washers BRB 8,4×16

Mounting

2 Insert the slot nuts of the second support bracket into

the support beam T-slots. Slide the bracket down so

that it does not protrude above the cross-section of

the beam.

1 Attach screws, nuts and washers to the support

bracket before mounting. (Screws and slot nuts are

support beam fasteners, T-bolts and nuts are con-

veyor beam fasteners.)

Slide the slot nuts of one support bracket into the sup-

port beam T-slots. Tighten the screws. Make sure that

the support bracket is aligned with the beam cross-

section as shown in the drawing.

3 Use a soft hammer to mount an end cap on to the

support beam.

4 Mount the first support bracket to the conveyor beam.

Pull the second bracket up and insert the T-bolts into

the conveyor beam T-slot. Tighten the nuts.

20 Assembly

Page 21

Conveyor beams (continued)

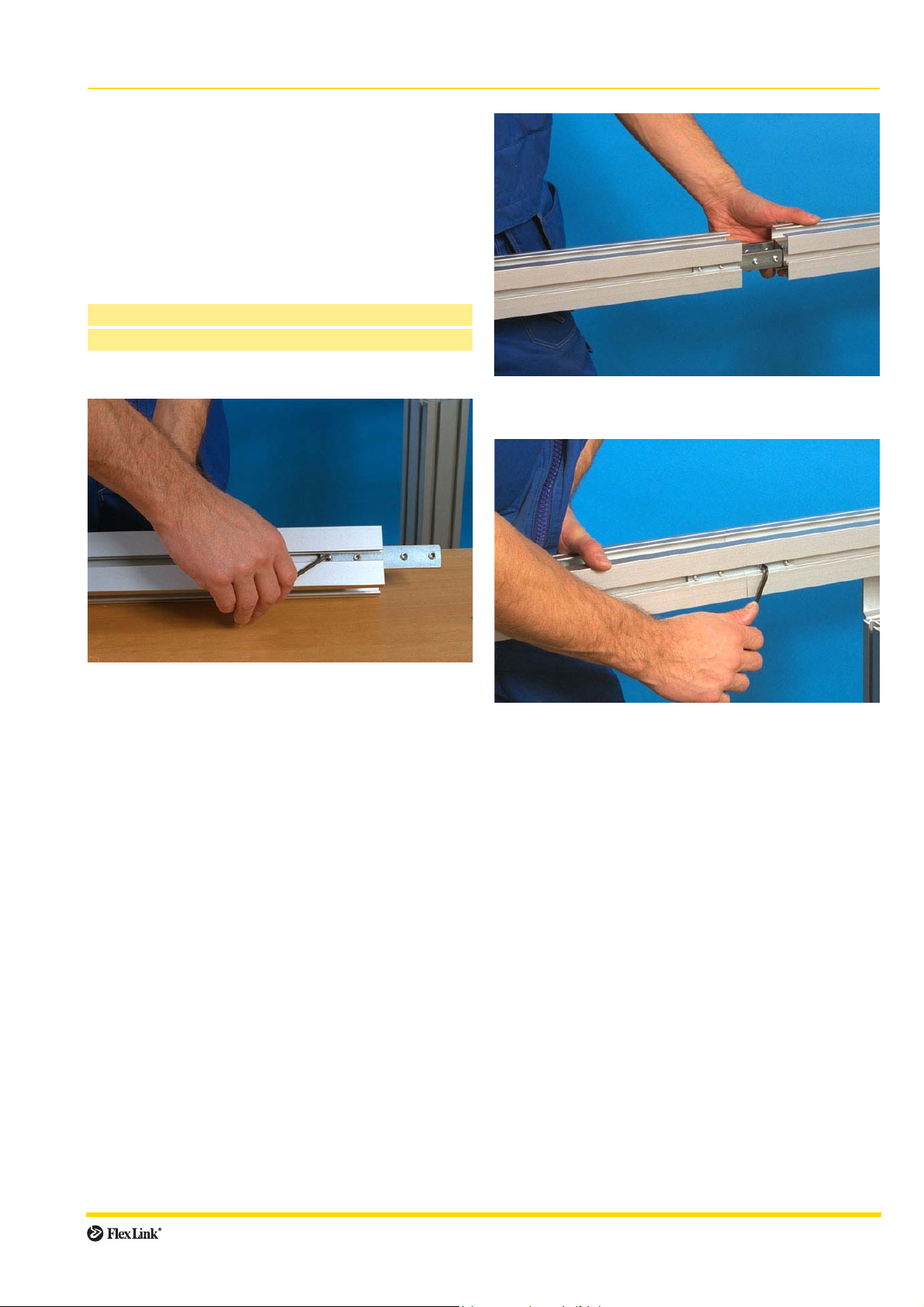

Assembling conveyor beams

The next step is to connect conveyor beams – straight

sections and bends – to each other. Connect all conveyor

beams according to the instructions below.

Straight sections X..CB

Wheel bends X..BH

Horizontal plain bends X..BP

Vertical plain bends X..BV

Allen key 4 mm

Connecting strips with set screws XLCJ

Mounting:

1 Connect two conveyor beam ends by inserting con-

necting strips into the beam T-slots. Use two connecting strips per beam joint.

2 Make sure that the set screws do not prevent the con-

nection strips from sliding into place.

3 Tighten the set screws using an Allen key.

Assemble the entire conveyor beam structure in the

same way. If the conveyor beam is too long to mount onto

the support structure in one continuous length, assemble

shorter lengths and connect them to each other once fastened to the support beams.

Assembly 21

Page 22

Drive units

Introduction

Step three is to mount drive and idler units to the frame

structure. All drive and idler units come with connecting

strips included. Attach them to the conveyor beam using

an Allen key and the set screws that are included.

Drive units can be attached to supports of various

kinds; check your drawing to see how your conveyor is

designed.

It should be remembered that conveyor chains should

always be pulled, not pushed, by the drive unit.

Mounting of end drive unit

X..EB 5 H

Allen key 4 mm

Mounting:

1 Mount the end drive unit on to the end of the con-

veyor:

Release the four set screws that are inserted into the

drive unit connecting strips. Insert the connecting

strips into the T-slot of the beam you want attached to

the end drive unit.

Make sure that the set screws do not prevent the connecting strips from sliding into place.

Caution:

When installing a drive unit, ensure that

the slip clutch is fully released.

The conveyor chain catenary of

end drive units must be maintained during the system lifetime.

When the conveyor chain is visible through the slot in the sideplate, it must be shortened.

2 Tighten the set screws using an Allen key.

22 Assembly

Page 23

Drive units (continued)

Intermediate drive unit

X..ER 5 H

Intermediate drive units can be installed anywhere along

the conveyor, although it should be mounted as close to

the end of the conveyor as possible.

Attach the drive unit to the conveyor beam using the

connecting strips that are included. (See mounting

instructions for end drive unit, page 22)

Caution:

When installing a drive unit, ensure that

the slip clutch is fully released.

The area near the guides for the return

loop of the chain should not be accessible

during conveyor operation.

There must be no conveyor chain catenary when

using intermediate drive units.

Adjustment of the position of the bridge area may be necessary, depending on weight and shape of the products

that are being transported. Adjust the bridge by loosening the two screws on the side below the bridge, and then

loosening the four remaining screws. Adjust the bridge

position and tighten all screws.

Caution:

When installing a drive unit, ensure that

the slip clutch is fully released.

The bridge area where the chain

goes down should not be accessible during conveyor operation.

The conveyor chain slack of catenary drive units must be main-

tained during the system lifetime.

When the conveyor chain is visible through the slot

in the plastic cover, it must be shortened.

Horizontal bend drive unit

X..EW 180/5 H

Catenary drive unit

X..EC 5 H

Catenary drive units are used in “endless chain” conveyor systems with no return chain.

Catenary drive units can be installed anywhere along

the conveyor length.

Attach the drive unit to the conveyor beam using the

connecting strips that are included. (See mounting

instructions for end drive unit, page 22)

The horizontal bend drive unit is used for endless conveyors with no return chain.

Attach the drive unit to the conveyor beam using the

connecting strips that are included. (See mounting

instructions for end drive unit, page 22)

Caution:

When installing a drive unit, ensure that

the slip clutch is fully released.

There must be no conveyor chain catenary

when using horizontal bend drive units.

The drive wheel should not be accessible

during conveyor operation.

Assembly 23

Page 24

Drive units (continued)

Double drive unit

X..EB 5 HD

Idler units

C/C 55 (XS), 66 (XL), 86 (XM), 106 (XH) and 106 (XK)

drive units are supplied with four connecting strips. However, since space is limited, only the two outer connecting

strips can be used for beam attachment. (See mounting

instructions for end drive unit, page 22)

C/C 90–350 (XS), 110–350 (XL), 130–350 (XM), 150–

350 (XH) and 150–350 (XK) drive units are connected to

the beam with four connecting strips. (See mounting

instructions for end drive unit, page 22)

Caution:

Ensure that the shaft is not accessible during conveyor operation.

When installing a drive unit,

ensure that the slip clutch is fully

released.

The conveyor chain catenary of

double drive units must be main-

tained during the system lifetime.

When the conveyor chain is visible through the slot

in the side-plate, it must be shortened.

Introduction

Idler units are used to guide the conveyor chain into the

return side of the conveyor. Connecting strips are already

attached to the unit.

Idler end unit

X..EJ

Idler bend unit

X..EK

The 90° idler bend can only be used with a return chain

together with the XL conveyor system.

24 Assembly

Page 25

Idler units (continued)

Mounting idler units

Allen key 4 mm

Mounting:

1 Insert the idler unit connecting strips into the

T-slots of the beam end.

Mounting idler end protective cover

Allen key

Mounting:

1 Remove three of the five M5×10 screws that holds the

idler end side plate in position.

2 Secure the idler unit to the beam using an Allen key to

tighten the set screws.

Caution:

The opening between the links when they

turn around the idler could be a risk. Idler

ends should not be accessible during conveyor operation. (For mounting of idler end

protective cover, see next page.)

Assembly 25

2 Slide the cover onto the idler end unit.

3 Insert and tighten the three M5 screws that are deliv-

ered with the cover

Page 26

Slide rail and support rail

Introduction

XLCR

The slide rail is attached to the sides of the conveyor

beam to reduce chain friction where the chain would

otherwise be in direct contact with the beam profile. It is

very important that the slide rail is installed properly, so

that the chain can run without disruption.

When the conveyor is to be mounted high above

ground level, it might be easier to mount the slide rail onto

a conveyor section while the conveyor beam is still on the

floor. If doing so, leave an extra end, approximately

300 mm longer than the beam, so that it can be cut off

and adjusted when the beam is finally installed.

Slide rail beam attachment

To ol s:

Slide rail installation tool

Cutting pliers

Mounting:

1 Start at an idler end unit. Separate the top and bottom

flange of the slide rail at the end of the rail and press

it into place.

3 Use the slide rail mounting tool to press the slide rail

into place. One end of the tool is used when slide rail

is mounted onto only one side of the beam, and the

other end is used when you mount slide rail onto the

second side.

4 Do not forget to mount slide rails both underneath and

on the upper side of the beam (unless top running

chain only).

2 Make sure that you mount the slide rail so that it snaps

on to the beam. The different types of slide rail do not

look alike, so check which flange should be on top.

26 Assembly

Page 27

Slide rail and support rail (continued)

Joining slide rail ends

Cutting pliers

Mounting:

1 Cut both slide rail ends in a 45° angle.

The beginning of a new slide rail section (in the direction of travel must be cut back a small angle.

2 Allow a space of approximately 10 mm between two

slide rail ends.

The arrow indicates travel direction.

3 Do not place two slide rail joints opposite each other.

Make sure there is a distance of at least

100 mm between them to make the chain run

smoother.

This does not apply to slide rail that begins by an idler

unit or after a drive unit, where joints are always parallel.

Try to let the slide rail run in as many continuous lengths

as possible, except in circumstances stated below:

• It is recommended to use short slide rails (2–3 m)

where chemicals may have an effect on the slide rail

composition.

• It is important to cut the slide rail and allow for elongation in high load areas. Cutting is required in wheel

bends (see following page), by idler units and where

the conveyor will be heavily loaded, especially by the

drive units. This prevents the slide rail from stretching

out and entering into the drive unit, which may block

the chain.

• Never join slide rail in horizontal or vertical bends,

since forces are higher on the slide rail in these sections. Instead, place the joint before the bend.

• Avoid joining slide rails on top of conveyor beam

joints.

Assembly 27

Page 28

Slide rail and support rail (continued)

Mounting slide rail in wheel bends

Cutting pliers

Before wheel bend:

Mounting:

1 Cut the slide rail end in a 45° angle.

After wheel bend:

Mounting:

1 Cut the slide rail in a 45° angle with a short back cut.

The slide rail must be longer than the conveyor beam

itself, and there should be a 2 mm distance between

the slide rail and the wheel of the bend.

2 The slide rail must be longer than the conveyor beam

itself, and there should be a 10 mm distance between

the slide rail and the wheel of the bend.

Make sure that the end of the slide rail is not bent up

or down.

2 In the outer bend, make sure that the slide rail is prop-

Horizontal plain bends

In plain bends with small radii, the slide rail for the inner

bend should be cut so that it is only 10 mm wide in the

bend. This is to prevent an uneven slide rail surface.

Stretch the rail while mounting.

Note:

28 Assembly

erly connected to the conveyor beam profile.

Plain bends with small radii should be

avoided, if at all possible. Always consult

FlexLink Systems for design assistance.

Page 29

Slide rail and support rail (continued)

Fixing slide rail to the conveyor beam

Hand drill

Drill fixture for slide rail 4,2 mm (XS: 3,2 mm)

Countersink

The beginning of each slide rail section must be fixed to

the beam, since the chain will cause the slide rail to be

pushed forward. Slide rail which moves into a wheel bend

or a drive unit can block the chain completely.

There are two different methods for fixing slide rail to

the conveyor beam: using aluminium rivets or plastic

screws. Either method can be used, but the riveting

method is more secure if the conveyor will run with high

operational speed or be heavily loaded.

Drilling slide rail

Procedure:

1 Drill two holes near the beginning of each slide rail

section. Use the drill fixture to ensure clean-cut holes

and the correct location of the holes. For drill bit

radius, see table.

The holes must be at the leading edge of the joint

piece, in the direction of travel, to hold the slide rail in

place when the conveyor is in use. Use a well-sharp-

ened drill-bit.

The arrow indicates running direction.

2 Use a countersink to deburr and countersink the

holes. Also make sure that there are no metal filings

left underneath the slide rail.

Conveyor system Drill bit diameter Rivet

XS ∅3,2 mm XLAH 3×6

XL/XM/XH ∅4,2 mm XLAH 4×6

Slide rail in conveyor beam section XLCH 5 V

When using articulated beam section XLCH 5 V, the slide

rail must be mounted across the entire beam section, and

cut off at the beginning of the following beam section.

Assembly 29

Page 30

Slide rail and support rail (continued)

Method 1: Using aluminium rivets

Rivet crimping pliers/rivet crimping clamp

Aluminium rivets

Mounting:

1 Insert rivets in the holes, using rivet crimping pliers or

a rivet crimping clamp. For type of rivet, see table on

previous page.

wrong

correct

3 Check that the rivets do not protrude over the surface

of the slide rail.

Check both top and underneath surface of slide rail for

protruding metal.

2 If working space is limited, the rivet crimping clamp

might be easier to use. The two crimping tools perform the same task, but the pliers are more efficient

and easier to use.

4 Keep a distance of approximately 30 mm between riv-

ets and idler unit. This is in case the idler unit has to

be removed after conveyor system assembly.

30 Assembly

Page 31

Slide rail and support rail (continued)

Method 2: Using plastic screws

Pliers/screwdriver

Knife

Hammer

Plastic screws XLAG 5

An alternative to aluminium rivets is to use plastic screws

XLAG 5:

Mounting:

3 Make sure the slide rail surface is smooth and that

screws do not protrude over the surface of the slide

rail. If the surface should be uneven, file the edges

smooth.

Check both top and underneath surface of slide rail for

protruding plastic or metal.

1 Press or screw the screws into the holes using a pair

of pliers or a screwdriver.

2 Cut off the screw heads by using a knife and a ham-

mer. The cut should be made away from the joint, in

the direction of chain travel.

4 Keep a distance of approximately 30 mm between

screws and idler unit. This is in case the idler unit has

to be removed after conveyor system assembly.

Assembly 31

Page 32

Slide rail and support rail (continued)

Mounting support rail in plain bends

Mounting:

1 Cut the support rail in a 45° angle. The cut should be

made at the leading edge of the rail, in the direction of

travel, to ensure a smooth entrance of the chain.

4 Drill a hole at the first end (in the direction of travel) of

the inner bend using a 4,2 mm drill bit. Leave a distance of 20 mm between the hole and the beam end.

Deburr the hole.

2 Mount the support rail on the inside of the beam pro-

file. Let the rail run along the entire bend, including the

straight sections of each end.

3 Cut the rail at the other end in a 90° angle using a

knife and a soft hammer.

5 Clamp the support rail to ensure a proper fit. Insert a

short piece of rail between the clamp and the support

rail to get a tight grip. Repeat this procedure along the

entire bend.

6 Insert a plastic XLAG 5 screw in the drilled hole and

tighten it. Make sure that the screw enters the support

rail.

32 Assembly

Page 33

Chain

Introduction

When all beams have been assembled and the slide rail

is in place, it is time to assemble and mount the chain on

to the conveyor system.

Joining chain ends

Assemble the chain by inserting the steel pin that comes

with each chain link, into the opposite end of another link.

Do this by using the FlexLink pin insertion tool.

Pliers

FlexLink chain tool

Mounting:

3 Line the FlexLink chain tool up with the pin. Slowly

depress the trigger until the pin seats.

1 Insert the plastic pivot with the slot facing outward.

2 Insert the steel pin halfway, using a pair of pliers.

Always use new steel pins and plastic pivots when

joining chain ends.

Wrong

4 Check that the chain is flexible in the joint, and that the

pin does not stick out or go through the other side.

Taking the chain apart:

1 Line the chain tool up with the pin.

2 Depress the trigger until the pin pops out.

3 Depress lever, pull insertion pin out.

4 Pull chain apart.

Assembly 33

Page 34

Chain (continued)

Mounting preparations

Procedure:

1 Remove the drive unit transmission cover.

3 Remove the side plate on the drive unit.

2 Release the slip clutch so that the drive shaft is free to

turn. (Slip clutch adjustment, see page 66)

With the slip clutch loose, make sure that the motor is

turning in the correct direction.

4 Before mounting, run a short piece of chain (0,5 m)

through the conveyor to ensure a smooth running system. If any obstructions are found, they should be

removed and the checking process repeated.

34 Assembly

Page 35

Chain (continued)

Mounting the chain

Make sure that the slip clutch is released allowing the

drive shaft to turn freely. (See previous page.)

Pin insertion tool X..MJ

Mounting:

1 Insert the chain into the underside of the drive unit.

Make sure the chain will be moving in the correct

direction, as indicated by the arrow located at the side

of all chain links.

3 Join 5 meter lengths of chain when necessary.

2 Feed the chain along the conveyor by pulling it

through the idler unit and back to the drive unit.

4 Stretch the chain and remove links if necessary, so

that the chain will exhibit some slack at the drive unit.

(Length adjustment, see page 37)

Connect the chain ends. (See page 33)

Assembly 35

Page 36

Chain (continued)

Mounting the chain using a beam section for

chain installation

X_CC 160/XKCC 200

Allen key

Pin insertion tool X..MJ

Clamp

Mounting:

3 Clamp the chain to the beam profile. Use the

FlexLink chain tool to remove a steel pin from the

chain, so that two links are separated.

1 Loosen the screws on the beam section flanges.

2 Remove the flange so that the chain becomes acces-

sible.

4 Remove excess links and use the chain tool to put the

chain back together again.

36 Assembly

Page 37

Chain (continued)

Length adjustment of the conveyor chain

End drive units, catenary drive units

1 Adjustment of the conveyor chain is carried out at the

drive end of the conveyor.

2 The transmission guard cover must be removed from

the drive unit and the slip clutch disengaged or trans-

mission chain removed. The conveyor chain should

now be free to travel within the conveyor beam profile.

3 Catenary protection plates should also be removed to

allow easy access for the conveyor chain pin insertion

tool.

4 The conveyor chain should be tensioned within the

conveyor system by pulling down the conveyor chain

at the chain catenary in the underside of the drive unit.

Clamp across the conveyor chain to trap the chain on

to the beam profile. The clamp should be placed over

the edges of the drive unit to reduce the risk of dam-

age to the aluminium profile.

5 Remove all slack links from the conveyor chain using

the pin insertion tool.

6 Rejoin the conveyor chain using a new steel pin and

plastic pivot.

7 Remove the chain clamp and replace the catenary

protection plate and transmission chain. The slip

clutch should also be reset.

8 Replace the transmission guard cover. The conveyor

is now ready for operation.

Intermediate drive units, horizontal bend drive units

1 Conveyors which have no conveyor chain catenary

should be assembled with a special section of conveyor beam (X..CC), which allows for the chain to be

easily inserted and adjusted for tension. (See previous page.)

2 Remove the lower part of this conveyor beam section

by releasing the four screws.

3 Lift the chain from this section of the beam and clamp

the conveyor chain as described above. Adjust the

chain tension as for end and catenary drive units.

In a wheel bend drive, the outer aluminium profile can be

removed by slackening the set screws in the beam connecting strips. The slide rail must be fitted to allow the

removal of this section.

1 After removal of the outer aluminium profile, the con-

veyor chain can be pulled out of the wheel bend disc.

Lift the chain upwards.

2 Remove chain links using the pin insertion tool.

3 New steel pins and plastic pivots must be used when

rejoining chain ends.

4 The tensioned chain can now be pulled back into

position on the bend guide disc, and the outer profile

put into place.

Assembly 37

Page 38

Guide rail system

Introduction

Guide rails are used to guide products being conveyed,

but also to prevent them from falling off the conveyor.

Guide rails are supported by guide rail brackets

attached to the sides of the conveyor beam. Follow the

mounting instructions for the type of bracket used in your

application.

Brackets should be placed approximately 500 to

1000 mm apart depending on type of product and if

accumulation occurs or not. If brackets are spaced at

greater distances than 1000 mm, there is a possibility

that guide rails will become deformed due to excessive

force.

Mounting fixed guide rail brackets (aluminium)

XLRB,XLRA

Box wrench 13 mm

Pliers

T-bolts XLAT 17

Nuts XLAN 8

Washers BRB 8,4×16

Spring pins XLAP 28

2 Use a pair of pliers to insert a spring pin between the

guide rail bracket and the guide rail.

Note

Do not tighten screws if angle plates are to be

attached to the conveyor. (Angle plates, see

page 46.)

Mounting:

1 Attach guide rail brackets along the conveyor, using T-

bolts and nuts. The distance between brackets should

be approximately 0,5–1,0 m.

38 Assembly

Page 39

Guide rail system (continued)

Distance pieces (spacers)

XLRD 6/XLRD 6 P

Distance pieces can be used to increase the maximum

track width, and are placed between the guide rail

bracket and the conveyor beam. For the XL conveyor

system, distance piece XLRD 6 P can also be used to

fasten angle plates. (See picture on page 46)

Longer T-bolts must be used if distance pieces are

used with guide rail brackets.

Mounting guide rail brackets (polyamide)

The adjustable guide rails, polyamide, include components for construction of a wide variety of guide rail configurations. This includes basic fixed types as well as

high and wide guide rails in various adjustable configurations.

The pictures below show one possible way to assemble guide rail brackets. The examples shown on the following page are assembled in a similar way.

Socket wrench 13 mm

Allen key 5 mm

T-bolts XLAT 17

Nuts XLAN 8

Washers BRB 8,4×16

2 Attach a guide rail clamp to the bracket. Tighten the

screw.

Mounting:

1 Fasten a guide rail bracket support to the conveyor

beam using T-bolt, nut and washer.

3 Attach the guide rail to the clamp. Tighten the screw.

Important:

Do not over-tighten screws!

Assembly 39

Page 40

Guide rail system (continued)

Application examples

Some examples of adjustable guide rail applications are

shown below:

Examples:

Distance pieces XLRD can be used to increase track

width. Use T-bolts or stud bolts when mounting the

bracket support and distance pieces to the conveyor

beam.

Pieces of XLRN spacer beam can be used to increase

track width instead of distance pieces. Do not forget to

place an XLRD spacer beam connector between the

spacer beam and the conveyor beam.

40 Assembly

Page 41

Guide rail system (continued)

Built-up guide rail brackets

Built-up guide rail brackets are made up from pieces of

small beam with T-slots on three or four sides. The beam

is cut to suitable lengths and connected to form brackets

with the desired height and width.

Special fittings are used to connect the beam pieces

to each other, to the conveyor beam and to the guide rail.

It is possible to use more than one guide rail on each

side.

There are several types of built-up guide rail brackets

(L brackets). Assembly instructions for two different types

are described on the following pages.

Allen key 5 mm

Box wrench 13 mm

Beam XCBB 3×24×34/44

Inner fitting/corner fitting XMRY 20/XMRW 20

Inner fitting XMRX 20

Guide rail bracket XLRC 20/20A

T-bolts XLAT 17

Nuts XLAN 8

Washers BRB 8,4×16

End caps XCBE 24×34/24×44

2 Attach two XMRX 20 inner fittings to the end of the L-

bracket.

Mounting:

1 a) L bracket Type 1: Use a XMRY 20 inner fitting to

connect two beam pieces. Tighten screws.

3 Mount the bracket to the conveyor beam using T-bolts,

nuts and washers.

b) L bracket Type 2: Use a XMRW 20 corner fitting to

connect two beam pieces that have been cut in a 45°

angle.

Assembly 41

Page 42

Guide rail system (continued)

Mounting guide rail bracket to L-beam:

1 a) Attach guide rail bracket XLRC 20 A using slot nut

and an Allen key.

3 Attach guide rail to the brackets using spring pins and

a pair of pliers.

b) Attach guide rail bracket XLRC 20 using a hex

head screw and slot nut.

2 Fasten end caps at the ends of all beams using a soft

faced hammer.

42 Assembly

Page 43

Guide rail system (continued)

Connecting guide rails

For connection of guide rails, you will need connecting

plugs (XLRJ 10/15) or connecting sleeves (XLRJ 100).

Mounting

Connecting plugs are pressed into two guide rail ends.

Guide rail ends

XLRE 10/15

Mounting:

Plug all guide rail ends with end plugs. Use a soft faced

hammer when inserting the plugs.

Connecting sleeves are fastened to the guide rail ends

with set screws and an Allen key.

Make sure you place the connecting sleeves on the

outer side of the guide rail.

Assembly 43

Page 44

Guide rail system (continued)

Guide rail cover

XLRT

Mounting:

To prevent products from being scratched, a plastic guide

rail cover can be snapped on to the inside of the guide rail

(15 mm guide rail only).

Guide discs/guide rails in bends

XLRG

At the inner bend of horizontal wheel bends, a plastic

guide disc can be used instead of regular guide rail.

Mounting:

1 Remove the wheel bend cap.

Make sure that all cover joints are smooth, so that products do not get caught or damaged. Do not join covers on

top of guide rail joints.

44 Assembly

2 Press the guide disc into place on top of the wheel

bend.

Page 45

Guide rail system (continued)

Bending guide rail

If the construction of your conveyor system requires customized guide rail bends, you can use the FlexLink guide

rail bending machine (3922963) to bend them according

to your own requirements:

Mounting:

3 Operate the crank to run the rail back and forth while

lowering the upper wheel step by step until the

desired radius and angle is achieved.

1 Mark the length of the rail to be bent. Leave an

approximately 200 mm straight section at each end.

2 Place the rail horizontally between the top wheel and

the lower wheels.

When bending guide rail, you should start bending

from the centre of the required radius.

To calculate the length of guide rail to be bent, use the following formula:

L = (6,28 × r × α )/360

L= length of bend, r=radius, α=desired angle, degrees

Add for straight section

If multiple bends with the same radius are to be made,

note the final position of the upper wheel indicator scale

to ensure correct radius of subsequent rails.

It is possible to bend angles up to 180°. Minimum

radius is 100 mm.

Assembly 45

Page 46

Angle plates

Introduction

X..RP, X..RM

If there is a risk that products will fall off while being conveyed, the gap between the actual conveyor and the

guide rails can be filled with angle plates. These are

attached to the beam by means of guide rail brackets and

T- b o l t s .

Guide rail brackets should be placed across all joints

between angle plates to ensure smooth and durable

joints. 10 mm guide rail is required if guide rail brackets

35×30 are being used to fasten angle plates

Angle plates and guide rail brackets (48×30) for the XL

conveyor system.

Mounting angle plates

Box wrench 13 mm

T-bolts XLAT 17

Nuts XLAN 8

Washers BRB 8,4×16

Mounting:

Attach guide rail brackets to the conveyor beam without

tightening the nuts. Fasten the angle plate by inserting it

into the slot on the side of the guide rail bracket. Tighten

screws.

Angle plates and guide rail brackets (49×42) for the XM

and XH conveyor systems.

XL conveyor system:

In addition to guide rail brackets, distance pieces

XLRD 6 P can be used to fasten angle plates.

46 Assembly

Page 47

Drip trays and drip catchers

Introduction

General information

Drip tray attachment requires drip tray brackets, which

are screwed on to the side of the conveyor beam. It is recommended that one bracket is positioned at each end of

the drip tray, as well as one additional bracket per meter

if the length of the drip tray exceeds one meter.

The screw slots in the drip tray brackets make it possible to adjust the height of the drip tray below the conveyor beam. If you have drain outlets along the drip tray

system, for example, you may want to have inclining drip

trays so that waste fluid flows to these outlets.

Using drip trays as a safety guard

The XLDB 21×100 drip tray bracket is equipped with a

key hole function. When mounted in the upper “hole” of

the key hole, the drip tray serves as a safety guard, preventing access to the return side of the chain. (See fig. 1

below.)

Caution:

Drip pans with sealing joints may be stiff

to mount on to the drip tray. You should

therefore avoid holding your fingers

between the drip pan and the drip tray as

you are pressing the pan towards the the

drip tray (see illustration below). The resistance

could suddenly release and may cause fingers to get

caught. (See fig. 2 below.)

X_DT and XHDS cutting lengths

How to use the table:

1 Measure the length of conveyor X_CB or X_CB_N,

under which you will mount the drip tray.

2 In the table, look up the products that will be mounted

adjacent to the drip tray. Read the value where the

row and the column corresponds.

3 Add the values from the table to the total length of the

conveyor beam, as measured in step 1. If the value in

the table is negative, it should be subtracted from the

total length of the conveyor beam.

4 Cut drip trays X_DT and drip catchers XHDS to the

calculated lengths.

Drip tray/

drip catcher

XSDT 0 +39 +35 -24 -10 +80 +110

XLDT 0 +55 +35 -25 -10 +80 +110

XMDT 0 +59 +35 -25 -10 +80 +110

XHDT 0 +31 +35 -25 -10 +80 +110

XKDT 0 +11 +35 -77 -20 +80 +115

XHDS L×83

XHDS L×53

* The wide, inlet, end of a drip pan for vertical bend.

** The narrow, outlet, end of a drip pan for vertical bend.

Example

An XL conveyor beam is 500 mm long.

The XLDT drip tray that is to be placed underneath the

beam will be connected to one XLDV drip pan for vertical

bend, and one XLDD end pan for idler end unit.

The table for cutting lengths reads +80 for XLDT/X_DV,

and +55 for XLDT/X_DD.

This means that the length of the drip tray should be 500

+ 80 + 55 mm = 635 mm.

See illustration below.

X_DC X_DD X_DE X_DH X_DJ X_DV-B* X_DV-

E**

0 -20 0 -130 -80 +20 +135

fig. 1 fig. 2

XLCB

500

XLDV

+80

Assembly 47

500 + 80 + 55 = 635

XLDT

XLDD

+55

Page 48

Drip trays and drip catchers (continued)

Mounting drip trays

X_DT

Connect drip trays to each other using connecting strips

(XLCJ 5×140) and set screws. Use silicone caulk to seal

joints.

Box wrench 13 mm

T-bolts XLAT 17

Nuts XLAN 8

Washers BRB 8,4×16

Square nuts XLAQ 8

Screws M6S 8×16

Connecting strips XLCJ 5×76

Drip tray bracket XLDB 21×100

Mounting:

3 Adjust the position of the drip tray. Tighten all screws.

1 Use T-bolts, nuts and washers to attach the drip tray

brackets to the conveyor beam T-slot.

2 Insert the required number of square nuts in the drip

tray T-slot. Attach the drip tray to the drip tray brackets. Do not tighten the screws fully.

Attach pans and end cap to the drip tray by inserting

square nuts into the slots on the drip tray. Tighten the

screws using a wrench.

4 If Type A or B beam support brackets with screw slots

are being used, drip tray brackets may not be needed.

The drip trays can then be attached directly on to the

beam support brackets if they are wide enough.

48 Assembly

Page 49

Drip trays and drip catchers (continued)

Drip pans, end pans, end caps

Drip pan for horizontal bend X..DH

End pan X..DE

End cap X..DC

End pan for idler end unit X..DD

Drip tray connector X..DJ

In addition to regular drip trays, you will need drip pans,

end pans and/or end caps. Drip pans are used in bends,

and end pans and caps are used at the ends of the drip

tray. The pans are equipped with threaded outlets so that

waste fluid can be drained into waste reservoirs.

Box wrench 13 mm

Square nuts

Screws M6S 8×16

Washers BRB 8,4×16

Mounting:

3 Insert screws and brackets and tighten them loosely.

1 Attach square nuts to one end of the drip pan and

tighten them loosely. (Use one pair with X_DC, X_DD

and X_DE; two pairs with X_DJ and X_DH.) Slide the

drip pan on to a drip tray section.

2 Slide the next drip tray section (if required), with the

square nuts attached, on to the drip pan.

4 Adjust the position of the drip tray and tighten the

screws.

Assembly 49

Page 50

Drip trays and drip catchers (continued)

Drip pan for vertical bend X..DV

Box wrench 13 mm

Square nuts

Screws M6S 8×16

Washers BRB 8,4×16

Supporting brackets

Screws M6S 5×6

Washers BRB 5,3×10

Mounting:

2 Mount the drip pan on to the beam. Do not tighten the

screws fully. Check that the drip pan follows the curve

of the conveyor beam. If not, adjust the position of the

pan until it does.

If used, attach the supporting brackets to the conveyor beam T-slots.

1 a) Mount two square nuts on to the drip pan.

If supporting brackets are required (for XH and XK 90°

vertical bends), mount them on to the vertical bends.

Do not tighten the screws fully.

b) If 90° bend, insert the square nuts directly into the

conveyor beam T-slot.

3 Tighten the screws.

50 Assembly

Page 51

Drip trays and drip catchers (continued)

Side-mounted drip catcher

XHDS

The purpose of side-mounted drip catchers is to guide

waste fluid into the drip tray when there is a risk that drips

will fall outside the tray, i.e. the products being conveyed

are wider than the track width itself.

Drip catchers are not available for the XS conveyor

system.

One XHDR 23 drip catcher assembly is required for

each drip catcher end, and one additional bracket

assembly for each meter if the length of the drip catcher

exceeds one meter.

For cutting lengths, see page 47.

Box wrench 13 mm

Drip catcher bracket assembly XHDR 23

T-bolts (included) XLAT 17

Nuts (included) XLAN 8

Washers (included) BRB 8,4×16

Mounting:

2 Fasten the drip catcher to the bracket assembly by

tightening the left nut. Use silicone caulk to seal joints

if necessary.

1 Fasten the bracket assembly to the beam by tighten-

ing the nut to the right.

3 The slot on the bracket assembly also allows angle

plate attachment.

Assembly 51

Page 52

Front piece

Introduction

The front piece is attached to a vertical or an inclined part

of a conveyor, to prevent products from falling off. It consists of one straight section and one upper and one lower

bend.

The front piece is connected to the conveyor beam by

means of a linkage kit (X..VK) and bend supports (X..

VS).

Box wrench 13 mm

Front piece X..VF 3/6

Upper bend X..VA 60R460

Lower bend X..VB 60R335

Sliding strip X..VG 2

Linkage kit X..VK 43/93

Locking levers X..VS 43/93

Front piece assembly

Mounting:

Sliding strip attachment

To prevent direct contact between the products and the

front piece surface, an X..VG 2 plastic sliding strip must

be inserted into the front piece.

Mounting:

1 Slide the strip into the slot on the inner side of the front

piece, before mounting the front piece on to the conveyor beam.

1 Connect straight piece and bends using the connect-

ing strips that are included.

2 For safe entry of the products being conveyed, the

2 Tighten the screws using a box wrench.

52 Assembly

protruding end of the sliding strip must be slightly bent

away from the conveyor chain surface to give a “funneling” effect. (Use heater) Fasten the sliding strip to

the front piece using rivets.

Page 53

Front piece (continued)

Mounting front piece

Mounting:

1 The front piece is fastened to the conveyor by means

of a linkage kit (1) and locking levers (2).

3 Attach bend supports and locking device to the front

piece and conveyor beam. Bend supports are

mounted on one side only.

2 Attach the support pairs, two on each side, first to the

front piece and then to the conveyor beam T-slot,

using a 13 mm wrench.

Assembly 53

4 Adjust the height of the front piece using the locking

levers on the bend supports and locking device.

Page 54

Final preparations

Plug beam ends

Ensure that end caps (XCBE) have been fitted to all aluminium profile ends. The beam profiles should be

deburred before fixing end caps. It may be necessary to

tap the cap into position using a soft-faced hammer.

Anchor feet to the floor

After the assembly of all components it may be necessary to anchor the conveyor support feet to the floor. Use

a type of fastener that is right for the kind of floor where

the conveyor is installed.

Instability of the conveyor during operation may result

in a dangerous operating environment or damage the

conveyor components.

Other preparations

• Adjust the height of the structural beam if necessary.

• Make sure that the installation is stable and that all

screws have been properly tightened.

• Use a plummet and/or water-level to make sure that

the construction is not askew.

• Make sure that all electrical equipment is properly

connected.

• Make sure that the conveyor is running in the correct

direction before starting the conveyor! Never run the

conveyor with tightened slip clutch until you have

ensured that the running direction is correct.

• Tighten the slip clutch to a suitable friction. (Slip clutch

adjustment, see page 66)

• Make sure that the transmission cover is attached to

the drive unit.

• In pallet installations, make sure that all pneumatic

equipment is properly connected.

Remember that conveyor chains should always be

pulled, not pushed, by the drive unit.

54 Assembly

Page 55

Conveyor system XK

Installation of slide rail on conveyor beam

XKCB N

Cutting pliers

Hammer

Screwdriver

Clamp

Knife

Drill

Drill bit ∅4,2 mm

Drill fixture 3920500

Plastic screws XWAG 5

Mounting:

3 Drill holes for plastic XWAG 5 screws.

1 Cut the slide rail in a 45° angle.

2 Mount slide rail on the lower flange of the conveyor

beam.

4 Use a screwdriver to insert the screws. Cut off the

screw heads using a knife and a hammer. File off protruding edges.

5 On the upper flange of the slide rail, use the drill fix-

ture to drill two holes in the slide rail before it enters

the XKCB N beam.

Assembly 55

Page 56

Conveyor system XK (continued)

I

6 Use a screwdriver to insert the screws. Cut off the

screw heads using a knife and a hammer. File off protruding edges. The cut should be made away from the

joint, in the direction of travel.

7 Use a clamp to press the slide rail on to the beam

flange where the type N beam begins.

9 Install the chain as shown in the picture.

8 Drill one additional hole and insert a screw in the slide

rail at the beginning of the type N beam section.

56 Assembly

Page 57

Conveyor system XK (continued)

Installation of slide rail in XK plain bends

Plain bends increase the tension in the chain and cause

higher stress on the slide rail. It is therefore recommended that slide rail is used on both the upper and

lower flanges in XK horizontal plain bends.

Cutting pliers

Knife

Hammer

Screwdriver

Drill

Drill bit ∅ 4,2 mm

Drill fixture 3920500

Mounting:

1 Cut the slide rail slightly, to ensure a smooth entry of

the chain. Mount slide rail on the lower flange of the

conveyor beam.

3 Remove the upper slide rail section. Anchor the lower

slide rail to the beam using XWAG 5 plastic screws.

Cut off all screw heads. File off protruding edges. The

cut should be made away from the joint, in the direction of travel.

Repeat the procedure for the opposite side.

4 Install slide rail on the upper flanges.

2 Mount a short piece of slide rail on the upper flange.

Use the drill fixture to drill holes through the slide rail

on the upper and lower flange. Use a drill bit that is

long enough to drill through both flanges.

Assembly 57

Page 58

XK pallet system

Installation of pallet locating station

It is very important that the foot is positioned correctly

and anchored to the floor before the locating station is

mounted.

Tape measure

Plumb bob

Drill

Drill bit

Allen key 5 mm, 6 mm

Spanner 13 mm

Screws M6S 8×20, M6S 8×16

Nuts XCAN 8

Washers BRB 8,4×16

Mounting

105

52,5

1 Plumb from both sides of the conveyor beam, and

mark the width of the beam on the floor.

1

110

130

220

260

3 From the mark, add 130 mm in each direction to get

the width of the foot. Place the foot in the correct position.

2 Mark the centre point between the two marks.

4 Drill holes in the floor, for the attachment of the foot.

58 Assembly

Page 59

XK pallet system (continued)

5 Fasten the foot to the floor.

8 Tighten the guide pins on one side. Loosen the other

pair.

6 Remove the cover from the locating station. Mount a

pair of XCBM 44 beams (≈270 mm long) underneath

the locating station, using M6S 8×20 screws, washers

and XCAN 8 slot nuts.

7 Tighten all screws.

9 Insert square nuts in the vertical beam T-slots. Use

angle brackets to mount short pieces of XCBM 44

beam on the vertical beam.

Assembly 59

Page 60

XK pallet system (continued)

10Lift up the locating station and fit the guide pins into

the T-slot on one side of the conveyor beam.

12Position the locating station in the correct position on

the conveyor beam. Raise the lower pair of beams so

that they meet the upper beam pair.

13Tighten the angle bracket screws.

11Tighten the two remaining guide pins.

60 Assembly

Page 61

XK pallet system (continued)

14Place two distance pieces (2,5 mm thick) between the

locating station and the conveyor beam, one on each

side of the beam, to keep the locating station centered.

17Mount the pallet stop.

15Connect the four beam pairs together using angle

brackets.

16Mount the cover on to the locating station.

18Position the pallet stop by placing a pallet onto the

locating station. Then tighten the pallet stop 0,5–

1,0 mm in front of the pallet (see drawing).

0,5–1,0

Assembly 61

Page 62

XK pallet system (continued)

Installation of guide rail for XK pallet system

Spanner 13 mm

Slide rail mounting tool 3926757

Set-square

Drill

Drill bit ∅ 4,2 mm

Cutting pliers

Set screw SK6SS 4×20

Screws XLAT 17

Nuts XLAN 8

Washers BRB 8,4×16

Mounting:

1 Cut guide rail to the correct length (length of the cor-

responding conveyor beam ±1,0 mm). Mount a piece

of straight guide rail. Use set-square and mounting

tool for correct positioning. Adjust the end of the rail to

be in line with the conveyor beam joint. Tighten the

screws.

3 If a drip catcher kit is to be used, the inner drip catcher

must be pre-mounted by using a short piece of guide

rail for adjustment.

4 Mount the guide rails for the inner and outer sections

of the bend. Do not tighten the guide rail brackets until

the next straight rail section is positioned and tightened.

2 Mount guide rail on the opposite side of the track (in

line with the first).

62 Assembly

5 Mount the next straight guide rail section: check that

the guide rail is aligned with the conveyor beam joint.

Tighten the guide rail bracket fasteners.

Page 63

XK pallet system (continued)

6 Mount the opposite guide rail section. Check that the

guide rail joints are aligned. Tighten the guide rail

bracket fasteners.

7 Adjust the position of the bend and fasten the con-

necting strips and guide rail brackets.

9 Drill two holes in the slide rail and fix it with plastic

screws.

10Install the rest of the slide rail using the mounting tool.

Cut the slide rail so that all joints are smooth (do not

cut in an angle).

8 Start mounting the slide rail approximately 200 mm

before the bend.

Assembly 63

Page 64

XK pallet system (continued)

11Mount the outer drip catcher in the bend. Mount set

screws as guide pins.

12Check that the slot in the special guide rail section for

locating station is properly positioned compared to

the rulers on the locating station.

Use set screws as guide pins to connect two guide rail

sections.

64 Assembly

Page 65

Start-up and testing

Safety considerations

To eliminate the risk of accidents, it is important to be

aware of certain areas of the conveyor where special

caution is required, during installation, operation and

maintenance. Some areas present a higher danger to

personal safety, and because of this various kinds of

safety devices need to be installed.

• All pinch and shear points as well as other exposed

moving parts that present a hazard to employees at

their workstations or their passageways must be safeguarded.

• Cleated conveyor chains are more susceptible of creating pinch and shear points than plain chain.

• When two or more pieces of equipment are interfaced, special attention must be given to the interfaced area to ensure proper safeguarding.

• For overhead equipment, guards must be provided if

products may fall off the equipment for some reason.

The same applies to all incline, decline and vertical

conveyors.

Safeguarding can be achieved by:

• Location – locate the hazardous area out of reach of

the personnel involved.

• Guards – mechanical barriers preventing entry into

the hazardous area or protecting against falling

goods.

• Control devices – machine controls preventing or

interrupting hazardous conditions.

• Warnings – instructions, warning labels, or sound or

light signals, alerting on hazardous conditions. Warnings shall be used when other means of safeguarding

will impair the function of the installation.

Caution:

It must be difficult to bypass or inactivate

safeguards during operation!

Safety devices should be designed to minimize discomfort or difficulties for operators.

Start-up and testing 65

Page 66

Slip clutch adjustment

Introduction

The slip clutch on the drive unit is a safety device which

allows the chain to stop if the load becomes excessive. It

has two purposes:

• Prevent damage to conveyor

• Prevent damage to the products on the conveyor

Where a slip clutch is fitted, it must be adjusted so that it

does not slip whenever the drive unit is started under full

load. The installation is carried out as follows:

Preparations for adjustment

1 Stop the conveyor.

2 Ensure that the conveyor can not be started acciden-

tally. For example: unplug the electric power plug.

3 Remove any load on the conveyor.

Caution:

If you try to adjust the slip clutch when

there is still load on the conveyor, the

accumulated tension in the chain can

cause severe injuries when you release

the clutch.

Slip clutch should not be adjusted until

1 Motor direction is confirmed

2 Conveyor is fully assembled

Adjustment

9

5

6

7

8

4

10

1

the angle (30°) between adjacent holes in the stop

ring (6). Check that screws (8) align with the holes in

the stop ring (6).

6 Negative X-value: (If the X value is positive (X≥0)

ignore step 6 and go to step 7.) Turn the outer ring (7)

clockwise with a hook wrench, the number of divisions

given by the table, i.e. the X value. One division is

defined as the angle (30°) between adjacent holes in

the stop ring (6). Check that screws (8) align with the

holes in the stop ring (6).

7 Tighten the three screws (8) to stop. Use 10 mm

wrench

Important:

The slip clutch is not a personal safety

device. It is primarily intended to protect the

equipment.

Clutch adjustment table

F

is the desired maximum traction force applied to the

max

chain by the drive unit. The clutch will start slipping at

forces above F

Note

The values in the table are approximate and apply to

new slip clutches.

F max (N) F max (N)

XSXLXM

450 450 100 19 1200 1200 1400 6

475 475 200 18 1300 1500 5

max.

XH

XW

1000 1200 8 2500 –5

1100 1300 7

XK X (div.) XMXHXW XK

X (div.)

525 300 17 1400 1600 4

575 400 16 1525 1700 3

625 500 15 1800 2

675 600 14 1900 1

725 700 13 2000 0

775 800 12 2100 –1

825 900 11 2200 –2

875 1000 10 2300 –3

925 1100 9 2400 –4

3

2

Example (XM, XH or XW conveyors)

1 Remove the transmission cover.

2 Unscrew the three screws (8) so that the outer ring (7)

can be rotated freely.

3 Hand-tighten the outer ring (7) to stop (no tools!).

4 Look for the desired maximum traction force in the

table to the right and determine the X value for that

force.

5 Positive X-value: (If the X value is negative (X≤0)

ignore step 5 and go to step 6.) Turn the outer ring (7)

counter-clockwise the number of divisions given by

the table, i.e. the X value. One division is defined as

66 Start-up and testing

You wish to set the clutch so that it permits a maximum

traction force of 900 N. Above that load, the clutch should

release.

From the table you find that the ring must be released

at least 9 divisions from hand-tightened position. Since

the ring should be turned by complete steps, you should

select 9 steps. This corresponds to three quarters (¾) of

a full turn. The clutch will release at approximately 925 N.

If you release the ring by 10 divisions the clutch will

release at 875 N.

Also see formulas for chain tension calculations in the

main conveyor catalogue, chapter "Multiflexing conveyors", section "Engineering guidelines".

Page 67

Start-up

Lubrication

The conveyor chain is lubrication-free. However, for

some specific applications where the operating environment is particularly hostile, regular lubrication of the slide

rail/conveyor chain will result in a lower coefficient of friction, longer life and reduced running costs. Use a silicone-based lubricant (LDSS 450 or an equivalent

lubricant).

Wear

The degree of wear on a conveyor depends on a number

of factors, such as:

• running time

• load, contact pressure

• speed

• product accumulation

• sharp or rough products

•chemicals

• foreign particles, e.g. chips, grinding particles, broken

glass, sand, sugar

•temperature

• plain bends

Try to minimize the running time for the conveyor by stopping it when there is no transport.

Multiple horizontal and vertical plain bends in a con-

veyor will often result in increased wear. One reason is

that the friction losses are large in plain bends. Also, the

contact surface between chain and slide rail is small and

the chain pull is acting towards the slide rail in the bends.

Run-in period

Two or three days are usually enough as a run-in period.