Page 1

Information from FlexLink No. 98-01-03

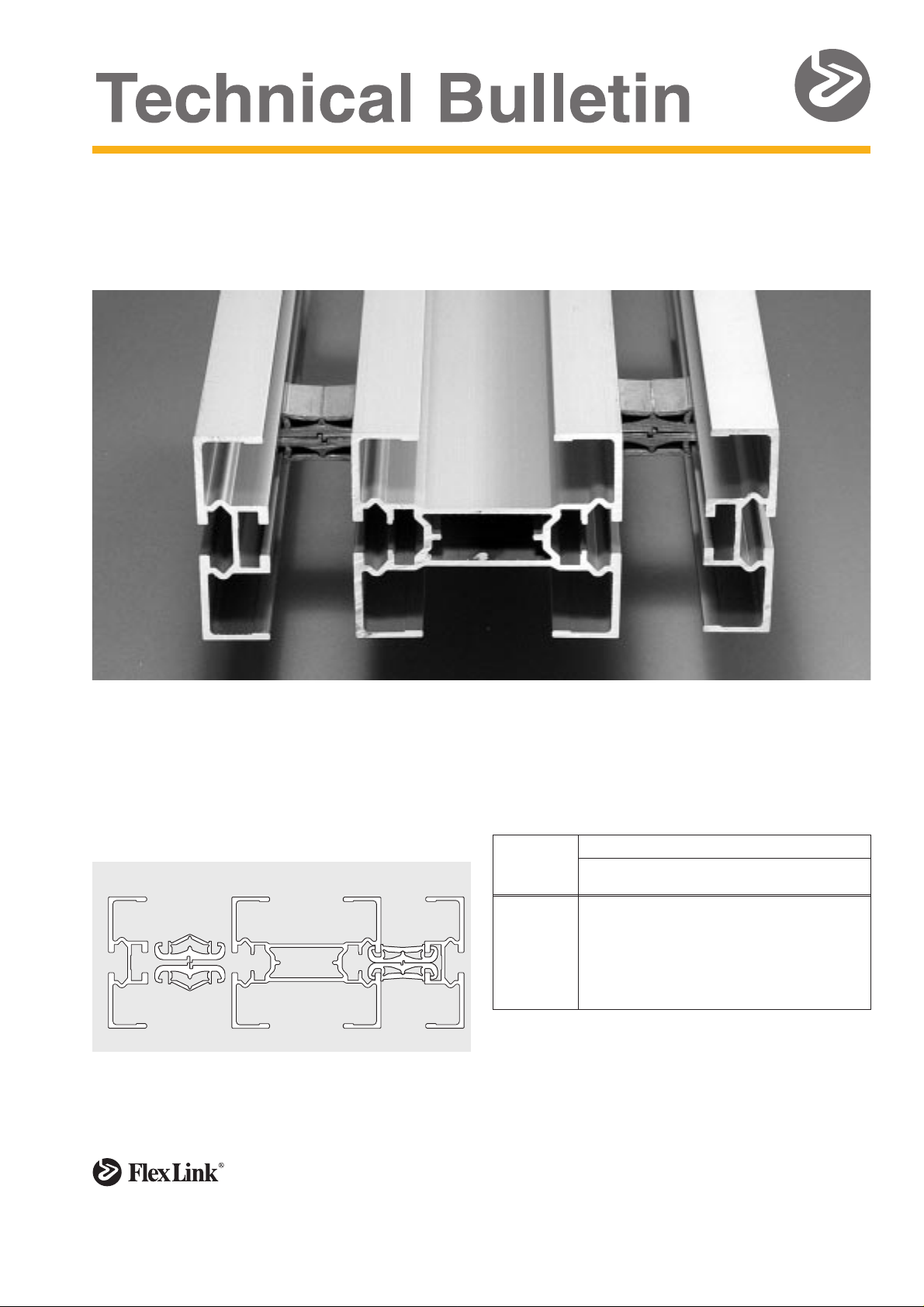

XB conveyor beam

Assembly instructions

The following tools are required:

•

Mounting tool for aluminium clip – 3923518

•

Allen key–4mm

•

Measuring tape

•

Set-square

•

Idler end unit – XBEJ A175

XBCB 3A H

XBCB 3A H

XBCB 3AH

XBCE 40

XBCE 40

XBCE 40

XBCB 3A85

XBCB 3A85

XBCB 3A85

The following components are required:

•

Beam (mid-section) – XBCB 3A85

•

Beam (outer section) – XBCB 3A H

•

Aluminium clips – XBCE 40

(for correct number, see table below)

Number of pieces

Beam length

(mm)

500–1000 1 1 4

1001–1500 1 1 6

1501–2000 1 2 8

2001–2500 1 2 10

2501–3000 1 2 12

XBCB 3A85 XBCB 3A H XCBE 40

(pairs)

Page 2

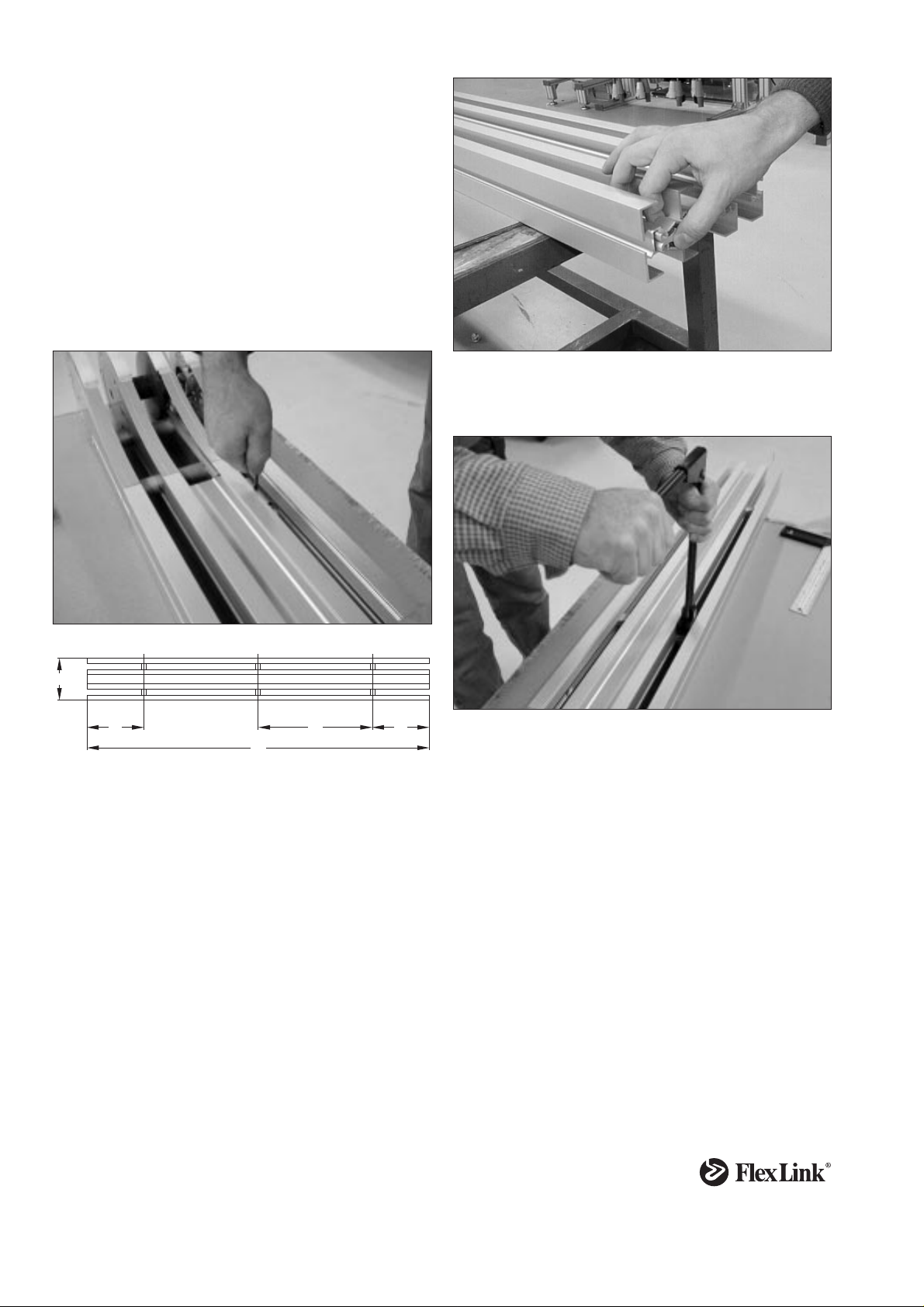

Assembly

1 Cut the three beams to the correct length. Note!

The beams are delivered in lengths of 3020±3 mm.

The length of the assembled XB beam must not be

shorter than 500 mm or exceed 3000 mm.

The lengths of the beams should not differ more

than ±0,5 mm, so they should all be cut at the

same time! (The beams can also be cut after assembly.)

2 Use an idler end unit as a mounting fixture, to en-

sure that the beams are correctly positioned horizontally and vertically.

3 Mount the three beams on to the idler unit. Loosely

tighten one set screw per connecting strip.

4 Insert the correct number of clips from the opposite

beam end. Position them at regular intervals along

the beam profile. (See below)

82

A

L

B

A) If L = 500–800, the distance A should be

150±10 mm, if L = 801–3000, the distance A should

be 250 mm.

A

5 Use the aluminium clip tool to press the two clips

closest to the idler unit together.

6 Loosen the connecting strip set screws and move

the idler unit to the other end of the beam. The set

screws do not need to be tightened.

7 Press the remaining clips together.

8 Remove the idler unit.

9 Use a set-square to check that the beam ends are

perpendicular to the beam side.

10 Cut the beam to the correct length, if this was not

done prior to assembly.

Note!

To simplify the assembly of XB beams, two idler end

units can be used instead of one.The second idler unit

is then placed at the second beam end once all clips

have been inserted into the beam. If two idler units are

used, step 6 can be ignored.

2 TB 98-01-03

Loading...

Loading...